Effective Life Cycle Management in SMEs: Use of a Sector-Based Approach to Overcome Barriers

Abstract

1. Introduction

2. Life Cycle Management

2.1. The Relevance of Life Cycle Management for the New Zealand Primary Industry Sectors

2.2. Guidance on Uptake of Life Cycle Management

3. Challenges for Uptake of Environmental Management amongst Small and Medium Sized Enterprises

3.1. Defining SMEs and Their Relevance for Environmental Management Research

- In the European Union, enterprises up to 10 employees are called micro, up to 50 employees small and up to 250 employees medium-sized enterprises [60];

- In the United States, SMEs are characterised as organisations having less than 500 employees [61];

- The Ministry of Economic Development (MED) of New Zealand defines SMEs as having less than 20 employees [62].

“A small business can be defined as a business that is independently managed by the owners, who own most of the shares, provide most of the finance and make most of the principal decisions.”

3.2. Enablers and Barriers for SMEs to Implement Environmental Management

3.2.1. Owner/Manager Influence

3.2.2. Environmental Culture

3.2.3. Resource Availability

3.2.4. Strategy

3.2.5. Knowledge of Environmental Issues

3.2.6. Market Requirements

3.2.7. Geographical Separation of Production and Consumption

4. Enablers and Barriers in Supply Chain Management

4.1. Defining Supply Chain Management

- “… an integrated approach to obtaining, producing and delivering products and services to customers” [131];

- “… to synchronise the requirements of the customer with the flow of material from suppliers in order to affect a balance between what are often seen as the conflicting goals of high customer service, low inventory investment and low unit cost” (Stevens, 1989, p. 3).

- “The management of supply chain operations, resources, information and funds in order to maximize the supply chain profitability while at the same time minimising the environmental impacts and maximising the social well-being” [136];

- “Integrating environmental concerns into the inter-organisational practices of SCM including reverse logistics” (Sarkis et al., 2011, p. 3);

- “Integrating environmental thinking into supply-chain, including product design, material sourcing and selection, manufacturing processes, delivery of the final product to the consumers as well as end-of-life management of the product after its useful life” [137];

- “… the management of material, information and capital flows as well as cooperation among companies along the supply chain while integrating goals from all three dimensions of sustainable development: economic, environmental and social, which are derived from customer and stakeholder requirements. In sustainable supply chains, environmental and social criteria need to be fulfilled by the members to remain within the supply chain, while it is expected that competitiveness would be maintained through meeting customer needs and related economic criteria “(Seuring et al., 2008).

4.2. Enablers and Barriers to Uptake of Supply Chain Management

4.2.1. Resources

4.2.2. Communication/Information Sharing between Supply Chain Entities

- Have frequent contact;

- Have an open bidirectional communication;

- Maintain informal communication;

- Have different channels of communication;

- Influence the decisions of each one through the dialogue or debate.

