Introduction of Biodiesel to Rail Transport: Lessons from the Road Sector

Abstract

1. Introduction

Background to World Biofuels

- To organize the lessons learned from the road sector using a decision-making framework.

- To gain understanding of the successes and failures experienced in the road sector from introducing biodiesel.

- To analyze if and how the lessons can be applied to the rail sector.

2. The Framework of the Study

3. The Lessons Learned from Road Transport

3.1. Regulating the Introduction of Biodiesel

3.1.1. Enforcing Tax Exemptions

3.1.2. Mandates Issued Due to Legislation

3.1.3. The Importance of Legislation and Political Structure in Introducing Biodiesel to Road Transport

- On 14 November 1975, The National Alcohol Programme was established through parliament [37], which outlined the objectives and financing of the programme.

- In the early 1990s, the ethanol program was under threat because of declining oil prices. People were reverting to using petrol as it was becoming cheaper once again. On 28 October 1993, legislation was passed that stated a 22% ethanol blend was to be used across the country [37].

3.2. The Economics of Using Biodiesel

3.2.1. The Costs of Using Tax Exemptions and Mandates

3.2.2. The Price of Ethanol and Economies of Scale

3.2.3. The Costs of Maintaining Vehicles Using Biodiesel

3.2.4. The Cost of Feedstock

3.3. Social Implications and Acceptance of Introducing Biodiesel to Transport

3.4. A Technological Perspective

3.4.1. Storage, Engine and Fuel Performance

- Fuel had to comply with DIN EN 14214 standards.

- A certificate must accompany each supply of fuel ensuring that it meets the required conditions. Any additives added to the fuel must be included in the certificate.

- Tanks must be emptied and cleaned when switching from summer to winter fuel.

- When a warranty claim is issued the manufacturer must have proof of the fuel’s origin.

3.4.2. Blending Diesel and Biodiesel

- Splash blending. This is widely available, but the least effective. First, the diesel is loaded into the tank followed by the biodiesel being pumped on top

3.5. Environmental Effects of Using Biodiesel in Automotive Vehicles

4. A Discussion on the Transition to Biodiesel Used in Locomotives and the Lessons Learned from the Road Sector

4.1. The Political and Policy Side of Introducing Biodiesel to Rail

- The political set up of a country

- The elasticities of the biofuel and fossil fuel

- Whether the fossil fuel price is endogenous or exogenous

- If a mandate is binding or non-binding

4.2. The Economics of the Policy Instruments Used and Their Application to Rail

4.3. Social Implications and Acceptance of Using Biodiesel in the Rail Sector

4.4. The Technological Aspects of Using Biodiesel in Locomotives

- Considering the lifespan of a locomotive there may be materials in older models, such as metals, that would be degraded if biodiesel were to be used. It may take longer to use biodiesel in the rail sector because the frequency of replacing locomotives is less than road transport. However, until rolling stock is replaced, it may be possible to work with manufacturers to establish the maximum blends they will allow when certain conditions are met. When locomotives need replacing, the rail companies must work with the manufacturers to help increase the possibility of using higher blends in the engine. If the government or biodiesel advocates help fund the development of biodiesel, in rail and in a partnership with engine manufacturers, the chances of using higher blends could become higher.

- This in turn may affect the cost of the overall maintenance. While the under-investigated understanding is that there are few changes in maintenance costs, it may differ for rail. Therefore this is the benchmark for maintenance costs, but checks and pilot tests would need to take place to assess if there is a similar trend to that of road.

4.5. Environmental Consequences of Using Biodiesel in the Rail Sector

5. Conclusions

- Using biodiesel can reduce most GHGs and most pollutant emissions, with potential health benefits.

- Tax incentives and mandates have promoted the production and consumption of biodiesel. Such incentives will likely be required for all rail sector, too

- The cost of producing biodiesel is larger than fossil fuels, with the price of feedstock an important constituent. These extra costs will likely be absorbed by the consumer or taxpayer. The cost competitiveness of biodiesel fuel depends on global oil prices too.

- Maintenance costs are perhaps more difficult to determine for rail due to the differences between the vehicles. This highlights the importance of working with locomotive manufacturers and train operators to determine these costs.

- The use of biodiesel as small blends may not require any modification to existing locomotives. However, warranties of locomotives for biodiesel blends is an important area requiring consultation.

- Longer life of rail locomotives compared to vehicles may be a barrier to rapid adoption of higher blends of biodiesel.

- Suitability of existing infrastructure and required modifications play a key role in introducing biodiesel into the market. This may be easier for rail compared to road due to fewer fueling stations.

- Policies and governance structure have an important role in the biofuel transition. A study of the political economy of transitions in the road sector will be useful for rail.

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency (IEA). World energy outlook 2015. In Organization for Economic Co-Operation and Development (OECD/IEA); IEA: Paris, France, 2015; Available online: https://www.iea.org/publications/freepublications/publication/WEO2015.pdf (accessed on 12 June 2017).

