A Critical Comparison of Alternative Distribution Configurations in Omni-Channel Retailing in Terms of Cost and Greenhouse Gas Emissions

Abstract

:1. Introduction

2. Research Background

3. Research Methodology

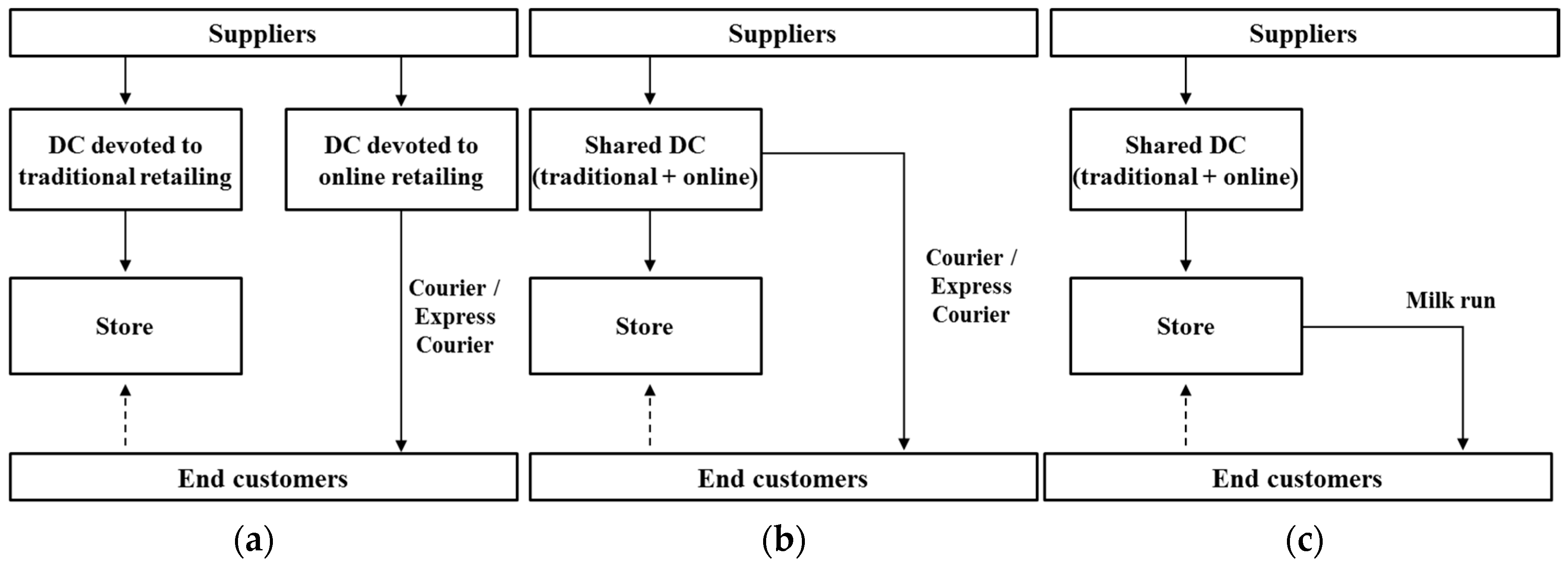

4. Description of Distribution Configurations

5. Model for Cost and Greenhouse Gas Emissions Assessment of a Distribution Configuration

- Distribution configuration: to compare multiple distribution configurations in terms of operational costs and CO2e emissions;

- Phase: to understand the role of each phase in determining the overall operational costs and in generating CO2e emissions;

- Activity: to investigate the impact of each activity on the overall phase cost and CO2e emissions.

