Sensitivity Analysis and Optimal Design of a Stator Coreless Axial Flux Permanent Magnet Synchronous Generator

Abstract

:1. Introduction

2. AFPMSG and Initial Design

2.1. Structure and Design Analysis

2.2. Improved Initial Design Procedure

2.3. Performance Analysis

3. Optimization Model and Sensitivity Analysis

3.1. Optimization Model of the AFPMSG

3.2. Sensitive Analysis for Design Parameters

4. Improved Genetic Algorithm

- (1)

- Generate intermediate population by crossing pairs in independently;

- (2)

- Execute mutation independently for each intermediate individual in to generate progeny population;

- (3)

- Select M pairs’ mother population as the new generation population from the union of parent population and offspring population ;

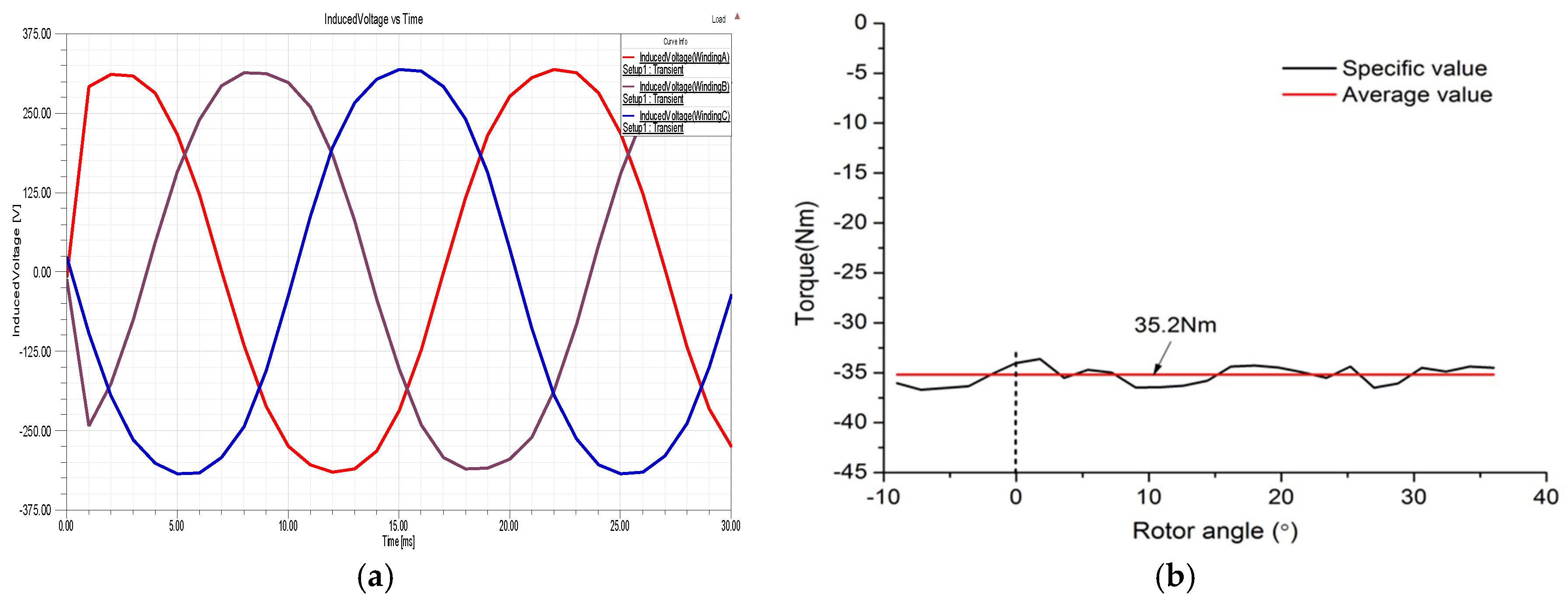

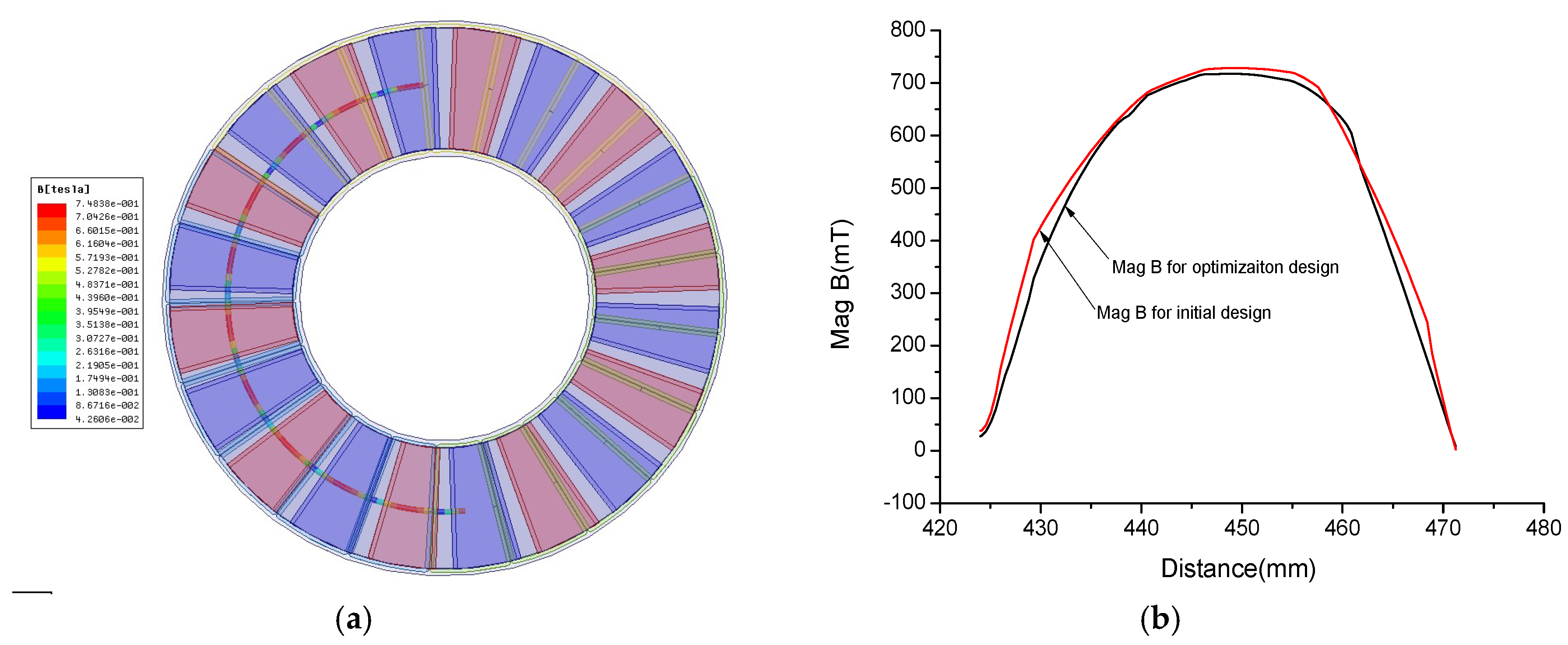

5. Optimal Design and Finite Element Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Caricchi, F.; Crescimbini, F.; Honrati, O. Modular axial-flux permanent-magnet motor for ship propulsion drives. IEEE Trans. Energy Convers. 1999, 14, 673–679. [Google Scholar] [CrossRef]

