Engineering Cocrystals of Poorly Water-Soluble Drugs to Enhance Dissolution in Aqueous Medium

Abstract

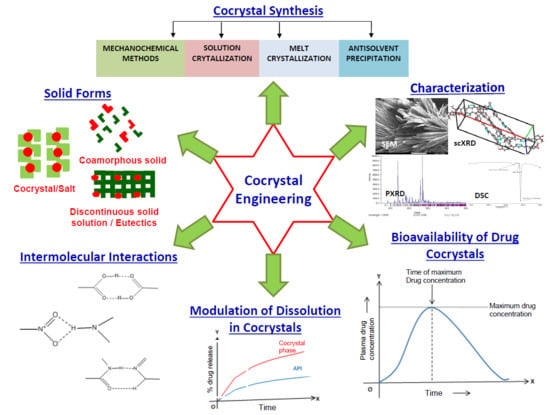

:1. Introduction

2. Types of Solid Forms Obtained from Cocrystallization

2.1. Cocrystals

2.2. Eutectics

2.3. Solid Solutions

2.4. Coamorphous Solids

2.5. Salts

2.6. Salt-Cocrystal Continuum

3. Factors Determining Cocrystallization

3.1. ∆pKa Rule

3.2. Hydrogen Bond Donors and Acceptors

- Mostly all good proton donors (such as –COOH, –NH4+) and acceptors (such as –OH, –NH3) are utilized in hydrogen bonding.

- Six-membered ring intramolecular hydrogen bonds (such as C-H…O) are formed first in preference to intermolecular hydrogen bonds (such as N-H…O and O-H…O)

- The best proton donors and acceptors available after intramolecular hydrogenbond formation then participate in intermolecular hydrogen bonds

- All acidic hydrogen atoms are included in hydrogen bonding in the crystal structure

3.3. Molecular Recognition Points

3.4. Flexibility of Synthon-Forming Functional Groups

3.5. Carbon Chain Length of Dicarboxylic Acid Coformers

3.6. Effect of Solvents

4. Screening Methods for Cocrystals

4.1. Computational Methods

4.2. Experimental Methods

4.2.1. Differential Scanning Calorimetric (DSC) Analysis

4.2.2. Phase Diagrams

5. Synthesis of Cocrystals

5.1. Batch Processes

5.2. Continuous Production of Cocrystals

- Batchwise variation in cocrystals quality can be rectified by means of continuous production by adopting a Quality-based Design (QbD) approach

- Continuous production of cocrystals is less labor intensive when compared to batch mode

- As compared to batch process, the maintenance of uniform particle distribution throughout the entire production, monitoring of quality of cocrystals by Process Analytical Technology (PAT) and maintaining consistency in the quality of products obtained is easier for continuous production

6. Characterization of Cocrystals

6.1. Structural Analysis

6.2. Thermal Analysis

6.3. Spectroscopic Analysis

6.4. Morphological Characterization

6.5. Drug Release Testing

7. Influence of Intermolecular Interactions on Cocrystallization

7.1. Hydrogen Bonding

7.2. Halogen Bonding

7.3. Ionic Interactions

7.4. Π…Π Stacking Interactions

7.5. Vanderwaal’s Interactions

8. Ternary and Quaternary Cocrystals

8.1. Approaches for Designing Ternary/Quaternary Cocrystals

- Hydrogen bond formation take place in a hierarchical manner (best donor forms hydrogen with the best acceptor, the second-best donor with the second-best acceptor) [103]

- A small number of specific intermolecular interactions such as hydrogen-bonding interactions can contribute to larger stabilization energy of the molecular crystals [269]

8.2. Advantages of Ternary/Quaternary Cocrystals

8.3. Disadvantages of Ternary/Quaternary Cocrystals

9. Polymorphism in Cocrystals

9.1. Synthon Polymorphism

9.2. Concomitant Polymorphism

9.3. Conformational Polymorphism

9.4. Packing Polymorphism

9.5. Pseudopolymorphism

9.6 Impact of Cocrystal Polymorphism on Solid-State Properties of API

10. Solubility and Dissolution Enhancement by Cocrystals

10.1. Cocrystal Solubilization

10.1.1. Phase Solubility Diagram (PSD)

10.1.2. Factors Influencing Solubility of Cocrystals

10.2. Dissolution of Cocrystals

- (i)

- (ii)

- Transformation of the amorphous or nanocrystalline drug clusters into a stable form through formation of a metastable phase by adopting Ostwald’s Law of Stages

- (iii)

10.2.1. Factors Influencing Dissolution of Cocrystals

10.2.2. Cocrystals with Low Dissolution Rates

11. In Vitro and In Vivo Studies

12. Challenges and Future Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Duarte, A.R.C.; Ferreira, A.S.D.; Barreiros, S.; Cabrita, E.; Reis, R.L.; Paiva, A. A comparison between pure active pharmaceutical ingredients and therapeutic deep eutectic solvents: Solubility and permeability studies. Eur. J. Pharm. Biopharm. 2017, 114, 296–304. [Google Scholar] [CrossRef] [PubMed]

- Edward, K.H.; Li, D. Drug Like Properties: Concept, Structure, Design and Methods, from ADME to Toxicity Optimization; Solubility Elsevier: New York, NY, USA, 2008; p. 56. [Google Scholar]

- Butler, J.M.; Dressman, J.B. The Developability Classification System: Application of Biopharmaceutics Concepts to Formulation Development. J. Pharm. Sci. 2010, 99, 4940–4954. [Google Scholar] [CrossRef] [PubMed]

- Sugano, K.; Terada, K. Rate- and Extent-Limiting Factors of Oral Drug Absorption: Theory and Applications. J. Pharm. Sci. 2015, 104, 2777–2788. [Google Scholar] [CrossRef] [PubMed]

- Ronak, S.; Stephen, T. Predicting and Selecting Formulations for Drug Discovery and Early Development. Available online: https://www.americanpharmaceuticalreview.com/Featured-Articles/341313-Predicting-and-Selecting-Formulations-for-Drug-Discovery-and-Early-Development/ (accessed on 12 July 2018).

- Lipert, M.P.; Roy, L.; Childs, S.L.; Rodriguez-Hornedo, N. Cocrystal solubilization in biorelevant media and its prediction from drug solubilization. J. Pharm. Sci. 2015, 104, 4153–4163. [Google Scholar] [CrossRef] [PubMed]

- Childs, S.L.; Kandi, P.; Lingireddy, S.R. Formulation of a Danazol Cocrystal with Controlled Supersaturation Plays an Essential Role in Improving Bioavailability. Mol. Pharm. 2013, 10, 3112–3127. [Google Scholar] [CrossRef] [PubMed]

- Kawabata, Y.; Wada, K.; Nakatani, M.; Yamada, S.; Onoue, S. Formulation design for poorly water-soluble drugs based on biopharmaceutics classification system: Basic approaches and practical applications. Int. J. Pharm. 2011, 420, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Good, D.J.; Rodriguez-Hornedo, N. Solubility Advantage of Pharmaceutical Cocrystals. Cryst. Growth Des. 2009, 9, 2252–2264. [Google Scholar] [CrossRef]

- Serajuddin, A.T.M. Salt formation to improve drug solubility. Adv. Drug Deliv. Rev. 2007, 59, 603–616. [Google Scholar] [CrossRef] [PubMed]

- Torchillin, V.P. Micellar nanocarriers: Pharmaceutical perspectives. Pharm. Res. 2007, 24, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Sharma, D.; Soni, M.; Kumar, S.; Gupta, G.D. Solubility enhancement-eminent role in poorly soluble drugs. Res. J. Pharm. Technol. 2009, 2, 220–224. [Google Scholar]

- Ter Horst, J.H.; Deij, M.A.; Cains, P.W. Discovering New Co-Crystals. Cryst. Growth Des. 2009, 9, 1531–1537. [Google Scholar] [CrossRef]

- Huang, L.; Tong, W. Impact of solid state properties on developability assessment of drug candidates. Adv. Drug Deliv. Rev. 2004, 56, 321–334. [Google Scholar] [CrossRef] [PubMed]

- Schultheiss, N.; Newman, A. Pharmaceutical Cocrystals and Their Physicochemical properties. Cryst. Growth Des. 2009, 9, 2950–2967. [Google Scholar] [CrossRef] [PubMed]

- Trask, A.V. An Overview of Pharmaceutical Cocrystals as Intellectual Property. Mol. Pharm. 2007, 4, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Bora, P.; Saikia, B.; Sarma, B. Regulation of π···π Stacking Interactions in Small Molecule Cocrystals and/or Salts for Physiochemical Property Modulation. Cryst. Growth Des. 2018, 18, 1448–1458. [Google Scholar] [CrossRef]

- Fatima, Z.; Srivastava, D.; Kaur, C.D. Multicomponent Pharmaceutical Cocrystals: A Novel Approach for Combination Therapy. Mini Rev. Med. Chem. 2018. [Google Scholar] [CrossRef]

- Thakuria, R.; Sarma, B. Drug-Drug and Drug-Nutraceutical Cocrystal/Salt as Alternative Medicine for Combination Therapy: A Crystal Engineering Approach. Crystals 2018, 8, 101. [Google Scholar] [CrossRef]

- Multidrug Co-Crystals Leading to Improved and Effective Therapeutics in Drug Development. Available online: https://sussexdrugdiscovery.wordpress.com/2016/04/25/multidrug-co-crystals-leading-to-improved-and-effective-therapeutics-in-drug-development/ (accessed on 25 October 2017).

- Valproate Information. Available online: https://www.fda.gov/drugs/drugsafety/postmarketdrugsafetyinformationforpatientsandproviders/ucm192645.htm (accessed on 6 June 2018).

- Goud, N.R.; Suresh, K.; Sanphui, P.; Nangia, A. Fast dissolving eutectic compositions of curcumin. Int. J. Pharm. 2012, 439, 63–72. [Google Scholar] [CrossRef] [PubMed]

- Cherukuvada, S.; Nangia, A. Fast dissolving eutectic compositions of two anti-tubercular drugs. CrystEngComm. 2012, 14, 2579–2588. [Google Scholar] [CrossRef]

- Sathisaran, I.; Dalvi, S.V. Crystal Engineering of Curcumin with Salicylic Acid and Hydroxyquinol as Coformers. Cryst. Growth Des. 2017, 17, 3974–3988. [Google Scholar] [CrossRef]

- Skieneh, J.M.; Sathisaran, I.; Dalvi, S.V.; Rohani, S. Co-amorphous form of Curcumin-Folic acid dihydrate with increased dissolution rate. Cryst. Growth Des. 2017, 17, 6273–6280. [Google Scholar] [CrossRef]

- Haneef, J.; Chadha, R. Drug-Drug Multicomponent Solid Forms: Cocrystal, Coamorphous and Eutectic of Three Poorly Soluble Antihypertensive Drugs Using Mechanochemical Approach. AAPS PharmSciTech. 2017, 18, 2279–2290. [Google Scholar] [CrossRef] [PubMed]

- Sanphui, P.; Goud, N.R.; Khandavilli, U.B.R.; Bhanoth, S.; Nangia, A. New polymorphs of curcumin. Chem. Commun. 2011, 47, 5013–5015. [Google Scholar] [CrossRef] [PubMed]

- Suresh, K.; Mannava, M.K.C.; Nangia, A. A novel curcumin-artemisinin coamorphous solid: Physical properties and pharmacokinetic profile. RSC Adv. 2014, 4, 58357–58361. [Google Scholar] [CrossRef]

- Pang, W.; Lv, J.; Du, S.; Wang, J.; Wang, J.; Zeng, Y. Preparation of Curcumin−Piperazine Coamorphous Phase and Fluorescence Spectroscopic and Density Functional Theory Simulation Studies on the Interaction with Bovine Serum Albumin. Mol. Pharm. 2017, 14, 3013–3024. [Google Scholar] [CrossRef] [PubMed]

- Lobmann, K.; Laitinen, R.; Grohganz, H.; Gordon, K.C.; Strachan, C.; Rades, T. Coamorphous Drug Systems: Enhanced Physical Stability and Dissolution Rate of Indomethacin and Naproxen. Mol. Pharm. 2011, 8, 1919–1928. [Google Scholar] [CrossRef] [PubMed]

