Economic Analysis of Geopolymer Brick Manufacturing: A French Case Study

Abstract

:1. Introduction

2. Materials, Methods, Objectives, and Research Methodology

2.1. Research Objectives

2.2. Cost Evaluation Method

- (1)

- Step 1: Brick formulation and geopolymer references:

- Reference geopolymer brick formulation;

- Determine characteristics of raw material;

- Study different formulations of geopolymer bricks.

- (2)

- Step 2: Calculation of the initial cost:

- Determination of unit prices for the different materials used;

- Identification of the different phases of production of geopolymer bricks;

- Calculation of the global cost of geopolymer and fired brick production for the different formulations studied.

- (3)

- Step 3–Business case analysis:

- Identification of parameters;

- Calculation of indicators related to the chosen parameters;

- Performance analysis based on fired brick of the Briqueterie du Nord de la France (BdN);

- Demonstration of the most efficient geopolymer brick formulations.

3. Material Input for Brick Manufacturing and Cost Analysis

3.1. Materials and Formulations Used in the Geopolymer Formulations

3.2. Parameter Used in the Economic Analysis

3.3. Cost of Fired Brick Manufacturing: Data Source

- (1)

- Extraction of raw materials (clay and sand);

- (2)

- Energy consumption: use of natural gas, electricity, and fuel throughout the production chain and in the factory premises; and

- (3)

- Maintenance and humanpower.

3.4. Cost of Geopolymer Brick Manufacturing

3.4.1. Cost of Raw Materials in the Geopolymer Formulations

3.4.2. Natural Gas and Domestic Fuel Oil Consumption

3.4.3. Electric Power Consumption

3.4.4. Maintenance and Labor Cost

3.4.5. Global Cost of Geopolymer Brick Manufacturing

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Olivier, J.G.; Peters, J.A.H.W. Trends in Global CO2 and Total Greenhouse Gas Emissions: 2018 Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2018. [Google Scholar]

- Davidovits, J. Geopolymers—Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Davidovits, P.J. 30 Years of Successes and Failures in Geopolymer Applications. Market Trends and Potential Breakthroughs. In Proceedings of the Geopolymer 2002 Conference, Melbourne, Australia, 28–29 October 2002; pp. 1–16. [Google Scholar]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Alkali-activated binders: A review Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr. Build. Mater. 2008, 22, 1305–1314. [Google Scholar] [CrossRef] [Green Version]

- Pacheco-Torgal, F.; Castro-Gomes, J.P.; Jalali, S. Adhesion characterization of tungsten mine waste geopolymeric binder. Influence of OPC concrete substrate surface treatment. Constr. Build. Mater. 2008, 22, 154–161. [Google Scholar] [CrossRef] [Green Version]

- Dutt, K.S.; Kumar, K.V.; Kishore, I.S.; Chowdary, C.M. A case ctudy on fly ash based Geo-polymer concrete. Int. J. Eng. Trends Technol. 2016, 34, 58–62. [Google Scholar] [CrossRef]

- Alonso, S.; Palomo, A. Alkaline activation of metakaolin and calcium hydroxide mixtures: Influence of temperature, activator concentration and solids ratio. Mater. Lett. 2001, 47, 55–62. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Properties of tungsten mine waste geopolymeric binder. Constr. Build. Mater. 2008, 22, 1201–1211. [Google Scholar] [CrossRef] [Green Version]

- Shi, C.; Fern, A. Stabilization / solidification of hazardous and radioactive wastes with alkali-activated cements. J. Hazard. Mater. 2006, 137, 1656–1663. [Google Scholar] [CrossRef]

- Pruett, R.J. Kaolin deposits and their uses: Northern Brazil and Georgia, USA. Appl. Clay Sci. 2016, 131, 3–13. [Google Scholar] [CrossRef]

