From Historical Silk Fabrics to Their Interactive Virtual Representation and 3D Printing

Abstract

:1. Introduction

2. State of the Art

2.1. The Production of Traditional Silk Textiles

2.2. Virtual Representation of Fabrics

2.3. 3D Printing of Fabrics

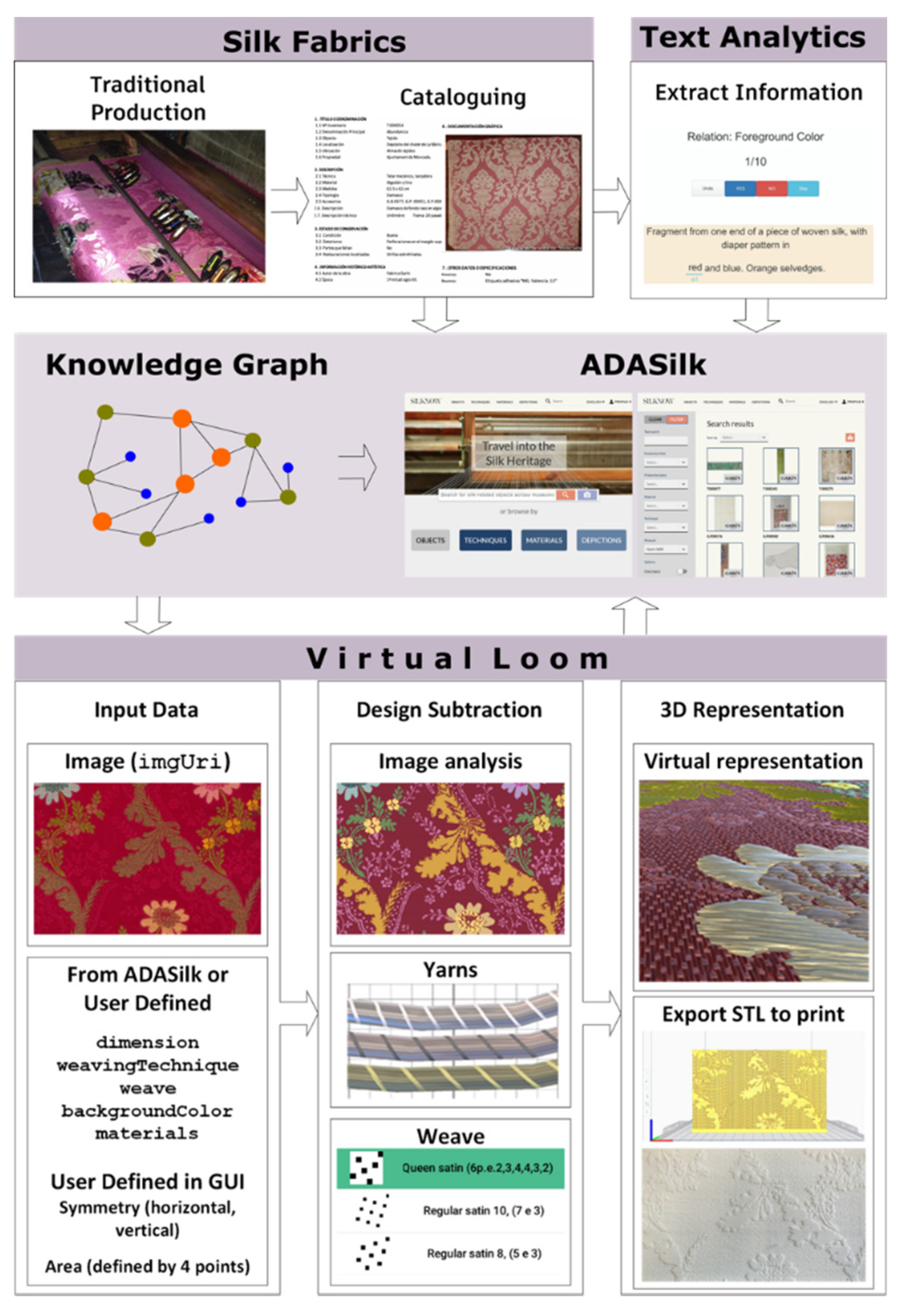

3. Methodology and Results

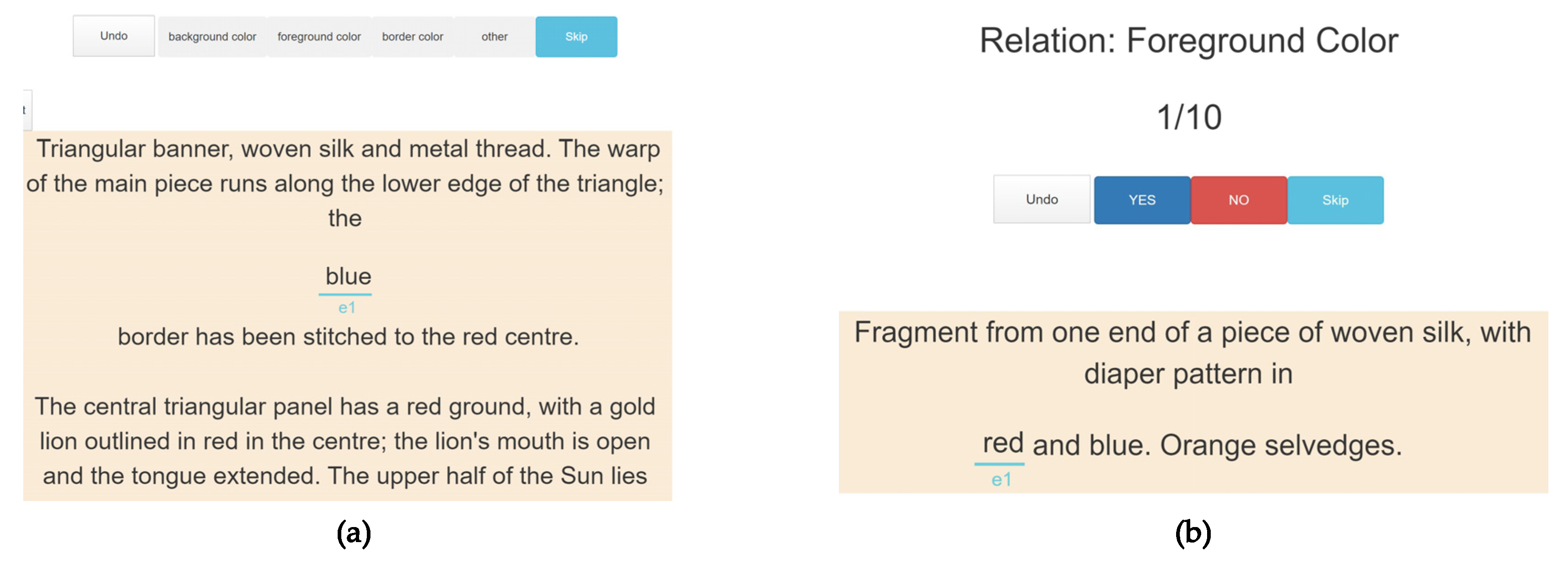

3.1. Text Analytics to Automatically Extract Data for Virtual Loom

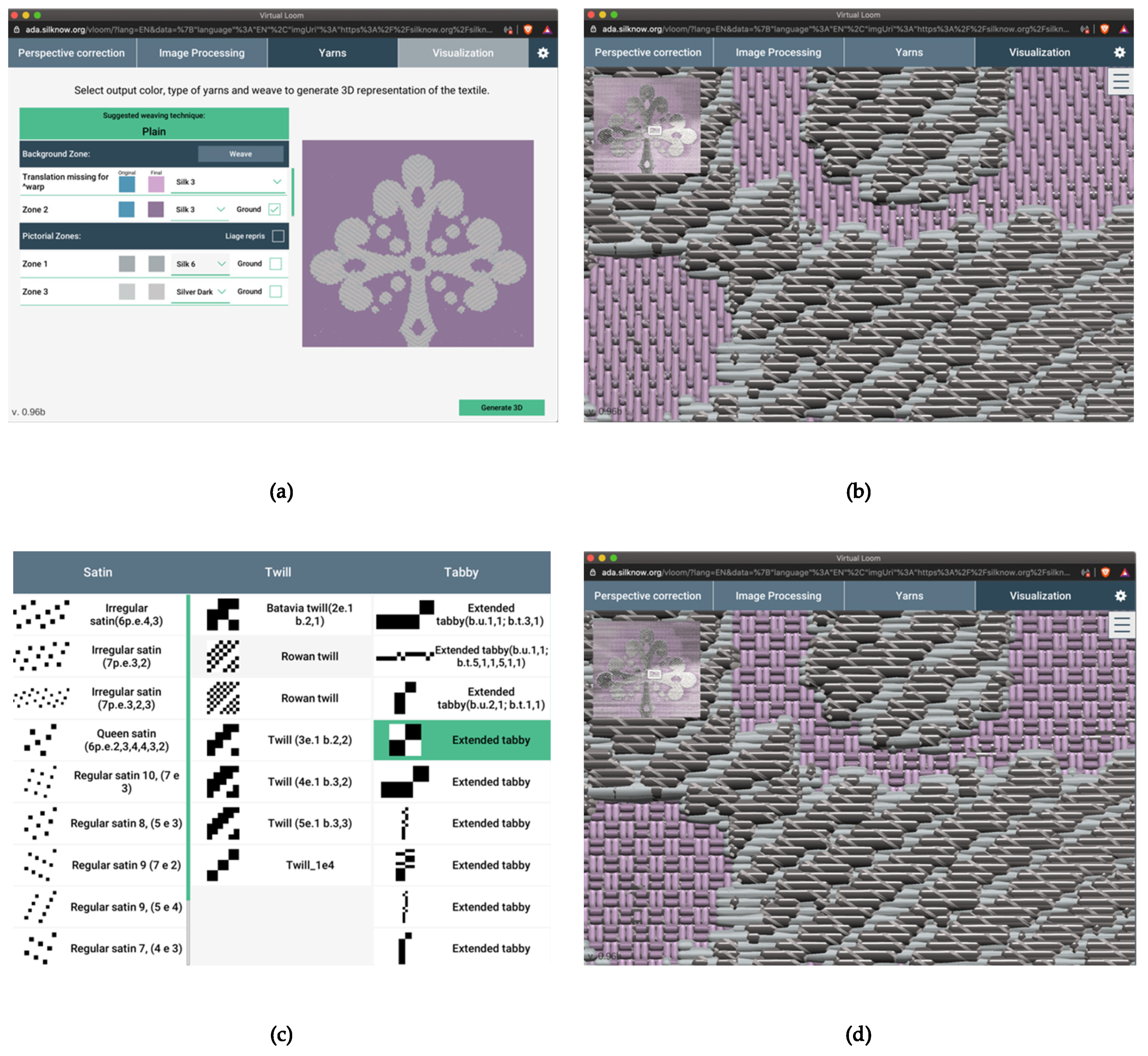

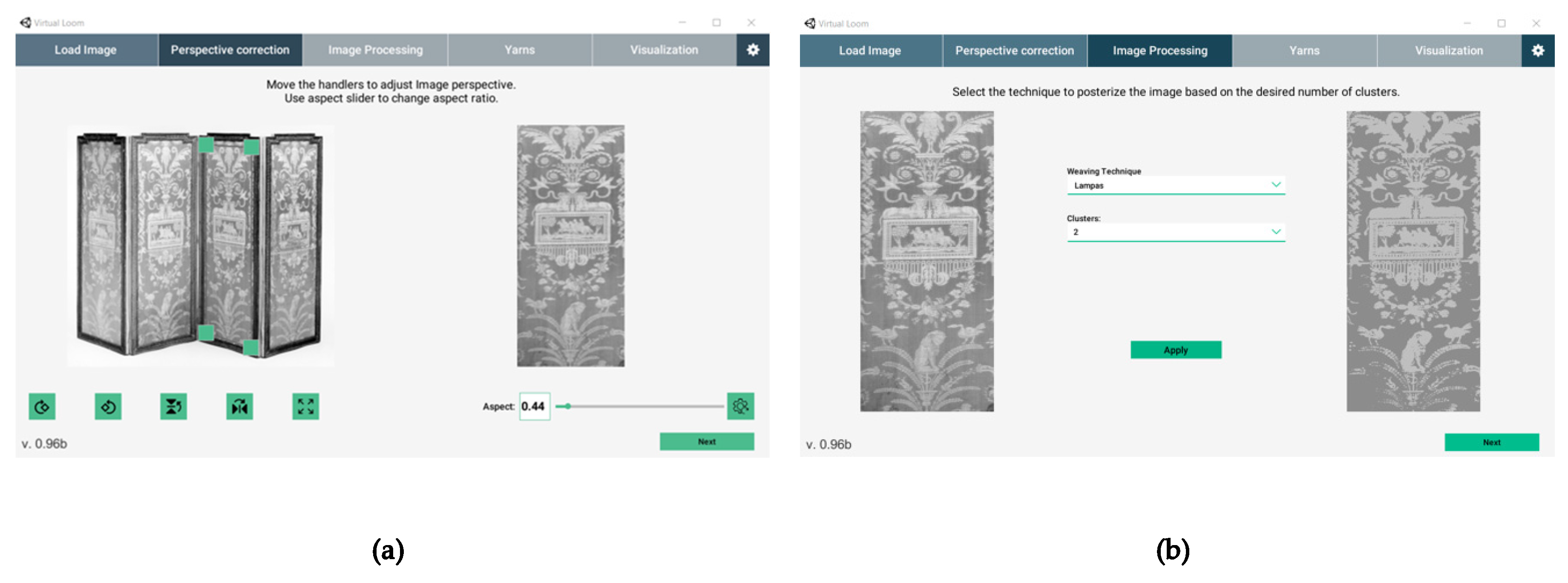

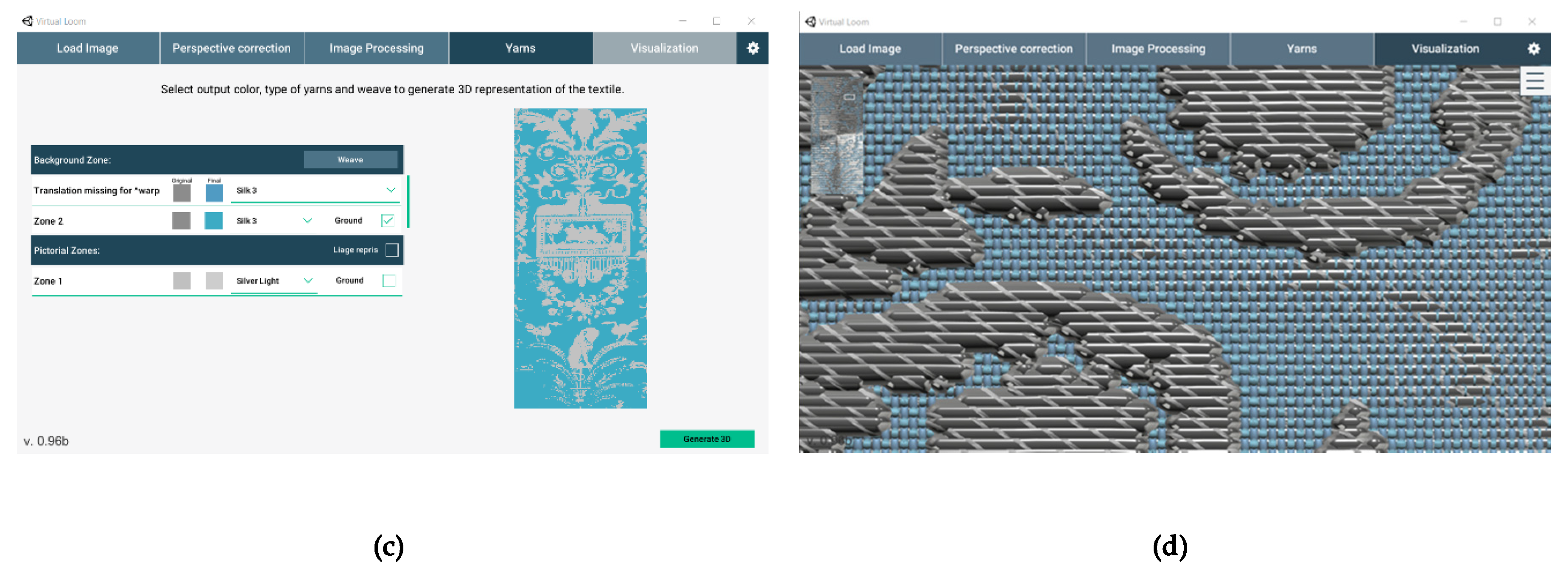

3.2. Interactive Virtual Representation of Silk Fabrics

3.3. 3D Printing of Silk Fabrics

3.3.1. Models Used to Show the Design

- Project a dense mesh grid onto the model from both sides: To create a watertight uniform mesh out of the sample, the grids are projected onto