Tensile Behavior and Diffusion of Moisture through Flax Fibers by Desorption Method

Abstract

:1. Introduction

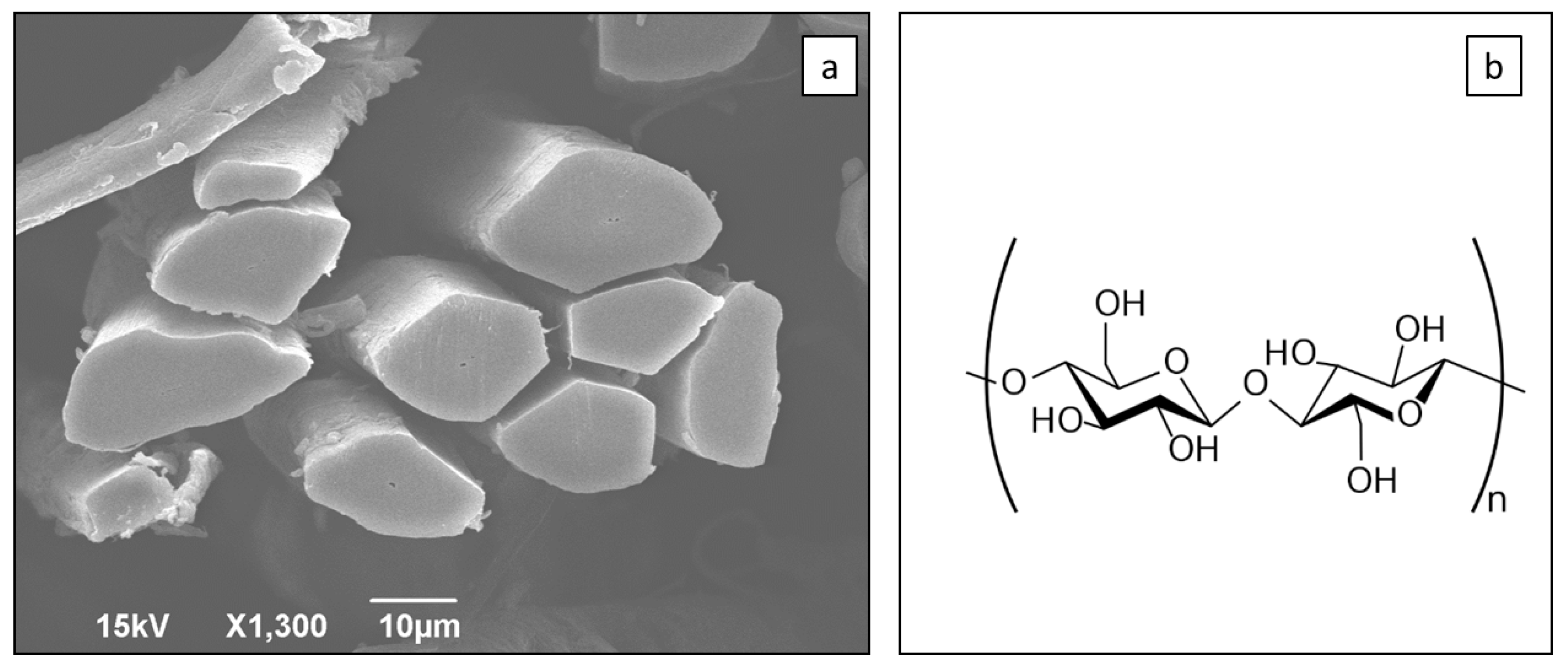

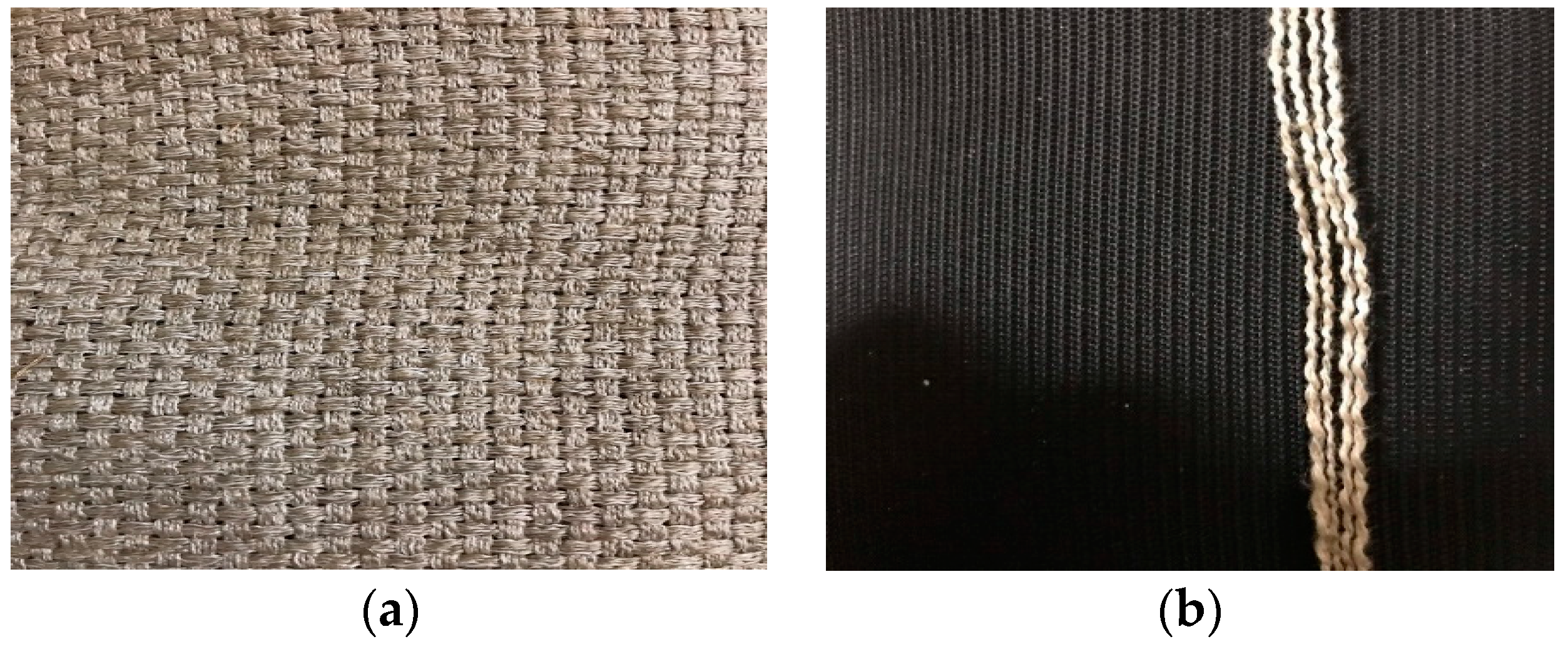

2. Materials and Methods

2.1. Moisture Diffusion Testing

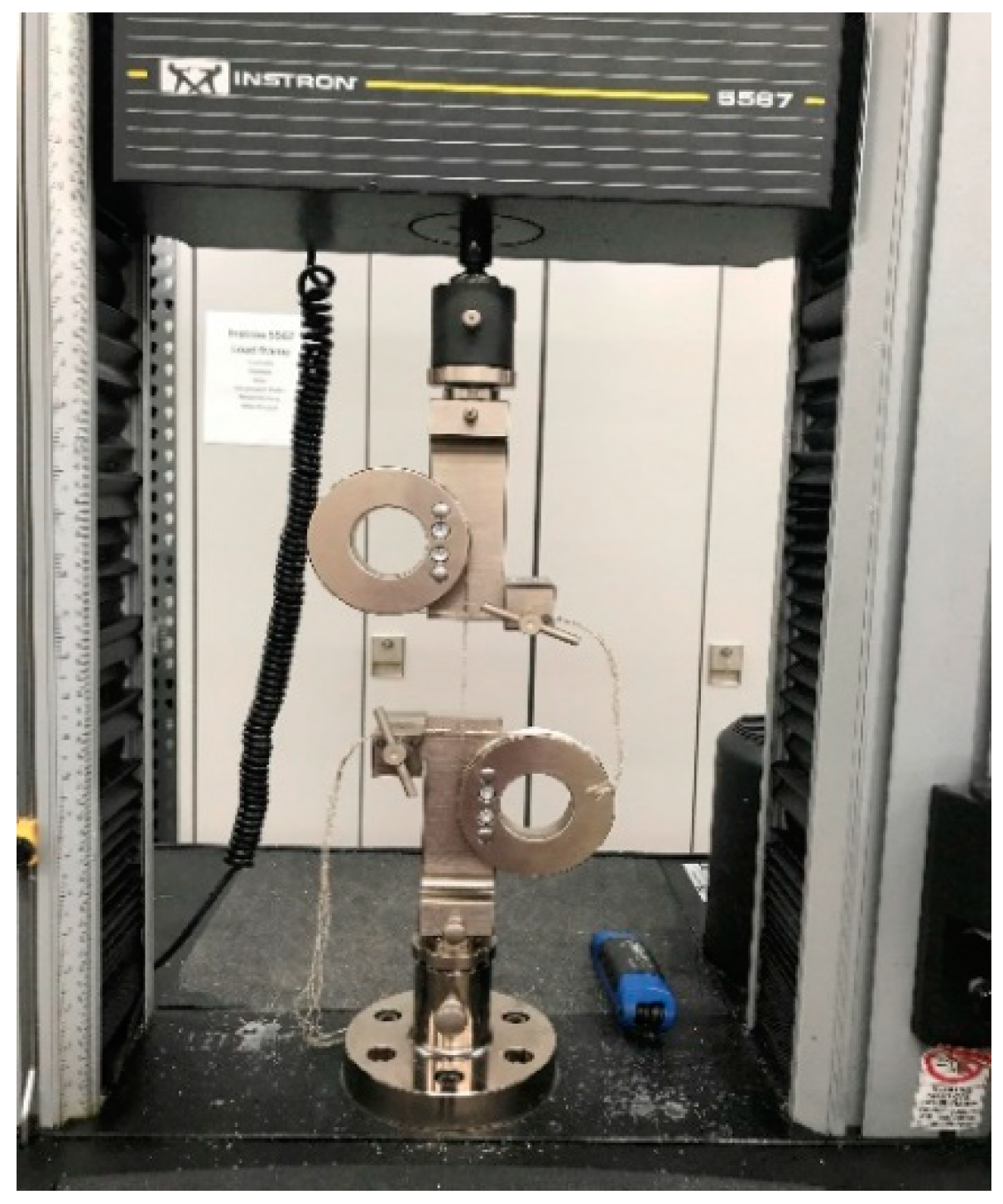

2.2. Tow Tensile Testing

3. Results

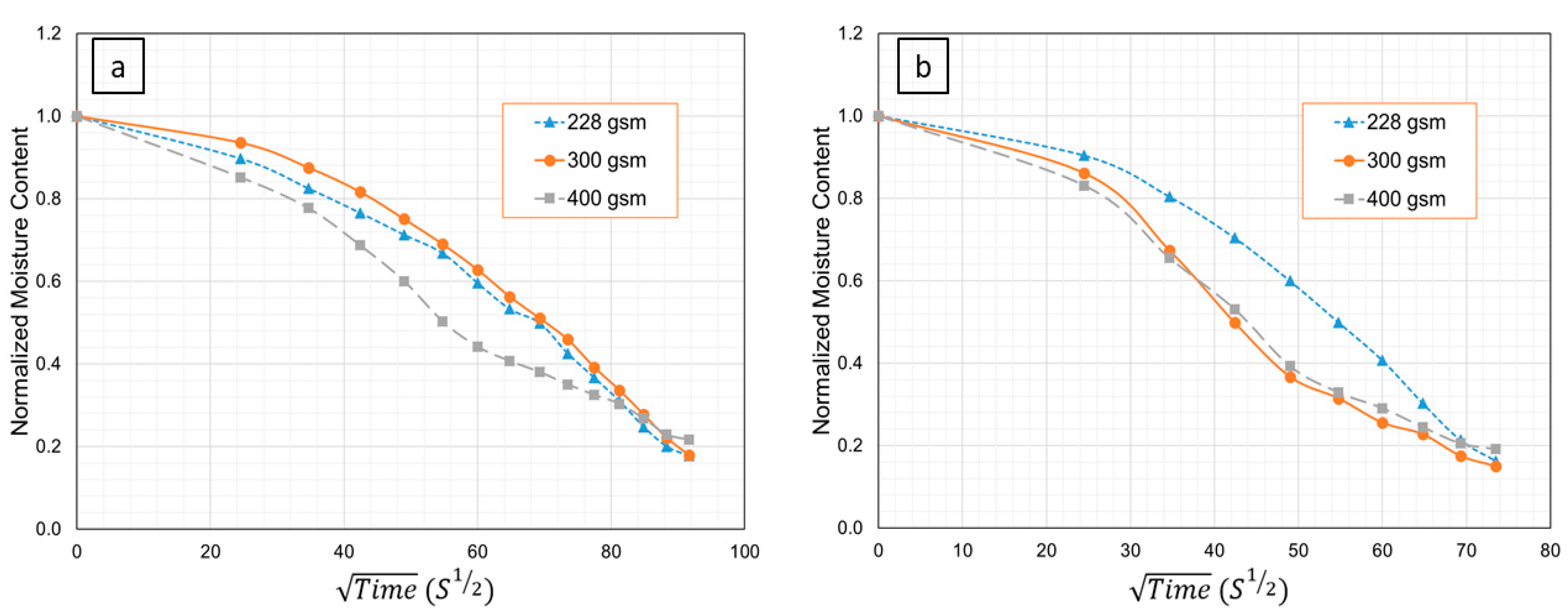

3.1. Moisture Desorption in Flax Fiber Non-Woven Random Mats

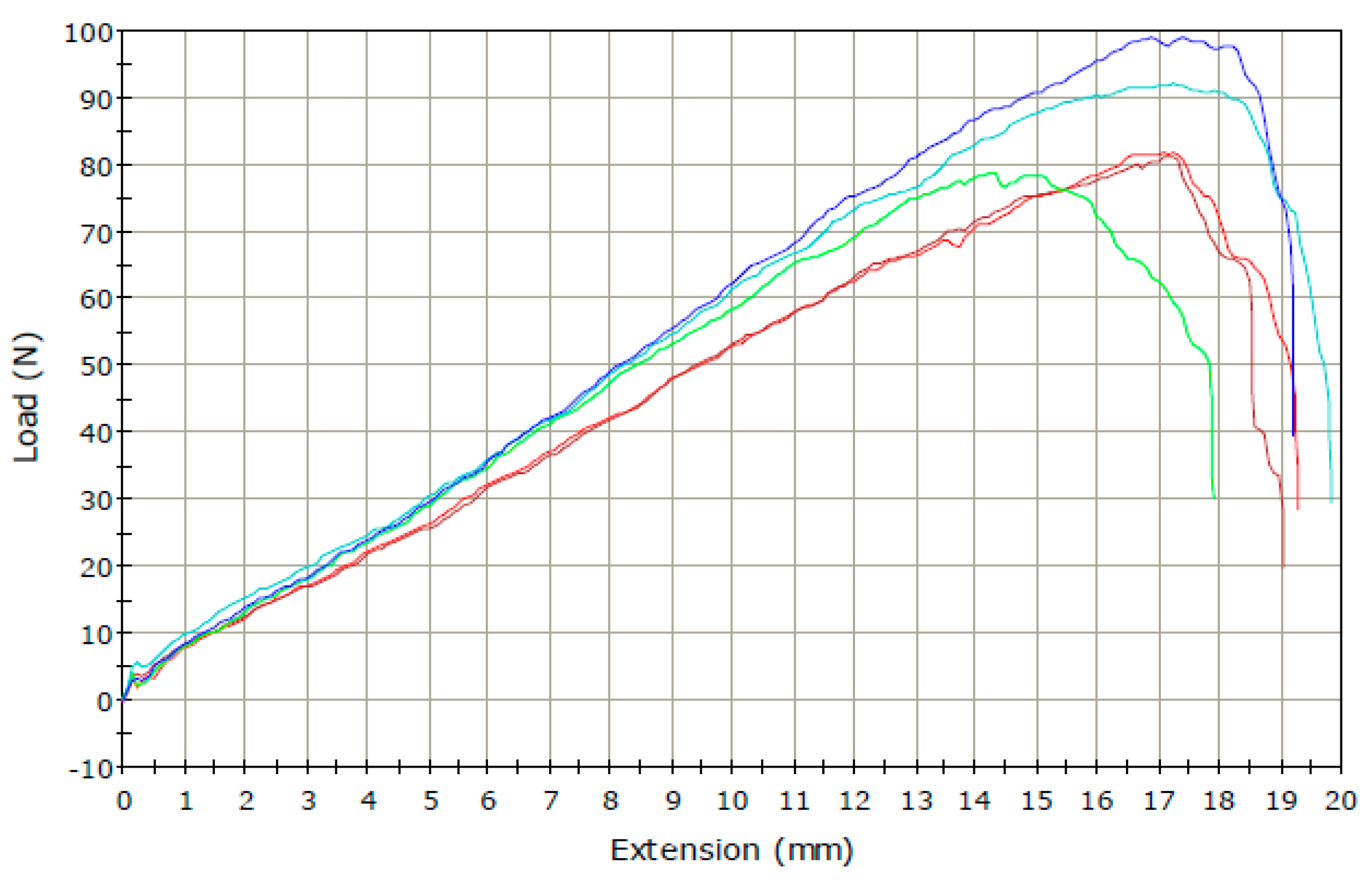

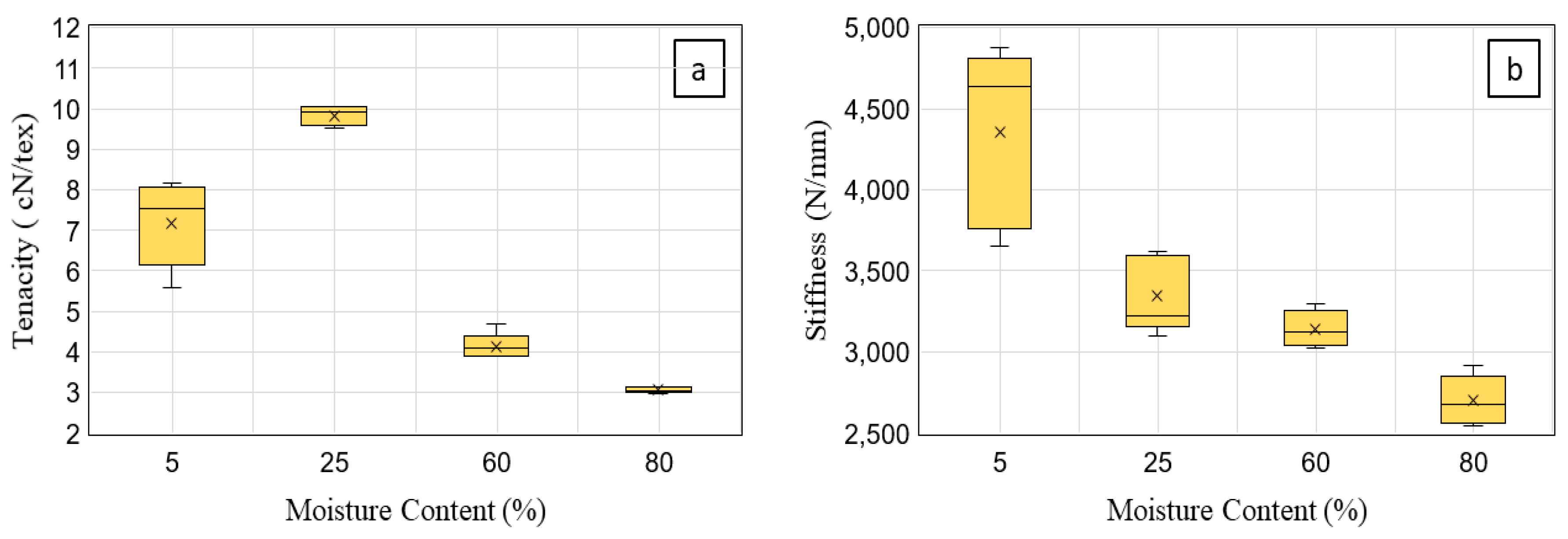

