Ferrite Film Loaded Frequency Selective Metamaterials for Sub-GHz Applications

Abstract

:1. Introduction

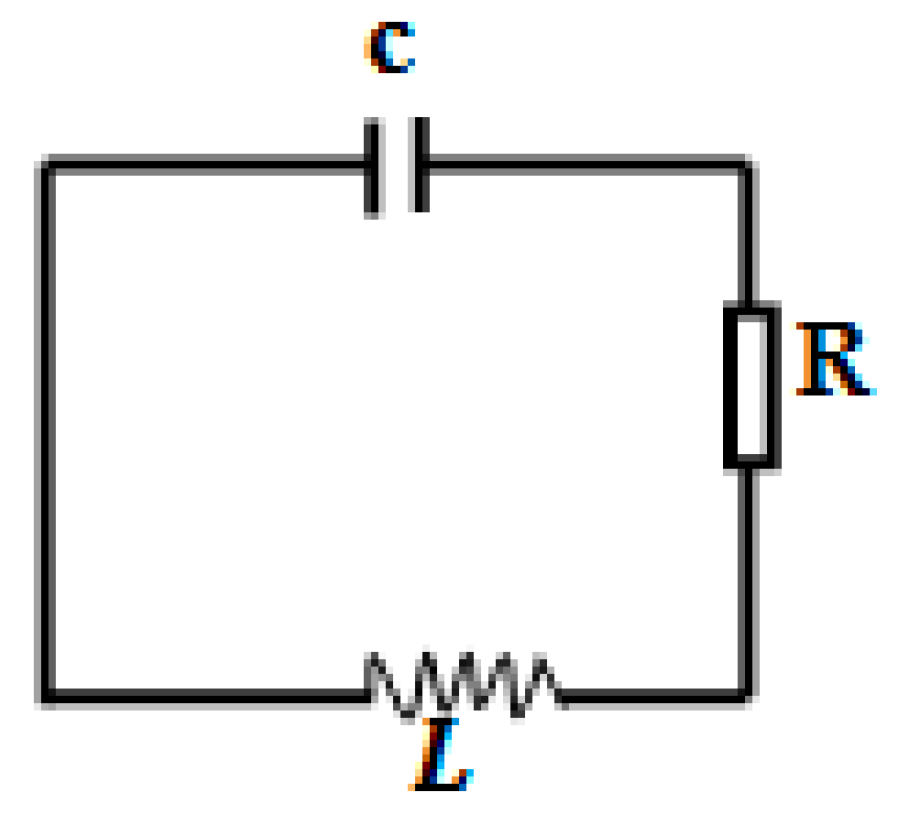

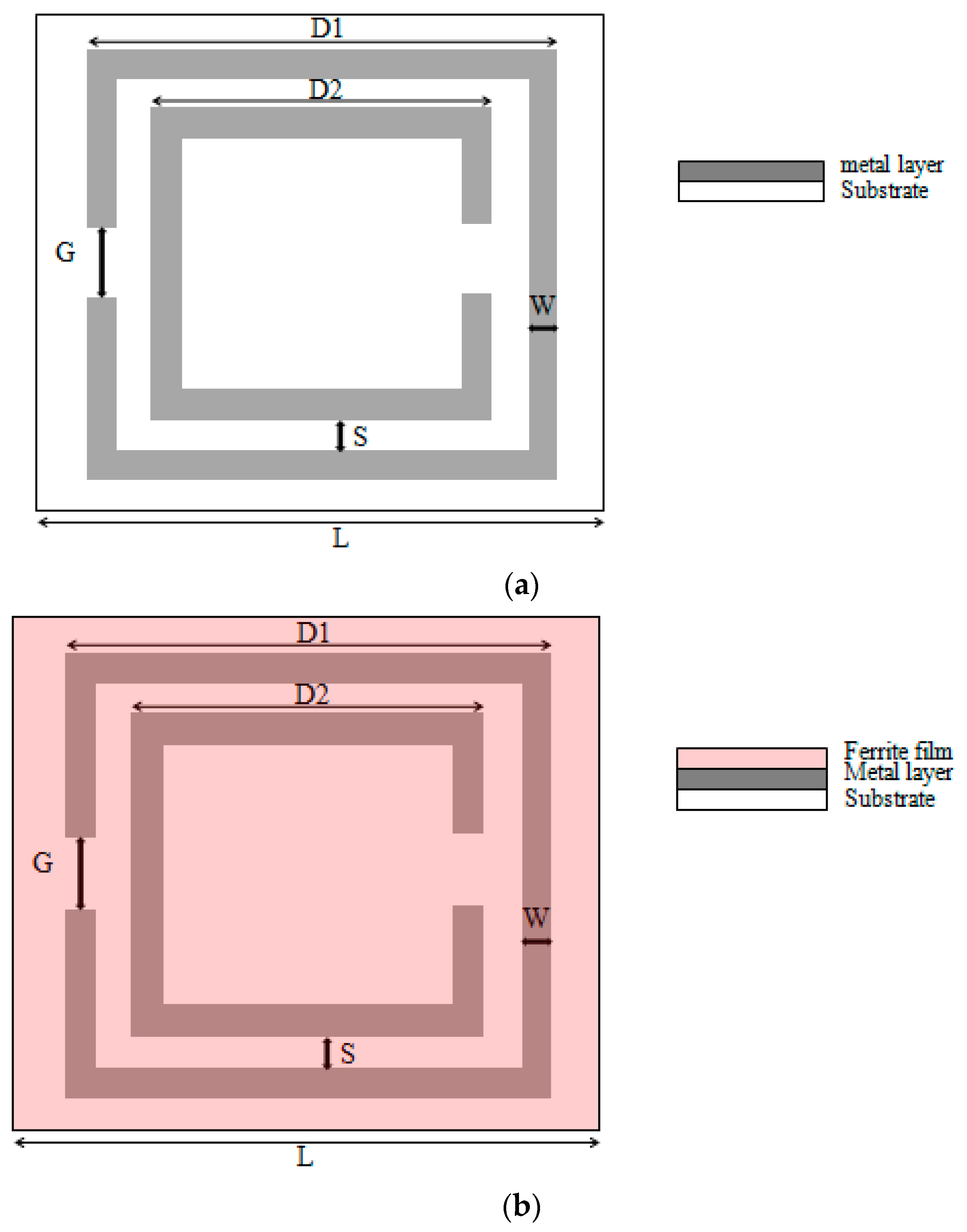

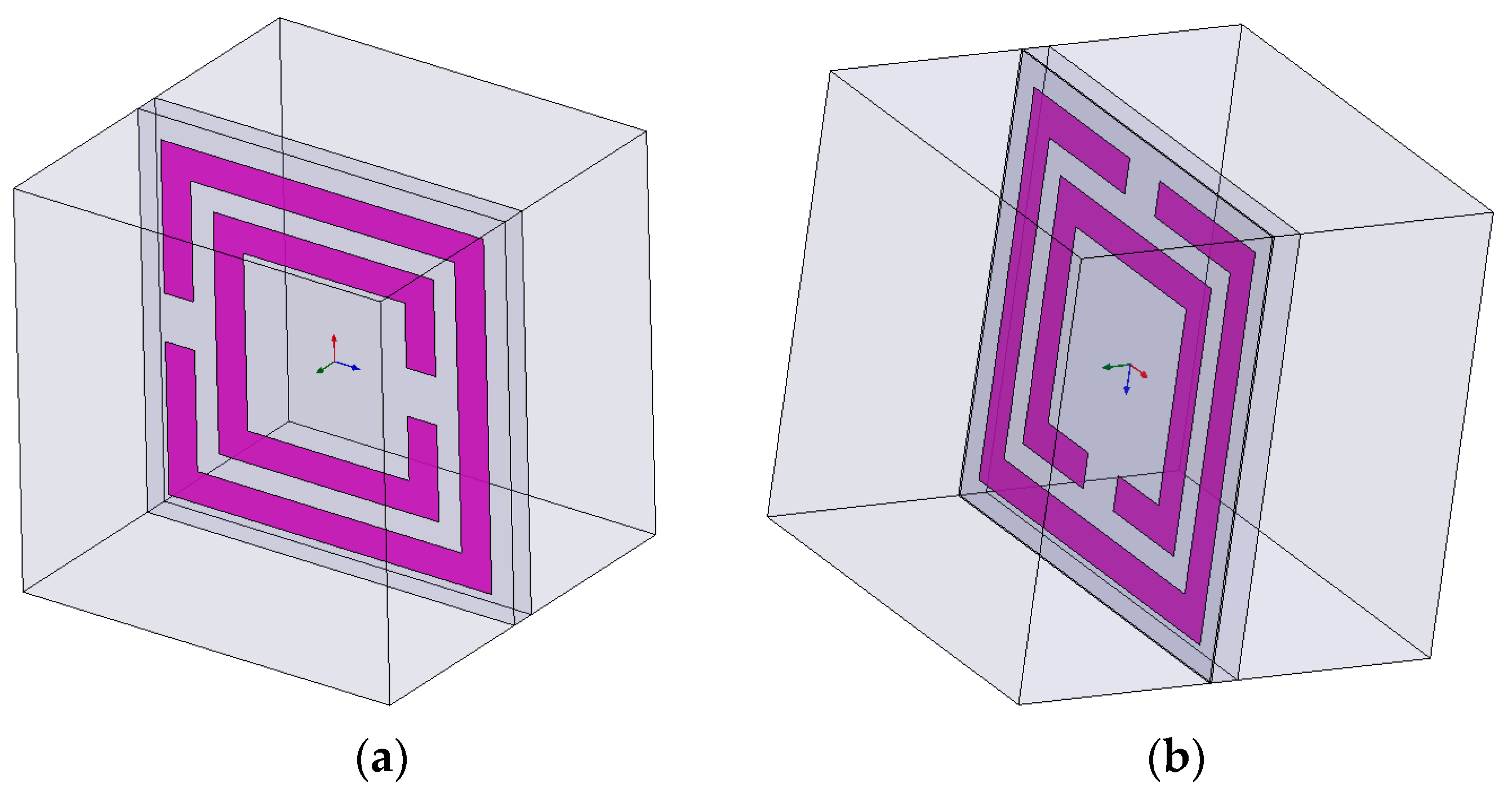

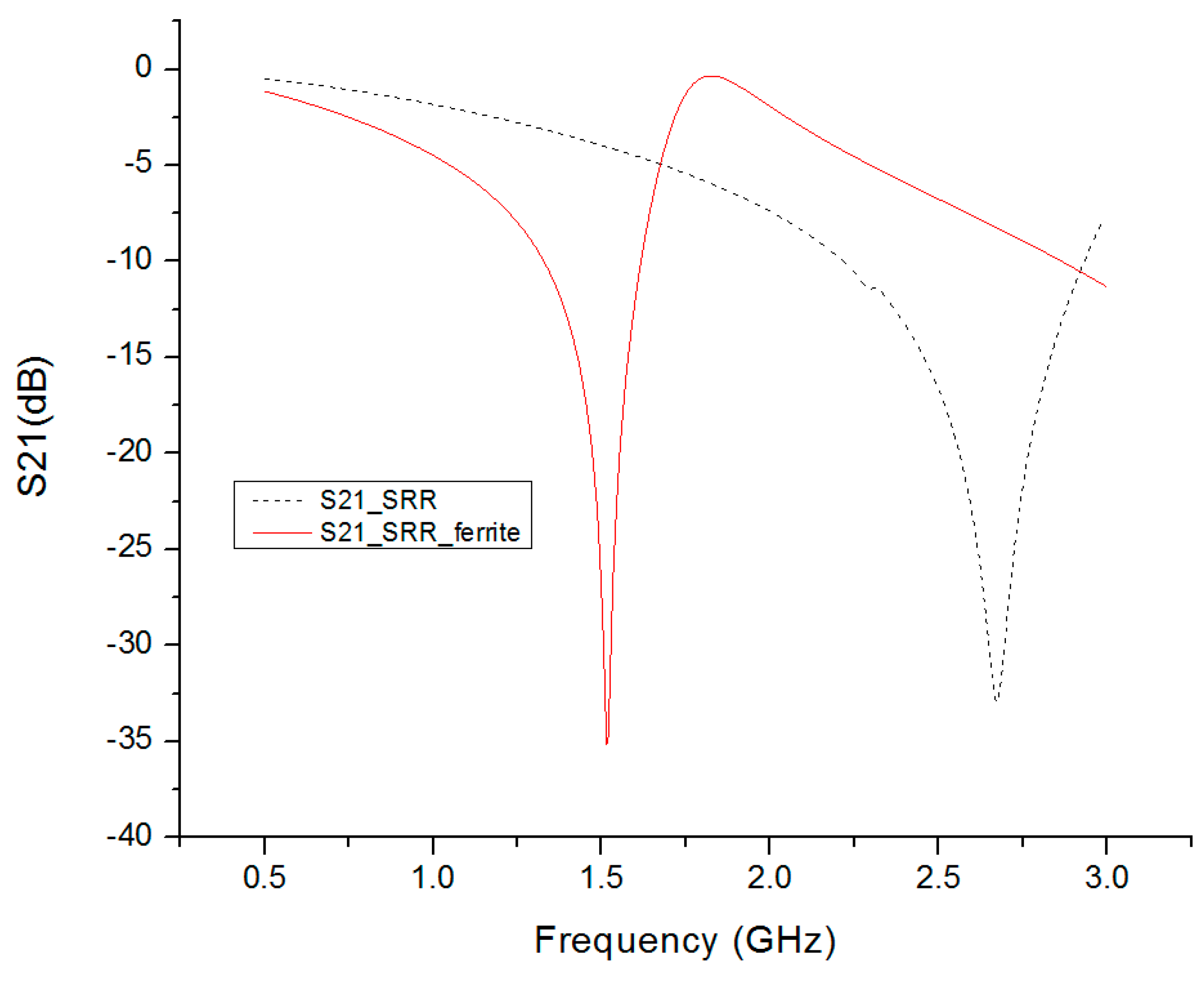

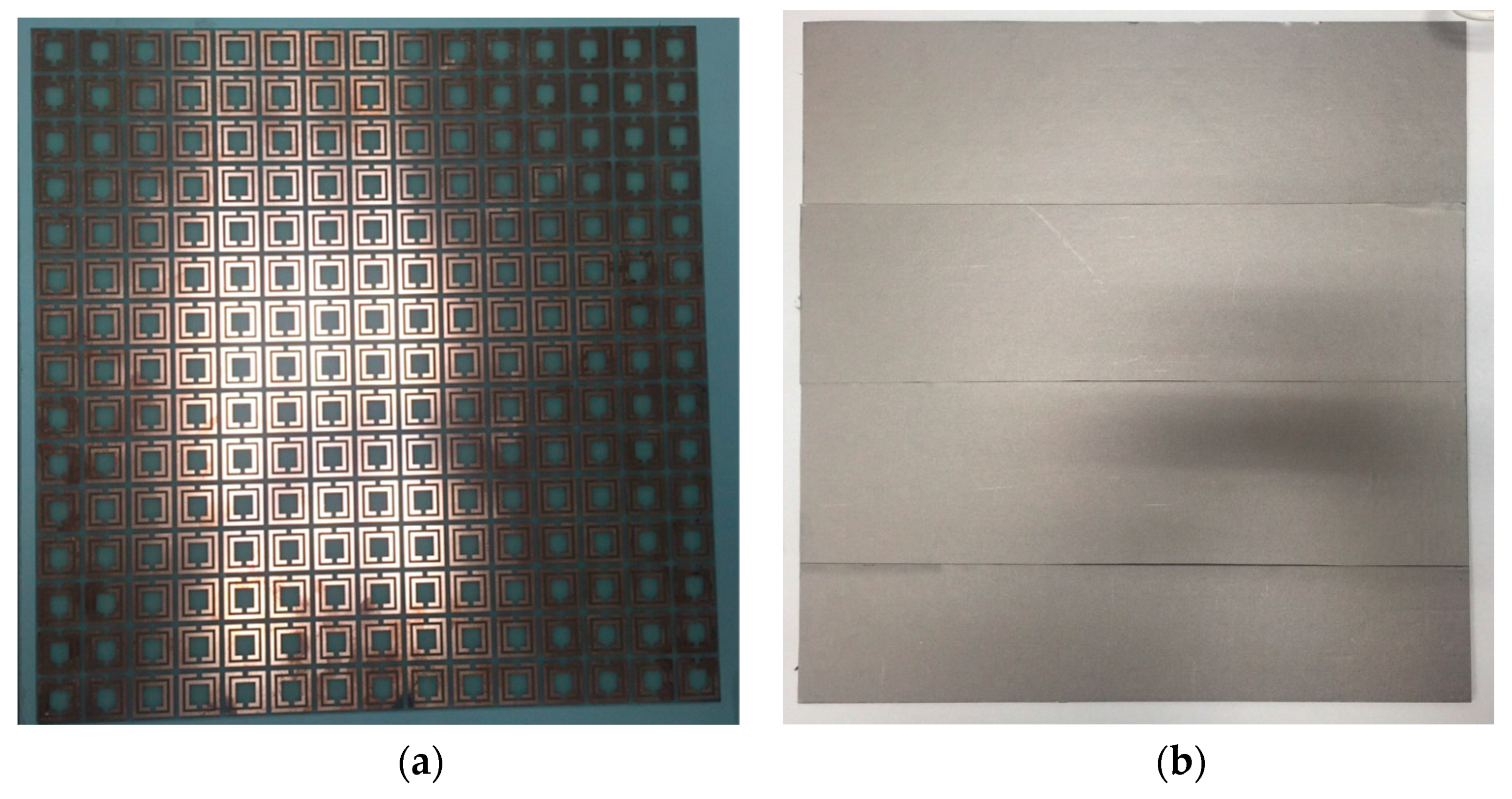

2. Design of SRR Metamaterials

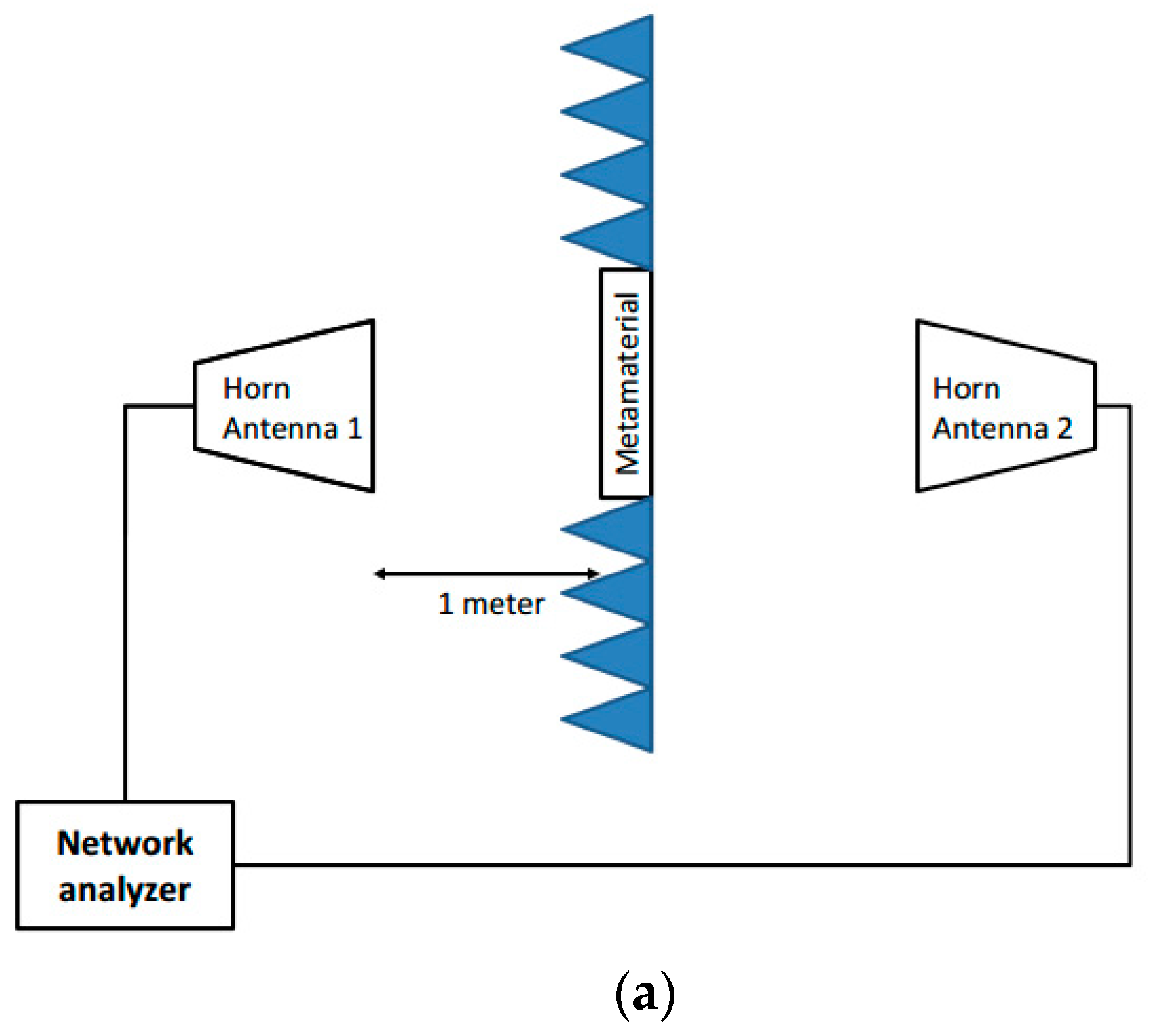

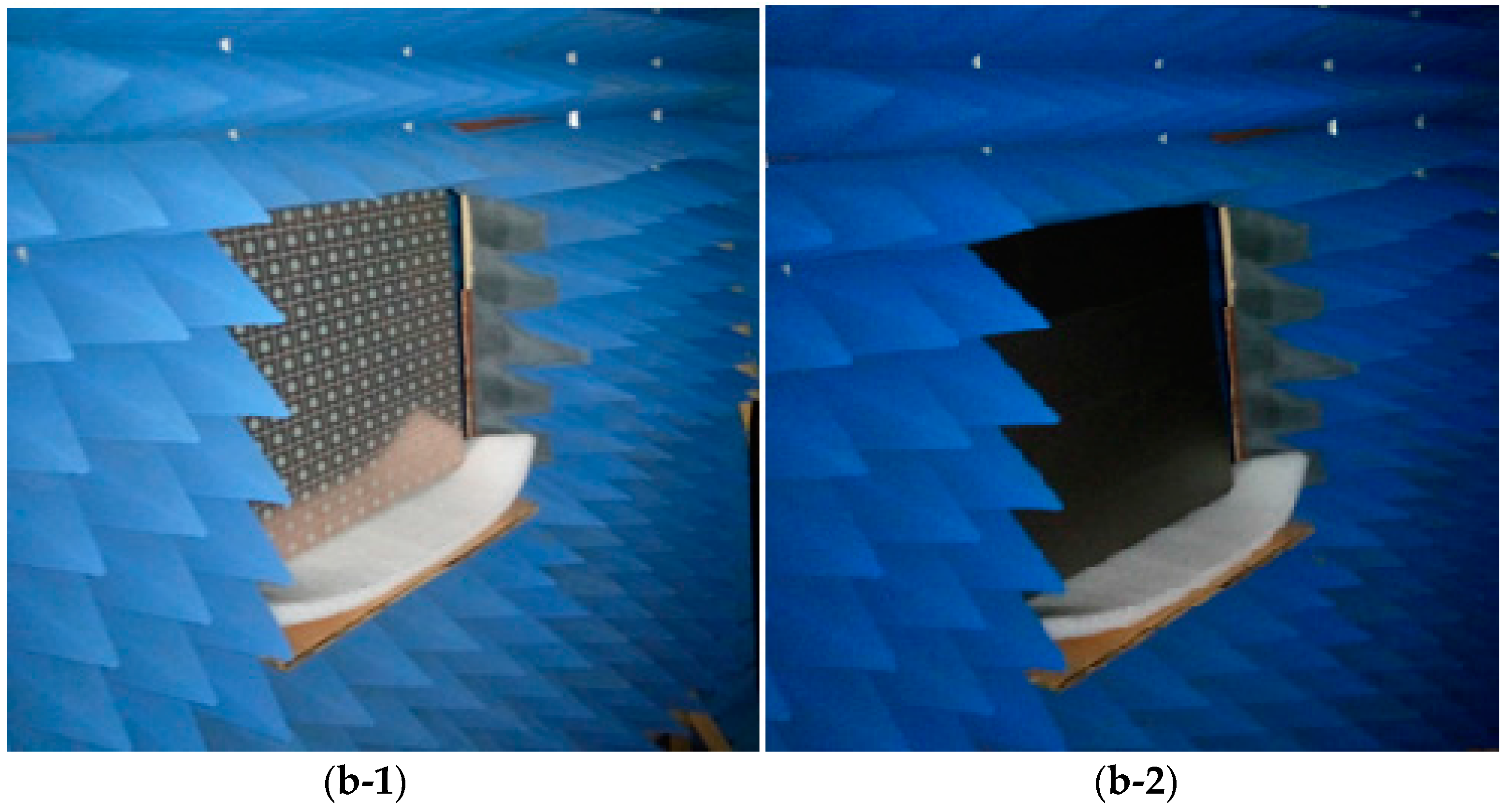

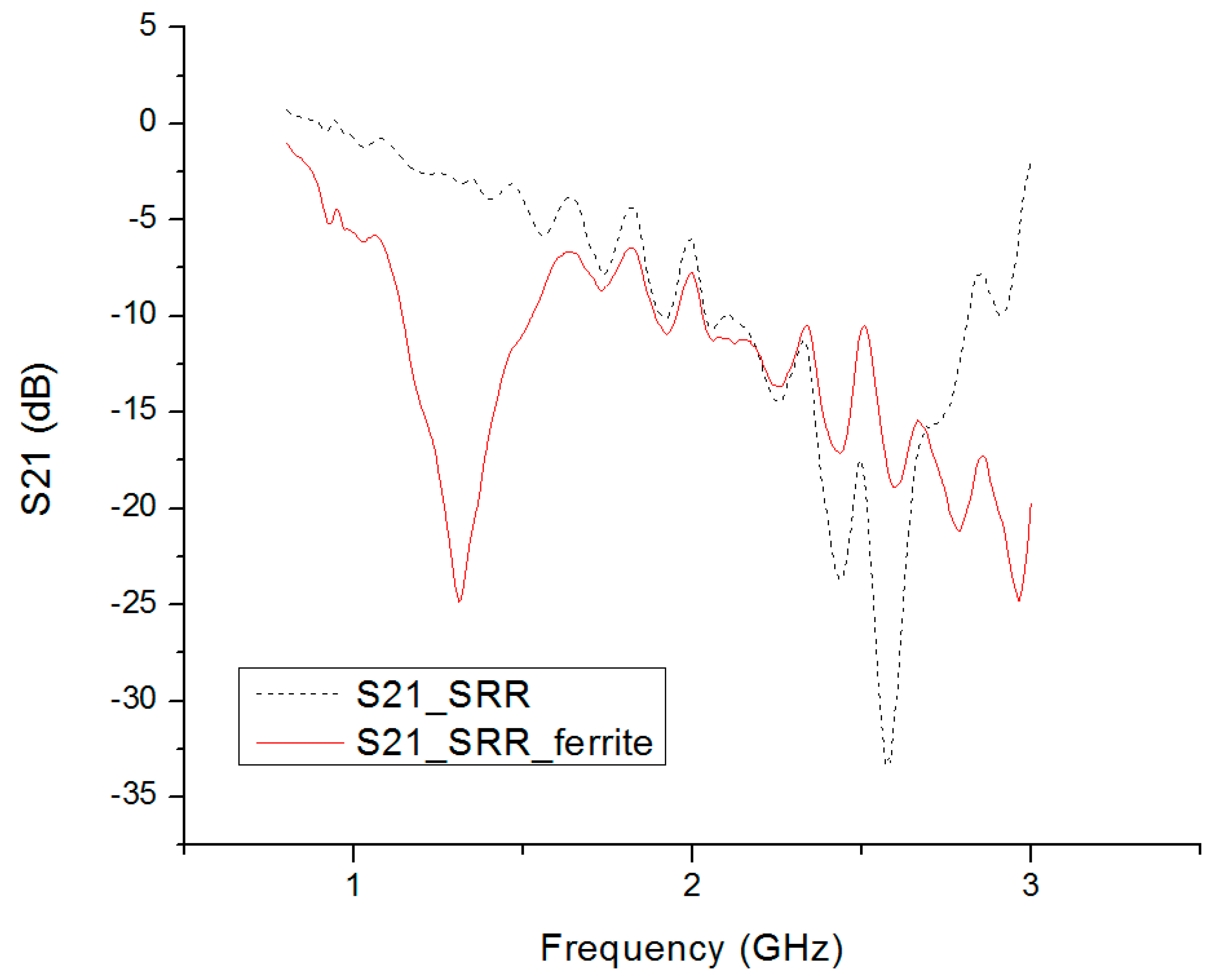

3. Prototype Preparation and Measurement Results

4. Discussion and Conclusions