- Bumby, J.R.; Martin, R. Axial-flux permanent-magnet air-cored generator for small-scale wind turbines. IEE Electr. Power Appl. 2005, 152, 1065–1070. [Google Scholar] [CrossRef]

- Yang, Y.P.; Liang, J.Y.; Xing, X.Y. Design and application of axial-flux permanent magnet wheel motors for an electric vehicle. In Proceedings of the Africon 03, Nairobi, Kenya, 23–25 September 2009; pp. 1–5. [Google Scholar]

- Capponi, F.G.; Donato, G.D.; Caricchi, F. Recent advances in axial-flux permanent-magnet machine technology. IEEE Trans. Ind. Appl. 2013, 48, 2190–2205. [Google Scholar] [CrossRef]

- Gieras, J.F.; Rong-jie, W.; Kamper, M.J. Axial Flux Permanent Magnet Brushless Machines; Springer: Berlin, Germany, 2008. [Google Scholar]

- Choi, J.-Y.; Lee, S.-H.; Ko, K.J.; Jang, S.-M. Improved analytical model for electromagnetic analysis of axial flux machines with double-sided permanent magnet rotor and coreless stator windings. IEEE Trans. Magn. 2011, 47, 2760–2763. [Google Scholar] [CrossRef]

- Gieras, J.F. Permanent Magnet Motor Technology: Design and Application; CRE Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Tang, R.Y. Modern Permanent Magnet Motor: Theory and Design; China Machine Press: Beijing, China, 1997; pp. 308–314. (In Chinese) [Google Scholar]

