Evaluation of Building Energy and Daylight Performance of Electrochromic Glazing for Optimal Control in Three Different Climate Zones

Abstract

1. Introduction

1.1. Research Background and Objective

1.2. Research Method and Scope

2. Optical Properties of Electrochromic Glazing

3. Simulation Conditions

3.1. Overview of the Analytical Simulation Model

3.2. Climate Zone and Weather Data

3.3. Control Conditions of EC Glazing

4. Results and Discussion

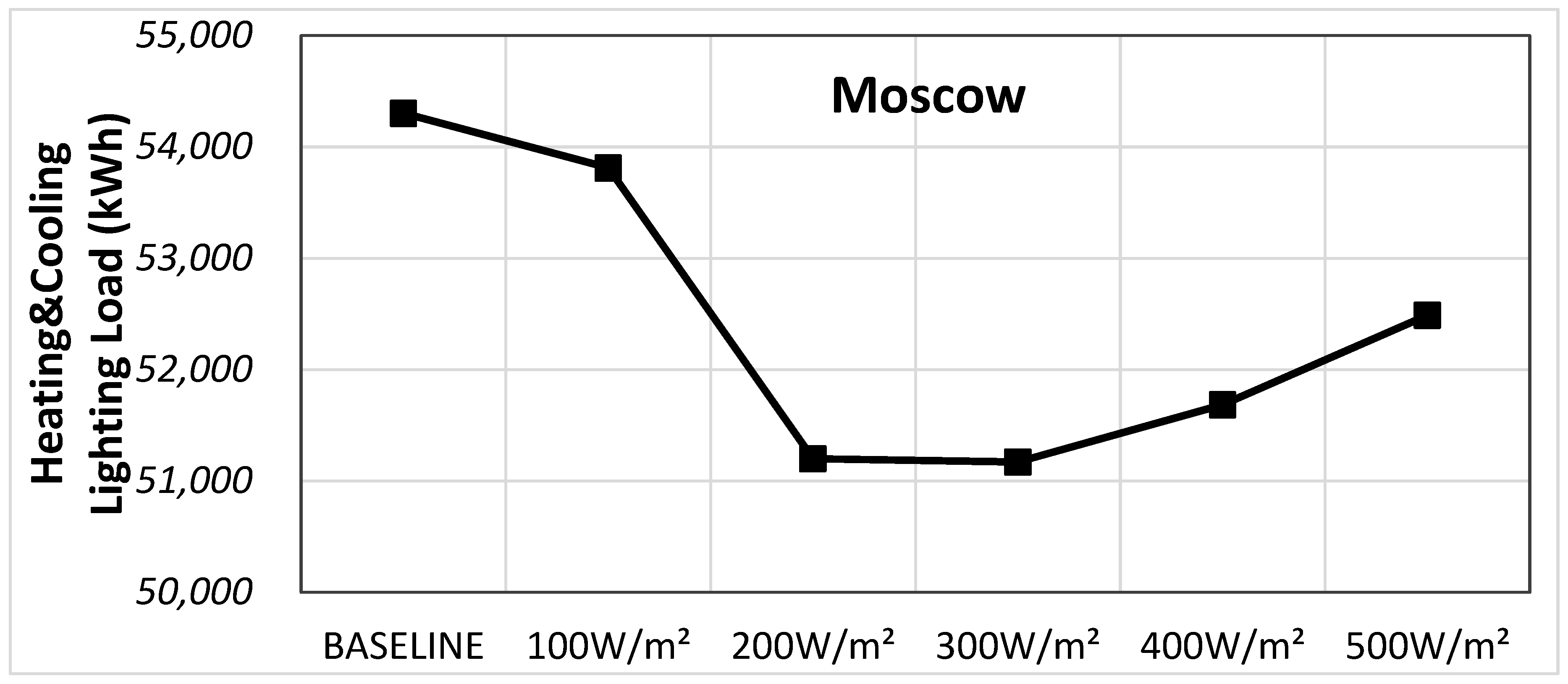

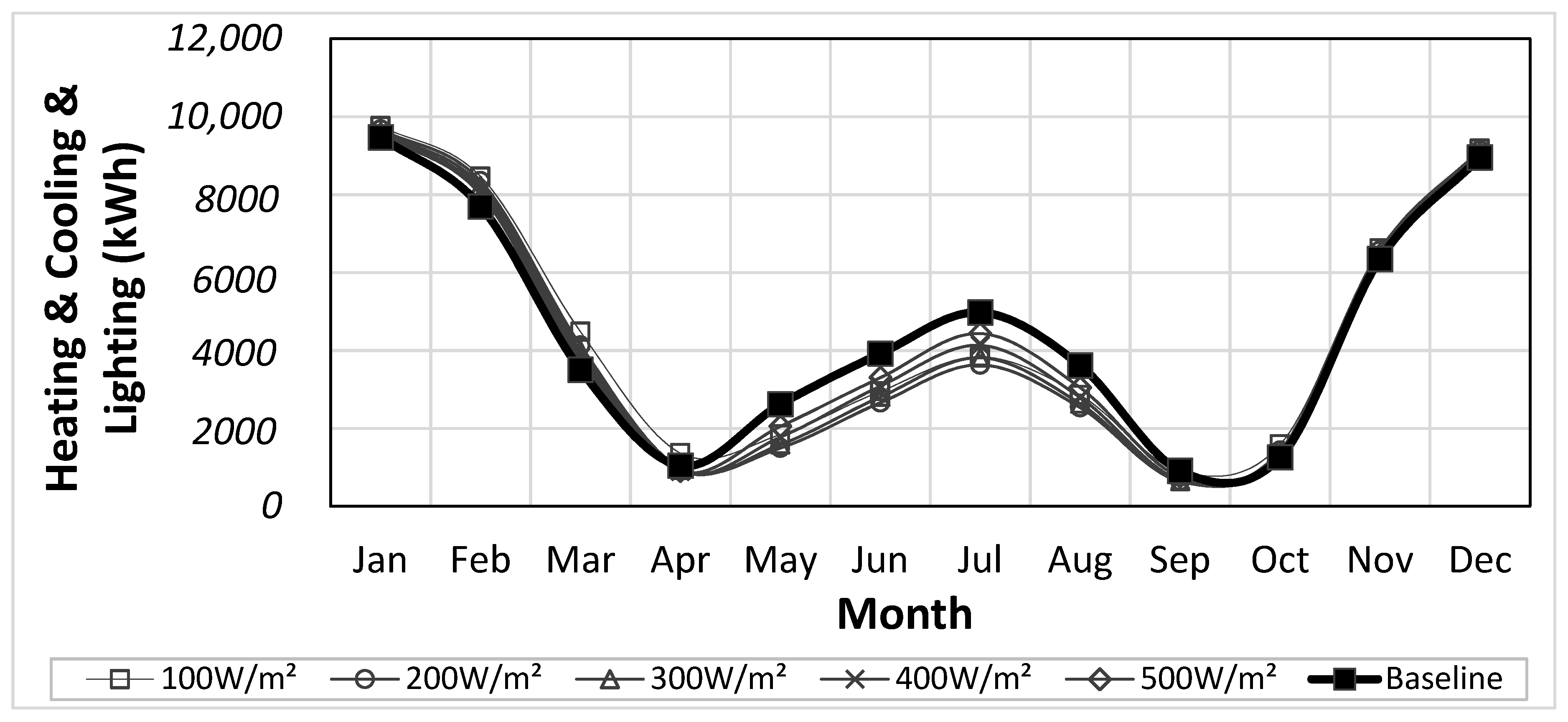

4.1. Analysis Results of Cooling, Heating, and Lighting Energies by Varying Solar Radiation

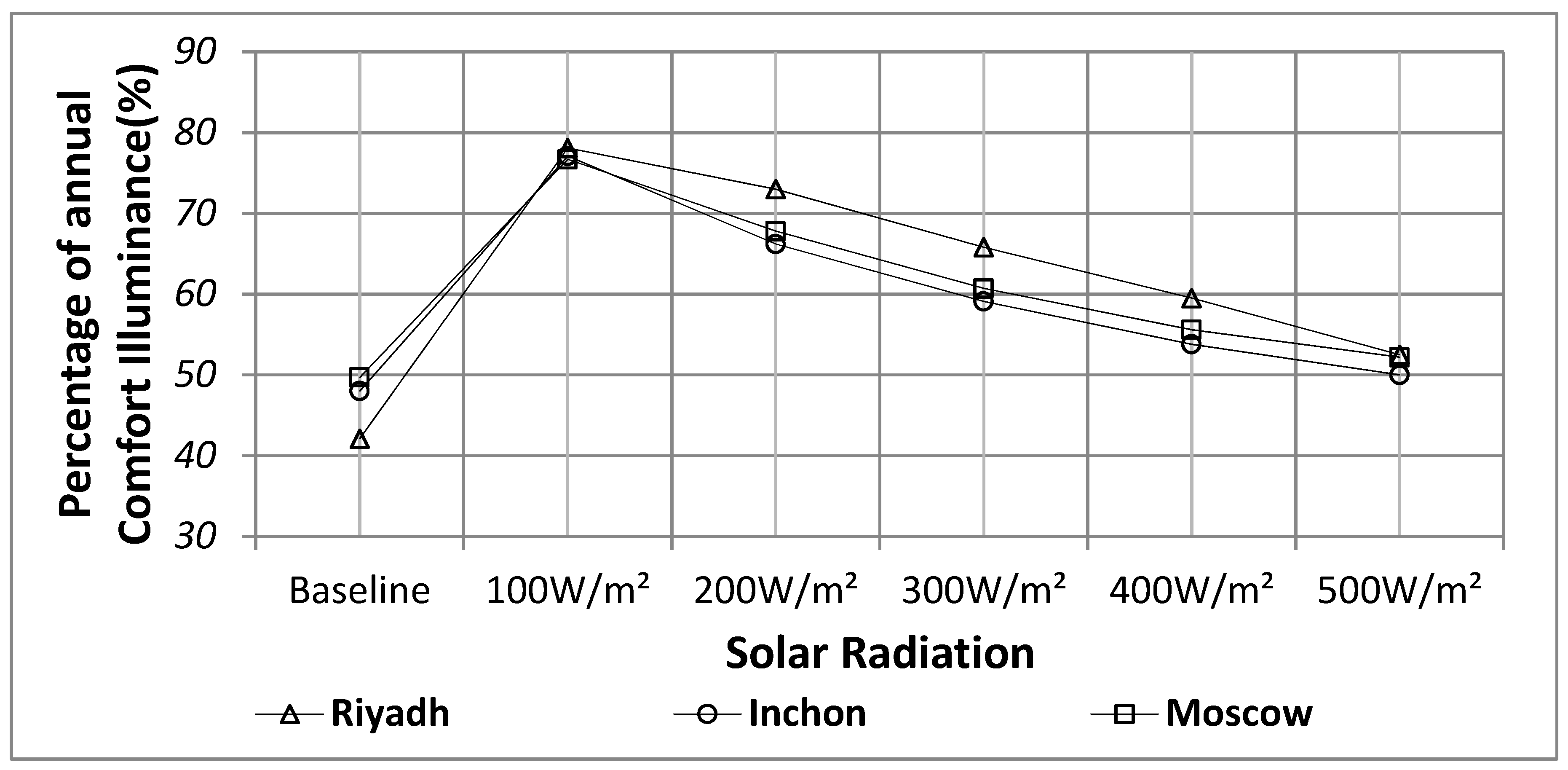

4.2. Analysis of Daylight Performance According to Solar Radiation Control

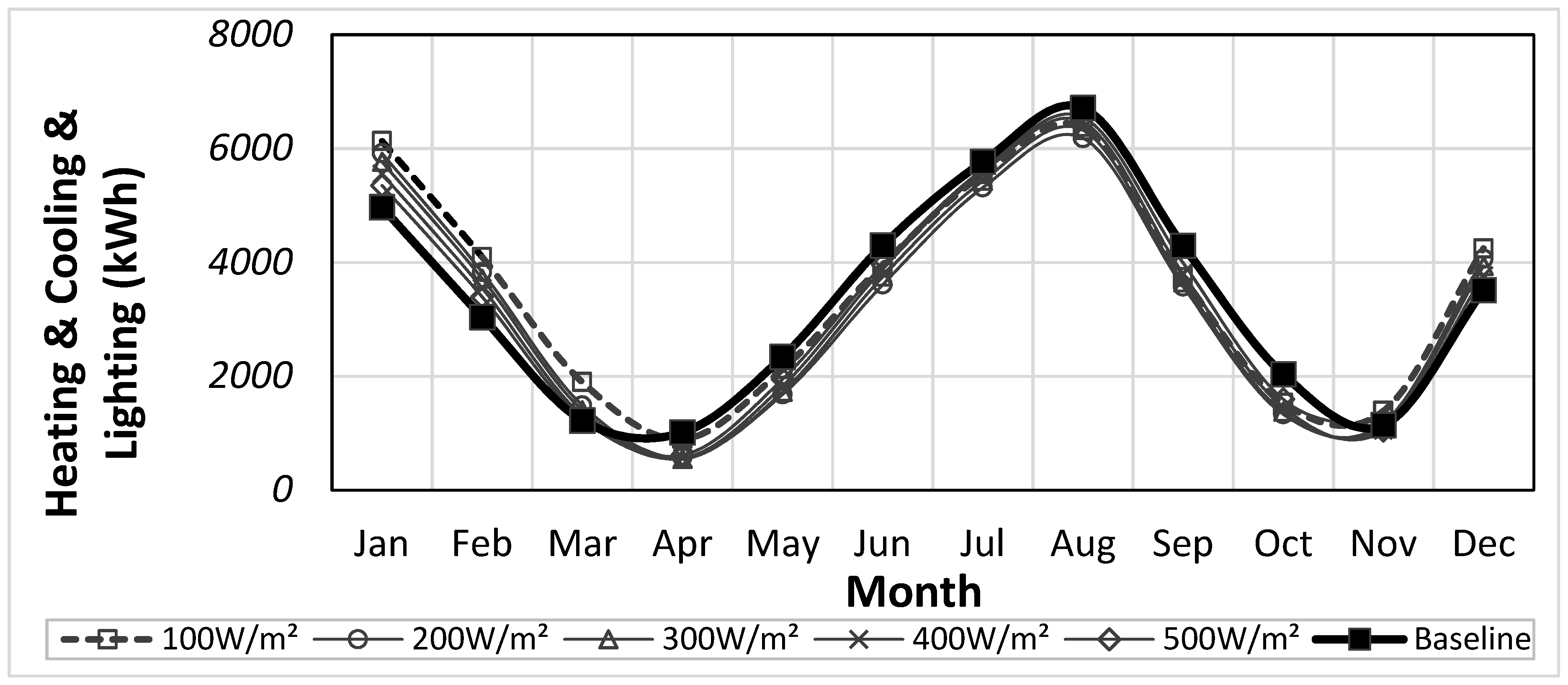

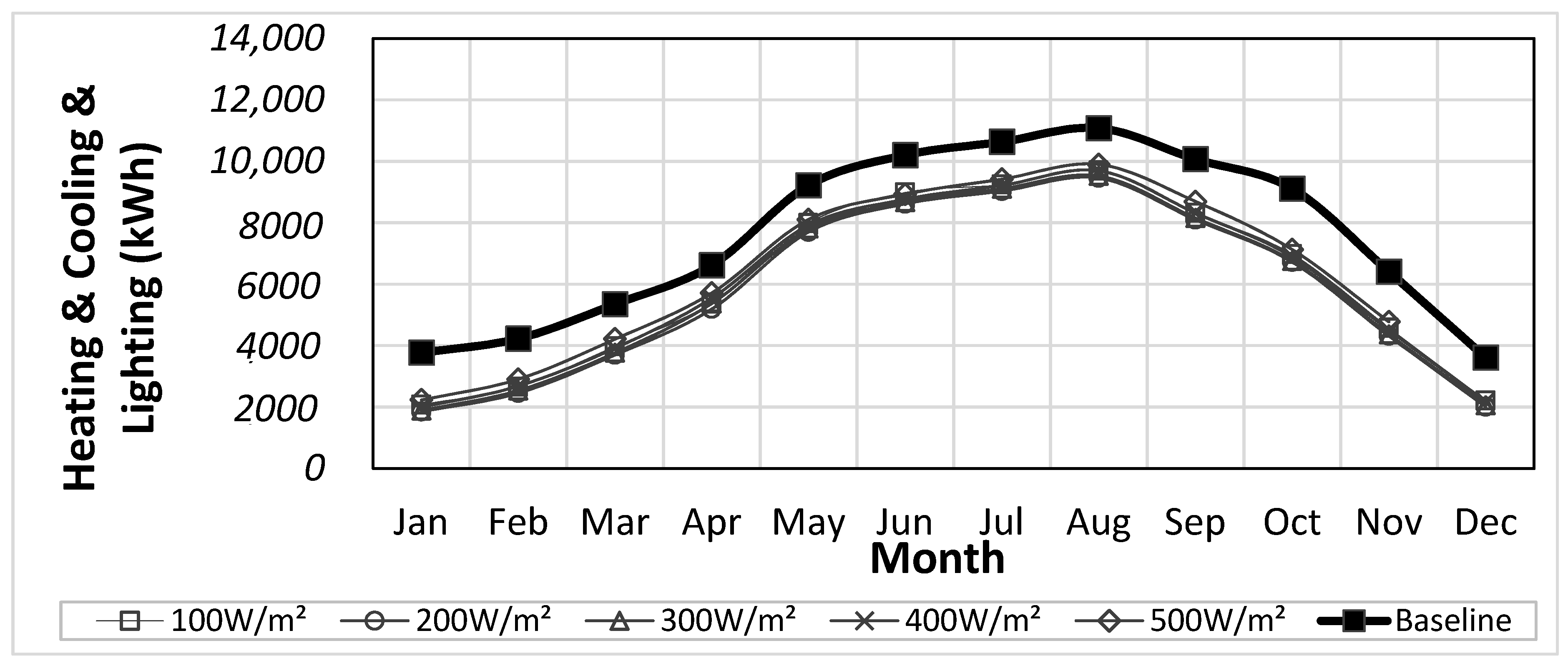

4.3. Analysis Results for Cooling, Heating and Lighting Energies According to Temperature Control

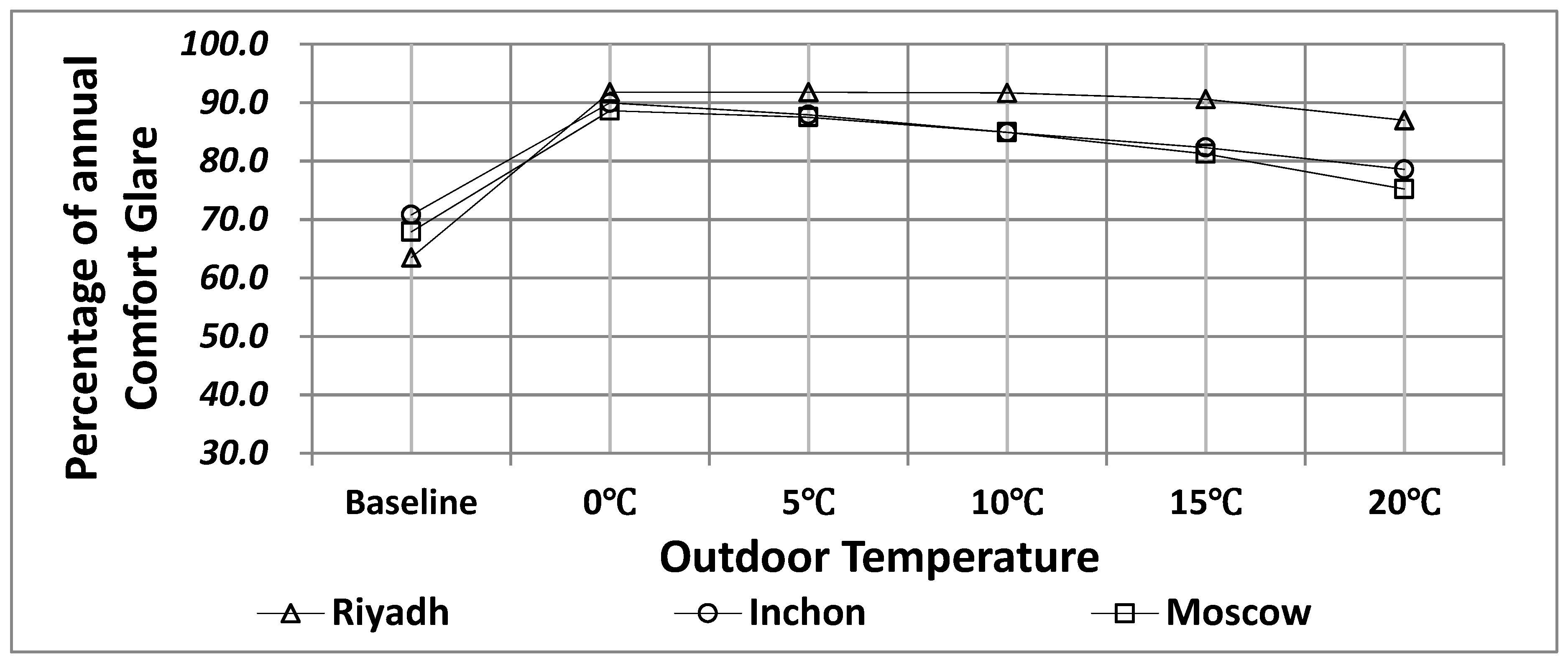

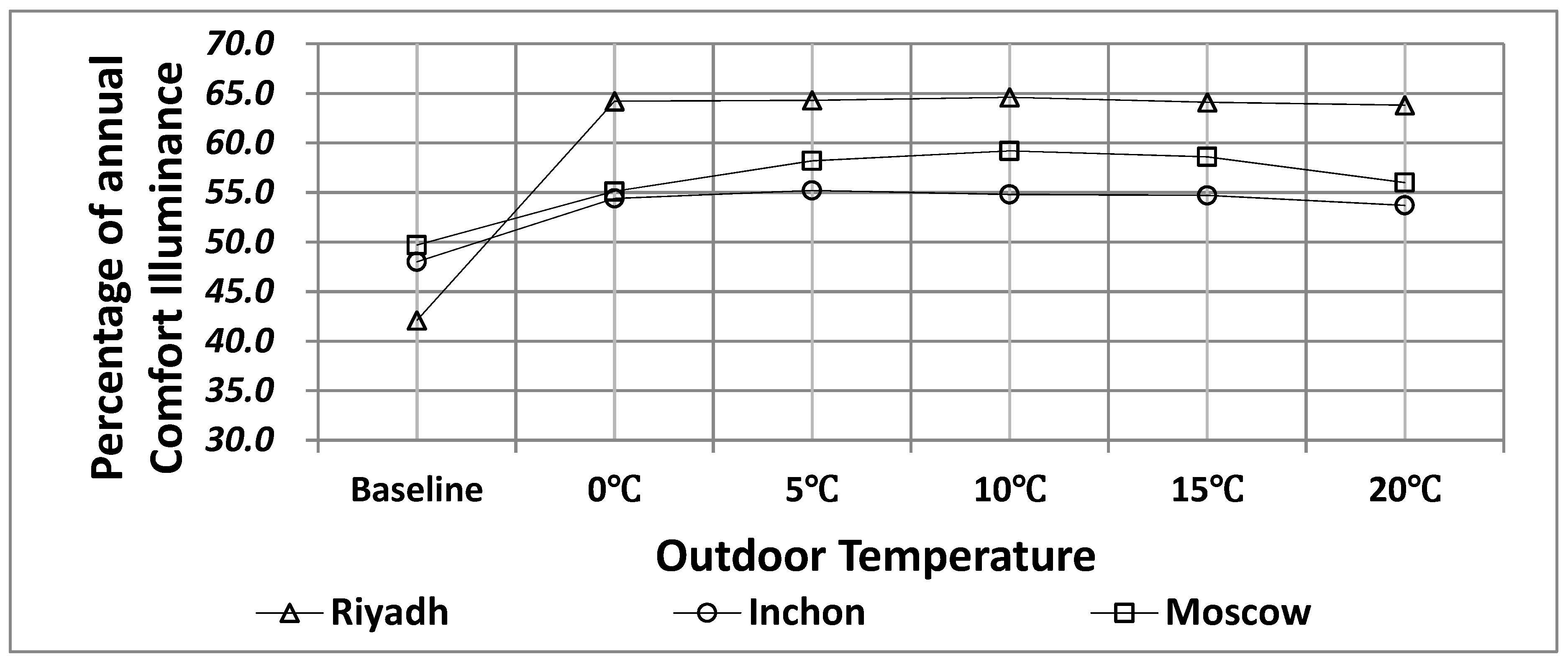