- Jensen, K.T.; Lobmann, K.; Rades, T.; Grohganz, H. Improving Co-Amorphous Drug Formulations by the Addition of theHighly Water Soluble Amino Acid, Proline. Pharmaceutics 2014, 6, 416–435. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Gniado, K.; Erxleben, A.; McArdle, P. Mechanochemical Reaction of Sulfathiazole with Carboxylic Acids: Formation of a Cocrystal, a Salt, and Coamorphous Solids. Cryst. Growth Des. 2013, 14, 803–813. [Google Scholar] [CrossRef]

- Bi, Y.; Xiao, D.; Ren, S.; Bi, S.; Wang, J.; Li, F. The Binary System of Ibuprofen-Nicotinamide UnderNanoscale Confinement: From Cocrystal to Coamorphous State. J. Pharm. Sci. 2017, 106, 3150–3155. [Google Scholar] [CrossRef] [PubMed]

- Cherukuvada, S.; Nangia, A. Eutectics as improved pharmaceutical materials: Design, properties and characterization. Chem. Commun. 2014, 50, 906–923. [Google Scholar] [CrossRef] [PubMed]

- Cheney, M.L.; Shan, N.; Healey, E.R.; Hanna, M.; Wojtas, L.; Zaworotko, M.J.; Sava, V.; Song, S.; Sanchez-Ramos, J.R. Effects of Crystal Form on Solubility and Pharmacokinetics: A Crystal Engineering Case Study of Lamotrigine. Cryst. Growth Des. 2010, 10, 394–405. [Google Scholar] [CrossRef]

- Healy, A.M.; Worku, Z.A.; Kumar, D.; Madi, A.M. Pharmaceutical solvates, hydrates and amorphous forms: A special emphasis on cocrystals. Adv. Drug Deliv. Rev. 2017, 117, 25–46. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khankari, R.K.; Grant, D.J.W. Pharmaceutical hydrates. Thermochim. Acta 1995, 248, 61–79. [Google Scholar] [CrossRef]

- Yamamoto, N.; Taga, T.; Machida, K. Structure of mixed crystals of benzoic acid and p-fluorobenzoic acid, and their energy evaluation by empirical potential functions. Acta Cryst. 1989, 45, 162–167. [Google Scholar] [CrossRef]

- Nath, N.K.; Saha, B.K.; Nangia, A. Isostructural polymorphs of triiodophloroglucinoland triiodoresorcinol. New J. Chem. 2008, 32, 1693–1701. [Google Scholar] [CrossRef]

- Chakraborty, S.; Desiraju, G.R. C−H···F Hydrogen Bonds in Solid Solutions of Benzoic Acid and 4-Fluorobenzoic acid. Cryst. Growth Des. 2018, 18, 3607–3615. [Google Scholar] [CrossRef]

- Elder, D.P.; Holm, R.; de Diego, H.L. Use of pharmaceutical salts and cocrystals to address the issue of poor solubility. Int. J. Pharm. 2013, 453, 88–100. [Google Scholar] [CrossRef] [PubMed]

- Blagden, N.; Coles, S.J.; Berry, D.J. Pharmaceutical co-crystals—Are we there yet? CrystEngComm. 2014, 16, 5753–5761. [Google Scholar] [CrossRef]

- Stahly, G.P. A survey of cocrystals reported prior to 2000. Cryst. Growth Des. 2009, 9, 4212–4229. [Google Scholar] [CrossRef]

- Sarma, B.; Chen, J.; Hsi, H.; Myerson, A.S. Solid forms of pharmaceuticals: Polymorphs, salts and cocrystals. Korean J. Chem. Eng. 2011, 28, 315–322. [Google Scholar] [CrossRef]

- Aitipamula, S.; Banerjee, R.; Bansal, A.K.; Biradha, K.; Cheney, M.L.; Choudhury, A.R.; Desiraju, G.R.; Dikundwar, A.G.; Dubey, R.; Duggirala, N.; et al. Polymorphs, Salts, and Cocrystals: What’s in a Name? Cryst. Growth Des. 2012, 12, 2147–2152. [Google Scholar] [CrossRef]

- Grothe, E.; Meekes, H.; Vlieg, E.; ter Horst, J.H.; de Gelder, R. Solvates, Salts, and Cocrystals: A proposal for a Feasible Classification System. Cryst. Growth Des. 2016, 16, 3237–3243. [Google Scholar] [CrossRef] [Green Version]

- Zachary, B. FDA to Reclassify Pharmaceutical Co-Crystals. Available online: http://www.raps.org/Regulatory-Focus/News/2016/08/16/25611/FDA-to-Reclassify-Pharmaceutical-Co-Crystals/ (accessed on 26 October 2017).

- Gadade, D.D.; Pekamwar, S.S. Pharmaceutical Cocrystals: Regulatory and Strategic Aspects, Design and Development. Adv. Pharm. Bull. 2016, 6, 479–494. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- US Food and Drug Administration. Guidance for Industry: Regulatory Classification of Pharmaceutical Co-Crystals; Center for Drug Evaluation and Research: Silver Spring, MD, USA, 2013.

- Reflection Paper on the Use of Cocrystals and Other Solid State Forms of Active Substances in Medicinal Products. Available online: http://docplayer.net/76383282-Reflection-paper-on-the-use-of-cocrystals-of-active-substances-in-medicinal-products.html (accessed on 28 July 2018).

- Stoler, E.; Warner, J.C. Non-Covalent Derivatives: Cocrystals and Eutectics. Molecules 2015, 20, 14833–14848. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wohler, F. Untersuchungen über das Chinon. Ann. Chem. Pharm. 1844, 51, 145–163. [Google Scholar] [CrossRef]

- CSD; Version 5.34, ConQuest 1.11; Cambridge Crystallographic Data Centre: Cambridge, UK, 2008.

- Etter, M.C. Hydrogen Bonds as Design Elements in Organic Chemistry. J. Phys. Chem. 1991, 95, 4601–4610. [Google Scholar] [CrossRef]

- Cherukuvada, S.; Row, T.N.G. Comprehending the Formation of Eutectics and Cocrystals in Terms of Design and Their Structural Interrelationships. Cryst. Growth Des. 2014, 14, 4187–4198. [Google Scholar] [CrossRef]

- Bevill, M.J.; Vlahova, P.I.; Smit, J.P. Polymorphic Cocrystals of Nutraceutical Compound p-Coumaric Acid with Nicotinamide: Characterization, Relative Solid-State Stability, and Conversion to Alternate Stoichiometries. Cryst. Growth Des. 2014, 14, 1438–1448. [Google Scholar] [CrossRef]

- Childs, S.L.; Chyall, L.J.; Dunlap, J.T.; Smolenskaya, V.N.; Stahly, B.C.; Stahly, G.P. Crystal Engineering Approach to Forming Cocrystals of Amine Hydrochlorides with Organic Acids. Molecular Complexes of Fluoxetine Hydrochloride with Benzoic, Succinic, and Fumaric Acids. J. Am. Chem. Soc. 2004, 126, 13335–13342. [Google Scholar] [CrossRef] [PubMed]

- McNamara, D.P.; Childs, S.L.; Giordano, J.; Iarriccio, A.; Cassidy, J.; Shet, M.S.; Mannion, R.; O’Donell, E.; Park, A. Use of a Glutaric Acid Cocrystal to Improve Oral Bioavailability of a Low Solubility API. Pharm. Res. 2006, 23, 1888–1897. [Google Scholar] [CrossRef] [PubMed]

- Stanton, M.K.; Bak, A. Physicochemical Properties of Pharmaceutical Co-crystals: A Case Study of Ten AMG 517 Co-crystals. Cryst. Growth Des. 2008, 8, 3856–3862. [Google Scholar] [CrossRef]

- Yan, Y.; Chen, J.; Lu, T. Simultaneously enhancing the solubility and permeability of acyclovir by crystal engineering approach. CrystEngComm 2013, 15, 6457–6460. [Google Scholar] [CrossRef]

- Masuda, T.; Yoshihashi, Y.; Yonemochi, E.; Fujii, K.; Uekusa, H.; Terada, K. Cocrystallization and amorphization induced by drug–excipient interaction improves the physical properties of acyclovir. Int. J. Pharm. 2012, 422, 160–169. [Google Scholar] [CrossRef] [PubMed]

- Lu, E.; Rodriguez-Hornedo, N.; Suryanarayanan, R. A rapid thermal method for cocrystal screening. CrystEngComm 2008, 10, 665–668. [Google Scholar] [CrossRef]

- Bethune, S.J.; Huang, N.; Jayasankar, A.; Rodriguez-Hornedo, N. Understanding and Predicting the Effect of Cocrystal Components and pH on Cocrystal Solubility. Cryst. Growth Des. 2009, 9, 3976–3988. [Google Scholar] [CrossRef]

- Childs, S.L.; Rodriguez-Hornedo, N.; Reddy, L.S.; Jayasankar, A.; Maheshwari, C.; McCausland, L.; Shipplett, R.; Stahly, B.C. Screening strategies based on solubility and solution composition generate pharmaceutically acceptable cocrystals ofcarbamazepine. CrystEngComm 2008, 10, 856–864. [Google Scholar] [CrossRef]

- Moradiya, H.G.; Islam, M.T.; Halsey, S.; Maniruzzaman, M.; Chowdhry, B.Z.; Snowden, M.J.; Douroumis, D. Continuous cocrystallisation of carbamazepine and trans-cinnamic acidviamelt extrusion processing. CrystEngComm 2014, 16, 3573–3583. [Google Scholar] [CrossRef]

- Salan, J.; Anderson, S.R.; Am, E.D.J. A Method to Produce and Scale-Up Cocrystals and Salts via Resonant Acoustic Mixing. U.S. Patent EP 2845852 A1, 11 March 2015. [Google Scholar]

- Drozd, K.V.; Manin, A.N.; Churakov, A.V.; Perlovich, G.L. Novel drug–drug cocrystals of carbamazepine with para-aminosalicylic acid: Screening, crystal structures and comparative study of carbamazepine cocrystal formation thermodynamics. CrystEngComm 2017, 19, 4273–4286. [Google Scholar] [CrossRef]

- Shewale, S.; Shete, A.S.; Doijad, R.C.; Kadam, S.S.; Patil, V.A.; Yadav, A.V. Formulation and Solid State Characterization of Nicotinamide-based Co-crystals of Fenofibrate. Ind. J. Pharm. Sci. 2015, 77, 328–334. [Google Scholar] [CrossRef]

- Yan, Y.; Chen, J.; Geng, N.; Lu, T. Improving the Solubility of Agomelatine via Cocrystals. Cryst. Growth Des. 2012, 12, 2226–2233. [Google Scholar] [CrossRef]

- Seaton, C.C.; Parkin, A. Making Benzamide Cocrystals with Benzoic Acids: The Influence of Chemical Structure. Cryst. Growth Des. 2011, 11, 1502–1511. [Google Scholar] [CrossRef]

- Da Silva, C.C.P.; Pepino, R.O.; de Melo, C.C.; Tenorio, J.C.; Ellena, J. Controlled Synthesis of New 5-Fluorocytosine Cocrystals Based on the pKa Rule. Cryst. Growth Des. 2014, 14, 4383–4393. [Google Scholar] [CrossRef]

- Sanphui, P.; Goud, N.R.; Khandavilli, U.B.R.; Nangia, A. Fast Dissolving Curcumin Cocrystals. Cryst. Growth Des. 2011, 11, 4135–4145. [Google Scholar] [CrossRef]

- Chow, S.F.; Shi, L.; Ng, W.W.; Leung, K.H.Y.; Nagapudi, K.; Sun, C.C.; Chow, A.H.L. Kinetic Entrapment of a Hidden Curcumin Cocrystal with Phloroglucinol. Cryst. Growth Des. 2014, 14, 5079–5089. [Google Scholar] [CrossRef]

- Su, H.; He, H.; Tian, Y.; Zhao, N.; Sun, F.; Zhang, X.; Jiang, Q.; Zhu, G. Syntheses and characterizations of two curcumin-based cocrystals. Inorg. Chem. Commun. 2015, 55, 92–95. [Google Scholar] [CrossRef]

- Moradiya, H.G.; Islam, M.T.; Scoutaris, N.; Halsey, S.A.; Chowdhry, B.Z.; Douroumis, D. Continuous Manufacturing of High Quality Pharmaceutical Cocrystals Integrated with Process Analytical Tools for In-Line Process Control. Cryst. Growth Des. 2016, 6, 3425–3434. [Google Scholar] [CrossRef] [Green Version]

- Daurte, I.; Temtem, M.; Cil, M.; Gaspar, F. Overcoming poor bioavailability through amorphous solid dispersions. Ind. Pharm. 2011, 30, 4–6. [Google Scholar]

- Fenofibrate Tablets, for Oral Use. Available online: https://www.accessdata.fda.gov/drugsatfda_docs/label/2012/022118s005lbl.pdf (accessed on 9 July 2018).

