Influence of Surface Treatment of Recycled Aggregates on Mechanical Properties and Bond Strength of Self-Compacting Concrete

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials and Sample Preparation

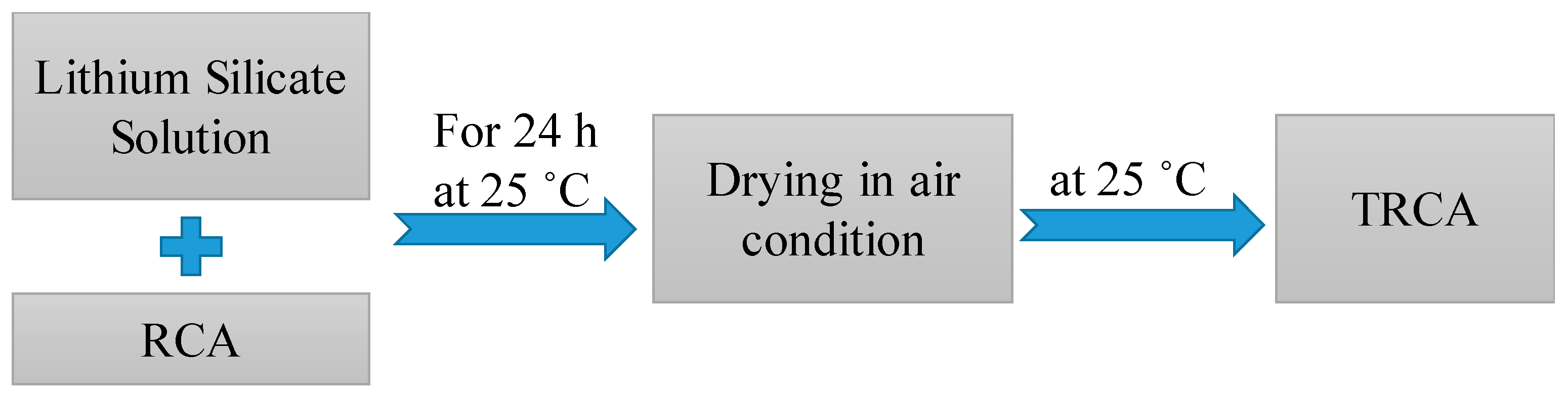

2.2. Treatment Procedure for RCA

2.3. Physical and Mechanical Tests

3. Results and Discussion

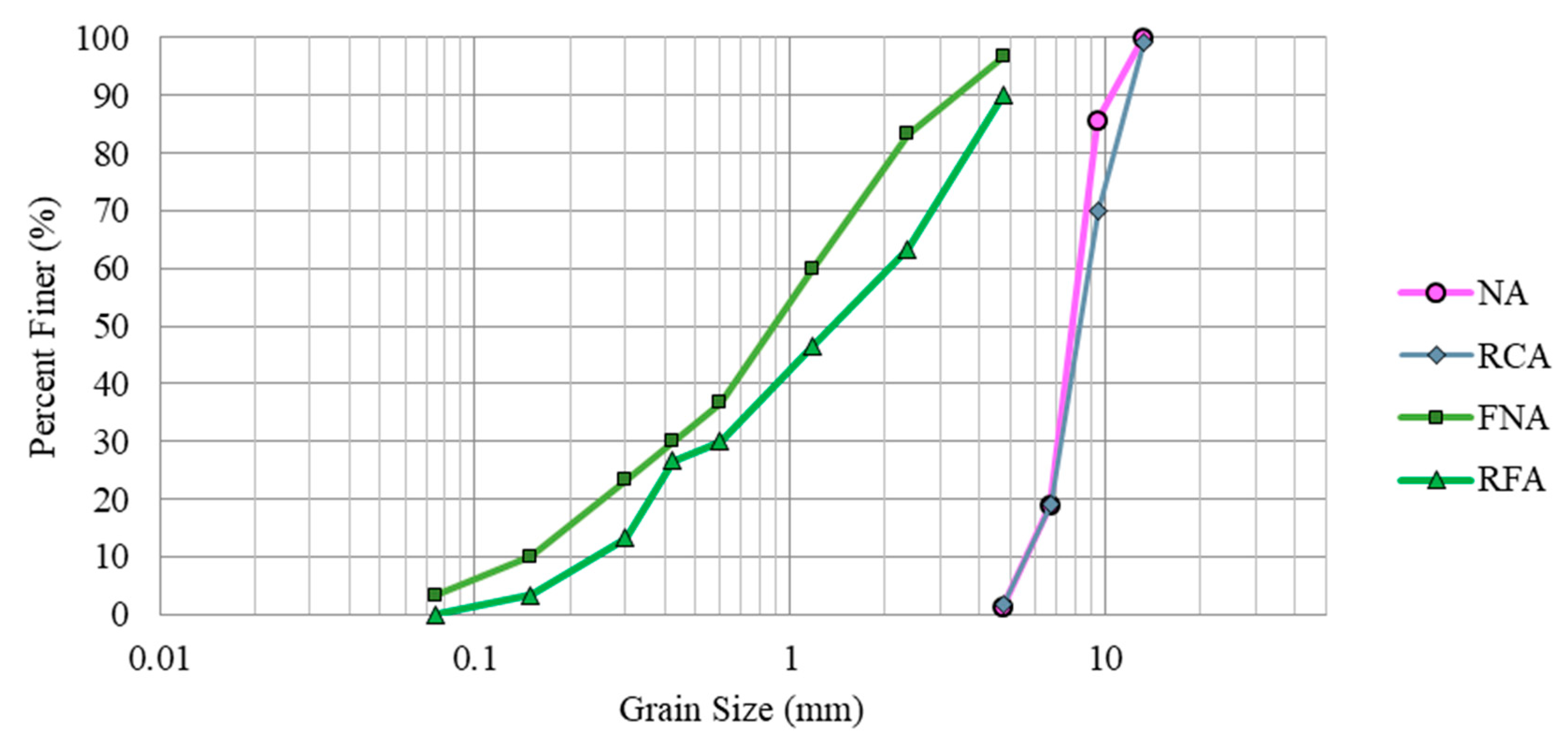

3.1. Particle Size Distribution

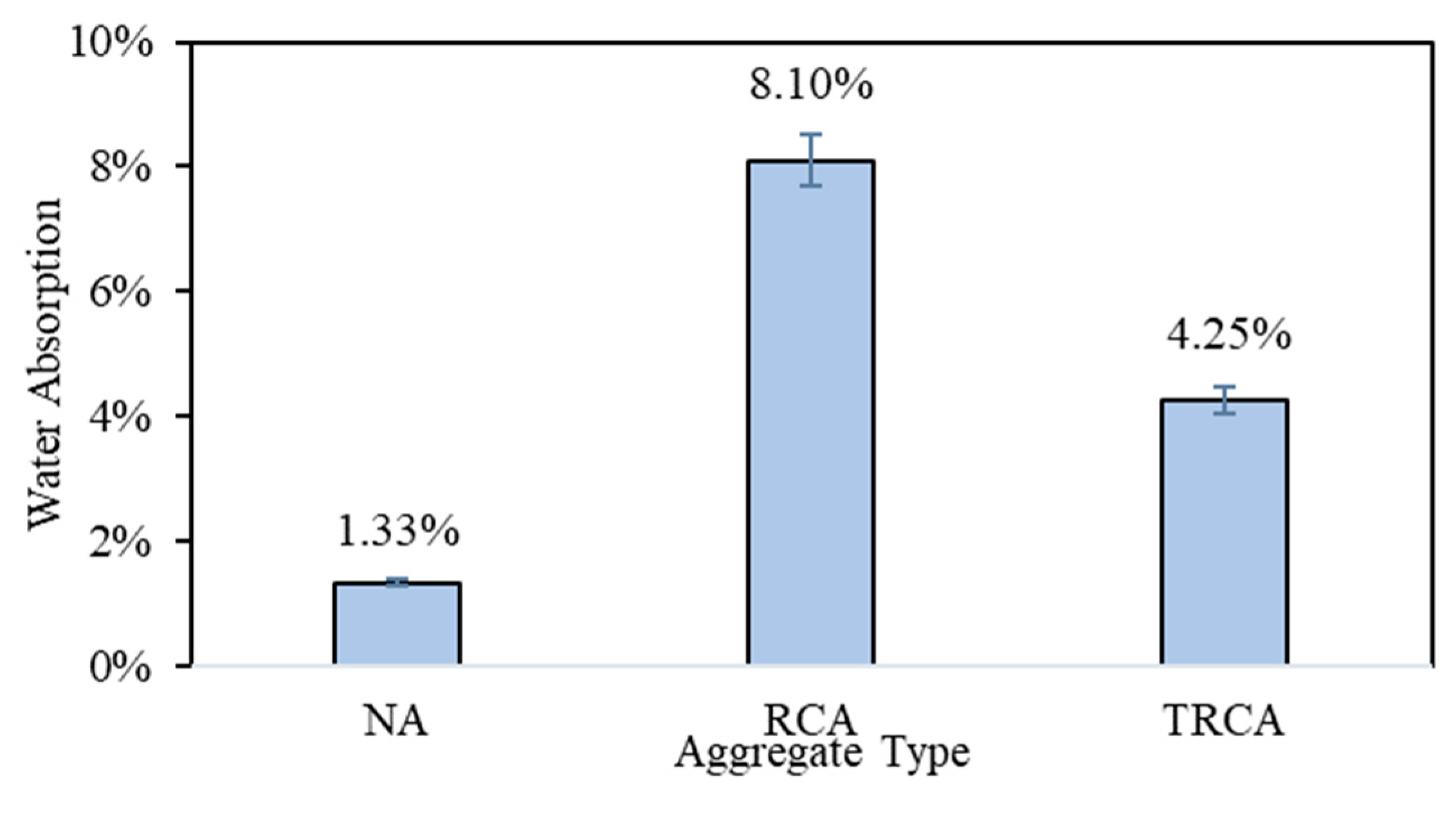

