2.1. Models

The general ADT model based on the Wiener process is given by:

where

X(

t) is the performance degradation value of product at time

t,

σ denotes the diffusion coefficient, which is assumed to be constant,

B(.) is the standard Brownian motion to describe the temporal variation of the degradation process, Λ(.) and

τ(.) are the monotonous functions with time,

θ and

γ are the time-scale parameters to present the linear or nonlinear modeling. Without loss of generality, the initial degradation value is set to be zero. If not,

X(

t) =

X(

t) −

X(0) will be used.

For the drift coefficient

μ(

S;

η), it is assumed to be dependent with the acceleration variable

S as the acceleration model. The acceleration model for both single and multiple acceleration variables is denoted as:

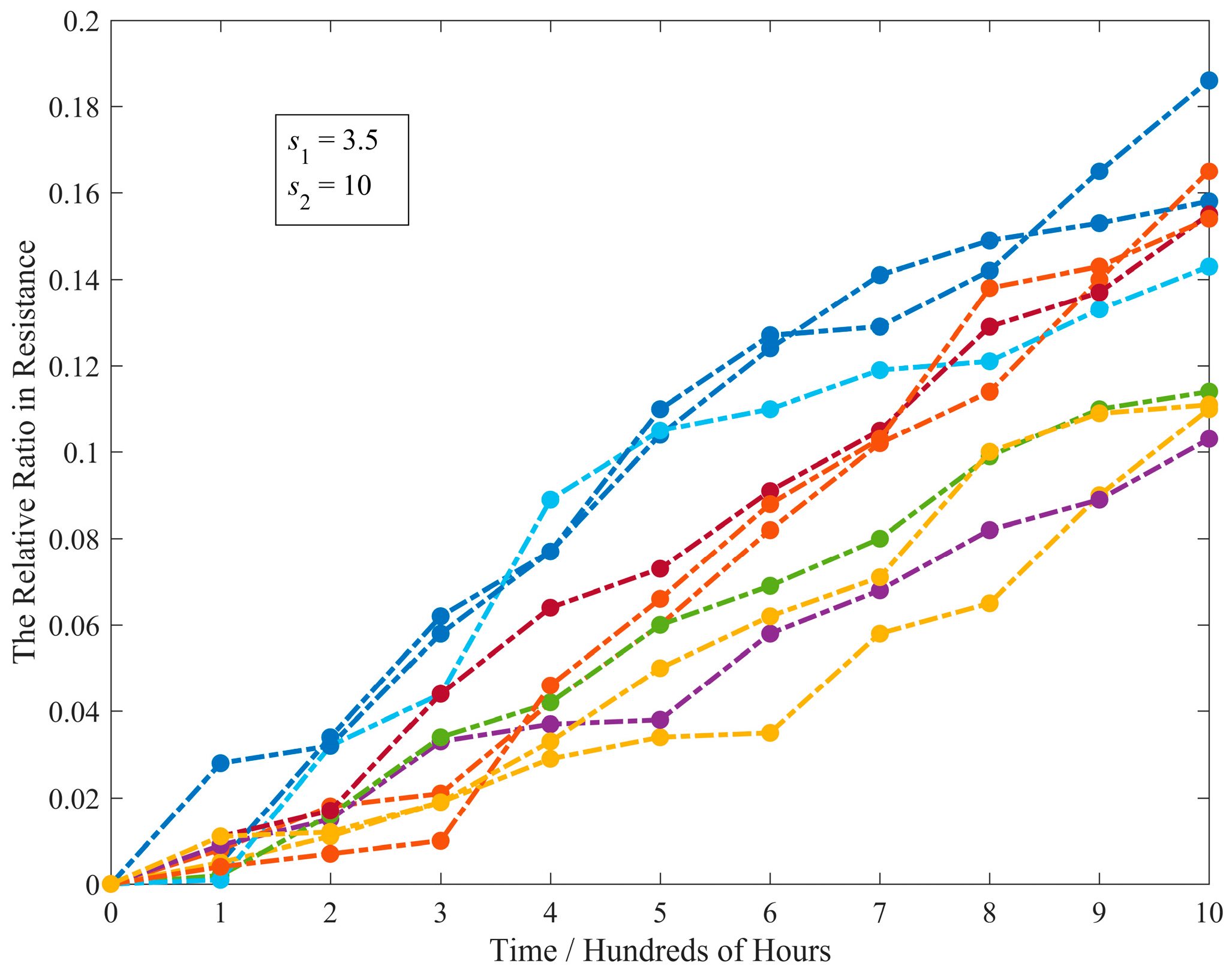

If there are p acceleration variables, then S = [s1, s2, …, sp] and η = [η0, η1, …, ηp], where sv is the vth acceleration stress type and ηv is the vth constant coefficient. While φ(.) is the continuous function of acceleration variables si, i = 1, 2, …, p. For instance, if φ(s) = exp(1/s), Equation (2) presents the Arrhenius relationship (exponential type); while if φ(s) = s, Equation (2) presents the Eyring relationship (power rule type).

Considering the unit-to-unit variation due to the inherent heterogeneity among the tested products, the drift coefficients

μ(

S;

