Uncertainty Analysis for the CH4 Emission Factor of Thermal Power Plant by Monte Carlo Simulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Designation of Subject Facilities and Sampling Period

2.2. Exhaust Gas Sampling Method

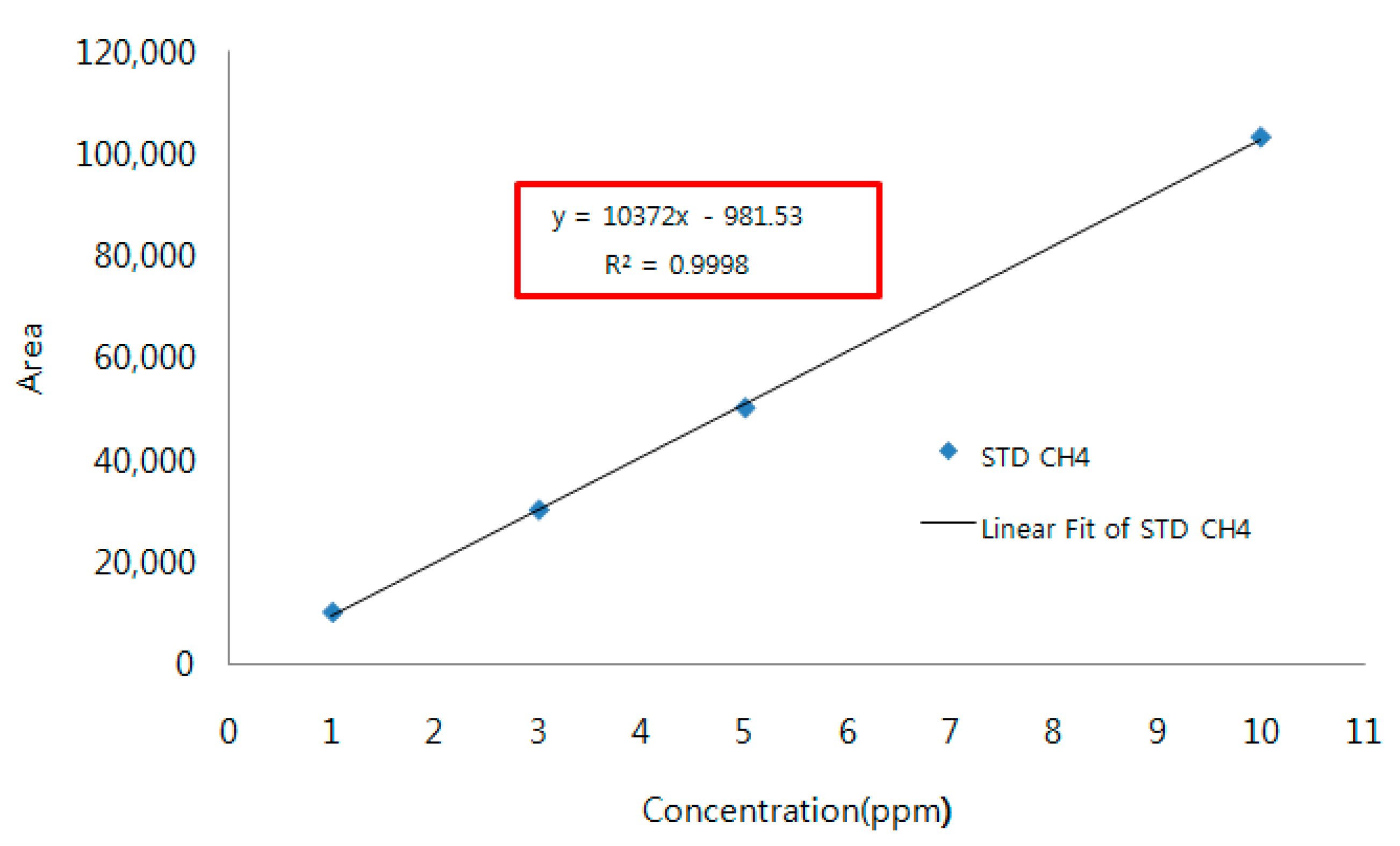

2.3. Analysis Method of CH4 Concentration

2.4. Calculation Method of CH4 Emission Factor

2.5. Goodness-of-Fit Test of Probability Density Function

2.6. Uncertainty Analysis by Monte Carlo Simulation

3. Result and Discussion

3.1. Exhaust Gas Analysis and CH4 Emission Factor

3.2. Monte Carlo Simulation

3.3. Uncertainty Range for CH4 Emission Factor of Thermal Power Plants

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rogelj, J.; den Elzen, M.; Höhne, N.; Fransen, T.; Fekete, H.; Winkler, H.; Schaeffer, R.; Sha, F.; Riahi, K.; Meinshausen, M. Paris Agreement climate proposals need a boost to keep warming well below 2 degree. Nature 2016, 534, 631–639. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Falkner, R. The Paris Agreement and the new logic of international climate politics. Int. Aff. 2016, 92, 1107–1125. [Google Scholar] [CrossRef]

- Hulme, M. 1.5 degree and climate research after the Paris Agreement. Nat. Clim. Chang. 2006, 6, 222–224. [Google Scholar] [CrossRef]

- UNFCCC. UN Framework Covention on Climate Change Conference of the Parties-21, The Paris Agreement Paris. 2015, pp. 18–19. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 3 August 2018).

- Penman, J.; Kruger, D.; Galbally, I.; Hiraishi, T.; Nyenzi, B.; Emmanuel, S.; Buendia, L.; Hoppaus, R.; Martinsen, T.; Meijer, J.; et al. Good Practice Guidance and Uncertainty Management in National Greenhouse Gas. Inventories; Intergovernmental Panel on Climate Change: Hayama, Japan, 2000. [Google Scholar]