- International Energy Agency (IEA). Tracking Progress: Transport. 2017. Available online: https://www.iea.org/etp/tracking2017/transport/ (accessed on 11 December 2018).

- Yin, X.; Chen, W.; Eom, J.; Clarke, L.E.; Kim, S.H.; Patel, P.L.; Yu, S.; Kyle, G.P. China’s transportation energy consumption and CO2 emissions from a global perspective. Energy Policy 2015, 82, 233–248. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, X.; Shao, S. Decoupling CO2 emissions and industrial growth in China over 1993–2013: The role of investment. Energy Econ. 2016, 60, 275–292. [Google Scholar] [CrossRef]

- Azad, A.K.; Al, E. Prospect of biofuels as an alternative transport fuel in Australia. Renew. Sustain. Energy Rev. 2015, 43, 331–351. [Google Scholar] [CrossRef]

- Kim, I.; Ismai, M. Growing Demand for Biofuel and its Impact on Sustainable Rural Development in Nigeria. Economy 2014, 1, 1–4. [Google Scholar]

- Papong, S.; Chom-In, T.; Noksa-nga, S.; Malakul, P. Life cycle energy efficiency and potentials of biodiesel production from palm oil in Thailand. Energy Policy 2010, 38, 226–233. [Google Scholar] [CrossRef]

- de Souza, S.P.; Pacca, S.; de Ávila, M.T.; Borges, J.L.B. Greenhouse gas emissions and energy balance of palm oil biofuel. Renew. Energy 2010, 35, 2552–2561. [Google Scholar] [CrossRef]

- Eshton, B.; Katima, J.H.Y.; Kituyi, E. Greenhouse gas emissions and energy balances of jatropha biodiesel as an alternative fuel in Tanzania. Biomass Bioenergy 2013, 58, 95–103. [Google Scholar] [CrossRef]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Norhasyima, R.S. Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: A review. Renew. Sustain. Energy Rev. 2011, 15, 3501–3515. [Google Scholar] [CrossRef]

- Akbar, E.; Yaakob, Z.; Kamarudin, S.K.; Ismail, M.; Salimon, J. Characteristic and Composition of Jatropha Curcas Oil Seed from Malaysia and its Potential as Biodiesel Feedstock Feedstock. Eur. J. Sci. Res. 2009, 29, 396–403. [Google Scholar] [CrossRef]

- Altenburg, T.; Dietz, H.; Hahl, M.; Nikolidakis, N.; Rosendahl, C.; Seelige, K. Biodiesel in India: Value Chain Organisation and Policy Options for Rural Development; Deutsches Institut für Entwicklungspolitik gGmbH: Bonn, Germany, 2009; ISBN 9783889853790. [Google Scholar]

- Atsushi, I.; Martin, H.R.; Yonas, E.M. Modal Choice between Rail and Road Transportation Evidence from Tanzania. 2017. Available online: http://hdl.handle.net/10986/28349 (accessed on 2 February 2018).

- Silalertruksa, T.; Bonnet, S.; Gheewala, S.H. Life cycle costing and externalities of palm oil biodiesel in Thailand. J. Clean. Prod. 2012, 28, 225–232. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels securing the planet’s future energy needs. Energy Convers. Manag. 2009, 50, 2239–2249. [Google Scholar] [CrossRef]

- Black, G.; Curran, H.J.; Pichon, S.; Simmie, J.M.; Zhukov, V. Bio-butanol: Combustion properties and detailed chemical kinetic model. Combust. Flame 2010, 157, 363–373. [Google Scholar] [CrossRef]