Author Contributions

Conflicts of Interest

References

- Yelin, D.; Oron, D.; Thiberge, S.; Moses, E.; Silberberg, Y. Multiphoton plasmon-resonance microscopy. Opt. Express 2003, 11, 1385–1391. [Google Scholar] [CrossRef] [PubMed]

- Veselago, V.G. The electrodynamics of substances with simultaneously negative values of permittivity and permeability. Sov. Phys. Uspekhi 1968, 10, 509–514. [Google Scholar] [CrossRef]

- Pendry, J.B.; Holden, A.J.; Stewart, W.J.; Youngs, I. Extremely low frequency plasmons in metallic mesostructures. Phys. Rev. Lett. 1996, 76, 4773–4776. [Google Scholar] [CrossRef] [PubMed]

- Soukoulis, C.M.; Linden, S.; Wegener, M. Negative refractive index at optical wavelengths. Science 2007, 315, 47–49. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Rahmat-Samii, Y. Mutual coupling reduction of microstrip antennas using electromagnetic band-gap structure. IEEE AP-S/URSA Int. Symp. Dig. 2001, 2, 478–481. [Google Scholar]

- Decker, M.; Staude, I.; Shishkin, I.I.; Samusev, K.B.; Parkinson, P.; Sreenivasan, V.K.; Minovich, A.; Miroshnichenko, A.E.; Zvyagin, A.; Jagadish, C.; et al. Dual-channel spontaneous emission of quantum dots in magnetic metamaterials. Nat. Commun. 