Evaluation Model and Empirical Study on the Competitiveness of the County Silicon Crystal Industry

Abstract

:1. Introduction

2. Materials and Methods

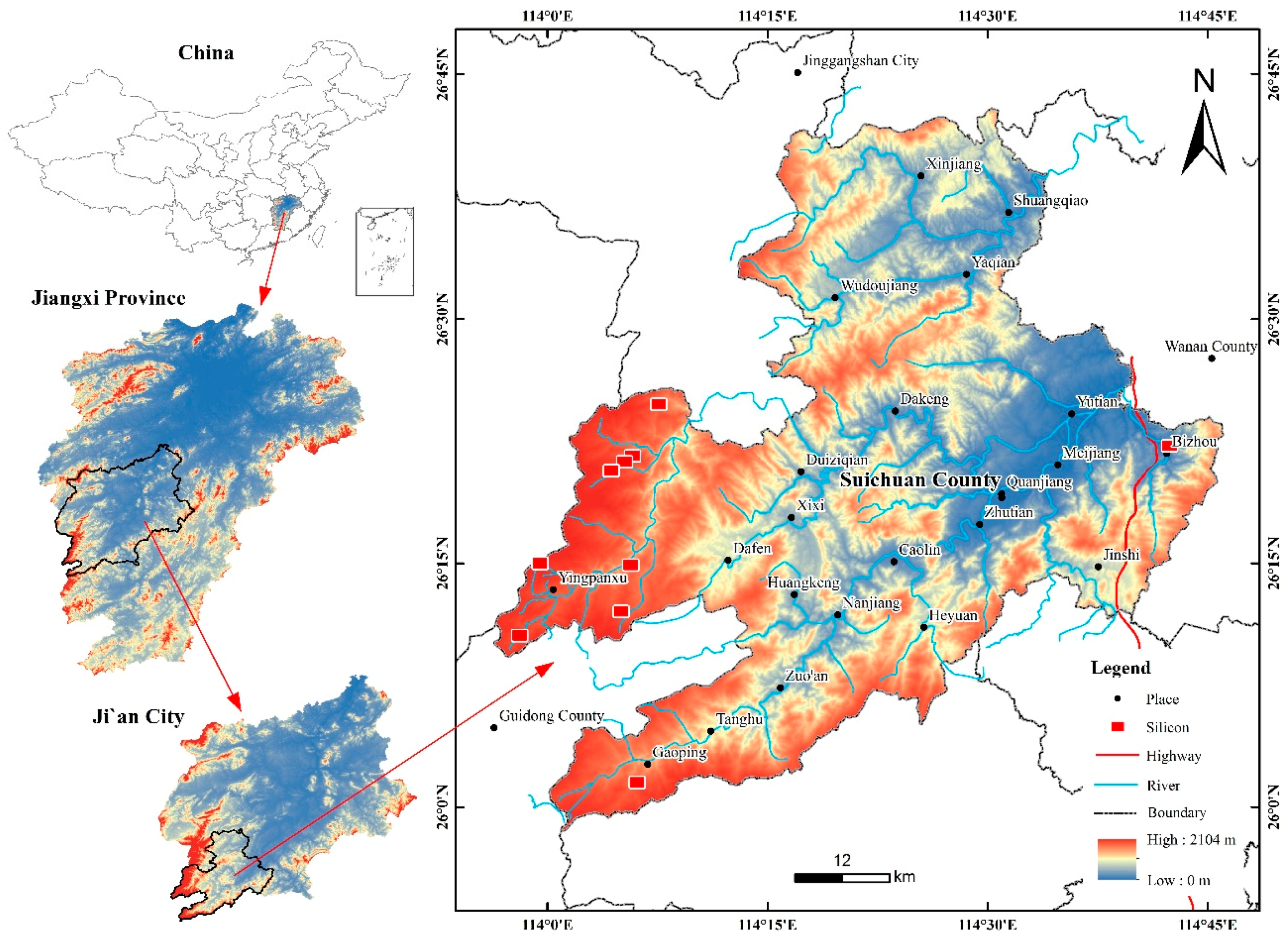

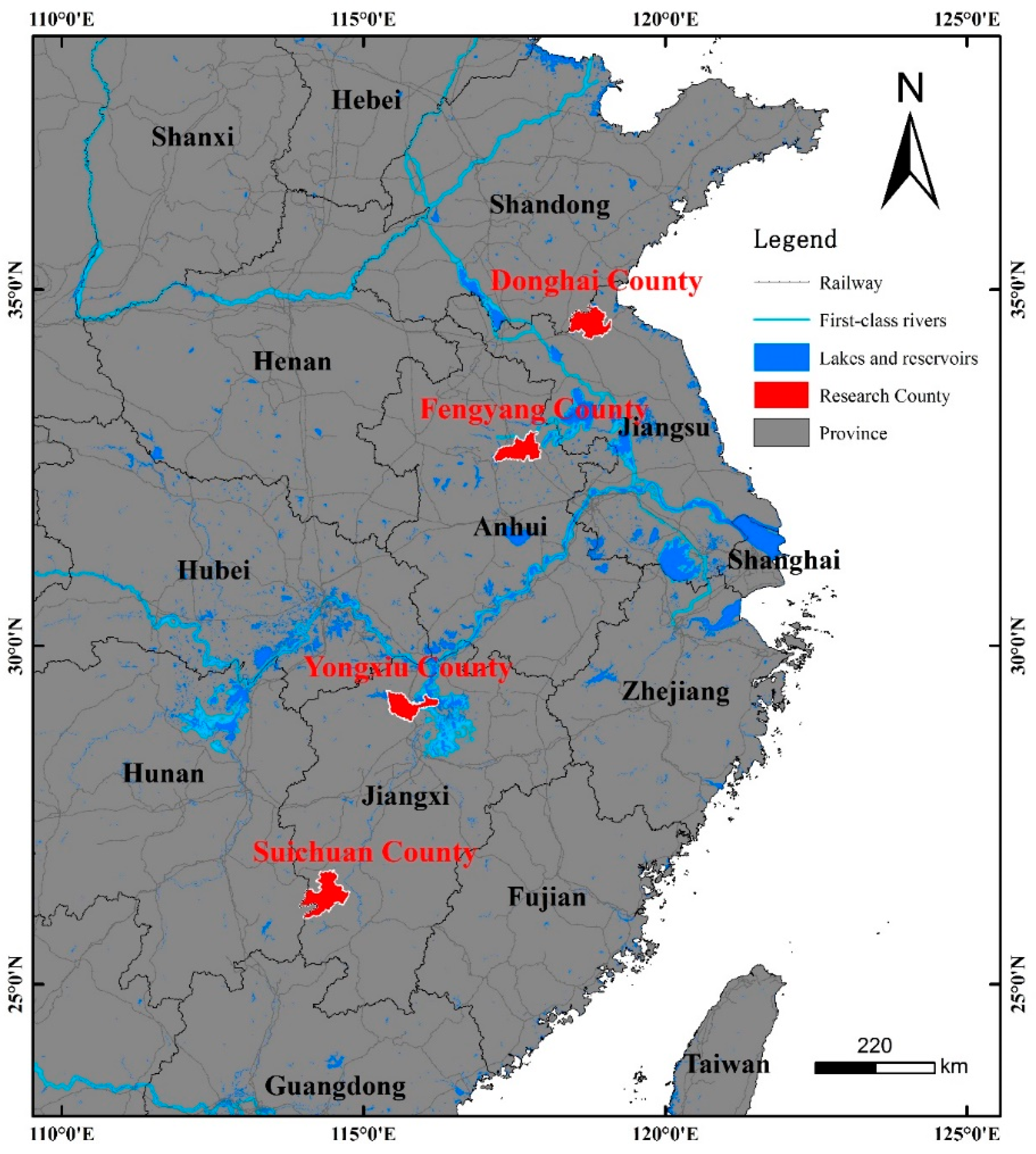

2.1. Study Area

2.2. Data Sources

2.3. Methods

2.3.1. SWOT–PEST Model

2.3.2. Grey Relational Model

3. Results and Discussion

3.1. Qualitative Analysis Based on the SWOT–PEST Model

3.2. Quantitative Analysis Based on the Grey Correlation Model

3.2.1. Establishing an Indicator System

3.2.2. Correlation Calculation

3.3. Qualitative and Quantitative Comprehensive Empirical Analysis

3.3.1. Overall Analysis

3.3.2. Stage Analysis

3.3.3. Analysis of Industrial Competitiveness in Suichuan County

3.4. Suggestions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Lin, X. Empirical analysis and strategy suggestions on the value-added capacity of photovoltaic industry value chain in China. Energy 2019, 180, 356–366. [Google Scholar] [CrossRef]