4.2.3. Culture

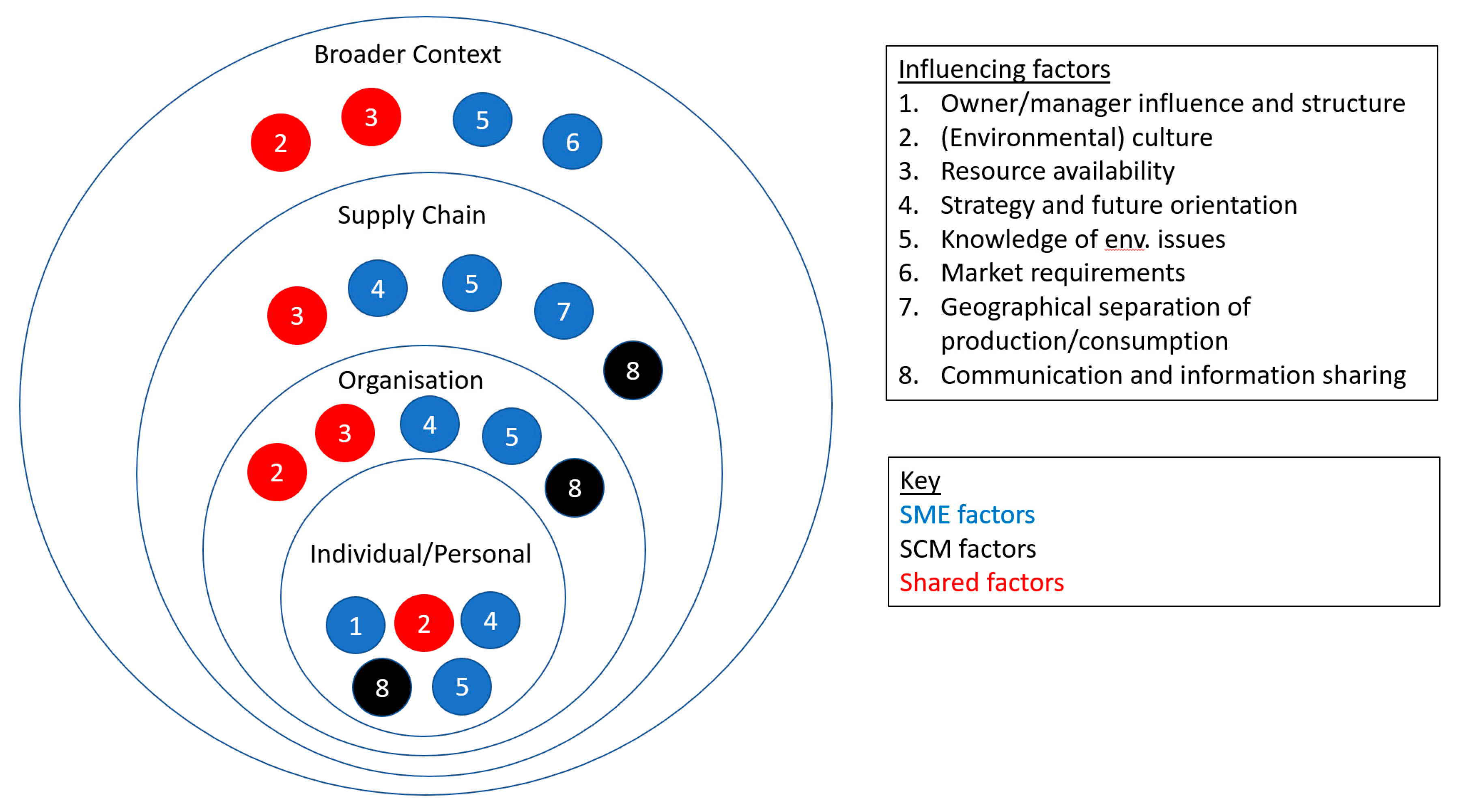

4.3. Factors Affecting Uptake of Life Cycle Management in SMEs

- SMEs: the characteristics that affect the effectiveness of environmental management (including LCM) implementation by SMEs include owner/manager influence, environmental culture, resources availability, future orientation, knowledge of environmental issues, market requirements, geographical separation of production and consumption, and awareness of own environmental impacts (Section 3.2);

- SCM: the factors that influence the effectiveness of SCM include resources, communication/information sharing between supply chain partners and culture (Section 4.2).

5. The Sector-Based Approach as a Way of Increasing the Uptake of LCM in SMEs

5.1. Defining Sector-Based LCM Approaches

5.2. Examples of Sector-Based Approaches

5.2.1. Greenhouse Gas Footprinting Strategy of the Ministry for Primary Industries (New Zealand)

5.2.2. Sustainable Winegrowing New Zealand

5.2.3. Australian Dairy Industry Sustainability Framework

5.2.4. European Plastics Sector

5.2.5. European Steel Sector

5.3. Benefits of Sector-Based Approaches to LCM

5.4. Disadvantages of Sector-Based Approaches to LCM

5.5. Summary of the Effectiveness of Using a Sector-Based Approach for LCM

6. Conclusions

Author Contributions

Conflicts of Interest

References

- World Business Council For Sustainable Development (WBCSD). COP22 Low-Emission Solutions Conference Emphasizes Need for Strong Leadership, Sound Climate Policies and Effective Economic Mechanisms. Available online: http://www.wbcsd.org/Clusters/Climate-Energy/News/Low-Emission-Solution-Conference-calls-for-strong-leadership-on-climate-change (accessed on 19 November 2016).

- World Business Council For Sustainable Development (WBCSD). Global Network Brochure. Available online: http://www.wbcsd.org/Overview/Global-Network/Resources/Global-Network-Brochure (accessed on 19 November 2016).

- World Business Council For Sustainable Development (WBCSD). Incubating Sustainable Business Growth—How to Accelerate Corporate Innovation to Drive Sustainable Business Growth. Available online: http://www.wbcsd.org/Projects/Education/Leadership-program/Resources/Incubating-sustainable-business-growth-How-to-accelerate-corporate-innovation-to-drive-sustainable-business-growth (accessed on 19 November 2016).

- United Nations Environment Programme (UNEP). Urban solutions: Making cities strong, smart, sustainable. Our Planet. 2016. Available online: https://europa.eu/capacity4dev/unep/documents/our-planet-october-2016-urban-solutions-making-cities-strong-smart-sustainable (accessed on 19 November 2017).

- United Nations Environment Programme (UNEP). Sustainable Consumption and Production. Available online: http://www.unep.org/rio20/About/SustainableConsumptionandProduction/tabid/102187/Default.aspx (accessed on 14 January 2017).

- Pure Advantage. Available online: http://pureadvantage.org/about/ (accessed on 14 January 2017).

- McLaren, S.J.; Smith, A.; Mithraratne, N.; Cleland, D.; Marquardt, M.; Frater, G.; Barber, A.; Rothmann, M. Carbon Footprinting for the Kiwifruit Supply Chain—Report on Implementation; Landcare Research: Wellington, New Zealand, 2008. [Google Scholar]

- Green Growth Advisory Group. Green Growth—Issues for New Zealand. 2011. Available online: https://www.businessnz.org.nz/__data/assets/pdf_file/0003/67863/111025-BusinessNZ-Submission-to-the-GGAG.pdf (accessed on 14 January 2017).

- Michaelis, L. The role of business in sustainable consumption. J. Clean. Prod. 2003, 11, 915–921. [Google Scholar] [CrossRef]

- Da Silva, E.; Jabbour, C.J.C.; Santos, F.C.A. Integrating environmental management and manufacturing strategy: An emerging competitive priority. Int. J. Environ. Technol. Manag. 2009, 10, 397–411. [Google Scholar] [CrossRef]

- Esty, D.; Winston, A. Green to Gold: How Smart Companies Use Environmental Strategy to Innovate, Create Value, and Build Competitive Advantage; John Wiley & Sons: New York, NY, USA, 2009. [Google Scholar]

- Johansson, G.; Winroth, M. Introducing environmental concern in manufacturing strategies: Implications for the decision criteria. Manag. Res. Rev. 2010, 33, 877–899. [Google Scholar] [CrossRef]

- Sarkis, J. Manufacturing’s role in corporate environmental sustainability-Concerns for the new millennium. Int. J. Oper. Prod. Manag. 2001, 21, 666–686. [Google Scholar] [CrossRef]

- McLaren, S.; Garnevska, E. Why Practice Life Cycle Management? Case Study of the New Zealand Wine Industry. In Proceedings of the Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector (LCA Food 2014), San Francisco, CA, USA, 8–10 October 2014; pp. 789–796. [Google Scholar]

- European Commission Environment. Being Wise with Waste: The EU’s Approach to Waste Management. 2010. Available online: http://ec.europa.eu/environment/waste/pdf/WASTE%20BROCHURE.pdf (accessed on 13 July 2017).