- Naghsh, M.; Shams, K. Synthesis of a kaolin-based geopolymer using a novel fusion method and its application in effective water softening. Appl. Clay Sci. 2017, 146, 238–245. [Google Scholar] [CrossRef]

- Selmani, S.; Sdiri, A.; Bouaziz, S.; Joussein, E.; Rossignol, S. Effects of metakaolin addition on geopolymer prepared from natural kaolinitic clay. Appl. Clay Sci. 2017, 146, 457–467. [Google Scholar] [CrossRef]

- Elizondo-Martinez, E.J.; Tataranni, P.; Rodriguez-Hernandez, J.; Castro-Fresno, D. Physical and mechanical characterization of sustainable and innovative porous concrete for urban pavements containing metakaolin. Sustainability 2020, 12, 4243. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.A.; Mejia de Gutiérrez, R.; Puertas, F. Effect of metakaolin on natural volcanic pozzolan-based geopolymer cement. Appl. Clay Sci. 2016, 132–133, 491–497. [Google Scholar] [CrossRef]

- Duxson, P.; Mallicoat, S.W.; Lukey, G.C.; Kriven, W.M.; van Deventer, J.S.J. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surfaces A Physicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Sisol, M.; Kudelas, D.; Marcin, M.; Holub, T.; Varga, P. Statistical evaluation of mechanical properties of slag-based alkali-activated material. Sustainability 2019, 11, 5935. [Google Scholar] [CrossRef] [Green Version]

- Jeong, Y.; Oh, J.E.; Jun, Y.; Park, J.; Ha, J.H.; Sohn, S.G. Influence of four additional activators on hydrated-lime [Ca (OH) 2] activated ground granulated blast-furnace slag. Cem. Concr. Compos. 2016, 65, 1–10. [Google Scholar] [CrossRef]

- Rousekov, I.; Bajza, A.; Zivica, V. Silica fume-basic blast furnace slag systems activated by an alkali silica fume activator. Cem. Concr. Res. 1997, 27, 1825–1828. [Google Scholar] [CrossRef]

- Khale, D.; Chaudhary, R. Mechanism of Geopolymerization and Factors Influencing Its Development: A review. J. Mater. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of Geopolymer Cements. In First International Conference on Alkaline Cements and Concretes; Kiev State Technical University: Kiev, Ukraine, 1994; pp. 131–149. [Google Scholar]

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A review and prospects for the minerals industry. Miner. Eng. 2007, 20, 1261–1277. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Abdollahnejad, Z.; Camões, A.F.; Jamshidi, M.; Ding, Y. Durability of alkali-activated binders: A clear advantage over Portland cement or an unproven issue? Constr. Build. Mater. 2012, 30, 400–405. [Google Scholar] [CrossRef] [Green Version]

- Amalia, F.; Akifah, N.; Irfanita, R.; Afifah, K.N.; Zulkifly, K.; Yong, H.C.; Abdullah, M.M.A.B.; Faris, M.A. Durability of Bricks Coated with Red mud Based Geopolymer Paste. In Proceedings of the International Conference on Advances in Materials and Manufacturing Applications (IConAMMA), Bangalore, India, 14–16 July 2016. [Google Scholar]

- Lavanya, G.; Jegan, J.; Lavanya, G.; Jegan, J. Durability Study on High Calcium Fly Ash Based Geopolymer Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 731056. [Google Scholar] [CrossRef] [Green Version]

- Fu, Y.; Cai, L.; Wu, Y. Freeze—thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Build. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. Alkali-activated binders: A review. Part 2. About materials and binders manufacture. Constr. Build. Mater. 2008, 22, 1315–1322. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Zhang, J.; Yu, Y.; Zhang, G. The strength and microstructure of two geopolymers derived from metakaolin and red mud-fly ash admixture: A comparative study. Constr. Build. Mater. 2012, 30, 80–91. [Google Scholar] [CrossRef]