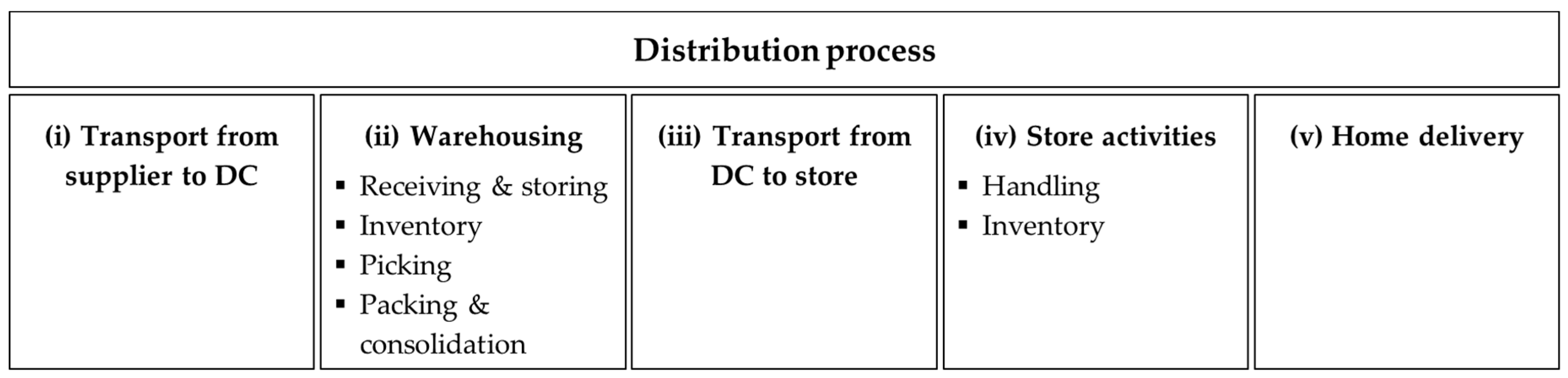

5.1. Distribution Process

- Transport from supplier to DC. This phase refers to the replenishment of the DC where online order fulfilment is performed; given a certain replenishment frequency, the truck capacity saturation is lower in Configuration 1 as flows of the online channel are not merged with those of the traditional channel;

- Warehousing. In all configurations, this phase considers the entire process performed within the DC and therefore refers to receiving, storing, inventory, picking, packing, and consolidation. In the case of a DC devoted to the online channel (i.e., Configuration 1), picking productivity is expected to be higher considering the lower size of this area compared to the other two alternatives; the handling activities are more complex as the DC places smaller orders to the supplier and therefore the percentage of received mixed pallets is higher;

- Transport from DC to store. This phase is required only in the case of the integrated warehouse and transport configuration as the courier’s network is used in the other alternatives;

- Store activities. This phase is required only in case of the integrated warehouse and transport configuration as in the other two alternatives the store is not involved in e-fulfilment; as mentioned before, in Configuration 1, the store has to perform handling activities and store orders received from the DC;

- Home delivery. It refers to the delivery performed by the courier in Configurations 1 and 2 and to the delivery tours starting from the store in Configuration 3.