η) are varied from product to product. Hence, we consider it as a random variable to present this kind of variation. Similar methods can be found in Peng and Tseng [

22], Wang [

23], and Si, et al. [

24]. Here, for simplicity, the coefficient

η0 in Equation (2) is assumed to follow a normal distribution with mean value

a and variance

b, i.e.,

η0 ~

N(

a,

b). The parameter values should be such that Pr(

μ(

S;

η) < 0) is nearly zero to avoid negative values existing in the drift coefficient of Equation (1). Thus, if such a random effect is not considered (

b = 0), Equation (2) will become the traditional acceleration model in Park and Padgett [

25].

The attraction of Equation (1) is that it can cover two commonly used Wiener processes in the ADT field as its limiting cases, which are:

Case 1. If Λ(

t;

θ) =

t and

τ(

t;

γ) =

t, Equation (1) is simplified to the traditional linear Wiener process, which is widely used for ADT analysis, see [

16,

25,

26,

27] and so on:

Case 2. If Λ(

t;

θ) =

τ(

t;

γ), Equation (1) reduces to a time-scale transformation Wiener process as in [

11,

18]:

Herein, if the time-scale transformation z = τ(t;γ) is used in Equation (4), then Case 2 will become a similar form of Case 1 as Y(z) = μ(S;η)z + σB(z).

Furthermore, if the acceleration variables in Equation (2) are set to be at normal stress levels where

μ(

S;

η) ~

N(

μ0,

), Equation (1) and its limiting cases (i.e., Equations (3) and (4)) are the degradation models used in traditional degradation analysis [

19,

20,

28].

