Evaluation of Tree Species for Biomass Energy Production in Northwest Spain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Collection and Samples

2.2. Energy Evaluation

2.2.1. Ultimate Analysis

2.2.2. Proximate Analysis

2.2.3. High Heating Value, HHV

2.3. Statistical Analysis

Discriminant Analysis

3. Results and Discussion

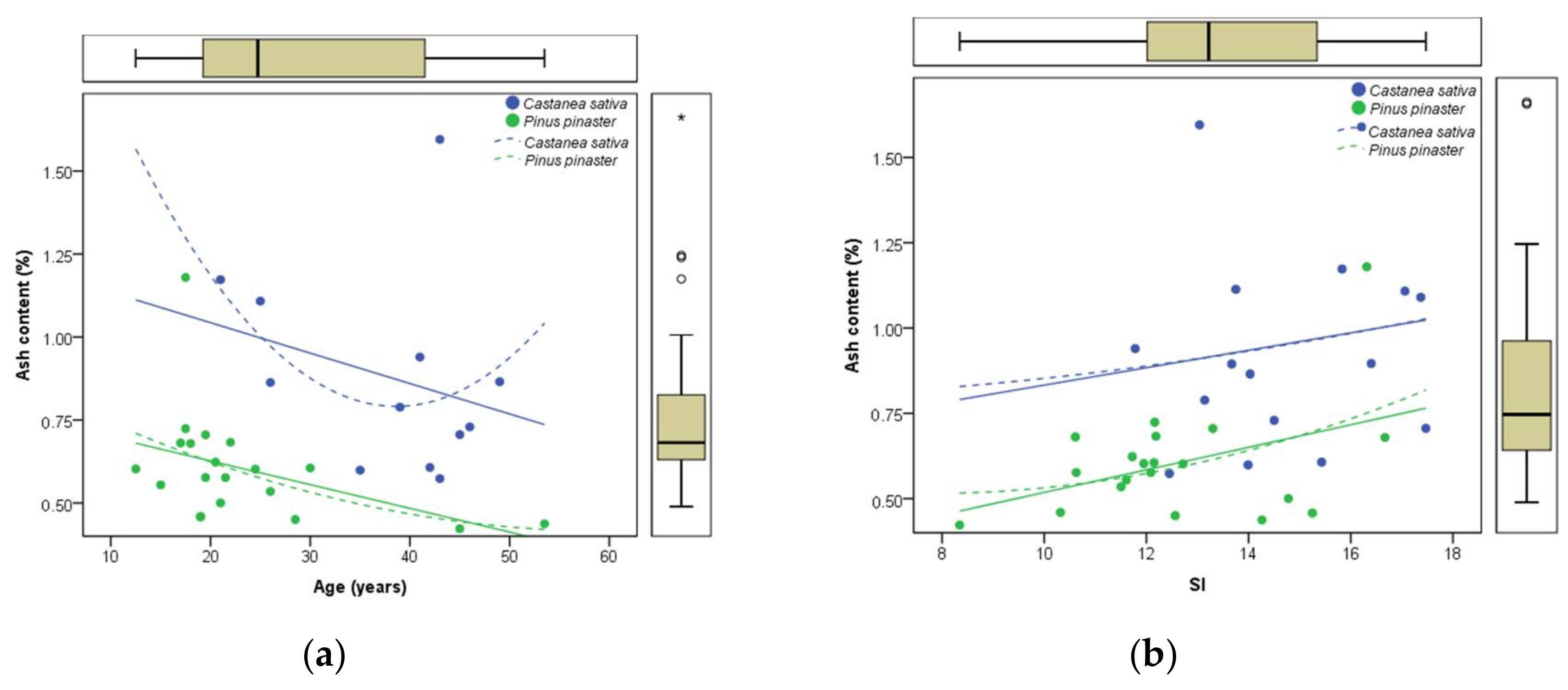

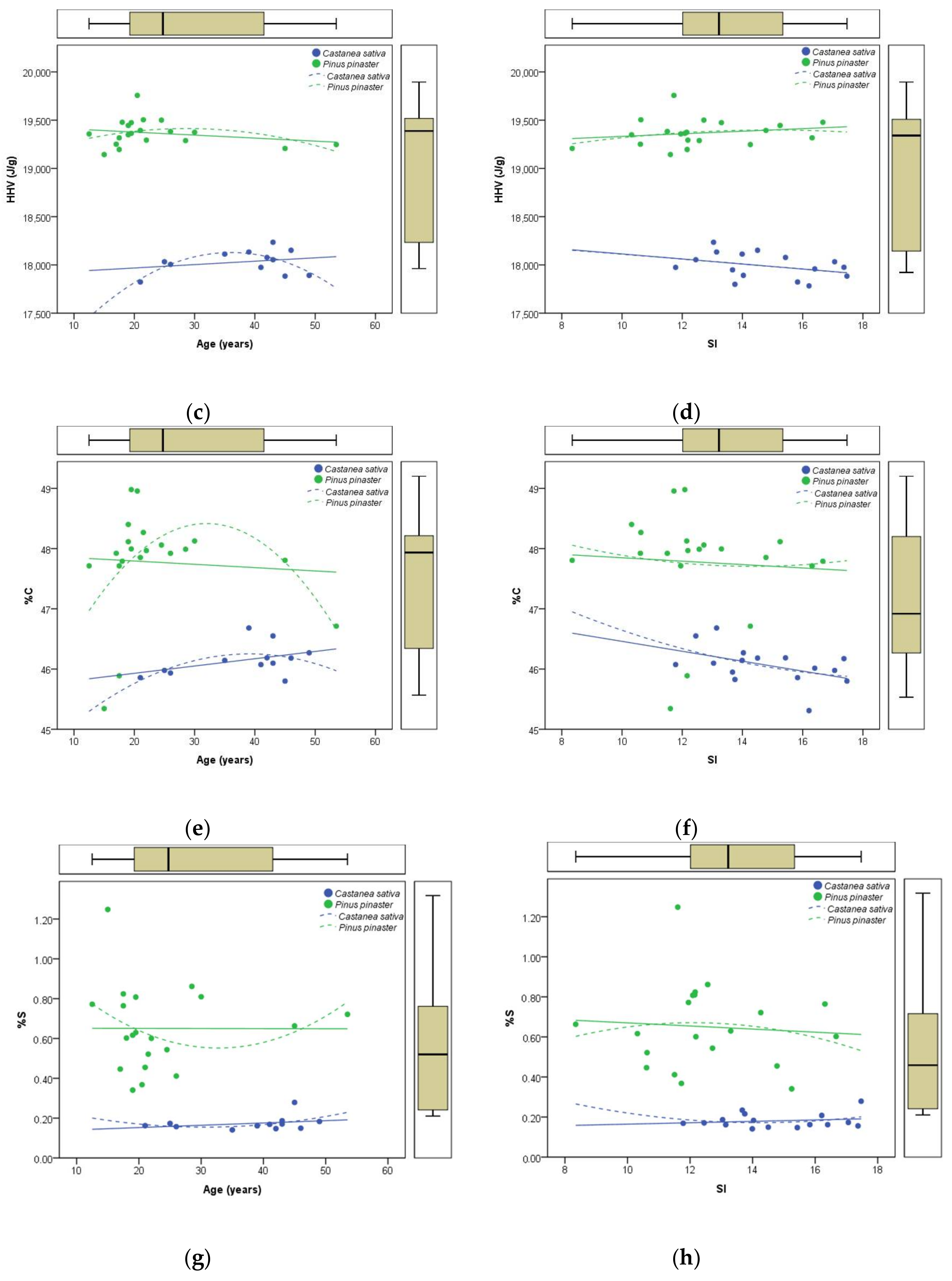

3.1. Ultimate Analysis

3.2. Proximate Analysis

3.3. High Heating Value, HHV

3.4. Forest Stand Classification

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Popp, J.; Lakner, Z.; Harangi-Rákos, M.; Fáric, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2004, 32, 559–578. [Google Scholar] [CrossRef]

- Rodrigues, A.; Loureiro, L.; Nunes, L.J.R. Torrefaction of woody biomasses from poplar SRC and Portuguese roundwood: Properties of torrefied products. Biomass Bioenergy 2018, 108, 55–65. [Google Scholar] [CrossRef]

- Dale, V.H.; Kline, K.L.; Wright, L.L.; Perlack, R.D.; Downing, M.; Graham, R.L. Interactions among bioenergy feedstock choices, landscape dynamics, and land use. Ecol. Appl. 2011, 21, 1039–1054. [Google Scholar] [CrossRef] [PubMed]

