Comparison of Carbon Dioxide Emissions of the Ordinary Reinforced Concrete Slab and the Voided Slab System During the Construction Phase: A Case Study of a Residential Building in South Korea

Abstract

:1. Introduction

2. Research Method

2.1. Overview of the CO2 Calculation Method

- (1)

- Embodied carbon dioxide emissions of building materials before the materials are transported to the construction site;

- (2)

- Carbon dioxide emissions from transporting the building materials to the construction site, which are the result of fuel consumption during the transportation process;

- (3)

- Carbon dioxide emissions from fuel consumption due to operation of equipment and machinery on site;

- (4)

- Carbon dioxide emissions from electricity usage at the construction site;

- (5)

- Carbon dioxide emissions from fuel consumption due to transporting the construction waste.

2.2. Calculation Method for Carbon Dioxide Emissions of Building Materials

2.3. Calculation Method for Transportation of Building Materials

2.4. Calculation Method for Carbon Dioxide Emissions from Fuel Consumption of Construction Equipment Operation

2.5. Calculation Method for Carbon Dioxide Emissions from Electricity Usage at the Construction Site

2.6. Calculation Method for Carbon Dioxide Emission from Fuel Consumption Due to Transportation of Construction Waste

3. Data Analysis

3.1. Total CO2 Emissions of the Ordinary Reinforced Concrete Slab and the Voided Slab System

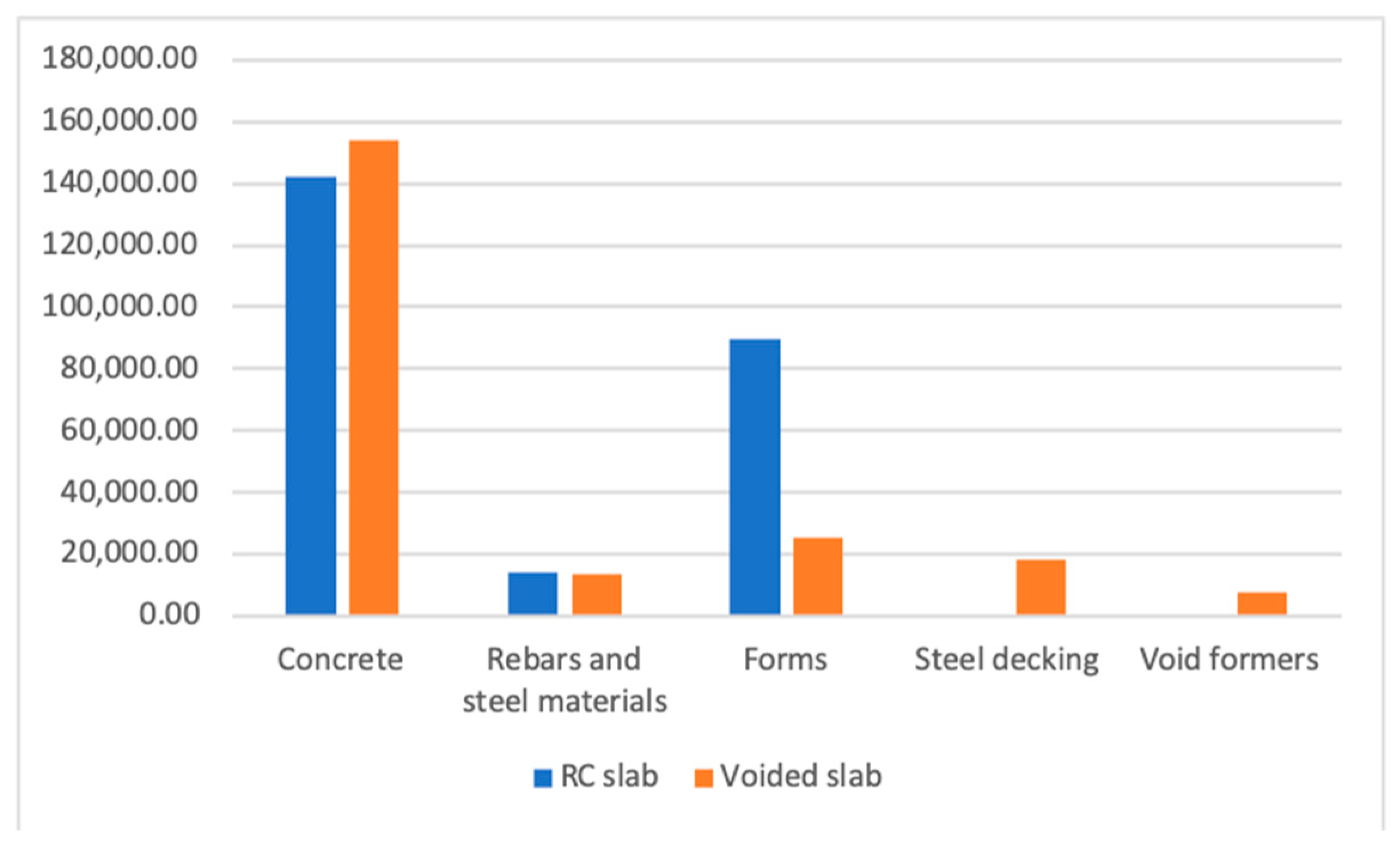

3.2. Carbon Dioxide Emissions of the Building Materials

3.3. Carbon Dioxide Emissions of Transporting Building Materials

3.4. Carbon Dioxide Emissions from Fuel Consumption of Construction Equipment Operation

3.5. Carbon Dioxide Emissions from Electricity Usage and Construction Waste Transportation

3.6. Comparison of the Carbon Dioxide Emissions by Structural Members

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kim, T.H.; Chae, C.U.; Kim, G.H.; Jang, H.J. Analysis of CO2 emissions characteristics of concrete used at construction sites. Sustainability 2016, 8, 348. [Google Scholar] [CrossRef]

- Baek, C.; Tae, S.; Kim, R.; Shin, S. Life cycle CO2 assessment by block type changes of apartment housing. Sustainability 2016, 8, 752. [Google Scholar] [CrossRef]