- Obonyo, E.; Kamseu, E.; Melo, U.C.; Leonelli, C. Advancing the use of secondary inputs in geopolymer binders for sustainable cementitious composites: A review. Sustainability 2011, 3, 410–423. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.; Cheng, T.; Lin, K.; Lin, K.; Wu, C.; Tsai, C. Geopolymer Technologies for Stabilization of Basic Oxygen Furnace Slags and Sustainable Application as Construction Materials. Sustainability 2020, 12, 5002. [Google Scholar] [CrossRef]

- Liew, Y.M.; Heah, C.Y.; Mohd Mustafa, A.B.; Kamarudin, H. Structure and properties of clay-based geopolymer cements: A review. Prog. Mater. Sci. 2016, 83, 595–629. [Google Scholar] [CrossRef]

- Mobili, A.; Belli, A.; Giosuè, C.; Bellezze, T.; Tittarelli, F. Metakaolin and fly ash alkali-activated mortars compared with cementitious mortars at the same strength class. Cem. Concr. Res. 2016, 88, 198–210. [Google Scholar] [CrossRef]

- Fabien, F.; Charlène, D.C. Geopolymers as waste encapsulation materials: Impact of anions on the materials properties. Adv. Sci. Technol. 2010, 69, 174–179. [Google Scholar]

- Cozzi, A.D.; Bannochie, C.J.; Burket, P.R.; Crawford, C.L. Immobilization of Radioactive Waste in Fly Ash Based Geopolymers. In Proceedings of the World of Coal Ash (WOCA) Conference, Denver, CO, USA, 9–12 May 2011. [Google Scholar]

- Tzanakos, A.; Mimilidou, K.; Anastasiadou, A.; Stratakis, E.; Gidarakos, K. Synthesis and heavy metal immobilization behaviors of medical waste and based geopolymer. In Proceedings of the 13th International Conference on Environmental Science and Technology, Athens, Greece, 5–7 September 2013. [Google Scholar]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Sumajouw, D.; Hardjito, S.E.; Wallah, B.V.; Rangan, D.M.J. Fly ash-based geopolymer concrete: Study of slender reinforced columns. J. Mater. Sci. 2007, 42, 3124–3130. [Google Scholar] [CrossRef]

- Gourley, T.; Duxson, P.; Setunge, S.; Lloyd, N.; Dechsler, M.; South, W. Geopolymer Concrete; Concrete Institute of Australia: North Sydney, NSW, Australia, 2011. [Google Scholar]

- Janardhanan, T.; Thaarrini, J.; Dhivya, S. Comparative Study on the Production Cost of Geopolymer and Conventional Concretes. Int. J. Civ. Eng. Res. 2016, 7, 117–124. [Google Scholar]

- Vilamová, Š.; Piecha, M. Economic evaluation of using of geopolymer from coal fly ash in the industry. Acta Montan. Slovaca 2016, 21, 139–145. [Google Scholar]

- You, S.; Ho, S.W.; Li, T.; Maneerung, T.; Wang, C.H. Techno-economic analysis of geopolymer production from the coal fly ash with high iron oxide and calcium oxide contents. J. Hazard. Mater. 2019, 361, 237–244. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Youssef, N.; Rabenantoandro, A.Z.; Dakhli, Z.; Chapiseau, C.; Waendendries, F.; Hage Chehade, F.; Lafhaj, Z. Reuse of waste bricks: A new generation of geopolymer bricks. SN Appl. Sci. 2019, 1, 1252. [Google Scholar] [CrossRef] [Green Version]

- Youssef, N.; Rabenantoandro, A.Z.; Dakhli, Z.; Hage Chehade, F.; Lafhaj, Z. Environmental evaluation of geopolymer bricks. In Proceedings of the MATEC Web of Conferences, INCER 2019, Beirut, Lebanon, 3–5 April 2019; pp. 1–5. [Google Scholar]