3.2. Water Absorption

3.3. Workability and Density

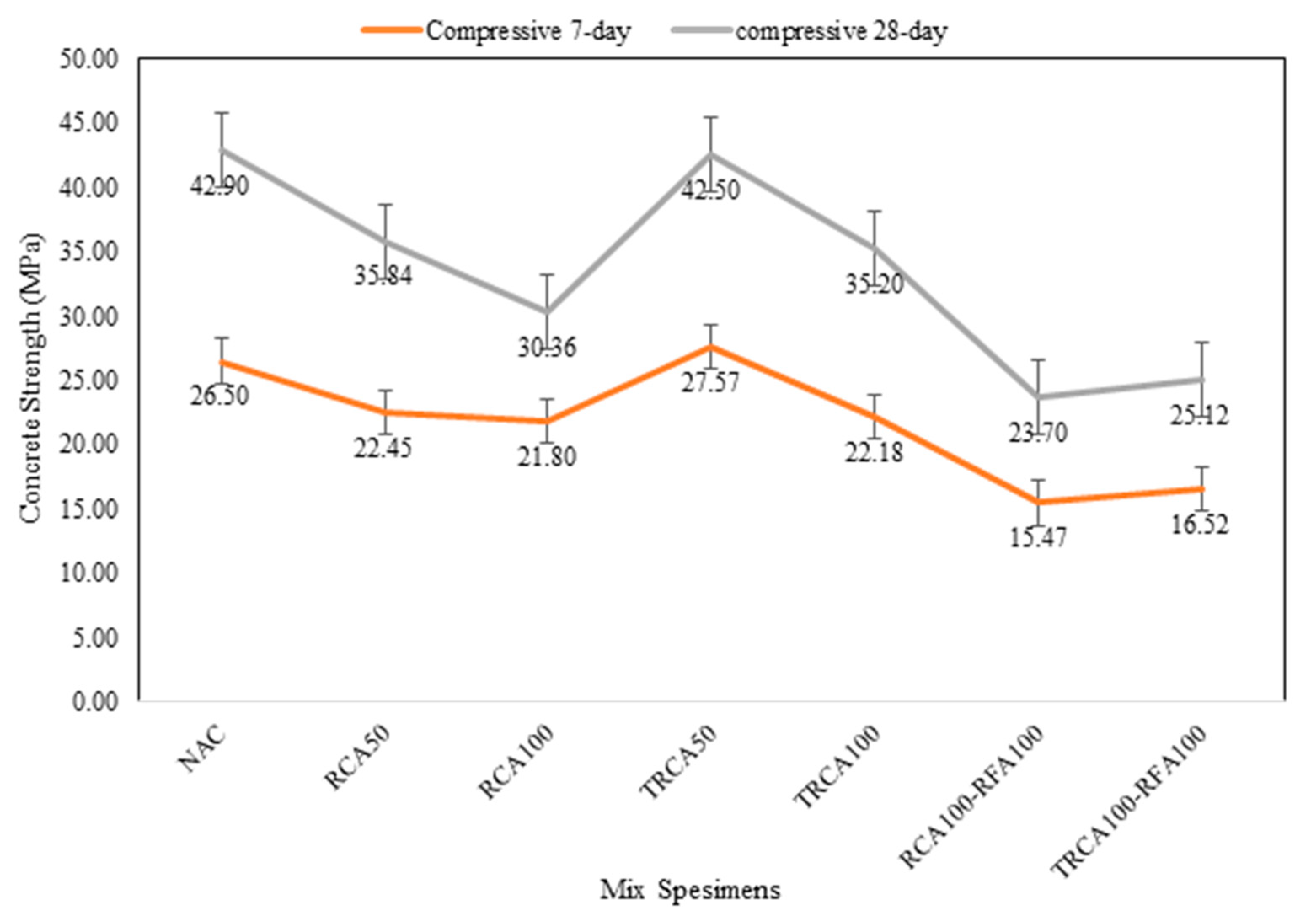

3.4. Compressive Strength

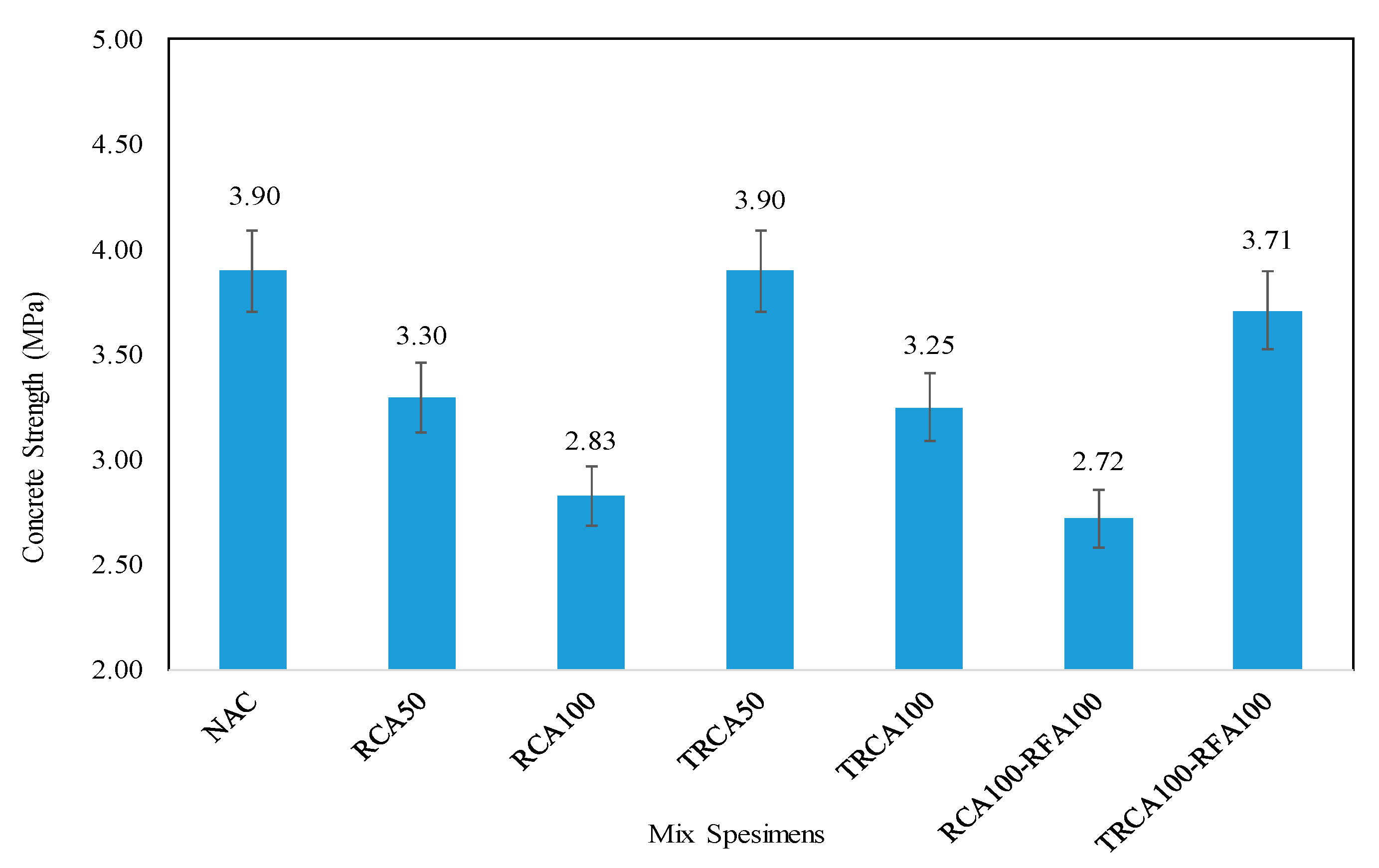

3.5. Tensile Strength

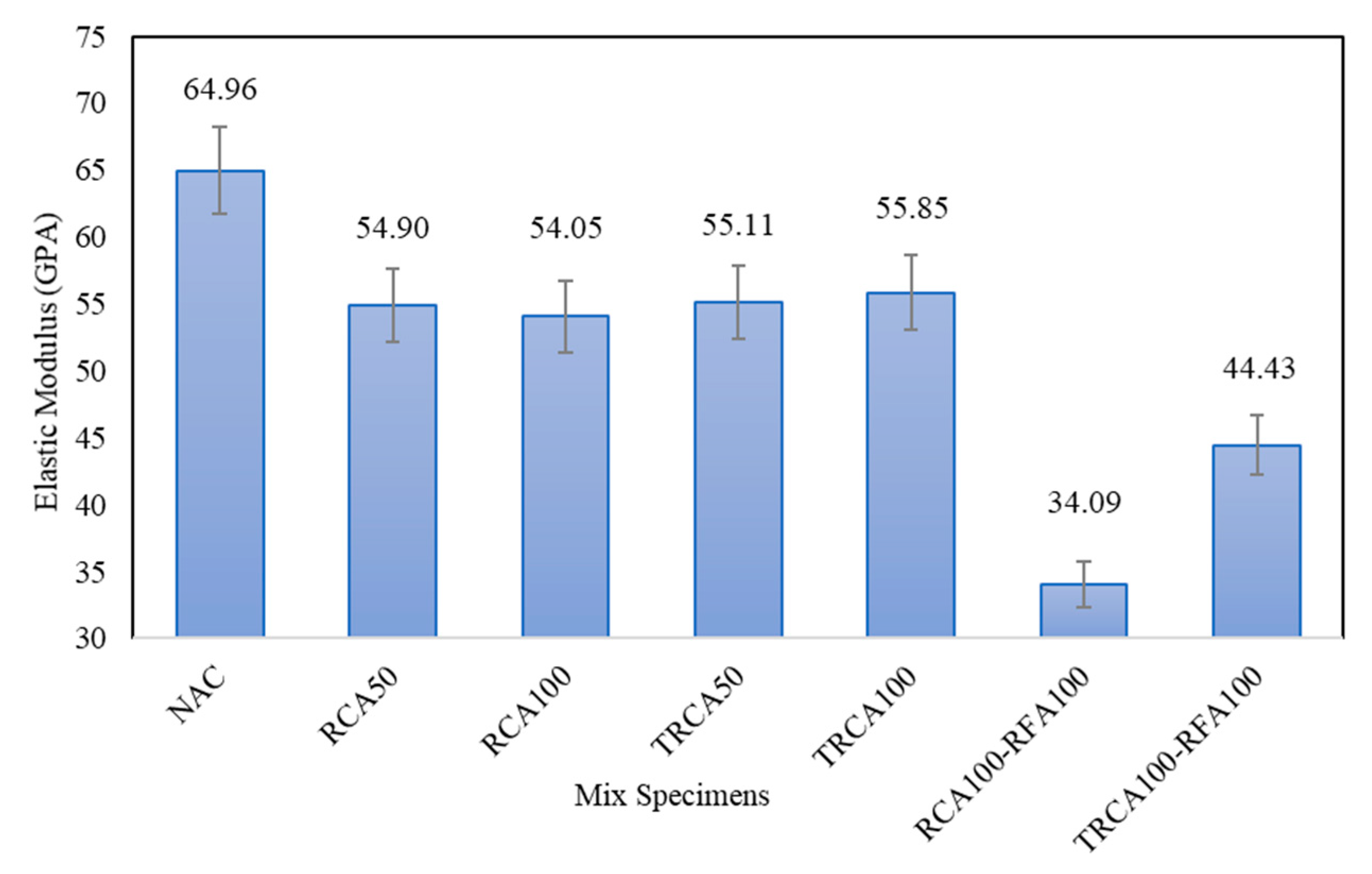