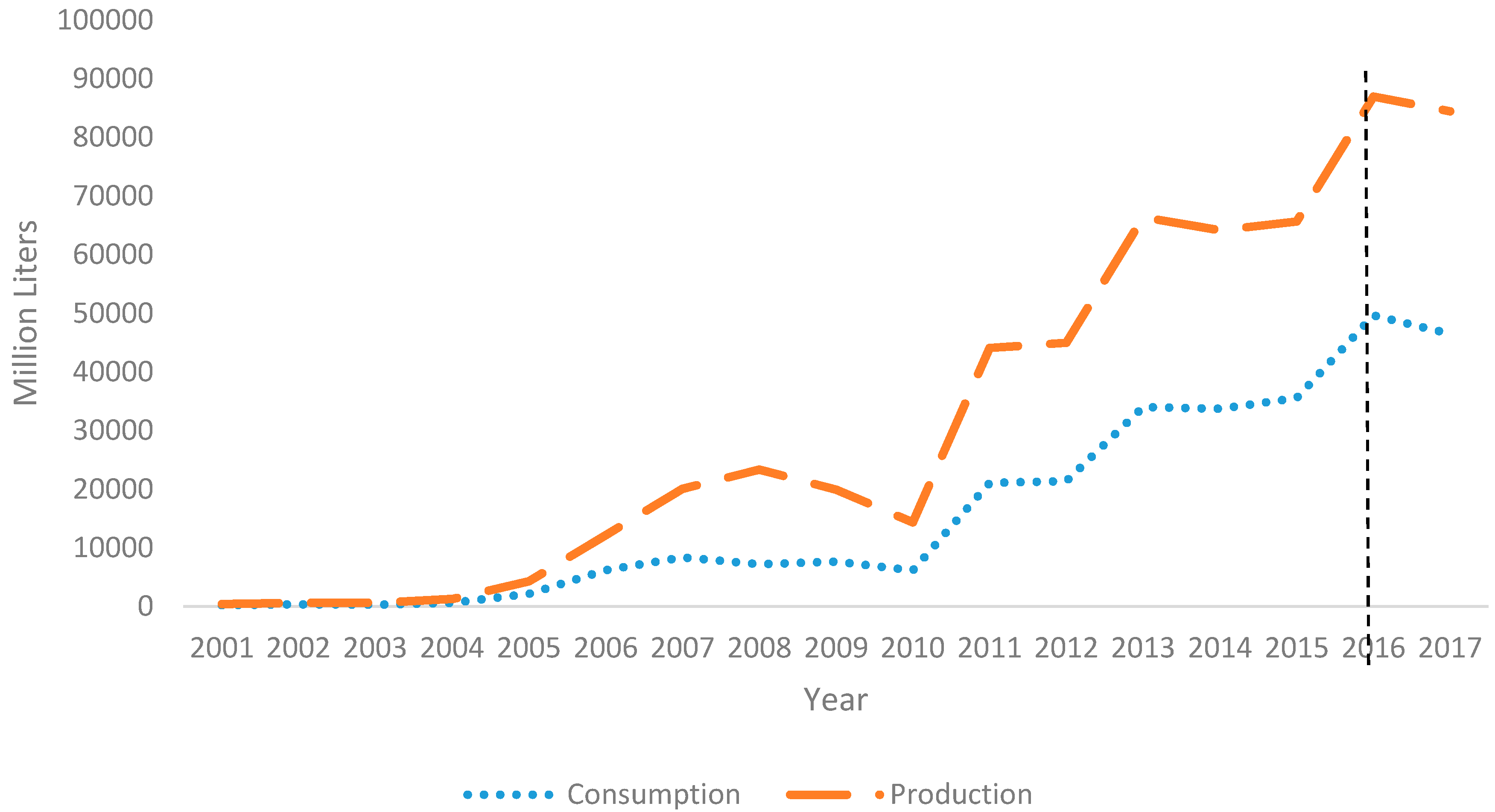

- International Energy Agency (IEA). Global Biofuels Production. 2018. Available online: https://www.iea.org/tcep/transport/biofuels/ (accessed on 22 October 2018).

- BP Global. Biofuels Production. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy/renewable-energy/biofuels-production.html (accessed on 15 May 2018).

- Nagy, G.; Marsi, G.; Hancsók, J. Study on Stability of Ethanol/Diesel Fuel Blend. In Proceedings of the European Congress of Chemical Engineering (ECCE-6), Copenhagen, Denmark, 16–20 September 2007; pp. 1–12. Available online: http://folk.ntnu.no/skoge/prost/proceedings/ecce6_sep07/upload/1036.pdf (accessed on 1 June 2018).

- Zalengera, C.; Blanchard, R.E.; Eames, P.C.; Juma, A.M.; Chitawo, M.L.; Gondwe, K.T. Overview of the Malawi energy situation and A PESTLE analysis for sustainable development of renewable energy. Renew. Sustain. Energy Rev. 2014, 38, 335–347. [Google Scholar] [CrossRef]

- Kolios, A.; Read, G. A Political, economic, social, technology, legal and environmental (PESTLE) approach for risk identification of the tidal industry in the United Kingdom. Energies 2013, 6, 5023–5045. [Google Scholar] [CrossRef]

- Basavaraj, G.; Parthasarathy Rao, P.; Ravinder Reddy, C.; Ashok Kumar, A.; Srinivasa Rao, P.; Reddy, B. A Review of the National Biofuel Policy in India: A Critique of the Need to Promote Alternative Feedstocks. 2012. Available online: http://oar.icrisat.org/6520/1/WPS_34.pdf (accessed on 9 April 2017).

- de Gorter, H.; Just, D.R. The social costs and benefits of biofuels: The intersection of environmental, energy and agricultural policy. Appl. Econ. Perspect. Policy 2010, 32, 4–32. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Eco-Tax Reform. 2012. Available online: https://www.iea.org/policiesandmeasures/pams/germany/name-22079-en.php (accessed on 22 October 2018).