- European Commission Environment. Waste Stream. Available online: http://ec.europa.eu/environment/waste/index.htm (accessed on 13 July 2011).

- European Commission Environment. REACH. Available online: http://ec.europa.eu/environment/chemicals/reach/reach_intro.htm (accessed on 22 August 2011).

- European Commission Environment. Waste: End of Life Vehicles. Available online: http://ec.europa.eu/environment/waste/elv_index.htm (accessed on 22 August 2011).

- Gmelin, H.; Seuring, S. Achieving sustainable new product development by integrating product life-cycle management capabilities. Int. J. Prod. Econ. 2014, 154, 166–177. [Google Scholar] [CrossRef]

- Collins, E.; Lawrence, S.; Pavlovich, K.; Ryan, C. Business networks and the uptake of sustainability practices: The case of New Zealand. J. Clean. Prod. 2007, 15, 729–740. [Google Scholar] [CrossRef]

- Aiyub, K.; Jahi, J.; Arifin, K.; Awang, A. Environmental performance in small and medium sized enterprises (SMEs) certified to ISO 14001 in the United Kingdom. Int. Bus. Manag. 2009, 3, 7–14. [Google Scholar]

- Borga, F.; Citterio, A.; Noci, G.; Pizzurno, E. Sustainability report in small enterprises: Case studies in Italian furniture companies. Bus. Strategy Environ. 2009, 18, 162–176. [Google Scholar] [CrossRef]

- Williamson, D.; Lynch-Wood, G.; Ramsay, J. Drivers of environmental behaviour in manufacturing SMEs and the implications for CSR. J. Bus. Ethics 2006, 67, 317–330. [Google Scholar] [CrossRef]

- Klewitz, J.; Hansen, E.G. Sustainability-oriented innovation of SMEs: A systematic review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Johnson, M.P.; Schaltegger, S. Two decades of sustainability management tools for SMEs: How far have we come? J. Small Bus. Manag. 2016, 54, 481–505. [Google Scholar] [CrossRef]

- Henriques, J.; Catarino, J. Sustainable value and cleaner production–research and application in 19 Portuguese SME. J. Clean. Prod. 2015, 96, 379–386. [Google Scholar] [CrossRef]

- Hörisch, J.; Johnson, M.P.; Schaltegger, S. Implementation of Sustainability Management and Company Size: A Knowledge-Based View. Bus. Strategy Environ. 2015, 24, 765–779. [Google Scholar] [CrossRef]

- Bourlakis, M.; Maglaras, G.; Aktas, E.; Gallear, D.; Fotopoulos, C. Firm size and sustainable performance in food supply chains: Insights from Greek SMEs. Int. J. Prod. Econ. 2014, 152, 112–130. [Google Scholar] [CrossRef]

- Seidel, M. Towards Environmentally Sustainable Manufacturing: A Strategic Framework for Small and Medium sized Enterprises. Ph.D. Thesis, The University of Auckland, Auckland, New Zealand, 2011. [Google Scholar]

- Hillary, R. Small and Medium-Sized Enterprises and the Environment: Business Imperatives; Greenleaf Publishing: Santa Monica, CA, USA, 2000. [Google Scholar]

- Sterzik, H.; McLaren, S.J.; Hume, A.; Garnevska, E.; McDevitt, J.E. Challenges and enablers for successful LCM uptake in the New Zealand kiwifruit industry. In Proceedings of the 8th Life Cycle Conference, Pathways to Greening Global Markets, Sydney, Australia, 16–18 July 2013. [Google Scholar]

- Gnoth, J. Leveraging export brands through a tourism destination brand. J. Brand Manag. 2002, 9, 262–280. [Google Scholar] [CrossRef]

- Brown, G.; Stone, L. Cleaner production in New Zealand: Taking stock. J. Clean. Prod. 2007, 15, 716–728. [Google Scholar] [CrossRef]

- Stern, N. Green Growth: Opportunities for New Zealand; The University of Auckland: Auckland, New Zealand, 2012. [Google Scholar]

- Jones, G.; Mowatt, S. National image as a competitive disadvantage: The case of the New Zealand organic food industry. Bus. Hist. 2016, 58, 1262–1288. [Google Scholar] [CrossRef]

- Sustainable Business Council. Annual Snapshot 2016/17. 2017. Available online: http://www.wbcsd.org/Overview/Global-Network/News/Sustainable-Business-Council-publishes-Annual-Snapshot-2016-2017 (accessed on 5 January 2018).

- Ministry for Primary Industries. Growing Exports. Available online: https://mpi.govt.nz/exporting/overview/growing-exports/ (accessed on 8 January 2017).

- Whitman, Z.; Seville, E.; Wilson, T.; Vargo, J. The Canterbury Earthquakes: The Impact on Farming Organisations; APEC: New York, NY, USA, 2012. [Google Scholar]

- United Nations Environment Programme (UNEP). Background Report for a UNEP Guide to Life Cycle Management—A Bridge to Sustainable Products; UNEP: Paris, France, 2006. [Google Scholar]

- Collins, E.; Roper, J.; Lawrence, S. Sustainability practices: Trends in New Zealand businesses. Bus. Strategy Environ. 2010, 19, 479–494. [Google Scholar] [CrossRef]

- Collins, E.; Dickie, C.; Weber, P. New Zealand & Australia: A New Zealand and Australian Overview of Ethics and Sustainability in SMEs. In Ethics in Small and Medium Sized Enterprises; Springer: Dordrecht, The Netherlands, 2011; pp. 85–97. [Google Scholar]

- Jüttner, U.; Ziegenbein, A. Supply Chain Risk Management for Small and Medium-Sized Businesses. Supply Chain Risk: A Handbook of Assessment, Management and Performance; Springer: Dordrecht, The Netherlands, 2009. Available online: https://link.springer.com/chapter/10.1007/978-0-387-79934-6_13 (accessed on 14 January 2017).

