Energy Recovery from the Organic Fraction of Municipal Solid Waste: A Real Options-Based Facility Assessment

Abstract

:1. Introduction

2. Anaerobic Digestion Technologies of OFMSW

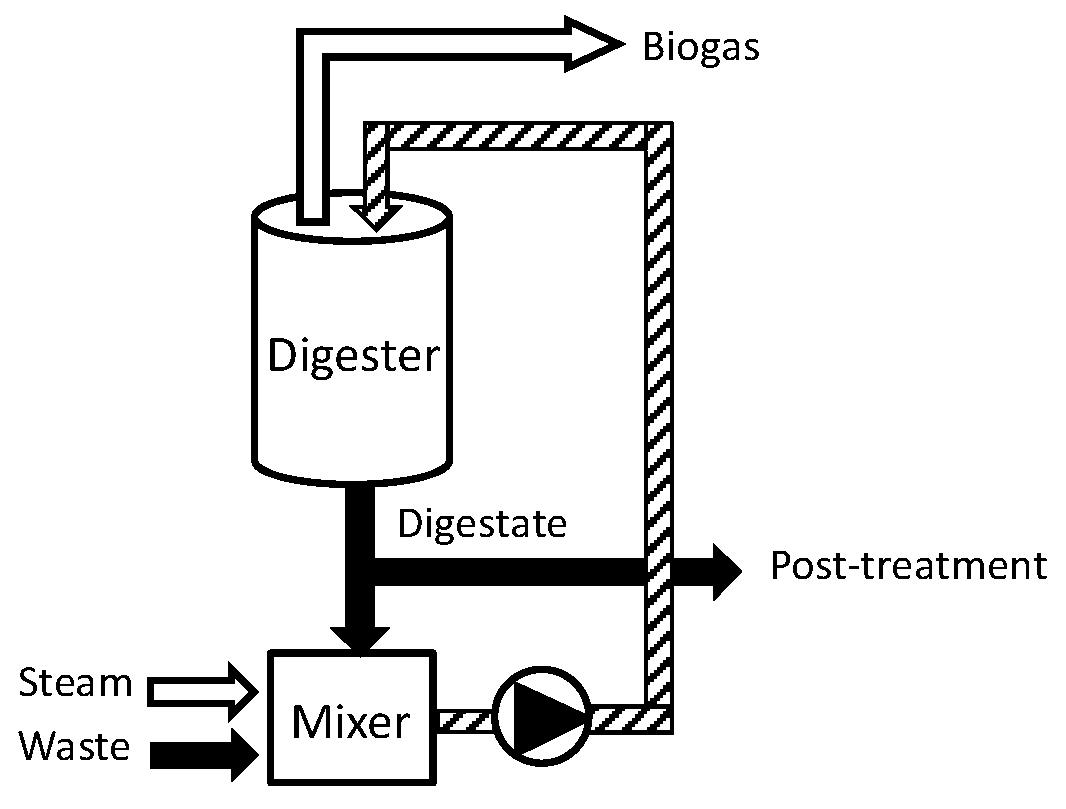

2.1. Continuous Processes

- Organic fraction is pre-treated to reduce its size (d < 40 (mm)).

- Pre-treated organic fraction is mixed with a small amount of steam and a large amount of digested residue coming from the digester.

- The mixture is pre-heated and pumped to the top of the digester.

- Depending on the feeding rate, the mixture takes from two to four days to reach the bottom of the digester; meanwhile, biogas obtained rises and exits from the digester through the roof and floes to the gas storage.

- The digested residue is extracted from the bottom of the digester by means of screws hanging underneath the conical outlet and is sent to further composting or is used as organic compost.