the sample from both sides. The density (number of rows and columns) in the grid and the resolution of the sample determines the resolution of the output mesh. This projection results in two separate grids, deformed accordingly to the base sample.

- Move the two projected grids apart from each other to add the width: To add the width to the final mesh, the two grids should be separated from each other by a few mm. This ensures that the model will be thick enough for the slicing algorithm.

- Close the gaps between the grids: To create a watertight model, the grids must be connected together. This is achieved by bridging the opposite grid edges.

- Model the stand: Even after adding thickness by moving the grids, these few mm can be too little to print reliably. Thin models are prone to falling. To ensure the printing process will be successful, an additional stand is added.

- Imprint the name of the fabric onto the stand (optional): In the scope of the SILKNOW project, there are many samples of historical silk fabrics that involve different designs and techniques. Therefore, having the sample name imprinted on the stand is desirable for learning purposes and to keep the printed samples in order.

- Join the grids to the stand into a watertight mesh using a Boolean union operation: The final step is to create one unified mesh out of the design mesh and the stand. This is achieved with a Boolean union operation. Boolean operations on triangular meshes are especially tricky for all 3D software, and it is not uncommon to create an erroneous Boolean mesh. It is advisable to check the final mesh for errors before printing. The final mesh is shown in Figure 7e,f.

