Optimal Scheduling of Integrated Energy System Considering Electric Vehicle Battery Swapping Station and Multiple Uncertainties

Abstract

:1. Introduction

- (1)

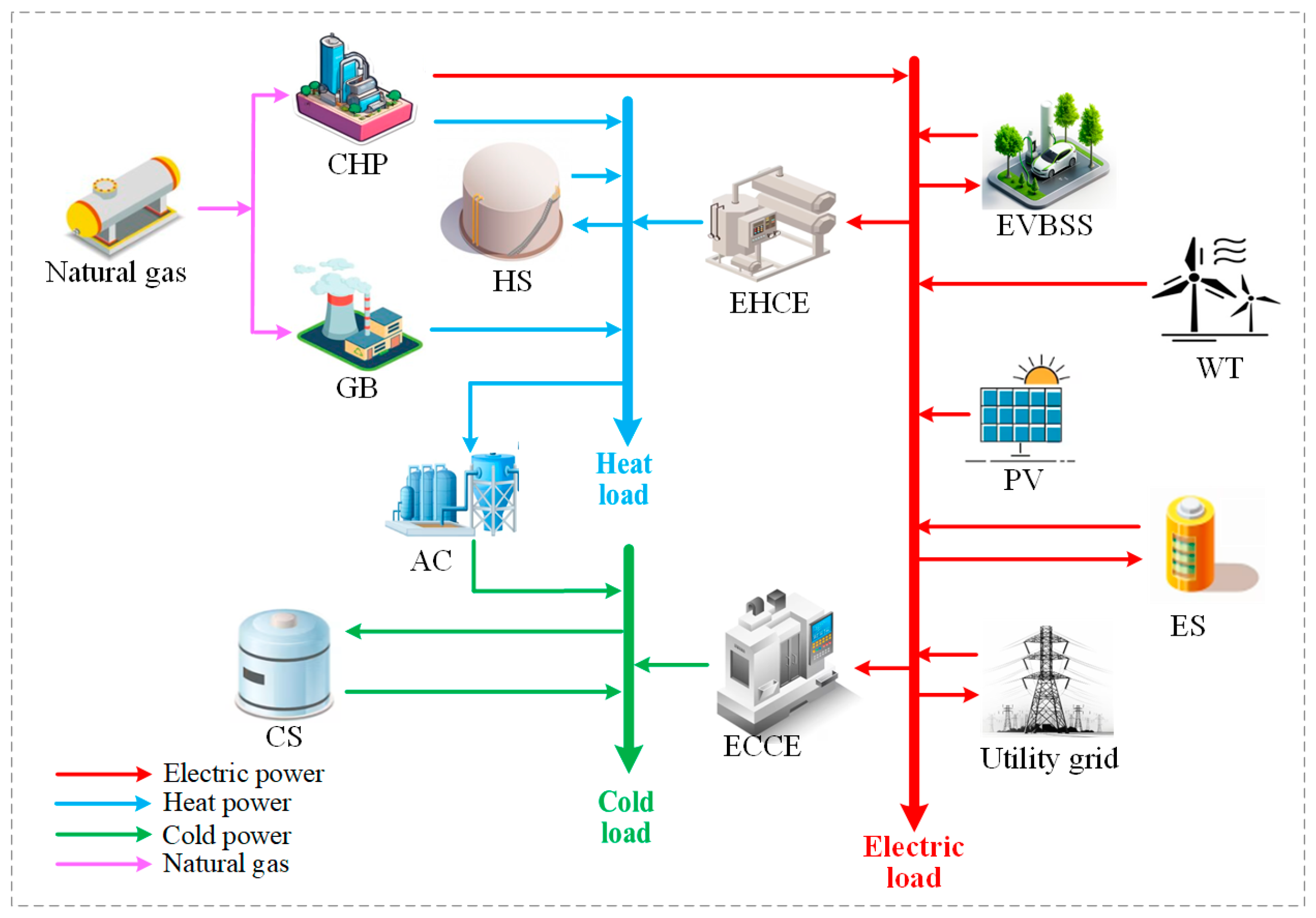

- An EV-IES comprises electric power, heat power and cold power, encompassing various energy sources and devices. Furthermore, it considers the battery replacement needs of EV users.

- (2)