3.2. Influence of Moisture on Tensile Properties of Flax Fiber Tows

4. Discussion

4.1. Moisture Desorption in Flax Fiber Non-Woven Random Mats

4.2. Influence of Moisture on Tensile Properties of Flax Fiber Tows

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Virta, R.L. Asbestos. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural fiber reinforced composites. Polym. Rev. 2012, 52, 259–320. [Google Scholar] [CrossRef]

- Sisti, L.; Totaro, G.; Vannini, M.; Celli, A. Retting process as a pretreatment of natural fibers for the development of polymer composites. In Lignocellulosic Composite Materials; Springer: Cham, Switzerland, 2018; pp. 97–135. [Google Scholar]

- Taylor, C.A.; Amiri, A.; Webster, D.C.; Ulven, C.A. Long-term behavior of bio-composites for structural applications. In Proceedings of The Composites and Advanced Materials Conference; CAMX: Anaheim, CA, USA, 2016. [Google Scholar]

- Fowler, P.A.; Hughes, J.M.; Elias, R.M. Biocomposites: Technology, environmental credentials and market forces. J. Sci. Food Agric. 2006, 86, 1781–1789. [Google Scholar] [CrossRef]

- Chand, N.; Tiwary, R.K.; Rohatgi, P.K. Bibliography Resource structure properties of natural cellulosic fibres ? an annotated bibliography. J. Mater. Sci. 1988, 23, 381–387. [Google Scholar] [CrossRef]

- Lilholt, H.; Lawther, J. Natural organic fibers. In Comprehensive Composite Materials; Elsevier: Amsterdam, The Netherlands, 2000; Volume 1, pp. 303–325. [Google Scholar]

- Franck, R.R. Bast and Other Plant Fibres; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Bolton, A.J. Natural fibers for plastic reinforcement. Mater. Technol. 1994, 9, 12–20. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M. Studies on jute composites—A literature review. Polym. Technol. Eng. 1995, 34, 729–792. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Sperber, V.E.; Faruk, O. Natural and Wood Fibre Reinforcement in Polymers; Rapra Technology Limited: Shrewsbury, Shropshire, UK, 2000. [Google Scholar]

- Netravali, A.N.; Chabba, S. Composites get greener. Mater. Today 2003, 6, 22–29. [Google Scholar] [CrossRef]

- Baillie, C. Green Composites: Polymer Composites and the Environment; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T.; Selke, S.; Harte, B.; Hinrichsen, G. Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Pickering, K.L. Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohyd. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Amiri, A.; Burkart, V.; Yu, A.; Webster, D.; Ulven, C. The potential of natural composite materials in structural design. In Sustainable Composites for Aerospace Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 269–291. [Google Scholar]

