Energy Recovery from Wastewater: A Study on Heating and Cooling of a Multipurpose Building with Sewage-Reclaimed Heat Energy

Abstract

:1. Introduction

2. Case Study Premises

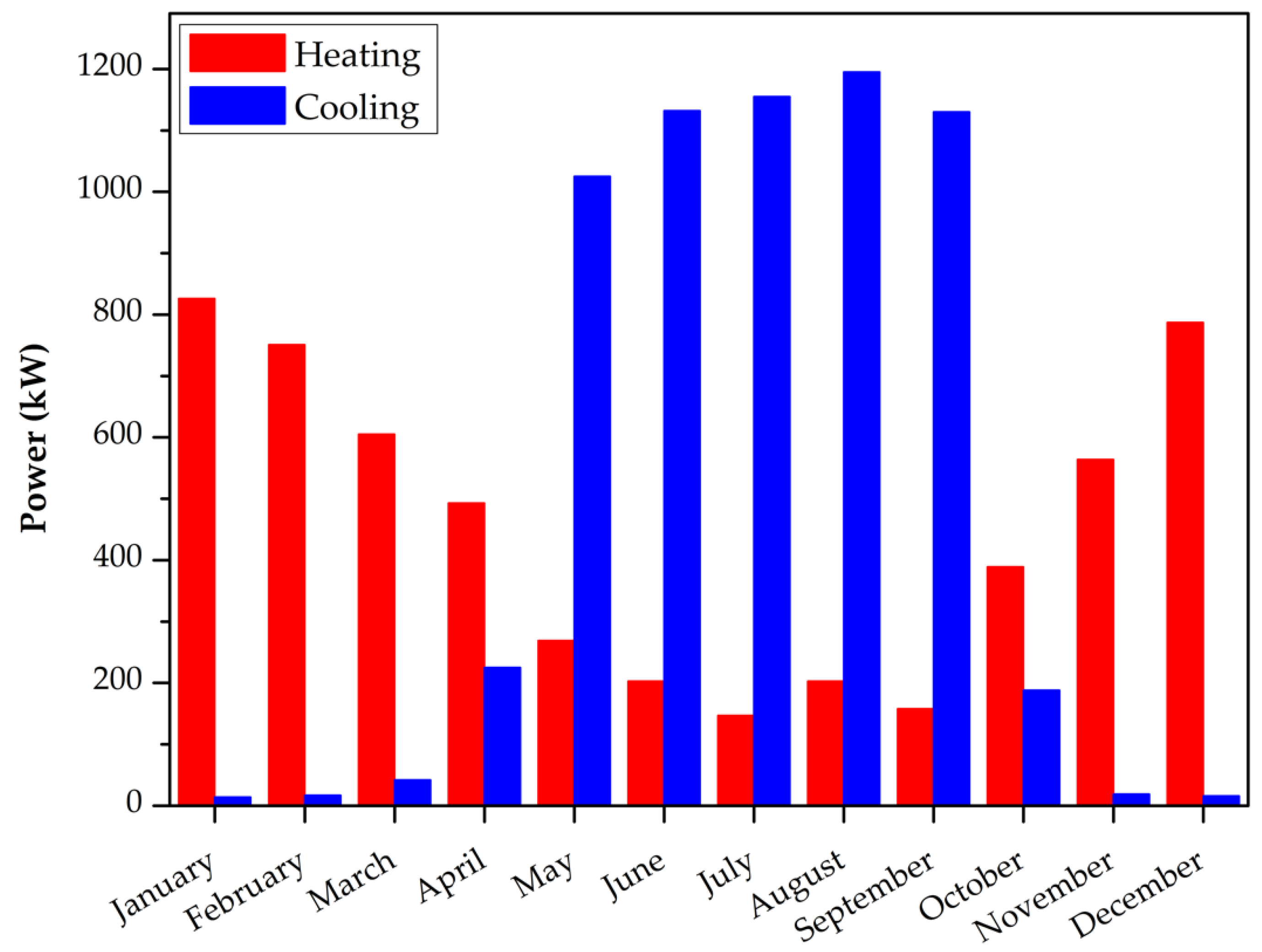

2.1. Target Building

2.2. The Sewer System

2.3. Heat Recovery: Influence on the Wastewater Temperature

3. Indoor Heating and Cooling Options

3.1. Conventional Indoor Heating and Cooling

3.2. Heat Recovery from Wastewater

4. Comparison and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Capodaglio, A.G.; Olsson, G. Energy issues in sustainable urban wastewater management: Use, demand reduction and recovery in the Urban Water Cycle. Sustainability 2019, in press. [Google Scholar]