- Henke, J.M.; Klepper, G.; Schmitz, N. Tax exemption for biofuels in Germany: Is bio-ethanol really an option for climate policy? Energy 2005, 30, 2617–2635. [Google Scholar] [CrossRef]

- Wiesenthal, T.; Leduc, G.; Christidis, P.; Schade, B.; Pelkmans, L.; Govaerts, L.; Georgopoulos, P. Biofuel support policies in Europe: Lessons learnt for the long way ahead. Renew. Sustain. Energy Rev. 2009, 13, 789–800. [Google Scholar] [CrossRef]

- Bomb, C.; McCormick, K.; Deurwaarder, E.; Kåberger, T. Biofuels for transport in Europe: Lessons from Germany and the UK. Energy Policy 2007, 35, 2256–2267. [Google Scholar] [CrossRef]

- Statistica. Volume of Biodiesel Fuel Consumed in the Transport Sector in Germany from 1995 to 2016 (In Kilotons of Oil Equivalent). 2018. Available online: https://www.statista.com/statistics/489476/volume-of-biodiesel-fuel-consumed-in-transport-in-germany/ (accessed on 30 June 2018).

- Raunch, A.; Thone, M.; FiFo Institute. Biofuels—At What Cost? Mandating Ethanol and Biodiesel Consumption in the United Kingdom; International Institute for Sustainable Development: Winnipeg, MB, Canada, 2012; pp. 1–60. Available online: http://www.iisd.org/gsi/sites/default/files/bf_awc_germany.pdf (accessed on 15 September 2018).

- Union Zur Forderung von Oel- und Proteinpflanzen E.V. (UFOP). Report on the Current Situation and Prospects—Extract from the UFOP Annual Report. 2016. Available online: https://www.ufop.de/files/9314/5372/7521/WEB_Auszug_Biodiesel_2015_EN.pdf (accessed on 19 March 2018).

- Rusco, F. Biofuels Infrastructure in the United States: Current Status and Future Challenges. 2012. Available online: https://www.oecd.org/futures/Biofuels%20Infrastructure%20in%20the%20United%20States%20Current%20Status%20and%20Future%20Challenges.pdf (accessed on 1 December 2017).

- Energy Information Administration (EIA). Petroleum and Other Liquids. Available online: https://www.eia.gov/dnav/pet/pet_move_expc_a_EPOORDB_EEX_mbbl_m.htm (accessed on 8 December 2018).

- Energy Information Administration (EIA). U.S. Biodiesel Production Still Increasing Despite Expiration of Tax Credit. 2017. Available online: https://www.eia.gov/todayinenergy/detail.php?id=34152 (accessed on 23 December 2018).

- Chin, M. Biofuels in Malaysia: An Analysis of the Legal and Institutional Framework. 2011. Available online: https://hdl.handle.net/10568/20808 (accessed on 14 September 2018).

- Lim, S.; Teong, L.K. Recent trends, opportunities and challenges of biodiesel in Malaysia: An overview. Renew. Sustain. Energy Rev. 2010, 14, 938–954. [Google Scholar] [CrossRef]

- Minnesota Department of Agriculture. About the Minnesota Biodiesel Program. Available online: http://www.mda.state.mn.us/renewable/biodiesel/aboutbiodiesel.aspx (accessed on 5 January 2017).

- Colares, J.F. A Brief History of Brazilian Biofuels Legislation. SSRN. 2008. Available online: https://scholarlycommons.law.case.edu/cgi/viewcontent.cgi?article=1169&context=faculty_publications (accessed on 15 May 2017).

- Nass, L.L.; Pereira, P.A.A.; Ellis, D. Biofuels in Brazil: An overview. Crop Sci. 2007, 47, 2228–2237. [Google Scholar] [CrossRef]

- Skidmore, T.E. The Politics of Military Rule in Brazil 1964-85; Oxford University Press: New York, NY, USA, 1989. [Google Scholar]

- Hira, A.; de Oliveira, L.G. No substitute for oil? How Brazil developed its ethanol industry. Energy Policy 2009, 37, 2450–2456. [Google Scholar] [CrossRef]

- Ziolkowska, J.; Meyers, W.; Meyer, S.; Binfield, J. Targets and Mandates: Lessons Learned from EU and US Biofuels Policy Mechanisms. AgBioForum 2010, 13, 398–412. [Google Scholar] [CrossRef]

- European Commision. National Action Plans. Available online: https://ec.europa.eu/energy/en/topics/renewable-energy/national-action-plans (accessed on 19 December 2018).

