A Model of BGA Thermal Fatigue Life Prediction Considering Load Sequence Effects

Abstract

:1. Introduction

2. Thermal Fatigue Life Prediction Model for BGA

2.1. Model Assumption

2.2. Base Model for BGA Fatigue Life

2.3. Load Sequence Effects in Model

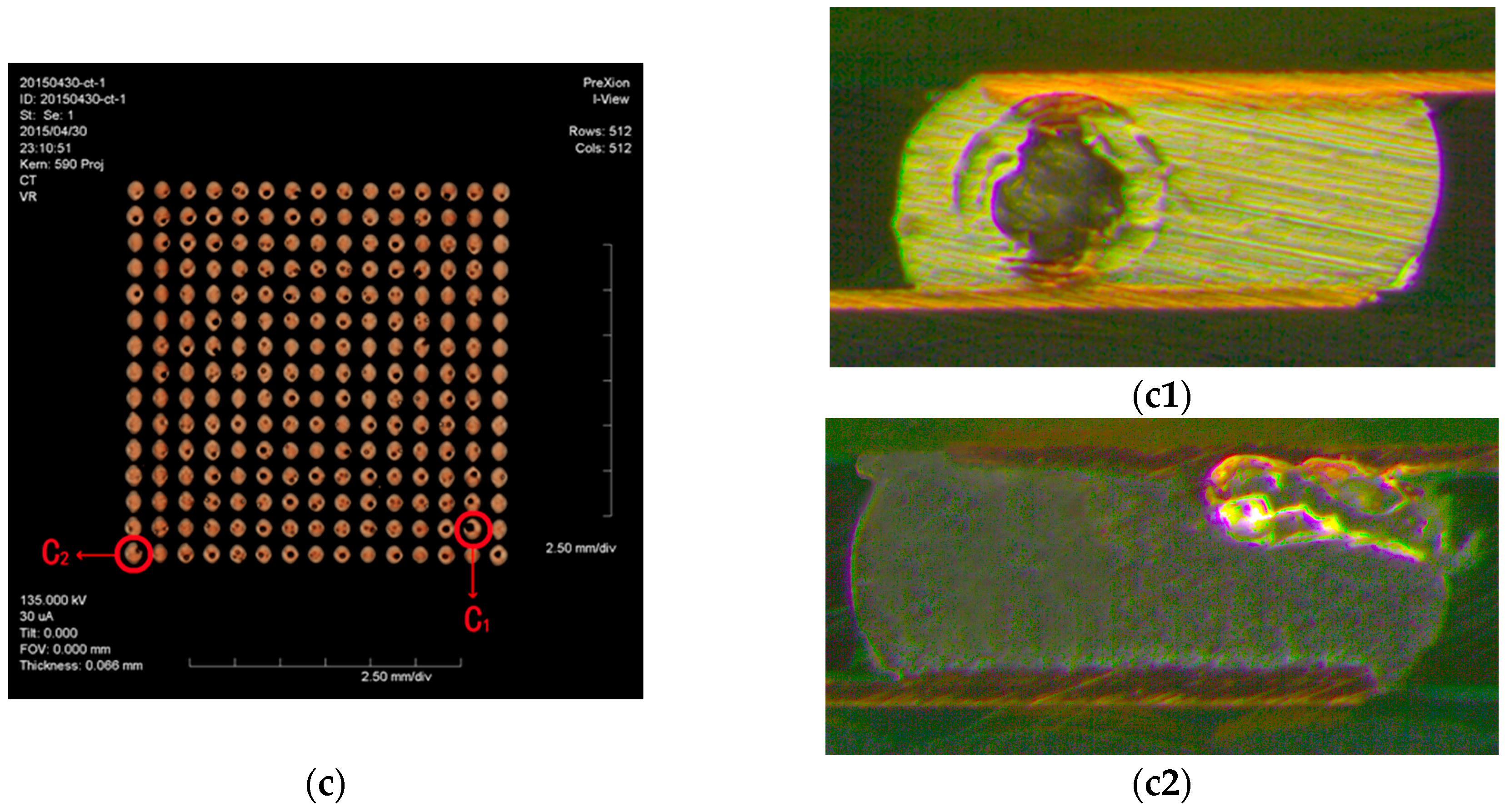

2.4. Parameters Determination Based on Historical Crack Length Data

3. Discussion of Numerical Computation Method for Model Parameter Determination

3.1. Parameters Determining Equations

3.2. Resistance Strain Theory