- Capodaglio, A.G.; Ghilardi, P.; Boguniewicz-Zablocka, J. New paradigms in urban water management for conservation and sustainability. Water Pract. Technol. 2016, 11, 176–186. [Google Scholar] [CrossRef] [Green Version]

- Capodaglio, A.G.; Callegari, A.; Cecconet, D.; Molognoni, D. Sustainability of decentralized wastewater treatment technologies. Water Pract. Technol. 2017, 12, 463–477. [Google Scholar] [CrossRef]

- Daneshgar, S.; Callegari, A.; Capodaglio, A.G.; Vaccari, D. The Potential Phosphorus Crisis: Resource Conservation and Possible Escape Technologies: A Review. Resources 2018, 7, 37. [Google Scholar] [CrossRef] [Green Version]

- Daneshgar, S.; Buttafava, A.; Callegari, A.; Capodaglio, A.G. Economic and energetic assessment of different phosphorus recovery options from aerobic sludge. J. Clean. Prod. 2019, 223, 729–738. [Google Scholar] [CrossRef]

- Cecconet, D.; Molognoni, D.; Callegari, A.; Capodaglio, A.G. Agro-food industry wastewater treatment with microbial fuel cells: Energetic recovery issues. Int. J. Hydrogen Energy 2018, 43, 500–511. [Google Scholar] [CrossRef]

- Cecconet, D.; Bolognesi, S.; Molognoni, D.; Callegari, A.; Capodaglio, A.G. Influence of reactor’s hydrodynamics on the performance of microbial fuel cells. J. Water Process Eng. 2018, 26, 281–288. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Molognoni, D.; Dallago, E.; Liberale, A.; Cella, R.; Longoni, P.; Pantaleoni, L. Microbial fuel cells for direct electrical energy recovery from urban wastewaters. Sci. World J. 2013, 2013, 634738. [Google Scholar] [CrossRef] [Green Version]

- Zhou, D.; Deng, Z. (Daniel) Ultra-low-head hydroelectric technology: A review. Renew. Sustain. Energy Rev. 2017, 78, 23–30. [Google Scholar] [CrossRef]

- Frijns, J.; Hofman, J.; Nederlof, M. The potential of (waste)water as energy carrier. Energy Convers. Manag. 2013, 65, 357–363. [Google Scholar] [CrossRef]

- Callegari, A.; Hlavinek, P.; Capodaglio, A.G. Production of energy (biodiesel) and recovery of materials (biochar) from pyrolysis of urban waste sludge. Rev. Ambiente Agua 2018, 13, 1. [Google Scholar] [CrossRef]

- Callegari, A.; Bolognesi, S.; Cecconet, D.; Capodaglio, A.G. Production technologies, current role, and future prospects of biofuels feedstocks: A state-of-the-art review. Crit. Rev. Environ. Sci. Technol. 2020, 50, 384–436. [Google Scholar] [CrossRef]

- Meggers, F.; Leibundgut, H. The potential of wastewater heat and exergy: Decentralized high-temperature recovery with a heat pump. Energy Build. 2011, 43, 879–886. [Google Scholar] [CrossRef]

- Hao, X.; Li, J.; van Loosdrecht, M.C.M.; Jiang, H.; Liu, R. Energy recovery from wastewater: Heat over organics. Water Res. 2019, 161, 74–77. [Google Scholar] [CrossRef]

- Hao, X.; Wang, X.; Liu, R.; Li, S.; van Loosdrecht, M.C.M.; Jiang, H. Environmental impacts of resource recovery from wastewater treatment plants. Water Res. 2019, 160, 268–277. [Google Scholar] [CrossRef]