5.2. Cost Assessment

5.3. Greenhouse Gas Emissions Assessment

6. Comparison of the Alternative Distribution Configuration

6.1. Main Data and Assumptions

6.2. Economic Impact Evaluation

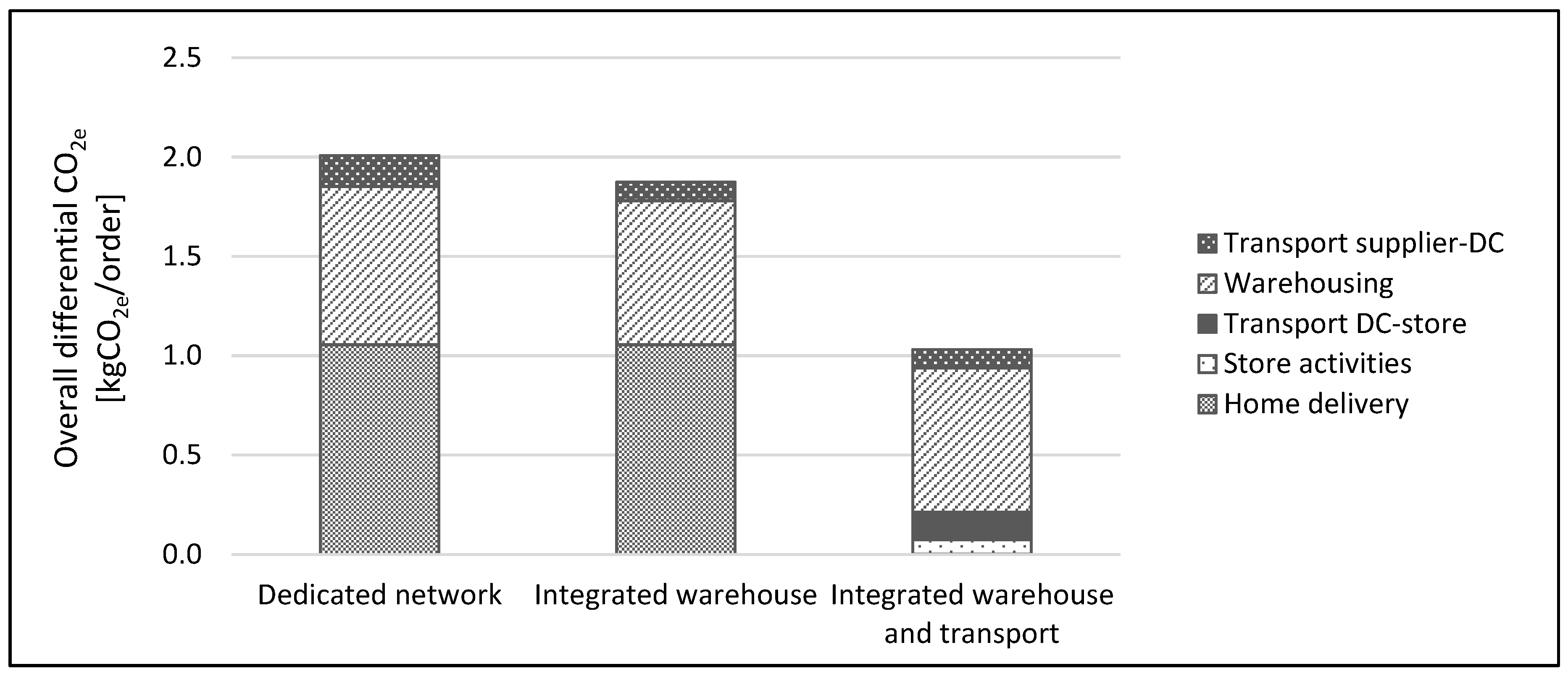

6.3. Environmental Impact Evaluation

7. Conclusions

Author Contributions

Conflicts of Interest

References

- Gallino, S.; Moreno, A. Integration of online and offline channels in retail: The impact of sharing reliable inventory availability information. Manag. Sci. 2014, 60, 1434–1451. [Google Scholar] [CrossRef]

- Piotrowicz, W.; Cuthbertson, R. Introduction to the special issue information technology in retail: Toward omnichannel retailing. Int. J. Electron. Commer. 2014, 18, 5–16. [Google Scholar] [CrossRef]

- Rigby, D. The future of shopping. Harv. Bus. Rev. 2011, 89, 65–76. [Google Scholar]

- Beck, N.; Rygl, D. Categorization of multiple channel retailing in Multi-, Cross-, and Omni-Channel Retailing for retailers and retailing. J. Retail. Consum. Serv. 2015, 27, 170–178. [Google Scholar] [CrossRef]

- Fairchild, A.M. Extending the network: Defining product delivery partnering preferences for Omni-channel commerce. Procedia Technol. 2014, 16, 447–451. [Google Scholar] [CrossRef]

- Piecyk, M.I.; McKinnon, A.C. Forecasting the Carbon Footprint of Road Transportation in 2020. Int. J. Prod. Econ. 2010, 128, 31–42. [Google Scholar] [CrossRef]

- Gevaers, R.; Van de Voorde, E.; Vanelslander, T. Characteristics and Typology of Last-Mile Logistics from an Innovative Perspective in an Urban Context. In Proceedings of the Transportation Research Board Annual Meeting, Washington, DC, USA, 25 January 2011. [Google Scholar]

- Bell, D.R.; Gallino, S.; Moreno, A. How to win in an Omni-channel world. MIT Sloan Manag. Rev. 2014, 56, 45–55. [Google Scholar]

- Hübner, A.; Holzapfel, A.; Kuhn, H. Operations management in multi-channel retailing: An exploratory study. Oper. Manag. Res. 2015, 8, 84–100. [Google Scholar] [CrossRef]

- Metters, R.; Walton, S. Strategic supply chain choices for multi-channel Internet retailers. Serv. Bus. 2007, 1, 317–331. [Google Scholar] [CrossRef]