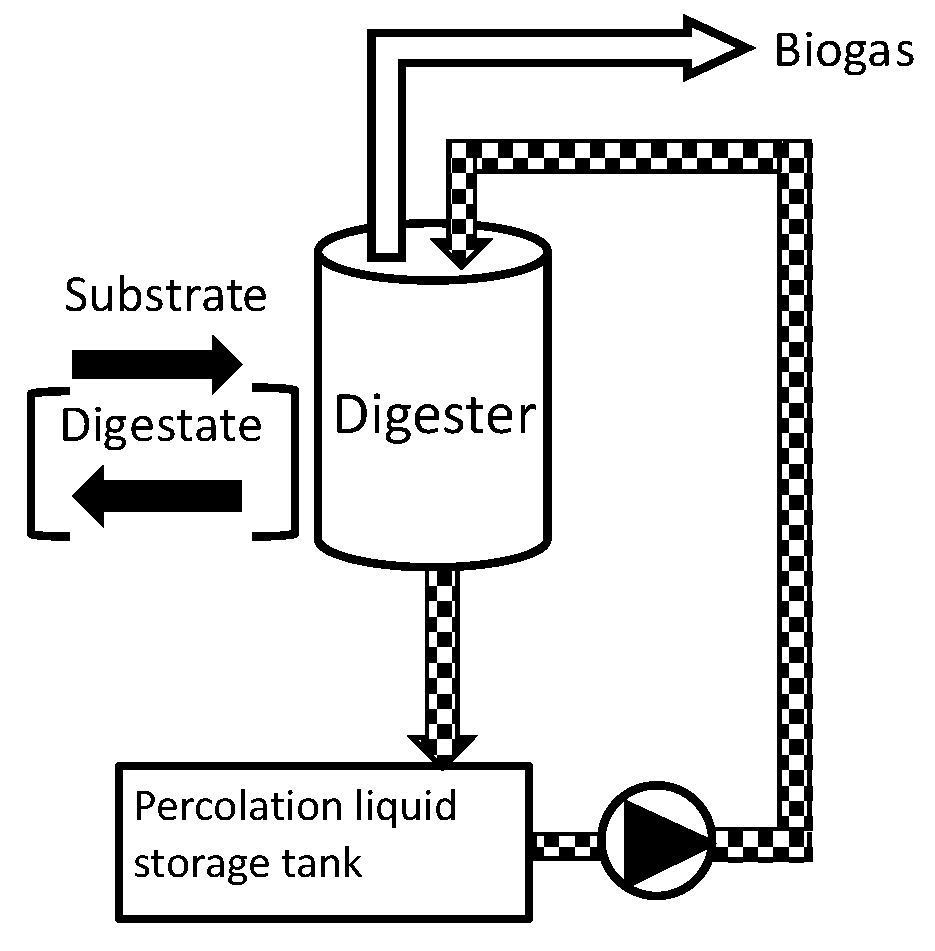

2.2. Batch Processes

- Organic matter, or bio-waste, is loaded in the reactor with a substratum already fermented.

- Percolation liquid is collected and then re-sprayed over the biomass in the digester.

- The produced biogas is pumped into a combined heat and power unit (endothermic engine).

- Once the fermentation process is completed, the digesters are emptied and the digested residue either undergoes further composting or is used as organic compost.