- Sun, Z.; To, S.; Yu, K.M. Feasibility investigation on ductile machining of single-crystal silicon for deep micro-structures by ultra-precision fly cutting. J. Manuf. Process. 2019, 45, 176–187. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Y.; Zeng, H.; Zhong, L.; Liu, K.; Cao, H.; Li, W.; Yan, H. Silicon carbide recovered from photovoltaic industry waste as photocatalysts for hydrogen production. J. Hazard. Mater. 2017, 329, 22–29. [Google Scholar] [CrossRef]

- Ansari Dezfoli, A.R.; Hwang, W.; Augusto, J.; Shukur, A.K.; Tzeng, S. Modeling of poly-crystalline silicon ingot crystallization during casting and theoretical suggestion for ingot quality improvement. Mat. Sci. Semicond. Proc. 2016, 53, 36–46. [Google Scholar] [CrossRef]

- Bye, G.; Ceccaroli, B. Solar grade silicon: Technology status and industrial trends. Sol. Energy Mat. Sol. Cells 2014, 130, 634–646. [Google Scholar] [CrossRef]

- Kim, C.U.; Yu, J.C.; Jung, E.D.; Choi, I.Y.; Park, W.; Lee, H.; Kim, I.; Lee, D.; Hong, K.K.; Song, M.H.; et al. Optimization of device design for low cost and high efficiency planar monolithic perovskite/silicon tandem solar cells. Nano Energy 2019, 60, 213–221. [Google Scholar] [CrossRef]