- Ministerio de Agricultura, Alimentación y Medio Ambiente (MAGRAMA). Cuarto Inventario Forestal Nacional y Tercer Mapa Forestal de España (1:25,000); Ministerio de Agricultura, Alimentación y Medio Ambiente: Madrid, Spain, 2012.

- Sociedad Asturiana de Estudios Económicos e Industriales (SADEI), Anuario Estadístico de Asturias. Instituto Asturiano de Estadística; Gobierno del Principado de Asturias: Oviedo, Spain, 2017.

- Suárez Antuña, F. La organización de los espacios mineros de la hulla en Asturias. In Revista Electrónica de Geografía y Ciencias Sociales; Universidad de Barcelona: Barcelona, Spain, 2005. [Google Scholar]

- Paredes-Sánchez, J.P.; García-Elcoro, V.E.; Rosillo-Calle, F.; Xiberta-Bernat, J. Assessment of forest bioenergy potential in a coal-producing area in Asturias (Spain) and recommendations for setting up a Biomass Logistic Centre (BLC). Appl. Energy 2016, 171, 133–141. [Google Scholar] [CrossRef]

- Dillen, S.Y.; Djomo, S.N.; Al Afas, N.; Vanbeveren, S.; Ceulemans, R. Biomass yield and energy balance of a short-rotation coppice with multiple clones on degraded land during 16 years. Biomass Bioenergy 2013, 56, 157–165. [Google Scholar] [CrossRef]

- Dimitriou, I.; Rutz, D. Sustainable Short Rotation Coppice, A Handbook. Available online: http://www.srcplus.eu/images/Handbook_SRCplus.pdf (accessed on 16 March 2018).

