Evaluation of the Improvement Effect of Limestone Powder Waste in the Stabilization of Swelling Clayey Soil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Soil

2.1.2. Additive

2.1.3. Mixed Soil

2.2. Methods

2.2.1. X-Ray Diffraction

2.2.2. X-Ray Fluorescence

2.2.3. Atterberg Limits

2.2.4. Free Swell Index

2.2.5. Unconfined Compressive Strength

2.2.6. One-dimensional Consolidation

2.2.7. Scanning Electron Microscopy (SEM)

3. Results

3.1. Atterberg Limits

3.2. Free swell index

3.3. Unconfined Compressive Strength

3.4. One-dimensional consolidation

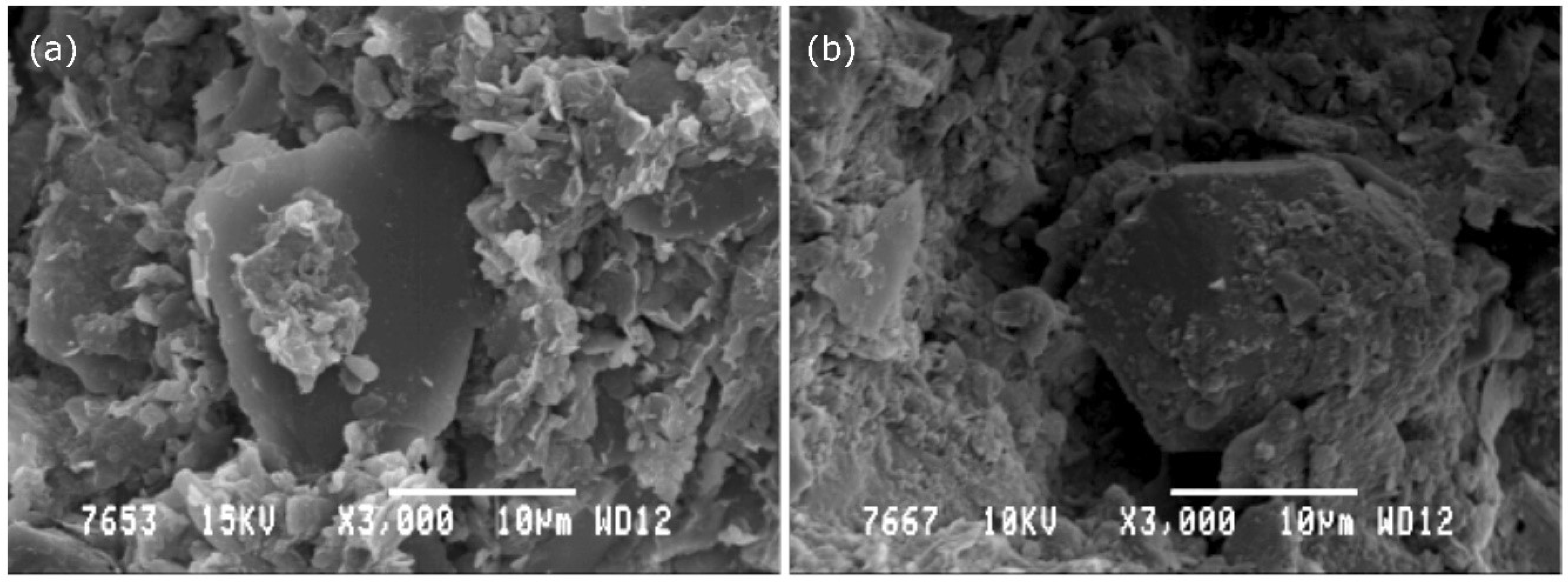

3.5. Scanning Electron Microscopy

4. Discussion

5. Conclusions

- There is a reduction of the Liquid Limit and Plasticity Index up to 17 and 32%, respectively, when 25% of the additive is added.

- The reduction of the free swelling index reaches a maximum value of 61% when 15% of powder is added.

- The unconfined compressive strength increases up to 148% for the maximum percentage of addition.

- A reduction of the compressibility of the mixed soil is observed. Cc and Cs indexes decreases up to 27% and 31%, respectively, when the soil is mixed with 25% of limestone powder.