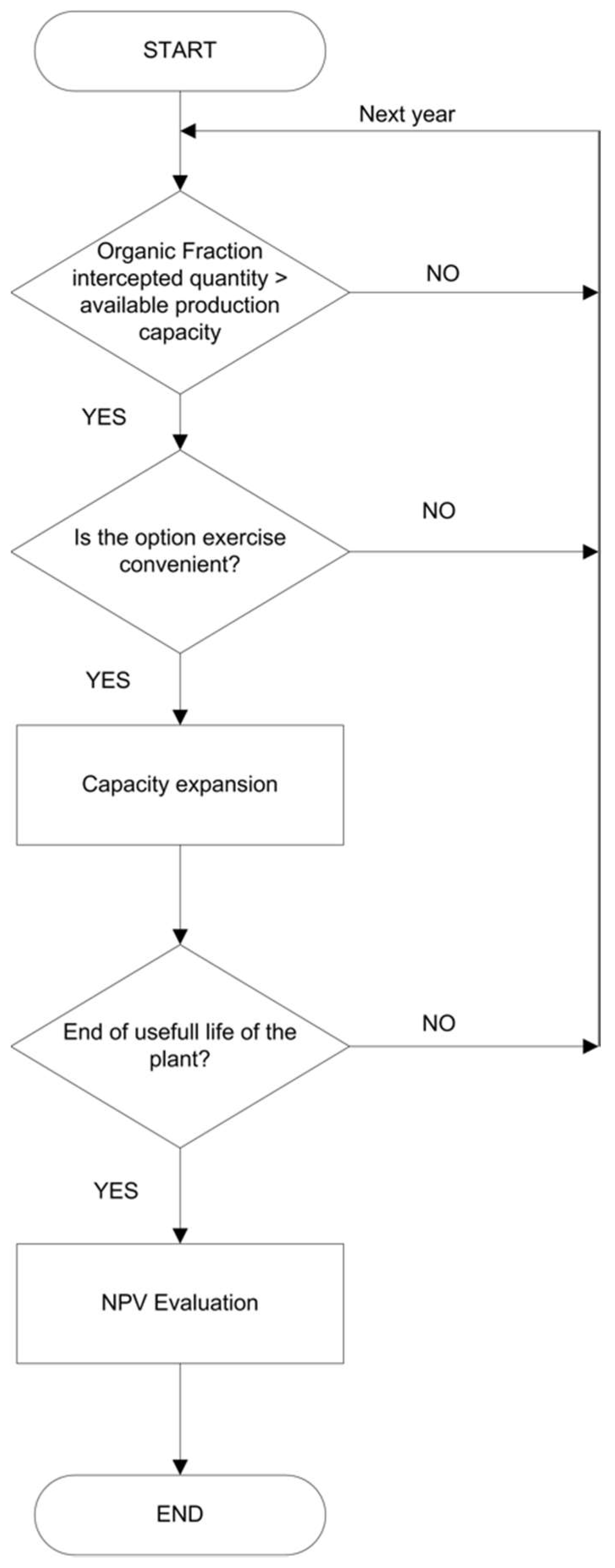

3. The Evaluation Model

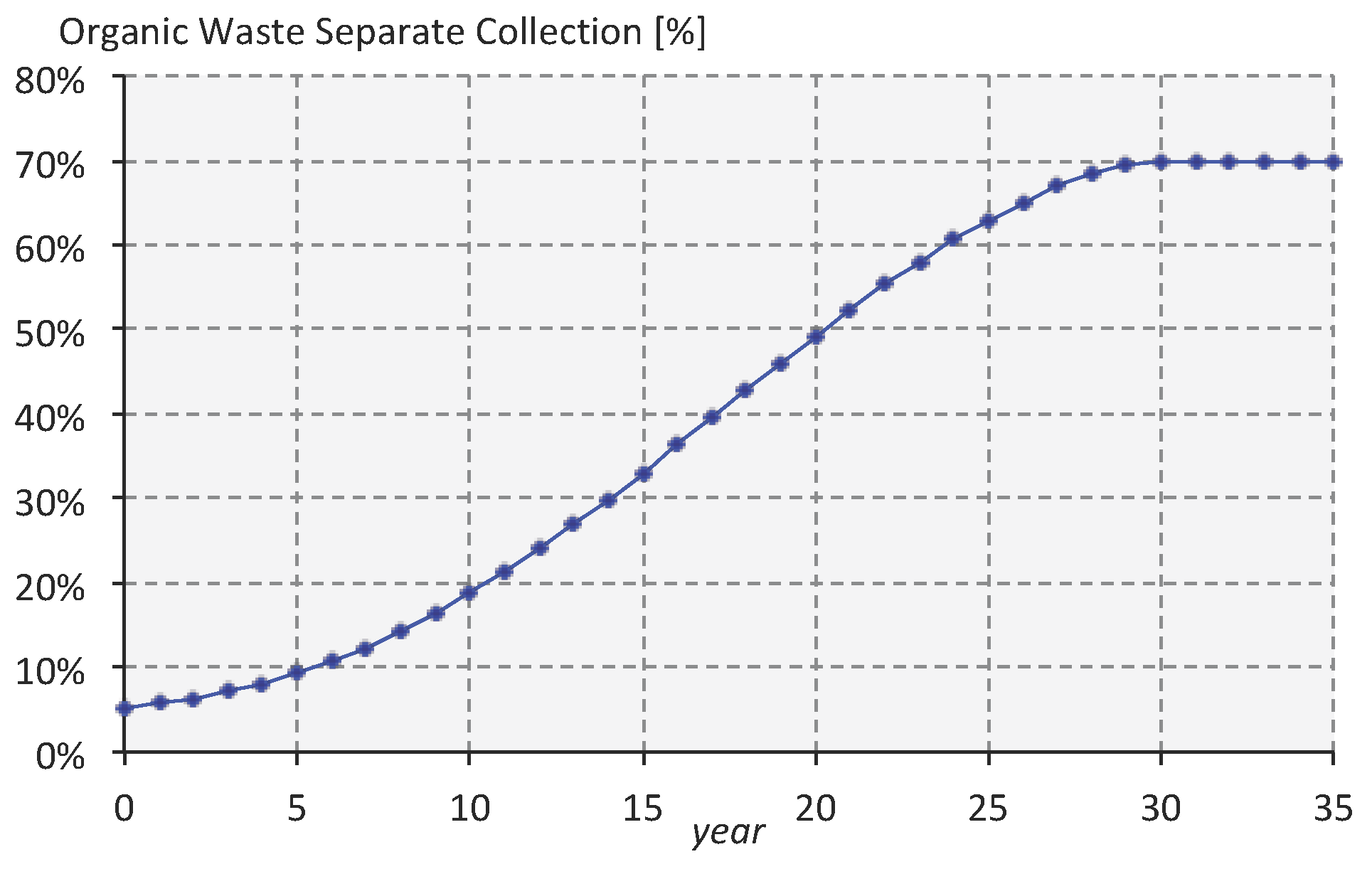

4. The Case Study

5. Conclusions

6. Limitations and Further Research

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Digiesi, S.; Mascolo, G.; Mossa, G.; Mummolo, G. New Models for Sustainable Logistics: Internalization of External Costs in Inventory Management; Springer Brief in Operations Management; Springer: Cham, Switzerland, 2016; ISBN 978-3-319-19709-8. [Google Scholar]

- Carli, R.; Dotoli, M.; Pellegrino, R.; Ranieri, L. Using multi-objective optimization for the integrated energy efficiency improvement of a smart city public buildings’ portfolio. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering, Gothenburg, Sweden, 24–28 August 2015; pp. 21–26. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Mummolo, G.; Ranieri, L. A mixed integer linear programming model for optimisation of organics management in an integrated solid waste system. J. Environ. Plan. Manag. 2008, 51, 833–845. [Google Scholar] [CrossRef]

- Carli, R.; Dotoli, M.; Pellegrino, R.; Ranieri, L. Measuring and managing the smartness of cities: A framework for classifying performance indicators. In Proceedings of the 2013 IEEE International Conference on Systems, Man and Cybernetics (SMC 2013), Manchester, UK, 13–16 October 2013; pp. 1288–1293. [Google Scholar] [CrossRef]

- The World Bank. What a Waste: A Global Review of Solid Waste Management; The Urban Development Series Knowledge Papers; The World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Al Seadi, T.; Lukehurst, C. Quality Management of Digestate from Biogas Plants Used as Fertilizer. IEA Bioenergy Task 37 Energy from Biogas Report. 2012. Available online: https://www.iea-biogas.net/files/daten-redaktion/download/publi-task37/digestate_quality_web_new.pdf (accessed on the 30 January 2018).