- Tang, Y.; Sun, H.; Yao, Q.; Wang, Y. The selection of key technologies by the silicon photovoltaic industry based on the Delphi method and AHP (analytic hierarchy process): Case study of China. Energy 2014, 75, 474–482. [Google Scholar] [CrossRef]

- Wang, H.X.; Xu, J.L.; Sheng, L.X. Study on the comprehensive utilization of resources city kitchen waste in China. Energy 2019, 173, 263–277. [Google Scholar] [CrossRef]

- Kanda, H.; Shibayama, N.; Uzum, A.; Umeyama, T.; Imahori, H.; Chiang, Y.; Chen, P.; Nazeeruddin, M.K.; Ito, S. Facile fabrication method of small-sized crystal silicon solar cells for ubiquitous applications and tandem device with perovskite solar cells. Mater. Today Energy 2018, 7, 190–198. [Google Scholar] [CrossRef]

- Zhang, P.; Qin, G.; Wang, Y. Risk Assessment System for Oil and Gas Pipelines Laid in One Ditch Based on Quantitative Risk Analysis. Energies 2019, 12, 981. [Google Scholar] [CrossRef]

- Chen, P. Analysis of the Industrial Status of Global Silicon Wafers. Mark. Anal. 2017, 34, 15–24. [Google Scholar]

- Gu, J.; Hu, H. On the Upgrade of Resource-Dependent Industrial Clusters-Based on the Development of Silicon Resources Industry of Donghai County. Ind. Econ. Res. 2007, 2, 57–63. [Google Scholar]

