Influence of Sintering Temperature on the Microstructure and Mechanical Properties of In Situ Reinforced Titanium Composites by Inductive Hot Pressing

Abstract

:1. Introduction

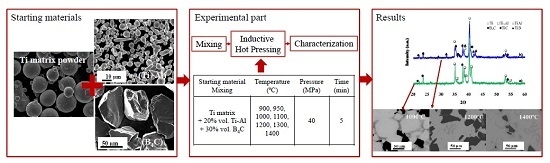

2. Materials and Methods

2.1. Experimental Procedure

2.1.1. Thermodynamic Analysis

2.1.2. Powder Preparation

2.1.3. Inductive Hot Consolidation Process

2.1.4. Specimen Characterization

3. Results and Discussion

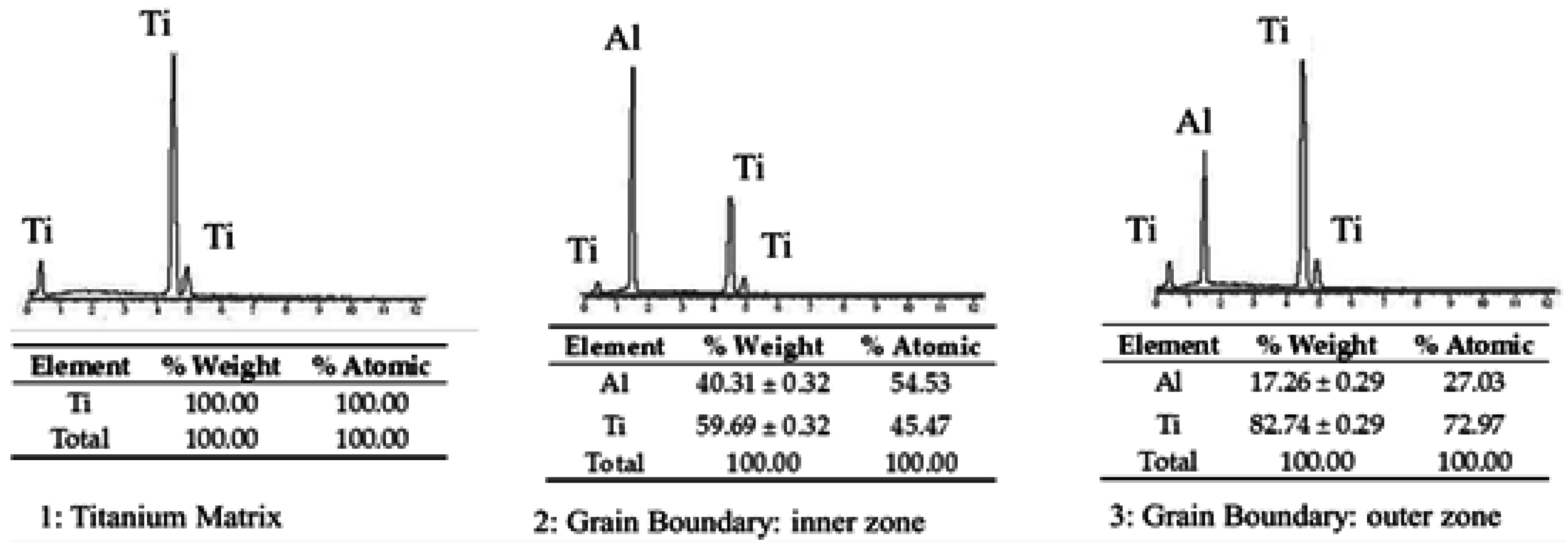

3.1. Microstructural Analysis

3.2. X-ray Diffraction

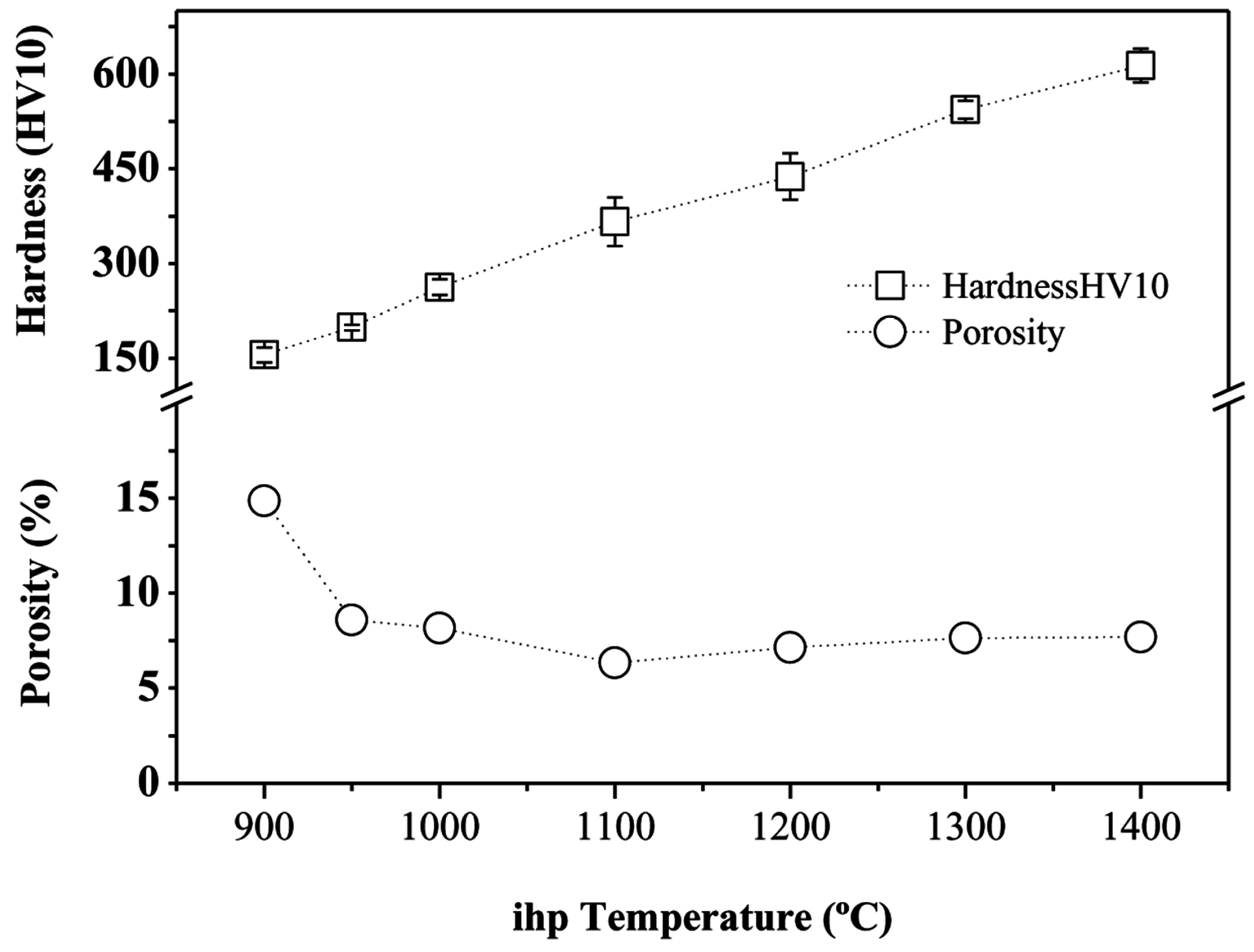

3.3. Densification, Hardness, and Young’s Modulus

4. Conclusions

- The microstructure of the composites was significantly affected by the processing temperature. In terms of microstructure change, an inflection change was observed between 1000 and 1200 °C. Whilst the matrix grains were visibly defined by the location of TiAl and Ti3Al at 900 °C, 950 °C, 1000 °C and less pronounced at 1100 °C, this phenomenon was not demonstrated in composites fabricated at higher temperatures due to the solubility of Al in Ti. Furthermore, the microstructure of the composites essentially evolved from the reaction of Ti and B4C.

- Based on the XRD results, it can be suggested that the in situ TiC and TiB compounds were not formed up to 1200 °C, since this reaction was incomplete. Even at 1400 °C, such a reaction was not finished since smaller B4C particles were observed in the microstructural analysis.

- By increasing the processing temperature, the hardness of the composites increased (30% for each 100 °C temperature increment), while the density increased slightly. The Young’s Modulus exhibited a similar trend, which increased by 20% at 1000 °C and gradually enhanced by 10% from there on.