3.6. Elastic Modulus

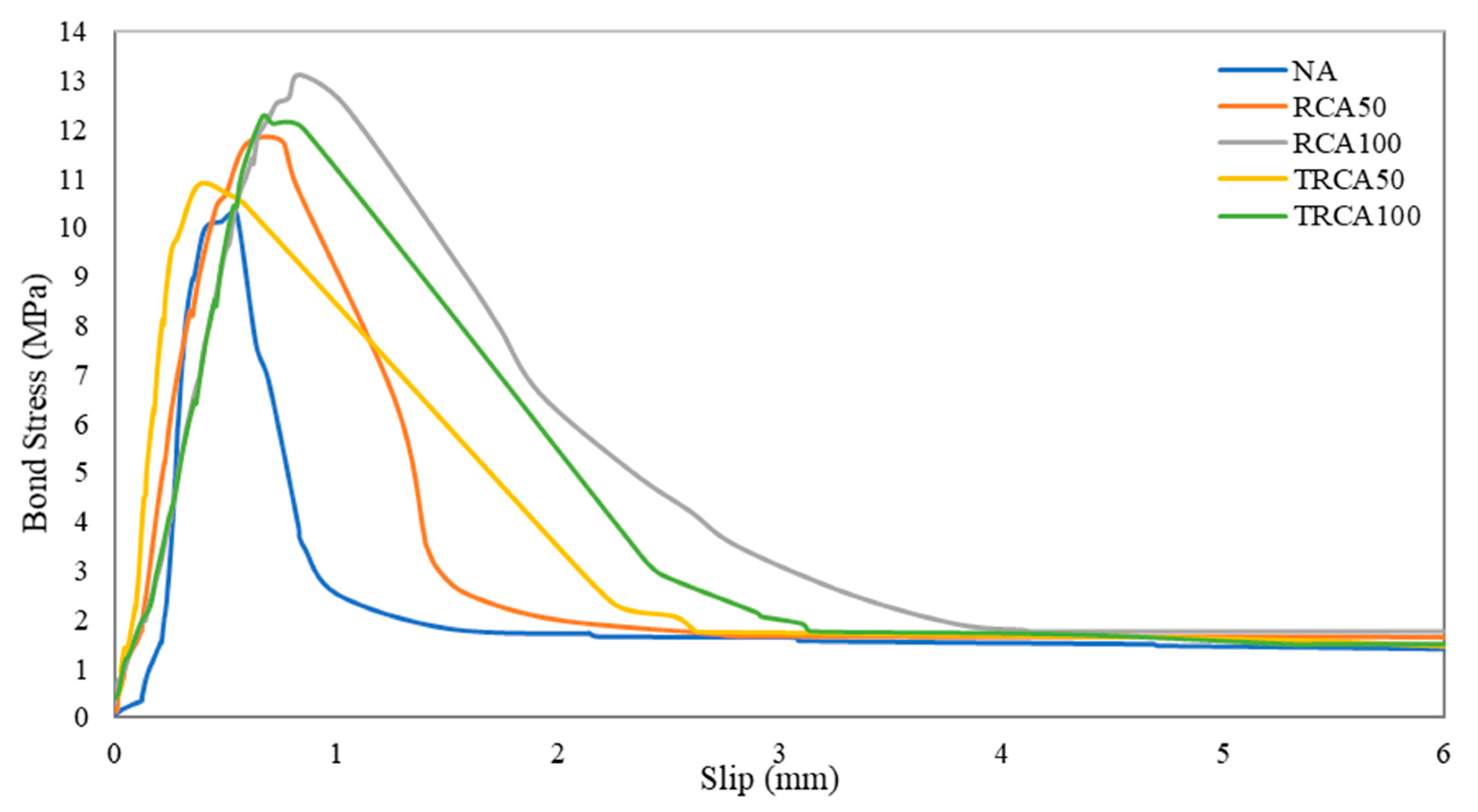

3.7. Pull-Out Test

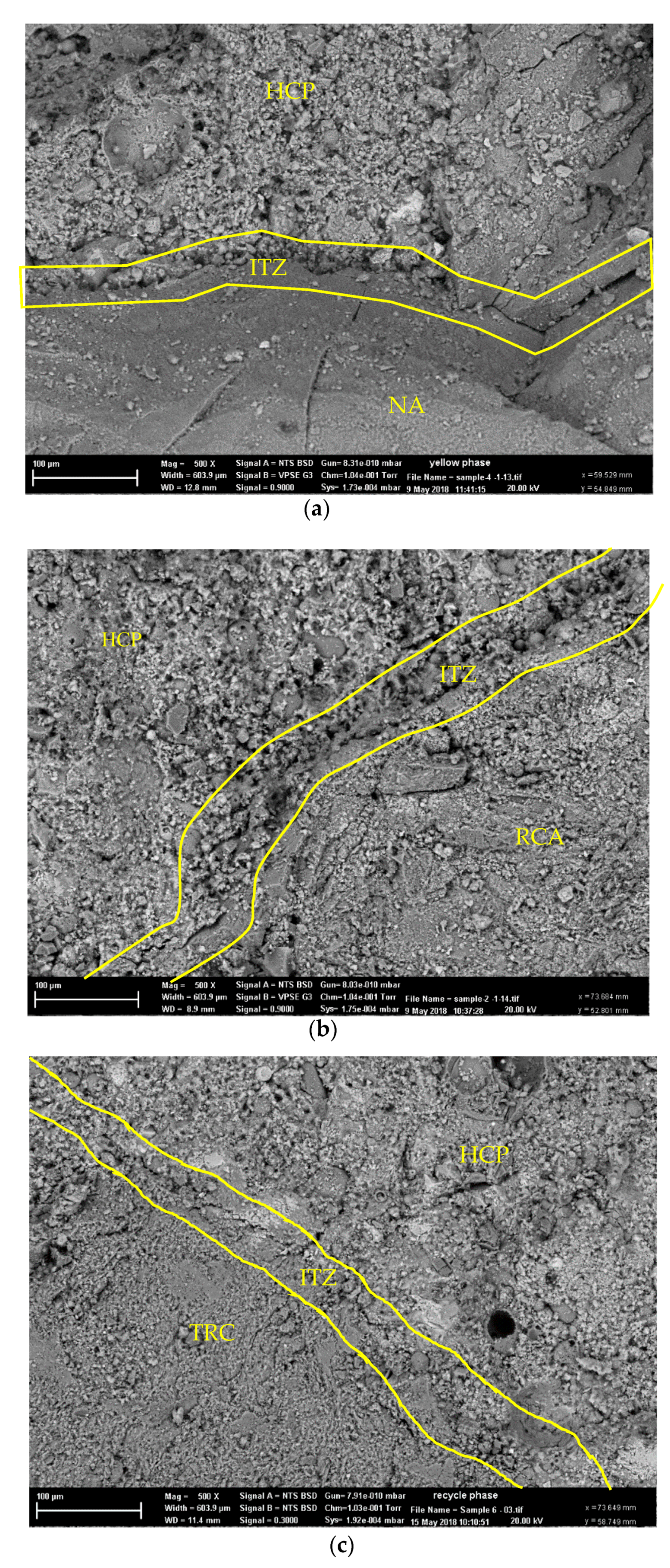

3.8. Microstructure Observation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thomas, M.D.A.; Fournier, B.; Folliard, K.J.; Ideker, J.H.; Resendez, Y. The Use of Lithium to Prevent or Mitigate Alkali-Silica Reaction in Concrete Pavements and Structures; Turner-Fairbank Highway Research Center: McLean, VA, USA, 2007.