- Verhoef, P.C.; Kannan, P.K.; Inman, J.J. From multi-channel retailing to Omni-channel retailing: Introduction to the special issue on multi-channel retailing. J. Retail. 2015, 91, 174–181. [Google Scholar] [CrossRef]

- Agatz, N.A.; Fleischmann, M.; Van Nunen, J.A. E-fulfillment and multi-channel distribution—A review. Eur. J. Oper. Res. 2008, 187, 339–356. [Google Scholar] [CrossRef]

- Edwards, J.B.; McKinnon, A.C.; Cullinane, S.L. Comparative analysis of the carbon footprints of conventional and online retailing: A “last mile” perspective. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 103–123. [Google Scholar] [CrossRef]

- Brown, J.R.; Guiffrida, A.L. Carbon emissions comparison of last mile delivery versus customer pickup. Int. J. Logist. Res. Appl. 2014, 17, 503–521. [Google Scholar] [CrossRef]

- Hübner, A.; Kuhn, H.; Wollenburg, J. Last mile fulfilment and distribution in Omni-channel grocery retailing: A strategic planning framework. Int. J. Retail Distrib. Manag. 2016, 44, 228–247. [Google Scholar] [CrossRef]

- Siikavirta, H.; Punakivi, M.; Karkkainen, M.; Linnanen, L. Effects of E-Commerce on Greenhouse Gas Emissions. J. Ind. Ecol. 2003, 6, 83–97. [Google Scholar] [CrossRef]

- Mangiaracina, R.; Perego, A.; Perotti, S.; Tumino, A. Assessing the environmental impact of logistics in online and offline B2C purchasing processes in the apparel industry. Int. J. Logist. Syst. Manag. 2016, 23, 98–124. [Google Scholar] [CrossRef]

- Colicchia, C.; Creazza, A.; Dallari, F.; Melacini, M. Eco-efficient supply chain networks: Development of a design framework and application to a real case study. Prod. Plan. Control 2016, 27, 157–168. [Google Scholar] [CrossRef]

- Tappia, E.; Marchet, G.; Melacini, M.; Perotti, S. Incorporating the environmental dimension in the assessment of automated warehouses. Prod. Plan. Control 2015, 26, 824–838. [Google Scholar] [CrossRef]

- MacKay, D.J.C. Sustainable Energy—Without the Hot Air, 1st ed.; UTI Cambridge: Cambridge, UK, 2009; ISBN 978-0-95-445293-3. [Google Scholar]

- DEFRA. Government Emission Conversion Factors for Greenhouse Gas Company Reporting, 2017. Available online: https://www.gov.uk/ (accessed on 4 December 2017).

- Lieb, K.J.; Lieb, R.C. Environmental sustainability in the third-party logistics (3PL) industry. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 524–533. [Google Scholar] [CrossRef]

- Colicchia, C.; Marchet, G.; Melacini, M.; Perotti, S. Building environmental sustainability: Empirical evidence from Logistics Service Providers. J. Clean. Prod. 2013, 59, 197–209. [Google Scholar] [CrossRef]

- Aronsson, H.; Huge-Brodin, M. The environmental impact of changing logistics structures. Int. J. Logist. Manag. 2006, 17, 394–415. [Google Scholar] [CrossRef]

- Kohn, C.; Huge-Brodin, M. Centralised distribution systems and the environment: How increased transport work can decrease the environmental impact of logistics. Int. J. Logist. Res. Appl. 2008, 11, 229–245. [Google Scholar] [CrossRef]

- Hovelaque, V.; Soler, L.G.; Hafsa, S. Supply chain organization and e-commerce: A model to analyze store-picking, warehouse-picking and drop-shipping. 4OR 2007, 5, 143–155. [Google Scholar] [CrossRef]

- Nahmias, M. Production and Operations Analysis, 4th ed.; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Bendoly, E.; Blocher, D.; Bretthauer, K.M.; Venkataramanan, M.A. Service and cost benefits through clicks-and-mortar integration: Implications for the centralization/decentralization debate. Eur. J. Oper. Res. 2007, 180, 426–442. [Google Scholar] [CrossRef]