- Domec, J.-C.; Ashley, E.; Fischer, M.; Noormets, A.; Boone, J.; Williamson, J.C.; King, J.S. Productivity, biomass partitioning, and energy yield of low-input short-rotation American sycamore (Platanus occidentalis L.) grown on marginal land: Effects of planting density and simulated drought. Bioenergy Res. 2017, 10, 903–914. [Google Scholar] [CrossRef]

- Lafleur, B.; Lalonde, O.; Labrecque, M. First-rotation performance of five short-rotation willow cultivars on different soil types and along a large climate gradient. Bioenergy Res. 2017, 10, 158–166. [Google Scholar] [CrossRef]

- Gandullo, J.M.; Blanco, A.; Sánchez, O.; Rubio, A.; Elena, R.; Gómez, V. Las Estaciones Ecológicas de los Castañares Españoles; Instituto Nacional de Investigación y Tecnología Agraria y Alimentaria; Ministerio de Educación y Ciencia: Madrid, Spain, 2004. [Google Scholar]

- Álvarez-Álvarez, P.; Afif-Khouri, E.; Cámara-Obregón, A.; Castedo-Dorado, F.; Barrio-Anta, M. Effects of foliar nutrients and environmental factors on site productivity in Pinus pinaster Ait. stands in Asturias (NW Spain). Ann. For. Sci. 2011, 68, 497–509. [Google Scholar] [CrossRef]

- Menéndez-Miguélez, M.; Álvarez-Álvarez, P.; Majada, J.; Canga, E. Effects of soil nutrients and environmental factors on site productivity in Castanea sativa Mill. coppice stands in NW Spain. New For. 2015, 46, 217–233. [Google Scholar] [CrossRef]

- Menéndez-Miguélez, M.; Canga, E.; Barrio-Anta, M.; Majada, J.; Álvarez-Álvarez, P. A three level system for estimating the biomass of Castanea sativa Mill. coppice stands in North-West Spain. For. Ecol. Manag. 2013, 291, 417–426. [Google Scholar] [CrossRef]

- Menéndez-Miguélez, M.; Álvarez-Álvarez, P.; Majada, J.; Canga, E. Management tools for Castanea sativa coppice stands in northwestern Spain. Bosque (Valdivia) 2016, 37, 119–133. [Google Scholar] [CrossRef]

- Arias-Rodil, M.; Barrio-Anta, M.; Diéguez-Aranda, U. Developing a dynamic growth model for maritime pine in Asturias (NW Spain): Comparison with nearby regions. Ann. For. Sci. 2016, 73, 297–320. [Google Scholar] [CrossRef]

- Castaño-Díaz, M.; Álvarez-Álvarez, P.; Tobin, B.; Nieuwenhuis, M.; Afif-Khouri, E.; Cámara-Obregón, A. Evaluation of the use of low-density LiDAR data to estimate structural attributes and biomass yield in a short-rotation willow coppice: An example in a field trial. Ann. For. Sci. 2017, 74, 16. [Google Scholar] [CrossRef]

- Kumar, R.; Pandey, K.K.; Chandrashekar, N.; Mohan, S. Effect of tree-age on calorific value and other fuel properties of Eucalyptus hybrid. J. For. Res. 2010, 21, 514–516. [Google Scholar] [CrossRef]

- Patel, B.; Gami, B. Biomass characterization and its use as solid fuel for combustion. Iran. J. Energy Environ. 2012, 3, 123–128. [Google Scholar] [CrossRef]

- Dibdiakova, J.; Gjølsjø, S.; Wang, L. Solid Biofuels from Forest-Fuel Specification and Quality Assurance. In Inherent properties of Norway Spruce Biomass in Some Geographical Locations in South Norway; Norwegian Institute of Forestry and Landscape: Ås, Norway, 2014. [Google Scholar]

- Costanza, J.K.; Abt, R.C.; McKerrow, A.J.; Collazo, J.A. Bioenergy production and forest landscape change in the southeastern United States. GCB Bioenergy 2017, 9, 924–939. [Google Scholar] [CrossRef]

- Warburg, C.T.; King’ondu, C.K. Energy characteristics of five indigenous tree species at Kitulangalo Forest Reserve in Morogoro, Tanzania. Int. J. Renew. Energy Res.-IJRER 2014, 4, 1078–1084. [Google Scholar]

- Johnson, J.M.; Coleman, M.D.; Gesch, R.; Jaradat, A.; Mitchell, R.; Reicosky, D.; Wilhelm, W.W. Biomass-bioenergy crops in the United States: A changing paradigm. Am. J. Plant Sci. Biotechnol. 2007, 1, 1–28. [Google Scholar]