- Stuckelberger, M.; Biron, R.; Wyrsch, N.; Haug, F.; Ballif, C. Review: Progress in solar cells from hydrogenated amorphous silicon. Renew. Sustain. Energy Rev. 2017, 76, 1497–1523. [Google Scholar] [CrossRef]

- Ciszek, T.F. Photovoltaic materials and crystal growth research and development in the Gigawatt era. J. Cryst. Growth 2014, 393, 2–6. [Google Scholar] [CrossRef]

- Tseng, F.; Hsieh, C.; Peng, Y.; Chu, Y. Using patent data to analyze trends and the technological strategies of the amorphous silicon thin-film solar cell industry. Technol. Forecast Soc. 2011, 78, 332–345. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, Q.L.; Nie, P.C. The Competitiveness and Economic Contribution of China’s Emerging Strategic Industries-Taking photovoltaic industry as an example. J. Xi’an Jiaotong Univ. Soc. Sci. 2013, 33, 15–21. [Google Scholar]

- Petersen, K.E. Dynamic micromechanics on silicon: Techniques and devices. IEEE Trans. Electron Devices 1978, 25, 1241–1250. [Google Scholar] [CrossRef]

- Muller, J.C.; Martinuzzi, S. Multicrystalline silicon material: Effects of classical and rapid thermal processes. J. Mater. Res. 1998, 13, 2721–2731. [Google Scholar] [CrossRef]

- Santos, M.F.M.; Fujiwara, E.; Schenkel, E.A. Processing of quartz lumps rejected by silicon industry to obtain a raw material for silica glass. Int. J. Miner. Process. 2015, 135, 65–70. [Google Scholar] [CrossRef]

- Borghi, M.; Castellan, C.; Signorini, S. Nonlinear silicon photonics. J. Opt. 2017, 9, 200–215. [Google Scholar] [CrossRef]

- Shou, Y. Progress in silicon materials. Color. Smelt. 1982, 5, 37–42. [Google Scholar]

- Tang, B.; Mo, X.; Wang, X. Current Status and Development Suggestions of Silicon Deep Processing in the East China Sea. Chem. Miner. Process. 2003, 32, 8–10. [Google Scholar]

- Gu, S. Development of Silicon Industry in Donghai County, Jiangsu Province Based on SCP Paradigm. Ind. Econ. 2018, 18, 160–161. [Google Scholar]

- Jia, W.; Tang, D. Analysis of Competitiveness of Silicon Industry in Donghai County—Based on Analysis of Porter Diamond Model. Jiangsu Bus. Theory 2009, 6, 142–144. [Google Scholar]

- Yu, Y.; Hao, S.; Chen, Y.; Xiao, H. Study on the Low-carbon Economy Development of Silicon Industrial Clusters in Fengyang County. Heilongjiang Agric. Sci. 2013, 28, 135–138. [Google Scholar]

- Kim, Y.; Park, J. A Sustainable Development Strategy for the Uzbekistan Textile Industry: The Results of a SWOT-AHP Analysis. Sustainability 2019, 11, 4613. [Google Scholar] [CrossRef]

- Pesce, M.; Shi, C.; Critto, A.; Wang, X.; Marcomini, A. SWOT Analysis of the Application of International Standard ISO 14001 in the Chinese Context. A Case Study of Guangdong Province. Sustainability 2018, 10, 3196. [Google Scholar] [CrossRef]

- Cai, Q.; Cai, Y.; Wen, Y. Spatially Differentiated Trends between Forest Pest-Induced Losses and Measures for Their Control in China. Sustainability 2019, 11, 73. [Google Scholar] [CrossRef]

- Laizer, H.C.; Chacha, M.N.; Ndakidemi, P.A. Farmers’ Knowledge, Perceptions and Practices in Managing Weeds and Insect Pests of Common Bean in Northern Tanzania. Sustainability 2019, 11, 4076. [Google Scholar] [CrossRef]

- Li, K. Based on the Perspective of Shared Economy Research on the Countermeasures of Urban Shared Bicycle Development. City Traffic. 2017, 3, 1005. [Google Scholar]