- IPCC. The 2006 IPCC Guidelines for National Greenhouse Gas Inventories. In General Guidance and Reporting; IPCC: Geneva, Switzerland, 2006; Volume 1. [Google Scholar]

- Law, A.M.; Kelton, W.D. Simulation Modeling and Analysis; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- IPCC. The 2006 IPCC Guidelines for National Greenhouse Gas Inventories. In Energy, Chapter 2: Stationary Combustion; IPCC: Geneva, Switzerland, 2006; Volume 2. [Google Scholar]

- Frey, H.C.; Zheng, J. Quantification of variability and uncertainty in lawn and garden equipment Nox and total hydrocarbon emissions factors. J. Air Waste Manag. Assoc. 2002, 52, 435–448. [Google Scholar] [CrossRef] [PubMed]

- Winiwarter, W.; Rypdal, K. Assessing the uncertainty associated with national greenhouse gas emission inventories: A case study for Austria. Atmos. Environ. 2001, 35, 5425–5440. [Google Scholar] [CrossRef]

- Experiments for the Examination of Air Pollutions; Ministry of Environment in Korea: Seoul, Korea, 2004.

- Wight, G.D. Fundamentals of Air Sampling; CRC Press (Lewis Publishers): Boca Raton, FL, USA, 1994; pp. 135–184. [Google Scholar]

- US-EPA. Method 18—Volatile Organic Compounds by Gas Chromatography. 2017. Available online: https://www.epa.gov/sites/production/files/2017-08/documents/method_18.pdf (accessed on 6 August 2018).

- QA/QC Handbook for the Environmental Pollutants Analysis and Sampling Techniques; National Institute of Environmental Research in Korea: Seoul, Korea, 2011.

- US-EPA. Appendix B to Part 136—Definition and Procedure for the Determination of the Method Detection Limit—Revision 1.11. Available online: https://www.law.cornell.edu/cfr/text/40/appendix-B_to_part_136 (accessed on 6 August 2018).