3.3.2. Models Used to Investigate the Weaving Techniques

3.3.3. Slicing and 3D Printing

4. Discussion

4.1. Sustainability in 3D Modelling of Traditional Silk Fabrics: Conservation and Creative Industries

4.2. Sustainability in 3D Printing Production

4.2.1. Using Bioplastics for 3D Printing

4.2.2. Making Filament from Recycled Plastic

4.2.3. 3D Printer Power Consumption

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Portalés, C.; Casas, S.; Alonso-Monasterio, P.; Viñals, M.J. Multi-Dimensional Acquisition, Representation, and Interaction of Cultural Heritage Tangible Assets: An Insight on Tourism Applications. In Handbook of Research on Technological Developments for Cultural Heritage and eTourism Applications; IGI-Global: Hershey, PA, USA, 2018; Volume 95, pp. 72–95. [Google Scholar] [CrossRef]

- Liarokapis, F.; Petridis, P.; Andrews, D.; de Freitas, S. Multimodal Serious Games Technologies for Cultural Heritage. In Mixed Reality and Gamification for Cultural Heritage; Ioannides, M., Magnenat-Thalmann, N., Papagiannakis, G., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 371–392. ISBN 978-3-319-49607-8. [Google Scholar]

- Alivizatou-Barakou, M.; Kitsikidis, A.; Tsalakanidou, F.; Dimitropoulos, K.; Giannis, C.; Nikolopoulos, S.; Al Kork, S.; Denby, B.; Buchman, L.; Adda-Decker, M.; et al. Intangible Cultural Heritage and New Technologies: Challenges and Opportunities for Cultural Preservation and Development. In Mixed Reality and Gamification for Cultural Heritage; Ioannides, M., Magnenat-Thalmann, N., Papagiannakis, G., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 129–158. ISBN 978-3-319-49607-8. [Google Scholar]

