Increasing Mechanical Properties of 2-D-Structured Electrospun Nylon 6 Non-Woven Fiber Mats

Abstract

:1. Introduction

2. Results and Discussion

2.1. Increase Nylon 6 Nanofiber Strength

2.2. Increase Fiber-Fiber Bonding

2.2.1. Beaded Fiber Effect

2.2.2. Annealing Nylon 6 Non-Woven Fiber Mats

2.2.3. Solvent Bonding Effect

2.3. Increase Packing Density of Electrospun Nylon 6 Non-Woven Fiber Mats to Increase Mechanical Properties

3. Materials and Methods

3.1. Materials

3.2. Preparation of Electrospun Solutions

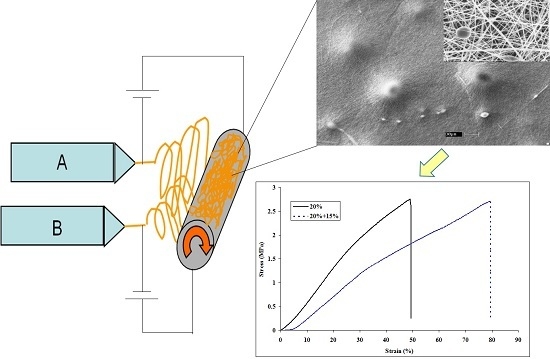

3.3. Electrospinning

3.4. Post Treatment of Electrospun Nylon 6 Non-Woven Fiber Mats

3.5. Scanning Electron Microscopy

3.6. Mechanical Testing

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tanioka, A.; Matsumoto, H.; Tsuboi, K. Electrospun nanofiber networks for electronics and optics. MRS Proc. 2009. [Google Scholar] [CrossRef]

- Mao, X.; Simeon, F.; Rutledge, G.C.; Hatton, T.A. Electrospun carbon nanofiber (CNF) webs with controlled density of states (DOS) for sensor applications. Adv. Mater. Weinh. Ger. 2013, 25, 1309–1314. [Google Scholar] [CrossRef] [PubMed]

- Xiang, C.; Taylor, A.G.; Hinestroza, J.P.; Frey, M.W. Controlled release of nonionic compounds from poly(lactic acid)/cellulose nanocrystal nanocomposite fibers. J. Appl. Polym. Sci. 2013, 127, 79–86. [Google Scholar] [CrossRef]

- He, W.; Horn, S.W.; Hussain, M.D. Improved bioavailability of orally administered mifepristone from PLGA nanoparticles. Int. J. Pharm. 2007, 334, 173–178. [Google Scholar] [CrossRef] [PubMed]

- Vargas, E.A.T.; do Vale Baracho, N.C.; de Brito, J.; de Queiroz, A.A. Hyperbranched polyglycerol electrospun nanofibers for wound dressing applications. Acta Biomater. 2010, 6, 1069–1078. [Google Scholar] [CrossRef] [PubMed]

- Kenawy, E.-R.; Bowlin, G.L.; Mansfield, K.; Layman, J.; Simpson, D.G.; Sanders, E.H.; Wnek, G.E. Release of tetracycline hydrochloride from electrospun poly(ethylene-co-vinylacetate), poly(lactic acid), and a blend. J. Control. Release 2002, 81, 57–64. [Google Scholar] [CrossRef]

- Kattamuri, N.; Shin, J.H.; Kang, B.; Lee, C.G.; Lee, J.K.; Suang, C. Development and surface characterization of positively charged filters. J. Mater. Sci. 2005, 40, 4531–4539. [Google Scholar] [CrossRef]

- Faccini, M.; Vaquero, C.; Amantia, D. Development of protective clothing against nanoparticle based on electrospun nanofibers. J. Nanomater. 2012, 2012. [Google Scholar] [CrossRef] [Green Version]

- Park, J.H.; Kim, B.S.; Yoo, Y.C.; Khil, M.S.; Kim, H.Y. Enhanced mechanical properties of multilayer nano-coated electrospun nylon 6 fibers via a layer-by-layer self-assembly. J. Appl. Polym. Sci. 2008, 107, 2211–2216. [Google Scholar] [CrossRef]

- Backer, S.; Petterson, D.R. Some principles of nonwoven fabrics1. Text. Res. J. 1960, 30, 704–711. [Google Scholar] [CrossRef]

- Li, L.; Bellan, L.M.; Craighead, H.G.; Frey, M.W. Formation and properties of nylon-6 and nylon-6/montmorillonite composite nanofibers. Polymer 2006, 47, 6208–6217. [Google Scholar] [CrossRef]

- Li, L.; Frey, M.W.; Green, T.B. Modification of air filter media with nylon-6 nanofibers. J. Eng. Fibers Fabr. 2006, 1, 1–23. [Google Scholar]

- Papkov, D.; Zou, Y.; Andalib, M.N.; Goponenko, A.; Cheng, S.Z.D.; Dzenis, Y.A. Simultaneously strong and tough ultrafine continuous nanofibers. ACS Nano 2013, 7, 3324–3331. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.H.; Kin, H.Y.; Ryu, Y.J.; Kim, K.W.; Choi, S.W. Mechanical behavior of electrospun fiber mats of poly(vinyl chloride)/polyurethane polyblends. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 1256–1262. [Google Scholar] [CrossRef]

- Kim, H.S.; Jin, H.-J.; Myung, S.J.; Chin, I.-J. Carbon nanotube-adsorbed electrospun nanofibrous membranes of nylon 6. Macromol. Rapid Commun. 2006, 27, 146–151. [Google Scholar] [CrossRef]