- Xu, Y.; Chen, J. Study on Preparation Technology of Recycled Aggregate Rapid Repair Concrete. In Proceedings of the 2010 International Conference on E-Product E-Service and E-Entertainment, Henan, China, 7–9 November 2010; pp. 1–4. [Google Scholar]

- Ismail, S.; Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 2013, 44, 464–476. [Google Scholar] [CrossRef]

- Senaratne, S.; Lambrousis, G.; Mirza, O.; Tam, V.W.Y.; Kang, W.H. Recycled Concrete in Structural Applications for Sustainable Construction Practices in Australia. Procedia Eng. 2017, 180, 751–758. [Google Scholar] [CrossRef]

- Radonjanin, V.; Malešev, M.; Marinković, S.; Al Malty, A.E.S. Green recycled aggregate concrete. Constr. Build. Mater. 2013, 47, 1503–1511. [Google Scholar] [CrossRef]

- Ryan, P.C.; O’Connor, A. Examination of Self-Compacting Concrete Options for Marine Bridge Applications. J. Bridge Eng. 2014, 19, 04014032. [Google Scholar] [CrossRef]

- Tang, W.; Ryan, P.; Cui, H.; Liao, W. Properties of self-compacting concrete with recycled coarse aggregate. Adv. Mater. Sci. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Mohseni, E.; Saadati, R.; Kordbacheh, N.; Parpinchi, Z.S.; Tang, W. Engineering and microstructural assessment of fibre-reinforced self-compacting concrete containing recycled coarse aggregate. J. Clean. Prod. 2017, 168, 605–613. [Google Scholar] [CrossRef]

- Tang, W.; Wang, Z.; Liu, Y.; Cui, H. Influence of red mud on fresh and hardened properties of self-compacting concrete. Constr. Build. Mater. 2018, 178, 288–300. [Google Scholar] [CrossRef]

- Su, N.; Hsu, K.C.; Chai, H.W. A simple mix design method for self-compacting concrete. Cem. Concr. Res. 2001, 31, 1799–1807. [Google Scholar] [CrossRef]

- Tuyan, M.; Mardani-Aghabaglou, A.; Ramyar, K. Freeze-thaw resistance, mechanical and transport properties of self-consolidating concrete incorporating coarse recycled concrete aggregate. Mater. Des. 2014, 53, 983–991. [Google Scholar] [CrossRef]

- Tang, W.C. Fresh Properties of Self-Compacting Concrete with Coarse Recycled Aggregate. Adv. Mater. Res. 2013, 602, 938–942. [Google Scholar] [CrossRef]

- Wang, H.L. Steel-concrete bond behaviour of self-compacting concrete with recycled aggregates. Mag. Concr. Res. 2016, 68, 678–691. [Google Scholar] [CrossRef]

- Ortiz, J.; de la Fuente, A.; Sebastia, F.M.; Segura, I.; Aguado, A. Steel-fibre-reinforced self-compacting concrete with 100% recycled mixed aggregates suitable for structural applications. Constr. Build. Mater. 2017, 156, 230–241. [Google Scholar] [CrossRef] [Green Version]

- Fiol, F.; Thomas, C.; Muñoz, C.; Ortega-López, V.; Manso, J. The influence of recycled aggregates from precast elements on the mechanical properties of structural self-compacting concrete. Constr. Build. Mater. 2018, 182, 309–323. [Google Scholar] [CrossRef]

- Singh, R.B.; Singh, B. Rheological behaviour of different grades of self-compacting concrete containing recycled aggregates. Constr. Build. Mater. 2018, 161, 354–364. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Wan, D.L.Y.; Muselin, G. Development of high-performance self-compacting concrete using waste recycled concrete aggregates and rubber granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Cui, H.; Shi, X.; Memon, S.A.; Xing, F.; Tang, W. Experimental study on the influence of water absorption of recycled coarse aggregates on properties of the resulting concretes. J. Mater. Civ. Eng. 2014, 27, 04014138. [Google Scholar] [CrossRef]

- Revathi, P.; Selvi, R.; Velin, S.J.J.; Otio, E.S.A. Investigations on fresh and hardened properties of recycled aggregate self compacting concrete. J. Inst. Eng. Ser. A 2013, 94, 179–185. [Google Scholar] [CrossRef]

- Etxeberria, M.; Mari, A.; Vazquez, E. Recycled aggregate concrete as structural material. Mater. Struct. 2007, 40, 529–541. [Google Scholar] [CrossRef]

- Xiao, Z.; Ling, T.C.; Kou, S.C.; Wang, Q.; Poon, C.S. Use of wastes derived from earthquakes for the production of concrete masonry partition wall blocks. Waste Manag. 2011, 31, 1859–1866. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Wan, H.W.; Etxeberria, M. Properties of concrete blocks prepared with low grade recycled aggregates. Waste Manag. 2009, 29, 2369–2377. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; de Brito, J.; Martínez-Abella, F.; González-Taboada, I.; Silva, P. Study of the rheology of self-compacting concrete with fine recycled concrete aggregates. Constr. Build. Mater. 2015, 96, 491–501. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Algın, Z.; Yazıcı, H. Effect of surface treatment methods on the properties of self-compacting concrete with recycled aggregates. Constr. Build. Mater. 2014, 64, 172–183. [Google Scholar] [CrossRef]

- Purushothaman, R.; Amirthavalli, R.R.; Karan, L. Influence of Treatment Methods on the Strength and Performance Characteristics of Recycled Aggregate Concrete. J. Mater. Civ. Eng. 2015, 27, 04014168. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Abhiram, K.; Manoj, B. Properties of treated recycled aggregates and its influence on concrete strength characteristics. Constr. Build. Mater. 2016, 111, 611–617. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Mechanical properties of concrete containing 100% treated coarse recycled concrete aggregate. Constr. Build. Mater. 2018, 163, 496–507. [Google Scholar] [CrossRef]

- Spaeth, V.; Djerbi Tegguer, A. Improvement of recycled concrete aggregate properties by polymer treatments. Int. J. Sustain. Built Environ. 2013, 2, 143–152. [Google Scholar] [CrossRef] [Green Version]

- Qiu, J.; Tng, D.Q.S.; Yang, E.H. Surface treatment of recycled concrete aggregates through microbial carbonate precipitation. Constr. Build. Mater. 2014, 57, 144–150. [Google Scholar] [CrossRef]