- Saur, K.; Donato, G.; Cobas Flores, E.; Frankl, P.; Jensen, A.A.; Kituyi, E.; Lee, K.M.; Swarr, T.; Tawfic, M.; Tukker, A. Draft Final Report of the LCM Definition Study; UNEP/SETAC Life Cycle Initiative: Paris, France, 2003. [Google Scholar]

- Sonnemann, G.; Gemechu, E.D.; Remmen, A.; Frydendal, J.; Jensen, A.A. Life Cycle Management: Implementing Sustainability in Business Practice. In Life Cycle Management; Springer: Dordrecht, The Netherlands, 2015; pp. 7–21. [Google Scholar]

- Frame, B.; Newton, B. Promoting sustainability through social marketing: Examples from New Zealand. Int. J. Consum. Stud. 2007, 31, 571–581. [Google Scholar] [CrossRef]

- Sterzik, H.; McLaren, S.J.; Garnevska, E.; Hume, A. Implementation of LCM in NZ Primary Industries Using a Sector-Based Approach. In Proceedings of the 3rd New Zealand Life Cycle Thinking and Policy: Towards a Sustainable Society, Wellington, New Zealand, 2–3 September 2014. [Google Scholar]

- Bank, W. Exports of Goods and Services (% of GDP). Available online: http://data.worldbank.org/indicator/NE.EXP.GNFS.ZS (accessed on 14 January 2017).

- Paxton, A. Food Miles Report; Safe Alliance: Montreal, QC, Canada, 1994. [Google Scholar]

- Smith, A.; Watkiss, P.; Tweddle, G.; McKinnon, A.; Browne, M.; Hunt, A.; Treleven, C.; Nash, C.; Cross, S. The Validity of Food Miles as an Indicator of Sustainable Development; AEA Technology: London, UK, 2005. [Google Scholar]

- Alliance, S. The Food Miles Report: The Dangers of Long Distance Food Transport; SAFE Alliance: London, UK, 1994. [Google Scholar]

- Saunders, C.; Barber, A.; Taylor, G. Food Miles—Comparative Energy/Emissions Performance of New Zealand’s Agriculture Industry; Research Report No. 285; Lincoln University: Lincoln, UK, 2006. [Google Scholar]

- Smith, A.; Stancu, C.; McKenzie, S. Food Miles—Practical Steps for New Zealand Exporters; Landcare Research: Lincoln, New Zealand, 2006. [Google Scholar]

- McLaren, S.J. Food miles: Fact or fiction. Hatched. In The Capacity for Sustainable Development; Landcare Research: Lincoln, New Zealand, 2009; Available online: http://www.landcareresearch.co.nz/services/sustainablesoc/hatched (accessed on 5 January 2018).

- Nemecek, T.; Jungbluth, N.; i Canals, L.M.; Schenck, R. Environmental impacts of food consumption and nutrition: Where are we and what is next? Int. J. Life Cycle Assess. 2016, 21, 607–620. [Google Scholar] [CrossRef]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-food systems: A review of the challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Remmen, A. An Introduction to Life-Cycle Thinking and Management; The Danish Ministry of the Environment: Copenhagen, Denmark, 2003. Available online: https://www2.mst.dk/Udgiv/publications/2003/87-7972-458-2/html/default_eng.htm (accessed on 5 January 2018).

- Remmen, A.; Jensen, A.A.; Frydendal, J. A Business Guide to Sustainability. In Life Cycle Management; United Nations Environment Programme: Paris, France, 2007. [Google Scholar]

- International Organisation for Standardisation (ISO). ISO 14001 Environmental Management System Standard; ISO: Geneve, Switzerland, 2004. [Google Scholar]

- United Nations Environment Programme (UNEP); Society of Environmental Toxicology and Chemistry (SETAC). Life Cycle Management: A Business Guide to Sustainability; UNEP: Paris, France, 2007. [Google Scholar]

- European Commission. What Is an SME? Available online: http://ec.europa.eu/growth/smes/business-friendly-environment/sme-definition_en (accessed on 19 November 2016).

- US International Trade Commission. Small and Medium-Sized Enterprises: Overview of Participation in U.S. Exports; US International Trade Commission: Washington, DC, USA, 2010.

- Ministry of Economic Development (MED). SMEs in New Zealand: Structure and Dynamics 2011; 2011; p. 10. Available online: http://www.mbie.govt.nz/info-services/business/business-growth-and-internationalisation/documents-image-library/Structure-and-Dynamics-2011.pdf (accessed on 5 January 2018).

- Ministry of Business, Innovation & Employment. The Small Business Sector Report. Available online: http://www.mbie.govt.nz/info-services/business/business-growth-agenda/pdf-and-image-library/2014/The%20Small%20Business%20Sector%20Report%202014%20-PDF%208.8%20MB-1.pdf (accessed on 14 January 2017).