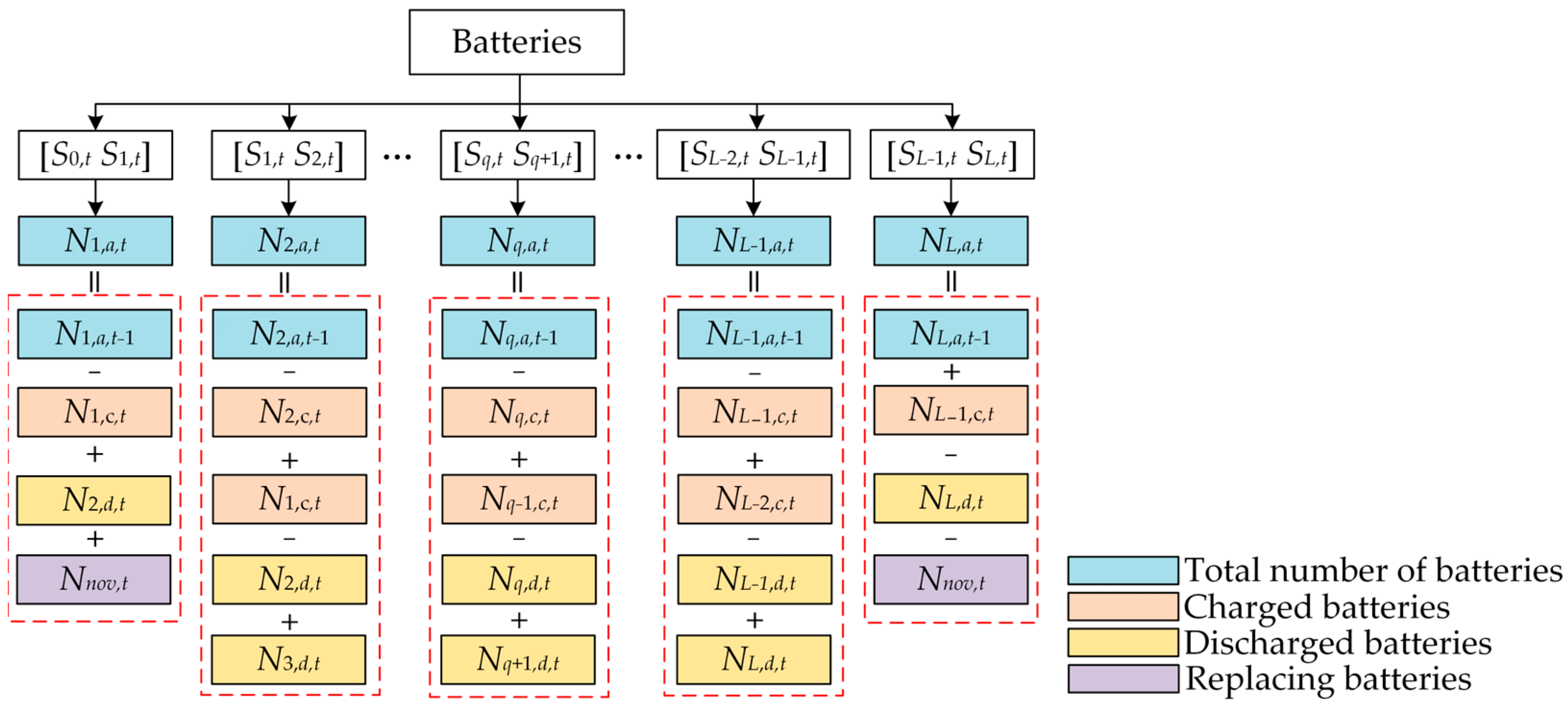

- For the large-scale battery clustering in an EVBSS, a classification scheduling strategy based on battery State of Charge (SOC) is proposed, integrating a battery charging and discharging priority function.

- (3)

- Aiming at the new energy output characteristics, the study proposes an improved uncertainty ensemble with multi-interval distribution characteristics to reduce the conservatism of the traditional box uncertainty. In addition, the N-1 contingency uncertainty ensemble is proposed for the discrete operating states of multiple devices in the IES.

- (4)