- Gordobil, O.; Moriana, R.; Zhang, L.; Labidi, J.; Sevastyanova, O. Assesment of technical lignins for uses in biofuels and biomaterials: Structure-related properties, proximate analysis and chemical modification. Ind. Crops Prod. 2016, 83, 155–165. [Google Scholar] [CrossRef]

- Biomass Energy Resource Center (BERC). Biomass Energy: Efficiency, Scale, and Sustainability; Biomass Energy Resource Center: Montpelier, VT, USA, 2009. [Google Scholar]

- Shafizadeh, F. Basic principles of direct combustion. In Biomass Conversion Process for Energy and Fuels; Sofer, S.S., Zabrosky, O.R., Eds.; Plenum Press: New York, NY, USA, 1981; pp. 103–112. [Google Scholar]

- Pérez, S.; Renedo, C.; Ortiz, A.; Mañana, M.; Silió, D. Energy evaluation of the Eucalyptus globulus and the Eucalyptus nitens in the north of Spain (Cantabria). Thermochim. Acta 2006, 451, 57–64. [Google Scholar] [CrossRef]

- Ghetti, P.; Ricca, L.; Angelini, L. Thermal analysis of biomass and corresponding pyrolysis products. Fuel 1996, 75, 565–573. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, J.; Shao, J.; Liu, Z.; Zhang, G.; Xu, T.; Guo, J.; Wang, H.; Xu, R.; Lin, H. Thermal behaviour and Kinetic analysis of co-combustion of waste biomass/low rank coal blends. Energy Convers. Manag. 2016, 124, 414–426. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Moisture Analysis of Particulate Wood Fuels; ASTM E 871-82; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM International. Standard Test Method for Ash in Wood; ASTM D 1102-84; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM International. Standard Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels; ASTM E 872-82; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Solar, J.; de Marco, I.; Caballero, B.M.; Lopez-Urionabarrenechea, A.; Rodriguez, N.; Aguirre, I.; Adrados, A. Influence of temperature and residence time in the pyrolysis of woody biomass waste in a continuous screw reactor. Biomass Bioenergy 2016, 95, 416–423. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Gross Calorific Value of Refuse-Derived Fuel by the Bomb Calorimeter; ASTM E 711-87; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Fisher, R.A. The use of multiple measurements in taxonomic problems. Ann. Eugen. 1936, 7, 179–188. [Google Scholar] [CrossRef]

- Nordin, A. Chemical and elemental characteristics of biomass fuels. Biomass Bioenergy 1994, 6, 339–347. [Google Scholar] [CrossRef]

- Dickinson, K.J.M.; Kirkpatrick, J.B. The flammability and energy content of some important plant species and fuel components in the forests of southeastern Tasmania. J. Biogeogr. 1985, 12, 121–134. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J.; Moreira, N. Proximate analysis, backwards stepwise regression between gross calorific value, ultimate and chemical analysis of wood. Bioresour. Technol. 2010, 101, 3808–3815. [Google Scholar] [CrossRef] [PubMed]

- García, R.; Pizaro, C.; Lavín, A.G.; Bueno, J.J. Characterization of Spanish biomass wastes for energy use. Bioresour. Technol. 2012, 103, 249–258. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization. Solid Biofuels-Fuel Specifications and Classes-Part 1: General Requirements (ISO 17225-1:2014), AENOR; UNE-EN ISO 17225-1:2014; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- González-García, M.; Hevia, A.; Majada, J.; Rubiera, F.; Barrio-Anta, M. Nutritional, carbon and energy evaluation of Eucalyptus nitens short rotation bioenergy plantations in northwestern Spain. iForest 2015, 9, 303–310. [Google Scholar] [CrossRef]

- Sims, R.E.H.; Senelwa, K.; Maiava, T.; Bullock, B.T. Eucalyptus species for biomass energy in New Zealand—Part II: Coppice performance. Biomass Bioenergy 1999, 17, 333–343. [Google Scholar] [CrossRef]

- Nati, C.; Montorselli, N.B.; Olmi, R. Wood biomass recovery from chestnut orchards: Results from a case study. Agrofor. Syst. 2016. [Google Scholar] [CrossRef]

- Francescato, V.; Antonini, E.; Bergomi, L.Z. Wood Fuels Handbook. AIEL-Italian Agroforestry Energy Association, Agripolis; Food and Agriculture Organization: Rome, Italy, 2008; p. 83. [Google Scholar]

- Demirbaş, A. Relationship between lignin contents and heating values of biomass. Energy Convers. Manag. 2001, 42, 183–188. [Google Scholar] [CrossRef]

- Howard, E.T. Heat of combustion of various southern pine materials. Wood Sci. 1973, 5, 194–197. [Google Scholar]

