Environmental Performance Analysis of Cement Production with CO2 Capture and Storage Technology in a Life-Cycle Perspective

Abstract

:1. Introduction

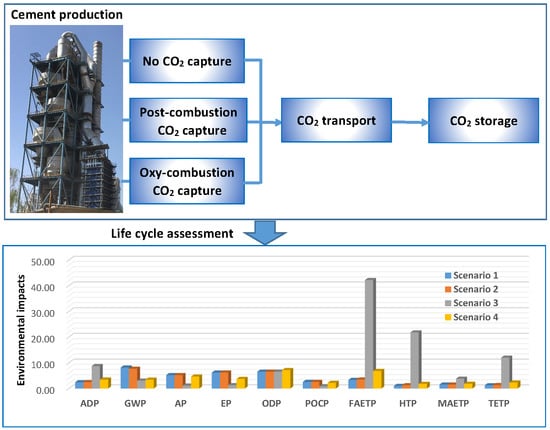

2. Methodology

2.1. System Boundary and Scenarios Designing

2.2. Inventory Analysis

2.3. The Classification of Environmental Impacts and LCA Software

3. Results and Discussion

3.1. Scenario Comparison and Analysis

3.2. Main Environmental Impact Sources Analysis

3.3. CHP Improvement Analysis

3.4. Sensitivity Analysis

3.5. Prospect Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- U.S. Geological Survey (USGS). Cement Statistics and Information. 2017. Available online: https://minerals.usgs.gov/minerals/pubs/commodity/cement/mcs-2017-cemen.pdf (accessed on 11 August 2017).

- International Energy Agency (IEA). Cement Technology Roadmap: Carbon Emissions Reductions up to 2050. 2009. Available online: https://doi.org/10.1787/9789264088061-en (accessed on 15 August 2017).

- IEA GHG. Deployment of CCS in the Cement Industry. 2013. Available online: https://www.ieaghg.org/publications/technical-reports (accessed on 16 August 2017).

- Intergovernmental Panel on Climate Change (IPCC). IPCC Special Report on Carbon Dioxide Capture and Storage: Prepared by Working Group III of the Intergovernmental Panel on Climate Change; Metz, B., Davidson, O., de Coninck, H.C., Loos, M., Meyer, L.A., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2005. [Google Scholar]

- Budinis, S.; Krevor, S.; Dowell, M.N.; Brandon, N.; Hawkes, A. An assessment of CCS costs, barriers and potential. Energy Strategy Rev. 2018, 22, 61–81. [Google Scholar] [CrossRef]

- Elias, R.S.; Wahab, M.I.M.; Fang, L. Retrofitting carbon capture and storage to natural gas-fired power plants: A real-options approach. J. Clean. Prod. 2018, 192, 722–734. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Bumb, P.; Shah, N. Carbon capture from pulverized coal power plant (PCPP): Solvent performance comparison at an industrial scale. Appl. Energy 2016, 163, 423–435. [Google Scholar] [CrossRef] [Green Version]

- Andrew, M.; Bijeljic, B.; Blunt, M. Pore-scale imaging of geological carbon dioxide storage under in situ conditions. Geophys. Res. Lett. 2013, 40, 3915–3918. [Google Scholar] [CrossRef] [Green Version]

- Fornel, A.; Estublier, A. To a dynamic update of the Sleipner CO2 storage geological model using 4D seismic data. Energy Procedia 2013, 37, 4902–4909. [Google Scholar] [CrossRef]

- Rubin, E.S.; Zhai, H. The cost of carbon capture and storage for natural gas combined cycle power plants. Environ. Sci. Technol. 2012, 46, 3076–3084. [Google Scholar] [CrossRef]

- Kuramochi, T.; Ramίrez, A.; Turkenburg, W.; Faaij, A. Comparative assessment of CO2 capture technologies for carbon-intensive industrial processes. Prog. Energy Combust. Sci. 2012, 38, 87–112. [Google Scholar] [CrossRef]