- Quested, T.; Hannah, J. Household Food and Drink Waste in the UK; Waste and Resources Action Programme (WRAP): Banbury, UK, 2009; ISBN 1-84405-430-6. Available online: http://www.wrap.org.uk/sites/files/wrap/Household_food_and_drink_waste_in_the_UK_-_report.pdf (accessed on the 30 January 2018).

- Browne, J.D.; Murphy, J.D. Assessment of the resource associated with biomethane from food waste. Appl. Energy 2013, 104, 170–177. [Google Scholar] [CrossRef]

- Fdez.-Güelfo, L.A.; Álvarez-Gallego, C.; Sales, D.; Romero García, L.I. Determination of critical and optimum conditions for biomethanization of OFMSW in a semi-continuous stirred tank reactor. Chem. Eng. J. 2011, 171, 418–424. [Google Scholar] [CrossRef]

- Themelis, N.J.; Ulloa, P.A. Methane generation in landfills. Renew. Energy 2007, 32, 1243–1257. [Google Scholar] [CrossRef]

- Li, S.; Yoo, H.K.; Macauley, M.; Palmer, K.; Shih, J.S. Assessing the role of renewable energy policies in landfill gas to energy projects. Energy Econ. 2015, 49, 687–697. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Macé, S.; Llabrés, P. Anaerobic digestion of organic solid waste. An overview of research achievements and perspectives. Bioresour. Technol. 2000, 74, 3–16. [Google Scholar] [CrossRef]

- California Environmental Protection Agency (CEPA). Current Anaerobic Digestion Technologies Used for Treatment of Municipal Organic Solid Waste. California Environmental Protection Agency. Available online: http://www.calrecycle.ca.gov/Publications/Documents/1275/2008011.pdf (accessed on the 14 October 2017).

- Barth, J. Markets for compost and digestate in Europe—Situation, requirements, future development. In Proceedings of the III Conferenza Internazionale sul Trattamento Biologico, Perugia, Italy, 15–16 April 2010. [Google Scholar]

- Digiesi, S.; Massaro, V.; Mossa, G.; Ranieri, L. The sustainability of anaerobic digestion plants: A win-win strategy for public and private bodies. J. Clean. Prod. 2015, 104, 445–459. [Google Scholar] [CrossRef]

- Caponio, G.; Digiesi, S.; Mossa, G.; Mummolo, G. Economic and environmental savings from upgraded biogas applications. In Proceedings of the XVIII Summer School “F. Turco”, Seigallia, Italy, 11–13 September 2013; ISBN 978-88-908649-0-2. [Google Scholar]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Zhenhong, Y.; Yongming, S. Semi-dry mesophilic anaerobic digestion of water sorted organic fraction of municipal solid waste (WS-OFMSW). Bioresour. Technol. 2010, 101, 2722–2728. [Google Scholar] [CrossRef] [PubMed]

- Walter, A.; Probst, M.; Hinterberger, S.; Müller, H.; Insam, H. Biotic and abiotic dynamics of a high solid-state anaerobic digestion box-type container system. Waste Manag. 2016, 49, 26–35. [Google Scholar] [CrossRef] [PubMed]

- Fisgativa, H.; Tremier, A.; Dabert, P. Characterizing the variability of food waste quality: A need for efficient valorisation through anaerobic digestion. Waste Manag. 2016, 50, 264–274. [Google Scholar] [CrossRef] [PubMed]

- Suwannarat, J.; Ritchie, R.J. Anaerobic digestion of food waste using yeast. Waste Manag. 2015, 42, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Nielfa, A.; Cano, R.; Fdz-Polanco, M. Theoretical methane production generated by the co-digestion of organic fraction municipal solid waste and biological sludge. Biotechnol. Rep. 2015, 5, 14–21. [Google Scholar] [CrossRef] [PubMed]

- Agyeman, F.O.; Tao, W. Anaerobic co-digestion of food waste and dairy manure: Effects of food waste particle size and organic loading rate. J. Environ. Manag. 2014, 133, 268–274. [Google Scholar] [CrossRef] [PubMed]

- Angelidaki, I.; Chen, X.; Cui, J.; Kaparaju, P.; Ellegaard, L. Thermophilic anaerobic digestion of source-sorted organic fraction of household municipal solid waste: Start-up procedure for continuously stirred tank reactor. Water Res. 2006, 40, 2621–2628. [Google Scholar] [CrossRef] [PubMed]

- Kusch, S. Understanding and management the start-up phase in dry anaerobic digestion. In Proceedings in Research Conference in Technical Disciplines; Publishing Institution of the University of Zilina: Zilina, Slovakia, 2013; Volume 1, pp. 26–30. ISBN 978-80-554-0807-1. [Google Scholar]

- Fernández, J.; Pérez, M.; Romero, L.I. Kinetics of mesophilic anaerobic digestion of the organic fraction of municipal solid waste: Influence of initial total solid concentration. Bioresour. Technol. 2010, 101, 6322–6328. [Google Scholar] [CrossRef] [PubMed]