3.3. Stress Range Simulation

3.3.1. Geometry Construction

3.3.2. Initial Simulation Setting

3.3.3. Mesh and Boundary Condition

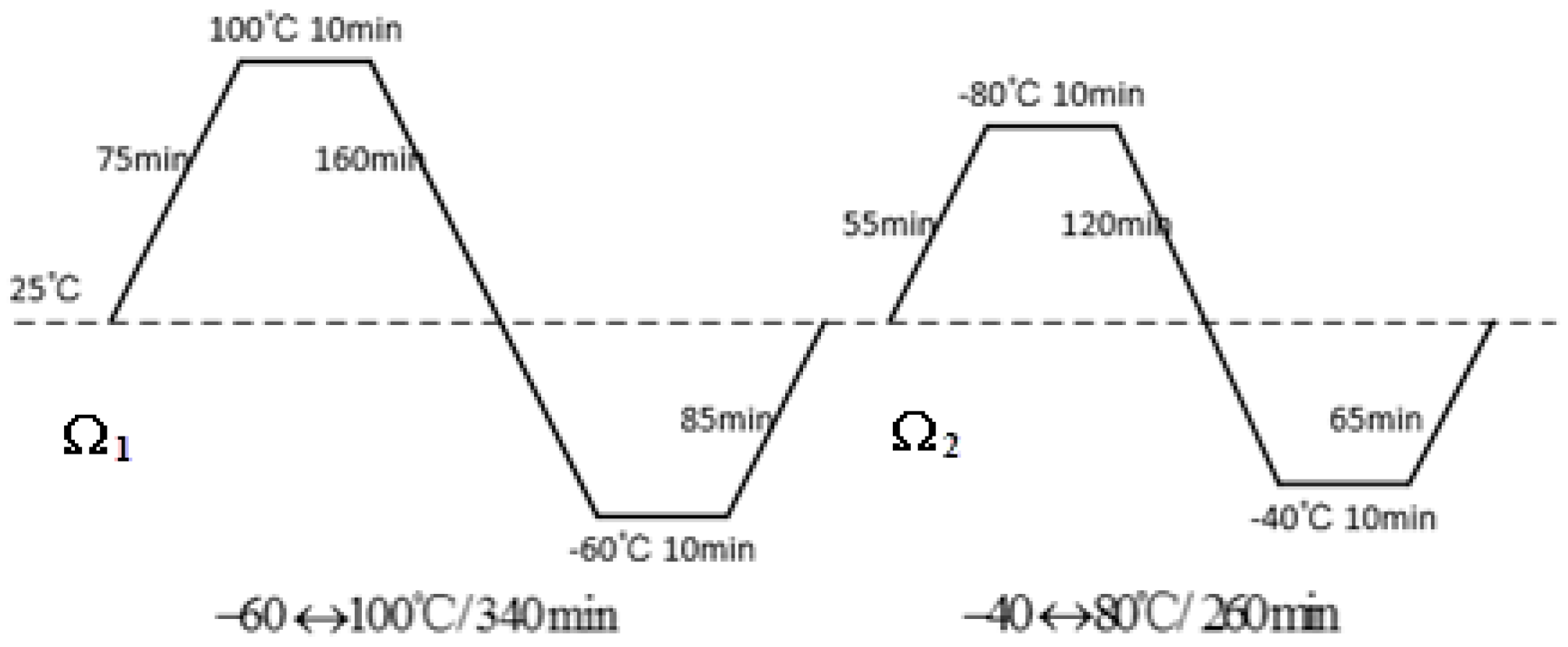

3.3.4. Thermal Load Profile

3.3.5. Equivalent Stress Range

3.4. Thermal Fatigue Life Computation

4. Experimental Verification

5. Conclusions

Author Contributions

Conflicts of Interest

Nomenclature

| the whole fatigue lifetime of solder joints, also the stress cycles of a specified character that a specimen sustains before failure of a specified nature occurs | |