- Tiffo, E.; Elimbi, A.; Manga, J.D.; Tchamba, A.B. Red ceramics produced from mixtures of kaolinite clay and waste glass. Braz. J. Sci. Technol. 2015, 2, 4. [Google Scholar] [CrossRef] [Green Version]

| Oxides (wt %) | Materials | |||

|---|---|---|---|---|

| Waste Bricks | Clay | GGBFS | Sand | |

| MgO | 1.41 | 1.15 | 5.76 | 0.47 |

| Al2O3 | 12.68 | 13.59 | 9.16 | 5.57 |

| SiO2 | 73.106 | 73.676 | 33.84 | 89.99 |

| K2O | 3.45 | 3.48 | 0.54 | 1.2 |

| CaO | 1.02 | 1.95 | 49.17 | 0.19 |

| TiO2 | 0.87 | 0.94 | 0.77 | 0.2 |

| MnO | 0.68 | 0.094 | 0.3 | 0.02 |

| Fe2O3 | 6.74 | 5.12 | 0.46 | 2.35 |

| Ni2O3 | 0.009 | - | - | 0.01 |

| Cu2O | 0.007 | - | - | - |

| ZnO | 0.02 | - | - | - |

| GaO3 | 0.008 | - | - | - |

| Formulations | Component of Different Geopolymer Brick Formulations (g) | ||||||