4.4. Analysis Results for Daylight Performance According to Temperature Control

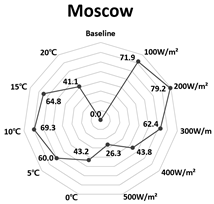

4.5. Derivation of Optimal Control Conditions by Comprehensively Considering Energy and Daylight Environment

5. Conclusions

- (1)

- The results of the analysis of the total annual energy according to the solar radiation control for EC glazing showed that the best conditions for Moscow, Inchon, and Riyadh were 300, 300, and 200 W/m2, respectively. The annual energy decreased by 23.4% at 200 W/m2 in Riyadh, which was the best result. As for the other cities, the annual energy was decreased by 4.0% at 300 W/m2 in Inchon, and 5.8% at 300 W/m2 in Moscow.When the daylight performance was analyzed by controlling the solar radiation for EC glazing, the percentage of annual DGI values below 22 was the highest for solar radiation of 100 W/m2 in each of the cities that were considered. Higher solar radiation was found to be more disadvantageous with respect to DGI. Analysis results of the percentage of annual comfort luminance showed that solar radiation of 100 W/m2 was the best condition for every city, which corresponded with the DGI analysis result.

- (2)

- Analysis of the total annual energy according to the temperature control for EC glazing yielded the best performance at 15 °C for Moscow, 20 °C for Inchon, and 0 °C for Riyadh. In particular, Riyadh achieved an 18.8% decrease in the annual energy at 0 °C, which was the best performance overall. In the case of Inchon, the annual energy decreased by 1.2% at 20 °C, and Moscow showed a 5.8% decrease at 15 °C.

- (3)

- Analysis of the daylight performance according to temperature control for EC glazing showed that the percentage of annual DGI values below 22 was the highest at 0 °C in every city. However, the result obtained for interior illuminance exhibited a trend that differed from that of DGI. The performance with respect to interior illuminance for Moscow, Inchon, and Riyadh was optimal at 10 °C, 5 °C, and 10 °C, respectively.

- (4)

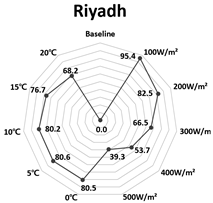