- Bretthauer, K.M.; Mahar, S.; Venakataramanan, M.A. Inventory and distribution strategies for retail/e-tail organizations. Comput. Ind. Eng. 2010, 58, 119–132. [Google Scholar] [CrossRef]

- Schneider, F.; Klabjan, D. Inventory control in multi-channel retail. Eur. J. Oper. Res. 2013, 227, 101–111. [Google Scholar] [CrossRef]

- Li, T.; Zhao, X.; Xie, J. Inventory management for dual sales channels with inventory-level-dependent demand. J. Oper. Res. Soc. 2015, 66, 488–499. [Google Scholar] [CrossRef]

- Agatz, N.A.; Campbell, A.; Fleischmann, M.; Savelsbergh, M. Time slot management in attended home delivery. Transp. Sci. 2011, 45, 435–449. [Google Scholar] [CrossRef] [Green Version]

- Boyer, K.K.; Prud’homme, A.M.; Chung, W. The last mile challenge: Evaluating the effects of customer density and delivery window patterns. J. Bus. Logist. 2009, 30, 185–201. [Google Scholar] [CrossRef]

- Stapleton, D.; Pati, S.; Beach, E.; Julmanichoti, P. Activity-based costing for logistics and marketing. Bus. Process Manag. J. 2004, 10, 584–597. [Google Scholar] [CrossRef]

- Goldsby, T.J.; Closs, D.J. Using activity-based costing to reengineer the reverse logistics channel. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 500–514. [Google Scholar] [CrossRef]

- ENEA (Agenzia nazionale per le nuove tecnologie, l’energia e lo sviluppo economico sostenibile). Indici di Benchmark di Consumo per Tipologie di Edificio ad uso Commercial Grande Distribuzione Applicabilità di Tecnologie Innovative nei Diversi Climi Italiani; ENEA: Roma, Italy, 2010; pp. 1–96. [Google Scholar]

- Tappia, E.; Roy, D.; de Koster, R.; Melacini, M. Modeling, Analysis, and Design Insights for Shuttle-Based Compact Storage Systems. Transp. Sci. 2017, 51, 269–295. [Google Scholar] [CrossRef]

| Cost Category | Cost Driver | Unit of Measure |

|---|---|---|

| Demand profile | Average daily online demand | (orders/day) |

| Average daily traditional demand | (orders/day) | |

| Coefficient of variation of online demand | - | |

| Coefficient of variation of traditional demand | - | |

| Correlation coefficient between online and traditional demand | - | |

| Online order profile | Average number of lines per order | (lines/order) |

| Average number of units per order line | (units/line) | |

| Product profile | Average unit value | (€/unit) |

| Average unit volume | (m3/unit) | |

| Delivery profile | Courier fare | (€/order) |

| Delivery area | (km2) | |

| Time available in a day | (hours) | |

| Drop-off time (product delivery, payment) | (hours/order) | |

| Average transfer speed | (km/hour) | |

| Daily cost of a vehicle | (€/day) | |

| Inventory management | Review interval of DC | (days) |

| Service level (k) | - | |

| Inventory carrying cost on product value—DC (space, obsolescence, capital costs) | (%/year) | |

| Handling activities | Picking productivity | (lines/hour) |

| Packing productivity | (orders/hour) | |

| Hourly cost of picking activities (labour, equipment) | (€/hour) | |

| Hourly cost of packing activities (labour) | (€/hour) | |

| Handling cost | (€/pallet) | |

| Store profile | Shipment cost from DC to stores | (€/m3 km) |

| Average distance from DC to stores | (km) | |

| Handling productivity in-store | (orders/hour) | |

| Hourly cost of handling activities (labour) | (€/hour) | |

| Review interval of stores | (days) | |

| Inventory carrying cost on product value—store (space) | (%/year) | |

| Suppliers profile | Shipment cost from suppliers to DC | (€/m3 km) |

| Average distance from suppliers to DC | (km) | |

| Average lead time | (days) | |

| Average pallet volume | (m3/pallet) |

| Activity | Expression |

|---|---|

| Transport from suppliers to DC | Shipment cost (€/m3 km) × Average distance Supplier-DC (km) × Average unit volume (m3/unit) × Average order line size (units/line) × Average order size (lines/order) |