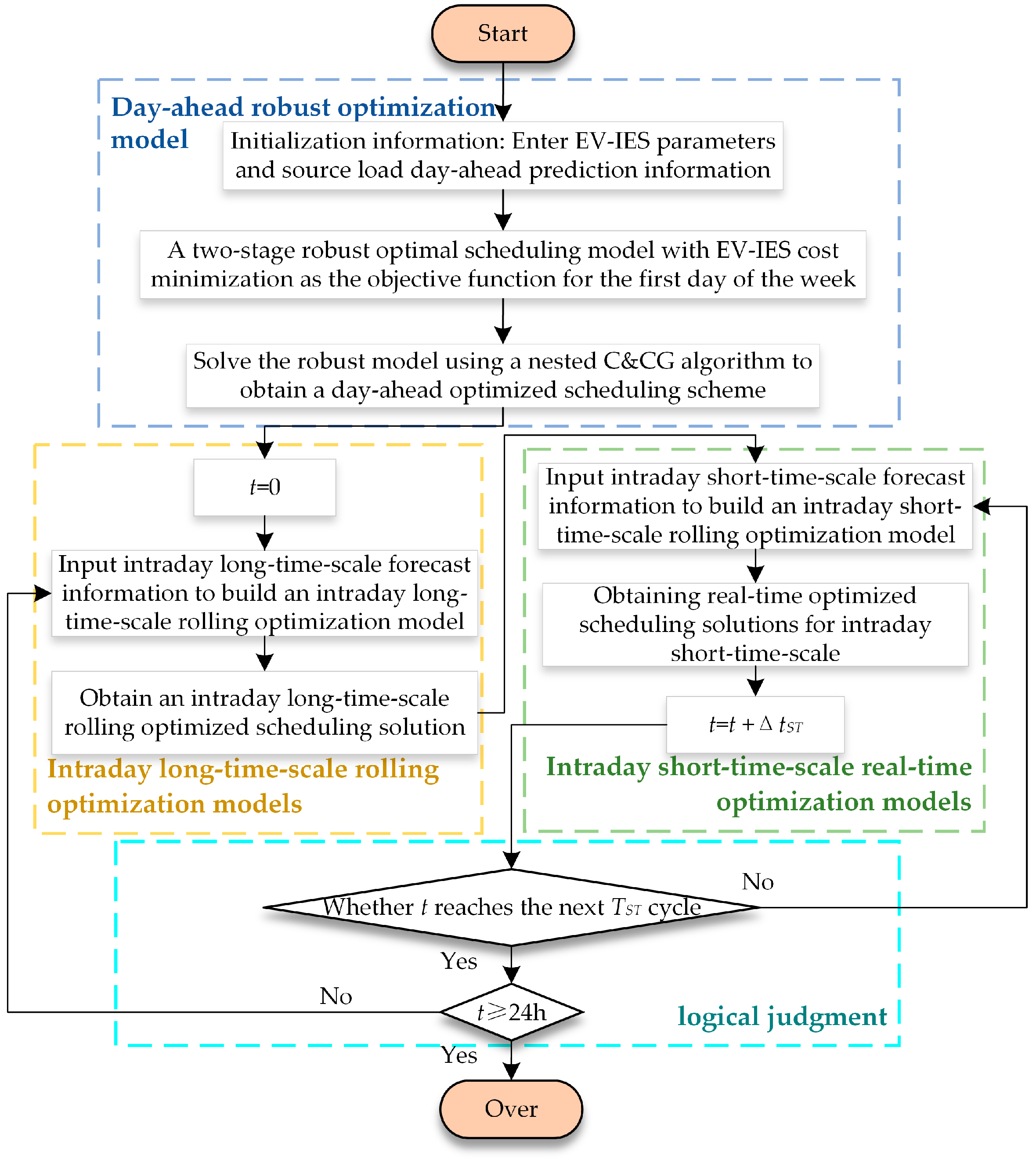

- An EV-IES multi-time-scale optimal scheduling model is established. Day-ahead robust optimization fully considered the multiple uncertainties in the system. According to the distribution of binary discrete variables in the robust model, the nested C&CG algorithm was used to solve the mixed integer robust model. Intraday optimal scheduling is based on the day-before robust optimization results to reduce the power fluctuation caused by the deviation in the predicted source load.

2. EV-IES Model

2.1. Objective Function

2.2. EV Battery Swapping Station

2.3. CHP Model

2.4. Utility Grid

2.5. GB Model

2.6. Electricity–Heat Conversion Equipment and Electricity–Cold Conversion Equipment

2.7. Absorption Chiller

2.8. Energy Storage System

2.9. Power Balance

3. Multi-Time-Scale Optimization Scheduling Model

3.1. Improving the Uncertainty Set

3.1.1. Uncertainty Set with Multi-Interval Distribution Characteristics

3.1.2. N-1 Uncertainty Set of Contingency State

3.2. EV-IES Multi-Time-Scale Optimization Scheduling Strategy

3.2.1. Day-Ahead, Two-Stage Robust Optimization

3.2.2. Intraday Long-Time-Scale Rolling Optimization Model

3.2.3. Intraday Short-Time-Scale Real-Time Optimization Model

3.3. Model Solving Method

3.3.1. The Main Problems

3.3.2. The Slave Problem

3.3.3. Solving Process of Nested C&CG Algorithm

- Initialization: Set the number of iterations as k = 1. Give the convergence threshold ε. Give a set of feasible solutions of the main problem x0, and bring them into the slave problem Equation (35) to obtain uk, yk, and zk. Set the upper bound UB = +∞ and the lower bound LB = −∞.

- Substitute uk into the main problem Equation (34) to solve for , and update the lower bound LB = min {LB, cTxk + ηk}.

- Substitute xk into the slave problem Equation (35) to solve uk+1, yk+1, and zk+1. The steps are as follows:

- (1)

- Initialization: Set the number of subproblem iterations n = 1. Give a set of u0 as the feasible solution of the inner-slave problem, and solve the inner-slave problem with u0 and xk to obtain yn and zn. Set the upper bound of the subproblem UBin = +∞ and the lower bound of the subproblem LBin = −∞.

- (2)

- Substitute xk and zn into the inner-main problem Equation (37) to solve for un and Φn, and update LBin = Φn.

- (3)

- Substitute xk and un into the inner-slave problem Equation (36) to solve for zn+1 and ϕn, and update UBin = ϕn.

- (4)

- If UBin − LBin < ε, then stop the iteration, output un, zn+1, and Φn, and update LB =cTxk + Φn. Otherwise, set n = n + 1, and return to (2) to continue the solution.

- If UB − LB < ε, stop the iteration and output the best result. Otherwise, set k = k + 1 and return to 2 to continue solving.

| Algorithm 1. Solving process of nested C&CG algorithm |

| 1: Initial LB = −∞, UB = ∞, k = 1, and ε, and solve the slave problem with x0 to obtain uk, yk, and zk |

| Repeat |

| 2: Solve the main problem with uk to obtain (xk and ηk), and update LB = min {LB, cTxk + ηk}. |

| 3: Solve the slave problem with xk to obtain (uk+1, yk+1, and zk+1). |

| Repeat |

| (1) Initial LBin = −∞, UBin = +∞, n = 1, and ε, and solve the inner-slave problem with (xk, u0) to obtain (yn, zn). |

| (2) Solve the inner-main problem with (xn and zn) to obtain (un and Φn), and update LBin = Φn. |

| (3) Solve the inner-salve problem with (xn and un) to obtain (zn+1 and ϕn), and update UBin = ϕn. |

| (4) n = n + 1. |

| Until UBin − LBin < ε, output (un+1, yn+1, zn+1, and Φn), and update UB = cTxk + Φn. |