- SEM images show a more compact microstructure of the soil when the limestone powder is added.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Cokca, E.; Yazici, V.; Ozaydin, V. Stabilization of Expansive Clays Using Granulated Blast Furnace Slag (GBFS) and GBFS-Cement. Geotech. Geol. Eng. 2009, 27, 489–499. [Google Scholar] [CrossRef]

- Mujtaba, H.; Aziz, T.; Farooq, K.; Sivakugan, N.; Das, B.M. Improvement in Engineering Properties of Expansive Soils using Ground Granulated Blast Furnace Slag. J. Geol. Soc. India 2018, 92, 357–362. [Google Scholar] [CrossRef]

- Yadu, L.; Tripathi, R.K. Effects of Granulated Blast Furnace Slag in the Engineering Behaviour of Stabilized Soft Soil. Procedia Eng. 2013, 51, 125–131. [Google Scholar] [CrossRef] [Green Version]

- Pathak, A.K.; Pandey, V.; Murari, K.; Singh, J.P. Soil stabilisation using ground granulated blast furnace slag. Int. J. Eng. Res. Appl. 2014, 4, 167–171. [Google Scholar]

- Phanikumar, B.R.; Nagaraju, T.V. Effect of Fly Ash and Rice Husk Ash on Index and Engineering Properties of Expansive Clays. Geotech. Geol. Eng. 2018, 1–12. [Google Scholar] [CrossRef]

- Phani Kumar, B.R.; Sharma, R.S. Effect of Fly Ash on Engineering Properties of Expansive Soils. J. Geotech. Geoenvironmental Eng. 2004, 130, 764–767. [Google Scholar] [CrossRef]

- Kolay, P.K.; Ramesh, K.C. Reduction of Expansive Index, Swelling and Compression Behavior of Kaolinite and Bentonite Clay with Sand and Class C Fly Ash. Geotech. Geol. Eng. 2016, 34, 87–101. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Phetchuay, C.; Chinkulkijniwat, A.; Cholaphatsorn, A. Strength development in silty clay stabilized with calcium carbide residue and fly ash. Soils Found. 2013, 53, 477–486. [Google Scholar] [CrossRef] [Green Version]

- Jose, J.; Jose, A.; Kurian, J.M.; Francis, J.; James, S.K. Stabilization of expansive soil using fly ash. Int. Res. J. Eng. Technol. 2018, 5, 3075–3078. [Google Scholar]

- Mir, B.A.; Sridharan, A. Physical and Compaction Behaviour of Clay Soil–Fly Ash Mixtures. Geotech. Geol. Eng. 2013, 31, 1059–1072. [Google Scholar] [CrossRef]

- Kang, X.; Ge, L.; Kang, G.-C.; Mathews, C. Laboratory investigation of the strength, stiffness, and thermal conductivity of fly ash and lime kiln dust stabilised clay subgrade materials. Road Mater. Pavement Des. 2015, 16, 928–945. [Google Scholar] [CrossRef]

- Roy, A. Soil stabilization using rice husk ash and cement. Int. J. Civ. Eng. Res. 2014, 5, 49–54. [Google Scholar]

- Kumar Yadav, A.; Gaurav, K.; Kishor, R.; Suman, S.K. Stabilization of alluvial soil for subgrade using rice husk ash, sugarcane bagasse ash and cow dung ash for rural roads. Int. J. Pavement Res. Technol. 2017, 10, 254–261. [Google Scholar] [CrossRef]

- Hasan, H.; Dang, L.; Khabbaz, H.; Fatahi, B.; Terzaghi, S. Remediation of Expansive Soils Using Agricultural Waste Bagasse Ash. Procedia Eng. 2016, 143, 1368–1375. [Google Scholar] [CrossRef] [Green Version]

- Marchán, P.; Regueiro, M.; González-Barros; Delgado, P. Natural stone in Spain: trends and perspectives (in Spanish). Boletín Geológico y Min. 2017, 128, 395–403. [Google Scholar] [CrossRef]

- SASIES Project. Sudges Frome Agglomerated Stones Industri for Environmental Sustainability Sasies. Available online: http://www.sasies.com/en/ (accessed on 17 December 2018).