- Liu, S.; Yang, Y.; Xie, N.; Forrest, J. New progress of Grey System Theory in the new millennium. Grey Syst. Theory Appl. 2016, 6, 2–31. [Google Scholar] [CrossRef]

- Hongyan, Y. The Construction Project Bid Evaluation Based on Gray Relational Model. Procedia Eng. 2011, 15, 4553–4557. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Yang, C.; Wang, J. Evaluation on Coal Industry Competitive Power base on Grey System Theory. Coal Eng. 2010, 7, 113–116. [Google Scholar]

- Deng, L.; Xu, B.; He, W. Research on Industrial Competitiveness Evaluation in China: Status and Outlook. Sci. Technol. Manag. Res. 2015, 35, 50–55. [Google Scholar]

- Xue, W.; Dong, W. Grey Relevance Analysis of Influencing Factors for China’s Dependence on Foreign Trade. Int. Econ. Trade Res. 2008, 24, 4–9. [Google Scholar]

- Deng, J. The Grey Control System. J. Huazhong Inst. Technol. 1982, 3, 9–18. [Google Scholar]

- Wei, Y.; Gao, Y.; Zeng, K. Limitations of Deng’s Incidence Degree and Evolution of Relational Axioms. Acta Anal. Funct. Appl. 2015, 17, 391–399. [Google Scholar]

- Zheng, J.; Wen, C. Mean-quantization Algorithm for Gray Correlation Degree. J. Hangzhou Dianzi Univ. 2010, 30, 165–168. [Google Scholar]

- Dong, Y.; Duan, Z. A New Determination Method for Identification Coefficient of Grey Relational Grade. J. Xi’an Univ. Archit. Technol. 2008, 4, 589–592. [Google Scholar]

- Jin, B. On the Identification and Discovery Logic of Realmeconomics. Chin. Ind. Econ. 2019, 11, 5–23. [Google Scholar]

- Jia, R.; Liu, Y. A Comparative Study on Industrial Competitiveness—A Case Study of Manufacture Industries in Eastern Coastal Provinces and Municipalities of China. Prog. Geogr. 2003, 22, 195–202. [Google Scholar]

| Primary Indicator | Indicator Codes | Secondary Indicators | Interpretation of Secondary Indicators | Units |

|---|---|---|---|---|

| Industrial agglomeration | X1 | Number of enterprises above designated size (X1) | Number of silicon crystal enterprises (X1) | - |

| X2 | Silicon crystal industry annual output value (X2) | Annual output value of silicon crystal industry (X2) | (100 million yuan) | |

| X3 | Number of employees in the silicon crystal industry (X3) | Personnel engaged in the silicon crystal industry (X3) | (ten thousand people) | |

| X4 | Silicon crystal industry added value (X4) | The annual output value of the silicon crystal industry this year − the annual output value of the silicon crystal industry (X4) | (100 million yuan) | |

| X5 | Number of supporting companies (X5) | Number of companies providing services to the upstream and downstream of the silicon industry chain (X5) | - | |

| X6 | Total output value of supporting enterprises (X6) | Annual output value of enterprises providing services in the upstream and downstream of the silicon crystal industry chain (X6) | (100 million yuan) | |

| Industrial competition | X7 | Market share (X7) | The county’s silicon crystal products occupy the domestic market (X7) | (%) |

| X8 | Scale enterprise growth rate (X8) | X8: The number of large-scale enterprises this year—the number of large-scale enterprises last year / the number of enterprises last year (X8) | (%) | |

| X9 | Number of brands (X9) | Number of corporate brands in the industry (X9) | - | |

| X10 | County export value (X10) | Foreign trade exports (X10) | (100 million US dollars) | |

| X11 | Annual output of silicon crystal products (X11) | The finished product of silicon crystal products (X11) | (cubic meters) | |

| X12 | Foreign investment situation (X12) | Foreign investment amount (X12) | (100 million yuan) | |