|---|---|---|---|---|---|---|---|

| Sand | Clay | WB | GGBFS | NaOH | Na2SiO3 | Water | |

| GC | 827 | 827 | 0 | 0 | 92.83 | 93.77 | 293.04 |

| GWB1 | 827 | 0 | 827 | 0 | 362 | 44 | 137 |

| GWB2 | 827 | 0 | 661.6 | 165.4 | 362 | 44 | 137 |

| GWB2 | 827 | 0 | 496.2 | 330.8 | 362 | 44 | 137 |

| GWB3 | 827 | 0 | 330.8 | 496.2 | 362 | 44 | 137 |

| GWB4 | 827 | 0 | 165.4 | 661.6 | 362 | 44 | 137 |

| GWB5 | 827 | 0 | 0 | 827 | 362 | 44 | 137 |

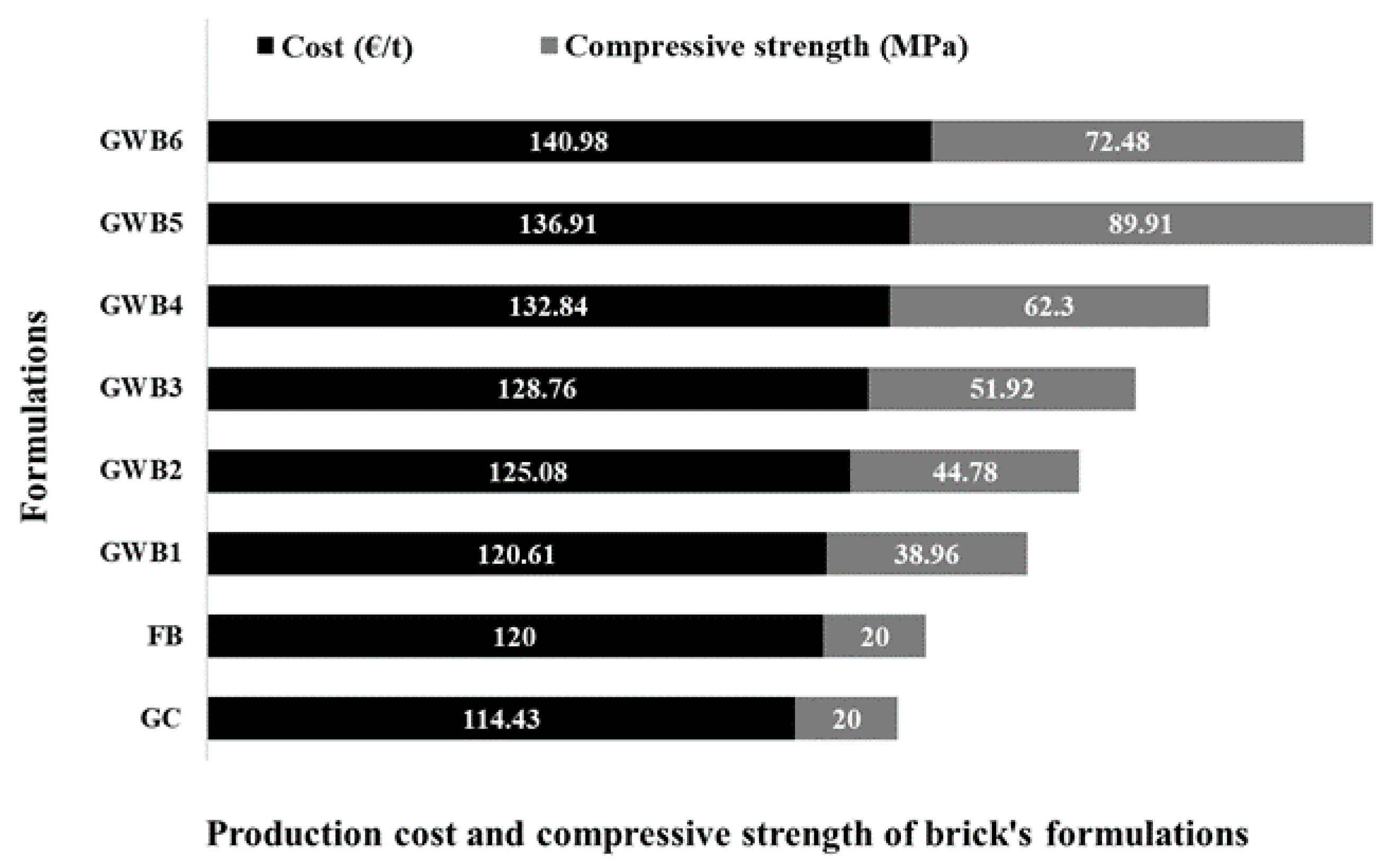

| Formulations | FB | GC | GWB1 | GWB2 | GWB3 | GWB4 | GWB5 | GWB6 |

|---|---|---|---|---|---|---|---|---|

| Rc (MPa) | 20 | 20 | 38.96 | 44.78 | 51.92 | 62.3 | 89.91 | 72.48 |

| Production Stages | Product | Quantity | Unit | Cost | Unit | Total Cost | Unit |

|---|---|---|---|---|---|---|---|

| Clay | 24,113 | t/year | 20 | EUR/t | 482,260 | EUR/year | |

| STAGE 1 | Sand | 10,620 | t/year | 40 | EUR/t | 424,800 | EUR/year |

| Materials, labor, | Water | 3355 | m3/year | 3 | EUR/m3 | 10,065 | EUR/year |

| and annual cost | Natural gas | 17,500,000 | kWh/year | 0.0589 | EUR/kWh | 1030,750 | EUR/year |

| Production | Electricity | 2446,125 | kWh/year | 0.1483 | EUR/kWh | 362,760 | EUR/year |

| Domestic fuel | 17,911 | L/year | 0.875 | EUR/L | 15,673 | EUR/year | |

| Maintenance | 350,000 | EUR/year | 350,000 | EUR/year | |||

| Labor | 350,000 | EUR/year | 350,000 | EUR/year | |||

| Total annual cost of fired brick production | 3026,308 | EUR/year | |||||

| STAGE 2 Annual production quantity of fired bricks | Annual production quantity of fired bricks | 25,219 | t/year | ||||

| STAGE 3 Calculation of the production cost of fired bricks | Production cost of one metric ton of fired bricks produced | 120 | EUR/t | ||||