| the total fatigue life cycles of ball grid arrays under the ith thermal load condition | |

| the total fatigue life of ball grid arrays consists of certain fatigue cycles under the ith thermal condition and the rest cycles under the jth condition | |

| the initial crack lifetime of solder joints, also the cycles to crack initiation | |

| the initial crack lifetime of solder joints under the ith thermal condition | |

| the crack propagation or growth lifetime of solder joints | |

| the crack propagation lifetime of solder joints under the ith condition | |

| the crack propagation lifetime of ball grid arrays consists of certain propagation cycles under the ith thermal condition and the rest cycles under the jth condition | |

| the actual cycles under the ith thermal condition, in which we assume that initial crack lifetime under ith thermal condition is included | |

| crack length, critical crack length, crack length at certain time point t, and the crack length at certain cycle times N | |

| crack growth rate under the ith thermal load condition | |

| the incremental viscoplastic strain energy density under the ith thermal load condition | |

| constant related to thermal cyclic stress range in crack propagation stage under the ith thermal load condition | |

| constant related the exponential increasing trend of crack growth ratio under the ith thermal load condition | |

| the correlation coefficients of material properties in Darveaux model | |

| material constants of the Darveaux model in the Paris formula | |

| the amplitude of stress intensity factor | |

| the differences between the maximum stress value and minimum stress value under certain load conditions | |

| the geometry influence function whose value is related to the sample size and load form | |

| model parameters related with and | |

| the unchangeable load profile under ith thermal condition | |

| the changeable load profile under ith condition then change to jth condition | |

| the resistance strain of solder joints | |

| the material resistivity and the resistivity of material at certain ambient temperatures | |

| the thickness of solder joint | |

| the cross-sectional area that perpendicular to the current, and | |

| the radius of welding points between solder point and PCB | |

| the time of heating-cooling process and the holding time | |

| the minimum temperature and the maximum temperature |

References

- Lee, W.W.; Nguyen, L.T.; Selvaduray, G.S. Solder joint fatigue models: Review and applicability to chip scale packages. Microelectron. Reliab. 2000, 40, 231–244. [Google Scholar] [CrossRef]

- Pang, H.L.; Low, T.H.; Xiong, B.S. Lead-free 95.5Sn-3.8Ag-0.7Cu solder joint reliabilityanalysis for Micro-BGA assembly. In Proceedings of the 50th Annual electronics components and technology conference, Las Vegas, NV, USA, 31 May–3 June 2005; pp. 131–136.

- Luan, J.E.; Tee, T.E.; Pek, E. Advanced numerical and experimental techniques for analysisof dynamic responses and solder joint reliability during drop impact. IEEE Trans. Componen. Packaging Tech. 2006, 29, 449–456. [Google Scholar] [CrossRef]

- Yang, L.; Yin, L.; Arafei, B.; Roggeman, B.; Borgesen, P. On the assessment of the life of SnAgCu solder joints in cycling with varying amplitudes. IEEE Trans. Componen. Packaging Tech. 2013, 3, 430–440. [Google Scholar] [CrossRef]

- Tang, H.; Basaran, C. Experimental characterization of material degradation of solder joint under fatigue loading. In Proceedings of the Eighth Intersociety Conference on IEEE, San Diego, CA, USA, 30 May–1 June 2002; pp. 896–902.