- Although the advantages and disadvantages of each control condition for EC glazing could be identified for each climate zone, an integrated method for evaluating the performance in terms of both the cooling, heating, and lighting energies and the daylight environment was required. This study utilized the EDPI to comprehensively evaluate the energy and daylight performance. The EDPI-based comprehensive analysis showed that solar radiation of 200 W/m2 was the optimal condition for Moscow and Inchon, whereas 100 W/m2 was optimal for Riyadh. As for the top 30% of conditions in each climate zone, solar radiation of 200 W/m2 was the best condition for Moscow, followed by 100 W/m2 and temperature of 10 °C. For Inchon, solar radiation of 200 W/m2 was the best condition, followed by 100 W/m2 and 300 W/m2. For Riyadh, solar radiation of 100 W/m2 was the best condition, followed by 200 W/m2 and temperature of 5 °C. Thus, in every climate zone analyzed, the solar radiation incident on a vertical surface was a more effective variable in controlling EC glazing than the outdoor temperature. Ultimately, solar radiation of 100–200 W/m2 proved to be the optimal control condition.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rezaei, S.D.; Shannigrahi, S.; Ramakrishna, S. A review of conventional, advanced, and smart glazing technologies and materials for improving indoor environment. Sol. Energy Mater. Sol. Cells 2017, 159, 26–51. [Google Scholar] [CrossRef]

- Piccolo, A.; Pennisi, A.; Simone, F. Daylighting performance of an electrochomic window in a small-scale test-cell. Sol. Energy 2009, 83, 832–844. [Google Scholar] [CrossRef]

- Fernandes, L.L.; Lee, E.S.; Ward, G. Lighting energy savings potential of split-pane electrochromic windows controlled for daylighting with visual comfort. Energy Build. 2013, 61, 8–20. [Google Scholar] [CrossRef]

- Rottmann, M.; Kraft, A.; Heckner, K.H.; Hausler, T.; Fischer, U.; Stenzel, H. Large-area electrochromic safety glass; switching behaviour and transmission control of solar radiation. In Proceedings of the 9th International Glass Conference on Glass Processing Days, Tampere, Finland, 17–20 June 2005. [Google Scholar]