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Material | d10 (μm) | d50 (μm) | d90 (μm) |

|---|---|---|---|

| Ti (matrix) | 84.70 | 116.74 | 162.37 |

| B4C | 39.95 | 63.31 | 98.68 |

| Fine Ti | 11.88 | 28.13 | 51.42 |

| Al | 2.61 | 6.12 | 14.87 |

References

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium alloys for aerospace applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Campbell, F.C. Chapter 4—Titanium. In Manufacturing Technology for Aerospace Structural Materials; Elsevier Science: Oxford, UK, 2006; pp. 119–174. [Google Scholar]

- Zadra, M.; Girardini, L. High-performance, low-cost titanium metal matrix composites. Mater. Sci. Eng. A 2014, 608, 155–163. [Google Scholar] [CrossRef]

- Campbell, F.C. Chapter 9—Metal matrix composites. In Manufacturing Technology for Aerospace Structural Materials; Elsevier Science: Oxford, UK, 2006; pp. 419–457. [Google Scholar]

- Gofrey, T.M.T.; Goodwin, P.S.; Ward-Close, C.M. Titanium particulate metal matrix composites-reinforcement, production methods, and mechanical properties. Adv. Eng. Mater. 2000, 2, 85–91. [Google Scholar] [CrossRef]

- Tjong, S.C.; Mai, Y.-W. Processing-structure-property aspects of particulate and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Balaji, V.S.; Kumaran, S. Densification and microstructural studies of titanium–boron carbide (B4C) powder mixture during spark plasma sintering. Powder Technol. 2014, 264, 536–540. [Google Scholar] [CrossRef]

- Jimoh, A.; Sigalas, I.; Hermann, M. In situ synthesis of titanium matrix composite (Ti-TiB-TiC) through sintering of TiH2-B4C. Mater. Sci. Appl. 2012, 3, 30–35. [Google Scholar]

- Geng, L.; Ni, D.R.; Zhang, J.; Zheng, Z.Z. Hybrid effect of TiBw and TiCp on tensile properties of in situ titanium matrix composites. J. Alloys Compd. 2008, 463, 488–492. [Google Scholar] [CrossRef]

- Vadayar, K.S.; Rani, S.D.; Prasad, V.V.B. Effect of boron carbide particle size and volume fraction of TiB-TiC reinforcement on fractography of PM processed titanium matrix composites. Procedia Mater. Sci. 2014, 6, 1329–1335. [Google Scholar] [CrossRef]

- Monticelli, C.; Frignani, A.; Bellosi, A.; Brunoro, G.; Trabanelli, G. The corrosion behaviour of titanium diboride in neutral chloride solution. Corros. Sci. 2001, 43, 979–992. [Google Scholar] [CrossRef]

- Wang, M.-M.; Lu, W.-J.; Qin, J.; Ma, F.; Lu, J.; Zhang, D. Effect of volume fraction of reinforcement on room temperature tensile property of in situ (TiB + TiC)/Ti matrix composites. Mater. Des. 2006, 27, 494–498. [Google Scholar] [CrossRef]

- Jimoh, A. In-Situ Particulate-Reinforcement of Titanium Matrix Composites with Borides. Ph.D. Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2010. [Google Scholar]

- Loria, E.A. Quo vadis gamma titanium aluminide. Intermetallics 2001, 9, 997–1001. [Google Scholar] [CrossRef]

- Yeh, C.L.; Shen, Y.G. Formation of TiAl–Ti2AlC in situ composites by combustion synthesis. Intermetallics 2009, 17, 169–173. [Google Scholar] [CrossRef]

- Peng, L.M.; Wang, J.H.; Li, H.; Zhao, J.H.; He, L.H. Synthesis and microstructural characterization of Ti–Al3Ti metal–intermetallic laminate (mil) composites. Scr. Mater. 2005, 52, 243–248. [Google Scholar] [CrossRef]

- Sun, Y.; Haly, J.; Kulkarni, K.; Aindow, M.; Lavernia, E.J. Influence of electric current on microstructure evolution in Ti/Al and Ti/TiAl3 during spark plasma sintering. J. Alloys Compd. 2015, 648, 1097–1103. [Google Scholar] [CrossRef]