- Hitch, M.; Ballantyne, S.M.; Hindle, S.R. Revaluing mine waste rock for carbon capture and storage. Int. J. Min. Reclam. Environ. 2010, 24, 64–79. [Google Scholar] [CrossRef] [Green Version]

- Hitch, M.; Dipple, G.M. Economic feasibility and sensitivity analysis of integrating industrial-scale mineral carbonation into mining operations. Miner. Eng. 2012, 39, 268–275. [Google Scholar] [CrossRef]

- Middleton, R.S.; Bielicki, J.M. A scalable infrastructure model for carbon capture and storage: SimCCS. Energy Policy 2009, 37, 1052–1060. [Google Scholar] [CrossRef]

- Middleton, R.S.; Kuby, M.J.; Bielicki, J.M. Generating candidate networks for optimization: The CO2 capture and storage optimization problem. Comput. Environ. Urban Syst. 2012, 36, 18–29. [Google Scholar] [CrossRef]

- Kelektsoglou, K. Carbon capture and storage: A review of mineral storage of CO2 in Greece. Sustainability 2018, 10, 4400. [Google Scholar] [CrossRef]

- Zhao, X.L.; Ma, R.; Zhang, F.; Zhong, Z.C.; Wang, B.D.; Wang, Y.S.; Li, Y.L.; Weng, L. The latest monitoring progress for Shenhua CO2 storage project in China. Int. J. Greenh. Gas Control 2017, 60, 199–206. [Google Scholar] [CrossRef]

- Pan, S.Y.; Chiang, P.C.; Pan, W.; Kim, H. Advances in state-of-art valorization technologies for captured CO2 toward sustainable carbon cycle. Crit. Rev. Environ. Sci. Technol. 2018, 48, 471–534. [Google Scholar] [CrossRef]

- IEA Greenhous Gas R&D Programme (IEA GHG). CO2 Capture in the Cement Industry. 2008. Available online: http://documents.ieaghg.org/index.php/s/YKm6B7zikUpPgGA?path=%2F2008 (accessed on 5 September 2017).

- Dubois, L.; Laribi, S.; Mouhoubi, S.; De Weireld, G.; Thomas, D. Study of the post-combustion CO2 capture applied to conventional and partial oxy-fuel cement plants. Energy Procedia 2017, 114, 6181–6196. [Google Scholar] [CrossRef]

- De Lena, E.; Spinelli, M.; Romano, M.C. CO2 capture in cement plants by “Tail-End” Calcium Looping process. Energy Procedia 2018, 148, 186–193. [Google Scholar] [CrossRef]

- Li, J.; Tharakan, P.; Macdonald, D.; Liang, X. Technological, economic and financial prospects of carbon dioxide capture in the cement industry. Energy Policy 2013, 61, 1377–1387. [Google Scholar] [CrossRef]

- Jakobsen, J.; Roussanaly, S.; Anantharaman, R. A techno-economic case study of CO2 capture, transport and storage chain from a cement plant in Norway. J. Clean. Prod. 2017, 144, 523–539. [Google Scholar] [CrossRef]

- Vatopoulos, K.; Tzimas, E. Assessment of CO2 capture technologies in cement manufacturing process. J. Clean. Prod. 2012, 32, 251–261. [Google Scholar] [CrossRef]

- Cormos, A.M.; Cormos, C.C. Reducing the carbon footprint of cement industry by post-combustion CO2 capture: Techno-economic and environmental assessment of a CCS project in Romania. Chem. Eng. Res. Des. 2017, 123, 230–239. [Google Scholar] [CrossRef]

- ISO. ISO 14044: Environmental Management—Life Cycle Assessment Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Baena-Moreno, F.M.; Rodríguez-Galán, M.; Vega, F.; Alonso-Fariñas, B.; Vilches Arenas, L.F.; Navarrete, B. Carbon capture and utilization technologies: A literature review and recent advances. Energy Sources Part A Recov. Utilization Environ. Effects 2019, 41, 1403–1433. [Google Scholar] [CrossRef]