- Eemeli, T.; Suvi, M.; Kauko, T.; Tuula, P.; Sanna, S. Estimation of annual CH4 and N2O emissions from fluidised bed combustion: An advanced measurement-based method and its application to Finland. Int. J. Greenh. Gas Control 2007, 1, 289–297. [Google Scholar]

- Lee, S.; Kim, J.; Lee, J.; Lee, S.; Jeon, E.C. A study on the evaluations of emission factors and uncertainty ranges for methane and nitrous oxide from combined-cycle power plant in Korea. Environ. Sci. Pollut. Res. 2012, 20, 461–468. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.; Kim, J.; Lee, J.; Jeon, E.-C. A Study on Methane and Nitrous Oxide Emissions Characteristics from Anthracite Circulating Fluidized Bed Power Plant in Korea. Sci. World J. 2012, 2012, 468214. [Google Scholar] [CrossRef] [PubMed]

- National Greenhouse Gas. Inventory Report of JAPAN; Greenhouse Gas Inventory Office of Japan: Ibaraki, Japan, 2017; pp. 327–328.

| Site | Capacity (MW) | Fuel Consumption (ton) | Fuel Type | Boiler Type |

|---|---|---|---|---|

| Plant A | 4000 | 13,260,016 | Bituminous Coal | Tangential firing |

| Plant B | 4000 | 13,082,285 | Bituminous Coal | Tangential firing |

| Plant C | 3340 | 10,205,312 | Bituminous Coal | Opposed Wall firing |

| Plant D | 1400 | 753,354 | Bunker-C oil | Opposed Wall firing |

| Plant E | 150 | 215,040 | Bunker-C oil | Tangential firing |

| Plant F | 40 | 94,349 | Bunker-C oil | Internal Engine |

| Plant G | 1800 | 1,954,381 | LNG | Combined Cycle |

| GC/FID | ||

|---|---|---|

| Column | Porapack Q 80/100 | |

| Carrier Gas | N2 (99.999%) | |

| low | Column | 30 mL/min |

| H2 | 30 mL/min | |

| Air | 300 mL/min | |

| Temperature | Oven | 80 °C |

| Injector | 100 °C | |

| Detector | 250 °C | |

| Detector Range | 0 | |

| Concentration | 1.00 ppm |

|---|---|

| Peak Area | |

| 1 | 11,856 |

| 2 | 11,827 |

| 3 | 11,702 |

| 4 | 11,727 |

| 5 | 11,792 |

| 6 | 11,745 |

| 7 | 11,790 |

| Mean | 11,777 |

| SD | 55 |

| SD × 3.14 | 173 |

| MDL | 10.61 ppb |

| CH4 | O2 | Theoretical Air Volume | Air Ratio | Theoretical Exhaust Gas Volume (Dry) | CH4 Emission Factor | ||