2013, 4, 2949. [Google Scholar] [CrossRef] [PubMed]

- Shurig, D.; Mock, J.; Justice, B.; Cummer, S.; Pendry, J.; Starr, A.; Smith, D. Metamaterial electromagnetic cloak at microwave frequencies. Science 2006, 314, 977–980. [Google Scholar] [CrossRef] [PubMed]

- Zheludev, N.I.; Kivshar, Y.S. From metamaterials to metadevices. Nat. Mater. 2012, 11, 917–924. [Google Scholar] [CrossRef] [PubMed]

- Lapine, M.; Shadrivov, I.V.; Powell, D.A.; Kivshar, Y.S. Magnetoelastic metamaterials. Nat. Mater. 2012, 11, 30–33. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, Z. Superlenses to overcome the diffraction limit. Nat. Mater. 2008, 7, 435–441. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Ji, C.; Mock, J.J.; Chin, J.Y.; Cui, T.J.; Smith, D.R. Broadband ground-plane cloak. Science 2009, 323, 366–369. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.R. A cloaking coating for murky media. Science 2014, 345, 384–385. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Liu, Y.; Lan, L.; Wu, T.; Jiang, W.; Ong, C.K.; He, S. First experimental demonstration of an isotropic electromagnetic cloak with strict conformal mapping. Sci. Rep. 2013, 3, 2182. [Google Scholar] [CrossRef] [PubMed]

- Lipworth, G.; Ensworth, J.; Seetharam, K.; Huang, D.; Lee, J.S.; Schmalenberg, P.; Nomura, T.; Reynolds, M.S.; Smith, D.R.; Urzhumov, Y. Magnetic metamaterial superlens for increased range wireless power transfer. Sci. Rep. 2014, 4, 3642. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoo, Y.J.; Ju, S.; Park, S.Y.; Kim, Y.J.; Bong, J.; Lim, T.; Kim, K.W.; Rhee, J.Y.; Lee, Y. Metamaterial absorber for electromagnetic waves in periodic water droplets. Sci. Rep. 2015, 5, 14018. [Google Scholar] [CrossRef] [PubMed]

- Su, P.; Zhao, Y.; Jia, S.; Shi, W.; Wang, H. An ultra-wideband and polarization-independent metasurface for RCS reduction. Sci. Rep. 2016, 6, 20387. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Liu, P.; Yang, M.; Wang, Q.; Song, J.; Dong, L. From flexible and stretchable meta-atom to metamaterial: A wearable microwave meta-skin with tunable frequency selective and cloaking effects. Sci. Rep. 2016, 6, 21921. [Google Scholar] [CrossRef] [PubMed]