- Martí, J.V.; García-Segura, T.; Yepes, V. Structural design of precast-prestressed concrete U-beam road bridges based on embodied energy. J. Clean. Prod. 2016, 120, 231–240. [Google Scholar] [CrossRef]

- Kim, T.; Tae, S. A study on the development of an evaluation system of CO2 emission in the production of concrete. J. Korea Concr. Inst. 2010, 22, 787–796. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life cycle analysis in the construction sector: Guiding the optimization of conventional Italian buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng.-Energy 2008, 161, 87–98. [Google Scholar] [CrossRef] [Green Version]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.-T.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef]

- Lee, J.; Tae, S.; Kim, R. A Study on the analysis of CO2 emissions of apartment housing in the construction process. Sustainability 2018, 10, 365. [Google Scholar] [CrossRef]

- Wang, J.; Tam, V.W.Y. Construction industry carbon dioxide emissions in Shenzhen, China. In Proceedings of the Institution of Civil Engineers-Waste and Resource Management; Thomas Telford Ltd.: London, UK, 2016; Volume 169, pp. 114–122. [Google Scholar]

- Intergovernmental Panel on Climate Change. Global Warming of 1.5C; Intergovernmental Panel on Climate Change: Incheon, South Korea, 2018. [Google Scholar]

- United Nations Environment Programme. Annual Report 2015; UNEP: Nairobi, Kenya, 2015. [Google Scholar]

- Campisi, D.; Gitto, S.; Morea, D. An evaluation of energy and economic efficiency in residential buildigns sector: A multi-criteria analysis on an Italian case study. Int. J. Energy Econ. Policy 2018, 8, 185–196. [Google Scholar]

- Yi, I.S.; Seo, K.S. Social Indicators in Korea; National Statistical Office: Seoul, Korea, 2010. [Google Scholar]

- Cole, R.J. Energy and greenhouse gas emissions associated with the construction of alternative structural systems. Build. Environ. 1999, 34, 335–348. [Google Scholar] [CrossRef]

- Yan, H.; Shen, Q.; Fan, L.C.; Wang, Y.; Zhang, L. Greenhouse gas emissions in building construction: A case study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef] [Green Version]

- González, M.J.; Navarro, J.G. Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: Practical case study of three houses of low environmental impact. Build. Environ. 2006, 41, 902–909. [Google Scholar] [CrossRef]