- Albert, M.-T.; Bernecker, R.; Rudolff, B. Understanding Heritage: Perspectives in Heritage Studies; Walter de Gruyter: Berlin, Germany, 2013; ISBN 978-3-11-030838-9. [Google Scholar]

- Aicardi, I.; Chiabrando, F.; Maria Lingua, A.; Noardo, F. Recent trends in cultural heritage 3D survey: The photogrammetric computer vision approach. J. Cult. Herit. 2018, 32, 257–266. [Google Scholar] [CrossRef]

- Grussenmeyer, P.; Alby, E.; Assali, P.; Poitevin, V.; Hullo, J.-F.; Smigiel, E. Accurate documentation in cultural heritage by merging TLS and high-resolution photogrammetric data. In Videometrics, Range Imaging, and Applications XI; International Society for Optics and Photonics: Washington, DC, USA, 2011; Volume 8085, p. 808508. [Google Scholar]

- Navarro, S.; Seguí, A.E.; Portalés, C.; Lerma, J.L.; Akasheh, T.; Haddad, N. Integration of tls Data and Non-Metric Imagery to Improve Photo Models and Recording-A Case Study on Djin Block no. 9, Petra (Jordan); IEEE: Piscataway, NJ, USA, 2009; pp. 58–63. [Google Scholar]

- Roman, C.; Inglis, G.; Rutter, J. Application of structured light imaging for high resolution mapping of underwater archaeological sites. In Proceedings of the OCEANS’10 IEEE SYDNEY, Sydney, Australia, 24–27 May 2010; pp. 1–9. [Google Scholar]

- León Muñoz, A.; Roca Cabrera, M. The Moncada Silk Museum, the case of the Garín factory. Datatèxtil 2016, 34, 2–10. [Google Scholar]

- Expinoza, F.; Grüzmacher, M.L. Manual de Conservación Preventiva de Textiles; Comité Nacional de Conservación Textil, Dirección de Bibliotecas, Archivos y Museos, Fundación Andes: Medellín, Colombia, 2002. [Google Scholar]

- Éri, I. Conserving Textiles: Studies in Honour of Ágnes Timár-Balázsy | ICCROM; Conservation Studies Number 7; ICCROM: Rome, Italy, 2009; ISBN 92-9077-218-2. [Google Scholar]

- Wijaya, W.; Ali, M.A.; Umer, R.; Khan, K.A.; Kelly, P.A.; Bickerton, S. An automatic methodology to CT-scans of 2D woven textile fabrics to structured finite element and voxel meshes. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105561. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Darwish, S.S. Effect of Museum Conditions on Historical Dyed Silk Fabric with Madder Dye. J. Polym. Environ. 2012, 20, 596–606. [Google Scholar] [CrossRef]

- Koussoulou, T. Photodegradation and photostabilization of historic silks in the museum environment–evaluation of a new conservation treatment. Pap. Inst. Archaeol. 1999, 10, 75–88. [Google Scholar] [CrossRef]

- Portalés, C.; Sebastián, J.; Alba, E.; Sevilla, J.; Gaitán, M.; Ruiz, P.; Fernández, M. Interactive Tools for the Preservation, Dissemination and Study of Silk Heritage—An Introduction to the SILKNOW Project. Multimodal Technol. Interact. 2018, 2, 28. [Google Scholar] [CrossRef] [Green Version]

- Portalés, C.; Sevilla, J.; Pérez, M.; León, A. A Proposal to Model Ancient Silk Weaving Techniques and Extracting Information from Digital Imagery—Ongoing Results of the SILKNOW Project; Faro: Algarve, Portugal, 2019. [Google Scholar]

- Gaitán, M.; Portalés, C.; Sevilla, J.; Alba, E. Applying Axial Symmetries to Historical Silk Fabrics: SILKNOW’s Virtual Loom. Symmetry 2020, 12, 742. [Google Scholar] [CrossRef]

- Gaitán, M.; Alba, E.; León, A.; Pérez, M.; Sevilla, J.; Portalés, C. Towards the Preservation and Dissemination of Historical Silk Weaving Techniques in the Digital Era. Heritage 2019, 2, 1892–1911. [Google Scholar] [CrossRef] [Green Version]