| Warehousing—Receiving and storing | (Handling cost (€/pallet)/Average pallet volume (m3/pallet)) × Average unit volume (m3/unit) × Average order line size (units/line) × Average order size (lines/order) |

| Warehousing—Inventory | DC’s order quantity (units): 2 + Coefficient of variation of online demand/(Coefficient of variation of online demand + Coefficient of variation of traditional demand) × safety stock (units)) × Service level k × Average unit value (€/unit) × Inventory carrying cost (%/year) |

| Warehousing—Picking | ((1/Picking productivity (lines/hour)) × Cost of picking activities (€/hour)) × Average order size (lines/order) |

| Warehousing—Packing and consolidation | (1/Packing productivity (orders/hour)) × Cost of packing activities (€/hour) |

| Transport from DC to store | Shipment cost (€/m3 km) × Average distance DC-store (km) × Average unit volume (m3/unit) × Average order line size (units/line) × Average order size (lines/order) |

| Store activities—Handling | (1/Handling productivity (orders/hour)) × Cost of handling activities (€/hour) |

| Store activities—Inventory | Store’s order quantity (units): 2 × Average unit value (€/unit) × Inventory carrying cost (%/year) |

| Home delivery | Courier fare (Conf. 1); Vehicle cost (€/day): (Time available (hours/day)/(Drop-off time (hours/order) + (Average demand (orders/day): Delivery area (km2)): Average transfer speed (km/hour)) (Conf. 2, 3) |

| GHG Emission Category | GHG Emission Driver | Unit of Measure |

|---|---|---|

| Product profile | Average unit weight | (kg/unit) |

| Delivery profile | Retailer online demand to total courier hub flow ratio | (%) |

| Courier hub energy consumption | (kWh/m3 year) | |

| Average courier hub size | (m3) | |

| Average distance between DC and courier hub | (km) | |

| GHG emission generated from DC to courier hub | (kg CO2e/tonne km) | |

| GHG emission generated from courier hub/store to customer’s home | (kg CO2e/tonne km) | |

| Carbon emission generated in the courier hub | (kg CO2/kWh) | |

| Inventory management and handling activities | DC energy consumption for good storage | (kWh/year) |

| Carbon emission generated for good storage and handling in the DC | (kg CO2/kWh) | |

| Store profile | Store energy consumption | (kWh/year) |

| Carbon emission generated in store | (kg CO2/kWh) | |

| Suppliers profile | GHG emission generated from suppliers to DC | (kg CO2e/tonne km) |

| Activity | Expression |

|---|---|

| Transport from suppliers to DC | GHG emission (kg CO2e/tonne km) × Average distance suppliers-DC (km) × Order weight (tonnes/order) |

| Warehousing | GHG emission (kg CO2/kWh) × DC energy consumption (kWh/year) × Online to offline demand ratio (%): Annual online demand (orders/year) |

| Transport from DC to store | GHG emission (kg CO2e/tonne km) × Average distance DC-store (km) × Order weight (tonnes/order) |

| Store activities | GHG emission (kg CO2/kWh) × Store energy consumption (kWh/year) × Online to offline demand ratio (%): Annual online demand (orders/year) |

| Home delivery | GHG emission (kg CO2e/tonne km) × Average distance DC-courier hub (km) × Order weight (tonnes/order) + GHG emission (kg CO2/kWh) × Courier hub energy consumption (kWh/m3 year) × Average courier hub size (m3) × Retailer online demand to total courier hub flow ratio: Annual online demand (orders/year) + GHG emission (kg CO2e/tonne km) × Average distance per customer in a tour (km) × Order weight (tonnes/order) (Conf. 1, 2); GHG emission (kg CO2e/tonne km) × Average distance per customer in a tour (km) × Order weight (tonnes/order) (Conf. 3) |

| Cost Category | Cost Driver | Value | Unit of Measure |

|---|---|---|---|

| Demand profile | Average daily online demand | 330 | (orders/day) |

| Average daily traditional demand | 6300 | (orders/day) | |

| Coefficient of variation of online demand | 2 | - | |

| Coefficient of variation of traditional demand | 1 | - | |

| Correlation coefficient between online and traditional demand | −0.5 | - | |

| Online order profile | Average number of lines per order | 1.2 | (lines/order) |