- Kim, H.-S.; Chae, Y.S.; Park, B.H.; Yoon, J.-S.; Kang, M.; Jin, H.-J. Thermal and electrical conductivity of poly(l-lactide)/multiwalled carbon nanotube nanocomposites. Curr. Appl. Phys. 2008, 8, 803–806. [Google Scholar] [CrossRef]

- Qian, D.; Dickey, E.C.; Andrews, R.; Rantell, T. Load transfer and deformation mechanisms in carbon nanotube-polystyrene composites. Appl. Phys. Lett. 2000, 76, 2868–2870. [Google Scholar] [CrossRef]

- Mahfuz, H.; Adnan, A.; Rangari, V.K.; Hasan, M.M.; Jeelani, S.; Wright, W.J.; DeTeresa, S.J. Enhancement of strength and stiffness of nylon 6 filaments through carbon nanotubes reinforcement. Appl. Phys. Lett. 2006, 88. [Google Scholar] [CrossRef]

- Bazbouz, M.B.; Stylios, G.K. The tensile properties of electrospun nylon 6 single nanofibers. J. Polym. Sci. B Polym. Phys. 2010, 48, 1719–1731. [Google Scholar] [CrossRef]

- Jeong, J.S.; Moon, J.S.; Jeon, S.Y.; Park, J.H.; Alegaonkar, P.S.; Yoo, J.B. Mechanical properties of electrospun PVA/MWNTs composite nanofibers. Thin Solid Films 2007, 515, 5136–5141. [Google Scholar] [CrossRef]

- You, Y.; Lee, S.W.; Lee, S.H.; Park, W.H. Thermal interfiber bonding of electrospun poly(l-lactic acid) nanofibers. Mater. Lett. 2006, 60, 1331–1333. [Google Scholar] [CrossRef]

- Choi, S.S.; Lee, S.G.; Joo, C.W.; Im, S.S.; Kim, S.H. Formation of interfiber bonding in electrospun poly(etherimide) nanofiber web. J. Mater. Sci. 2004, 39, 1511–1513. [Google Scholar] [CrossRef]

- Standard Test Method for Tensile Properties of Plastics; ASTM D 638-14; American Society of Testing and Materials: West Conshohocken, PA, USA, 2014.

| Tensile Properties | 20% | 20% + 1% CNTs |

|---|---|---|

| Young‘s modulus (MPa) | 4.81 ± 1.03 | 7.25 ± 1.96 |

| Tensile strength (MPa) | 2.03 ± 0.99 | 3.80 ± 1.87 |

| Elongation (%) | 54.1 ± 14.6 | 63.7 ± 19.2 |

| Toughness (MPa) | 0.64 ± 0.48 | 1.51 ± 1.05 |

| Tensile Properties | Before Annealing | After Annealing |

|---|---|---|

| Young’s modulus (MPa) | 4.81 ± 1.03 | 4.12 ± 1.33 |

| Tensile strength (MPa) | 1.63 ± 0.50 | 2.06 ± 0.72 |

| Elongation (%) | 45.6 ± 13.2 | 58.2 ± 11.4 |

| Toughness (MPa) | 0.41 ± 0.23 | 0.69 ± 0.30 |

| Tensile Properties | Before Exposure | After Exposure |

|---|---|---|

| Young’s modulus (MPa) | 4.81 ± 1.03 | 7.50 ± 2.41 |

| Tensile strength (MPa) | 2.03 ± 0.99 | 3.40 ± 1.26 |

| Elongation (%) | 54.1 ± 14.6 | 48.1 ± 8.9 |

| Toughness (MPa) | 0.64 ± 0.48 | 0.89 ± 0.55 |

| Tensile Properties | 20% | Exposed (20% + 1% CNTs) |

|---|---|---|

| Young’s modulus (MPa) | 4.81 ± 1.03 | 9.90 ± 2.20 |

| Tensile strength (MPa) | 2.03 ± 0.99 | 4.33 ± 0.94 |

| Elongation (%) | 54.1 ± 14.6 | 50.0 ± 4.7 |

| Toughness (MPa) | 0.64 ± 0.48 | 1.25 ± 0.36 |

| Tensile Properties | 20% | 20% + 15% |

|---|---|---|

| Young’s modulus (MPa) | 4.81 ± 1.72 | 4.48 ± 1.65 |

| Tensile strength (MPa) | 2.03 ± 0.99 | 2.59 ± 1.25 |

| Elongation (%) | 54.1 ± 14.6 | 75.4 ± 12.2 |

| Toughness (MPa) | 0.64 ± 0.48 | 1.12 ± 0.77 |

| A | B | Feed Rate (mL/h) |

|---|---|---|

| 20% | 20% | 0.5 |

| 20% | 15% | 0.5 |

| 20% | 10% | 0.5 |

| 15% | 15% | 0.5 |

| 15% | 10% | 0.5 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, C.; Frey, M.W. Increasing Mechanical Properties of 2-D-Structured Electrospun Nylon 6 Non-Woven Fiber Mats. Materials 2016, 9, 270. https://doi.org/10.3390/ma9040270

Xiang C, Frey MW. Increasing Mechanical Properties of 2-D-Structured Electrospun Nylon 6 Non-Woven Fiber Mats. Materials. 2016; 9(4):270. https://doi.org/10.3390/ma9040270

Chicago/Turabian StyleXiang, Chunhui, and Margaret W. Frey. 2016. "Increasing Mechanical Properties of 2-D-Structured Electrospun Nylon 6 Non-Woven Fiber Mats" Materials 9, no. 4: 270. https://doi.org/10.3390/ma9040270

APA StyleXiang, C., & Frey, M. W. (2016). Increasing Mechanical Properties of 2-D-Structured Electrospun Nylon 6 Non-Woven Fiber Mats. Materials, 9(4), 270. https://doi.org/10.3390/ma9040270