- Okuyama, S.; Yu, Q.; Akutsu, T. Reliable evaluation method for solder joints in vehicle electronics devices considering the actual use conditions. In Proceedings of the 13th IEEE Intersociety Conference on IEEE, San Diego, CA, USA, 30 May–1 June 2012; pp. 654–658.

- Fatemi, A.; Yang, L. Cumulative fatigue damage and life prediction theories: A survey of the state of the art for homogeneous materials. Int. J. Fatigue 1998, 20, 9–34. [Google Scholar] [CrossRef]

- Robert, D.; Sabira, E.; Corey, R.; Christopher, J.B.; Nabeel, Z. Crack initiation and growth in WLCSP solder joints. In Proceedings of the 2011 IEEE 61st Electronic Components and Technology Conference (ECTC), IEEE, Lake Buena Vista, FL, USA, 29 May–1 June 2011; pp. 940–953.

- Manson, S.S.; Halford, G.R. Treatment of Multiaxial Creep-Fatigue by Strain Range Partitioning. In Proceedings of the Winter Annual Meeting of the Am. Soc. of Mechanical Engineers, NASA Lewis Research Center, New York, NY, USA, 6–10 December 1976.

- Yang, L.; Liang, Y.; Roggeman, B.; Borgesen, P. Effects of microstructure evolution on damage accumulation in lead-free solder joints. In Proceedings of the 60th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 1–4 June 2010; pp. 1518–1523.

- Bao, Y.W.; Li, W.H.; Qiu, Y. Investigation in biaxial-stress effect on mode I fracture resistance of brittle materials by FEM simulation and K–G–J–δ relationship. Mater. Lett. 2005, 59, 439–445. [Google Scholar] [CrossRef]

- Bao, Y.W.; Liu, L.Z.; Zhou, Y.C. Assessing the elastic parameters and energy-dissipation capacity of solid materials: A residual indent may tell all. Acta Mater. 2005, 53, 4857–4862. [Google Scholar] [CrossRef]

- Lin, C.K.; Teng, H.Y. Creep properties of Sn-3.5 Ag-0.5 Cu lead-free solder under step-loading. J. Mater. Sci. Mater. Electron. 2006, 17, 577–586. [Google Scholar] [CrossRef]

- Lall, P.; Vaidya, R.; More, V.; Goebel, K. Assessment of Accrued Damage and Remaining Useful Life in Leadfree Electronics Subjected to Multiple Thermal Environments of Thermal Aging and Thermal Cycling. IEEE Trans. Componen. Packaging Tech. 2012, 2, 634–649. [Google Scholar] [CrossRef]

- Darveaux, R.; Banerji, K.; Mawer, A.; Dody, G. Reliability of plastic ball grid array assembly. Ball Grid Array Technol. 1995, 379–442. [Google Scholar]

- Fiedler, B.; Fine, M.; Kao, K.; Keer, L. Monitoring Fatigue Cracking in Interconnects in a Ball Grid Array by Measuring Electrical Resistance. J. Electron. Packaging 2012, 134, 2346–2350. [Google Scholar] [CrossRef]

- Vormwald, M. Classification of Load Sequence Effects in Metallic Structures. Procedia Eng. 2015, 101, 534–542. [Google Scholar] [CrossRef]

- Vormwald, M. Fatigue crack propagation under large cyclic plastic strain conditions. Procedia Mater. Sci. 2014, 3, 301–306. [Google Scholar] [CrossRef]

- Lindfield, G.; John, P. Numerical Methods: Using MATLAB; Academic Press: Pittsburgh, PA, USA, 2012. [Google Scholar]

- Jiang, L.; Yang, K.; Zhou, J.; Xiang, K.; Wang, W. Quantification of creep strain in small lead-free solder joints with the in situ micro-electronic resistance measurement. Microelectro. Reliab. 2008, 48, 438–444. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Zhao, J.; Mutoh, Y.; Miyashita, Y.; Wang, L. Fatigue crack growth behavior of Sn–Pb and Sn-based lead-free solders. Eng. Fracture Mech. 2003, 70, 2187–2197. [Google Scholar] [CrossRef]

- ANSYS Structural Analysis Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2013.