- Granqvist, C.G.; Bayrak Pehlivan, I.; Niklasson, G.A. Electrochromics on a roll: Web-coating and lamination for smart windows. Surf. Coat. Technol. 2017, 6–11. [Google Scholar] [CrossRef]

- Costanzo, V.; Evola, G.; Marletta, L. Thermal and visual performance of real and theoretical thermochromic glazing solutions for office buildings. Sol. Energy Mater. Sol. Cells 2016, 149, 110–120. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Daylighting performance and glare calculation of a suspended particle device switchable glazing. Sol. Energy 2016, 132, 114–128. [Google Scholar] [CrossRef]

- Ghosh, A.; Mallick, T.K. Evaluation of colour properties due to switching behaviour of a PDLC glazing for adaptive building integration. Renew. Energy 2018, 120, 126–133. [Google Scholar] [CrossRef]

- Reilly, S.; Arasteh, D.; Selkowitz, S.E. Thermal and optical analysis of switchable window glazings. Sol. Energy Mater 1991, 22, 1–14. [Google Scholar] [CrossRef]

- Lee, E.S.; Yazdanian, M.; Selkowitz, S. The Energy-Savings Potential of Electrochromic Windows in the US Commercial Buildings Sector; University of California: Oakland, CA, USA, 2004. [Google Scholar]

- Tavares, P.F.; Gaspar, A.R.; Martins, A.G.; Frontini, F. Evaluation of electrochromic windows impact in the energy performance of buildings in Mediterranean climates. Energy Policy 2014, 67, 68–81. [Google Scholar] [CrossRef]

- Ajaji, Y.; André, P. Thermal comfort and visual comfort in an office building equipped with smart electrochromic glazing: An experimental study. Energy Proc. 2015, 78, 2464–2469. [Google Scholar] [CrossRef]

- Papaefthimiou, S.; Syrrakou, E.; Yianoulis, P. Energy performance assessment of an electrochromic window. Thin Solid Films 2006, 502, 257–264. [Google Scholar] [CrossRef]

- Oh, M.; Roh, S.; Jang, M.; Park, J. Evaluation of heating and cooling load according to applying electrochromic glass to office building envelope in South Korea. Int. J. Sustain. Build. Technol. Urban Dev. 2018, 9, 158–169. [Google Scholar] [CrossRef]

- DeForest, N.; Shehabi, A.; Garcia, G.; Greenbalt, J.; Masanet, E.; Lee, E.S.; Selkowitz, S.; Milliron, D.J. Regional performance targets for transparent near-infrared switching electrochromic window glazings. Build. Environ. 2013, 61, 160–168. [Google Scholar] [CrossRef]

- Cannavale, G.E.; Eperon, P.; Cossari, A.; Abate, H.J.; Snaith, G.; Gigli, P. Photovoltachromic cells for building integration. Energy Environ. Sci. 2015, 8, 1578–1584. [Google Scholar] [CrossRef]

- HALIO Glass, Asahi Glass Co. (AGC). Available online: https://halioglass.com (accessed on 9 October 2018).

- Oh, M.; Tae, S.; Hwang, S. Analysis of heating and cooling loads of electrochromic glazing in high-rise residential buildings in South Korea. Sustainability 2018, 10, 1121. [Google Scholar] [CrossRef]

- Oh, M.; Park, J.; Roh, S.; Lee, C. Deducing the Optimal Control Method for Electrochromic Triple Glazing through an Integrated Evaluation of Building Energy and Daylight Performance. Energies 2018, 11, 2205. [Google Scholar] [CrossRef]

- LBNL. Available online: https://windows.lbl.gov/software/optics (accessed on 9 October 2018).

- LBNL. Available online: https://windows.lbl.gov/software/window (accessed on 9 October 2018).

- EnergyPlus. EnergyPlus Input Output Reference. The Encyclopedic Reference to EnergyPlus Input and Output. 2012. Available online: http://www.energyplus.gov (accessed on 9 October 2018).

- Arasteh, D.K.; Kohler, J.C.; Griffith, B.T. Draft, Modeling Windows in EnergyPlus with Only U, SHGC, and Optionally VT; Lawrence Berkeley National Laboratory Report; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2009.

- Lomanowski, B.A.; Wright, J.L. Modeling fenestration with shading devices in building energy simulation: A practical approach. In Proceedings of the 11th International IBPSA Conference, Glasgow, Scotland, 27–30 July 2009. [Google Scholar]

- The Korean Ministry of Land, Transport and Maritime Affairs, Standard for Energy Saving Design in Buildings. 2017. Available online: http://www.molit.go.kr (accessed on 9 October 2018).

- EnergyPlus, EnergyPlus Engineering Reference. The Reference to EnergyPlus Calculations. 2012. Available online: http://www.energyplus.gov (accessed on 9 October 2018).

- ASHRAE Fundamentals Handbook; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2009.

- Building Act in South Korea. Available online: http://www.law.go.kr (accessed on 11 December 2018).

- EnergyPlus Weather Data. Department of Energy. Available online: https://energyplus.net/weather (accessed on 9 October 2018).

- Hopkinson, R.G. Glare from daylighting in buildings. Appl. Ergon. 1972, 3, 206–215. [Google Scholar] [CrossRef]

- Korean agency for technology and standards, KS (Korean Industrial Standard) A 3011 (Recommended Levels of Illumination). Available online: https://standard.go.kr/ (accessed on 5 January 2019).