- Groundwork. Small Firms and the Environment; Groundwork Foundation: Birmingham, UK, 2005. [Google Scholar]

- Parker, C.M.; Redmond, J.; Simpson, M. A review of interventions to encourage SMEs to make environmental improvements. Environ. Plan. C Gov. Policy 2009, 27, 279–301. [Google Scholar] [CrossRef]

- Agan, Y.; Acar, M.F.; Borodin, A. Drivers of environmental processes and their impact on performance: A study of Turkish SMEs. J. Clean. Prod. 2013, 51, 23–33. [Google Scholar] [CrossRef]

- Halila, F.; Tell, J. Creating synergies between SMEs and universities for ISO 14001 certification. J. Clean. Prod. 2013, 48, 85–92. [Google Scholar] [CrossRef]

- Arvizu-Piña, V.A.; Burgos, A.C. Promoting sustainability in Mexico’s building sector via environmental product declarations. Int. J. Life Cycle Assess. 2017, 22, 1744–1759. [Google Scholar] [CrossRef]

- Schaper, M. The challenge of environmental responsibility and sustainable development: Implications for SME and entrepreneurship academics. In Radical Changes in the World: Will SMEs Soar or Crash? Füglistaller, U., Pleitner, H.J., Volery, T., Weber, W., Eds.; University of St. Gallen: St. Gallen, Switzerland, 2002; pp. 541–553. [Google Scholar]

- ECOTEC Research & Consulting Ltd. Report on SMEs and the Environment; Final Report Prepared for the European Commission; DG Environment: Luxembourg, 2000; pp. 44–48. [Google Scholar]

- Al Zaabi, S.; Al Dhaheri, N.; Diabat, A. Analysis of interaction between the barriers for the implementation of sustainable supply chain management. Int. J. Adv. Manuf. Technol. 2013, 68, 895–905. [Google Scholar] [CrossRef]

- O’Regan, N.; Ghobadian, A. The Need to Rethink Strategy in SMEs; University of Sheffield: Sheffield, UK, 1998. [Google Scholar]

- Papagiannakis, G.; Lioukas, S. Values, attitudes and perceptions of managers as predictors of corporate environmental responsiveness. J. Environ. Manag. 2012, 100, 41–51. [Google Scholar] [CrossRef] [PubMed]

- Mandl, I.; Dorr, A. CSR and Competitiveness-European SMEs’ Good Practice; Consolidated European Report; Austrian Institute for SME Research: Vienna, Austria, 2007. [Google Scholar]

- Seidel, M.; Seidel, R.; Tedford, D.; Cross, R.; Wait, L.; Haemmerle, E. Overcoming Barriers to Implementing Environmentally Benign Manufacturing Practices: Strategic Tools for SMEs. Environ. Qual. Manag. 2009, 37–55. [Google Scholar] [CrossRef]

- Giunipero, L.C.; Hooker, R.E.; Denslow, D. Purchasing and supply management sustainability: Drivers and barriers. J. Purch. Supply Manag. 2012, 18, 258–269. [Google Scholar] [CrossRef]

- Cucchiella, F.; Koh, L.; Walker, H.; Jones, N. Sustainable supply chain management across the UK private sector. Supply Chain Manag. 2012, 17, 15–28. [Google Scholar]

- Muduli, K.; Govindan, K.; Barve, A.; Geng, Y. Barriers to green supply chain management in Indian mining industries: A graph theoretic approach. J. Clean. Prod. 2013, 47, 335–344. [Google Scholar] [CrossRef]

- Massoud, M.; Tabcharani, R.; Nakkash, R.; Jamali, D. Environmental performance improvement and ISO 14001: Case of Lebanon. Environ. Impact 2012, 162, 109. [Google Scholar]

- Johnson, M.P. Sustainability Management and Small and Medium-Sized Enterprises: Managers’ Awareness and Implementation of Innovative Tools. Corp. Soc. Responsib. Environ. Manag. 2015, 22, 271–285. [Google Scholar] [CrossRef]

- Linton, R. Acculturation in Seven American Indian Tribes; Wiley: Hoboken, NJ, USA, 1963. [Google Scholar]

- Altman, I.; Chemers, M.M. Culture and Environment; CUP Archive: Cambridge, UK, 1984; Available online: https://www.cmu.edu/ARIS_3/text/text_rapoport.html (accessed on 5 January 2018).

- Schumacher, I. The endogenous formation of an environmental culture. Eur. Econ. Rev. 2015, 76, 200–221. [Google Scholar] [CrossRef]

- Thun, J.-H.; Muller, A. An empirical analysis of green supply chain management in the German automotive industry. Bus. Strategy Environ. 2010, 19, 238–248. [Google Scholar] [CrossRef]

- Stoica, M.; Florea, L.; Lukacs, E. The Effect of Organizational Culture on the Responsiveness of Small and Medium-Sized Enterprises to Environmental Change: An Empirical Study in Romania. In Challenges, Performances and Tendencies in Organisation Management; World Scientific: Singapore, 2016; pp. 289–296. Available online: http://www.worldscientific.com/doi/abs/10.1142/9789814656023_0031 (accessed on 5 January 2018).

- Boiral, O.; Baron, C.; Gunnlaugson, O. Environmental leadership and consciousness development: A Case study among Canadian SMEs. J. Bus. Ethics 2014, 123, 363–383. [Google Scholar] [CrossRef]

- Sugita, M.; Takahashi, T. Influence of corporate culture on environmental management performance: An empirical study of japanese firms. Corp. Soc. Respons. Environ. Manag. 2015, 22, 182–192. [Google Scholar] [CrossRef]

- Uhlaner, L.M.; Berent-Braun, M.M.; Jeurissen, R.J.; de Wit, G. Beyond size: Predicting engagement in environmental management practices of Dutch SMEs. J. Bus. Ethics 2012, 109, 411–429. [Google Scholar] [CrossRef]

- Abdelzaher, D.M.; Abdelzaher, A. Beyond environmental regulations: Exploring the potential of “eco-Islam” in boosting environmental ethics within SMEs in Arab markets. J. Bus. Ethics 2017, 145, 1–15. [Google Scholar] [CrossRef]

- Graafland, J.; Smid, H. Environmental impacts of SMEs and the effects of formal management tools: Evidence from EU’s largest survey. Corp. Soc. Respons. Environ. Manag. 2015. [Google Scholar] [CrossRef]

- Carrillo-Hermosilla, J.; Del Río, P.; Könnölä, T. Diversity of eco-innovations: Reflections from selected case studies. J. Clean. Prod. 2010, 18, 1073–1083. [Google Scholar] [CrossRef]

- Hillary, R. Environmental management systems and the smaller enterprise. J. Clean. Prod. 2004, 12, 561–569. [Google Scholar] [CrossRef]

- Young, G. Opportunities and Challenges Related to SME Implementation of EMSs; Sydney, Australia. 2010. Available online: http://synapsechronicles.com/wp-content/uploads/2010/05/Opportunities-and-challenges-related-to-SME-implementation-of-EMSs.pdf (accessed on 14 January 2017).