- Huang, Y.; Zhou, T.; Dong, J.; Guo, B.; Zhang, L. An overview on developments and researches of axial flux permanent magnet machines. Proc. CSEE 2015, 35, 192–205. [Google Scholar]

- Kahourzade, S.; Mahmoudi, A.; Ping, H.W.; Nasir Uddin, M. A comprehensive review of axial-flux permanent-magnet machines. Can. J. Electr. Comput. Eng. 2014, 37, 19–33. [Google Scholar] [CrossRef]

- Huang, S.; Luo, J.; Leonardi, F.; Lipo, T.A. A comparison of power density for axial flux machines based on general purpose sizing equations. Energy Convers. IEEE Trans. 1999, 14, 185–192. [Google Scholar] [CrossRef]

- Kahourzade, S.; Mahmoudi, A.; Rahim, N.A.; Hew, W.H. Sizing equation and Finite Element Analysis optimum design of axial-flux permanent-magnet motor for electric vehicle direct drive. In Proceedings of the IEEE International Power Engineering & Optimization Conference, Melaka, Malaysia, 6–7 June 2012. [Google Scholar]

- Park, S.J.; Jeong, J.-H. Improved Analytical Modeling of Axial Flux Machine with a Double-Sided Permanent Magnet Rotor and Slotless Stator Based on an Analytical Method. IEEE Trans. Magn. 2012, 48, 2945–2948. [Google Scholar]

- Bumby, J.R.; Martin, R.; Mueller, M.A.; Spooner, E.; Brown, N.L.; Chalmers, B.J. Electromagnetic design of axial-flux permanent magnet machine. IEE Proc. Electr. Power Appl. 2004, 151, 151–160. [Google Scholar] [CrossRef]

- Abbaszadeh, K.; Maroufian, S.S. Axial flux permanent magnet motor modeling using magnetic equivalent circuit. In Proceedings of the 21st Iranian Conference on Electrical Engineering (ICEE), Mashhad, Iran, 14–16 May 2013; pp. 1–6. [Google Scholar]

- Daghigh, A.; Javadi, H.; Torkaman, H. Design optimization of direct-coupled ironless axial flux permanent magnet synchronous wind generator with low cost and high annual energy yield. IEEE Trans. Magn. 2016, 52, 1–11. [Google Scholar] [CrossRef]

- Huang, Y.; Ge, B.; Dong, J.; Lin, H.; Zhu, J.; Guo, Y. 3-D analytical modeling of no-load magnetic field of ironless axial flux permanent magnet machine. IEEE Trans. Magn. 2012, 48, 2929–2932. [Google Scholar] [CrossRef]

- Rahman, K.M. Application of direct-drive wheel motor for fuel cell electric and hybrid electric vehicle propulsion system. IEEE Trans. Ind. Appl. 2006, 42, 1185–1192. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Rahim, N.A.; Ping, H.W. Axial-flux permanent-magnet motor design for electric vehicle direct drive using sizing equation and finite element analysis. Prog. Electromagn. Res. 2012, 122, 467–496. [Google Scholar] [CrossRef]

- Gholamian, S.A. Optimun Design and Manufacturing of Aixal Flux Permanent Magnet Motor for Electric Vehicle Application. Ph.D. Dissertation, K. N. Toosi University of Technology, Tehran, Iran, January 2008. [Google Scholar]

- Jung, S.-Y.; Jung, H.; Hahn, S.-C.; Jung, H.-K.; Lee, C.-G. Opitmal design of direct-driven PM wind generator for maximum annual energy production. IEEE Trans. Magn. 2008, 44, 1062–1065. [Google Scholar] [CrossRef]

- Barba, P.D.; Savini, A.; Wiak, S. Field Models in Electricity and Magnetism; Springer: Dordrecht, The Netherlands, 2008. [Google Scholar]

- Barba, P.D. Multiobjective Shape Design in Electricity and Magnetism, 1st ed.; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar]

- Rostami, N.; Feyzi, M.R.; Pyrhonen, J.; Parviainen, A.; Behjat, V. Genetic algorithm approach for improved design of a variable speed axial-flux permanent-magnet synchronous generator. IEEE Trans. Magn. 2012, 48, 4860–4865. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Kahourzade, S.; Rahim, N.A.; Hew, W.-P. Design, analysis, and prototyping of an axial-flux permanent magnet motor based on genetic algorithm and finite-element analysis. IEEE Trans. Magn. 2013, 49, 1479–1492. [Google Scholar] [CrossRef]

- Lok, C.L.; Vengadaesvaran, B.; Ramesh, S. Implementation of hybrid pattern search–genetic algorithm into optimizing axial-flux permanent magnet coreless generator (AFPMG). Electr. Eng. 2016, 99, 1–11. [Google Scholar] [CrossRef]