| 4: k = k + 1. |

| Until UB − LB < ε, output the best result. |

3.3.4. Multi-Time-Scale Model Solution

4. Case Study

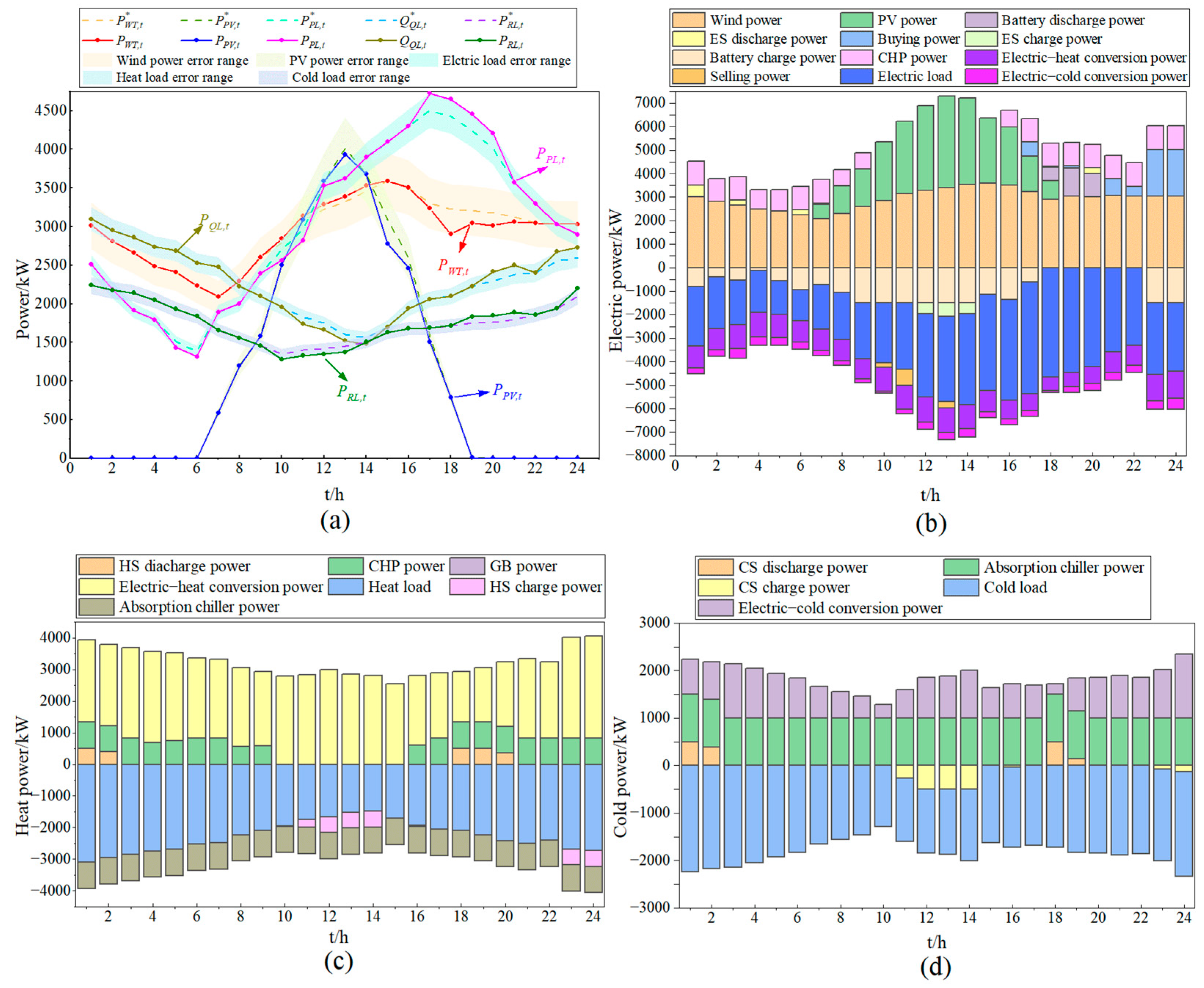

4.1. IES Optimal Scheduling Scheme without N-1 Contingency States

4.2. IES Optimal Scheduling Scheme Considering N-1 Contingency States

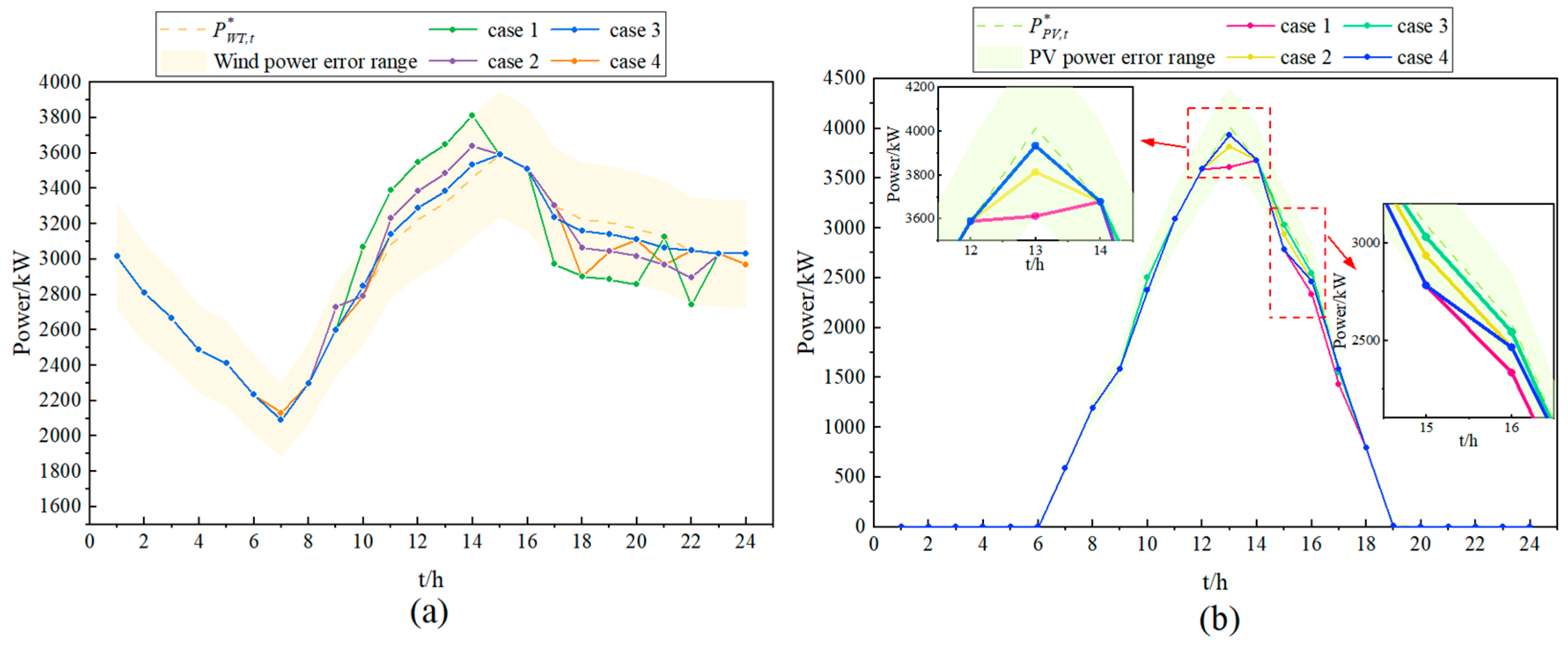

4.3. Multi-Interval Uncertainty Set Analysis

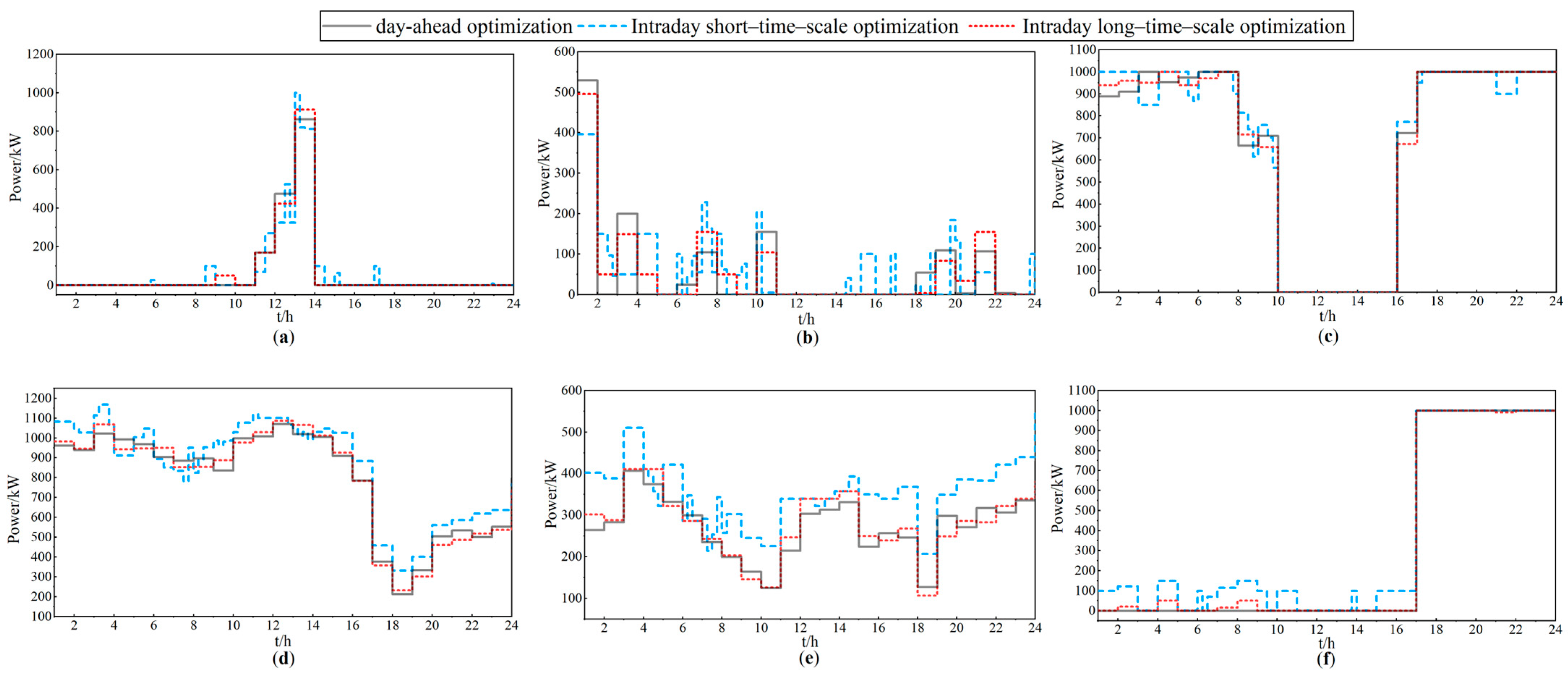

4.4. Analysis of Intraday Multi-Time-Scale Optimal Scheduling Results

4.5. Analysis of Battery Charge and Discharge Prioritization Algorithm

4.6. Analysis of Nested C&CG Algorithm

5. Conclusions

- (1)

- Integration of EVBSSs in IESs not only meets the battery swapping needs of EV users but also utilizes large-scale battery clusters to co-schedule with ES for better energy transfer.