- Pérez, S.; Renedo, C.J.; Ortiz, A.; Delgado, F.; Fernández, I. Energy potential of native shrub species in northern Spain. Renew. Energy 2014, 62, 79–83. [Google Scholar] [CrossRef]

| Species | N | nstool | dn | G | Ho | SI | Age | |

|---|---|---|---|---|---|---|---|---|

| Chestnut coppice | Minimum | 410.265 | 1.000 | 12.730 | 16.475 | 12.157 | 11.780 | 21.000 |

| (Castanea sativa) | Maximum | 4229.975 | 8.000 | 24.750 | 104.199 | 25.014 | 17.470 | 49.000 |

| Mean | 1781.699 | 2.487 | 18.395 | 39.633 | 18.119 | 14.757 | 37.917 | |

| Std. Deviation | 1009.776 | 1.887 | 3.658 | 19.219 | 3.417 | 1.808 | 9.150 | |

| Maritime pine | Minimum | 466.667 | --- | 10.368 | 14.633 | 7.400 | 8.344 | 12.500 |

| (Pinus pinaster) | Maximum | 2075.000 | --- | 36.960 | 76.249 | 27.300 | 16.670 | 53.500 |

| Mean | 1178.417 | --- | 19.427 | 34.915 | 13.795 | 12.556 | 23.350 | |

| Std. Deviation | 407.692 | --- | 7.090 | 17.015 | 4.333 | 2.061 | 9.916 | |

| Beapré | Minimum | 9382.675 | 1.000 | 8.100 | 0.007 | 1.250 | --- | 5.000 |

| (Populus x interamericana ) | Maximum | 18,765.350 | 2.000 | 0.100 | 48.349 | 10.400 | --- | 5.000 |

| Mean | 10,296.033 | 1.097 | 3.301 | 10.770 | 4.911 | --- | 5.000 | |

| Std. Deviation | 2787.453 | 0.297 | 1.933 | 11.525 | 2.107 | --- | 0.000 | |

| AF2 | Minimum | 9382.675 | 1.000 | 0.720 | 0.382 | 2.000 | --- | 6.000 |

| (Populus x canadensis ) | Maximum | 28,148.025 | 3.000 | 11.560 | 98.476 | 10.600 | --- | 6.000 |

| Mean | 11,259.210 | 1.200 | 5.376 | 25.397 | 6.716 | --- | 6.000 | |

| Std. Deviation | 4266.194 | 0.455 | 2.369 | 19.831 | 1.899 | --- | 0.000 | |

| I-214 | Minimum | 9382.675 | 1.000 | 0.380 | 0.106 | 1.390 | --- | 6.000 |

| (Populus x euramericana ) | Maximum | 37,530.700 | 4.000 | 5.040 | 18.719 | 10.000 | --- | 6.000 |

| Mean | 12,025.682 | 1.282 | 2.364 | 5.139 | 4.295 | --- | 6.000 | |

| Std. Deviation | 5060.957 | 0.539 | 1.184 | 4.685 | 1.714 | --- | 0.000 | |

| Olof | Minimum | 9.382.675 | 1.000 | 0.200 | 0.029 | 1.300 | --- | 6.000 |

| (Salix viminalis x (S. schwerinii x S. viminalis)) | Maximum | 37,530.700 | 4.000 | 7.630 | 42.901 | 11.100 | --- | 6.000 |

| Mean | 15,235.235 | 1.624 | 2.704 | 6.455 | 5.744 | --- | 6.000 | |

| Std. Deviation | 6.464.223 | 0.689 | 1.205 | 5.786 | 2.247 | --- | 0.000 | |

| Tordis | Minimum | 9382.675 | 1.000 | 0.690 | 0.351 | 1.800 | --- | 6.000 |

| ((Salix viminalis x (S. schwerinii x S. Viminalis)) | Maximum | 37,530.700 | 4.000 | 5.270 | 20.466 | 10.000 | --- | 6.000 |

| Mean | 18,920.864 | 2.017 | 2.823 | 6.377 | 5.982 | --- | 6.000 | |

| Std. Deviation | 6885.967 | 0.734 | 0.827 | 3.553 | 1.479 | --- | 0.000 |

| Species | Proximate Analysis | Calorimetry | Ultimate Analysis | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| %Moi. | %Ash | %VM | %FC | HHV (J/g) | %C | %H | %S | %N | %O | |||

| Chestnut (C. sativa) | Crown (%) | Minimum | 3.577 | 1.333 | 71.193 | 17.257 | 18,051.333 | 45.580 | 6.168 | 0.163 | 0.195 | 45.160 |

| Maximun | 8.179 | 3.148 | 76.379 | 19.976 | 18,680.667 | 46.910 | 6.448 | 0.348 | 1.288 | 47.505 | ||

| Mean | 6.209 | 2.016 | 73.410 | 18.366 | 18,261.567 | 46.193 | 6.310 | 0.197 | 0.613 | 46.687 | ||

| Std. Deviation | 1.150 | 0.475 | 1.465 | 0.779 | 146.309 | 0.351 | 0.077 | 0.048 | 0.255 | 0.509 | ||

| Bark (%) | Minimum | 3.771 | 2.515 | 54.983 | 15.605 | 16,358.667 | 43.430 | 5.769 | 0.133 | 0.185 | 47.183 | |

