5.1. Reaction Propagation under Explosive Loading

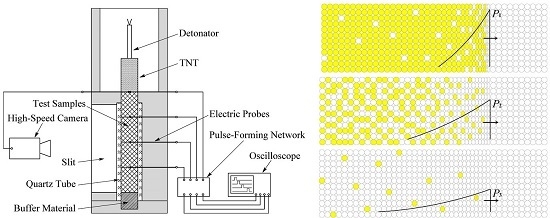

This section describes the reaction propagation of PTFE/Ti/W energetic materials with low porosity under explosive loading, with a corresponding schematic illustration shown in

Figure 8.

When detonation wave of TNT reaches the interface between the explosive and the energetic test samples, a triangular shock pulse with initial peak pressure

P1 generates and propagates into the test samples. As the shock-induced instantaneous temperature rises, a chemical reaction occurs shortly behind the shock front [

18]. Initially, a high temperature rise is expected due to the intense shock compression, which induces a prompt and powerful chemical reaction between Ti and PTFE. As a result, a bright light with a distinct boundary can be observed.

As the shock wave propagates, the waveform changes gradually. The peak pressure decreases to

P2, and the pulse duration increases due to the rarefaction wave following the shock front. The rarefaction wave takes energy away from the shock pulse. The chemical reaction energy has no sufficient rapidity or quantity to balance the energy losses of rarefaction wave, resulting in a reduction of the shock-induced temperature rise and therefore decreasing the extent of reaction between Ti and PTFE. Less reactant is converted into product, and the reaction is not as prompt as in the initial state. Consequently, the light dims and the boundary becomes blurred.

Figure 9 depicts a residual sample after test No. 2. Microscopically, the reaction surface is rough and porous, providing direct evidence of the incomplete reaction.

As the peak pressure of the shock pulse attenuates to P3, the pulse duration further increases and shock temperature further decreases. At this time, the reaction occurs only at a few points, and the reaction is so weak that little light can be observed. Finally, the light goes out because of the further attenuation of the shock wave.

These results demonstrate that the reaction propagation of PTFE/Ti/W energetic materials with low porosity is not self-sustained. The energy released by the chemical reaction is insufficient to compensate for energy loss caused by the shock attenuation. The shock-induced chemical reaction is very sensitive to the shock pressure, and the energy release is directly related to shock temperature. Accordingly, it is necessary to calculate the shock parameters under explosive loading for different energetic samples.

5.2. Theoretical Calculation of Shock Parameters

This section presents a theoretical calculation of shock parameters based on experimental data, from which the shock pressure and shock temperature are obtained for different samples.

The time when shock front reaches each electric probe can be averaged for samples with the same material proportions, and a second-order polynomial can be used to fit a time–distance relationship based on the least squares theory. The fitting curve can be expressed as follows:

where

t and

x are the time and distance, respectively, at which the shock front reaches the electric probes; and

a and

b are fitting coefficients, which are listed in

Table 3. The fitting curves for different samples are shown in

Figure 10. Then the shock wave velocity can be expressed as:

The

US–x curves for different samples are presented in

Figure 11.

McQueen [

19] derived a popular equation of state (EOS) for porous materials:

where

P is the shock wave pressure;

C,

S, and

are the longitudinal elastic wave velocity at zero pressure, empirical Hugoniot coefficient, and specific volume of the fully dense solid with TMD, respectively; and

,

V00, and

V are the Grüneisen coefficient, initial specific volume, and post-shock specific volume of the porous material, respectively.

The following expression is an approximate equation that can be used based on the assumption that

is a constant [

20]:

The parameters

C,

S, and

can be estimated from the experimental data of the constituent materials by mass-weighted average method, as follows:

where

mi is the mass fraction of constituent materials, the parameters of which are listed in

Table 4.

According to the one-dimensional shock wave theory, the mass conservation equation and momentum conservation equation for porous materials under shock loading can be written as follows:

where

is the post-shock particle velocity. Substituting Equation (9) into Equation (8), pressure can be derived as:

Combining Equations (5), (6), and (10) can establish the relationship between pressure

P and distance

x of shock wave propagation.