| Materials | Cost (EUR/t) |

|---|---|

| Clay | 20 |

| Sand | 40 |

| Waste bricks | 10 |

| GGBFS | 65 |

| Sodium silicate (Na2SiO3) | 268.2 |

| Sodium hydroxide (NaOH) | 470.7 |

| Water | 3 |

| Electric Power Consumption | |||||

|---|---|---|---|---|---|

| Phase | kW/h | h/day | kWh /day | J/week | kWh/week |

| Maturing | 52.39 | 5 | 261.95 | 5 | 1309.75 |

| Molding | 284.88 | 10 | 2848.80 | 5 | 14244 |

| Dryer | 120.28 | 24 | 2886.72 | 7 | 20,207.04 |

| Keller | 1.54 | 6 | 9.24 | 5.5 | 50.82 |

| Set up in the kiln | 9.39 | 11 | 103.29 | 5 | 516.45 |

| Automatic sawing | 11.11 | 6 | 66.66 | 5 | 333.3 |

| Removing from the kiln | 10.03 | 11 | 110.33 | 5.5 | 606.815 |

| Lightning (production and building) | 8.63 | 12 | 103.56 | 5 | 517.8 |

| workshop | 0.49 | 16 | 7.84 | 5 | 39.2 |

| Office utilities | 4.93 | 8 | 39.44 | 5 | 197.2 |

| Social local | 3.26 | 8 | 26.08 | 5.5 | 143.44 |

| External lighting | 2.83 | 6 | 16.98 | 5 | 84.9 |

| Total weekly electric power consumption by the French brickwork | 38,251 | ||||

| Production Cost of One Metric Ton of Geopolymer Bricks According to Different Formulations (EUR/t) | |||||||

|---|---|---|---|---|---|---|---|

| Product (EUR/t) | GC | GWB1 | GWB2 | GWB3 | GWB4 | GWB5 | GWB6 |

| WB | 0 | 3.70 | 2.96 | 2.22 | 1.48 | 0.74 | 0 |

| GGBFS | 0 | 0 | 4.81 | 9.63 | 14.44 | 19.26 | 24.07 |

| Sand | 15.28 | 14.81 | 14.81 | 14.81 | 14.81 | 14.81 | 14.81 |

| Clay | 7.64 | 0 | 0 | 0 | 0 | 0 | 0 |

| Na2SiO3 | 10.71 | 39.64 | 39.64 | 39.64 | 39.64 | 39.64 | 39.64 |

| NaOH | 27 | 8.86 | 8.86 | 8.865 | 8.86 | 8.86 | 8.86 |

| Water | 0.396 | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 |

| Natural gas | 19.75 | 19.75 | 19.75 | 19.75 | 19.75 | 19.75 | 19.75 |

| Electric power | 10.23 | 10.23 | 10.23 | 10.23 | 10.23 | 10.23 | 10.23 |

| Fuel | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 | 0.60 |

| Maintenance | 9.38 | 9.38 | 9.38 | 9.38 | 9.38 | 9.38 | 9.38 |

| Labor | 13.42 | 13.42 | 13.42 | 13.42 | 13.42 | 13.42 | 13.42 |

| Total Cost | 114.43 | 120.61 | 125.08 | 128.76 | 132.84 | 136.91 | 140.98 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Youssef, N.; Lafhaj, Z.; Chapiseau, C. Economic Analysis of Geopolymer Brick Manufacturing: A French Case Study. Sustainability 2020, 12, 7403. https://doi.org/10.3390/su12187403

Youssef N, Lafhaj Z, Chapiseau C. Economic Analysis of Geopolymer Brick Manufacturing: A French Case Study. Sustainability. 2020; 12(18):7403. https://doi.org/10.3390/su12187403

Chicago/Turabian StyleYoussef, Nicolas, Zoubeir Lafhaj, and Christophe Chapiseau. 2020. "Economic Analysis of Geopolymer Brick Manufacturing: A French Case Study" Sustainability 12, no. 18: 7403. https://doi.org/10.3390/su12187403