- Yang, C.-H.; Wang, F.; Ai, T.-T.; Zhu, J.-F. Microstructure and mechanical properties of in situ TiAl/Ti2AlC composites prepared by reactive hot pressing. Ceram. Int. 2014, 40, 8165–8171. [Google Scholar] [CrossRef]

- Al-Dabbagh, J.B.; Rozman, M.T.; Mahadzir, I.; Siti Aisyah, H. Structural and phase formation of TiAl alloys synthesized by mechanical alloying and heat treatment. Int. J. Nanoelectron. Mater. 2015, 8, 23–32. [Google Scholar]

- Li, S.; Sun, B.; Kondoh, K.; Mimoto, T.; Imai, H. Influence of carbon reinforcements on the mechanical properties of Ti composites via powder metallurgy and hot extrusion. In Materials Science Forum; Trans Tech Publications: Pfaffikon, Switzerland, 2013; Volume 750, pp. 40–43. [Google Scholar]

- Ni, D.R.; Geng, L.; Zhang, J.; Zheng, Z.Z. Fabrication and tensile properties of in situ TiBw and TiCp hybrid-reinforced titanium matrix composites based on Ti–B4C–C. Mater. Sci. Eng. A 2008, 478, 291–296. [Google Scholar] [CrossRef]

- Radhakrishna Bhat, B.V.; Subramanyam, J.; Bhanu Prasad, V.V. Preparation of Ti-TiB-TiC & Ti-TiB composites by in-situ reaction hot pressing. Mater. Sci. Eng. A 2002, 325, 126–130. [Google Scholar]

- Boyarchenko, O.D.; Kamynina, O.K.; Sytschev, A.E.; Vadchenko, S.G.; Gotman, I.; Umarov, L.M. Synthesis of Ti-Al-based materials by thermal explosion. Int. J. Self-Propag. High-Temp. Synth. 2010, 19, 285–291. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J.-M.; Cho, Y.-H.; Kim, S.-H.; Yu, H. Effect of the Ti/B4C mole ratio on the reaction products and reaction mechanism in an Al–Ti–B4C powder mixture. Mater. Chem. Phys. 2014, 147, 925–933. [Google Scholar] [CrossRef]

- Li, Y.; Li, Q.; Liu, W.; Shu, G. Effect of Ti content and stirring time on microstructure and mechanical behavior of Al-B4C composites. J. Alloys Compd. 2016, 684, 496–503. [Google Scholar] [CrossRef]

- ASM-International. Nondestructive Evaluation and Quality Control, 9th ed.; ASM-International: Russell Township, OH, USA, 1989. [Google Scholar]

- Liu, B.X.; Huang, L.J.; Geng, L.; Kaveendran, B.; Wang, B.; Song, X.Q.; Cui, X.P. Gradient grain distribution and enhanced properties of novel laminated Ti–TiBw/Ti composites by reaction hot-pressing. Mater. Sci. Eng. A 2014, 595, 257–265. [Google Scholar] [CrossRef]

- Liu, B.X.; Huang, L.J.; Geng, L.; Wang, B.; Cui, X.P. Effects of reinforcement volume fraction on tensile behaviors of laminated Ti–TiBw/Ti composites. Mater. Sci. Eng. A 2014, 610, 344–349. [Google Scholar] [CrossRef]

- Shamekh, M.; Pugh, M.; Medraj, M. Understanding the reaction mechanism of in-situ synthesized (TiC–TiB2)/AZ91 magnesium matrix composites. Mater. Chem. Phys. 2012, 135, 193–205. [Google Scholar] [CrossRef]

- Cui, X.; Fan, G.; Huang, L.; Gong, J.; Wu, H.; Zhang, T.; Geng, L.; Meng, S. Preparation of a novel layer-structured Ti3Al matrix composite sheet by liquid–solid reaction between al foils and TiB/Ti composite foils. Mater. Des. 2016, 101, 181–187. [Google Scholar] [CrossRef]

- Cui, X.; Fan, G.; Geng, L.; Wang, Y.; Zhang, H.; Peng, H.-X. Fabrication of fully dense TiAl-based composite sheets with a novel microlaminated microstructure. Scr. Mater. 2012, 66, 276–279. [Google Scholar] [CrossRef]