| Division | EC Glass (Clear) | EC Glass (Colored) | |

|---|---|---|---|

| Thickness (mm) | 3 | 3 | |

| Solar Transmittance | front | 0.481 | 0.065 |

| back | 0.481 | 0.065 | |

| Solar Reflectance | front | 0.214 | 0.181 |

| back | 0.190 | 0.168 | |

| Visible Transmittance | front | 0.648 | 0.120 |

| back | 0.648 | 0.120 | |

| Visible Reflectance | front | 0.128 | 0.074 |

| back | 0.111 | 0.062 | |

| Front and back side emissivity | 0.840 | 0.840 | |

| Conductivity (W/mK) | 1.000 | 1.000 | |

| Division | Electrochromic Double Glazing (6-mm EC Glass + 12-mm Air + 6-mm Low-e) | |

|---|---|---|

| Clear Mode | Darkened Mode | |

| U-value 1 | 1.639 | 1.639 |

| SHGC 2 | 0.408 | 0.127 |

| Tvis 3 | 0.521 | 0.096 |

| Division | Materials | Thermal & Optical Properties | |

|---|---|---|---|

| Exterior wall | 200 mm concrete 155 t insulation 19 mm gypsum board | U-value 0.202 W/m2K | |

| Exterior Floor | 105 mm insulation 200 mm concrete | U-value 0.291 W/m2K | |

| Exterior Roof | 100 mm concrete 220 mm insulation Ceiling air space Acoustic tile | U-value 0.136 W/m2K | |

| Glazing | 26 mm double glazing (8 mm Electrochromic + 12 air + 6 mm low-e glass) | Clear | Darkened |

| SHGC 0.408 Tvis 0.521 U-value 1.639 W/m2K | SHGC 0.127 Tvis 0.096 U-value 1.639 W/m2K | ||

| Division | Moscow | Inchon | Riyadh | |

|---|---|---|---|---|

| Outdoor Temperature (°C) | Max | 30.5 | 32.6 | 45.6 |

| Min | −25.0 | −11.7 | 4.0 | |

| Average | 5.5 | 11.9 | 26.2 | |

| Direct Solar Radiation (W/m2) | Max | 873.4 | 1013.7 | 935.3 |

| Min | - | - | - | |

| Average | 74.6 | 86.7 | 258.5 | |

| Energy (kWh) | Baseline | 100 W/m2 | 200 W/m2 | 300 W/m2 | 400 W/m2 | 500 W/m2 |

|---|---|---|---|---|---|---|

| Heating | 32,729.3 | 35,059.3 | 34,730.3 | 34,335.5 | 33,930.0 | 33,592.6 |

| Cooling | 15,149.9 | 8899.4 | 9196.9 | 9993.8 | 11,144.9 | 12,391.7 |

| Lighting | 6424.0 | 9853.9 | 7273.5 | 6841.2 | 6610.2 | 6504.2 |

| Total | 54,303.2 | 53,812.6 | 51,200.6 | 51,170.5 | 51,685.1 | 52,488.5 |

| Energy (kWh) | Baseline | 100 W/m2 | 200 W/m2 | 300 W/m2 | 400 W/m2 | 500 W/m2 |

|---|---|---|---|---|---|---|

| Heating | 10,966.1 | 13,915.5 | 13,547.1 | 13,153.4 | 12,548.4 | 12,078.9 |

| Cooling | 24,608.2 | 18,912.5 | 19,410.1 | 20,301.6 | 21,261.5 | 22,102.7 |

| Lighting | 4770.1 | 9099.3 | 5786.6 | 5274.8 | 4993.0 | 4855.9 |

| Total | 40,344.4 | 41,927.3 | 38,743.8 | 38,729.8 | 38,803.0 | 39,037.6 |

| Energy (kWh) | Baseline | 100 W/m2 | 200 W/m2 | 300 W/m2 | 400 W/m2 | 500 W/m2 |