- Konstantinidis, K.; Feresidis, A.P. Broadband near-zero index metamaterials. J. Opt. 2015, 17, 105104. [Google Scholar] [CrossRef]

- Xu, H.-X.; Wang, G.-M.; Tao, Z.; Cui, T.J. High-directivity emissions with flexible beam numbers and beam directions using gradient-refractive-index fractal metamaterial. Sci. Rep. 2014, 4, 5744. [Google Scholar] [CrossRef] [PubMed]

- Orazbayev, B.; Beruete, M.; Pacheco-Peña, V.; Crespo, G.; Teniente, J.; Navarro-Cía, M. Soret fishnet metalens antenna. Sci. Rep. 2015. [Google Scholar] [CrossRef] [PubMed]

- Qi, M.Q.; Tang, W.X.; Ma, H.F.; Pan, B.C.; Tao, Z.; Sun, Y.Z.; Cui, T.J. Suppressing side-lobe radiations of horn antenna by loading metamaterial lens. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Qi, M.Q.; Tang, W.X.; Cui, T.J. A broadband bessel beam launcher using metamaterial lens. Sci. Rep. 2015, 5, 11732. [Google Scholar] [PubMed]

- El Badawe, M.; Almoneef, T.S.; Ramahi, O.M. A true metasurface antenna. Sci. Rep. 2016, 6, 19268. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Yuen, M.M.F. Passive UHF RFID packaging with electromagnetic band gap (EBG) material for metallic objects tracking. IEEE Trans. Comp. Packag. Manuf. Technol. 2011, 1, 1140–1146. [Google Scholar] [CrossRef]

- Bi, K.; Guo, Y.; Liu, X.; Zhao, Q.; Xiao, J.; Lei, M.; Zhou, J. Magnetically tunable Mie resonance-based dielectric metamaterials. Sci. Rep. 2014, 4, 7001. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.S.; Wang, Z.; Zhang, R.; Wang, H.; Lin, S.; Yu, F.; Moser, H.O. A meta-substrate to enhance the bandwidth of metamaterials. Sci. Rep. 2014, 4, 5264. [Google Scholar] [CrossRef] [PubMed]

- Bi, K.; Guo, Y.; Zhou, J.; Dong, G.; Zhao, H.; Zhao, Q.; Xiao, Z.; Liu, X.; Lan, C. Negative and near zero refraction metamaterials based on permanent magnetic ferrites. Sci. Rep. 2014, 4, 4139. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Cong, L.; Lin, H.; Xiao, B.; Yang, H.; Singh, R. Tunable electromagnetically induced transparency in coupled three dimensional split-ring-resonator metamaterials. Sci. Rep. 2016, 6, 20801. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Liu, X.; Zhou, J.; Kudyshev, Z.; Litchinitser, N.M. Experimental demonstration of anomalous field enhancement in all-dielectric transition magnetic metamaterials. Sci. Rep. 2015, 5, 16154. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Wang, J.; Wang, J.; Ma, H.; Du, H.; Zhang, J.; Qu, S.; Xu, Z. Reconfigurable all-dielectric metamaterial frequency selective surface based on high-permittivity ceramics. Sci. Rep. 2016, 6, 24178. [Google Scholar] [CrossRef] [PubMed]

- Datasheet of RF-M; Zhejiang GH Magnet Electricity Co.: Jinhua, China, 2016.

| Substance | Weight Percentage (wt %) |

|---|---|

| Iron | 65–85 |

| Silicon | 2–7 |

| Aluminum | 3–8 |

| PU (Polyurethane) | 10–20 |

| Additive | 1–3 |

| Name | Resonant Frequency (Simulation) | Resonant Frequency (Measurement) | Bandwidth (Simulation) | Bandwidth (Measurement) |

|---|---|---|---|---|

| SRR | 2.68 GHz | 2.58 GHz | 0.26 GHz | 0.51 GHz |

| SRR-ferrite | 1.5 GHz | 1.3 GHz | 0.39 GHz | 0.78 GHz |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, B.; Yuen, M.M.F.; Ye, T. Ferrite Film Loaded Frequency Selective Metamaterials for Sub-GHz Applications. Materials 2016, 9, 1009. https://doi.org/10.3390/ma9121009

Gao B, Yuen MMF, Ye T. Ferrite Film Loaded Frequency Selective Metamaterials for Sub-GHz Applications. Materials. 2016; 9(12):1009. https://doi.org/10.3390/ma9121009

Chicago/Turabian StyleGao, Bo, Matthew M. F. Yuen, and Terry Ye. 2016. "Ferrite Film Loaded Frequency Selective Metamaterials for Sub-GHz Applications" Materials 9, no. 12: 1009. https://doi.org/10.3390/ma9121009