- Lewis, K.; Cassells, S. Barriers and drivers for environmental practice uptake in SMEs: A New Zealand perspective. Int. J. Bus. Stud. 2010, 18, 7. [Google Scholar]

- Comas Martí, J.M.; Seifert, R.W. Assessing the comprehensiveness of supply chain environmental strategies. Bus. Strategy Environ. 2013, 22, 339–356. [Google Scholar] [CrossRef]

- Nilsson-Lindén, H.; Baumann, H.; Rosén, M.; Diedrich, A. Organizing life cycle management in practice: Challenges of a multinational manufacturing corporation. Int. J. Life Cycle Assess. 2014, 1–15. [Google Scholar] [CrossRef]

- Cox, J.; Sarkis, J.; Wells, W. Exploring organisational recycling market development: The Texas Mexico border. In Greener Marketing: A Global Perspective on Greener Marketing Practice; Polonsky, M.J., Charter, M., Eds.; Greenleaf: Sheffield, UK, 1999; pp. 381–394. [Google Scholar]

- Min, H.; Galle, W.P. Green purchasing strategies: Trends and implications. Int. J. Purch. Mater. Manag. 1997, 33, 10–17. [Google Scholar] [CrossRef]

- Linnanen, L.; Bostrom, T.; Meittinen, P. Life Cycle Management: Integrated approach towards corporate environmental issues. Bus. Strategy Environ. 1995, 4, 117–127. [Google Scholar] [CrossRef]

- Ageron, B.; Gunasekaran, A.; Spalanzani, A. Sustainable supply management: An empirical study. Int. J. Prod. Econ. 2012, 140, 168–182. [Google Scholar] [CrossRef]

- Condon, L. Sustainability and small to medium sized enterprises: How to engage them. Aust. J. Environ. Educ. 2004, 20, 57. [Google Scholar] [CrossRef]

- Singh, H.D.B. Achieving environmental sustainability of Small and Medium Enterprises through selective supplier development programs. Int. J. Adv. Res. Manag. Soc. Sci. 2015, 4, 35–50. [Google Scholar]

- Wu, Z.; Pagell, M. Balancing priorities: Decision-making in sustainable supply chain management. J. Oper. Manag. 2011, 29, 577–590. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Pérez-Luño, A.; Saparito, P.; Gopalakrishnan, S. Small and Medium-Sized Enterprise’s Entrepreneurial versus Market Orientation and the Creation of Tacit Knowledge. J. Small Bus. Manag. 2016, 54, 262–278. [Google Scholar] [CrossRef]

- Eriksson, H.; Eriksson, H. Outcome of quality management practices: Differences among public and private, manufacturing and service, SME and large organisations. Int. J. Qual. Reliab. Manag. 2016, 33, 1394–1405. [Google Scholar] [CrossRef]

- Redmond, J.; Wolfram Cox, J.; Curtis, J.; Kirk-Brown, A.; Walker, B. Beyond business as usual: How (and why) the habit discontinuity hypothesis can inform SME engagement in environmental sustainability practices. Australas. J. Environ. Manag. 2016, 23, 426–442. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, J.W. Integrating suppliers into green product innovation development: An empirical case study in the semiconductor industry. Bus. Strategy Environ. 2011, 20, 527–538. [Google Scholar] [CrossRef]

- Murillo-Luna, J.L.; Garcés-Ayerbe, C.; Rivera-Torres, P. Barriers to the adoption of proactive environmental strategies. J. Clean. Prod. 2011, 19, 1417–1425. [Google Scholar] [CrossRef]

- Chan, E.S.; Hon, A.H.; Okumus, F.; Chan, W. An empirical study of environmental practices and employee ecological behavior in the hotel industry. J. Hosp. Tour. Res. 2014. [Google Scholar] [CrossRef]

- Sinding, K. Environmental management beyond the boundaries of the firm: Definitions and constraints. Bus. Strategy Environ. 2000, 9, 79–91. [Google Scholar] [CrossRef]

- Chan, E.S.; Okumus, F.; Chan, W. Barriers to environmental technology adoption in hotels. J. Hosp. Tour. Res. 2015. [Google Scholar] [CrossRef]

- European Commission Environment. Reviews of the Directive on the Restriction of Certain Hazardous Substances in Electrical and Electronic Equipment. Available online: http://ec.europa.eu/environment/waste/rohs_eee/events_rohs2_en.htm (accessed on 5 January 2018).

- European Chemicals Agency. REACH. Available online: https://echa.europa.eu/regulations/reach (accessed on 25 February 2017).