- García-Gusano, D.; Garraín, D.; Herrera, I.; Cabal, H.; Lechón, Y. Life cycle assessment of applying CO2 post-combustion capture to the Spanish cement production. J. Clean. Prod. 2015, 104, 328–338. [Google Scholar] [CrossRef]

- Volkart, K.; Bauer, C.; Boulet, C. Life cycle assessment of carbon capture and storage in power generation and industry in Europe. Int. J. Greenh. Gas Control 2013, 16, 91–106. [Google Scholar] [CrossRef]

- Schakel, W.; Hung, C.R.; Tokheim, L.A.; Strønnm, A.H.; Worrell, E.; Ramírez, A. Impact of fuel selection on the environmental performance of post-combustion calcium looping applied to a cement plant. Appl. Energy 2018, 210, 75–87. [Google Scholar] [CrossRef]

- Rolfe, A.; Huang, Y.; Haaf, M.; Pita, A.; Rezvani, S.; Dave, A.; Hewitt, N.J. Technical and environmental study of calcium carbonate looping versus oxy-fuel options for low CO2 emission cement plants. Int. J. Greenh. Gas Control 2018, 75, 85–97. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Technology Roadmap-Carbon Capture and Storage-2013 Edition. Available online: https://webstore.iea.org/technology-roadmap-carbon-capture-and-storage-2013 (accessed on 15 August 2017).

- [Dataset] Institutes of the ETH Domain and the Swiss Federal Offices. Ecoinvent Database v3. Available online: http://www.ecoinvent.org/database/ecoinvent-33/ecoinvent-33.html (accessed on 15 April 2018).

- Wildbolz, C. Life Cycle Assessment of Selected Technologies for CO2 Transport and Sequestration. Diploma Thesis, Swiss Federal Institute of Technology, Zurich, Switzerland, 2007. [Google Scholar]

- [Dataset] University of Stuttgart—Institute of Energy Economics and the Rational Use of Energy—IER, 2008. Cost Assessment of Sustainable Energy Systems: Database on life cycle emissions for electricity and heat generation technologies 2005/2010, 2020 and 2030. Version updated to 15th May 2008. Available online: http://www.feem-project.net/cases/downloads_presentation.php (accessed on 10 September 2017).

| Materials/Fuels/Energy | Unit | Base Production | Post-Combustion | Oxy-Combustion | |

|---|---|---|---|---|---|

| Inputs | Coal a | Kg/t cement | 63.30 | 291.60 | 72.06 |

| Petroleum coke a | Kg/t cement | 31.90 | 31.90 | 27.09 | |

| Electricity a | (kWh/t cement) | 80.81 | −22.73 | 174.56 | |

| Limestone a | Kg/t cement | 1245.97 | 1258.51 | 1256.74 | |

| Iron oxide a | Kg/t cement | 7.47 | 7.47 | 7.54 | |

| Gypsum a | Kg/t cement | 40.00 | 23.63 | 40 | |

| Ammonia a | Kg/t cement | 0 | 1.85 | 0 | |

| MEA a | Kg/t cement | 0 | 2.24 | 0 | |

| Outputs | Cement products a | Kg/t cement | 1000.00 | 1000.00 | 1000.00 |

| CO2 captured a | Kg/t cement | 0 | 1067.73 | 465.01 | |

| CO2 emitted a | Kg/t cement | 728.40 | 188.42 | 282.85 | |

| SO2 emitted b | Kg/t cement | 2.28 | 0 | 2.57 | |

| NO2 emitted b | Kg/t cement | 4.56 | 0 | 2.57 | |

| Particulates, <2.5um c | Kg/t cement | 0.0219 | 0.0109 | 0.0219 | |

| Particulates, >10um c | Kg/t cement | 0.0052 | 0.0026 | 0.0052 | |

| Particulates, >2.5um, and <10um c | Kg/t cement | 0.0072 | 0.0036 | 0.0072 |

| Processes | Input/Output | Materials/Energy | Units | Amount |

|---|---|---|---|---|

| Transportation | Input | Diesel, burned in building machine | MJ/km | 3.31E + 06 |