- Carbonara, N.; Pellegrino, R. Public-private partnerships for energy efficiency projects: A win-win model to choose the energy performance contracting structure. J. Clean. Prod. 2018, 170, 1064–1075. [Google Scholar] [CrossRef]

- Kumar, R.L. An options view of investments in expansion-flexible manufacturing systems. Int. J. Prod. Econ. 1995, 38, 281–291. [Google Scholar] [CrossRef]

- Karsak, E.E.; Ozogul, C.O. Valuation of expansion flexibility in flexible manufacturing system investments using sequential exchange options. Int. J. Syst. Sci. 2005, 36, 243–253. [Google Scholar] [CrossRef]

- Agenzia Nazionale per la Protezione dell’Ambiente (ANPA). Il Trattamento Anaerobico dei Rifiuti—Aspetti Progettuali e Gestionali; Manuali e Linee Guida; ANPA: Roma, Italy, 2002; ISBN 88-448-0053-5. [Google Scholar]

- Murphy, J.D.; McKeogh, E. Technical, economic and environmental analysis of energy production from municipal solid waste. Renew. Energy 2004, 29, 1043–1057. [Google Scholar] [CrossRef]

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The anaerobic digestion of solid organic waste. Waste Manag. 2011, 31, 1737–1744. [Google Scholar] [CrossRef] [PubMed]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimization of the anaerobic digestion of agricultural resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef] [PubMed]

- Kusch, S.; Schäfer, W.; Kranert, M. Dry digestion of organic residues. In Integrated Waste Management—Volume I; Kumar, S., Ed.; InTech: Rijeka, Croatia, 2000; ISBN 978-953-307-469-6. [Google Scholar]

- Mata-Alvarez, J. (Ed.) Biomethanization of the Organic Fraction of Municipal Solid Wastes; IWA Publishing: London, UK, 2003; ISBN 1900222140. [Google Scholar]

- De Baere, L. Will anaerobic digestion of solid waste survive in the future? Water Sci. Technol. 2006, 53, 187–194. [Google Scholar] [CrossRef] [PubMed]

- Spendlin, H.-H.; Stegmann, R. Anaerobic fermentation of the vegeable, fruit, and yard waste. In Proceedings of the 5th International Solid Wastes Conference, Copenhagen, Denmark, 11–16 September 1988; Academic Press: London, UK, 1988; Volume 2, pp. 25–31. [Google Scholar]

- Baeten, D.; Verstraete, W. In-reactor anaerobic digestion of MSW-organics. In Science and Engineering of Composting: Design, Environmental, Microbiological and Utilization Aspects; Hoitink, H.A.J., Keener, H.M., Eds.; Renaissance Publications: Worthington, OH, USA, 1993; pp. 111–129. [Google Scholar]

- Oleszkiewicz, J.A.; Poggi-Varaldo, H.M. High-solids anaerobic digestion of mixed municipal and industrial wastes. J. Environ. Eng. 1997, 123, 1087–1092. [Google Scholar] [CrossRef]

- Kraft, E. Trockenfermentation—Brücke zwischen abfallbehandlung und landwirtschaft? In Gülzower Fachgespräche 23, Gülzower Fachgespräch “Trockenfermentation”; Fachagentur Nachwachsende Rohstoffe e.V. (FNR): Gülzow, Germany, 2004; pp. 81–95. [Google Scholar]

- De Baere, L. The Dranco Technology: A Unique Digestion Technology for Solid Organic Waste; Organic Waste Systems (OWS): Brussels, Beligium, 2010. [Google Scholar]

- Nizami, A.S.; Murphy, J.D. What type of digester configurations should be employed to produce biomethane from grass silage? Renew. Sustain. Energy Rev. 2010, 14, 1558–1568. [Google Scholar] [CrossRef]

- Dixit, A.K.; Pindyck, R.S. The Options Approach to Capital Investment. Harv. Bus. Rev. 1995, 73, 105–118. [Google Scholar]

- Black, F.; Scholes, M. The pricing of options figureand corporate liabilities. J. Political Econ. 1973, 81, 637–654. [Google Scholar] [CrossRef]

- Cox, J.C.; Ross, S.A.; Rubinstein, M. Option pricing: A simplified approach. J. Financ. Econ. 1979, 7, 229–263. [Google Scholar] [CrossRef]

- Boyle, P.P. Options: A Monte Carlo Approach. J. Financ. Econ. 1977, 4, 323–338. [Google Scholar] [CrossRef]

- Lander, D.M.; Pinches, G.E. Challenges to the Practical Implementation of Modelling and Valuing Real Options. Q. Rev. Econ. Financ. 1998, 38, 537–567. [Google Scholar] [CrossRef]

- De Neufville, R.; Scholtes, S.; Wang, T. Real options by spreadsheet: Parking garage case example. J. Infrastruct. Syst. 2006, 12, 107–111. [Google Scholar] [CrossRef]