- Zhu, Y.G.; Kou, S.C.; Poon, C.S.; Dai, J.G.; Li, Q.Y. Influence of silane-based water repellent on the durability properties of recycled aggregate concrete. Cem. Concr. Compos. 2013, 35, 32–38. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of concrete prepared with PVA-impregnated recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 649–654. [Google Scholar] [CrossRef]

- Kong, D.; Lei, T.; Zheng, J.; Ma, C.; Jiang, J.; Jiang, J. Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 701–708. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr. Compos. 2017, 84, 214–221. [Google Scholar] [CrossRef]

- Zapała-Sławeta, J. Alkali Silica Reaction In The Presence Of Metakaolin-The Significant Role of Calcium Hydroxide. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Prague, Czech Republic, 2017; Volume 245, p. 022020. [Google Scholar]

- Katz, A. Treatments for the improvement of recycled aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Effect surface treatment of recycled concrete aggregate on properties of fresh and hardened concrete. In Proceedings of the 2013 IEEE Business Engineering and Industrial Applications Colloquium (BEIAC), Langkawi, Malaysia, 7–9 April 2013; pp. 651–656. [Google Scholar]

- Ismail, S.; Ramli, M. Mechanical strength and drying shrinkage properties of concrete containing treated coarse recycled concrete aggregates. Constr. Build. Mater. 2014, 68, 726–739. [Google Scholar] [CrossRef]

- Kazemian, F.; Rooholamini, H.; Hassani, A. Mechanical and fracture properties of concrete containing treated and untreated recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 690–700. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H.; Zhou, Y. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Folliard, K.J.; Thomas, M.D.A.; Fournier, B.; Kurtis, K.E.; Ideker, J.H. Interim Recommendations for the Use of Lithium to Mitigate or Prevent Alkali-Slica Reaction (ASR); FHWA Report No. FHWA-RD-06-073; Federal Highway Administration: McLean, VA, USA, 2006.

- Jiang, L.; Xue, X.; Zhang, W.; Yang, J.; Zhang, H.; Li, Y.; Zhang, R.; Zhang, Z.; Xu, L.; Qu, J.; et al. The investigation of factors affecting the water impermeability of inorganic sodium silicate-based concrete sealers. Constr. Build. Mater. 2015, 93, 729–736. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H.D. Influence of recycled coarse aggregates on the bond behavior of deformed bars in concrete. Eng. Struct. 2013, 48, 133–143. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H.D. Evaluation of the bond behavior of steel reinforcing bars in recycled fine aggregate concrete. Cem. Concr. Compos. 2014, 46, 8–18. [Google Scholar] [CrossRef]

- Prince, M.J.R.; Singh, B. Bond behaviour of normal-and high-strength recycled aggregate concrete. Struct. Concr. 2015, 16, 56–70. [Google Scholar] [CrossRef]

- Kim, S.W.; Yun, H.D.; Park, W.S.; Jang, Y.I. Bond strength prediction for deformed steel rebar embedded in recycled coarse aggregate concrete. Mater. Des. 2015, 83, 257–269. [Google Scholar] [CrossRef]

- Xiao, J.; Falkner, H. Bond behaviour between recycled aggregate concrete and steel rebars. Constr. Build. Mater. 2007, 21, 395–401. [Google Scholar] [CrossRef]

- Xing, G.; Zhou, C.; Wu, T.; Liu, B. Experimental study on bond behavior between plain reinforcing bars and concrete. Adv. Mater. Sci. Eng. 2015, 2015, 10–19. [Google Scholar] [CrossRef]

- Standards Association of Australia. Methods for Sampling and Testing Aggregates Particle Size Distribution—Sieving Method; SAI Global: Sydney, Australia, 2016. [Google Scholar]

- EFNARC. Specication Guidelines for Self-Compacting Concrete; European Federationof producers and Applicators of Specialist Products for Structures: Farnham, UK, 2005. [Google Scholar]

- Nasvik, J. Lithium Silicate Densifiers. Concrete Construction. Available online: https://www.concreteconstruction.net/products/lithium-silicate-densifiers_o (accessed on 1 August 2019).

- Vinay Kumar, B.M.; Ananthan, H.; Balaji, K.V.A. Experimental studies on utilization of coarse and finer fractions of recycled concrete aggregates in self compacting concrete mixes. J. Build. Eng. 2017, 9, 100–108. [Google Scholar] [CrossRef]

- Grdic, Z.J.; Toplicic-Curcic, G.A.; Despotovic, I.M.; Ristic, N.S. Properties of self-compacting concrete prepared with coarse recycled concrete aggregate. Constr. Build. Mater. 2010, 24, 1129–1133. [Google Scholar] [CrossRef]

- Kebaïli, O.; Mouret, M.; Arabia, N.; Cassagnabere, F. Adverse effect of the mass substitution of natural aggregates by air-dried recycled concrete aggregates on the self-compacting ability of concrete: Evidence and analysis through an example. J. Clean. Prod. 2015, 87, 752–761. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Öz, H.Ö.; Taha, I.; Yasemin, M.T. Failure characteristics of self-compacting concretes made with recycled aggregates. Constr. Build. Mater. 2015, 98, 334–344. [Google Scholar] [CrossRef]

- Omrane, M.; Kenai, S.; Kadri, E.H.; Aït-Mokhtar, A. Performance and durability of self compacting concrete using recycled concrete aggregates and natural pozzolan. J. Clean. Prod. 2017, 165, 415–430. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Salam, A.; Jumaat, M.Z.; Jaafar, F.F.; Saad, H.B. Properties of high-workability concrete with recycled concrete aggregate. Mater. Res. 2011, 14, 248–255. [Google Scholar] [Green Version]

- Kheder, G.; Al-Windawi, S. Variation in mechanical properties of natural and recycled aggregate concrete as related to the strength of their binding mortar. Mater. Struct. 2005, 38, 701–709. [Google Scholar] [CrossRef]