- Faeges, M. Stable Suspensions of Acetyl Salicylic Acid. U.S. Patent US3316150A, 25 April 1967. [Google Scholar]

- Chadha, K.; Karan, M.; Chadha, R.; Bhalla, Y.; Vasisht, K. Is Failure of Cocrystallization Actually a Failure? Eutectic Formation in Cocrystal Screening of Hesperetin. J. Pharm. Sci. 2017, 106, 2026–2036. [Google Scholar] [CrossRef] [PubMed]

- Sangster, J. Phase Diagrams and Thermodynamic Properties of Binary Systems of Drugs. J. Phys. Chem. Ref. Data 1999, 28, 889–930. [Google Scholar] [CrossRef]

- Gorniak, A.; Karolewicz, B.; Zurawska-Plaksej, E.; Pluta, J. Thermal, spectroscopic, and dissolution studies of the simvastatin–acetylsalicylic acid mixtures. J. Therm. Anal. Calorim. 2013, 111, 2125–2132. [Google Scholar] [CrossRef]

- Ganduri, R.; Cherukuvada, S.; Row, T.N.G. Multicomponent Adducts of Pyridoxine: An Evaluation of the Formation of Eutectics and Molecular Salts. Cryst. Growth Des. 2015, 15, 3474–3480. [Google Scholar] [CrossRef]

- Haneef, J.; Chadha, R. Antioxidant-Based Eutectics of Irbesartan: Viable Multicomponent Forms for the Management of Hypertension. AAPS PharmSciTech 2017. [Google Scholar] [CrossRef] [PubMed]

- Oliviera, M.A.; Peterson, M.L.; Klein, D. Continuously Substituted Solid Solutions of Organic Co-Crystals. Cryst. Growth Des. 2008, 8, 4487–4493. [Google Scholar] [CrossRef]

- Chieng, N.; Aaltonen, J.; Saville, D.; Rades, T. Physical characterization and stability of amorphous indomethacin and ranitidine hydrochloride binary systems prepared by mechanical activation. Eur. J. Pharm. Biopharm. 2009, 71, 47–54. [Google Scholar] [CrossRef] [PubMed]

- Dengale, S.J.; Grohganz, H.; Rades, T.; Lobmann, K. Recent advances in co-amorphous drug formulations. Adv. Drug Deliv. Rev. 2016, 100, 116–125. [Google Scholar] [CrossRef] [PubMed]

- Newman, A.; Reutzel-Edens, S.M.; Zografi, G. Coamorphous Active Pharmaceutical Ingredient—Small Molecule Mixtures: Considerations in the Choice of Coformers for Enhancing Dissolution and Oral Bioavailability. J. Pharm. Sci. 2018, 107, 5–17. [Google Scholar] [CrossRef] [PubMed]

- Shayanfar, A.; Ghavimi, H.; Hamishekhar, H.; Jouyban, A. Coamorphous Atorvastatin Calcium to Improve its Physicochemical and Pharmacokinetic Properties. J. Pharm. Pharm. Sci. 2013, 16, 577–587. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mannava, M.K.C.; Suresh, K.; Bommaka, M.K.; Konga, D.B.; Nangia, A. Curcumin-Artemisinin Coamorphous Solid: Xenograft Model Preclinical Study. Pharmaceutics 2018, 10, 7. [Google Scholar] [CrossRef] [PubMed]

- Gu, C.H.; Grant, D.J.W. Handbook of Experimental Pharmacology: Stereochemical Aspects of Drug Action and Disposition; Eichelbaum, M., Testa, B., Somogyi, A., Eds.; Springer: Berlin, Germany, 2003. [Google Scholar]

- Aakeroy, C.B.; Fasulo, M.E.; Desper, J. Cocrystal or Salt: Does It Really Matter? Mol. Pharm. 2007, 4, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Bowker, M.J. Chapter 7. A Procedure for Salt Selection and Optimization. In Handbook of Pharmaceutical Salts: Properties, Selection, and Use; Stahl, P.H., Wermuth, C.G., Eds.; Wiley-VCH: Weinheim, Germany, 2002; pp. 163–164. [Google Scholar]

- Childs, S.L.; Stahly, G.P.; Park, A. The Salt-Cocrystal Continuum: The Influence of Crystal Structure on Ionization State. Mol. Pharm. 2007, 4, 323–328. [Google Scholar] [CrossRef] [PubMed]

- Black, S.N.; Collier, E.A.; Davey, R.J.; Roberts, R.J. Structure, Solubility, Screening, and Synthesis of Molecular Salts. J. Pharm. Sci. 2007, 96, 1053–1068. [Google Scholar] [CrossRef] [PubMed]

- Babu, N.J.; Nangia, A. Solubility Advantage of Amorphous Drugs and Pharmaceutical Cocrystals. Cryst. Growth Des. 2011, 11, 2662–2679. [Google Scholar] [CrossRef]

- Jacobs, A.; Noa, F.M.A. Hybrid Salt–Cocrystal Solvate: p-Coumaric Acid and Quinine System. J. Chem. Crystallogr. 2014, 44, 57–62. [Google Scholar] [CrossRef]

- Bhogala, B.R.; Basavoju, S.; Nangia, A. Tape and layer structuresin cocrystals of some di- and tricarboxylic acids with 4,4’-bipyridines and isonicotinamide. From binary to ternary cocrystals. CrystEngComm 2005, 7, 551–562. [Google Scholar] [CrossRef]

- Berry, D.J.; Steed, J.W. Pharmaceutical cocrystals, salts and multicomponent systems; intermolecular interactions and property based design. Adv. Drug. Deliv. Rev. 2017, 117, 3–24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shattock, T.R.; Arora, K.K.; Vishweshwar, P.; Zaworotko, M.J. Hierarchy of Supramolecular Synthons: Persistent Carboxylic Acid⋯Pyridine Hydrogen Bonds in Cocrystals that also Contain a Hydroxyl Moiety. Cryst. Growth Des. 2008, 8, 4533–4545. [Google Scholar] [CrossRef]

- Rajput, L.; Banik, M.; Yarava, J.R.; Joseph, S.; Pandey, M.K.; Nishiyama, Y.; Desiraju, G.R. Exploring the salt–cocrystal continuum with solidstate NMR using natural-abundance samples: Implications for crystal engineering. IUCrJ 2017, 4, 466–475. [Google Scholar] [CrossRef] [PubMed]

- Mittapalli, S.; Mannava, M.K.C.; Khandavilli, U.B.R.; Allu, S.; Nangia, A. Soluble Salts and Cocrystals of Clotrimazole. Cryst. Growth Des. 2015, 15, 2493–2504. [Google Scholar] [CrossRef]

- Aitipamula, S.; Chow, P.S.; Tan, R.B.H. Polymorphism in cocrystals: A review and assessment of its significance. CrystEngComm 2014, 16, 3451–3465. [Google Scholar] [CrossRef]

- Etter, M.C. Encoding and decoding hydrogen bond patterns of organic compunds. Acc. Chem. Res. 1990, 23, 120–126. [Google Scholar] [CrossRef]

- Donohue, J. The Hydrogen Bond in Organic Crystals. J. Phys. Chem. 1952, 56, 502–510. [Google Scholar] [CrossRef]

- Almarsson, O.; Zaworotko, M.J. Crystal engineering of the composition of pharmaceutical phases. Do pharmaceutical co-crystals represent a new path to improved medicines? Chem. Commun. 2004, 1889–1896, 1889–1896. [Google Scholar] [CrossRef] [PubMed]

- Corey, E.J. General methods for the construction of complex molecules. Pure Appl. Chem. 1967, 14, 30–37. [Google Scholar] [CrossRef]

- Desiraju, G.R. Supramolecular Synthons in Crystal Engineering—A New Organic Synthesis. Angew. Chem. Int. Ed. Engl. 1995, 34, 2311–2327. [Google Scholar] [CrossRef]

- Aakeroy, C.B.; Beatty, A.M.; Helfrich, B.A.; Nieuwenhuyzen, M. Do Polymorphic Compounds Make Good Cocrystallizing Agents? A Structural Case Study that Demonstrates the Importance of Synthon Flexibility. Cryst. Growth Des. 2003, 3, 159–165. [Google Scholar] [CrossRef]

- Shevchenko, A.; Miroshnyk, I.; Pietila, L.; Haarala, J.; Salmia, J.; Sinervo, K.; Mirza, S.; Veen, B.; Kolehmainen, E.; Ylirussi, J. Diversity in Itraconazole Cocrystals with Aliphatic Dicarboxylic Acids of Varying Chain Length. Cryst. Growth Des. 2013, 13, 4877–4884. [Google Scholar] [CrossRef]

- Lee, K.; Kim, K.; Ulrich, J. Formation of Salicylic Acid/4,4′-Dipyridyl Cocrystals Based on the Ternary Phase Diagram. Chem. Eng. Technol. 2015, 38, 1073–1080. [Google Scholar] [CrossRef]

- Robertson, C.C.; Wright, J.S.; Carrington, E.J.; Perutz, R.N.; Hunter, C.A.; Brammer, L. Hydrogen bonding vs. Halogen bonding: The solvent decides. Chem. Sci. 2017, 8, 5392–5398. [Google Scholar] [CrossRef] [PubMed]

- Issa, N.; Karamertzanis, P.G.; Welch, G.W.A.; Price, S.L. Can the Formation of Pharmaceutical Cocrystals Be Computationally Predicted? I. Comparison of Lattice Energies. Cryst. Growth Des. 2009, 9, 442–453. [Google Scholar] [CrossRef]

- Kuleshova, L.N.; Hofmann, D.W.M.; Boese, R. Lattice energy calculation—A quick tool for screening of cocrystals and estimation of relative solubility. Case of flavonoids. Chem. Phys. Lett. 2013, 564, 26–32. [Google Scholar] [CrossRef]

- Chan, H.C.S.; Kendrick, J.; Neumann, M.A.; Leusen, F.J.J. Towards ab initio screening of co-crystal formation through lattice energy calculations and crystal structure prediction of nicotinamide, isonicotinamide, picolinamide and paracetamol multi-component crystals. CrystEngComm 2013, 15, 3799–3807. [Google Scholar] [CrossRef]

- Karamertzanis, P.G.; Kazantsev, A.V.; Issa, N.; Welch, G.W.A.; Adjiman, C.S.; Pantelides, C.C.; Price, S.L. Can the Formation of Pharmaceutical Cocrystals Be Computationally Predicted? 2. Crystal Structure Prediction. J. Chem. Theory Comput. 2009, 5, 1432–1448. [Google Scholar] [CrossRef] [PubMed]

- Grecu, T.; Hunter, C.A.; Gardiner, E.J.; McCabe, J.F. Validation of a Computational Cocrystal Prediction Tool; Comparison of Virtual and Experimental Cocrystal Screening Results. Cryst. Growth Des. 2014, 14, 165–171. [Google Scholar] [CrossRef]

- Grecu, T.; Adams, H.; Hunter, C.A.; McCabe, J.F.; Portell, A.; Prohens, R. Virtual Screening Identifies New Cocrystals of Nalidixic Acid. Cryst. Growth Des. 2014, 14, 1749–1755. [Google Scholar] [CrossRef]

- Grecu, T.; Prohens, R.; McCabe, J.F.; Carrington, E.J.; Wright, J.S.; Brammer, L.; Hunter, C.A. Cocrystals of spironolactone and griseofulvin based on an in silico screening method. Cryst. Growth Des. 2017, 19, 3592–3599. [Google Scholar] [CrossRef] [Green Version]

- Wood, P.A.; Feeder, N.; Furlow, M.; Galek, P.T.A.; Groom, C.R.; Pidcock, E. Knowledge-based approaches to co-crystal design. CrystEngComm 2014, 16, 5839–5848. [Google Scholar] [CrossRef]