|---|---|---|---|---|---|---|---|

| ppm | %(vol) | m3/kg | - | m3/kg | kg CH4/TJ | ||

| Plant A | |||||||

| Fuel type | Bituminous Coal | ||||||

| Boiler type | Tangential firing | ||||||

| Mean | 0.51 | 5.62 | 7.17 | 1.40 | 6.98 | 0.14 | |

| SD | 0.18 | 2.05 | 0.15 | 0.31 | 0.15 | 0.05 | |

| RSD(%) | 35.4 | 36.5 | 2.0 | 22.4 | 2.1 | 33.3 | |

| N | 15 | 15 | 15 | 15 | 15 | 15 | |

| Plant B | |||||||

| Fuel type | Bituminous Coal | ||||||

| Boiler type | Tangential firing | ||||||

| Mean | 0.54 | 5.25 | 7.19 | 1.33 | 7.01 | 0.15 | |

| SD | 0.38 | 0.59 | 0.21 | 0.05 | 0.20 | 0.11 | |

| RSD(%) | 71.7 | 11.3 | 2.9 | 3.9 | 2.8 | 73.1 | |

| N | 32 | 32 | 32 | 32 | 32 | 32 | |

| Plant C | |||||||

| Fuel type | Bituminous Coal | ||||||

| Boiler type | Opposed Wall Firing | ||||||

| Mean | 0.30 | 3.89 | 7.50 | 1.23 | 7.30 | 0.08 | |

| SD | 0.07 | 0.18 | 0.14 | 0.01 | 0.13 | 0.02 | |

| RSD(%) | 22.1 | 4.6 | 1.9 | 1.0 | 1.8 | 20.7 | |

| N | 15 | 15 | 15 | 15 | 15 | 15 | |

| Plant D | |||||||

| Fuel type | B-C oil | ||||||

| Boiler type | Opposed Wall Firing | ||||||

| Mean | 0.69 | 5.89 | 10.60 | 1.39 | 10.01 | 0.17 | |

| SD | 0.37 | 0.01 | 0.01 | 0.01 | 0.01 | 0.09 | |

| RSD(%) | 54.0 | 0.1 | 0.1 | 1.0 | 1.1 | 54.0 | |

| N | 15 | 15 | 15 | 15 | 15 | 15 | |

| Plant E | |||||||

| Fuel type | B-C oil | ||||||

| Boiler type | Tangential firing | ||||||

| Mean | 0.48 | 5.81 | 10.94 | 1.38 | 10.28 | 0.12 | |

| SD | 0.13 | 0.18 | 0.12 | 0.02 | 0.11 | 0.03 | |

| RSD(%) | 27.9 | 3.2 | 1.1 | 1.2 | 1.1 | 26.5 | |

| N | 17 | 17 | 17 | 17 | 17 | 17 | |

| Plant F | |||||||

| Fuel type | B-C oil | ||||||

| Boiler type | Internal Engine | ||||||

| Mean | 1.03 | 14.38 | 10.98 | 3.18 | 10.32 | 0.61 | |

| SD | 0.26 | 0.16 | 0.11 | 0.08 | 0.10 | 0.16 | |

| RSD(%) | 25.4 | 1.1 | 1.0 | 2.5 | 1.0 | 26.5 | |

| N | 27 | 27 | 27 | 27 | 27 | 27 | |

| Plant G | |||||||

| Fuel type | LNG | ||||||

| Boiler type | Combined Cycle | ||||||

| Mean | 0.11 | 13.70 | 10.09 | 2.88 | 8.20 | 0.05 | |

| SD | 0.08 | 0.07 | 0.00 | 0.03 | 0.01 | 0.04 | |

| RSD(%) | 76.93 | 0.5 | 0.0 | 1.0 | 0.1 | 76.93 | |

| N | 41 | 20 | 20 | 20 | 20 | 41 | |

| Fuel Type | Boiler Type | Emission Factor (kg CH4/TJ) | Uncertainty Rage (%, 95% Confidence) | ||

|---|---|---|---|---|---|

| This Study | 2006 IPCC G/L | This Study | 2006 IPCC G/L | ||

| Bituminous coal | Tangential firing | 0.14 | 0.7 | −46.6~+145.2 | 50~150 |

| opposed wall firing | 0.08 | 0.7 | −25.3~+70.9 | ||

| B-C | opposed wall firing | 0.17 | 0.8 | −47.7~+201.1 | |

| Tangential firing | 0.12 | 0.8 | −39.0~+93.5 | ||

| Internal Engine | 0.61 | - | −38.7~+106.1 | ||

| LNG | Combined Cycle | 0.05 | 1.0 | −89.9~+325.9 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, C.; Kang, S.; Kim, M.; Hong, Y.; Jeon, E.-c. Uncertainty Analysis for the CH4 Emission Factor of Thermal Power Plant by Monte Carlo Simulation. Sustainability 2018, 10, 3448. https://doi.org/10.3390/su10103448

Cho C, Kang S, Kim M, Hong Y, Jeon E-c. Uncertainty Analysis for the CH4 Emission Factor of Thermal Power Plant by Monte Carlo Simulation. Sustainability. 2018; 10(10):3448. https://doi.org/10.3390/su10103448

Chicago/Turabian StyleCho, Changsang, Seongmin Kang, Minwook Kim, Yoonjung Hong, and Eui-chan Jeon. 2018. "Uncertainty Analysis for the CH4 Emission Factor of Thermal Power Plant by Monte Carlo Simulation" Sustainability 10, no. 10: 3448. https://doi.org/10.3390/su10103448