|---|---|---|---|---|---|---|

| Heating | 0.0 | 0.9 | 0.6 | 0.4 | 0.2 | 0.0 |

| Cooling | 86,239.4 | 62,334.7 | 63,139.6 | 64,756.4 | 66,827.2 | 69,896.1 |

| Lighting | 4040.4 | 9727.1 | 5987.0 | 5232.9 | 4782.3 | 4461.2 |

| Total | 90,279.8 | 72,062.7 | 67,127.2 | 69,989.6 | 71,609.6 | 74,357.4 |

| Division | DGI below 22 (%) | Daylight Illuminance 150–1500 lx (%) | ||||

|---|---|---|---|---|---|---|

| Moscow | Inchon | Riyadh | Moscow | Inchon | Riyadh | |

| Baseline | 67.9 | 70.8 | 63.5 | 49.7 | 48.0 | 42.1 |

| 100 W/m2 | 89.6 | 92.2 | 91.7 | 76.7 | 77.1 | 78.1 |

| 200 W/m2 | 83.5 | 86.4 | 80.9 | 67.8 | 66.2 | 73.0 |

| 300 W/m2 | 78.0 | 80.5 | 74.2 | 60.7 | 59.1 | 65.8 |

| 400 W/m2 | 73.6 | 76.1 | 70.4 | 55.6 | 53.8 | 59.5 |

| 500 W/m2 | 70.5 | 73.1 | 67.4 | 52.2 | 50.0 | 52.5 |

| Energy (kWh) | Baseline | 0 °C | 5 °C | 10 °C | 15 °C | 20 °C |

|---|---|---|---|---|---|---|

| Heating | 32,729.3 | 33,391.8 | 33,062.1 | 32,784.4 | 32,734.9 | 32,730.2 |

| Cooling | 15,149.9 | 8870.6 | 8893.6 | 9131.0 | 10,060.2 | 12,293.6 |

| Lighting | 6424.0 | 11,600.8 | 10,517.3 | 9431.9 | 8368.7 | 7202.4 |

| Total | 54,303.2 | 53,863.2 | 52,473.1 | 51,347.2 | 51,163.8 | 52,226.2 |

| Energy (kWh) | Baseline | 0 °C | 5 °C | 10 °C | 15 °C | 20 °C |

|---|---|---|---|---|---|---|

| Heating | 10,966.1 | 12,080.7 | 11,443.0 | 11,035.0 | 10,967.4 | 10,966.6 |

| Cooling | 24,608.2 | 19,372.0 | 19,398.2 | 19,648.8 | 20,351.8 | 21,599.7 |

| Lighting | 4770.1 | 11,386.2 | 10,625.3 | 9577.9 | 8641.7 | 7306.9 |

| Total | 40,344.4 | 42,838.9 | 41,466.4 | 40,261.6 | 39,960.9 | 39,873.2 |

| Energy (kWh) | Baseline | 0 °C | 5 °C | 10 °C | 15 °C | 20 °C |

|---|---|---|---|---|---|---|

| Heating | 0.0 | 1.1 | 1.1 | 0.3 | 0.0 | 0.0 |

| Cooling | 86,239.4 | 62,429.1 | 62,439.8 | 62,866.7 | 64,477.8 | 67,819.5 |

| Lighting | 4040.4 | 10,899.0 | 10,897.0 | 10,828.1 | 10,333.8 | 9511.3 |

| Total | 90,279.8 | 73,329.1 | 73,337.9 | 73,695.1 | 74,811.6 | 77,330.8 |

| Division | DGI under 22 (%) | Daylight Illuminance 150–1500 lx (%) | ||||

|---|---|---|---|---|---|---|

| Moscow | Inchon | Riyadh | Moscow | Inchon | Riyadh | |

| Baseline | 67.9 | 70.8 | 63.5 | 49.7 | 48.0 | 42.1 |

| 0 °C | 88.6 | 89.9 | 91.8 | 55.1 | 54.4 | 64.2 |

| 5 °C | 87.5 | 87.9 | 91.8 | 58.2 | 55.2 | 64.3 |

| 10 °C | 84.9 | 84.9 | 91.7 | 59.2 | 54.8 | 64.6 |

| 15 °C | 81.2 | 82.3 | 90.6 | 58.6 | 54.7 | 64.1 |

| 20 °C | 75.2 | 78.6 | 87.0 | 56.0 | 53.7 | 63.8 |

| Division | EDPI | EDPI Chart | ||||

|---|---|---|---|---|---|---|

| DGI below 22 | Percentage of Lux 150–1500 lx | Total Energy (kWh) | Average | |||

| Moscow | Baseline | 0.0 | 0.0 | 0.0 | 0.0 |  |

| 100 W/m2 | 100.0 | 100.0 | 15.6 | 71.9 | ||

| 200 W/m2 | 71.8 | 67.0 | 98.8 | 79.2 | ||

| 300 W/m2 | 46.8 | 40.7 | 99.8 | 62.4 | ||

| 400 W/m2 | 26.3 | 21.9 | 83.4 | 43.8 | ||

| 500 W/m2 | 11.9 | 9.3 | 57.8 | 26.3 | ||

| 0 °C | 95.5 | 20.0 | 14.0 | 43.2 | ||

| 5 °C | 90.4 | 31.5 | 58.3 | 60.0 | ||

| 10 °C | 78.5 | 35.2 | 94.2 | 69.3 | ||

| 15 °C | 61.5 | 33.0 | 100.0 | 64.8 | ||

| 20 °C | 33.7 | 23.3 | 66.2 | 41.1 | ||

| Inchon | Baseline | 0.0 | 0.0 | 60.7 | 20.2 |  |

| 100 W/m2 | 100.0 | 100.0 | 22.2 | 74.1 | ||

| 200 W/m2 | 73.0 | 62.5 | 99.7 | 78.4 | ||

| 300 W/m2 | 45.6 | 38.1 | 100.0 | 61.2 | ||

| 400 W/m2 | 24.8 | 19.9 | 98.2 | 47.7 | ||

| 500 W/m2 | 10.9 | 6.9 | 92.5 | 36.8 | ||

| 0 °C | 89.6 | 22.0 | 0.0 | 37.2 | ||

| 5 °C | 80.0 | 24.7 | 33.4 | 46.0 | ||

| 10 °C | 65.9 | 23.4 | 62.7 | 50.7 | ||

| 15 °C | 53.8 | 23.0 | 70.0 | 48.9 | ||

| 20 °C | 36.3 | 19.6 | 72.2 | 42.7 | ||

| Riyadh | Baseline | 0.0 | 0.0 | 0.0 | 0.0 |  |

| 100 W/m2 | 100.0 | 100.0 | 86.1 | 95.4 | ||

| 200 W/m2 | 61.7 | 85.8 | 100.0 | 82.5 | ||

| 300 W/m2 | 37.7 | 65.8 | 95.9 | 66.5 | ||

| 400 W/m2 | 24.5 | 48.3 | 88.3 | 53.7 | ||

| 500 W/m2 | 13.7 | 28.9 | 75.3 | 39.3 | ||

| 0 °C | 100.0 | 61.4 | 80.1 | 80.5 | ||

| 5 °C | 100.0 | 61.7 | 80.1 | 80.6 | ||

| 10 °C | 99.7 | 62.5 | 78.4 | 80.2 | ||

| 15 °C | 95.8 | 61.1 | 73.1 | 76.7 | ||

| 20 °C | 83.1 | 60.3 | 61.2 | 68.2 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, M.; Jang, M.; Moon, J.; Roh, S. Evaluation of Building Energy and Daylight Performance of Electrochromic Glazing for Optimal Control in Three Different Climate Zones. Sustainability 2019, 11, 287. https://doi.org/10.3390/su11010287

Oh M, Jang M, Moon J, Roh S. Evaluation of Building Energy and Daylight Performance of Electrochromic Glazing for Optimal Control in Three Different Climate Zones. Sustainability. 2019; 11(1):287. https://doi.org/10.3390/su11010287

Chicago/Turabian StyleOh, Myunghwan, Minsu Jang, Jaesik Moon, and Seungjun Roh. 2019. "Evaluation of Building Energy and Daylight Performance of Electrochromic Glazing for Optimal Control in Three Different Climate Zones" Sustainability 11, no. 1: 287. https://doi.org/10.3390/su11010287

APA StyleOh, M., Jang, M., Moon, J., & Roh, S. (2019). Evaluation of Building Energy and Daylight Performance of Electrochromic Glazing for Optimal Control in Three Different Climate Zones. Sustainability, 11(1), 287. https://doi.org/10.3390/su11010287