- Amiri, A.; Krosbakken, T.; Schoen, W.; Theisen, D.; Ulven, C.A. Design and manufacturing of a hybrid flax/carbon fiber composite bicycle frame. Proc. Inst. Mech. Eng. Part. P J. Sports Eng. Technol. 2018, 232, 28–38. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. J. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Naveen, J.; Sathish Kumar, T.P.; Satheesh Kumar, S. Effect of moisture absorption on the tensile behavior of woven hybrid natural fiber reinforced polymer composites. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 1091–1095. [Google Scholar]

- Grigoriu, A.; Mustata, A. Flax and hemp-natural alternatives in the field of medical textiles. Buletin Institutului Politehnic Din Iasi, Tome LVI (LX), Lasi, Romania. 2010. Available online: http://www.tex.tuiasi.ro/BIP/1_2010/17-23_2_Grigoriu_.pdf (accessed on 1 June 2019).

- Austin, D.F. Plants for people. Econ. Bot. 2003, 57, 668. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Flax Production. Available online: http://www.fao.org/tempref/docrep/fao/009/a0439e/a0439e22.pdf (accessed on 16 May 2019).

- Moothoo, J.; Allaoui, S.; Ouagne, P.; Soulat, D. A study of the tensile behaviour of flax tows and their potential for composite processing. Mater. Des. 2014, 55, 764–772. [Google Scholar] [CrossRef]

- Amiri, A. Characterization, Long-Term Behavior Evaluation and Thermo-Mechanical Properties of Untreated and Treated Flax Fiber-Reinforced Composites. Ph.D. Dissertation, North Dakota State University, Fargo, ND, USA, 2017. [Google Scholar]

- Salnikov, V.V.; Ageeva, M.V.; Yumashev, V.N.; Lozovaya, V.V. Ultrastructural analysis of bast fibers. Rus. Plant. Physiol. 1993, 40, 416–421. [Google Scholar]

- Bogoeva-Gaceva, G.; Avella, M.; Malinconico, M.; Buzarovska, A.; Grozdanov, A.; Gentile, G.; Errico, M.E. Natural fiber eco-composites. Polym. Compos. 2007, 28, 98–107. [Google Scholar] [CrossRef]

- Maldas, D.; Kokta, B.V.; Daneault, C. Influence of coupling agents and treatments on the mechanical properties of cellulose fiber–polystyrene composites. J. Appl. Polym. Sci. 1989, 37, 751–775. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.; Olayo, R.; Herrera-Franco, P. Chemical modification of henequén fibers with an organosilane coupling agent. Compos. Part B Eng. 1999, 30, 321–331. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Vallade, J. Endosperme ou albumen? Petite histoire d’un choix terminologique relatif à l’organisation de l’ovule et de la graine chez les Phanérogames. Acta Bot. Gallica 2004, 151, 205–219. [Google Scholar] [CrossRef]

- Bowes, B.G. A Colour Atlas of Plant Structure; Manson Publishing Ltd.: London, UK, 1996. [Google Scholar]

- Bos, H.L.; Donald, A.M. In situ ESEM study of the deformation of elementary flax fibres. J. Mater. Sci. 1999, 34, 3029–3034. [Google Scholar] [CrossRef]

- Bledzki, A. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Mustata, A. Factors influencing fiber-fiber friction in the case of bleached flax. Cellul. Chem. Technol. 1997, 31, 405–413. [Google Scholar]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Fangueiro, R.; Rana, S. Natural Fibres: Advances in Science and Technology Towards Industrial Applications; Springer: Berlin, Germany, 2016. [Google Scholar]