- Istituto Superiore per la Protezione e la Ricerca Ambientale (ISPRA). Rapporto Rifiuti Urbani—Edizione 2009; ISPRA: Roma, Italy, 2009; ISBN 978-88-448-0430-5. [Google Scholar]

| Criteria | Advantages | Disadvantages |

|---|---|---|

| Technological | - No need of mixers inside the reactor; - Strength and resistance to heavy inert materials and plastic; - No hydraulic short circulation. | Waste with low content of solid substance (<20% TS) cannot be treated alone. |

| Biological | - Low loss of biodegradable organic matter in the pre-treatment; - High Organic Loading Rate (OLR) applicable; - Resistance at peak concentrations of substrate or toxic substances. | Minimum possibility of diluting inhibitory substances and excessive organic loads with fresh water. |

| Environmental and economical | - Minimum and economic pre-treatment; - Reduced volumes of the reactors; - Reduced use of fresh water; - Minimum reactor heating request. | High investment costs due to equipment used for treatment. |

| Municipalities | Population | MSW (t/y) | Separate Collection 2008 | Separate Collection 2009 |

|---|---|---|---|---|

| 9 | 497,593 | 287,000 | 16.1% | 17.6% |

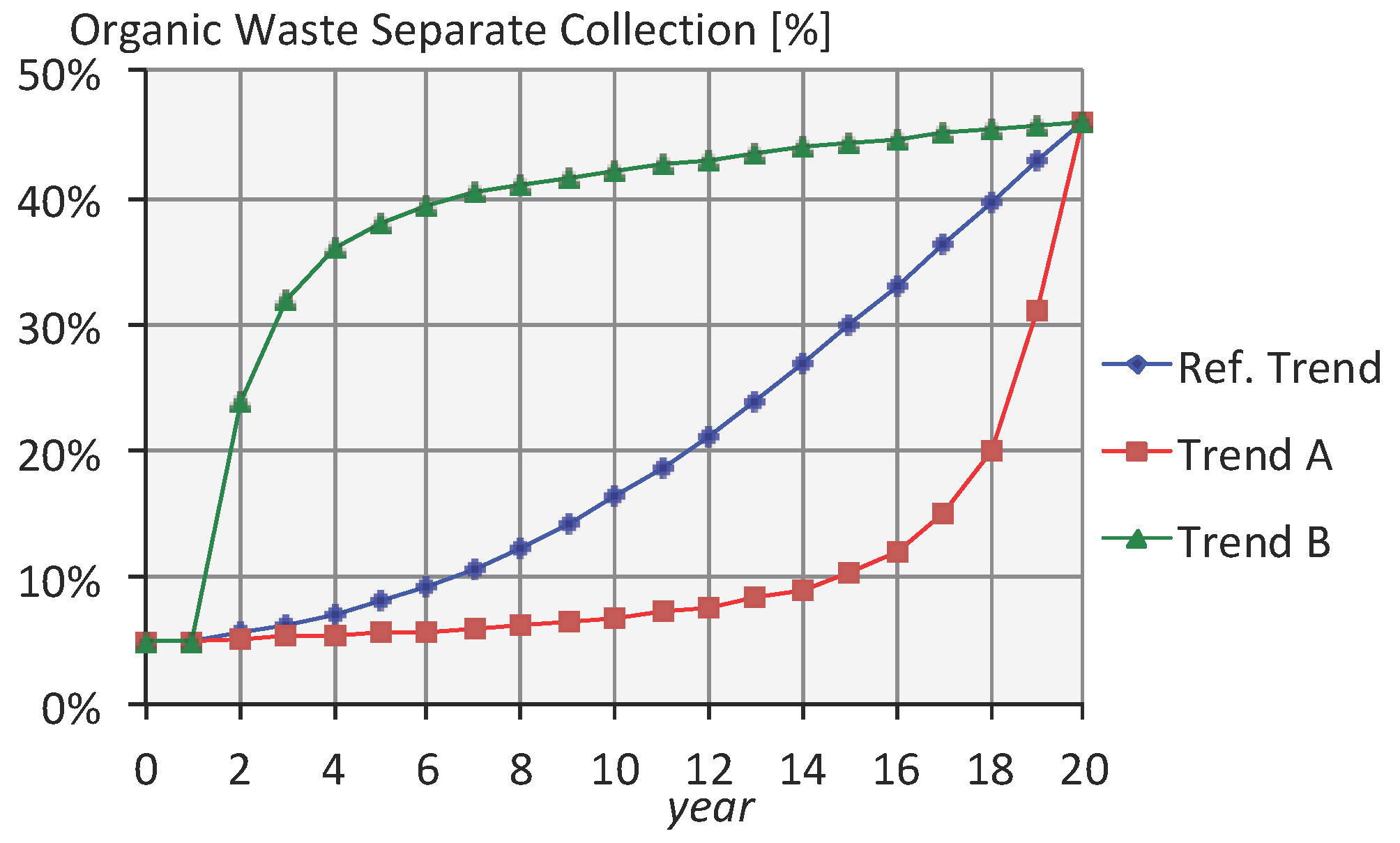

| Category | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| OFMSW collection rate | <10% | 10–20% | 20–30% | >30% |