- Zou, S.; Kanimba, E.; Diller, T.E.; Tian, Z.; He, Z. Modeling assisted evaluation of direct electricity generation from waste heat of wastewater via a thermoelectric generator. Sci. Total Environ. 2018, 635, 1215–1224. [Google Scholar] [CrossRef]

- Cipolla, S.S.; Maglionico, M. Heat recovery from urban wastewater: Analysis of the variability of flow rate and temperature. Energy Build. 2014, 69, 122–130. [Google Scholar] [CrossRef]

- Hepbasli, A.; Biyik, E.; Ekren, O.; Gunerhan, H.; Araz, M. A key review of wastewater source heat pump (WWSHP) systems. Energy Convers. Manag. 2014, 88, 700–722. [Google Scholar] [CrossRef]

- Kretschmer, F.; Simperler, L.; Ertl, T. Analysing wastewater temperature development in a sewer system as a basis for the evaluation of wastewater heat recovery potentials. Energy Build. 2016, 128, 639–648. [Google Scholar] [CrossRef]

- Mattsson, J.; Hedström, A.; Westerlund, L.; Dahl, J.; Ashley, R.M.; Viklander, M. Impacts on Rural Wastewater Systems in Subarctic Regions due to Changes in Inputs from Households. J. Cold Reg. Eng. 2018, 32, 04017019. [Google Scholar] [CrossRef]

- Callegari, A.; Boguniewicz-Zablocka, J.; Capodaglio, A.G. Energy recovery and efficiency improvement for an activated sludge, agro-food WWTP upgrade. Water Pract. Technol. 2018, 13, 909–921. [Google Scholar] [CrossRef]

- Guo, X.; Hendel, M. Urban water networks as an alternative source for district heating and emergency heat-wave cooling. Energy 2018, 145, 79–87. [Google Scholar] [CrossRef] [Green Version]

- Wanner, O.; Panagiotidis, V.; Clavadetscher, P.; Siegrist, H. Effect of heat recovery from raw wastewater on nitrification and nitrogen removal in activated sludge plants. Water Res. 2005, 39, 4725–4734. [Google Scholar] [CrossRef] [PubMed]

- Funamizu, N.A.; Iida, M.; Sakakura, Y.; Takakuwa, T. Reuse of heat energy in wastewater: Implementation examples in Japan. Water Sci. Technol. 2001, 43, 277–285. [Google Scholar] [CrossRef] [PubMed]

- Adamcová, D.; Vaverková, M.; Brouskova, E. The toxicity of two types of sewage sludge from wastewater treatment plant for plants in Czech Republic. J. Ecol. Eng. 2016, 17, 33–37. [Google Scholar] [CrossRef] [Green Version]

- Huber, Energy from Wastewater, HUBER Heat Exchanger RoWin. Available online: https://www.huber.de/products/energy-from-wastewater.html (accessed on 27 November 2019).

- Culha, O.; Gunerhan, H.; Biyik, E.; Ekren, O.; Hepbasli, A. Heat exchanger applications in wastewater source heat pumps for buildings: A key review. Energy Build. 2015, 104, 215–232. [Google Scholar] [CrossRef]

- Raček, J.; Úterský, M.; Ševčík, J.; Dufek, Z.; Hlavínek, P. Energy recovery from wastewater for heating and cooling of multifunctional building in Brno: Modeling the connection. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management, SGEM, Albena, Bulgaria, 29 June–5 July 2017; Volume 17, pp. 519–526. [Google Scholar]

- Kretschmer, F.; Neugebauer, G.; Stoeglehner, G.; Ertl, T. Participation as a key aspect for establishing wastewater as a source of renewable energy. Energies 2018, 11, 3232. [Google Scholar] [CrossRef] [Green Version]

- Kretschmer, F.; Ertl, T. Chances and Barriers of Wastewater Heat Recovery from a Multidisciplinary Perspective. In Frontiers in Water-Energy-Nexus Nature-Based Solutions, Advanced Technologies and Best Practices for Environmental Sustainability; Springer: Cham, Switzerland, 2020; pp. 297–299. [Google Scholar]

- Grady, C.P.L.; Daigger, G.T.; Love, N.G.; Filipe, C.D.M. Biological Wastewater Treatment, 3rd ed.; IWA Publishing & CRC Press: London, UK, 2011; ISBN 9780849396793. [Google Scholar]