- Vigneshpandian, G.V.; Shruthi, E.A.; Venkatasubramanian, C.; Muthu, D. Utilisation of Waste Marble Dust as Fine Aggregate in Concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol UK, 2017; Volume 80, p. 12007. [Google Scholar]

- Kishore, I.S.; Chowdary, C.M. A Study on Waste Utilization of Marble Dust in High Strength Concrete Mix. Int. J. Civ. Eng. Technol. 2015, 6, 12. [Google Scholar]

- Boukhelkhal, A.; Azzouz, L.; Belaïdi, A.S.E.; Benabed, B. Effects of marble powder as a partial replacement of cement on some engineering properties of self-compacting concrete. J. Adhes. Sci. Technol. 2016, 30, 2405–2419. [Google Scholar] [CrossRef]

- Singh, D.; Afaque Khan, M.; Kumar, A. Review on the study of compressive strength of concrete using marble dust as partial replacement of cement. Int. Res. J. Eng. Technol. 2016, 03, 524–526. [Google Scholar]

- Sivrikaya, O.; Kıyıldı, K.R.; Karaca, Z. Recycling waste from natural stone processing plants to stabilise clayey soil. Environ. Earth Sci. 2014, 71, 4397–4407. [Google Scholar] [CrossRef]

- Saygili, A. Use of Waste Marble Dust for Stabilization of Clayey Soil. Mater. Sci. 2015, 21, 601–606. [Google Scholar] [CrossRef]

- Sabat, A.K.; Nanda, R.P. Effect of marble dust on strength and durability of Rice husk ash stabilised expansive soil. Int. J. Civ. Struct. Eng. 2011, 1, 939–948. [Google Scholar]

- Ali, R.; Khan, H.; Shah, A.A. Expansive Soil Stabilization Using Marble Dust and and Bagasse Ash. Int. J. Sci. Res. 2014, 3, 2812–2816. [Google Scholar]

- Sol-Sánchez, M.; Castro, J.; Ureña, C.G.; Azañón, J.M. Stabilisation of clayey and marly soils using industrial wastes: pH and laser granulometry indicators. Eng. Geol. 2016, 200, 10–17. [Google Scholar] [CrossRef]

- Brooks, R.; Asce, F.; Udoeyo, F.F.; Asce, A.M.; Takkalapelli, K.V. Geotechnical Properties of Problem Soils Stabilized with Fly Ash and Limestone Dust in Philadelphia. J. Mater. Civ. Eng. 2011, 23, 711–716. [Google Scholar] [CrossRef]

- Ogila, W.A.M. The impact of natural ornamental limestone dust on swelling characteristics of high expansive soils. Environ. Earth Sci. 2016, 75, 1493. [Google Scholar] [CrossRef]

- Sabat, A.K.; Muni, P.K. Effects of limestone dust on geotechnical properties of an expansive soil. Int. J. Appl. Eng. Res. 2015, 10, 37724–37730. [Google Scholar]

- Irfan, M.; Chen, Y.; Ali, M.; Abrar, M.; Qadri, A.; Bhutta, O.; Irfan, M.; Chen, Y.; Ali, M.; Abrar, M.; Qadri, A.; Bhutta, O. Geotechnical Properties of Effluent-Contaminated Cohesive Soils and Their Stabilization Using Industrial By-Products. Processes 2018, 6, 203. [Google Scholar] [CrossRef]

- Moseley, M.P.; Kirsch, K. Ground Improvement, 2nd ed.; Taylor & Francis: Abingdon, UK, 2004; ISBN 0-415-27455-9. [Google Scholar]

- ASTM International ASTM D2487-11. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Skempton, A.W. The Colloidal ‘Activity’ of Clays. In Proceedings of the Third International Conference on Soil Mechanics and Foundation Engineering, Zurich, Switzerland, 1953; pp. 57–61. [Google Scholar]

- Seed, H.; Woodward, J.; Lundgren, R. Prediction of Swelling Potential for Compacted Clays. J. Soil Mech. Found. Div. 1962, 88, 53–88. [Google Scholar]

- El-Mahllawy, M.; Kandeel, A.; Abdel Latif, M.; El Nagar, A. The Feasibility of Using Marble Cutting Waste in a Sustainable Building Clay Industry. Recycling 2018, 3, 39. [Google Scholar] [CrossRef]

- AENOR UNE 103103. Determination of the Liquid Limit of a Soil by the Casagrande Apparatus Method. 1994. (In Spanish). Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas/une/?c=N0007830 (accessed on 21 January 2019).

- AENOR UNE 103104. Test for Plastic Limit of a Soil. 1993. (In Spanish). Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas/UNE?c=N0007831 (accessed on 20 October 2018).

- ASTM International ASTM D4318-17. Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- AENOR UNE 103601. AENOR UNE 103601. Test for Free Swelling of Soil in Oedometer Device. (In Spanish). Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas/UNE?c=N0007855 (accessed on 21 January 2019).