- Biondi, V.; Iraldo, F.; Meredith, S. Achieving sustainability through environmental innovation: The role of SMEs. Int. J. Technol. Manag. 2002, 24, 612–626. [Google Scholar] [CrossRef]

- Rutherfoord, R.; Blackburn, R.A.; Spence, L.J. Environmental management and the small firm: An international comparison. Int. J. Entrep. Behav. Res. 2000, 6, 310–326. [Google Scholar] [CrossRef]

- Hernandez-Pardo, R.J.; Bhamra, T.; Bhamra, R. Exploring SME perceptions of sustainable product service systems. IEEE Trans. Eng. Manag. 2013, 60, 483–495. [Google Scholar] [CrossRef]

- Norrman, A.; Jansson, U. Ericsson’s proactive supply chain risk management approach after a serious sub-supplier accident. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 434–456. [Google Scholar] [CrossRef]

- Kache, F.; Seuring, S. Linking collaboration and integration to risk and performance in supply chains via a review of literature reviews. Supply Chain Manag. 2014, 19, 664–682. [Google Scholar] [CrossRef]

- Arzu Akyuz, G.; Erman Erkan, T. Supply chain performance measurement: A literature review. Int. J. Prod. Res. 2010, 48, 5137–5155. [Google Scholar] [CrossRef]

- Accorsi, R.; Manzini, R.; Pini, C.; Penazzi, S. On the design of closed-loop networks for product life cycle management: Economic, environmental and geography considerations. J. Transp. Geogr. 2015, 48, 121–134. [Google Scholar] [CrossRef]

- Lewis, K.V.; Cassells, S.; Roxas, H. SMEs and the potential for a collaborative path to environmental responsibility. Bus. Strategy Environ. 2015, 24, 750–764. [Google Scholar] [CrossRef]

- Swink, M.; Narasimhan, R.; Wang, C. Managing beyond the factory walls: Effects of four types of strategic integration on manufacturing plant performance. J. Oper. Manag. 2007, 25, 148–164. [Google Scholar] [CrossRef]

- Song, M.; Di Benedetto, C.A. Supplier’s involvement and success of radical new product development in new ventures. J. Oper. Manag. 2008, 26, 1–22. [Google Scholar] [CrossRef]

- Martinsuo, M.; Ahola, T. Supplier integration in complex delivery projects: Comparison between different buyer–supplier relationships. Int. J. Proj. Manag. 2010, 28, 107–116. [Google Scholar] [CrossRef]

- Handfield, R.B.; Nichols, E.L.; Ernest, L. Introduction to Supply Chain Management; Prentice Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Christopher, M. Logistics & Supply Chain Management; Pearson: Cambridge, UK, 2016. [Google Scholar]

- Mangan, J.; Lalwani, C.; Lalwani, C.L. Global Logistics and Supply Chain Management; John Wiley & Sons: New York, NY, USA, 2016. [Google Scholar]

- Fredendall, L.D.; Hill, E. Basics of Supply Chain Management; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Gilling, R.I.; Ulmer, J.M. Major Challenges in Supply Chain Management. Insights Chang. World J. 2016, 2016, 35–49. [Google Scholar]

- Gardiner, D. Operations Management for Business Excellence; Pearson: North Shore, New Zealand, 2010. [Google Scholar]

- Green, K.; Morton, B.; New, S. Green purchasing and supply policies: Do they improve companies’ environmental performance? Supply Chain Manag. 1998, 3, 89–95. [Google Scholar] [CrossRef]

- Carter, C.R.; Kale, R.; Grimm, C.M. Environmental purchasing and firm performance: An empirical investigation. Transp. Res. Part E Logist. Transp. Rev. 2000, 36, 219–228. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Siferd, S.P. Environmental purchasing: A framework for theory development. Eur. J. Purch. Supply Manag. 2001, 7, 61–73. [Google Scholar] [CrossRef]

- Hamner, B. Effects of green purchasing strategies on supplier behaviour. In Greening the Supply Chain; Springer: Berlin, Germany, 2006; pp. 25–37. [Google Scholar]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Parody, A.; Viloria, A.; Gonzalez, F. Methodology for Measuring the Level of Collaboration in a Supply Chain by Making Surveys. 2017. Available online: http://hdl.handle.net/11323/920 (accessed on 5 January 2018).

- Wisner, J.; Tan, K.-C.; Leong, G. Principles of Supply Chain Management: A Balanced Approach; Cengage Learning: Clifton Park, NY, USA, 2015. [Google Scholar]

- Ritchie, B.; Brindley, C. Disintermediation, disintegration and risk in the SME global supply chain. Manag. Decis. 2000, 38, 575–583. [Google Scholar] [CrossRef]

- Frohlich, M.T.; Westbrook, R. Arcs of integration: An international study of supply chain strategies. J. Oper. Manag. 2001, 19, 185–200. [Google Scholar] [CrossRef]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste; FAO: Rome, Italy, 2011. [Google Scholar]

- Fiala, P. Information sharing in supply chains. Omega 2005, 33, 419–423. [Google Scholar] [CrossRef]

- Knemeyer, A.M.; Zinn, W.; Eroglu, C. Proactive planning for catastrophic events in supply chains. J. Oper. Manag. 2009, 27, 141–153. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.-H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Sharfman, M.P.; Shaft, T.M.; Anex, R.P. The road to cooperative supply-chain environmental management: Trust and uncertainty among pro-active firms. Bus. Strategy Environ. 2009, 18, 1–13. [Google Scholar] [CrossRef]

- Gold, S. Sustainable supply chain management and inter-organizational resources: A literature review. Corp. Soc. Respons. Environ. Manag. 2010, 17, 230–245. [Google Scholar] [CrossRef]

- Hoejmose, S.; Brammer, S.; Millington, A. “Green” supply chain management: The role of trust and top management in B2B and B2C markets. Ind. Mark. Manag. 2012, 41, 609–620. [Google Scholar] [CrossRef]

- Ojha, D.; Shockley, J.; Acharya, C. Supply chain organizational infrastructure for promoting entrepreneurial emphasis and innovativeness: The role of trust and learning. Int. J. Prod. Econ. 2016, 179, 212–227. [Google Scholar] [CrossRef]

- Mortimer, C. Enablers and Barriers to Adoption of Life Cycle Management; NZLCM Centre Working Paper Series; NZLCM: Palmerston North, New Zealand, 2011; Volume 1. [Google Scholar]

- Seuring, S. Supply chain management for sustainable products–insights from research applying mixed methodologies. Bus. Strategy Environ. 2011, 20, 471–484. [Google Scholar] [CrossRef]

- Landcare Research. Life Cycle Assessments Pay Dividends. Available online: http://www.landcareresearch.co.nz/publications/innovation-stories/earlier2/life-cycle-assessments-pay-dividends (accessed on 5 January 2018).