- (2)

- Limited discretization of the deviation intervals of uncertain variables to form a multi-interval distribution error set effectively reduces the conservatism of the original box-type uncertainty set. Meanwhile, including the N-1 contingency states of multiple devices in the uncertainty set, although it leads to a slight increase in system costs, enables more effective response to emergencies when the system fails.

- (3)

- Adopting a multi-time-scale optimization scheduling strategy, transferring the results of robust optimization in advance to real-time optimization, and reallocating power within a shorter forecast period to address prediction deviations.

- (4)

- Using nested C&CG algorithms to solve two-stage robust models with multiple discrete variables, achieving real-time scheduling of multiple units within IESs. Although, increasing the operational demands on advance scheduling can improve the economic operation of IES.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, G.; Yi, C.; Xiao, H.; Wu, Q.; Zeng, L.; Yan, Q.; Zhang, M. Multi-Objective Optimization of Integrated Energy Systems Considering Renewable Energy Uncertainty and Electric Vehicles. IEEE Trans. Smart Grid 2023, 14, 4322–4332. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Wang, R.; Sun, B.; Xie, W. Two-Stage Robust Optimization Model for Capacity Configuration of Biogas-Solar-Wind Integrated Energy System. IEEE Trans. Ind. Appl. 2023, 59, 662–675. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Y.; Xu, Q. Day-ahead robust optimal dispatch of integrated energy station considering battery exchange service. J. Energy Storage 2022, 50, 104228. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Y.; Dong, L. Low carbon-oriented planning of shared energy storage station for multiple integrated energy systems considering energy-carbon flow and carbon emission reduction. Energy 2024, 290, 130139. [Google Scholar] [CrossRef]

- Guo, Z.; Bian, H.; Zhou, C. An electric vehicle charging load prediction model for different functional areas based on multithreaded acceleration. J. Energy Storage 2023, 73, 108921. [Google Scholar] [CrossRef]

- Fakhrooeian, P.; Pitz, V. A New Control Strategy for Energy Management of Bidirectional Chargers for Electric Vehicles to Minimize Peak Load in Low-Voltage Grids with PV Generation. World Electr. Veh. J. 2022, 13, 218. [Google Scholar] [CrossRef]

- Cheng, K.; Zou, Y.; Xin, X.; Gong, S. Optimal lane expansion model for a battery electric vehicle transportation network considering range anxiety and demand uncertainty. J. Clearn. Prod. 2020, 276, 124198. [Google Scholar] [CrossRef]

- Ruppert, M.; Baumgartner, N.; Märtz, A.; Signer, T. Impact of V2G Flexibility on Congestion Management in the German Transmission Grid. World Electr. Veh. J. 2023, 14, 328. [Google Scholar] [CrossRef]

- Wang, A.; Li, Q.; Cao, F.; Hu, D. Driving range evaluation of electric vehicle with transcritical CO2 thermal management system under different battery temperature controls. J. Clearn. Prod. 2024, 434, 140208. [Google Scholar] [CrossRef]

- Yuvaraj, T.; Devabalaji, K.; Kumar, J.; Thanikanti, S.; Nwulu, N. A Comprehensive Review and Analysis of the Allocation of Electric Vehicle Charging Stations in Distribution Networks. IEEE Access 2024, 12, 5404–5461. [Google Scholar] [CrossRef]

- Zhu, F.; Li, Y.; Lu, L.; Wang, H.; Li, L.; Li, K.; Ouyang, M. Life cycle optimization framework of charging–swapping integrated energy supply systems for multi-type vehicles. Appl. Energy 2023, 351, 121759. [Google Scholar] [CrossRef]

- Xie, D.; Chu, H.; Gu, C.; Li, F.; Zhang, Y. A Novel Dispatching Control Strategy for EVs Intelligent Integrated Stations. IEEE Trans. Smart Grid 2017, 8, 802–811. [Google Scholar] [CrossRef]

- Ahmad, F.; Alam, M.; Shariff, S. A Cost-Efficient Energy Management System for Battery Swapping Station. IEEE Syst. J. 2019, 13, 4355–4364. [Google Scholar] [CrossRef]

- Yin, B.; Liao, X.; Qian, B.; Ma, J.; Lei, R. Optimal Scheduling of Electric Vehicle Integrated Energy Station Using a Novel Many-Objective Stochastic Competitive Optimization Algorithm. IEEE Access 2023, 11, 129043–129059. [Google Scholar] [CrossRef]