- Shaoyu, S.; Hongxia, G. Mechanism, Design and Application of Permanent Magnet Generator; Machinery Industry Press: Beijing, China, 2012. [Google Scholar]

- Kamper, M.J.; Wang, R.J.; Rossouw, F.G. Analysis and performance of axial flux permanent-magnet machine with air-cored nonoverlapping concentrated stator windings. IEEE Trans. Ind. Appl. 2008, 44, 1495–1504. [Google Scholar] [CrossRef]

- Zhang, Z.; Matveev, A.; Nilssen, R.; Nysveen, A. Large-diameter ironless permanent magnet generator for offshore wind power application. In Proceedings of the 20th International Conference on Electrical Machines, Marseille, France, 2–5 September 2012. [Google Scholar]

- Wang, R.J.; Kamper, M.J. Calculation of eddy current loss in axial field permanent-magnet machine with coreless stator. Energy Convers. IEEE Trans. 2004, 19, 532–538. [Google Scholar] [CrossRef]

- Ansoft Company. Ansoft User Manual; Ansoft Company: Pittsburgh, PA, USA, 2007. [Google Scholar]

- Zhao, B.; Zhang, H. Application of Ansoft 12 in Engineering Electromagnetic Field; China Water Resources and Hydropower Press: Beijing, China, 2010. [Google Scholar]

- Zhang, Z.; Matveev, A.; Nilssen, R.; Nysveen, A. Ironless permanent-magnet generators for offshore wind turbines. IEEE Trans. Ind. Appl. 2014, 50, 1835–1846. [Google Scholar] [CrossRef]

- Mitchell, M. An Introduction to Genetic Algorithms; MIT Press: Manchester, UK, 1996. [Google Scholar]

- Haupt, R.L. An introduction to genetic algorithms for electromagnetics. IEEE Antennas Propagat. Mag. 2002, 37, 7–15. [Google Scholar] [CrossRef]

| Design Parameters | Values |

|---|---|

| Outer diameter (mm) | 380 |

| Inner diameter (mm) | 210 |

| Thickness of permanent magnet (PM) (mm) | 10 |

| Pole arc coefficient | 0.8 |

| Air gap length (mm) | 1.2 |

| Thickness of stator (mm) | 9 |

| Thickness of rotor yoke (mm) | 10 |

| Structural Parameters of AFPMSG | Values | |

|---|---|---|

| Initial Design | Optimized Design | |

| Outer diameter (mm) | 380 | 380 |

| Inner diameter (mm) | 210 | 227.5 |

| Thickness of PM (mm) | 10 | 9.3 |

| Pole arc coefficient | 0.8 | 0.77 |

| Air gap length (mm) | 1.2 | 1 |

| Thickness of stator (mm) | 9 | 9 |

| Rotor yoke thickness (mm) | 10 | 8.6 |

| Generator Parameters | Before Optimization | After Optimization | Change Rate |

|---|---|---|---|

| Induced voltage (V) | 322.54 | 316.06 | −2% |

| Average torque (N·m) | 35.2 | 34.4 | −2.27% |

| Output power (kW) | 1.105 | 1.08 | −2.26% |

| Efficiency | 91.3% | 92% | 0.76% |

| Copper (mm3) | 228.6 | 228.9 | 0.13% |

| Fe (mm3) | 1543 | 1249 | −19% |

| PM (mm3) | 1235 | 1040 | −15.8% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Zhou, S.; Mi, H.; Wen, Y.; Liu, H.; Zhang, G.; Guo, J. Sensitivity Analysis and Optimal Design of a Stator Coreless Axial Flux Permanent Magnet Synchronous Generator. Sustainability 2019, 11, 1414. https://doi.org/10.3390/su11051414

Wang W, Zhou S, Mi H, Wen Y, Liu H, Zhang G, Guo J. Sensitivity Analysis and Optimal Design of a Stator Coreless Axial Flux Permanent Magnet Synchronous Generator. Sustainability. 2019; 11(5):1414. https://doi.org/10.3390/su11051414

Chicago/Turabian StyleWang, Wenqiang, Shaoqi Zhou, Hongju Mi, Yadong Wen, Hua Liu, Guoping Zhang, and Jianyong Guo. 2019. "Sensitivity Analysis and Optimal Design of a Stator Coreless Axial Flux Permanent Magnet Synchronous Generator" Sustainability 11, no. 5: 1414. https://doi.org/10.3390/su11051414