- Ehresmann, M.; Amiri, A.; Ulven, C. The effect of different variables on in-plane radial permeability of natural fiber mats. J. Reinf. Plast. Compos. 2018, 37, 1191–1201. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.; Baillie, C. A study of the effect of surface treatments on the tensile strength of flax fibres: Part II. Application of Weibull statistics. Compos. Part A Appl. Sci. Manuf. 2007, 38, 629–638. [Google Scholar] [CrossRef]

- Andersons, J.; Spārniņš, E.; Joffe, R.; Wallstrom, L. Strength distribution of elementary flax fibres. Compos. Sci. Technol. 2005, 65, 693–702. [Google Scholar] [CrossRef]

- Joffe, R.; Andersons, J.; Wallström, L. Strength and adhesion characteristics of elementary flax fibres with different surface treatments. Compos. Part A Appl. Sci. Manuf. 2003, 34, 603–612. [Google Scholar] [CrossRef]

- Bos, H.L.; Oever, M.J.A.V.D.; Peters, O.C.J.J. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; El Mahi, A.; Poilâne, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax–fibres and glass–fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Amiri, A.; Ulven, C. Surface treatment of flax fiber. In Proceedings of the 65th Flax Institute of the United States, Fargo, ND, USA, 27–28 March 2014. [Google Scholar]

- Stamboulis, A.; Baillie, C.A.; Garkhail, S.K.; Van Melick, H.G.H.; Peijs, T. Environmental durability of flax fibres and their composites based on polypropylene matrix. Appl. Compos. Mater. 2000, 7, 273–294. [Google Scholar] [CrossRef]

- Brett, C.T.; Waldron, K.W. Physiology and Biochemistry of Plant Cell Walls; Springer: Berlin, Germany, 1996. [Google Scholar]

- Morton, W.; Hearle, J. Physical Properties of Textile Fibers, 4th ed.; Wood Head Publishing Limited: Cambridge, UK, 2008. [Google Scholar]

- Stamboulis, A.; Baillie, C.; Peijs, T. Effects of environmental conditions on mechanical and physical properties of flax fibers. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1105–1115. [Google Scholar] [CrossRef]

- Springer, G. Environmental Effects on Composite Materials; Springer: Berlin, Germany, 1981; Volume 1. [Google Scholar]

- ASTM D2256-02 Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method. In Annual Book of ASTM Standards; D. ASTM International: West Conshohocken, PA, USA, 1972.

- Feng, H.; Li, J.; Wang, L. Preparation of biodegradable flax shive cellulose-based superabsorbent polymer under microwave irradiation. BioResources 2010, 5, 1484–1495. [Google Scholar]

- Warner, S.B. Fiber Science; Pearson College Division: London, UK, 1995. [Google Scholar]

| Moisture (%) | Tenacity (cN/tex) | Stiffness (N/mm) | Elongation at Failure (%) |

|---|---|---|---|

| 5 | 7.18 ± 0.94 | 4352.80 ± 495.69 | 12.78 ± 0.98 |

| 25 | 9.83 ± 0.21 | 3342.28 ± 208.27 | 22.74 ± 3.67 |

| 60 | 4.13 ± 0.29 | 3141.40 ± 100.95 | 21.49 ± 3.23 |

| 80 | 3.06 ± 0.07 | 2700.88 ± 135.42 | 28.27 ± 0.34 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radkar, S.S.; Amiri, A.; Ulven, C.A. Tensile Behavior and Diffusion of Moisture through Flax Fibers by Desorption Method. Sustainability 2019, 11, 3558. https://doi.org/10.3390/su11133558

Radkar SS, Amiri A, Ulven CA. Tensile Behavior and Diffusion of Moisture through Flax Fibers by Desorption Method. Sustainability. 2019; 11(13):3558. https://doi.org/10.3390/su11133558

Chicago/Turabian StyleRadkar, Swarda S., Ali Amiri, and Chad A. Ulven. 2019. "Tensile Behavior and Diffusion of Moisture through Flax Fibers by Desorption Method" Sustainability 11, no. 13: 3558. https://doi.org/10.3390/su11133558