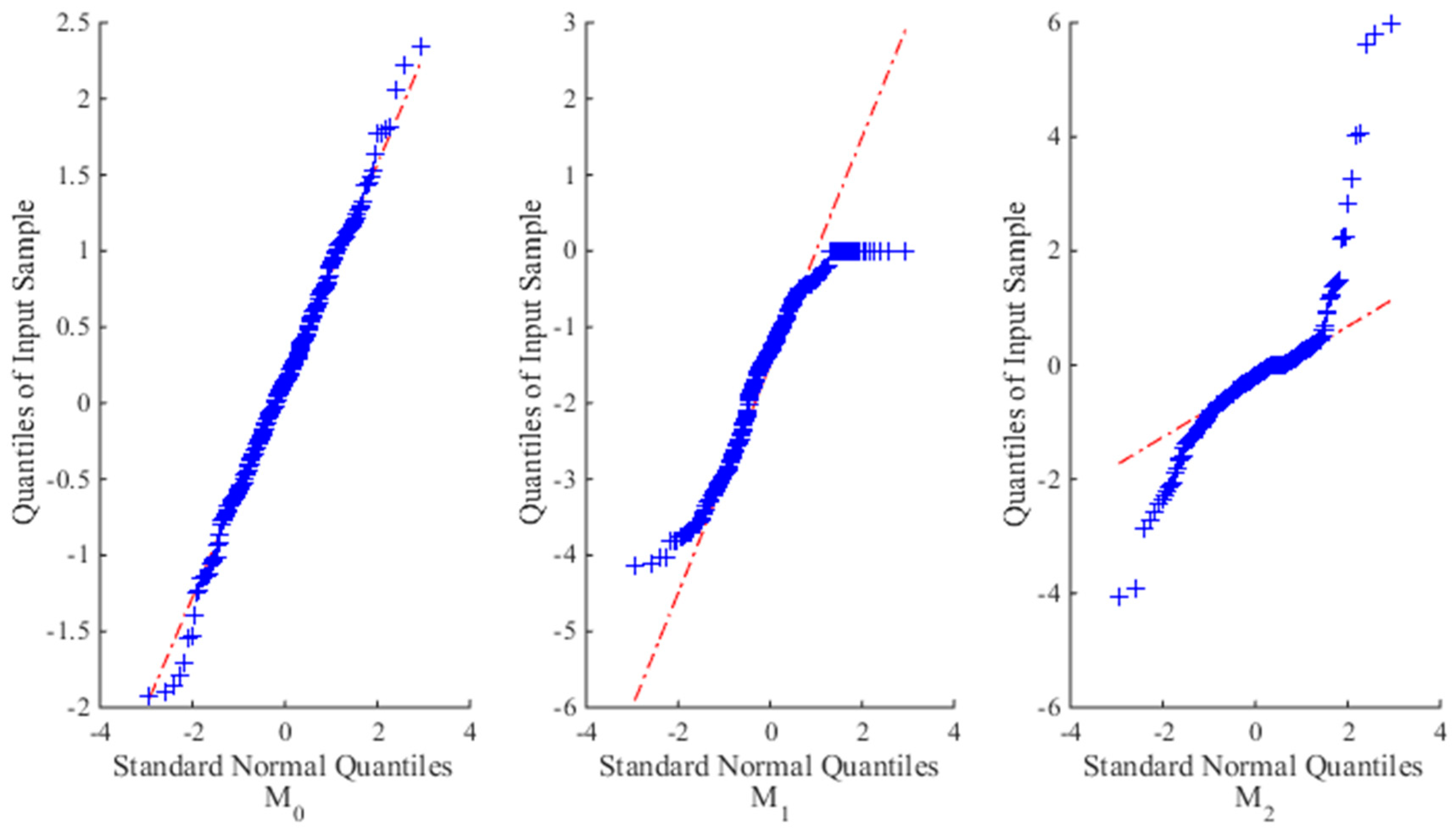

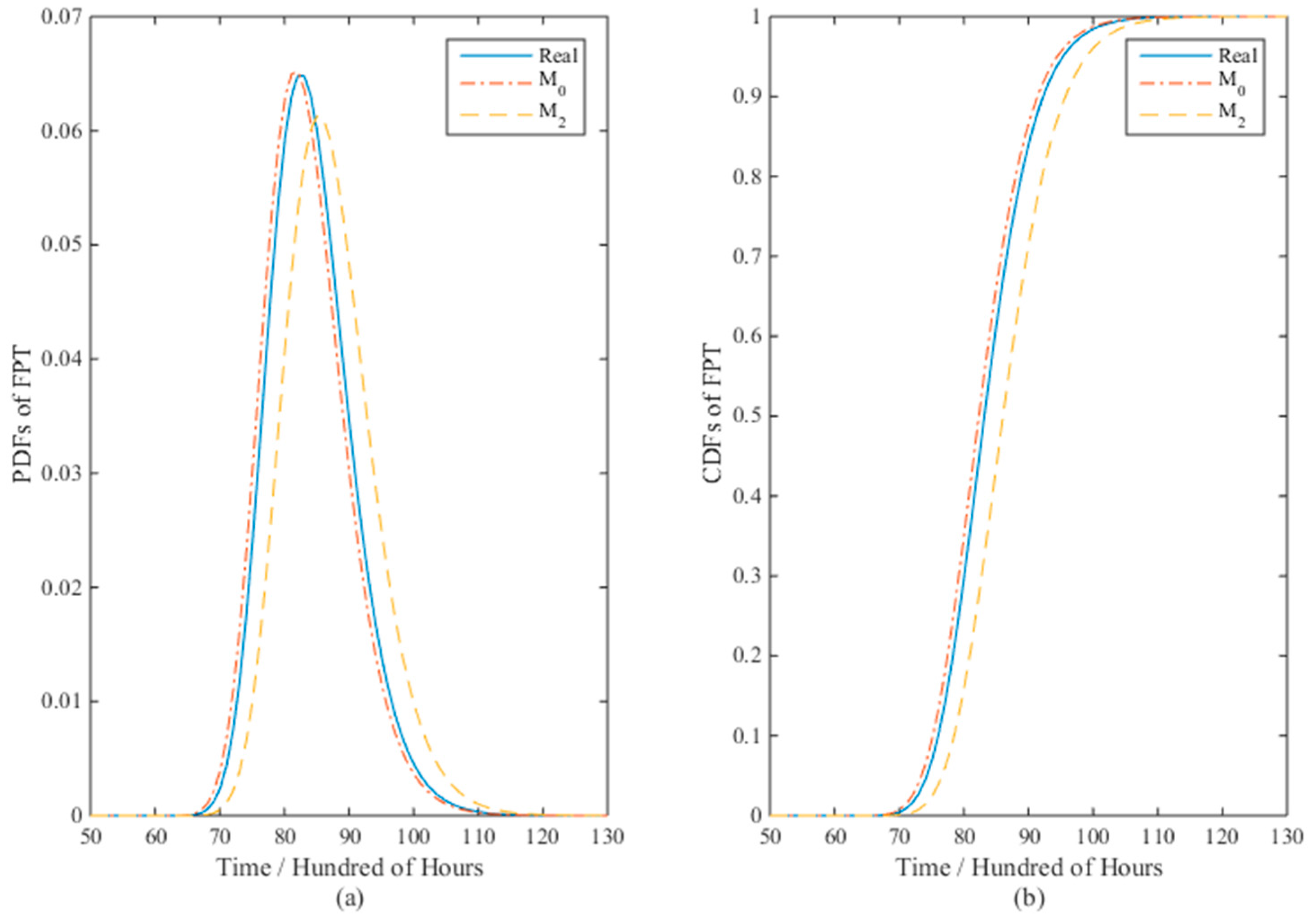

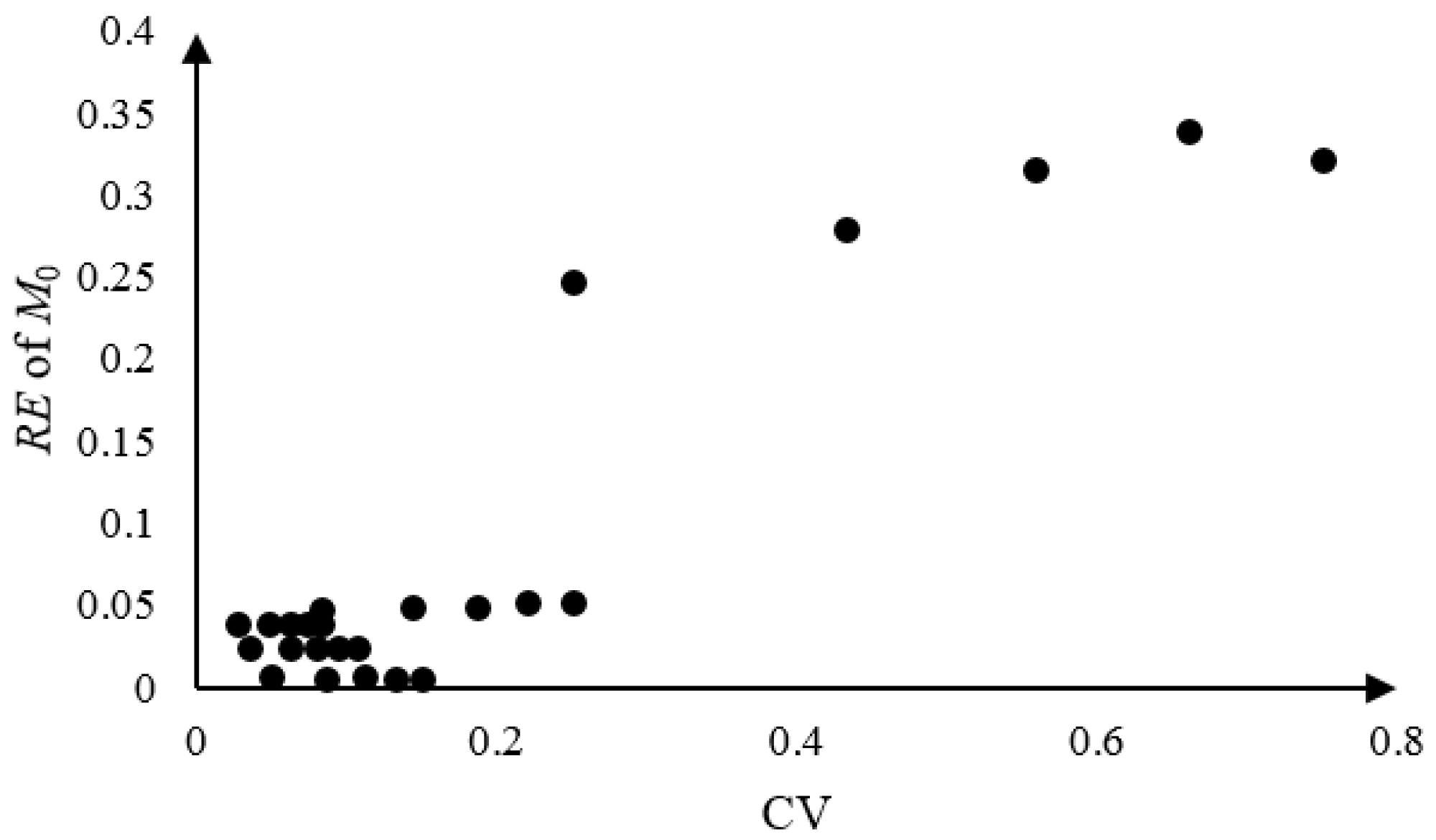

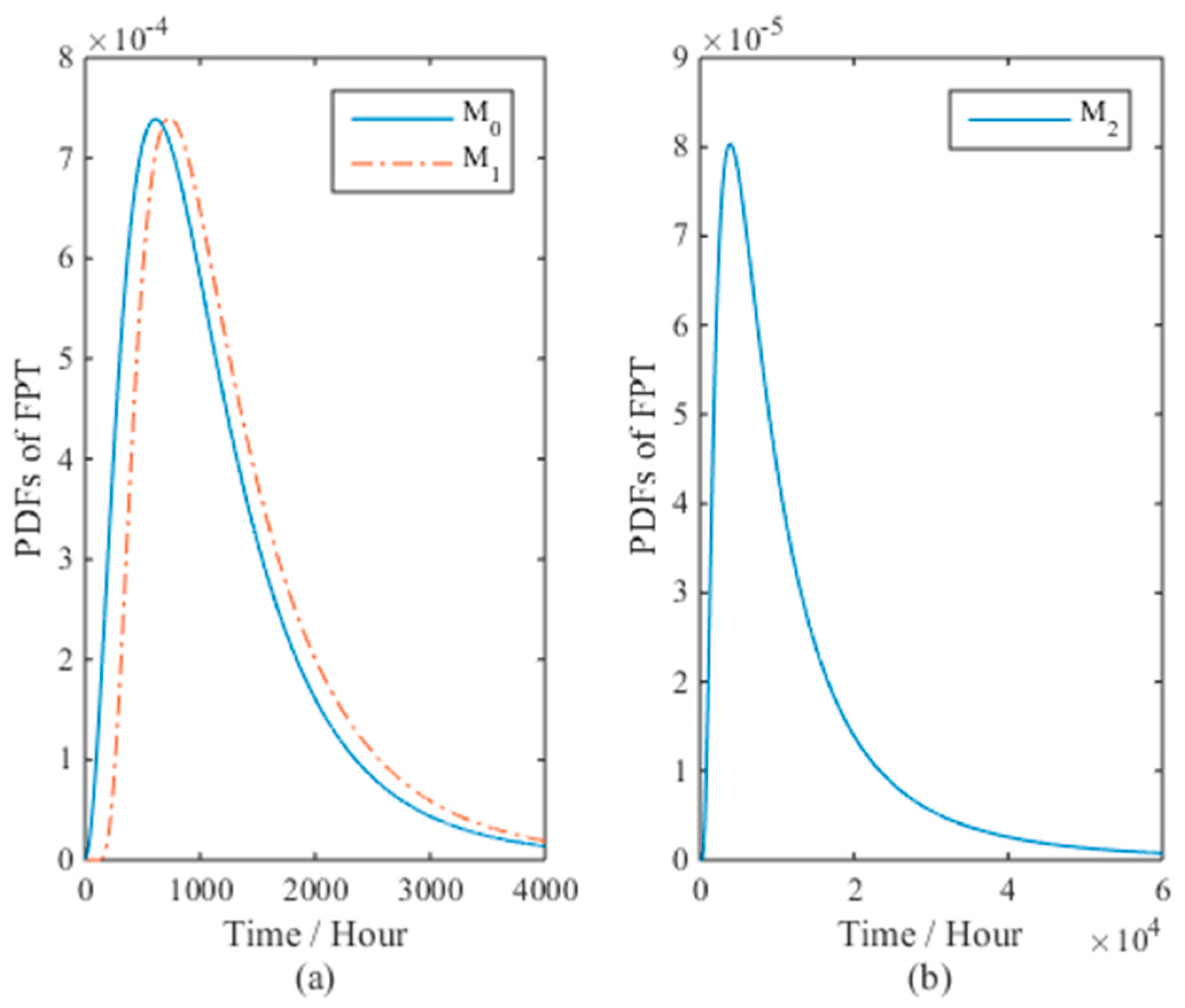

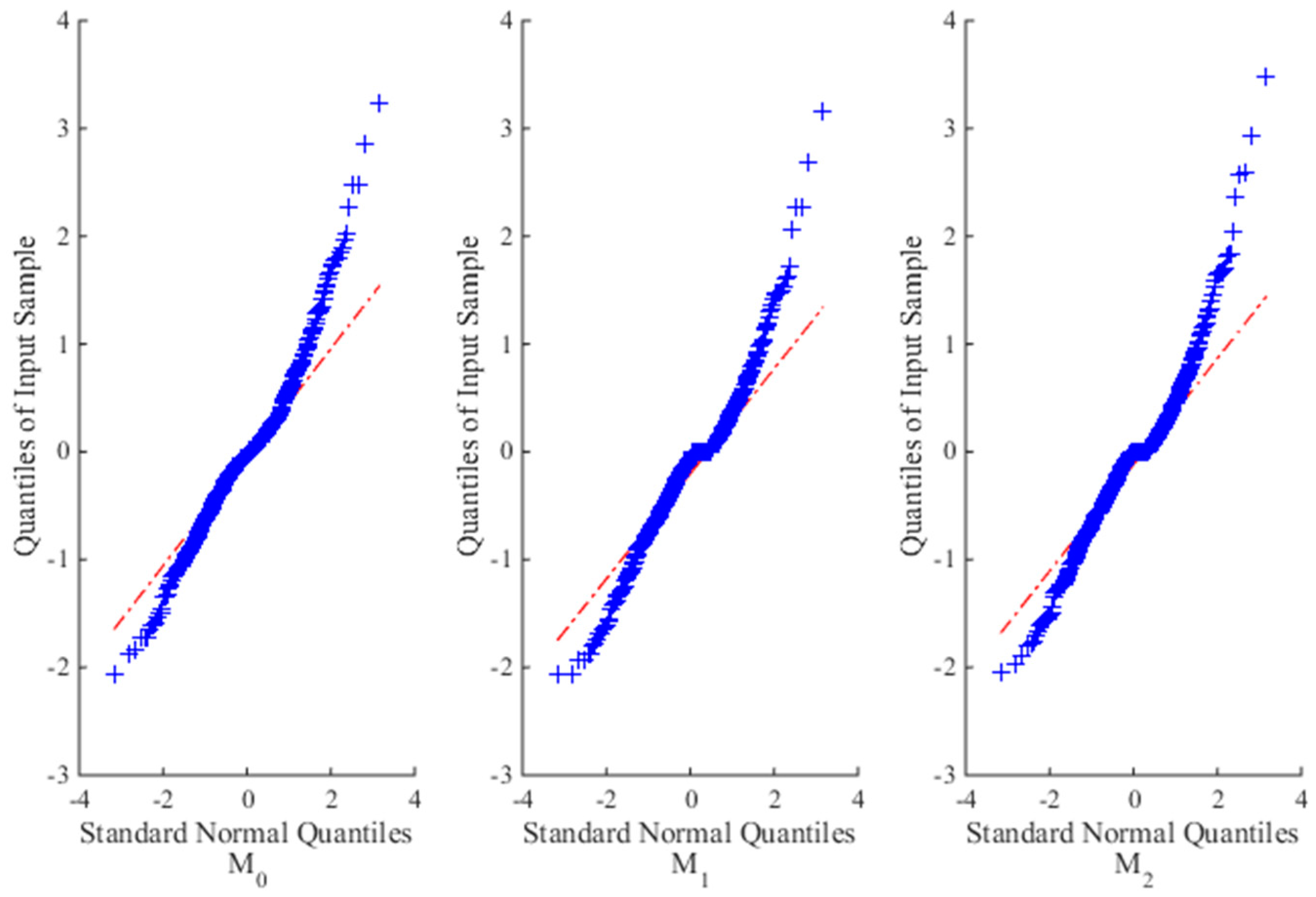

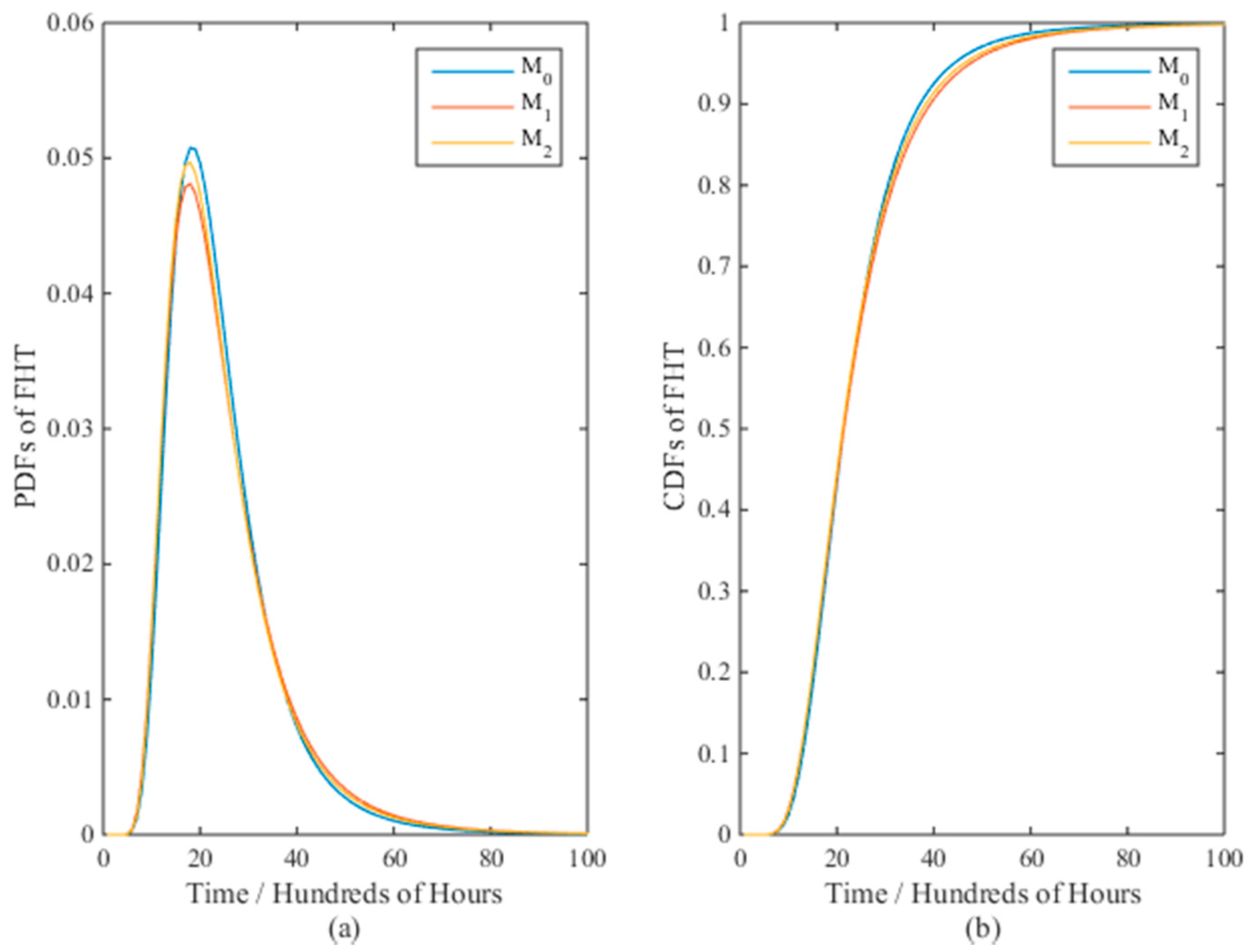

As described above, the general ADT model in Equation (1) can present the uncertainties from the unit-to-unit variation (b ≠ 0) and temporal variation of the degradation process, and can be used in the situations with single (p = 1) and multiple (p > 1) acceleration variables for linear and nonlinear degradation processes. For clarity, Equation (1) is named M0, while Equations (3) and (4) are M1 and M2. Since