| Input | Steel, low-alloyed, at plant | kg/km | 2.70E + 05 | |

| Input | Rock wool, packed, at plant | kg/km | 5.12E + 03 | |

| Output | CO2, leaked | kg/km | 2.60E − 04 | |

| Storage | Input | electricity | kWh/kg CO2 | 6.68E − 03 |

| Units | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 | |

|---|---|---|---|---|---|

| Abiotic depletion potential (ADP) | MJ | 2.44 × 103 | 2.50 × 103 | 8.75 × 103 | 3.48 × 103 |

| Global warming potential (GWP) | kg CO2-Equiv. | 8.17 × 102 | 7.70 × 102 | 3.06 × 102 | 3.45 × 102 |

| Acidification potential (AP) | kg SO2-Equiv. | 5.21 × 100 | 5.22 × 10−1 | 1.15 × 100 | 4.67 × 100 |

| Eutrophication potential (EP) | Kg Phosphate-Equiv. | 6.20 × 10−1 | 6.22 × 10−1 | 1.32 × 10−1 | 3.73 × 10−1 |

| Ozone Layer Depletion Potential (ODP) | kg R11-Equiv. | 6.53 × 10−11 | 6.53 × 10−11 | 6.55 × 10−11 | 7.18 × 10−11 |

| Photochem Ozone Creation Potential (POCP) | kg Ethene-Equiv. | 2.58 × 10−1 | 2.57 × 10−1 | 8.90 × 10−2 | 2.22 × 10−1 |

| Freshwater Aquatic Ecotoxicity Potential (FAETP) | kg DCB-Equiv. | 3.34 × 10−1 | 3.51 × 10−1 | 4.22 × 10−1 | 6.83 × 10−1 |

| Human Toxicity Potential (HTP) | kg DCB-Equiv. | 1.01 × 101 | 1.30 × 101 | 2.18 × 102 | 1.82 × 101 |

| Marine Aquatic Ecotoxicity Potential (MAETP) | kg DCB-Equiv. | 1.54 × 103 | 1.55 × 103 | 3.82 × 103 | 1.86 × 103 |

| Terrestric Ecotoxicity Potential (TETP) | kg DCB-Equiv. | 1.25 × 10−1 | 1.35 × 10−1 | 1.20 × 100 | 2.33 × 10−1 |

| Parameters | Post-Combustion CO2 Capture | Oxy-Combustion CO2 Capture | ||

|---|---|---|---|---|

| MEA | Ammonia | Electricity for ASU | Electricity for CO2 Compression | |

| GWP | 0.00% | 0.12% | 1.50% | 2.23% |

| AP | 0.01% | 0.04% | 0.72% | 1.07% |

| EP | 0.44% | 0.05% | 0.86% | 1.28% |

| ODP | 0.00% | 0.00% | 0.00% | 0.00% |

| POCP | 0.00% | 0.05% | 0.99% | 1.47% |

| FAETP | 0.20% | 0.00% | 3.21% | 4.76% |

| HTP | 7.03% | 0.00% | 3.15% | 4.67% |

| MAETP | 0.00% | 0.08% | 2.16% | 3.20% |

| TETP | 0.00% | 0.00% | 3.15% | 4.66% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, J.; Middleton, R.S.; Li, Y. Environmental Performance Analysis of Cement Production with CO2 Capture and Storage Technology in a Life-Cycle Perspective. Sustainability 2019, 11, 2626. https://doi.org/10.3390/su11092626

An J, Middleton RS, Li Y. Environmental Performance Analysis of Cement Production with CO2 Capture and Storage Technology in a Life-Cycle Perspective. Sustainability. 2019; 11(9):2626. https://doi.org/10.3390/su11092626

Chicago/Turabian StyleAn, Jing, Richard S. Middleton, and Yingnan Li. 2019. "Environmental Performance Analysis of Cement Production with CO2 Capture and Storage Technology in a Life-Cycle Perspective" Sustainability 11, no. 9: 2626. https://doi.org/10.3390/su11092626