- Bozbas, K. Biodiesel as an alternative motor fuel: Production and policies in the European Union. Renew. Sustain. Energy Rev. 2008, 12, 542–552. [Google Scholar] [CrossRef]

- Gheewala, S.H.; Damen, B.; Shi, X. Biofuels: Economic, environmental and social benefits and costs for developing countries in Asia. Wiley Interdiscip. Rev. Clim. Chang. 2013, 4, 497–511. [Google Scholar] [CrossRef]

- Charles, C.; Gerasimchuk, I.; Bridle, R.; Moerenhout, T.; Asmelash, E.; Laan, T. A Review of Costs and Benefits of o f EU Biofuel Policies; International Institute for Sustainable Development: Winnipeg, MB, Canada, 2013; pp. 23–25. [Google Scholar]

- Gee, S.; McMeekin, A. Eco-Innovation Systems and Problem Sequences: The Contrasting Cases of US and Brazilian Biofuels. Ind. Innov. 2011, 18, 301–315. [Google Scholar] [CrossRef]

- Zapata, C.; Nieuwenhuis, P. Driving on liquid sunshine—The brazilian biofuel experience: A policy driven analysis. Bus. Strateg. Environ. 2009, 18, 528–541. [Google Scholar] [CrossRef]

- Goldemberg, J.; Coelho, S.T.; Nastari, P.M.; Lucon, O. Ethanol learning curve—The Brazilian experience. Biomass Bioenergy 2004, 26, 301–304. [Google Scholar] [CrossRef]

- Solomon, B.D.; Krishna, K. The coming sustainable energy transition: History, strategies, and outlook. Energy Policy 2011, 39, 7422–7431. [Google Scholar] [CrossRef]

- Lehtonen, M. Social sustainability of the Brazilian bioethanol: Power relations in a centre-periphery perspective. Biomass Bioenergy 2011, 35, 2425–2434. [Google Scholar] [CrossRef]

- Proc, K.; Barnitt, R.; Hayes, R.R.; Ratcliff, M.; McCormick, R.L. 100,000-Mile Evaluation of Transit Buses Operated on Biodiesel Blends (B20); SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Barnitt, R.; McCormick, R.; Lammert, M. St. Louis Metro Biodiesel (B20) Transit Bus Evaluation. 2008. Available online: https://www.nrel.gov/docs/fy08osti/43486.pdf (accessed on 13 April 2017).

- Greater London Authority The Mayor’s Biodiesel Programme. 2015. Available online: https://www.london.gov.uk/sites/default/files/gla_-_biodiesel_operational_note_june_2015_0.pdf (accessed on 19 December 2017).

- Gaeta-Bernardi, A.; Parente, V. Organic municipal solid waste (MSW) as feedstock for biodiesel production: A fi nancial feasibility analysis. Renew. Energy 2016, 86, 1422–1432. [Google Scholar] [CrossRef]

- Balat, M. Potential alternatives to edible oils for biodiesel production—A review of current work. Energy Convers. Manag. 2011, 52, 1479–1492. [Google Scholar] [CrossRef]

- Canakci, M.; Sanli, H. Biodiesel production from various feedstocks and their effects on the fuel properties. J. Ind. Microbiol. Biotechnol. 2008, 35, 431–441. [Google Scholar] [CrossRef] [PubMed]

- Gui, M.M.; Lee, K.T.; Bhatia, S. Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 2008, 33, 1646–1653. [Google Scholar] [CrossRef]

- Karmee, S.K.; Patria, R.D.; Sze, C.; Lin, K. Techno-Economic Evaluation of Biodiesel Production from Waste Cooking Oil—A Case Study of Hong Kong. Int. J. Mol. Sci. 2015, 16, 4362–4371. [Google Scholar] [CrossRef]

- Barnwal, B.K.; Sharma, M.P. Prospects of biodiesel production from vegetable oils in India. Renew. Sustain. Energy Rev. 2005, 9, 363–378. [Google Scholar] [CrossRef]

- Coelho, S.T.; Goldemberg, J.; Lucon, O.; Guardabassi, P. Brazilian sugarcane ethanol: Lessons learned. Energy Sustain. Dev. 2006, 10, 26–39. [Google Scholar] [CrossRef]

- Christensen, E.; McCormick, R.L. Long-term storage stability of biodiesel and biodiesel blends. Fuel Process. Technol. 2014, 128, 339–348. [Google Scholar] [CrossRef]

- SAE. Biodiesel in Automotive Application. Lessons Learned. 2014. Available online: https://global.ihs.com/doc_detail.cfm?item_s_key=00640279 (accessed on 9 January 2017).

- Shahid, E.M.; Jamal, Y. A review of biodiesel as vehicular fuel. Renew. Sustain. Energy Rev. 2008, 12, 2477–2487. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Hazrat, M.A.; Liaquat, A.M.; Shahabuddin, M.; Varman, M. Prospects of biodiesel from Jatropha in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 5007–5020. [Google Scholar] [CrossRef]

- Pramanik, K. Properties and use of jatropha curcas oil and diesel fuel blends in compression ignition engine. Renew. Energy 2003, 28, 239–248. [Google Scholar] [CrossRef]

- Lane, J. Biofuels Mandates Around the World: 2016. Available online: http://www.biofuelsdigest.com/bdigest/2016/01/03/biofuels-mandates-around-the-world-2016/ (accessed on 18 December 2016).