- ASTM International ASTM D4546-08. Standard Test Methods for One-Dimensional Swell or Collapse of Cohesive Soils; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Carter, M.; Bentley, S.P. Soil Properties and Their Correlations, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2016; ISBN 9781119130871. [Google Scholar]

- AENOR UNE 103400. Simple Compression Rupture Test in Soil Test Specimens. (In Spanish). Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas/UNE?c=N0007845 (accessed on 21 January 2019).

- ASTM International ASTM D1266/D2166M-16. Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- AENOR UNE 103405. Geotechnics. One-Dimensional Consolidation Test in an Edometric Cell. (In Spanish). Available online: Available online: https://www.aenor.com/normas-y-libros/buscador-de-normas/UNE?c=N0007849 (accessed on 21 January 2019).

- Ekundayo, O.I.; Adepehin, J. Alternative Approach to Clay Stabilization Using Granite and Dolerite Dusts. Geotech. Geol. Eng. 2017, 35, 1657–1664. [Google Scholar] [CrossRef]

- Ni, Q.; Tan, T.S.; Dasari, G.R.; Hight, D.W. Contribution of fines to the compressive strength of mixed soils. Géotechnique 2004, 54, 561–569. [Google Scholar] [CrossRef]

- Chittoori, B.; Asce, M.; Puppala, J.A.; Asce, F.; Raavi, A. Strength and Stiffness Characterization of Controlled Low-Strength Material Using Native High-Plasticity Clay. J. Mater. Civ. Eng. 2014, 26. [Google Scholar] [CrossRef]

- Hassan, M.M.; Lojander, M.; Ravaska, O. Characteristics of soft clay stabilized for construction purposes. In Advances in Transpotation Geotechnics; Taylor & Francis: Nottingham, UK, 2008; pp. 651–656. [Google Scholar]

- Ayeldeen, M.; Hara, Y.; Kitazume, M.; Negm, A. Unconfined Compressive Strength of Compacted Disturbed Cement-Stabilized Soft Clay. Int. J. Geosynth. Ground Eng. 2016, 2, 28. [Google Scholar] [CrossRef]

- Han, J. Principles and Practices of Ground Improvement; John Wiley & Sons, Inc.: New York, NY, USA, 2015; ISBN 978-1-118-25991-7. [Google Scholar]

| Property | Value | Property | Value |

|---|---|---|---|

| % Sand (0.06–2 mm) | 15 | Plasticity Index | 20.8 |

| % Silt (0.002–0.06) | 60 | Activity | 0.83 |

| % Clay (<0.002 mm) | 25 | Free swelling | 5.70 1 |

| Liquid Limit | 44.6 | Particle density (kN/m3) | 26.0 |

| Plastic Limit | 23.8 | Soil classification (USCS) | CL |

| Compound | Soil Mass % | Additive Mass % |

|---|---|---|

| Na2O | 0.919 | 0.183 |

| MgO | 5.290 | 5.085 |

| Al2O3 | 13.902 | 0.571 |

| SiO2 | 36.669 | 1.353 |

| P2O5 | 0.316 | 0.139 |

| SO3 | 2.760 | 0.273 |

| Cl | 0.248 | 0.101 |

| K2O | 2.907 | 0.105 |

| CaO | 14.722 | 62.658 |

| TiO2 | 0.644 | 0.036 |

| Cr2O3 | 0.018 | 0.258 |

| MnO | 0.070 | 0.034 |

| Fe2O3 | 5.461 | 0.041 |

| SrO | 0.175 | -- |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pastor, J.L.; Tomás, R.; Cano, M.; Riquelme, A.; Gutiérrez, E. Evaluation of the Improvement Effect of Limestone Powder Waste in the Stabilization of Swelling Clayey Soil. Sustainability 2019, 11, 679. https://doi.org/10.3390/su11030679

Pastor JL, Tomás R, Cano M, Riquelme A, Gutiérrez E. Evaluation of the Improvement Effect of Limestone Powder Waste in the Stabilization of Swelling Clayey Soil. Sustainability. 2019; 11(3):679. https://doi.org/10.3390/su11030679

Chicago/Turabian StylePastor, José Luis, Roberto Tomás, Miguel Cano, Adrián Riquelme, and Erick Gutiérrez. 2019. "Evaluation of the Improvement Effect of Limestone Powder Waste in the Stabilization of Swelling Clayey Soil" Sustainability 11, no. 3: 679. https://doi.org/10.3390/su11030679