- Rao, M.C.; Bhattacharyya, S.; Barai, S. Influence of field recycled coarse aggregate on properties of concrete. Mater. Struct. 2011, 44, 205–220. [Google Scholar]

- Pandurangana, K.; Dayanithya, A.; Om Prakashb, S. Influence of treatment methods on the bond strength of recycled aggregate concrete. Constr. Build. Mater. 2016, 120, 212–221. [Google Scholar] [CrossRef]

- Breccolotti, M.; Materazzi, A.L. Structural reliability of bonding between steel rebars and recycled aggregate concrete. Constr. Build. Mater. 2013, 47, 927–934. [Google Scholar] [CrossRef]

- Kakizaki, M.; Harada, M.; Soshiroda, T.; Kubota, S.; Ikeda, T.; Kasai, Y. Strength and elastic modulus of recycled aggregate concrete. In Proceedings of the 2nd International RILEM Symposium on Demolition and Reuse of Concrete and Masonry, Tokyo, Japan, 7–11 November 1988; pp. 565–574. [Google Scholar]

- Corinaldesi, V.; Moriconi, G.J.C. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- ACI. Bond and Development of Straight Reinforcing Bars in Tension; ACI: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Perera, S.; Mutsuyoshi, H. Shear Behavior of Reinforced High-Strength Concrete Beams. ACI Struct. J. 2013, 110, 43–52. [Google Scholar]

- Santos, W.F.; Quattrone, M.; Angulo, S.C. Treatments on CDW recycled aggregates surface using silane-based water repellent. Key Eng. Mater. 2015, 668, 197–206. [Google Scholar] [CrossRef]

- Pliya, P.; Cree, D.; Hajiloo, H.; Beaucour, A.L.; Green, M.; Noumowé, A. High-Strength Concrete Containing Recycled Coarse Aggregate Subjected to Elevated Temperatures. Fire Technol. 2019, 1–18. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Paiva, H.; Silva, A.; Velosa, A.; Cachim, P.; Ferreira, V. Microstructure and hardened state properties on pozzolan-containing concrete. Constr. Build. Mater. 2017, 140, 374–384. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Li, Y.; Pan, X.; Poon, C.S.; Xie, Z. Influence of carbonated recycled concrete aggregate on properties of cement mortar. Constr. Build. Mater. 2015, 98, 1–7. [Google Scholar] [CrossRef]

| Mix Code | Cement | Fly Ash | Coarse Natural Aggregate (NA) | Fine Natural Aggregate (FNA) | Water | Recycled Fine Aggregate (RFA) | Recycled Coarse Aggregate (RCA) | Super-Plasticizer |

|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (mL) | |

| NAC | 320 | 220 | 870 | 645 | 195 | 0 | 0 | 120 |

| RCA50 | 320 | 220 | 435 | 645 | 195 | 0 | 435 | 120 |

| RCA100 | 320 | 220 | 0 | 645 | 195 | 0 | 870 | 140 |

| TRCA50 | 320 | 220 | 435 | 645 | 195 | 0 | 435 | 200 |

| TRCA100 | 320 | 220 | 0 | 645 | 195 | 0 | 870 | 200 |

| RCA100-RFA100 | 320 | 220 | 0 | 0 | 195 | 645 | 870 | 300 |

| TRCA100-RFA100 | 320 | 220 | 0 | 0 | 195 | 645 | 870 | 300 |

| Test | EFNARC 2005 [49] | |

|---|---|---|

| Class | Target Limits | |

| Slump Flow Diameter (mm) | SF1 | (520–700 ± 80) |

| SF2 | (640–800 ± 80) | |

| SF3 | (740–900 ± 80) | |

| Viscosity T500 (s) | VS1 | ≤2 |

| VS2 | >2 | |

| Mix Code | Slump Flow Diameter | Slump Flow Class [49] | T500 | Viscosity Class [49] |

|---|---|---|---|---|

| (mm) | (s) | |||

| NAC | 700 | SF2 | 0.98 | VS1 |

| RCA50 | 570 | SF1 | 1.9 | VS1 |

| RCA100 | 520 | SF1 | 1.2 | VS1 |

| TRCA50 | 790 | SF3 | 1.0 | VS1 |

| TRCA100 | 700 | SF3 | 1.1 | VS1 |

| RCA100-RFA100 | 520 | SF1 | 4.95 | VS2 |

| TRCA100-RFA100 | 570 | SF1 | 2.32 | VS2 |

| Mix Code | Density (kg/m3) |

|---|---|

| NAC | 2330.16 |

| RCA50 | 2235.26 |

| RCA100 | 2262.27 |

| TRCA50 | 2226.09 |

| TRCA100 | 2161.99 |

| RCA100-RFA100 | 2095.99 |

| TRCA100-RFA100 | 2114.96 |

| Mix Code | Bond Strength (MPa) | BI |

|---|---|---|

| NAC | 10.28 | 11.00 |

| RCA50 | 11.76 | 10.87 |

| RCA100 | 13.11 | 10.74 |

| TRCA50 | 10.89 | 10.90 |

| TRCA100 | 12.25 | 10.83 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, W.; Khavarian, M.; Yousefi, A.; Chan, R.W.K.; Cui, H. Influence of Surface Treatment of Recycled Aggregates on Mechanical Properties and Bond Strength of Self-Compacting Concrete. Sustainability 2019, 11, 4182. https://doi.org/10.3390/su11154182

Tang W, Khavarian M, Yousefi A, Chan RWK, Cui H. Influence of Surface Treatment of Recycled Aggregates on Mechanical Properties and Bond Strength of Self-Compacting Concrete. Sustainability. 2019; 11(15):4182. https://doi.org/10.3390/su11154182

Chicago/Turabian StyleTang, Waiching, Mehrnoush Khavarian, Ali Yousefi, Ricky W. K. Chan, and Hongzhi Cui. 2019. "Influence of Surface Treatment of Recycled Aggregates on Mechanical Properties and Bond Strength of Self-Compacting Concrete" Sustainability 11, no. 15: 4182. https://doi.org/10.3390/su11154182