| Maximun | 10.593 | 5.715 | 73.208 | 35.575 | 18,287.667 | 45.780 | 6.353 | 0.353 | 0.617 | 50.085 | ||

| Mean | 7.767 | 3.979 | 66.909 | 21.187 | 17,180.883 | 44.890 | 5.994 | 0.184 | 0.353 | 48.579 | ||

| Std. Deviation | 1.540 | 0.929 | 3.650 | 3.772 | 452.616 | 0.642 | 0.131 | 0.046 | 0.103 | 0.721 | ||

| Wood (%) | Minimum | 2.583 | 0.062 | 64.046 | 14.422 | 17,779.333 | 45.440 | 5.960 | 0.134 | 0.086 | 46.671 | |

| Maximun | 7.501 | 0.303 | 81.492 | 20.908 | 18,202.667 | 46.840 | 6.322 | 0.388 | 0.157 | 48.087 | ||

| Mean | 5.800 | 0.131 | 76.080 | 17.449 | 17,973.217 | 46.081 | 6.159 | 0.179 | 0.108 | 47.473 | ||

| Std. Deviation | 1.313 | 0.056 | 3.680 | 1.556 | 119.409 | 0.316 | 0.098 | 0.068 | 0.016 | 0.314 | ||

| Maritime pine (P. pinaster) | Crown (%) | Minimum | 5.110 | 1.152 | 72.271 | 17.151 | 19,435.000 | 46.160 | 5.910 | 0.366 | 0.480 | 41.468 |

| Maximun | 7.711 | 2.044 | 75.861 | 19.277 | 20,375.333 | 49.910 | 6.699 | 1.418 | 3.083 | 44.278 | ||

| Mean | 6.288 | 1.447 | 73.924 | 18.341 | 19,964.833 | 48.705 | 6.433 | 0.802 | 0.968 | 43.092 | ||

| Std. Deviation | 0.652 | 0.212 | 1.039 | 0.649 | 229.757 | 0.841 | 0.192 | 0.404 | 0.607 | 0.902 | ||

| Bark (%) | Minimum | 6.607 | 0.482 | 62.888 | 22.093 | 19,351.333 | 48.440 | 5.477 | 0.334 | 0.208 | 41.141 | |

| Maximun | 8.988 | 5.817 | 66.802 | 27.716 | 20,580.000 | 51.930 | 6.092 | 1.412 | 1.280 | 44.257 | ||

| Mean | 7.861 | 0.971 | 64.834 | 26.333 | 19,838.367 | 50.385 | 5.862 | 0.656 | 0.395 | 42.701 | ||

| Std. Deviation | 0.721 | 1.160 | 1.132 | 1.283 | 321.028 | 0.896 | 0.178 | 0.320 | 0.298 | 0.815 | ||

| Wood (%) | Minimum | 6.119 | 0.182 | 78.195 | 10.560 | 18,843.667 | 44.300 | 5.837 | 0.301 | 0.147 | 43.989 | |

| Maximun | 8.654 | 0.353 | 81.468 | 13.941 | 19,554.000 | 48.820 | 6.460 | 1.193 | 2.466 | 47.565 | ||

| Mean | 7.001 | 0.272 | 79.552 | 13.243 | 19,093.250 | 46.978 | 6.277 | 0.610 | 0.439 | 45.695 | ||

| Std. Deviation | 0.628 | 0.038 | 0.759 | 0.731 | 163.492 | 1.058 | 0.151 | 0.211 | 0.606 | 0.667 | ||

| Species | Descriptive Statistics | Biomass Fraction | ||

|---|---|---|---|---|

| Wood (%) | Bark (%) | Crown (%) | ||

| Chestnut | Minimum | 16,298 | 2267 | 8345 |

| Maximum | 83,951 | 10,403 | 81,433 | |

| Mean | 66,898 | 6614 | 26,487 | |

| Std. Deviation | 12,262 | 1631 | 13,162 | |

| Maritime pine | Minimum | 57,257 | 8505 | 11,085 |

| Maximum | 76,000 | 17,895 | 33,626 | |

| Mean | 66,641 | 12,467 | 20,891 | |

| Std. Deviation | 5118 | 2155 | 5601 | |

| SRWC | Total | --- | --- | 100.000 |

| Proximate Analysis | Calorimetry | Ultimate Analysis | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Species | Clone | Moi.% | Ash% | VM% | FC% | HHV (J/g) | %C | %H | %S | %N | %O | |

| Willow | Olof | Minimum | 6.074 | 1.016 | 75.932 | 15.637 | 18,368.667 | 45.220 | 6.363 | 0.142 | 0.139 | 47.651 |

| Maximum | 6.901 | 1.267 | 77.031 | 15.926 | 18,539.333 | 45.650 | 6.378 | 0.194 | 0.179 | 48.066 | ||

| Mean | 6.406 | 1.174 | 76.662 | 15.757 | 18,458.000 | 45.387 | 6.373 | 0.162 | 0.163 | 47.915 | ||