- Delori, A.; Galek, P.T.A.; Pidcock, E.; Patni, M.; Jones, W. Knowledge-based hydrogen bond prediction and the synthesis of salts and cocrystals of the anti-malarial drug pyrimethamine with various drug and GRAS molecules. CrystEngComm 2013, 15, 2916–2928. [Google Scholar] [CrossRef]

- Mohammad, M.A.; Alhalaweh, A.; Velaga, S.P. Hansen solubility parameter as a tool to predict cocrystal formation. Int. J. Pharm. 2011, 407, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Abramov, Y.A.; Loschen, C.; Klamt, A. Rational coformer or solvent selection for pharmaceutical cocrystallization or desolvation. J. Pharm. Sci. 2012, 101, 3687–3697. [Google Scholar] [CrossRef] [PubMed]

- Abramov, Y.A. Virtual hydrate screening and coformer selection for improved relative humidity stability. CrystEngComm 2015, 17, 5216–5224. [Google Scholar] [CrossRef]

- Habgood, M.; Deij, M.A.; Mazurek, J.; Price, S.L.; ter Horst, J.H. Carbamazepine Cocrystallization with Pyridine Carboxamides: Rationalization by Complementary Phase Diagrams and Crystal Energy Landscapes. Cryst. Growth Des. 2010, 10, 903–912. [Google Scholar] [CrossRef]

- Fabian, L. Cambridge Structural Database Analysis of Molecular Complementarity in Cocrystals. Cryst. Growth Des. 2009, 9, 1436–1443. [Google Scholar] [CrossRef]

- Musumeci, D.; Hunter, C.A.; Prohens, R.; Scuderi, S.; McCabe, J.F. Virtual cocrystal sceening. Chem. Sci. 2011, 2, 883–890. [Google Scholar] [CrossRef]

- Cysewski, P. Transferability of cocrystallization propensities between aromatic and heteroaromatic amides. Struct. Chem. 2016, 27, 1403–1412. [Google Scholar] [CrossRef] [Green Version]

- Loschen, C.; Klamt, A. Solubility prediction, solvate and cocrystal screening as tools for rational crystal engineering. J. Pharm. Pharmacol. 2015, 67, 803–811. [Google Scholar] [CrossRef] [PubMed]

- Solomos, M.A.; Mohammadi, C.; Urbelis, J.H.; Koch, E.S.; Osborne, R.; Usala, C.C.; Swift, J.A. Predicting Cocrystallization Based on Heterodimer Energies: The Case of N,N′-Diphenylureas and Triphenylphosphine Oxide. Cryst. Growth Des. 2015, 15, 5068–5074. [Google Scholar] [CrossRef]

- Stepanovs, D.; Jure, M.; Kuleshova, L.N.; Hofmann, D.W.M.; Mishnev, A. Cocrystals of Pentoxifylline: In Silico and Experimental Screening. Cryst. Growth Des. 2015, 15, 3652–3660. [Google Scholar] [CrossRef]

- Cysewski, P. In silico screening of dicarboxylic acids for cocrystallization with phenylpiperazine derivatives based on both cocrystallization propensity and solubility advantage. J. Mol. Model. 2017, 23, 136. [Google Scholar] [CrossRef] [PubMed]

- Cysewski, P. Heat of formation distributions of components involved in bi-component cocrystals and simple binary eutectic mixtures. New J. Chem. 2016, 40, 187–194. [Google Scholar] [CrossRef]

- Newman, A. Specialized Solid Form Screening Techniques. Org. Process Res. Dev. 2013, 17, 457–471. [Google Scholar] [CrossRef]

- Meng, F.; Li, Y.; Liu, X.; Li, B.; Wang, L. Single-Crystal Structures and Typical Hydrogen-Bonding Motifs of Supramolecular Cocrystals Containing 1,4-Di(1H-imidazol-1-yl) benzene. Cryst. Growth Des. 2015, 15, 4518–4525. [Google Scholar] [CrossRef]

- Thomas, R.; Gopalan, R.S.; Kulkarni, G.U.; Rao, C.N.R. Hydrogen bonding patterns in the cocrystals of 5-nitrouracil with several donor and acceptor molecules. Beilstein J. Org. Chem. 2005. [Google Scholar] [CrossRef] [PubMed]

- Mohana, M.; Muthiah, P.T.; McMillen, C.D. Supramolecular hydrogen-bonding patterns in 1:1 cocrystals of 5-fluorouracil with 4-methylbenzoic acid and 3-nitrobenzoic acid. Acta Cryst. 2017, 73, 259–263. [Google Scholar] [CrossRef] [PubMed]

- Oswald, I.D.H.; Motherwell, W.D.S.; Parsons, S. Formation of quinol co-crystals with hydrogen-bond acceptors. Acta Cryst. 2005, 61, 46–57. [Google Scholar] [CrossRef] [PubMed]

- Weyna, D.R.; Cheney, M.L.; Shan, N.; Hanna, M.; Wojtas, L.; Zaworotko, M.J. Crystal engineering of multiple-component organic solids: Pharmaceutical cocrystals of tadalafil with persistent hydrogen bonding motifs. CrystEngComm 2012, 14, 2377–2380. [Google Scholar] [CrossRef]

- Kamali, N.; Aljohani, M.; McArdle, P.; Erxleben, A. Hydrogen Bonding Networks and Solid-State Conversions in Benzamidinium Salts. Cryst. Growth Des. 2015, 15, 3905–3916. [Google Scholar] [CrossRef] [Green Version]

- Yamashita, H.; Hirakura, Y.; Yuda, M.; Teramura, T.; Terada, K. Detection of cocrystal formation based on binary phase diagrams using thermal analysis. Pharm. Res. 2013, 30, 70–80. [Google Scholar] [CrossRef] [PubMed]

- Yamashita, H.; Hirakura, Y.; Yuda, M.; Terada, K. Coformer Screening Using Thermal Analysis Based on Binary Phase Diagrams. Pharm. Res. 2014, 31, 1946–1957. [Google Scholar] [CrossRef] [PubMed]

- Saganowska, P.; Weselowski, M. DSC as a screening tool for rapid co-crystal detection in binary mixtures of benzodiazepines with co-formers. J. Therm. Anal. Calorim. 2017. [Google Scholar] [CrossRef]

- Craye, G.; Lobmann, K.; Grohganz, H.; Rades, T.; Laitinen, R. Characterization of Amorphous and Co-Amorphous Simvastatin Formulations Prepared by Spray Drying. Molecules 2015, 20, 21532–21548. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, S.; Harasimowicz, M.T.; de Villiers, M.M.; Yu, L. Cocrystals of Nicotinamide and (R)-Mandelic Acid in Many Ratios with Anomalous Formation Properties. J. Am. Chem. Soc. 2013, 135, 18981–18989. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Chen, J.; Lu, T. Thermodynamics and preliminary pharmaceutical characterization of a melatonin–pimelic acid cocrystal prepared by a melt crystallization method. CrystEngComm 2015, 17, 612–620. [Google Scholar] [CrossRef]

- Chiarella, R.A.; Davey, R.J.; Peterson, M.L. Making Co-crystals-The Utility of Ternary Phase Diagrams. Cryst. Growth Des. 2007, 7, 1223–1226. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, H.; Rasmuson, A.C. Thermodynamics and crystallization of a theophylline–salicylic acid cocrystal. CrystEngComm 2015, 17, 4125–4135. [Google Scholar] [CrossRef]

- Sun, X.; Yin, Q.; Ding, S.; Shen, Z.; Bao, Y.; Gong, J.; Hou, B.; Hao, H.; Wang, Y.; Wang, J.; et al. Solid−Liquid Phase Equilibrium and Ternary Phase Diagrams of Ibuprofen−Nicotinamide Cocrystals in Ethanol and Ethanol/Water Mixtures at (298.15 and 313.15) K. J. Chem. Eng. Data 2015, 60, 1166–1172. [Google Scholar] [CrossRef]

- Good, D.J.; Rodriguez-Hornedo, N. Cocrystal Eutectic Constants and Prediction of Solubility Behavior. Cryst. Growth Des. 2010, 10, 1028–1032. [Google Scholar] [CrossRef]

- Lange, L.; Lehmkemper, K.; Sadowski, G. Predicting the Aqueous Solubility of Pharmaceutical Cocrystals as a Function of pH and Temperature. Cryst. Growth Des. 2016, 16, 2726–2740. [Google Scholar] [CrossRef]

- Karki, S.; Friscic, T.; Jones, W.; Motherwell, W.D.S. Screening for Pharmaceutical Cocrystal Hydrates via Neat and Liquid-Assisted Grinding. Mol. Pharm. 2007, 4, 347–354. [Google Scholar] [CrossRef] [PubMed]

- Chadwick, K.; Davey, R.; Cross, W. How does grinding produce co-crystals? Insights from the case of benzophenone and diphenylamine. CrystEngComm 2007, 9, 732–734. [Google Scholar] [CrossRef]

- Friscic, T. New opportunities for materials synthesis using mechanochemistry. J. Mater. Chem. 2010, 20, 7599–7605. [Google Scholar] [CrossRef]

- Weyna, D.R.; Shattock, T.; Vishweshwar, P.; Zaworotko, M.J. Synthesis and Structural Characterization of Cocrystals and Pharmaceutical Cocrystals: Mechanochemistry vs Slow Evaporation from Solution. Cryst. Growth Des. 2009, 9, 1106–1123. [Google Scholar] [CrossRef]

- Aher, S.; Dhumal, R.; Mahadik, K.; Paradkar, A.; York, P. Ultrasound assisted cocrystallization from solution (USSC) containing a non-congruently soluble cocrystal component pair: Caffeine/maleic acid. Eur. J. Pharm. Sci. 2010, 41, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Aher, S.; Dhumal, R.; Mahadik, K.; Ketolainen, J.; Paradkar, A. Effect of cocrystallization techniques on compressional properties of caffeine/oxalic acid 2:1 cocrystal. Pharm. Dev. Technol. 2013, 18, 55–60. [Google Scholar] [CrossRef] [PubMed]

- Takata, N.; Shiraki, K.; Takano, R.; Hayashi, Y.; Terada, K. Cocrystal Screening of Stanolone and Mestanolone Using Slurry Crystallization. Cryst. Growth Des. 2008, 8, 3032–3037. [Google Scholar] [CrossRef]

- Bucar, D.; Henry, R.F.; Lou, X.; Duerst, R.W.; MacGillivray, L.R.; Zhang, G.G.Z. Cocrystals of Caffeine and Hydroxybenzoic Acids Composed of Multiple Supramolecular Heterosynthons: Screening via Solution-Mediated Phase Transformation and Structural Characterization. Cryst. Growth Des. 2009, 9, 1932–1943. [Google Scholar] [CrossRef]

- Jayasankar, A.; Good, D.J.; Rodriguez-Hornedo, N. Mechanisms by Which Moisture Generates Cocrystals. Mol. Pharm. 2007, 4, 360–372. [Google Scholar] [CrossRef] [PubMed]

- Good, D.; Miranda, C.; Rodriguez-Hornedo, N. Dependence of cocrystal formation and thermodynamic stability on moisture sorption by amorphous polymer. CrystEngComm 2011, 13, 1181–1189. [Google Scholar] [CrossRef]

- Seo, J.; Hwang, K.; Lee, S.; Kim, D.; Park, E. Preparation and characterization of adefovir dipivoxil–stearic acid cocrystal with enhanced physicochemical properties. Pharm. Dev. Technol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Pando, C.; Cabanas, A.; Cuadra, I.A. Preparation of pharmaceutical co-crystals through sustainable processes using supercritical carbon dioxide: A review. RSC Adv. 2016, 6, 71134–71150. [Google Scholar] [CrossRef]

- Ter Horst, J.H.; Cains, P.W. Co-Crystal Polymorphs from a Solvent-Mediated Transformation. Cryst. Growth Des. 2008, 8, 2537–2542. [Google Scholar] [CrossRef]

- Friscic, T.; Jones, W. Recent Advances in Understanding the Mechanism of Cocrystal Formation via Grinding. Cryst. Growth Des. 2009, 9, 1621–1637. [Google Scholar] [CrossRef]