model M1 and M2 are widely used in the ADT field, in this paper, we concentrate on the comparison of M1 and M2 with M0 to verify the effectiveness of the proposed model for both linear and nonlinear ADT analyses.

For the evaluation of lifetime and reliability, the probability distribution function (PDF) of the failure time should be given, which will be derived in the following section.

2.2. Derivation of the Failure Time Distribution under the Given Stress Level

Although ADT is implemented at accelerated stress levels, the lifetime and reliability evaluation are conducted at the given normal stress level S0 = [, ,⋯, ], where is the vth acceleration stress type under normal level. Thus, the drift coefficient μ(S0;η) follows a normal distribution. Therefore, we simplify the notation of μ(S0;η) to μ in the derivation of the failure time distribution. From Equation (2), it is known that μ ~ N(μ0, ), where and .

In general, the failure time is defined as the time when degradation path

X(

t) first exceeds the failure threshold

ω, i.e., the first passage time (FPT):

Let a time transformation

z =

τ(

t;

γ); thus

t =

τ−1(

z;

γ). We define

ρ(

z;

θ) = Λ(

τ−1(

z;

γ);

θ). So, Equation (1) becomes [

20]:

and its drift coefficient is:

For simplicity, let

h(

z;

θ) =

dρ(

z;

θ)/