- Union Zur Forderung von Oel- und Proteinpflanzen E.V. (UFOP). Commercial vehicle manufacturer approvals on using biodiesel (B100). 2010. Available online: https://www.ufop.de/files/3813/3940/7470/201006_Biodiesel_approvals_B100.pdf (accessed on 21 March 2018).

- Gärtner, S.O.; Reinhardt, G.A. Biodiesel Initiatives in Germany. 2005. Available online: https://www.ifeu.de/landwirtschaft/pdf/premia-biodiesel-germany.pdf (accessed on 16 September 2018).

- Archer Daniels Midland Company. Biodiesel Technical Information; Archer Daniels Midland Company: Chicago, IL, USA, No accurate publication date.

- Scharffbillig, J.; Clark, E. A Biodiesel Blend Handling Guide. Minnesota Biodiesel Technical Cold Weather Issues Team Handling Subcommittee. 2014. Available online: http://www.cleanairchoice.org/pdf/MNBiodieselBlendHandlingGuide.pdf (accessed on 12 December 2017).

- Lam, M.K.; Lee, K.T.; Mohamed, A. Life cycle assessment for the production of biodiesel: A case study in Malaysia for palm oil versus jatropha oil. Biofuels Bioprod. Biorefining 2009, 3, 601–612. [Google Scholar] [CrossRef]

- Markel, E.; Sims, C.; English, B.C. Policy uncertainty and the optimal investment decisions of second-generation biofuel producers. Energy Econ. 2018, 76, 89–100. [Google Scholar] [CrossRef]

- Basha, S.A.; Gopal, K.R.; Jebaraj, S. A review on biodiesel production, combustion, emissions and performance. Renew. Sustain. Energy Rev. 2009, 13, 1628–1634. [Google Scholar] [CrossRef]

- Wang, W.G.; Lyons, D.W.; Clark, N.N.; Gautam, M.; Norton, P.M. Emissions from nine heavy trucks fueled by diesel and biodiesel blend without engine modification. Environ. Sci. Technol. 2000, 34, 933–939. [Google Scholar] [CrossRef]

- Pradeep, V.; Sharma, R.P. Use of HOT EGR for NOx control in a compression ignition engine fuelled with bio-diesel from Jatropha oil. Renew. Energy 2007, 32, 1136–1154. [Google Scholar] [CrossRef]

- Chang, D.Y.Z.; Van Gerpen, J.H.; Lee, I.; Johnson, L.A.; Hammond, E.G.; Marley, S.J. Fuel properties and emissions of soybean oil esters as diesel fuel. JAOCS J. Am. Oil Chem. Soc. 1996, 73, 1549–1555. [Google Scholar] [CrossRef]

- Schumacher, L.; Borgelt, S.; Hires, W.; Wetherell, W.; Nevils, A. 100,000 Miles of Fueling 5.9 L Cummins Engines with 100% Biodiesel; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Szybist, J.P.; Boehman, A.L.; Taylor, J.D.; McCormick, R.L. Evaluation of formulation strategies to eliminate the biodiesel NO x effect. Fuel Process. Technol. 2005, 86, 1109–1126. [Google Scholar] [CrossRef]

- Peterson, C.L.; Reece, D.L.; Thompson, J.C.; Beck, S.M.; Chase, C. Ethyl ester of rapeseed used as a biodiesel fuel—A case study. Biomass Bioenergy 1996, 10, 331–336. [Google Scholar] [CrossRef]

- McDonald, J.; Purcell, D.; McClure, B.; Kittelson, D. Emissions Characteristics of Soy Methyl Ester Fuels in an IDI Compression Ignition Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1995. [Google Scholar]

- Yusuf, N.N.A.N.; Kamarudin, S.K.; Yaakub, Z. Overview on the current trends in biodiesel production. Energy Convers. Manag. 2011, 52, 2741–2751. [Google Scholar] [CrossRef]

- Li, H.; Song, C.; Lv, G.; Pang, H.; Qiao, Y. Assessment of the impact of post-injection on exhaust pollutantsemitted from a diesel engine fueled with biodiesel. Renew. Energy 2017, 114, 924–933. [Google Scholar] [CrossRef]

- Tan, P.; Hu, Z.; Lou, D.; Li, Z. Exhaust emissions from a light-duty diesel engine with Jatropha biodiesel fuel. Energy 2012, 39, 356–362. [Google Scholar] [CrossRef]

- Osborne, D.; Fritz, S.; Glenn, D. The Effects of Biodiesel Fuel Blends on Exhaust Emissions From a General Electric Tier 2 Line-Haul Locomotive. J. Eng. Gas Turbines Power 2011, 133, 102803. [Google Scholar] [CrossRef]

- de L.T. Oliveira, G.; McKay, B.; Plank, C. How biofuel policies backfire: Misguided goals, inefficient mechanisms, and political-ecological blind spots. Energy Policy 2017, 108, 765–775. [Google Scholar] [CrossRef]