- Trask, A.V.; Jones, W. Crystal Engineering of Organic Cocrystals by the Solid-State Grinding Approach. In Organic Solid State Reactions. Topics in Current Chemistry; Toda, F., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 254, pp. 41–70. [Google Scholar]

- Tilborg, A.; Michaux, C.; Norberg, B.; Wouters, J. Advantages of cocrystallization in the field of solid-state pharmaceutical chemistry: L-Proline and MnCl2. Eur. J. Med. Chem. 2010, 45, 3511–3517. [Google Scholar] [CrossRef] [PubMed]

- Rastogi, R.P.; Bassi, P.S.; Chadha, S.L. Kinetics of reaction between naphthalene and picric acid in the solid state. J. Phys. Chem. 1962, 66, 2707–2708. [Google Scholar] [CrossRef]

- Rastogi, R.P.; Bassi, P.S.; Chadha, S.L. Mechanism of the reaction between hydrocarbons and picric acid in the solid state. J. Phys. Chem. 1963, 67, 2569–2573. [Google Scholar] [CrossRef]

- Rastogi, R.P.; Singh, N.B. Solid-State Reactions between Picric acid and Naphthols. J. Phys. Chem. 1966, 70, 3315–3324. [Google Scholar] [CrossRef]

- Rastogi, R.P.; Singh, N.B. Solid-State Reactivity of Picric Acid and Substituted Hydrocarbons. J. Phys. Chem. 1968, 72, 4446–4449. [Google Scholar] [CrossRef]

- Rehder, S.; Klukkert, M.; Lobmann, K.A.M.; Strachan, C.J.; Sakmann, A.; Gordon, K.; Rades, T.; Leopold, C.S. Investigation of the Formation Process of Two Piracetam Cocrystals during Grinding. Pharmaceutics 2011, 3, 706–722. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alhalaweh, A.; George, S.; Basavoju, S.; Childs, S.L.; Rizvi, S.A.A.; Velaga, S.P. Pharmaceutical cocrystals of nitrofurantoin: Screening, characterization and crystal structure analysis. CrystEngComm 2012, 14, 5078–5088. [Google Scholar] [CrossRef]

- Kuroda, R.; Higashiguchi, K.; Hasebe, S.; Imai, Y. Crystal to crystal transformation in the solid state. CrystEngComm 2004, 6, 464–468. [Google Scholar] [CrossRef]

- Ji, C.; Hoffman, M.C.; Mehta, M.A. Catalytic Effect of Solvent Vapors on the Spontaneous Formation of Caffeine−Malonic Acid Cocrystal. CrystEngComm 2017, 17, 1456–1459. [Google Scholar] [CrossRef]

- Ruecroft, G.; Hipkiss, D.; Ly, T.; Maxted, N.; Cains, P.W. Sonocrystallization: The use of ultrasound for improved industrial crystallization. Org. Process Res. Dev. 2005, 9, 923–932. [Google Scholar] [CrossRef]

- Luque de Castro, M.D.; Priego-Capote, F. Ultrasound-assisted crystallization (sonocrystallization). Ultrason. Sonochem. 2007, 14, 717–724. [Google Scholar] [CrossRef] [PubMed]

- Childs, S.L.; Mougin-Andres, P.M.; Stahly, B.C. Screening for Solid Forms by Ultrasound Crystallization and Cocrystallization Using Ultrasound. U.S. Patent US20110251426A1, 13 October 2011. [Google Scholar]

- Morrison, H.; Mrozek-Morrison, M.; Toschi, J.; Luu, V.; Tan, H.; Daurio, D. High Throughput Bench-Top Co-crystal Screening via a Floating Foam Rack/Sonic Bath Method. Org. Process. Res. Dev. 2013, 17, 533–539. [Google Scholar] [CrossRef]

- Ross, S.A.; Lamprou, D.A.; Douroumis, D. Engineering and manufacturing of pharmaceutical co-crystals: A review of solvent-free manufacturing technologies. Chem. Commun. 2016, 52, 8772–8786. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Daurio, D.; Nagapudi, K.; Li, L.; Quan, P.; Nunez, F.A. Application of twin screw extrusion to the manufacture of cocrystals: Scale-up of AMG 517-sorbic acid cocrystal production. Faraday Discuss. 2014, 170, 235–249. [Google Scholar] [CrossRef] [PubMed]

- Chavan, R.B.; Thipparaboina, R.; Yadav, B.; Shastri, N.R. Continuous manufacturing of co-crystals: Challenges and prospects. Drug Deliv. Transl. Res. 2018. [Google Scholar] [CrossRef] [PubMed]

- Thipparaboina, R.; Kumar, D.; Chavan, R.B.; Shastri, N.R. Multidrug co-crystals: Towards the development of effective therapeutic hybrids. Drug Discov. Today 2016. [Google Scholar] [CrossRef] [PubMed]

- Daurio, D.; Medina, C.; Saw, R.; Nagapudi, K.; Alvarez-Nunez, F. Application of Twin Screw Extrusion in the Manufacture of Cocrystals, Part I: Four Case Studies. Pharmaceutics 2011, 3, 582–600. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, S.; Yu, T.; Tian, Y.; McCoy, C.P.; Jones, D.S.; Andrews, G.P. Mechanochemical Synthesis of Pharmaceutical Cocrystal Suspensions via Hot Melt Extrusion: Feasibility Studies and Physicochemical Characterization. Mol. Pharm. 2016, 13, 3054–3068. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kulkarni, C.; Wood, C.; Kelly, A.L.; Gough, T.; Blagden, N.; Paradkar, A. Stoichiometric Control of Co-Crystal Formation by Solvent Free Continuous Co-Crystallization (SFCC). Cryst. Growth Des. 2015, 15, 5648–5651. [Google Scholar] [CrossRef] [Green Version]

- Alhalaweh, A.; Velaga, S.P. Formation of Cocrystals from Stoichiometric Solutions of Incongruently Saturating Systems by Spray Drying. Cryst. Growth Des. 2010, 10, 3302–3305. [Google Scholar] [CrossRef]

- Spitzer, D.; Risse, B.; Schnell, F.; Pichot, V.; Klaumunzer, M.; Schaefer, M.R. Continuous engineering of nano-cocrystals for medical and energetic applications. Sci. Rep. 2014. [Google Scholar] [CrossRef] [PubMed]

- Korde, S.; Pagire, S.; Pan, H.; Seaton, C.; Kelly, A.; Chen, Y.; Wang, Q.; Coates, P.; Paradkar, A. Continuous Manufacturing of Cocrystals Using Solid State Shear Milling Technology. Cryst. Growth Des. 2018, 18, 2297–2304. [Google Scholar] [CrossRef]

- Padrela, L.; Rodrigues, M.A.; Velaga, S.P.; Matos, H.A.; de Azevedo, E.G. Formation of indomethacin–saccharin cocrystals using supercritical fluid technology. Eur. J. Pharm. Sci. 2009, 38, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Padrela, L.; Rodrigues, M.A.; Velaga, S.P.; Fernandes, A.C.; Matos, H.A.; de Azevedo, E.G. Screening for pharmaceutical cocrystals using the supercritical fluid enhanced atomization process. J. Supercrit. Fluids 2010, 53, 156–164. [Google Scholar] [CrossRef]

- Fucke, K.; Myz, S.A.; Shakhtshneider, T.P.; Boldyreva, E.V.; Griesser, U.J. How good are the crystallization methods for co-crystals? A comparative study of piroxicam. New J. Chem. 2012, 36, 1969–1977. [Google Scholar] [CrossRef]

- Seefeldt, K.; Miller, J.; Alvarez-Nunez, F.; Rodriguez-Hornedo, N. Crystallization pathways and kinetics of carbamazepine–nicotinamide cocrystals from the amorphous state byin situthermomicroscopy, spectroscopy, and calorimetry studies. J. Pharm. Sci. 2007, 96, 1147–1158. [Google Scholar] [CrossRef] [PubMed]

- Crawford, D.E.; Miskimmin, C.K.G.; Albadarin, A.B.; Walker, G.; James, S.L. Organic synthesis by Twin Screw Extrusion (TSE): Continuous, scalable and solvent-free. Green Chem. 2017, 19, 1507–1518. [Google Scholar] [CrossRef]

- Ober, C.A.; Gupta, R.B. Formation of Itraconazole-Succinic Acid Cocrystals by Gas Antisolvent Cocrystallization. AAPS PharmSciTech 2012, 13, 1396–1406. [Google Scholar] [CrossRef] [PubMed]

- Ober, C.A.; Montgomery, S.E.; Gupta, R.B. Formation of itraconazole/l-malic acid cocrystals by gas antisolvent cocrystallization. Powder Technol. 2013, 236, 122–131. [Google Scholar] [CrossRef]

- Imchalee, R.; Charoenchaitrakool, M. Gas anti-solvent processing of a new sulfamethoxazole-l-malic acid cocrystal. J. Ind. Eng. Chem. 2015, 25, 12–15. [Google Scholar] [CrossRef]

- Tiago, J.M.; Padrela, L.; Rodrigues, M.A.; Matos, H.A.; Almeida, A.J.; de Azevedo, E.G. Single-Step Co-crystallization and Lipid Dispersion by Supercritical Enhanced Atomization. Cryst. Growth Des. 2013, 13, 4940–4947. [Google Scholar] [CrossRef]

- Padrela, L.; Rodrigues, M.A.; Tiago, J.; Velaga, S.P.; Matos, H.A.; de Azevedo, E.G. Tuning physicochemical properties of theophylline by cocrystallization using the supercritical fluid enhanced atomization technique. J. Supercrit. Fluids 2014, 86, 129–136. [Google Scholar] [CrossRef]

- Mullers, K.C.; Paisana, M.; Wahl, M.A. Simultaneous Formation and Micronization of Pharmaceutical Cocrystals by Rapid Expansion of Supercritical Solutions (RESS). Pharm. Res. 2015, 32, 702–713. [Google Scholar] [CrossRef] [PubMed]

- Werner, P.E.; Eriksson, L.; Westdahl, M. TREOR, a semi-exhaustive trial-and-error powder indexing program for all symmetries. J. Appl. Cryst. 1985, 18, 367–370. [Google Scholar] [CrossRef]

- Visser, J.W. A fully automatic program for finding the unit cell from powder data. J. Appl. Cryst. 1969, 2, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Zlokazov, V.B. MRIAAU—A program for autoindexing multiphase polycrystals. J. Appl. Cryst. 1992, 25, 69–72. [Google Scholar] [CrossRef]

- David, W.I.F.; Shankland, K.; van de Streek, J.; Pidcock, E.; Motherwell, W.D.S.; Cole, J.C. DASH: A program for crystal structure determination from powder diffraction data. J. Appl. Cryst. 2006, 39, 910–915. [Google Scholar] [CrossRef]

- Bortolloti, M.; Lonardelli, I. ReX.Cell: A user-friendly program for powder diffraction indexing. J. Appl. Cryst. 2013, 46, 259–261. [Google Scholar] [CrossRef]

- Coelho, A.A. TOPAS and TOPAS-Academic: An optimization program integrating computer algebra and crystallographic objects written in C++. J. Appl. Cryst. 2018, 51, 210–218. [Google Scholar] [CrossRef]

- Altomare, A.; Corriero, N.; Cuocci, C.; Falcicchio, A.; Moliterni, A.; Rizzi, R. EXPO software for solving crystal structures by powder diffraction data: Methods and application. Cryst. Res. Technol. 2015. [Google Scholar] [CrossRef]

- International Union of Crystallography, Crystallographic Software List. Available online: https://www.iucr.org/resources/other-directories/software?result_42405_result_page=X (accessed on 10 May 2018).