| Industrial innovation capability | X13 | Science and technology annual research and development costs (X13) | Technology research and development investment costs (X13) | (100 million yuan) |

| X14 | Number of scientific and technological innovation talents (X14) | Science and technology talents engaged in research and development in the county (X14) | - | |

| X15 | Number of scientific research institutions (X15) | The number of institutions including enterprise R&D centers and cooperation platforms with universities (X15) | - | |

| X16 | Number of patents (X16) | The number of patents applied by the county during the year (X16) | - | |

| Industrial sustainability | X17 | Government funding (X17) | silicon crystal industry and infrastructure construction (X17) | (100 million yuan) |

| X18 | Annual mining of silicon resources (X18) | Provided silicon ore (X18) | (ten thousand tons) | |

| X19 | Average annual salary of employees (X19) | Average annual salary of employees (X19) | (ten thousand yuan) | |

| X20 | Years of exploitation of silicon resources (X20) | The amount of silicon ore resources mined in the year (X20) | (years) |

| Impact Factors | 2017 | 2013 | 2009 | Comprehensive Correlation Coefficient of Suichuan | Comprehensive Correlation Coefficient of Others | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Suichuan County | Donghai County | Fengyang County | Yongxiu County | Suichuan County | Donghai County | Fengyang County | Yongxiu County | Suichuan County | Donghai County | Fengyang County | Yongxiu County | |||

| X1 | 0.4519 | 0.9068 | 0.5363 | 0.3911 | 0.3767 | 0.5364 | 0.7584 | 0.4169 | 0.4504 | 0.5390 | 0.4892 | 0.6798 | 0.4263 | 0.5838 |

| X2 | 0.5526 | 0.9207 | 0.6575 | 0.4368 | 0.5858 | 0.6908 | 0.5436 | 0.4650 | 0.5308 | 0.5729 | 0.4849 | 0.4729 | 0.5564 | 0.5828 |

| X3 | 0.3747 | 0.3439 | 0.2999 | 0.7185 | 0.2972 | 0.9184 | 0.3541 | 0.6519 | 0.6641 | 0.4547 | 0.2942 | 0.5808 | 0.4453 | 0.5129 |

| X4 | 0.6845 | 0.3861 | 0.4978 | 0.6778 | 0.7175 | 0.9715 | 0.8821 | 0.5927 | 0.6127 | 0.3137 | 0.5776 | 0.4381 | 0.6716 | 0.5930 |

| X5 | 0.4748 | 0.5802 | 0.8466 | 0.6959 | 0.4215 | 0.4244 | 0.9086 | 0.5319 | 0.4572 | 0.6390 | 0.4230 | 0.5774 | 0.4512 | 0.6252 |

| X6 | 0.5420 | 0.7161 | 0.3785 | 0.6985 | 0.4680 | 0.4710 | 0.4714 | 0.8521 | 0.2195 | 0.4106 | 0.2998 | 0.6299 | 0.4098 | 0.5475 |

| X7 | 0.3242 | 0.4852 | 0.5310 | 0.6699 | 0.4429 | 0.5114 | 0.5980 | 0.6424 | 0.2969 | 0.6402 | 0.5567 | 0.6318 | 0.3547 | 0.5852 |

| X8 | 0.5351 | 0.9986 | 0.6828 | 0.5947 | 0.9824 | 0.8332 | 0.8268 | 0.7453 | 0.4824 | 0.8789 | 0.9696 | 0.5046 | 0.6666 | 0.7816 |

| X9 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| X10 | 0.9873 | 0.3497 | 0.8127 | 0.9057 | 0.6740 | 0.8744 | 0.9849 | 0.9654 | 0.6734 | 0.8619 | 0.8207 | 0.8229 | 0.7782 | 0.8220 |

| X11 | 0.6406 | 0.9899 | 0.9482 | 0.7391 | 0.6779 | 0.8134 | 0.7805 | 0.6911 | 0.6815 | 0.8114 | 0.7552 | 0.7882 | 0.6667 | 0.8130 |