- Sheridan, C.; Petersen, J.; Rohwer, J. On modifying the arrhenius equation to compensate for temperature changes for reactions within biological systems. Water SA 2012, 38, 149–151. [Google Scholar] [CrossRef] [Green Version]

- Stenstrom, M.K.; Gilbert, R.G. Effects of alpha, beta and theta factor upon the design, specification and operation of aeration systems. Water Res. 1981, 15, 643–654. [Google Scholar] [CrossRef]

- Mines, R.O.; Callier, M.C.; Drabek, B.J.; Butler, A.J. Comparison of oxygen transfer parameters and oxygen demands in bioreactors operated at low and high dissolved oxygen levels. J. Environ. Sci. Health Part A 2017, 52, 341–349. [Google Scholar] [CrossRef]

- Marais, G.V.R.; Ekama, G.A. The activated sludge process part I—Steady state behaviour. Water SA 1976, 2, 164–200. [Google Scholar]

- Novak, J.T. Temperature-substrate in biological treatment. Journal (Water Pollut. Control Fed.) 1974, 46, 1984–1994. [Google Scholar]

- van Handeel, A.C.; van der Lubbe, J.G.M. Handbook of Biological Wastewater Treatment, 2nd ed.; IWA Publishing: London, UK, 2012; ISBN 9781780400808. [Google Scholar]

- Abdel-Aal, M.; Schellart, A.; Kroll, S.; Mohamed, M.; Tait, S. Modelling the potential for multi-location in-sewer heat recovery at a city scale under different seasonal scenarios. Water Res. 2018, 145, 618–630. [Google Scholar] [CrossRef] [PubMed]

- Elías-Maxil, J.A.; Van Der Hoek, J.P.; Hofman, J.; Rietveld, L. Energy in the urban water cycle: Actions to reduce the total expenditure of fossil fuels with emphasis on heat reclamation from urban water. Renew. Sustain. Energy Rev. 2014, 30, 808–820. [Google Scholar] [CrossRef] [Green Version]

- Pelda, J.; Holler, S. Methodology to evaluate and map the potential of waste heat from sewage water by using internationally available open data. Energy Procedia 2018, 149, 555–564. [Google Scholar] [CrossRef]

| Q | Month | Year | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (L s−1) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | - |

| Max | 427.9 | 454.8 | 338.0 | 389.7 | 344.7 | 425.6 | 299.8 | 313.3 | 389.7 | 470.6 | 405.4 | 427.9 | 470.6 |

| Min | 167.2 | 200.9 | 171.7 | 160.4 | 182.9 | 135.7 | 158.2 | 147.0 | 144.7 | 164.9 | 131.2 | 167.2 | 131.2 |

| Mean | 302.8 | 354.1 | 272.6 | 286.1 | 268.5 | 287.7 | 233.4 | 240.0 | 272.8 | 391.7 | 304.3 | 302.8 | 291.9 |

| SD | 72.5 | 76.8 | 57.3 | 66.1 | 52.3 | 84.1 | 40.1 | 53.2 | 67.4 | 95.1 | 91.6 | 72.5 | 83.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cecconet, D.; Raček, J.; Callegari, A.; Hlavínek, P. Energy Recovery from Wastewater: A Study on Heating and Cooling of a Multipurpose Building with Sewage-Reclaimed Heat Energy. Sustainability 2020, 12, 116. https://doi.org/10.3390/su12010116

Cecconet D, Raček J, Callegari A, Hlavínek P. Energy Recovery from Wastewater: A Study on Heating and Cooling of a Multipurpose Building with Sewage-Reclaimed Heat Energy. Sustainability. 2020; 12(1):116. https://doi.org/10.3390/su12010116

Chicago/Turabian StyleCecconet, Daniele, Jakub Raček, Arianna Callegari, and Petr Hlavínek. 2020. "Energy Recovery from Wastewater: A Study on Heating and Cooling of a Multipurpose Building with Sewage-Reclaimed Heat Energy" Sustainability 12, no. 1: 116. https://doi.org/10.3390/su12010116