- Park, J.; Tae, S.; Kim, T. Life cycle CO2 assessment of concrete by compressive strength on construction site in Korea. Renew. Sustain. Energy Rev. 2012, 16, 2940–2946. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Wang, F. Assessment of embodied carbon emissions for building construction in China: Comparative case studies using alternative methods. Energy Build. 2016, 130, 330–340. [Google Scholar] [CrossRef]

- Peng, C. Calculation of a building’s life cycle carbon emissions based on Ecotect and building information modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- Li, L.; Chen, K. Quantitative assessment of carbon dioxide emissions in construction projects: A case study in Shenzhen. J. Clean. Prod. 2017, 141, 394–408. [Google Scholar] [CrossRef]

- Kumar, V.; Hewage, K.; Sadiq, R. Life cycle assessment of residential buildings: A case study in Canada. Int. J. Energy Environ. Eng. 2015, 9, 1017–1025. [Google Scholar]

- You, F.; Hu, D.; Zhang, H.; Guo, Z.; Zhao, Y.; Wang, B.; Yuan, Y. Carbon emissions in the life cycle of urban building system in China—A case study of residential buildings. Ecol. Complex. 2011, 8, 201–212. [Google Scholar] [CrossRef]

- Gan, V.J.; Chan, C.; Tse, K.; Lo, I.M.; Cheng, J.C. A comparative analysis of embodied carbon in high-rise buildings regarding different design parameters. J. Clean. Prod. 2017, 161, 663–675. [Google Scholar] [CrossRef]

- Dong, Y.H.; Jaillon, L.C.; Chu, P.; Poon, C. Comparing carbon emissions of precast and cast-In-Situ construction methods—A case study of high-rise private building. Constr. Build. Mater. 2015, 99, 39–53. [Google Scholar] [CrossRef]

- Guggemos, A.A.; Horvath, A. Comparison of environmental effects of steel-and concrete-framed buildings. J. Infrastruct. Syst. 2005, 11, 93–101. [Google Scholar] [CrossRef]

- Han, Y.-S.; Kim, S.-D. A comparative study on CO2 amount of construction material in structural design. J. Archit. Inst. Korea 2005, 25, 203–206. [Google Scholar]

- Xing, S.; Xu, Z.; Jun, G. Inventory analysis of LCA on steel-and concrete-construction office buildings. Energy Build. 2008, 40, 1188–1193. [Google Scholar] [CrossRef]

- Kim, T.; Chae, C.; Kim, G.; Jang, H. Analysis of CO2 emission characteristics of concrete used at construction sites. Sustainability 2016, 8. [Google Scholar] [CrossRef]

- Lee, S.; Park, W.; Lee, H. Life cycle CO2 assessment method for concrete using CO2 balance and suggestion to decrease LCCO2 of concrete in South-Korean apartment. Energy Build. 2013, 58, 93–102. [Google Scholar] [CrossRef]

- Cho, S.-H.; Chae, C.-U. A study on life cycle CO2 emissions of low-carbon building in South Korea. Sustainability 2016, 8, 579. [Google Scholar] [CrossRef]

- Cho, S.H.; Chae, C.-U. The comparative study on the environmental impact assessment of construction material through the application of carbon reducing element-focused on global warming potential of concrete products. Int. J. Korea Inst. Ecol. Archit. Environ. 2015, 33, 149–156. [Google Scholar]

- Tae, S.; Baek, C.; Shin, S. Life cycle CO2 evaluation on reinforced concrete structures with high-strength concrete. Environ. Impact Assess. Rev. 2011, 31, 253–260. [Google Scholar] [CrossRef]

- Cho, S.; Na, S. The reduction of CO2 emissions by application of high-strength reinforcing bars to three different structural systems in South Korea. Sustainability 2017, 9, 1652. [Google Scholar]

- Aldejohann, M.; Schnellenbach-Held, M. Investigations on the shear capacity of biaxial hollow slabs-test results and evaluation. Darmstadt Concr. 2003, 18, 532–545. [Google Scholar]

- Cho, S.; Na, S. Evaluation of the Flexural Performance and CO2 Emissions of the Voided Slab. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef]