dz. Under some mild assumptions, the PDF of the FPT for the new degradation process

Y(

z) is (see Theorem 2 in Si, et al. [

24]):

In consideration of the random effect due to unit-to-unit variation, the uncertainty of

μ should be included in the PDF of the FPT. We compute the result by the law of total probability, i.e.,:

In order to explicitly obtain the formula of Equation (9), Theorem 3 of Si, et al. [

24] is introduced and modified accordingly; that is:

Theorem 1. If μ ~ N(μ0, ), and ω, A, B, C∈

R, then:

Therefore, we substitute Equations (8) into (9) according to Equation (10). The result is:

where

Q =

ρ2(

z;

θ)

+

σ2z.

Hence, the PDF of the FPT for the general model can be obtained by the reverse process of the time transformation

z =

τ(

t;

γ) through Equation (11); that is:

where

Q = Λ

2(

t;

θ)

+

σ2τ(

t;

γ);

G = Λ(

t;

θ) −

h(

τ(

t;

γ);

θ)

τ(

t;

γ).

Supposing that Λ(

t;

θ) =

tθ and

τ(

t;

γ) =

tγ, Equation (12) becomes:

Herein, the relationship ∫

pT(

t)

dt = 1 should be satisfied. Therefore, the PDF and cumulative distribution function (CDF) of the FPT for model

M0 are modified as:

For

M1, i.e., Λ(

t;

θ) =

t and

τ(

t;

γ) =

t, the PDF of the FPT for

M1 is known as an inverse Gaussian distribution [

29]. Considering the random effect, the PDF and CDF of the FPT are [

22,

28]:

Obviously, Equation (15) is a limiting case of Equation (14) if we substitute θ = γ = 1 into Equation (13), where ∫pT(t)dt = 1.

For

M2, i.e., Λ(

t;

θ) =

τ(

t;

γ), the PDF of the FPT for

M2 is in accordance with Equation (15) through a time-scale transformation by replacing t into Λ(

t;

θ) or

τ(

t;

γ) [

18,

30], which is also a limiting case of Equation (14).

In the following section, the problems of parameter estimation will be addressed for CSADT and SSADT. After that, the PDF and CDF of the FPT at normal stress levels will be computed through Equation (14) for the lifetime and reliability evaluation of long lifespan products.