- Sanphui, P.; Bolla, G.; Nangia, A.; Chernyshev, V. Acemetacin cocrystals and salts: Structure solution from powder X-ray data and form selection of the piperazine salt. IUCrJ 2014, 1, 136–150. [Google Scholar] [CrossRef] [PubMed]

- Chadha, K.; Karan, M.; Bhalla, Y.; Chadha, R.; Khullar, S.; Mandal, S.; Vasisht, K. Cocrystals of Hesperetin: Structural, Pharmacokinetic, and Pharmacodynamic Evaluation. Cryst. Growth Des. 2017, 5, 2386–2405. [Google Scholar] [CrossRef]

- Berry, D.J.; Seaton, C.C.; Clegg, W.; Harrington, R.W.; Coles, S.J.; Horton, P.N.; Hursthouse, M.B.; Storey, R.; Jones, W.; Friscic, T.; et al. Applying Hot-Stage Microscopy to Co-Crystal Screening: A Study of Nicotinamide with Seven Active Pharmaceutical Ingredients. Cryst. Growth Des. 2008, 8, 1697–1712. [Google Scholar] [CrossRef] [Green Version]

- Leksic, E.; Pavlovic, G.; Mestrovic, E. Cocrystals of Lamotrigine Based on Coformers Involving Carbonyl Group Discovered by Hot-Stage Microscopy and DSC Screening. Cryst. Growth Des. 2012, 12, 1847–1858. [Google Scholar] [CrossRef]

- Lu, J.; Rohani, S. Preparation and Characterization of Theophylline−Nicotinamide Cocrystal. Cryst. Growth Des. 2009, 13, 1269–1275. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, C.; Xu, B.; Sun, B. A cocrystal strategy for the precipitation of liquid 2,3-dimethyl pyrazine with hydroxyl substituted benzoic acid and a Hirshfeld surfaces analysis of them. CrystEngComm 2012, 14, 6860–6868. [Google Scholar] [CrossRef]

- Aitipamula, S.; Wong, A.B.H.; Chow, P.S.; Tan, R.B.H. Polymorphism and phase transformations of a cocrystal of nicotinamide and pimelic acid. CrystEngComm 2012, 14, 8193–8198. [Google Scholar] [CrossRef]

- Aitipamula, S.; Chow, P.S.; Tan, R.B.H. Dimorphs of a 1:1 cocrystal of ethenzamide and saccharin: Solid-state grinding methods result in metastable polymorph. CrystEngComm 2009, 11, 889–895. [Google Scholar] [CrossRef]

- Aitipamula, S.; Chow, P.S.; Tan, R.B.H. Conformational and enantiotropic polymorphism of a 1:1 cocrystal involving ethenzamide and ehylmalonic acid. CrystEngComm 2010, 12, 3691–3697. [Google Scholar] [CrossRef]

- Zhang, S.; Rasmuson, A.C. Thermodynamics and Crystallization of the Theophylline−Glutaric Acid Cocrystal. Cryst. Growth Des. 2013, 13, 1153–1161. [Google Scholar] [CrossRef]

- Chi, Z.; Wang, M.; Yang, L.; Li, X.; Cong, X.; Liu, S.; Cai, B. Fourier transform near-infrared spectroscopy used for purity determination of rhein-l-arginine cocrystal (argirein). Anal. Sci. 2013, 29, 661–664. [Google Scholar] [CrossRef] [PubMed]

- Vogt, F.G.; Clawson, J.S.; Strohmeier, M.; Edwards, A.J.; Pham, T.N.; Watson, S.A. Solid-State NMR Analysis of Organic Cocrystals and Complexes. Cryst. Growth Des. 2009, 9, 921–937. [Google Scholar] [CrossRef]

- Maruyoshi, K.; Iuga, D.; Antzutkin, O.N.; Alhalaweh, A.; Velaga, S.P.; Brown, S.P. Identifying the intermolecular hydrogen-bonding supramolecular synthons in an indomethacin–nicotinamide cocrystal by solid-state NMR. Chem. Commun. 2012, 48, 10844–10846. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Matzger, A.J. Influence of Coformer Stoichiometric Ratio on Pharmaceutical Cocrystal Dissolution: Three Cocrystals of Carbamazepine/4-Aminobenzoic Acid. Mol. Pharm. 2016, 13, 990–995. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vangala, V.R.; Chow, P.S.; Schreyer, M.; Lau, G.; Tan, R.B.H. Thermal and in Situ X-ray Diffraction Analysis of a Dimorphic Co-Crystal, 1:1 Caffeine–Glutaric Acid. Cryst. Growth Des. 2016, 16, 578–586. [Google Scholar] [CrossRef] [Green Version]

- Song, L.; Robeyns, K.; Leyssens, T. Crystallizing Ionic Cocrystals: Structural Characteristics, Thermal Behavior, and Crystallization Development of a Piracetam-CaCl2 Cocrystallization Process. Cryst. Growth Des. 2018, 18, 3215–3221. [Google Scholar] [CrossRef]

- Proffen, T.; Page, K.L.; McLain, S.E.; Clausen, B.; Darling, T.W.; Tencate, J.A.; Lee, S.Y.; Ustundag, E. Atomic pair distribution function analysis of materials containing crystalline and amorphous phases. Z. Kristallogr. 2005, 220, 1002–1008. [Google Scholar] [CrossRef]

- Charron, D.M.; Ajito, K.; Kim, J.; Ueno, Y. Chemical Mapping of Pharmaceutical Cocrystals Using Terahertz Spectroscopic Imaging. Anal. Chem. 2013, 85, 1980–1984. [Google Scholar] [CrossRef] [PubMed]

- Inoue, M.; Hisada, H.; Koide, T.; Carriere, J.; Heyler, R.; Fukami, T. In Situ Monitoring of Crystalline Transformation of Carbamazepine Using Probe-Type Low-Frequency Raman Spectroscopy. Org. Process Res. Dev. 2017, 21, 262–265. [Google Scholar] [CrossRef]

- Lee, M.; Chun, N.; Kim, M.; Kim, P.; Song, K.; Choi, G.J. In Situ Monitoring of Antisolvent Cocrystallization by Combining Near-Infrared and Raman Spectroscopies. Cryst. Growth Des. 2015, 15, 4385–4393. [Google Scholar] [CrossRef]

- Rodriguez-Hornedo, N.; Nehm, S.J.; Seefeldt, K.F.; Pagan-Torres, Y.; Falkiewicz, C.J. Reaction Crystallization of Pharmaceutical Molecular Complexes. Mol. Pharm. 2006, 3, 362–367. [Google Scholar] [CrossRef] [PubMed]

- Fan, G.; Yang, X.; Liang, R.; Zhao, J.; Li, S.; Yan, D. Molecular cocrystals of diphenyloxazole with tunable fluorescence, up-conversion emission and dielectric properties. CrystEngComm 2016, 18, 240–249. [Google Scholar] [CrossRef]

- Regulatory Classification of Pharmaceutical Co-Crystals Guidance for Industry. Available online: https://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM281764.pdf (accessed on 13 July 2018).

- Peltonen, L. Practical guidelines for the characterization and quality control of pure drug nanoparticles and nano-cocrystals in the pharmaceutical industry. Adv. Drug Deliv. Rev. 2018, in press. [Google Scholar] [CrossRef] [PubMed]

- Sanphui, P.; Devi, V.K.; Clara, D.; Malviya, N.; Ganguly, S.; Desiraju, G.R. Cocrystals of Hydrochlorothiazide: Solubility and Diffusion/Permeability Enhancements through Drug−Coformer Interactions. Mol. Pharm. 2015, 12, 1615–1622. [Google Scholar] [CrossRef] [PubMed]

- Remenar, J.; MacPhee, M.; Lynn-Peterson, M.; Lynn-Morissette, S.; Almarsson, O. CIS-Itraconazole Crystalline Forms and Related Processes, Pharmaceutical Compositions and Methods. U.S. Patent US7078526B2, 18 July 2006. [Google Scholar]

- Zaworotko, M.J. Polymorphism in co-crystals. In Proceedings of the IQPC Pharmaceutical Cocrystals Conference, Amsterdam, The Netherlands, 26–27 September 2006. [Google Scholar]

- Glasstone, S. Textbook of Physical Chemistry; McMillan: London, UK, 1940; p. 389. [Google Scholar]

- Dunitz, J.D. Crystal and co-crystal: A second opinion. CrystEngComm 2003, 5, 506. [Google Scholar] [CrossRef]

- Lara-Ochoa, F.; Espinosa-Perez, G. Cocrystals Definitions. Supramol. Chem. 2007, 19, 553–557. [Google Scholar] [CrossRef]

- Bis, J.A.; Vishweshwar, P.; Weyna, D.; Zaworotko, M.J. Hierarchy of Supramolecular Synthons: Persistent Hydroxyl⋯Pyridine Hydrogen Bonds in Cocrystals That Contain a Cyano Acceptor. Mol. Pharm. 2007, 4, 401–416. [Google Scholar] [CrossRef] [PubMed]

- Kavuru, P.; Aboarayes, D.; Arora, K.K.; Clarke, H.D.; Kennedy, A.; Marshall, L.; Ong, T.T.; Perman, J.; Pujari, T.; Wojtas, L.; et al. Hierarchy of Supramolecular Synthons: Persistent Hydrogen Bonds between Carboxylates and Weakly Acidic Hydroxyl Moieties in Cocrystals of Zwitterions. Cryst. Growth Des. 2010, 10, 3568–3584. [Google Scholar] [CrossRef]

- Sarma, B.; Saikia, B. Hydrogen bond synthon competition in the stabilization of theophylline cocrystals. CrystEngComm 2014, 16, 4753–4765. [Google Scholar] [CrossRef]

- Gilday, L.C.; Robinson, S.W.; Barendt, T.A.; Langton, M.J.; Mullaney, B.R.; Beer, P.D. Halogen Bonding in Supramolecular Chemistry. Chem. Rev. 2015, 115, 7118–7195. [Google Scholar] [CrossRef] [PubMed]

- Cavallo, G.; Metrangolo, P.; Milani, R.; Pilati, T.; Priimagi, A.; Resnati, G.; Terraneo, G. The Halogen Bond. Chem. Rev. 2016, 116, 2478–2601. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mukherjee, A.; Tothadi, S.; Desiraju, G.R. Halogen Bonds in Crystal Engineering: Like Hydrogen Bonds yet Different. Acc. Chem. Res. 2014, 47, 2514–2524. [Google Scholar] [CrossRef] [PubMed]

- Novick, S.E.; Janda, K.C.; Klemperer, W. HFClF: Structure and Bonding. J. Chem. Phys. 1976, 65, 5115–5121. [Google Scholar] [CrossRef]

- Alkorta, I.; Elguero, J. Non-Conventional Hydrogen Bonds. Chem. Soc. Rev. 1998, 27, 163–170. [Google Scholar] [CrossRef]

- Desiraju, G.R.; Steiner, T. The Weak Hydrogen Bond in Structural Chemistry and Biology; Oxford University Press: Oxford, UK, 1999. [Google Scholar]

- Choquesillo-Lazarte, D.; Nemec, V.; Cincic, D. Halogen bonded cocrystals of active pharmaceutical ingredients: Pyrazinamide, lidocaine and pentoxifylline in combination with haloperfluorinated compounds. CrystEngComm 2017, 19, 5293–5299. [Google Scholar] [CrossRef]

- Braga, D.; Grepioni, F.; Lampronti, G.I.; Maini, L.; Turrina, A. Ionic Co-crystals of Organic Molecules with Metal Halides: A New Prospect in the Solid Formulation of Active Pharmaceutical Ingredients. Cryst. Growth Des. 2011, 11, 5621–5627. [Google Scholar] [CrossRef]

- Perumalla, S.R.; Sun, C.C. Improved solid-state stability of salts by cocrystallization between conjugate acid–base pairs. CrystEngComm 2013, 15, 5756–5759. [Google Scholar] [CrossRef]

- Braga, D.; Grepioni, F.; Maini, L.; Prosperi, S.; Gobetto, R.; Chierotti, M.R. From unexpected reactions to a new family of ionic co-crystals: The case of barbituric acid with alkali bromides and caesium iodide. Chem. Commun. 2010, 46, 7715–7717. [Google Scholar] [CrossRef] [PubMed]

- Braga, D.; Grepioni, F.; Maini, L.; Capucci, D.; Nanna, S.; Wouters, J.; Aerts, L.; Quere, L. Combining piracetam and lithium salts: Ionic co-crystals andco-drugs? Chem. Commun. 2012, 48, 8219–8221. [Google Scholar] [CrossRef] [PubMed]

- Grepioni, F.; Wouters, J.; Braga, D.; Nanna, S.; Fours, B.; Coquerel, G.; Longfils, G.; Rome, S.; Aerts, L.; Quere, L. Ionic co-crystals of racetams: Solid-state properties enhancement of neutral active pharmaceutical ingredients via addition of Mg2+ and Ca2+ chlorides. CrystEngComm 2014, 16, 5887–5896. [Google Scholar] [CrossRef]