- He, C.; Zhu, J.; Cheung, K.; Borghetti, A.; Zhang, D.; Zhu, H. Optimal planning of integrated energy system considering swapping station and carbon capture power system. Energy Rep. 2023, 12, 165–170. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Jia, C. Electric Vehicle and Photovoltaic Power Scenario Generation under Extreme High-Temperature Weather. World Electr. Veh. J. 2024, 15, 11. [Google Scholar] [CrossRef]

- Zhou, D.; Zhu, Z. Urban integrated energy system stochastic robust optimization scheduling under multiple uncertainties. Energy Rep. 2023, 9, 1357–1366. [Google Scholar] [CrossRef]

- Wang, P.; Zheng, L.; Diao, T.; Huang, S.; Bai, X. Robust Bilevel Optimal Dispatch of Park Integrated Energy System Considering Renewable Energy Uncertainty. Energies 2023, 16, 7302. [Google Scholar] [CrossRef]

- Fan, W.; Tan, Q.; Zhang, A.; Ju, L.; Wang, Y.; Yin, Z.; Li, X. A Bi-level optimization model of integrated energy system considering wind power uncertainty. Renew. Energy 2023, 202, 973–991. [Google Scholar] [CrossRef]

- Dong, Y.; Zhang, H.; Ma, P.; Wang, C.; Zhou, X. A hybrid robust-interval optimization approach for integrated energy systems planning under uncertainties. Energy 2023, 274, 127267. [Google Scholar] [CrossRef]

- Wang, S.; Sun, W. Capacity Value Assessment for a Combined Power Plant System of New Energy and Energy Storage Based on Robust Scheduling Rules. Sustainability 2023, 15, 15327. [Google Scholar] [CrossRef]

- Ma, G.; Li, J.; Zhang, X. A Review on Optimal Energy Management of Multimicrogrid System Considering Uncertainties. IEEE Access 2022, 10, 77081–77098. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, P.; Gu, W. A bi-level planning approach for hybrid AC-DC distribution system considering N-1 security criterion. Appl. Energy 2018, 230, 417–428. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, C.; Li, K.; Wang, Z. An integrated design for hybrid combined cooling heating and power system with compressed air energy storage. Appl. Energy 2018, 210, 1151–1166. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, J.; Chen, J.; Ye, C.; Gong, Y. Two-Stage Co-Optimization of a Park-Level Integrated Energy System Considering Grid Interaction. IEEE Access 2023, 11, 66400–66414. [Google Scholar] [CrossRef]

- Yang, J.; Liu, W.; Ma, K.; Yue, Z.; Zhu, A.; Guo, S. An optimal battery allocation model for battery swapping station of electric vehicles. Energy 2023, 272, 127109. [Google Scholar] [CrossRef]

- Pineda, S.; Morales, J.M. Solving linear bilevel problems using Big-Ms: Not all that glitters is gold. IEEE Trans. Power Syst. 2019, 34, 2469–2471. [Google Scholar] [CrossRef]

- Ding, T.; Bo, R.; Gu, W.; Sun, H. Big-M based MIQP method for economic dispatch with disjoint prohibited zones. IEEE Trans. Power Syst. 2014, 29, 976–977. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, F.; Shu, S.; Le, J.; Zhu, S. Distributionally robust optimization scheduling of electricity and natural gas integrated energy system considering confidence bands for probability density functions. Int. J. Electr. Power Energy Syst. 2020, 123, 106321. [Google Scholar] [CrossRef]

- Wang, H.; Fang, Y.; Zhang, X.; Dong, Z.; Yu, X. Robust dispatching of integrated energy system considering economic operation domain and low carbon emission. Energy Rep. 2022, 8, 252–264. [Google Scholar] [CrossRef]

- Chen, X.; Li, N. Leveraging Two-Stage Adaptive Robust Optimization for Power Flexibility Aggregation. IEEE Trans. Smart Grid 2021, 12, 3954–3965. [Google Scholar] [CrossRef]

- Li, P.; Song, L.; Qu, J.; Huang, Y.; Wu, X.; Lu, X.; Xia, S. A Two-Stage Distributionally Robust Optimization Model for Wind Farms and Storage Units Jointly Operated Power Systems. IEEE Access 2021, 9, 111132–111142. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, G.; Liu, Y.; Ding, L.; Shui, Y. Data-Driven Distributionally Robust Optimization-Based Coordinated Dispatching for Cascaded Hydro-PV-PSH Combined System. Electronics 2024, 13, 667. [Google Scholar] [CrossRef]

- Hao, J.; Huang, T.; Xu, Q.; Sun, Y. Robust Optimal Scheduling of Microgrid with Electric Vehicles Based on Stackelberg Game. Sustainability 2023, 15, 16682. [Google Scholar] [CrossRef]

| Refs. | Coupling Resources | Battery Model | Uncertainty Element | Robust Solution Algorithm |

|---|---|---|---|---|

| [2] | Wind, solar, biogas | --- | Wind, solar, electric load, heat load, cold load | C&CG |

| [11] | --- | EV charging station and battery swapping station, battery fast charging model | --- | --- |

| [12] | --- | Battery charging process, battery discharging process, charging and discharging power regulation model | --- | --- |

| [13] | --- | Battery charging process, battery discharging process, energy price incentive model | --- | --- |

| [14] | Solar, EV-IES | Battery charging process, battery discharging process | --- | --- |

| [15] | Wind, solar, natural gas, EVBSS | Battery charging process, battery discharging process | Wind, solar | --- |