- Halverson, D.C.; Pyzik, A.J.; Aksay, I.A.; Snowden, W.E. Processing of boron carbide-aluminum composites. J. Am. Ceram. Soc. 1989, 72, 775–780. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Khayyam, H.; Abdizadeh, H.; Karbalaei Akbari, M.; Pakseresht, A.H.; Ghasali, E.; Naebe, M. Boron carbide reinforced aluminium matrix composite: Physical, mechanical characterization and mathematical modeling. Mater. Sci. Eng. A 2016, 658, 135–149. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Khayyam, H.; Abdizadeh, H.; Karbalaei Akbari, M.; Pakseresht, A.H.; Abdi, F.; Abbasi, A.; Naebe, M. Efects of B4C, TiB2 and ZrSiO4 ceramic particles on mechanical properties of aluminium matrix composites: Experimental investigation and predictive modeling. Ceram. Int. 2016, 42, 6206–6220. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Rajabi, S.; Shirvanimoghaddam, K.; Baharvandi, H.R. Wear and friction behavior of nanosized TiB2 and TiO2 particle-reinforced casting A356 aluminium nanocomposites: A comparative study focusing on particle capture in matrix. J. Compos. Mater. 2015, 1–17. [Google Scholar]

- Qin, Y.X.; Lu, W.J.; Sheng, X.F.; Yang, Z.F.; Zhang, D. Mechanical properties of in situ synthesized titanium matrix composites at elevates temperatures. Mater. Trans. 2003, 44, 2282–2287. [Google Scholar] [CrossRef]

- Vayadar, K.S.; Rani, S.D.; Prasad, V.V.B. Microstructural and mechanical characteristics of in-situ titanium matrix composites. Int. J. Theor. Appl. Res. Mech. Eng. 2012, 2. [Google Scholar] [CrossRef]

| Manufacturing Temperature (°C) | Geometrical Density, ρ (g/cm3) | Archimedes’ Density, ρ (g/cm3) | Young’s Modulus, E (GPa) | Specific Stiffness, E/ρ (GPa/g·cm3) |

|---|---|---|---|---|

| 900 | 3.51 | 3.53 | 113 | 37.01 |

| 950 | 3.50 | 3.62 | 138 | 38.12 |

| 1000 | 3.56 | 3.65 | 164 | 44.93 |

| 1100 | 3.53 | 3.66 | 167 | 45.62 |

| 1200 | 3.59 | 3.71 | 186 | 50.13 |

| 1300 | 3.73 | 3.81 | 211 | 55.38 |

| 1400 | 3.80 | 3.88 | 237 | 61.08 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arévalo, C.; Montealegre-Meléndez, I.; Ariza, E.; Kitzmantel, M.; Rubio-Escudero, C.; Neubauer, E. Influence of Sintering Temperature on the Microstructure and Mechanical Properties of In Situ Reinforced Titanium Composites by Inductive Hot Pressing. Materials 2016, 9, 919. https://doi.org/10.3390/ma9110919

Arévalo C, Montealegre-Meléndez I, Ariza E, Kitzmantel M, Rubio-Escudero C, Neubauer E. Influence of Sintering Temperature on the Microstructure and Mechanical Properties of In Situ Reinforced Titanium Composites by Inductive Hot Pressing. Materials. 2016; 9(11):919. https://doi.org/10.3390/ma9110919

Chicago/Turabian StyleArévalo, Cristina, Isabel Montealegre-Meléndez, Enrique Ariza, Michael Kitzmantel, Cristina Rubio-Escudero, and Erich Neubauer. 2016. "Influence of Sintering Temperature on the Microstructure and Mechanical Properties of In Situ Reinforced Titanium Composites by Inductive Hot Pressing" Materials 9, no. 11: 919. https://doi.org/10.3390/ma9110919

APA StyleArévalo, C., Montealegre-Meléndez, I., Ariza, E., Kitzmantel, M., Rubio-Escudero, C., & Neubauer, E. (2016). Influence of Sintering Temperature on the Microstructure and Mechanical Properties of In Situ Reinforced Titanium Composites by Inductive Hot Pressing. Materials, 9(11), 919. https://doi.org/10.3390/ma9110919