- Smith, A.J.; Kim, S.; Duggirala, N.K.; Jin, J.; Wojtas, L.; Ehrhart, J.; Giunta, B.; Tan, J.; Zaworotko, M.J.; Shytle, R.D. Improving Lithium Therapeutics by Crystal Engineering of Novel Ionic Cocrystals. Mol. Pharm. 2013, 10, 4728–4738. [Google Scholar] [CrossRef] [PubMed]

- Santra, R.; Ghosh, N.; Biradha, K. Crystal engineering with acid andpyridine heteromeric synthon: Neutral and ionic co-crystals. New J. Chem. 2008, 32, 1673–1676. [Google Scholar] [CrossRef]

- Buist, A.R.; Kennedy, A.R. Ionic Cocrystals of Pharmaceutical Compounds: Sodium Complexes of Carbamazepine. Cryst. Growth Des. 2014, 14, 6508–6513. [Google Scholar] [CrossRef] [Green Version]

- Saha, S.; Desiraju, G.R. Using structural modularity in cocrystals to engineer properties: Elasticity. Chem. Commun. 2016, 52, 7676–7679. [Google Scholar] [CrossRef] [PubMed]

- Sangtani, E.; Sahu, S.K.; Thorat, S.H.; Gawade, R.L.; Jha, K.K.; Munshi, P.; Gonnade, R.G. Furosemide Cocrysals with Pyridines: An Interesting Case of Color Cocrystal Polymorphism. Cryst. Growth Des. 2015, 15, 5858–5872. [Google Scholar] [CrossRef]

- Sangtani, E.; Mandal, S.K.; Sreelakshmi, A.S.; Munshi, P.; Gonnade, R.G. Salts and Cocrystals of Furosemide wih Pyridines: Differences in π-Stacking and Color Polymorphism. Cryst. Growth Des. 2017, 17, 3071–3087. [Google Scholar] [CrossRef]

- Chalmers, M.J.; Wang, Y.; Novick, S.; Sato, M.; Bryant, H.U.; Montrose-Rafizdeh, C.; Griffin, P.R.; Dodge, J.A. Hydrophobic Interactions Improve Selectivity to ERα for Benzothiophene SERMs. ACS Med. Chem. Lett. 2012, 3, 207–210. [Google Scholar] [CrossRef] [PubMed]

- Schamme, B.; Couvrat, N.; Tognetti, V.; Delbreilh, L.; Dupray, V.; Dargent, E.; Coquerel, G. Investigation of Drug–Excipient Interactions in Biclotymol Amorphous Solid Dispersions. Mol. Pharm. 2018, 15, 1112–1125. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Song, Y.; Liu, Y.; Li, Y.; Wu, Z.; Yan, C. Drug-Bridge-Drug Ternary Cocrystallization Strategy for Antituberculosis Drugs Combination. Cryst. Growth Des. 2018, 18, 1283–1286. [Google Scholar] [CrossRef]

- Aitipamula, S.; Wong, A.B.H.; Chow, P.S.; Tan, R.B.H. Novel solid forms of the anti-tuberculosis drug: Ternary and polymorphic cocrystals. CrystEngComm 2013, 15, 5877–5887. [Google Scholar] [CrossRef]

- Mir, N.A.; Dubey, R.; Desiraju, G.R. Four- and five-component molecular solids: Crystal engineering strategies based on structural inequivalence. IUCrJ 2016, 3, 96–101. [Google Scholar] [CrossRef] [PubMed]

- Adsmond, D.A.; Sinha, A.S.; Khandavilli, U.B.R.; Maguire, A.R.; Lawrence, S.E. Design and Synthesis of Ternary Cocrystals Using Carboxyphenols and Two Complementary Acceptor Compounds. Cryst. Growth Des. 2016, 16, 59–69. [Google Scholar] [CrossRef]

- Dubey, R.; Mir, N.A.; Desiraju, G.R. Quaternary cocrystals: Combinatorial synthetic strategies based on long-range synthon Aufbau modules (LSAM). IUCrJ 2016, 3, 102–107. [Google Scholar] [CrossRef] [PubMed]

- Aakeroy, C.B.; Beatty, A.M.; Helfrich, B.A. “Total Synthesis” Supramolecular Style: Design and Hydrogen-Bond-Directed Assembly of Ternary Supermolecules. Angew. Chem. Int. Ed. 2001, 40, 3240–3242. [Google Scholar] [CrossRef] [Green Version]

- Bolla, G.; Nangia, A. Binary and ternary cocrystals of sulfa drug acetazolamide with pyridine carboxamides and cyclic amides. IUCrJ 2016, 3, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Tothadi, S.; Sanphui, P.; Desiraju, G.R. Obtaining Synthon Modularity in Ternary Cocrystals with Hydrogen Bonds and Halogen Bonds. Cryst. Growth Des. 2014, 14, 5293–5302. [Google Scholar] [CrossRef]

- Dauber, P.; Hagler, A.T. Crystal Packing, Hydrogen Bonding, and the Effect of Crystal Forces on Molecular Conformation. Acc. Chem. Res. 1980, 13, 105–112. [Google Scholar] [CrossRef]

- Kitaigorodskii, A. Organic Chemical Crystallography; Consultants Bureau: New York, NY, USA, 1961. [Google Scholar]

- Dubey, R.; Desiraju, G.R. Combinatorial Crystal Synthesis: Structural Landscape of Phloroglucinol:1,2-bis(4-pyridyl)ethylene and Phloroglucinol:Phenazine. Angew. Chem. Int. Ed. 2014, 53, 13178–13182. [Google Scholar] [CrossRef] [PubMed]

- Dubey, R.; Desiraju, G.R. Combinatorial selection of molecular conformations and supramolecular synthons in quercetin cocrystal landscapes: A route to ternary solids. IUCrJ 2015, 2, 402–408. [Google Scholar] [CrossRef] [PubMed]

- Pyrazinamide. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/pyrazinamide#section=Solubility (accessed on 22 May 2018).

- Isoniazid. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/isoniazid#section=Solubility (accessed on 22 May 2018).

- Wang, J.; Ye, C.; Zhu, B.; Zhou, C.; Mei, X. Pharmaceutical cocrystals of the anti-tuberculosis drug pyrazinamide with dicarboxylic and tricarboxylic acids. CrystEngComm 2015, 17, 747–752. [Google Scholar] [CrossRef]

- Sarcevica, I.; Orola, L.; Veidis, M.V.; Podjava, A.; Belyakov, S. Crystal and Molecular Structure and Stability of Isoniazid Cocrystals with Selected Carboxylic Acids. Cryst. Growth Des. 2013, 13, 1082–1090. [Google Scholar] [CrossRef]

- Bhogala, B.R.; Nangia, A. Ternary and quaternary co-crystals of 1,3-cis,5-cis-cyclohexanetricarboxylic acid and 4,4′-bipyridines. New J. Chem. 2008, 32, 800–807. [Google Scholar] [CrossRef]

- Tilborg, A.; Leyssens, T.; Norberg, B.; Wouters, J. Structural Study of Prolinium/Fumaric Acid Zwitterionic Cocrystals: Focus on Hydrogen-Bonding Pattern Involving Zwitterionic (Ionic) Heterosynthons. Cryst. Growth Des. 2013, 13, 2373–2389. [Google Scholar] [CrossRef]

- Cheung, E.Y.; Kitchin, S.J.; Harris, K.D.M.; Imai, Y.; Tajima, N.; Kuroda, R. Direct Structure Determination of a Multicomponent Molecular Crystal Prepared by a Solid-State Grinding Procedure. J. Am. Chem. Soc. 2003, 125, 14658–14659. [Google Scholar] [CrossRef] [PubMed]

- Allu, S.; Bolla, G.; Tothadi, S.; Nangia, A. Supramolecular Synthons in Bumetanide Cocrystals and Ternary Products. Cryst. Growth Des. 2017, 17, 4225–4236. [Google Scholar] [CrossRef]

- ANDAs: Pharmaceutical Solid Polymorphism. Available online: https://www.fda.gov/downloads/Drugs/Guidances/UCM072866.pdf (accessed on 24 October 2017).

- Datta, S.; Grant, D.J.W. Crystal structures of drugs: Advances in determination, rediction and engineering. Nat. Rev. Drug Discov. 2004, 3, 42–57. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Stephenson, G.A.; Mitchell, C.A.; Bunnell, C.A.; Snorek, S.V.; Bowyer, J.J.; Borchardt, T.B.; Stowell, J.G.; Byrn, S.R. Thermochemistry and Conformational polymorphism of a Hexamorphic Crystal System. J. Am. Chem. Soc. 2000, 122, 585–591. [Google Scholar] [CrossRef]

- Sun, C.; Grant, D.J.W. Influence of Crystal Structure on the Tableting Properties of Sulfamerazine Polymorphs. Pharm. Res. 2001, 18, 274–280. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, A.; Desiraju, G.R. Synthon polymorphism and pseudopolymorphism in co-crystals. The 4,4′-bipyridine–4-hydroxybenzoic acid structural landscape. Chem. Commun. 2011, 47, 4090–4092. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, A.; Tothadi, S.; Chakraborty, S.; Ganguly, S.; Desiraju, G.R. Synthon identification in co-crystals and polymorphs with IR spectroscopy. Primary amides as a case study. CrystEngComm 2013, 15, 4640–4654. [Google Scholar] [CrossRef]

- Kaur, R.; Perumal, S.S.R.R.; Bhattacharyya, A.J.; Yashonath, S.; Row, T.N.G. Structural Insights into Proton Conduction in Gallic Acid–Isoniazid Cocrystals. Cryst. Growth Des. 2014, 14, 423–426. [Google Scholar] [CrossRef]

- Kaur, R.; Cherukuvada, S.; Managutti, P.B.; Row, T.N.G. A gallic acid–succinimide co-crystal landscape: Polymorphism, pseudopolymorphism, variable stoichiometry co-crystals and concomitant growth of non-solvated and solvated co-crystals. CrystEngComm 2016, 18, 3191–3203. [Google Scholar] [CrossRef]

- Ghosh, S.; Bag, P.P.; Reddy, C.M. Co-Crystals of Sulfamethazine with Some Carboxylic Acids and Amides: Co-Former Assisted Tautomerism in an Active Pharmaceutical Ingredient and Hydrogen Bond Competition Study. Cryst. Growth Des. 2011, 11, 3489–3503. [Google Scholar] [CrossRef]

- Sreekanth, B.R.; Vishweshwar, P.; Vyas, K. Supramolecular synthon polymorphism in 2:1 co-crystal of 4-hydroxybenzoic acid and 2,3,5,6-tetramethylpyrazine. Chem. Commun. 2007, 2375–2377. [Google Scholar] [CrossRef]

- Sanphui, P.; Babu, N.J.; Nangia, A. Temozolomide Cocrystals with Carboxamide Coformers. Cryst. Growth Des. 2013, 13, 2208–2219. [Google Scholar] [CrossRef]

- Goud, N.R.; Nangia, A. Synthon polymorphs of sulfacetamide–acetamidecocrystal based on N–H⋯O=S and N–H⋯O=C hydrogen bonding. CrystEngComm 2013, 15, 7456–7461. [Google Scholar] [CrossRef]

- Li, S.; Chen, J.; Lu, T. Synthon polymorphs of 1:1 co-crystal of 5-fluorouracil and 4-hydroxybenzoic acid: Their relative stability and solvent polarity dependence of grinding outcomes. CrystEngComm 2014, 16, 6450–6458. [Google Scholar] [CrossRef]

- Aitipamula, S.; Chow, P.S.; Tan, R.B.H. Polymorphs and solvates of a cocrystal involving an analgesic drug, ethenzamide, and 3,5-dinitrobenzoic acid. Cryst. Growth Des. 2010, 10, 2229–2238. [Google Scholar] [CrossRef]

- Ueto, T.; Takata, N.; Muroyama, N.; Nedu, A.; Sasaki, A.; Tanida, S.; Terada, K. Polymorphs and a Hydrate of Furosemide–Nicotinamide 1:1 Cocrystal. Cryst. Growth Des. 2012, 12, 485–494. [Google Scholar] [CrossRef]