| Occurrences (#) | 73 | 25 | 10 | 6 |

| OFMSW collection rate increase: | ||||

| Mean | 0.8% | 2.1% | 3.6% | 2.9% |

| StDev | 2.4% | 3.9% | 4.0% | 2.2% |

| Parameter | Value | Unit |

|---|---|---|

| Probabilistic Parameters | ||

| Pg (Bekon) | Uniform (240,530) | m3 of biogas/t of volatile solids |

| Pg (Dranco) | Uniform (550,780) | m3 of biogas/t of volatile solids |

| Correlation coefficient biogas production in Dranco and Bekon | 0.8 | - |

| Deterministic Parameters | ||

| Useful life of the plant | 20 | Years |

| Biogas methane concentration | 60 | % (in volume) |

| Biogas burned in security torch | 10 | % (in volume) |

| Engine-generator electrical efficiency | 40 | % |

| Treatment and post treatment (composting) electricity consumption | 18 (Bekon); 128 (Dranco) | kWh/t of OFMSW |

| Parameter | Value | Unit |

|---|---|---|

| Common data | ||

| pOF | 40 | €/t |

| pe | 0.08 | €/kWh |

| pINC | 0.088 | €/kWh |

| Bekon data | ||

| copB | 35 | €/t |

| ΔCexpminB | 2500 | t |

| Investment for ΔCexpminB | 976.19 | k€ |

| Dranco data | ||

| copD | 20 | €/t |

| CPmaxD | 50,000 | t/year |

| Initial investment | 20,000 | k€ |

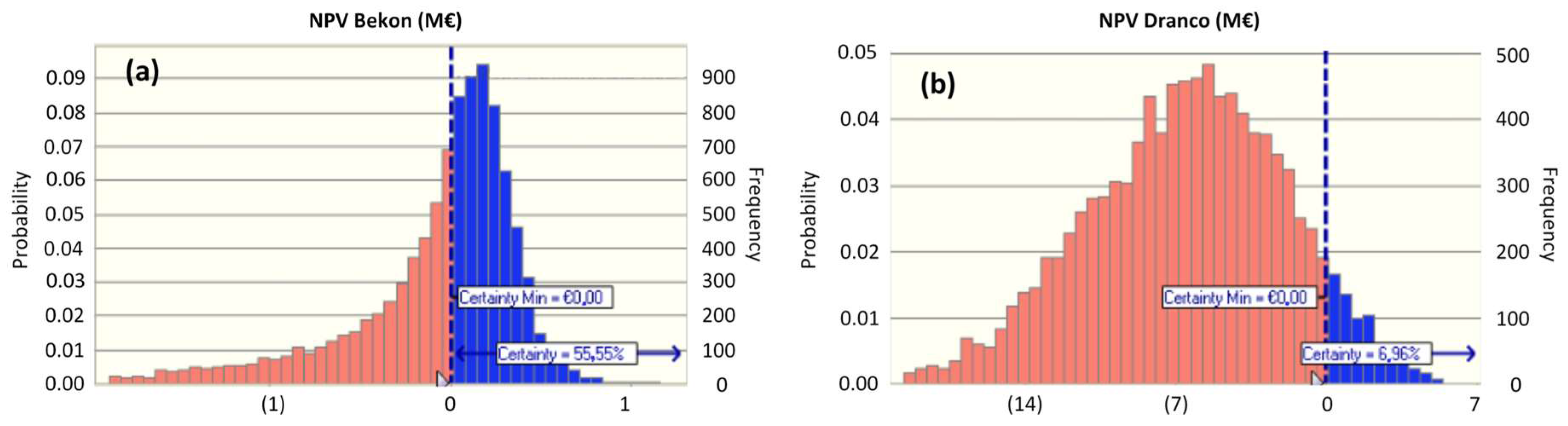

| Parameter | Bekon (a) | Dranco (b) |

|---|---|---|

| Mean | −131 | −6592 |

| Median | 44 | −6304 |

| StDev | 626 | 4679 |

| Minimum | −10,103 | −32,959 |

| Maximum | 1220 | 8084 |

| Technology | Mean (k€) | Median (k€) | StDev (k€) | Min (k€) | Max (k€) | Prob (NPV > 0) | |