Figure 12 presents the

P–x curves for different samples. As

Figure 12 shows, the initial pressure varies from 17 to 20.7 GPa due to differences in wave impedance. The 70.7% TMD 16PTFE/8Ti/76W has the highest initial pressure, since it has the highest actual density. On the contrary, the initial pressure is the lowest in 98.8% TMD 68PTFE/32Ti because of its lowest actual density. The 70.7% TMD 16PTFE/8Ti/76W does not show a great reduction in pressure because its greater reactivity compensates for the effect of higher actual density and porosity. In contrast, the shock pressure in sample 96.7% TMD 45PTFE/55W attenuates the most rapidly as a result of its inertness.

When the shock wave propagates in the test samples, the material is compressed and experiences an instantaneous temperature rise. The thermodynamic process at the shock front is assumed to be adiabatic. The energy conservation equation for the Hugoniot shock process is written as follows:

where

E is specific internal energy along the Hugoniot curve; and

E0 and

P0 refer to initial internal energy and pressure, respectively. When

P0 equals zero, the shock temperature

T can be expressed by the following equation based on the assumption that the change of internal energy is completely converted into shock temperature,

where

T0 is ambient initial temperature, and

Cv is the heat capacity at constant volume, which can be estimated by mass-weighted average method,

Figure 13 presents the relationship between shock temperature

T and distance

x for different samples. As illustrated in the

T–x space, the temperature decreases rapidly as a result of shock pressure reduction. The temperature rise is more obvious in 70.7% TMD 16PTFE/8Ti/76W than in other materials because of its relatively high porosity. The temperature decreases the most rapidly in 96.7% TMD 45PTFE/55W due to its inertness.

5.3. Analysis of Differences in Energy Release

The shock-induced chemical reaction process is assumed to be temperature-controlled. The energy release

q can be characterized by the following equation:

where

N is the molar number of the reactant per unit volume,

y is the reaction extent, which is related to the shock temperature, and

is the heat release per mole of reactant.

Table 5 lists the molar numbers of reactants per unit volume for different samples.

The reaction extent can be calculated through chemical reaction kinetics. The Avrami–Erofeev equation is popularly used to describe solid state reactions under a high rate of temperature rising, the equation is expressed as follows [

21]:

where

T is absolute temperature,

Ea is apparent activation energy,

R is molar gas constant, and

n is a coefficient related to boundary conditions and reaction mechanisms. The reaction parameters of PTFE/Ti are tabulated in

Table 6 and the

y–T curve of PTFE/Ti is shown in

Figure 14.

Then, the relationship between energy release

q and distance

x can be established for different samples, as shown in

Figure 15.

As

Figure 15 shows, all samples release a relatively large amount of energy at the beginning because of the high temperature rise. As the propagation distance increases, the temperature gradually decreases. As a result, the reaction extent decreases, which is reflected by reductions in brightness. Finally, the light goes out, indicating that the energy release has decreased almost to zero.

Compared with 98.8% TMD 68PTFE/32Ti, 90.3% TMD 34PTFE/16Ti/50W experiences a similar shock temperature. However, the quantity of reactant decreases when the inert tungsten powder is added, leading to a decrease in energy release per unit volume. In addition, the W absorbs some of the energy released by the reaction in heating up the inert W particles, which will further reduce the energy. Consequently, the reaction produces a relatively dim light.

Compared with 90.3% TMD 34PTFE/16Ti/50W, the quantity of reactant for 70.7% TMD 16PTFE/8Ti/76W is even further decreased, and the W further absorbs the energy released by the reaction. However, the shock temperature is more dramatic due to the significant increase in porosity, leading to a higher energy release. Therefore, the reaction produces a brighter light with a longer continuous distance.

In summary, the results of these experiments demonstrate that the energy release of PTFE/Ti/W composites under explosive loading is influenced by propagation distance, W content, and porosity.