- Tothadi, S.; Desiraju, G.R. Synthon Modularity in 4-Hydroxybenzamide–Dicarboxylic Acid Cocrystals. Cryst. Growth Des. 2012, 12, 6188–6198. [Google Scholar] [CrossRef]

- Porter, W.W., III; Elie, S.C.; Matzger, A.J. Polymorphism in Carbamazepine Cocrystals. Cryst. Growth Des. 2008, 8, 14–16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Babu, N.J.; Reddy, L.S.; Aitipamula, S.; Nangia, A. Polymorphs and polymorphic cocrystals of temozolomide. Chem. Asian J. 2008, 3, 1122–1133. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Guzei, I.A.; de Villiers, M.M.; Yu, L.; Krzyzaniak, J.F. Formation Enthalpies and Polymorphs of Nicotinamide–R-Mandelic Acid Co-Crystals. Cryst. Growth Des. 2012, 12, 4090–4097. [Google Scholar] [CrossRef]

- Nanubolu, J.B.; Ravikumar, K. Designing a new cocrystal of olanzapine drug and observation of concomitant polymorphism in a ternary cocrystal system. CrystEngComm 2017, 19, 355–366. [Google Scholar] [CrossRef]

- Shattock, T.R.; Vishweshwar, P.; Wang, Z.; Zaworotko, M.J. 18-Fold Interpretation and Concomitant Polymorphism in the 2:3 Co-Crystal of Trimesic Acid and 1,2-bis(4-pyridyl)ethane. Cryst. Growth Des. 2005, 5, 2046–2049. [Google Scholar] [CrossRef]

- Bis, J.A.; Vishweshwar, P.; Middleton, R.A.; Zaworotko, M.J. Concomitant and Conformational Polymorphism, Conformational Isomorphism, and Phase Relationships in 4-Cyanopyridine-4,4′-biphenol Cocrystals. Cryst. Growth Des. 2006, 6, 1048–1053. [Google Scholar] [CrossRef]

- Trask, A.V.; Motherwell, W.D.S.; Jones, W. Pharmaceutical Cocrystallization: Engineering a Remedy for Caffeine Hydration. Cryst. Growth Des. 2005, 5, 1013–1021. [Google Scholar] [CrossRef] [Green Version]

- Bolla, G.; Mittapalli, S.; Nangia, A. Celecoxib cocrystal polymorphs with cyclic amides: Synthons of a sulfonamide drug with carboxamide coformers. CrystEngComm 2014, 16, 24–27. [Google Scholar] [CrossRef]

- Skovsgaard, S.; Bond, A.D. Co-crystallisationofbenzoic acid derivatives with N-containing bases in solution and by mechanicalgrinding: Stoichiometric variants, polymorphism and twinning. CrystEngComm 2009, 11, 444–453. [Google Scholar] [CrossRef]

- Tothadi, S. Polymorphism in cocrystals of urea: 4,4′-bipyridine and salicylic acid: 4,4′-bipyridine. CrystEngComm 2014, 16, 7587–7597. [Google Scholar] [CrossRef]

- Surov, A.O.; Manin, A.N.; Voronin, A.P.; Churakov, A.V.; Perlovich, G.L.; Vener, M.V. Weak Interactions Cause Packing Polymorphism in Pharmaceutical Two-Component Crystals. The Case Study of the Salicylamide Cocrystal. Cryst. Growth Des. 2017, 17, 1425–1437. [Google Scholar] [CrossRef]

- CSD; Version 5.34, ConQuest 1.15; Cambridge Crystallographic Data Centre: Cambridge, UK, 2012; February 2013 Update.

- Mukherjee, A.; Desiraju, G.R. Combinatorial Exploration of the Structural Landscape of Acid−Pyridine Cocrystals. Cryst. Growth Des. 2014, 14, 1375–1385. [Google Scholar] [CrossRef]

- Pagire, S.K.; Jadav, N.; Vangala, V.R.; Whiteside, B.; Paradkar, A. Thermodynamic Investigation of Carbamazepine-SaccharinCo-crystal Polymorphs. J. Pharm. Sci. 2017, 106, 2009–2014. [Google Scholar] [CrossRef] [PubMed]

- Fischer, F.; Heidrich, A.; Greiser, A.; Benemann, S.; Rademann, K.; Emmerling, F. Polymorphism of Mechanochemically Synthesized Cocrystals: A Case Study. Cryst. Growth Des. 2016, 16, 1701–1707. [Google Scholar] [CrossRef]

- Hildebrand, J.H.; Scott, R.L. The Solubility of Nonelectrolytes; Reinhold Publishing: New York, NY, USA, 1950. [Google Scholar]

- Rao, V.M.; Sanghvi, R.; Zhu, H. Solubility of pharmaceutical solids. In Developing Solid Oral Dosage Forms. Pharmaceutical Theory and Practice; Qiu, Y., Chen, Y., Zhang, G.G.Z., Eds.; Academic Press: New York, NY, USA, 2009; pp. 3–24. [Google Scholar]

- Thakuria, R.; Delori, A.; Jones, W.; Lipert, M.P.; Roy, L.; Rodriguez-Hornedo, N. Pharmaceutical cocrystals and poorly water soluble drugs. Int. J. Pharm. 2013, 453, 101–125. [Google Scholar] [CrossRef] [PubMed]

- Anderson, B.D.; Conradi, R.A. Predictive relationships in the water solubility of salts of a nonsteroidal anti-inflammatory drug. J. Pharm. Sci. 1985, 74, 815–820. [Google Scholar] [CrossRef] [PubMed]

- Maheshwari, C.; Andre, V.; Reddy, S.; Roy, L.; Duarte, T.; Rodriguez-Hornedo, N. Tailoring aqueous solubility of a highly soluble compound via cocrystallization: Effect of coformer ionization, pHmax and solute-solvent interactions. CrystEngComm 2012, 14, 4801–4811. [Google Scholar] [CrossRef]

- Kuminek, G.; Cao, F.; Rocha, A.B.O.; Cardoso, S.G.; Rodriguez-Hornedo, N. Cocrystals to facilitate delivery of poorly soluble compounds beyond-rule-of-5. Adv. Drug Deliv. Rev. 2016, 101, 143–166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lipert, M.P.; Rodriguez-Hornedo, N. Cocrystal Transition Points: Role of Cocrystal Solubility, Drug Solubility, and Solubilizing Agents. Mol. Pharm. 2015, 12, 3535–3546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.M.; Rodriguez-Hornedo, N. Cocrystals Mitigate Negative Effects of High pH on Solubility and Dissolution of a Basic Drug. Cryst. Growth Des. 2018, 18, 1358–1366. [Google Scholar] [CrossRef]

- Remenar, J.F.; Morissette, S.L.; Peterson, M.L.; Moulton, B.; MacPhee, J.M.; Guzman, H.R.; Almarsson, O. Crystal engineering of novel cocrystals of a triazole drug with 1,4-dicarboxylic acids. J. Am. Chem. Soc. 2003, 125, 8456–8457. [Google Scholar] [CrossRef] [PubMed]

- Reddy, L.S.; Bethune, S.J.; Kampf, J.W.; Rodriguez-Hornedo, N. Cocrystals and salts of gabapentin: pH dependent cocrystal stability and solubility. Cryst. Growth Des. 2009, 9, 378–385. [Google Scholar] [CrossRef]

- Shikhar, A.; Bommana, M.M.; Gupta, S.S.; Squillante, E. Formulation development of Carbamazepine–Nicotinamide co-crystals complexed with -cyclodextrin using supercritical fluid process. J. Supercrit. Fluids 2011, 55, 1070–1078. [Google Scholar] [CrossRef]

- Guzman, H.R.; Tawa, M.; Zhang, Z.; Ratanabanangkoon, P.; Shaw, P.; Gardner, C.L.; Chen, H.; Moreau, J.-P.; Almarsson, O.; Remenar, J.F. Combined use of crystalline salt forms and precipitation inhibitors to improve oral absorption of celecoxib from solid oral formulations. J. Pharm. Sci. 2007, 96, 2686–2702. [Google Scholar] [CrossRef] [PubMed]

- Maghsoodi, M. Role of Solvents in Improvement of Dissolution Rate of Drugs: Crystal Habit and Crystal Agglomeration. Adv. Pharm. Bull. 2015, 5, 13–18. [Google Scholar] [PubMed]

- Serrano, D.R.; O’Connell, P.; Paluch, K.J.; Walsh, D.; Healy, A.M. Cocrystal habit engineering to improve drug dissolution and alter derived powder properties. J. Pharm. Pharmacol. 2016, 68, 665–677. [Google Scholar] [CrossRef] [PubMed]

- Cao, F.; Amidon, G.L.; Rodriguez-Hornedo, N.; Amidon, G.E. Mechanistic Analysis of Cocrystal Dissolution as a Function of pH and Micellar Solubilization. Mol. Pharm. 2016, 13, 1030–1046. [Google Scholar] [CrossRef] [PubMed]

- Goud, N.R.; Khan, R.A.; Nangia, A. Modulating the solubility of sulfacetamide by means of cocrystals. CrystEngComm 2014, 16, 5859–5869. [Google Scholar] [CrossRef]

- Gately, S.T.; Triezenberg, S.J. Solid Forms of Curcumin. U.S. Patent WO 2012138907A2, 11 October 2012. [Google Scholar]

- Kaur, R.; Cavanagh, K.L.; Rodriguez-Hornedo, N.; Matzger, A.J. Multidrug Cocrystal of Anticonvulsants; Influence of Strong Intermolecular Interactions on Physicochemical Properties. Cryst. Growth Des. 2017, 17, 5012–5016. [Google Scholar] [CrossRef]

- Dalpiaz, A.; Ferretti, V.; Bertolasi, V.; Pavan, B.; Monari, A.; Pastore, M. From Physical Mixtures to Co-Crystals: How the Coformers Can Modify Solubility and Biological Activity of Carbamazepine. Mol. Pharm. 2018, 15, 268–278. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.; Arjmand, F.; Khan, R.A.; Alsalme, A.; Ahmad, M.; Tabassum, S. Biological evaluation of dinuclear copper complex/dichloroacetic acid cocrystal against human breast cancer: Design, synthesis, characterization, DFT studies and cytotoxicity assays. RSC Adv. 2017, 7, 47920–47932. [Google Scholar] [CrossRef]

- Saha, R.; Sengupta, S.; Dey, S.K.; Steele, I.M.; Bhattacharyya, A.; Biswas, S.; Kumar, S. A pharmaceutical cocrystal with potential anticancer activity. RSC Adv. 2014, 4, 49070–49078. [Google Scholar] [CrossRef]

| Property | Eutectic Phase | Cocrystal | Solid Solution | Reference(s) |

|---|---|---|---|---|

| Structural similarity of the parent molecules | Similar or dissimilar | Similar or dissimilar | Similar | [55] |

| Isomorphous or non-isomorphous | Isomorphous/non-isomorphous | Isomorphous/non-isomorphous | Isomorphous | [34,55] |

| Melting point of the solid formed | Lower melting than the parent components | Mostly in between the melting points of parent molecules but may also be higher or lower than the parent molecules | Exhibits a solidus-liquidus melting behavior | [34,55] |

| Binary phase diagram | ‘V’-shaped curve | ‘W’-shaped curve | Unary phase diagram | [34,55] |

| Intermolecular interactions | Short-range and weaker non-covalent adhesive interactions | Stronger and non-covalent adhesive interactions (hydrogen bonding, halogen bonding, Π-Π interactions, etc.) | Stronger and non-covalent cohesive interactions | [34,55] |

| Arrangement of molecules in crystal lattice | Molecules are randomly arranged | Molecules are well organized and well-packed | Molecules are well organized | [34,55] |

| Predominant thermodynamic force of the system | Entropy | Enthalpy | Enthalpy | [34,55] |

| Crystal structure of the solid formed | No significant change from the parent components | Characterized by a new crystal phase formation and hence possess a new crystal structure | Characterized by a new crystal phase formation and therefore possess a new crystal structure | [34,55] |

| Thermodynamic stability of the solid formed | Less stable | More stable than eutectics | More stable than eutectics | [34] |

| Name of the API | Therapeutic Use of the API | Binary/Ternary System | Name of the Coformer | Stoichiometric Ratio of the Cocrystal | Preparation Method | Comments on Dissolution Behavior | Reference(s) |

|---|---|---|---|---|---|---|---|