- Rodgers, B.; Punch, J.; Jarvis, J. Finite element modelling of a BGA package subjected to thermal and power cycling. In Proceedings of the The Eighth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, 2002, ITHERM 2002, San Diego, CA, USA, 30 May–1 June 2002; pp. 993–1000.

- Kim, Y.G.; Han, B.; Choi, S.; Kim, S.K. Bottom Leaded Plastic (BLP) package: A new design with enhanced solder joint reliability. In Proceedings of the Electronic Components and Technology Conference, Orlando, FL, USA, 28–31 May 1996; pp. 448–452.

- Lau, J.H.; Lee, S.W.R.; Lee, R.S. Chip Scale Package (CSP): Design, Materials, Process, Reliability & Applications; McGraw-Hill Professional: New York, NY, USA, 1999. [Google Scholar]

- Ghaffarian, R. Effect of Area Array Package Types on Assembly Reliability and Comments on IPC-9701A. APEX 2016, in press. [Google Scholar]

| Model Components | Whole Package | PCB | Upper Copper Backing | Lower Copper Backing | Nickel Pad |

|---|---|---|---|---|---|

| (mm) | 6 × 8 × 1.3 | 40 × 40 × 0.5 | 0.45 × 0.027 | 0.514 × 0.018 | 0.45 × 0.005 |

| Welded-Spot pitch | Chip | Substrate | Binder | Colloid | |

| (mm) | 0.8 | 4 × 5.6 × 0.254 | 6 × 8 × 0.2366 | 6 × 8 × 0.0254 | 6 × 8 × 0.53 |

| Solder joint | |||||

| diameter () | total height | upper cylinder height | material | ||

| (mm) | 0.514 | 0.322 | 0.034 | 63Sn37Pb | |

| Component Category | Elasticity Modulus (GPa) | Poisson’s Ratio | CTE (10−6/°C) |

|---|---|---|---|

| Solder joint | 30 | 0.35 | 21 |

| PCB (FR4) | 48.2 | 0.3 | 19.17 |

| Substrate | 16.85 | 0.3 | 16 |

| Copper backing | 129 | 0.38 | 16.9 |

| Specimen plate | 17.4 | 0.15 | 15 |

| Model Variables | ||

|---|---|---|

| Equivalent stress range (MPA) | 221.462 | 64.322 |

| Plastic shear strain range | 0.03068 | 0.02334 |

| Fatigue life | 1198 | 2045 |

| Fatigue Variables | ||||

|---|---|---|---|---|

| 1211 | 2088 | 2004 | 1297 | |

| 121 | 208 | 121 | 208 | |

| 1090 | 1880 | 1762 | 881 | |

| / | / | 121 | 208 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Li, Y.; Sun, Y.; Mosleh, A. A Model of BGA Thermal Fatigue Life Prediction Considering Load Sequence Effects. Materials 2016, 9, 860. https://doi.org/10.3390/ma9100860

Hu W, Li Y, Sun Y, Mosleh A. A Model of BGA Thermal Fatigue Life Prediction Considering Load Sequence Effects. Materials. 2016; 9(10):860. https://doi.org/10.3390/ma9100860

Chicago/Turabian StyleHu, Weiwei, Yaqiu Li, Yufeng Sun, and Ali Mosleh. 2016. "A Model of BGA Thermal Fatigue Life Prediction Considering Load Sequence Effects" Materials 9, no. 10: 860. https://doi.org/10.3390/ma9100860

APA StyleHu, W., Li, Y., Sun, Y., & Mosleh, A. (2016). A Model of BGA Thermal Fatigue Life Prediction Considering Load Sequence Effects. Materials, 9(10), 860. https://doi.org/10.3390/ma9100860