| Std. Deviation | 0.437 | 0.138 | 0.632 | 0.151 | 85.614 | 0.231 | 0.008 | 0.028 | 0.021 | 0.230 | ||

| Tordis | Minimum | 6.794 | 1.120 | 75.042 | 15.826 | 18,157.000 | 45.313 | 6.340 | 0.129 | 0.150 | 47.645 | |

| Maximum | 7.424 | 1.250 | 75.864 | 17.001 | 18,511.667 | 45.613 | 6.368 | 0.211 | 0.253 | 48.027 | ||

| Mean | 7.106 | 1.193 | 75.330 | 16.370 | 18,318.778 | 45.492 | 6.358 | 0.163 | 0.189 | 47.797 | ||

| Std. Deviation | 0.315 | 0.067 | 0.463 | 0.592 | 179.368 | 0.158 | 0.015 | 0.043 | 0.056 | 0.202 | ||

| Poplar | I214 | Minimum | 6.203 | 2.102 | 75.560 | 15.262 | 18,132.667 | 45.000 | 6.234 | 0.140 | 0.118 | 48.252 |

| Maximum | 6.665 | 2.236 | 76.341 | 15.538 | 18,250.000 | 45.203 | 6.288 | 0.182 | 0.192 | 48.380 | ||

| Mean | 6.450 | 2.177 | 75.985 | 15.388 | 18,185.000 | 45.106 | 6.259 | 0.164 | 0.146 | 48.326 | ||

| Std. Deviation | 0.233 | 0.068 | 0.395 | 0.140 | 59.683 | 0.102 | 0.027 | 0.022 | 0.040 | 0.066 | ||

| AF2 | Minimum | 5.787 | 1.521 | 75.923 | 14.697 | 18,396.333 | 45.493 | 6.251 | 0.138 | 0.125 | 47.779 | |

| Maximum | 6.375 | 1.911 | 77.407 | 16.258 | 18,446.000 | 45.650 | 6.274 | 0.156 | 0.173 | 47.933 | ||

| Mean | 6.023 | 1.704 | 76.904 | 15.369 | 18,419.667 | 45.578 | 6.261 | 0.148 | 0.153 | 47.861 | ||

| Std. Deviation | 0.310 | 0.196 | 0.849 | 0.803 | 24.969 | 0.079 | 0.011 | 0.009 | 0.025 | 0.077 | ||

| Beaupré | Minimum | 5.557 | 1.819 | 75.526 | 14.778 | 18,277.000 | 45.473 | 6.281 | 0.138 | 0.108 | 47.318 | |

| Maximum | 7.117 | 1.902 | 77.515 | 15.724 | 18,560.667 | 46.130 | 6.381 | 0.141 | 0.112 | 47.961 | ||

| Mean | 6.187 | 1.859 | 76.634 | 15.319 | 18,386.111 | 45.704 | 6.321 | 0.139 | 0.110 | 47.725 | ||

| Std. Deviation | 0.822 | 0.041 | 1.014 | 0.488 | 152.738 | 0.369 | 0.053 | 0.002 | 0.002 | 0.354 | ||

| Chestnut | Minimum | 3.033 | 0.573 | 67.926 | 15.661 | 17,782.884 | 45.309 | 6.043 | 0.140 | 0.115 | 46.802 | |

| Maximum | 7.950 | 1.594 | 78.732 | 23.016 | 18,234.779 | 46.681 | 6.322 | 0.334 | 0.446 | 47.937 | ||

| Mean | 6.066 | 0.920 | 74.718 | 18.294 | 17,997.549 | 46.039 | 6.184 | 0.185 | 0.245 | 47.345 | ||

| Std. Deviation | 1.174 | 0.289 | 2.230 | 1.461 | 127.473 | 0.284 | 0.073 | 0.048 | 0.102 | 0.271 | ||

| Maritime Pine | Minimum | 6.186 | 0.422 | 75.432 | 13.495 | 19,143.673 | 45.343 | 5.806 | 0.341 | 0.187 | 43.523 | |

| Maximum | 8.216 | 1.179 | 78.232 | 16.621 | 19,756.892 | 48.980 | 6.420 | 1.248 | 2.283 | 46.329 | ||

| Mean | 6.947 | 0.602 | 76.575 | 15.975 | 19,366.277 | 47.775 | 6.260 | 0.650 | 0.494 | 44.820 | ||

| Std. Deviation | 0.567 | 0.165 | 0.722 | 0.677 | 138.918 | 0.856 | 0.151 | 0.213 | 0.523 | 0.568 | ||

| Species | Moi. (%) | Ash (%) | VM (%) | FC (%) | HHV (J/g) | %C | %H | %S | %N | %O | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chestnut (C. sativa) | Age | Correlation | 0.519 | −0.284 | −0.061 | −0.289 | 0.263 | 0.423 | −0.017 | 0.293 | −0.363 | −0.289 |