| [16] | Wind, solar | --- | Wind, solar, electric load, heat load | C&CG |

| [17] | Wind, solar, natural gas | --- | Wind, solar | KKT |

| [18] | Wind, gas | --- | Wind | KKT |

| [19] | Wind, solar, natural gas | --- | Wind, solar | KKT, HRIO |

| [20] | Wind, solar | --- | Wind, solar | C&CG |

| [21] | --- | --- | N-1 contingency | --- |

| This paper | Wind, solar, natural gas, EVBSS | Battery charging process, battery discharging process, charging and discharging priority function | Wind, solar, electric load, heat load, cold load, N-1 contingency | Nested C&CG |

| Parameter | Value | Parameter | Value | Parameter | Value | Parameter | Value | |

|---|---|---|---|---|---|---|---|---|

| EVBSS | K | 7 | 5 kW | 4.5 kW | T | 24 h | ||

| Δt | 1 h | Nmax | 300 | |||||

| [S1,t S2,t] | [0.15 0.25] | [S2,t S3,t] | [0.25 0.35] | N1,a,0 | 260 | N2,a,0 | 25 | |

| [S3,t S4,t] | [0.35 0.45] | [S4,t S5,t] | [0.45 0.55] | N3,a,0 | 25 | N4,a,0 | 30 | |

| [S5,t S6,t] | [0.55 0.65] | [S6,t S7,t] | [0.65 0.75] | N5,a,0 | 25 | N6,a,0 | 35 | |

| [S7,t S8,t] | [0.75 0.85] | N7,a,0 | 300 | |||||

| CHP | 0.45 | 400 kW | 1000 kW | ηCHP | 0.3 | |||

| 20 CNY | mCHP | 0.03 CNY/kWh | Lng | 9.7 kWh/m3 | ||||

| GB | ηGB | 0.93 | 1000 kW | mgas | 2.8 CNY/m3 | mGB | 0.005 | |

| EHCE | Ceh | 2.8 | 2000 kW | |||||

| ECCE | Cec | 2.8 | 800 kW | |||||

| AC | Cac | 1.2 | 1000 kW | |||||

| Energy storage system | 1500 kWh | 0.92 | 0.93 | 0.2 | ||||

| 0.9 | 2000 kWh | 1000 kW | 1000 kW | |||||

| 1200 kWh | 0.93 | 0.93 | 0.1 | |||||

| 0.9 | 2000 kWh | 500 kW | 500 kW | |||||

| 1200 kWh | 0.92 | 0.92 | 0.1 | |||||

| 0.9 | 2000 kWh | 500 kW | 500 kW | |||||

| τh, τc | 0.99 | mes | 0.005 CNY/kWh | mhs, mhc | 0.001 CNY/kWh | |||

| Utility grid | Pb,max | 2000 kW | Ps,max | 2000 kW | msell | 0.4 CNY/kWh | ||

| Case 1 | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|

| Cost/CNY | 28,133 | 24,558 | 23,312 | 22,539 |

| WT | Case | Cost/CNY | PV | Case | Cost/CNY | ||||||

| 1 | 10 | 0 | 0 | 23,718 | 1 | 8 | 0 | 0 | 21,906 | ||

| 2 | 7 | 1 | 2 | 23,155 | 2 | 6 | 1 | 1 | 21,668 | ||

| 3 | 4 | 2 | 4 | 22,409 | 3 | 4 | 1 | 3 | 21,345 | ||

| 4 | 1 | 3 | 6 | 21,617 | 4 | 2 | 2 | 4 | 20,934 | ||

| 5 | 0 | 2 | 8 | 21,190 | 5 | 0 | 0 | 8 | 20,526 | ||

| 6 | 0 | 0 | 10 | 20,957 | 6 | 0 | 4 | 4 | 20,749 | ||

| 7 | 0 | 6 | 4 | 21,643 | 7 | 0 | 6 | 2 | 20,888 | ||

| 8 | 0 | 10 | 0 | 21,993 | 8 | 0 | 8 | 0 | 20,984 |

| Case 1 | Case 2 | Case 3 | |

|---|---|---|---|

| Electricity purchasing cost/CNY | 3030 | 3030 | 4427 |

| Electricity selling income/CNY | 397.6 | 397.6 | 0 |

| Total cost/CNY | 22,539 | 22,539 | 24,959 |

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | |

|---|---|---|---|---|---|

| Cost/CNY | 20,227 | 28,430 | 24,377 | 27,940 | 23,755 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, H.; Ren, Q.; Guo, Z.; Zhou, C. Optimal Scheduling of Integrated Energy System Considering Electric Vehicle Battery Swapping Station and Multiple Uncertainties. World Electr. Veh. J. 2024, 15, 170. https://doi.org/10.3390/wevj15040170

Bian H, Ren Q, Guo Z, Zhou C. Optimal Scheduling of Integrated Energy System Considering Electric Vehicle Battery Swapping Station and Multiple Uncertainties. World Electric Vehicle Journal. 2024; 15(4):170. https://doi.org/10.3390/wevj15040170

Chicago/Turabian StyleBian, Haihong, Quance Ren, Zhengyang Guo, and Chengang Zhou. 2024. "Optimal Scheduling of Integrated Energy System Considering Electric Vehicle Battery Swapping Station and Multiple Uncertainties" World Electric Vehicle Journal 15, no. 4: 170. https://doi.org/10.3390/wevj15040170