- Nuñez, H.M.; Önal, H. An economic analysis of transportation fuel policies in Brazil: Fuel choice, land use, and environmental impacts. Energy Econ. 2016, 55, 319–331. [Google Scholar] [CrossRef]

- Saravanan, A.P.; Mathimani, T.; Deviram, G.; Rajendran, K.; Pugazhendhi, A. Biofuel policy in India: A review of policy barriers in sustainable marketing of biofuel. J. Clean. Prod. 2018, 193, 734–747. [Google Scholar] [CrossRef]

- Kumar Biswas, P.; Pohit, S. What ails India’s biodiesel programme? Energy Policy 2013, 52, 789–796. [Google Scholar] [CrossRef]

- Han, H.; Zongwei, L.; Fuquan, Z.; Jingzheng, R.; Shiyan, C.; Ke, R.; Jiuyu Dua, E. Biofuel for vehicle use in China: Current status, future potential and policy implications. Renew. Sustain. Energy Rev. 2018, 82, 645–653. [Google Scholar] [CrossRef]

- European Commission. Renewable Energy Directive 2009/28/EC; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Khanna, M.; Nuñez, H.M.; Zilberman, D. Who pays and who gains from fuel policies in Brazil? Energy Econ. 2016, 54, 133–143. [Google Scholar] [CrossRef]

- Thompson, W.; Whistance, J.; Meyer, S. Effects of US biofuel policies on US and world petroleum product markets with consequences for greenhouse gas emissions. Energy Policy 2011, 39, 5509–5518. [Google Scholar] [CrossRef]

- Lapan, H.; Moschini, G.C. Second-best biofuel policies and the welfare effects of quantity mandates and subsidies. J. Environ. Econ. Manag. 2012, 63, 224–241. [Google Scholar] [CrossRef]

- Babcock, B.A. Mandates, Tax Credits, and Tariffs: Does the U.S. Biofuels Industry Need Them All? 2010. Available online: https://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=1000&context=card_policybriefs (accessed on 2 January 2019).

- Fritz, S.G. Evaluation of Biodiesel Fuel in an EMD GP38-2 Locomotive; National Renewable Energy Laboratory: Golden, CO, USA, 2005.

- Sze, C.; Whinihan, J.; Olson, B.; Schenk, C.; Sobotowski, R. Impact of Test Cycle and Biodiesel Concentration on Emissions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Prueksakorn, K.; Gheewala, S.H.; Malakul, P.; Bonnet, S. Energy analysis of Jatropha plantation systems for biodiesel production in Thailand. Energy Sustain. Dev. 2010, 14, 1–5. [Google Scholar] [CrossRef]

- Whitaker, M.; Heath, G. Life Cycle Assessment Comparing the Use of Jatropha Biodiesel in the Indian Road and Rail Sectors Life Cycle Assessment Comparing the Use of Jatropha Biodiesel in the Indian Road and Rail Sectors; National Renewable Energy Laboratory: Golden, CO, USA, 2010; p. 143.

- Sharma, A.; Strezov, V. Life cycle environmental and economic impact assessment of alternative transport fuels and power-train technologies. Energy 2017, 133, 1132–1141. [Google Scholar] [CrossRef]

| Study | Time Frame | Number of Buses | Km/L | Maintenance Cost (US $/km) | Bus Engine and System Maintenance Costs (US $/km) | % Overall Difference Compared to Diesel | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Diesel | Biodiesel | Diesel | Biodiesel | Diesel | Biodiesel | Diesel | Biodiesel | |||

| A Barnitt et al. (2006) [51] | 24 months | 4 | 5 | 1.6 | 1.6 | 0.86 | 0.82 | 0.08 | 0.02 | 5.2% lower |

| B Barnitt et al. (2008) [52] | 12 months | 7 | 8 | 1.3 | 1.2 | 0.91 | 0.91 | 0.08 | 0.12 | 0.32% higher |

| Feedstock | Type of Feedstock | Cost (US $/L) | Difference to Diesel (More to Less Expensive) (US $/L) | Reference |

|---|---|---|---|---|

| Palm Oil | Edible | 0.63–0.64 | 0.0 to 0.06 | Balat (2011) [55] Canaki (2008) [56] Gui (2008) [57] |

| Rapeseed | Edible | 0.54–0.62 | 0.04 to −0.04 | Balat (2011) [55] Gui (2008) [57] |

| Tallow | Waste | 0.22–0.63 | 0.06 to −0.36 | Balat (2011) [55] Canaki (2008) [56] |

| Waste Oil | Waste | 0.25–1.01 | 0.16 to −0.48 | Balat (2011) [55] Canaki (2008) [56] Bozbas (2008) [43] Karmee (2015) [58] |

| Soybean | Edible | 0.53–0.57 | −0.01 to −0.05 | Balat (2011) [55] Canaki (2008) [56] Gui (2008) [57] |