- Saunders, C.; Barber, A. Food Miles—Comparative Energy/Emissions Performance of New Zealand’s Agriculture Industry; Lincoln University: Lincoln, UK, 2006. [Google Scholar]

- Mithraratne, N.; McLaren, S.J.; Barber, A. Carbon Footprinting for the Kiwifruit Supply Chain—Report on Methodology and Scoping Study. 2008. Available online: https://www.landcareresearch.co.nz/publications/researchpubs/Kiwifruit_Methodology_Report_2010.pdf (accessed on 5 January 2018).

- Hume, A.; Barber, A.; East, A.; McLaren, S.J.; Deurer, M.; Clothier, B.; Palmer, J. Carbon Footprinting for the Apple Supply Chain: Methodology and Scoping Study. 2009. Available online: https://www.landcareresearch.co.nz/publications/researchpubs/Apple_Summary_Report.pdf (accessed on 5 January 2018).

- Greenhalgh, S.; Mithraratne, N.; Sinclair, R.; Smith, A.; McConachy, E.; Barber, A. GHG Product Account Guidelines for the Wine Industry; Ministry of Agriculture and Forestry: Wellington, New Zealand, 2011.

- Hume, A.; Coelho, C. Assessment of the Water Footprint of Fresh Kiwifruit—Methods and Scoping Report. 2010. Available online: http://www.lcanz.org.nz/sites/default/files/17/assessment_of_the_water_footprint_of_fresh_kiwifruit_methods_and_scoping....pdf (accessed on 5 January 2018).

- NZ Wine. Sustainable Winegrowing. Available online: http://www.nzwine.com/sustainability/towards-100-sustainability-1/ (accessed on 5 January 2018).

- Garnevska, E.; McLaren, S.; Hiroki, S. Yealands Wine Group: Balancing Business and Sustainability. Int. Food Agribus. Manag. Rev. 2014, 17, 237. [Google Scholar]

- Marshall, R.S.; Akoorie, M.E.; Hamann, R.; Sinha, P. Environmental practices in the wine industry: An empirical application of the theory of reasoned action and stakeholder theory in the United States and New Zealand. J. World Bus. 2010, 45, 405–414. [Google Scholar] [CrossRef]

- Hughey, K.F.; Tait, S.V.; O’Connell, M.J. Qualitative evaluation of three ‘environmental management systems’ in the New Zealand wine industry. J. Clean. Prod. 2005, 13, 1175–1187. [Google Scholar] [CrossRef]

- Dairy Australia. Australian Dairy Industry. Dairy Australia, 2014. Available online: https://www.dairyaustralia.com.au/about-dairy-australia/about-the-industry (accessed on 25 January 2018).

- Dairy Australia. Australian Dairy Industry Sustainability Framework. Available online: http://www.dairyaustralia.com.au/Industry-information/Sustainability/Industry-sustainability.aspx (accessed on 21 January 2017).

- Dairy Sustainability Framework. What Is the Dairy Sustainability Framework. Available online: https://www.youtube.com/watch?v=AyobvGsZmW8 (accessed on 21 January 2017).

- PlasticsEurope. Life Cycle Thinking. Available online: http://www.plasticseurope.org/plasticssustainability/life-cycle-thinking-1746.aspx (accessed on 5 January 2018).

- Sustainable Steel. Overview. Available online: https://www.steel-sustainability.org/esust (accessed on 5 January 2018).

- Schmidt, J.; Helme, N.; Lee, J.; Houdashelt, M. Sector-based approach to the post-2012 climate change policy architecture. Clim. Policy 2008, 8, 494–515. [Google Scholar] [CrossRef]

- Luckman, P. Sustainability Branding for the New Zealand Wool Industry—A Farmer-Led Approach; Creative Decisions Ltd.: London, UK, 2012. [Google Scholar]

- Bradley, R.; Baumert, K.A.; Childs, B.; Herzog, T.; Pershing, J. Slicing the Pie: Sector-Based Approaches to International Climate Agreements; World Resources Institute: Washington, DC, USA, 2007; pp. 1–7. [Google Scholar]

- Yealands Family Wines. Sustainability Awards. Available online: http://www.yealands.co.nz/pages/yealands-estate/sustainability-awards (accessed on 5 January 2018).

- Villa Maria. Most Awarded Winery. Available online: http://www.villamaria.co.nz/about/awards (accessed on 5 January 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seidel-Sterzik, H.; McLaren, S.; Garnevska, E. Effective Life Cycle Management in SMEs: Use of a Sector-Based Approach to Overcome Barriers. Sustainability 2018, 10, 359. https://doi.org/10.3390/su10020359

Seidel-Sterzik H, McLaren S, Garnevska E. Effective Life Cycle Management in SMEs: Use of a Sector-Based Approach to Overcome Barriers. Sustainability. 2018; 10(2):359. https://doi.org/10.3390/su10020359

Chicago/Turabian StyleSeidel-Sterzik, Helene, Sarah McLaren, and Elena Garnevska. 2018. "Effective Life Cycle Management in SMEs: Use of a Sector-Based Approach to Overcome Barriers" Sustainability 10, no. 2: 359. https://doi.org/10.3390/su10020359

APA StyleSeidel-Sterzik, H., McLaren, S., & Garnevska, E. (2018). Effective Life Cycle Management in SMEs: Use of a Sector-Based Approach to Overcome Barriers. Sustainability, 10(2), 359. https://doi.org/10.3390/su10020359