- Ibrahim, I.; Elliott, K.; Abdullah, R.; Kueh, A.; Sarbini, N. Experimental study on the shear behaviour of precast concrete hollow core slabs with concrete topping. Eng. Struct. 2016, 125, 80–90. [Google Scholar] [CrossRef]

- Lee, K.; Lee, G.; Hwang, H. Hollow Core Slab by Light Weight Assembly. Patent 1009584070000, 10 May 2010. [Google Scholar]

- Chung, J.-H.; Jung, H.-S.; Bae, B.-I.; Choi, C.-S.; Choi, H.-K. Two-Way Flexural Behavior of Donut-Type Voided Slabs. Int. J. Concr. Struct. Mater. 2018, 12, 26. [Google Scholar] [CrossRef]

- Lave, L.; Hendrickson, C.; Horvath, A.; Joshi, S. Economic input-output models for environment life-cycle assessment. Environ. Sci. Technol. 2002, 32, e191. [Google Scholar]

- Miller, R.E.; Blair, P.D. Input-Output Analysis: Foundations and Extensions; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Gay, P.W.; Proops, J.L. Carbon dioxide production by the UK economy: An input-output assessment. Appl. Energy 1993, 44, 113–130. [Google Scholar] [CrossRef]

- Minx, J.C.; Wiedmann, T.; Wood, R.; Peters, G.; Lenzen, M.; Owen, A.; Scott, K.; Barrett, J.; Hubacek, K.; Baiocchi, G.; et al. Input–output analysis and carbon footprinting: An overview of applications. Econ. Syst. Res. 2009, 21, 187–216. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilarino, V.; Perez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO14044: Life Cycle Assessment (Requirement and Guidelines); International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO:21930: Environmental Declaration of Building Product; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life cycle primary energy use and carbon emission of an eight-storey wood-framed apartment building. Energy Build. 2010, 42, 230–242. [Google Scholar] [CrossRef]

- Suzuki, M.; Oka, T. Estimation of life cycle energy consumption and CO2 emission of office buildings in Japan. Energy Build. 1998, 28, 33–41. [Google Scholar] [CrossRef]

- American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318-05) and Commentary (ACI 318R-05); American Concrete Institute: Farmington Hills, MI, USA, 2005. [Google Scholar]

- American Society of Civil Engineers. Minimum Design Loads and Associated Criteria for Buildings and Other Structures (7–10); American Society of Civil Engineers: Reston, VA, USA, 2010. [Google Scholar]

- The Korea Environmental Industry & Technology Institute (KEITI). Korea LCI DB Information Network. 2017. Available online: http://www.epd.or.kr/en/lci/lci_intro.asp (accessed on 2 April 2019).

- Korea Ministry of Land, Infrastructure and Transport. Standard Specification for Construction; Korea Ministry of Land, Infrastructure and Transport: Sejong, Korea, 2013. [Google Scholar]

| Design guidance | American Concrete Institute (ACI 318-05, Building code requirement for reinforced concrete [49]) American Society of Civil Engineers (ASCE/SEI 7-10, Minimum design loads and associated criteria for buildings and other structures [50]) |

| Compressive strength of the concrete | fck = 24 MPa |

| Tensile strength of the rebars | fy = 400 MPa |

| Dead load | 7.94 kN/m2 |

| Live load | 4.00 kN/m2 |

| Materials | Unit | Emission Factors (kg CO2-eq/unit) | Resource |

|---|---|---|---|

| Ready-mixed concrete (25-240-15) | m3 | 4.20 × 102 | The Korean National Life-Cycle Inventory Database (KLCI DB) |

| Rebars | kg | 3.40 × 101 | |

| Forms | m2 | 1.46 × 102 | |

| Expanded polystyrene (EPS) | kg | 1.87 × 101 | |

| Steel decking | m2 | 3.85 × 101 |

| Materials | Distance (Unit: km) | Type of Transportation |

|---|---|---|

| Ready mixed concrete | 25 | Concrete mixer |

| Reinforcing bars | 380 | Lorry (11.5 ton) |

| Steel decking | 110 | Lorry (11.5 ton) |

| Forms | 30 | Lorry (4.5 ton) |

| Void formers | 40 | Lorry (4.5 ton) |

| Type of fuel | Unit | Emission Factors (kg CO2-eq/unit) | Resource |

|---|---|---|---|

| Diesel | kg | 6.82 × 10−2 | National LCI DB [51] |

| Petrol | kg | 8.32 × 10−2 | National LCI DB [1] |

| Sources | Ordinary Reinforced Concrete Slab (O) | Voided Slab System (V) | Reduction | Percentage ([O - V] / O) | |||