| X12 | 0.9371 | 0.7713 | 0.4273 | 0.7841 | 0.6099 | 0.9007 | 0.6378 | 0.6770 | 0.4597 | 0.7519 | 0.9833 | 0.5163 | 0.6689 | 0.7166 |

| X13 | 0.7616 | 0.9807 | 0.4724 | 0.6226 | 0.6179 | 0.8669 | 0.9232 | 0.6681 | 0.4516 | 0.8033 | 0.8875 | 0.5033 | 0.6104 | 0.7476 |

| X14 | 0.7515 | 0.4911 | 0.9381 | 0.6206 | 0.2746 | 0.5327 | 0.2751 | 0.5565 | 0.3360 | 0.4167 | 0.9334 | 0.6478 | 0.4540 | 0.6013 |

| X15 | 0.6678 | 0.9599 | 0.7316 | 0.4044 | 0.3441 | 0.7111 | 0.5660 | 0.3985 | 0.6454 | 0.9667 | 0.6725 | 0.7911 | 0.5524 | 0.6891 |

| X16 | 0.6354 | 0.5750 | 0.9871 | 0.3317 | 0.2074 | 0.4633 | 0.6569 | 0.3170 | 0.6240 | 0.8069 | 0.8235 | 0.9161 | 0.4889 | 0.6531 |

| X17 | 0.5303 | 0.3529 | 0.7876 | 0.5799 | 0.4328 | 0.7104 | 0.9416 | 0.6146 | 0.2972 | 0.8400 | 0.4283 | 0.3552 | 0.4201 | 0.6234 |

| X18 | 0.3773 | 0.9406 | 0.3969 | 0.5999 | 0.3719 | 0.4491 | 0.4561 | 0.6679 | 0.3181 | 0.4872 | 0.3434 | 0.8025 | 0.3558 | 0.5715 |

| X19 | 0.6018 | 0.9389 | 0.5085 | 0.7579 | 0.6286 | 0.4879 | 0.5865 | 0.5003 | 0.3765 | 0.4636 | 0.5591 | 0.4886 | 0.5356 | 0.5879 |

| X20 | 0.2956 | 0.3865 | 0.6625 | 0.9924 | 0.3765 | 0.4234 | 0.5174 | 0.8107 | 0.5778 | 0.2920 | 0.5710 | 0.7678 | 0.4166 | 0.6026 |

| Primary Indicator | Comprehensive Correlation Coefficient | Relevance Ranking |

|---|---|---|

| Industrial agglomeration | 0.5540 | 4 |

| Industrial competition | 0.7621 | 1 |

| Industrial innovation capability | 0.6362 | 2 |

| Industrial sustainability | 0.5553 | 3 |

| Years | Suichuan County | Donghai County | Fengyang County | Yongxiu County |

|---|---|---|---|---|

| 2017 | 0.6063 | 0.7037 | 0.6552 | 0.6611 |

| 2013 | 0.5454 | 0.6795 | 0.6834 | 0.6383 |

| 2009 | 0.5078 | 0.6475 | 0.6436 | 0.6457 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Peng, K.; Peng, H.; Zhang, J.; Zeng, M.; Huang, C. Evaluation Model and Empirical Study on the Competitiveness of the County Silicon Crystal Industry. Sustainability 2019, 11, 5360. https://doi.org/10.3390/su11195360

Pan Y, Peng K, Peng H, Zhang J, Zeng M, Huang C. Evaluation Model and Empirical Study on the Competitiveness of the County Silicon Crystal Industry. Sustainability. 2019; 11(19):5360. https://doi.org/10.3390/su11195360

Chicago/Turabian StylePan, Yujie, Ke Peng, Hongxia Peng, Jing Zhang, Min Zeng, and Changsheng Huang. 2019. "Evaluation Model and Empirical Study on the Competitiveness of the County Silicon Crystal Industry" Sustainability 11, no. 19: 5360. https://doi.org/10.3390/su11195360