| Sig. (2-tailed) | 0.084 | 0.372 | 0.851 | 0.362 | 0.409 | 0.170 | 0.959 | 0.355 | 0.246 | 0.362 | ||

| N | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | ||

| dn | Correlation | 0.491 | −0.445 | −0.160 | −0.070 | −0.141 | 0.022 | −0.364 | 0.513 | −0.431 | 0.184 | |

| Sig. (2-tailed) | 0.105 | 0.147 | 0.619 | 0.828 | 0.663 | 0.945 | 0.244 | 0.088 | 0.162 | 0.567 | ||

| N | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | ||

| N | Correlation | −0.506 | 0.408 | 0.462 | −0.387 | −0.135 | −0.235 | 0.388 | −0.258 | 0.276 | 0.093 | |

| Sig. (2-tailed) | 0.038 | 0.104 | 0.062 | 0.125 | 0.606 | 0.364 | 0.124 | 0.317 | 0.283 | 0.721 | ||

| N | 17 | 17 | 17 | 17 | 17 | 17 | 17 | 17 | 17 | 17 | ||

| G | Correlation | 0.015 | −0.367 | 0.071 | −0.051 | 0.085 | −0.036 | −0.317 | 0.421 | −0.295 | 0.164 | |

| Sig. (2-tailed) | 0.953 | 0.148 | 0.788 | 0.847 | 0.747 | 0.892 | 0.216 | 0.092 | 0.251 | 0.529 | ||

| N | 17 | 17 | 17 | 17 | 17 | 17 | 17 | 17 | 17 | 17 | ||

| SI | Correlation | −0.004 | 0.147 | 0.009 | −0.041 | −0.354 | −0.475 | −0.167 | 0.173 | 0.302 | 0.425 | |

| Sig. (2-tailed) | 0.987 | 0.586 | 0.974 | 0.881 | 0.178 | 0.063 | 0.536 | 0.522 | 0.256 | 0.100 | ||

| N | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | ||

| Maritime pine (P. pinaster) | Age | Correlation | −0.314 | −0.428 | 0.248 | 0.103 | −0.223 | −0.062 | −0.173 | −0.002 | 0.175 | −0.018 |

| Sig. (2-tailed) | 0.178 | 0.060 | 0.293 | 0.665 | 0.345 | 0.794 | 0.466 | 0.992 | 0.461 | 0.940 | ||

| N | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| dn | Correlation | −0.320 | −0.411 | 0.328 | −0.019 | −0.021 | −0.011 | −0.221 | −0.220 | 0.082 | 0.083 | |

| Sig. (2-tailed) | 0.169 | 0.072 | 0.158 | 0.937 | 0.929 | 0.963 | 0.349 | 0.352 | 0.731 | 0.728 | ||

| N | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| N | Correlation | 0.127 | 0.311 | −0.237 | 0.070 | −0.227 | −0.001 | 0.012 | 0.075 | −0.138 | 0.097 | |

| Sig. (2-tailed) | 0.594 | 0.181 | 0.315 | 0.769 | 0.335 | 0.998 | 0.959 | 0.753 | 0.561 | 0.685 | ||

| N | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| G | Correlation | −0.167 | −0.216 | 0.180 | 0.001 | −0.091 | 0.039 | −0.230 | −0.068 | 0.079 | −0.047 | |

| Sig. (2-tailed) | 0.481 | 0.360 | 0.448 | 0.996 | 0.702 | 0.869 | 0.330 | 0.776 | 0.742 | 0.845 | ||

| N | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

| SI | Correlation | 0.203 | 0.412 | 0.114 | −0.392 | 0.199 | −0.066 | −0.041 | −0.075 | 0.066 | 0.081 | |

| Sig. (2-tailed) | 0.390 | 0.071 | 0.632 | 0.087 | 0.400 | 0.781 | 0.864 | 0.754 | 0.782 | 0.736 | ||

| N | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-Álvarez, P.; Pizarro, C.; Barrio-Anta, M.; Cámara-Obregón, A.; Bueno, J.L.M.; Álvarez, A.; Gutiérrez, I.; Burslem, D.F.R.P. Evaluation of Tree Species for Biomass Energy Production in Northwest Spain. Forests 2018, 9, 160. https://doi.org/10.3390/f9040160

Álvarez-Álvarez P, Pizarro C, Barrio-Anta M, Cámara-Obregón A, Bueno JLM, Álvarez A, Gutiérrez I, Burslem DFRP. Evaluation of Tree Species for Biomass Energy Production in Northwest Spain. Forests. 2018; 9(4):160. https://doi.org/10.3390/f9040160

Chicago/Turabian StyleÁlvarez-Álvarez, Pedro, Consuelo Pizarro, Marcos Barrio-Anta, Asunción Cámara-Obregón, Julio Luis María Bueno, Ana Álvarez, Inés Gutiérrez, and David F. R. P. Burslem. 2018. "Evaluation of Tree Species for Biomass Energy Production in Northwest Spain" Forests 9, no. 4: 160. https://doi.org/10.3390/f9040160