|---|---|---|---|---|---|---|---|

| Trend A | Bekon | −750 | −295 | 1200 | −8412 | 1085 | 34.00% |

| Dranco | −13,089 | −13,068 | 4430 | −29,401 | 2945 | 0.12% | |

| Reference Scenario | Bekon | −131 | 44 | 626 | −10,103 | 1220 | 55.55% |

| Dranco | −6592 | −6304 | 4680 | −32,959 | 8084 | 6.96% | |

| Trend B | Bekon | 595 | 520 | 597 | −1613 | 3180 | 87.88% |

| Dranco | 11,470 | 12,301 | 3303 | −5625 | 17,287 | 100% |

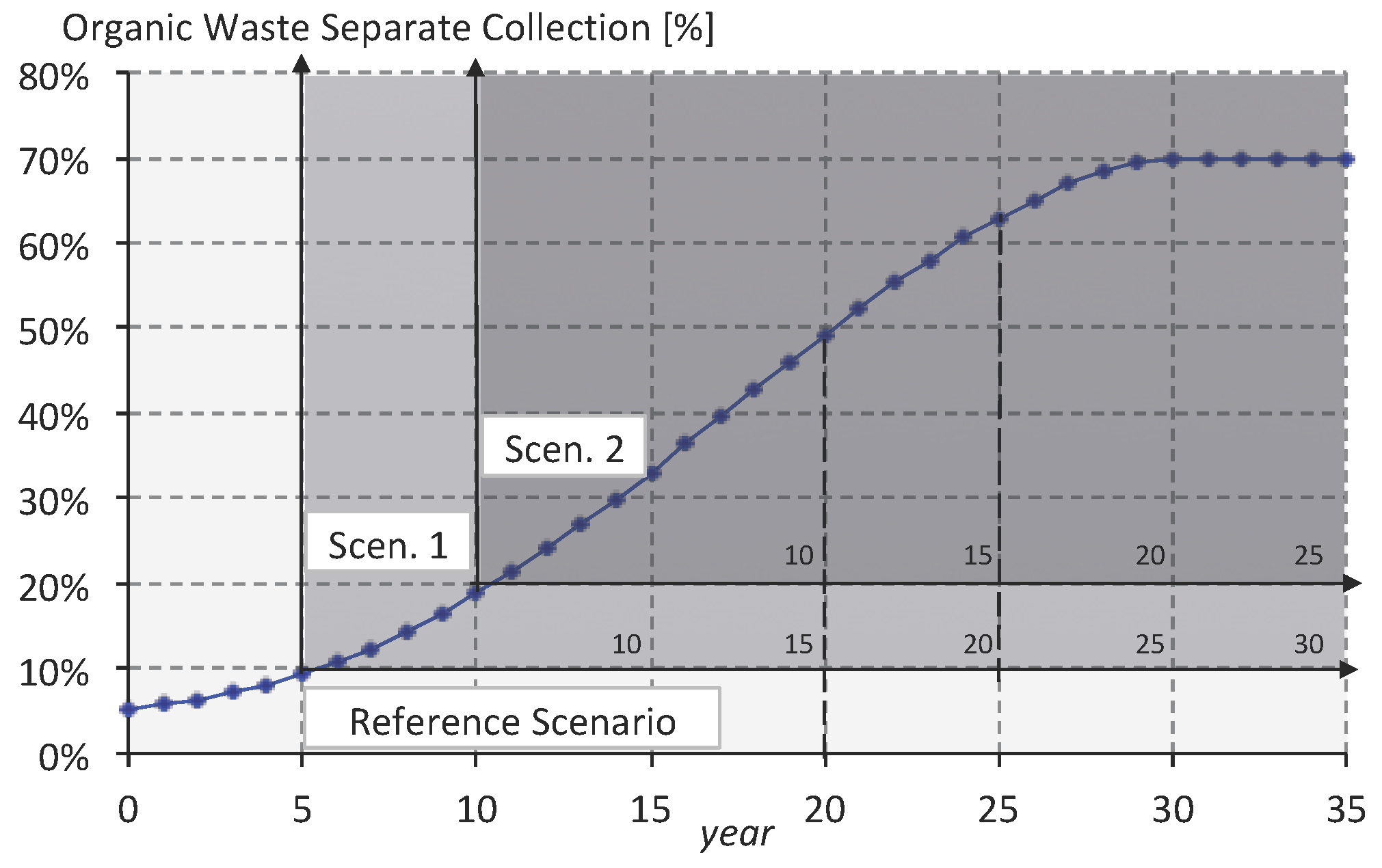

| Technology | Mean (€) | Median | StDev (k€) | Min (k€) | Max (k€) | Prob (NPV > 0) | |

|---|---|---|---|---|---|---|---|

| Reference Scenario | Bekon | −131 | 44 | 626 | −10,103 | 1220 | 55.55% |

| Dranco | −6592 | −6304 | 4680 | −32,959 | 8084 | 6.96% | |

| Scenario 1 | Bekon | 199 | 257 | 457 | −4783 | 1849 | 78.59% |

| Dranco | −123 | 366 | 4949 | −20,678 | 11,739 | 52.75% | |

| Scenario 2 | Bekon | 703 | 694 | 557 | −3533 | 3390 | 91.71% |

| Dranco | 9164 | 9779 | 3800 | −11,796 | 17,115 | 97.48% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ranieri, L.; Mossa, G.; Pellegrino, R.; Digiesi, S. Energy Recovery from the Organic Fraction of Municipal Solid Waste: A Real Options-Based Facility Assessment. Sustainability 2018, 10, 368. https://doi.org/10.3390/su10020368

Ranieri L, Mossa G, Pellegrino R, Digiesi S. Energy Recovery from the Organic Fraction of Municipal Solid Waste: A Real Options-Based Facility Assessment. Sustainability. 2018; 10(2):368. https://doi.org/10.3390/su10020368

Chicago/Turabian StyleRanieri, Luigi, Giorgio Mossa, Roberta Pellegrino, and Salvatore Digiesi. 2018. "Energy Recovery from the Organic Fraction of Municipal Solid Waste: A Real Options-Based Facility Assessment" Sustainability 10, no. 2: 368. https://doi.org/10.3390/su10020368