| Average number of units per order line | 1 | (units/line) | |

| Product profile | Average unit price | 300 | (€/unit) |

| Average unit volume | 0.035 | (m3/unit) | |

| Delivery profile | Courier fare | 8 | (€/order) |

| Delivery area | 20 | (km2) | |

| Time available in a day | 8 | (hours) | |

| Drop-off time (product delivery, payment) | 0.25 | (h) | |

| Average transfer speed | 15 | (km/hour) | |

| Daily cost of a vehicle | 150 | (€/day) | |

| Inventory management | Review interval of DC | 10 | (days) |

| Service level | 98 | (%) | |

| Inventory carrying cost on product value—DC (space, obsolescence, capital costs) | 25 (Conf. 1); 20 (Conf. 2, 3) | (%/year) | |

| Handling activities | Picking productivity | 50 (Conf. 1); 45 (Conf. 2, 3) | (lines/hour) |

| Packing productivity | 30 | (orders/hour) | |

| Hourly cost of picking activities (labour, equipment) | 20 | (€/hour) | |

| Hourly cost of packing activities (labour) | 18 | (€/hour) | |

| Handling cost | 1 (Conf. 1); 0.5 (Conf. 2, 3) | (€/pallet) | |

| Store profile | Shipment cost from DC to stores | 0.07 | (€/m3 km) |

| Average distance from DC to stores | 150 | (km) | |

| Handling productivity in-store | 20 | (orders/hour) | |

| Hourly cost of handling activities (labour) | 21 | (€/hour) | |

| Review interval of stores | 1 | (days) | |

| Inventory carrying cost on product value—store (space) | 20 | (%/year) | |

| Suppliers profile | Shipment cost from suppliers to DC | 0.2 (Conf. 1); 0.1 (Conf. 2, 3) | (€/m3 km) |

| Average distance from suppliers to DC | 100 | (km) | |

| Average pallet volume | 0.8 (Conf. 1); 1.152 (Conf. 2, 3) | (m3/pallet) | |

| Average lead time | 3 | (days) |

| Cost Category | Cost Driver | Value | Unit of Measure |

|---|---|---|---|

| Product profile | Average unit weight | 10 | (kg/unit) |

| Delivery profile | Retailer online demand to total courier hub flow ratio | 5 | (%) |

| Courier hub energy consumption | 48.5 1 | (kWh/m3 year) | |

| Average courier hub size | 125,000 | (m3) | |

| Average distance between DC and courier hub | 50 | (km) | |

| GHG emission generated from DC to courier hub | 0.077 2 | (kg CO2e/tonne km) | |

| GHG emission generated from courier hub/store to customer’s home | 0.518 2 | (kg CO2e/tonne km) | |

| Inventory management and handling activities | DC energy consumption for good storage | 145,000 (Conf. 1); 130,000 (Conf. 2, 3) | (kWh/year) |

| CO2 emission generated for good storage and handling in the DC | 0.667 3 | (kg CO2/kWh) | |

| Store profile | Store energy consumption | 13,000 | (kWh/year) |

| CO2 emission generated in store | 0.667 3 | (kg CO2/kWh) | |

| Suppliers profile | GHG emission generated from suppliers to DC | 0.129 2 (Conf. 1); 0.077 2 (Conf. 2, 3) | (kg CO2e/tonne km) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melacini, M.; Tappia, E. A Critical Comparison of Alternative Distribution Configurations in Omni-Channel Retailing in Terms of Cost and Greenhouse Gas Emissions. Sustainability 2018, 10, 307. https://doi.org/10.3390/su10020307

Melacini M, Tappia E. A Critical Comparison of Alternative Distribution Configurations in Omni-Channel Retailing in Terms of Cost and Greenhouse Gas Emissions. Sustainability. 2018; 10(2):307. https://doi.org/10.3390/su10020307

Chicago/Turabian StyleMelacini, Marco, and Elena Tappia. 2018. "A Critical Comparison of Alternative Distribution Configurations in Omni-Channel Retailing in Terms of Cost and Greenhouse Gas Emissions" Sustainability 10, no. 2: 307. https://doi.org/10.3390/su10020307