| Sunflower | Edible | 0.54–0.62 | 0.04 to −0.04 | Barnwal (2005) [59] |

| Peanut | Edible | 1.1 | 0.52 | Balat (2011) [55] |

| Diesel | Crude Oil | 0.58 | na | Barnwal (2005) [59] |

| Emission | % Change | References |

|---|---|---|

| PM | −30 to −38 | Peterson (1996) [79] Li (2017) [82] |

| HC | −67 | Peterson (1996) [79] Tan (2012) [83] Basha (2009) [73] Osborne (2011) [84] |

| CO | −46 to 50 | Peterson (1996) [79] Wang (2000) [74] Pradeep (2007) [75] Basha (2009) [73] Osborne (2011) [84] Tan (2012) [83] Li (2017) [82] |

| NOx | 8.89 to 13.2 | Chang (1996) [76] Wang (2000) [74] Pradeep (2007) [75] Osborne (2011) [84] Tan (2012) [83] |

| Item | Success/Failure for Road | Explanation of the Lesson Learnt from the Road Sector | Application to Rail |

|---|---|---|---|

| Policy, political and regulation | |||

| Mandates | + − | Mandates are a success or failure depending on whose perspective is being considered. Mandates ensure that biodiesel is used and there is no direct cost to the government. However, any increased costs to the fuel supplier will likely be passed onto the consumer. | Mandates will likely lead to an increased cost to rail users and freight companies. |

| Tax exemption | + − | This may affect the budget of a country in order to finance introducing biodiesel. | Diesel used in the rail sector is often exempt from tax, so tax exemptions on biodiesel would likely not be a useful policy instrument. |

| Legislation | + | Laws can provide structure and a framework to introduce biodiesel. | Legislation can strengthen the legal position of introducing biodiesel to rail. |

| Economic | |||

| Maintenance and maintenance costs | + | The parts which need replacing in vehicles that use biodiesel is different to that of diesel. But this has limited impacts on the cost. | This provides a benchmark for rail, but locomotives will have different aging conditions for components and thus different maintenance requirements to automobiles. |

| Learning curve and economies of scale in production | + | As more knowledge is gained the marginal cost of producing biodiesel will likely decrease. | Producing biodiesel for road or rail will be the same, therefore rail will experience reduced biodiesel production costs. |

| Rise in demand for biodiesel | + | A rise in demand can lead to several advantages in the biodiesel industry such as economies of scale, reduced GHGs and the possibility of increased energy security. However, increased NOx emissions could damage the health of the public adding a financial burden to the health care system | Bulk buying leads to a decrease in marginal costs. |

| Cost of feedstock | + | The cost of biodiesel feedstock leads to an increase in overall price of biodiesel making it less competitive against diesel | The extra cost in the production stage will likely lead to increased prices for rail users |

| Crude oil prices | + − | As oil prices increase biodiesel will likely become more competitive. However, the opposite is also possible with a decrease in oil prices. | As biodiesel is a substitute for diesel the cost of diesel’s raw material (crude oil) will influence biodiesel prices |

| Social | |||

| Employment increase | + | There is an increase of employment across the supply chain. | If the biodiesel industry already existed in a country then the extra employment gained from introducing biodiesel to rail would not be as great as a country where the industry did not exist. |

| Technological | |||

| Refueling and blending | + | There are recommendations for the length of time to store biodiesel. There are different options for blending biodiesel and diesel. No changes needed for low blends | The use of biodiesel in lower blends does not need modifications in refueling stations. |

| Higher blend | + | Germany has used B100, but this was after rigorous testing and working with car manufacturers | Governments need to work with locomotive manufacturers |

| Environmental | |||

| Environmental change | + | CO2, PM, CO, HC, and SO2 are reduced with the use of biodiesel. The larger the blend the bigger the reductions. However, NOx increases. | Generally, emissions and pollutants are reduced. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stead, C.; Wadud, Z.; Nash, C.; Li, H. Introduction of Biodiesel to Rail Transport: Lessons from the Road Sector. Sustainability 2019, 11, 904. https://doi.org/10.3390/su11030904

Stead C, Wadud Z, Nash C, Li H. Introduction of Biodiesel to Rail Transport: Lessons from the Road Sector. Sustainability. 2019; 11(3):904. https://doi.org/10.3390/su11030904

Chicago/Turabian StyleStead, Charlotte, Zia Wadud, Chris Nash, and Hu Li. 2019. "Introduction of Biodiesel to Rail Transport: Lessons from the Road Sector" Sustainability 11, no. 3: 904. https://doi.org/10.3390/su11030904

APA StyleStead, C., Wadud, Z., Nash, C., & Li, H. (2019). Introduction of Biodiesel to Rail Transport: Lessons from the Road Sector. Sustainability, 11(3), 904. https://doi.org/10.3390/su11030904