|---|---|---|---|---|---|---|---|

| CO2 | % | CO2 | % | O - V | % | ||

| E1 | 246,082 | 95.6 | 211,116 | 96.5 | 34,966 | 91.1 | 14.2 |

| E2 | 8744 | 3.4 | 5327 | 2.4 | 3417 | 8.9 | 39.1 |

| E3 | 351 | 0.14 | 363 | 0.17 | -12 | -0.03 | -3.2 |

| E4 | 830 | 0.32 | 820 | 0.37 | 10 | 0.03 | 1.2 |

| E5 | 1223 | 0.50 | 1174 | 0.54 | 13 | 0.03 | 1.1 |

| Total | 257,230 | 100 | 218,800 | 100 | 38,394 | 100 | 14.9 |

| Materials | Ordinary Reinforced Concrete | Voided Slab System | Reduction | Sources | ||||

|---|---|---|---|---|---|---|---|---|

| kg CO2 | % | kg CO2 | % | kg CO2 | % | |||

| Concrete | Slab | 61,043 | 24.8 | 92,820 | 43.9 | −31,777 | −12.9 | KLCI DB [51] |

| Beams and girders | 81,383 | 33.1 | 61,315 | 29.0 | 20,068 | 8.2 | ||

| Sub-total | 142,426 | 57.9 | 154,135 | 72.9 | −11,709 | −4.7 | ||

| Rebars and steel materials | Slab | 4403 | 1.8 | 6617 | 3.1 | −459 | −0.2 | |

| Beams and girders | 9750 | 4.0 | 6929 | 3.3 | 587 | 0.3 | ||

| Sub-total | 13,546 | 5.8 | 13,546 | 6.4 | 125 | 0.1 | ||

| Forms | Slab | 48,110 | 19.6 | 0 | 0 | 48,110 | 19.6 | |

| Beams and girders | 41,392 | 16.8 | 25,269 | 12.0 | 16,123 | 6.6 | ||

| Sub-total | 89,502 | 36.4 | 25,269 | 12.0 | 64,233 | 26.2 | ||

| Steel decking | N.A. | N.A. | 18,165 | 8.6 | −18,165 | −7.4 | ||

| Void formers | N.A. | N.A. | 7,836 | 0 | −0.000008 | 0 | ||

| Total | 246,082 | 100 | 218,951 | 100 | 27,131 | 12.4 | ||

| Ordinary Reinforced Concrete Slab | Voided Slab System | |

|---|---|---|

| Volume of concrete (m3) | 339.11 | 366.99 |

| Concrete pouring time (hour) | 9.0 | 9.7 |

| Fuel in the active time (l) | 66.69 | 72.17 |

| Fuel in the idling time (l) | 50.78 | 54.57 |

| CO2 emissions (kg CO2) | 351 | 363 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paik, I.; Na, S. Comparison of Carbon Dioxide Emissions of the Ordinary Reinforced Concrete Slab and the Voided Slab System During the Construction Phase: A Case Study of a Residential Building in South Korea. Sustainability 2019, 11, 3571. https://doi.org/10.3390/su11133571

Paik I, Na S. Comparison of Carbon Dioxide Emissions of the Ordinary Reinforced Concrete Slab and the Voided Slab System During the Construction Phase: A Case Study of a Residential Building in South Korea. Sustainability. 2019; 11(13):3571. https://doi.org/10.3390/su11133571

Chicago/Turabian StylePaik, Inkwan, and Seunguk Na. 2019. "Comparison of Carbon Dioxide Emissions of the Ordinary Reinforced Concrete Slab and the Voided Slab System During the Construction Phase: A Case Study of a Residential Building in South Korea" Sustainability 11, no. 13: 3571. https://doi.org/10.3390/su11133571