- Gang, Z.; Bingbing, D.; Wenjuan, Z.; Yali, Y.; Hui, Z. Design and implementation of interactive system for Tujia brocade virtual weaving based on kinect. In Proceedings of the 2017 23rd International Conference on Automation and Computing (ICAC), Huddersfield, UK, 7–8 September 2017; pp. 1–5. [Google Scholar]

- MAGIC FABRIC—A Blog about 3D Fashion. Available online: https://magicfabricblog.com/ (accessed on 3 September 2020).

- Boyce, A.; Doran, K.; Campbell, A.; Pickford, S.; Culler, D.; Barnes, T. BeadLoom Game: Adding competitive, user generated, and social features to increase motivation. In Proceedings of the 6th International Conference on Foundations of Digital Games, Bordeaux, France, 29 June–1 July 2011; Association for Computing Machinery: New York, NY, USA, 2011; pp. 139–146. [Google Scholar]

- Clair, K.S. La Trama del Mondo. I Tessuti che Hanno Fatto la Storia; UTET: Torino, Italy, 2019; ISBN 978-88-511-7430-9. [Google Scholar]

- Orsini, B. Alle origini del tessuto. In Il filo Della Storia; Constantini, M., Silvestri, I., Eds.; CLUEB: Bologna, Italy, 2005. [Google Scholar]

- Ota, Y. L’industria tessile. In Instituto Della Enciclopedia Italiana, Enciclopedia Italiana di Scienze Lettere ed Arti: Il Contributo Italiano alla Storia del Pensiero; RICCI: Roma, Italy, 2013; pp. 615–629. [Google Scholar]

- Donnanno, A. Modabolario. Parole e Immagini Della Moda. Dizionario Tecnico-Creativo, 2nd ed.; Ikon: Milano, Italy, 2018; ISBN 978-88-89628-36-2. [Google Scholar]

- Azzali, M. Dizionario di Costume e Moda. Dal filo all’abito, 2nd ed.; Mancosu Editore: Roma, Italy, 2015; ISBN 978-88-96589-21-2. [Google Scholar]

- Boccherini, T.; Marabelli, P. Atlante di Storia del Tessuto. Itinerario nell’arte Tessile Dall’antichità al Déco. Ediz. Italiana e Inglese; MCM—Maria Cristina de Montemayor: Florence, Italy, 1995; ISBN 978-88-906708-2-4. [Google Scholar]

- Gentile, A. Dizionario Etimologico dell’arte Tessile; Società Editrice Napoletana: Naples, Italy, 1981. [Google Scholar]

- Regensteiner, E. The Art of Weaving; Schiffer Pub.: Atglen, PA, USA, 1986; ISBN 978-0-88740-079-7. [Google Scholar]

- Devoti, D. L’arte del Tessuto in Europa; Bramante: Rome, Italy, 1993; ISBN 978-88-7939-005-7. [Google Scholar]

- Cuoghi Costantini, M. I tessuti del ’700: La seduzione della tecnologia. In La Collezione Gandini del Museo Civico di Modena. I tessuti del XVIII e XIX secolo; Devoti, D., Guandalini, G., Bazzani, E., Cuoghi Costantini, M., Eds.; TESSUTI: Bologna, Italy, 1985; p. 457. [Google Scholar]

- Espolines de Garín. 1820. Available online: http://garin1820.com/ (accessed on 3 September 2020).

- Wu, K.; Yuksel, C. Real-time Fiber-level Cloth Rendering. In Proceedings of the 21st ACM SIGGRAPH Symposium on Interactive 3D Graphics and Games, San Francisco, CA, USA, 25–27 February 2017; ACM: New York, NY, USA, 2017; pp. 5:1–5:8. [Google Scholar]

- Kaldor, J.M.; James, D.L.; Marschner, S. Simulating Knitted Cloth at the Yarn Level. In Proceedings of the ACM SIGGRAPH 2008 Papers; ACM: New York, NY, USA, 2008; pp. 65:1–65:9. [Google Scholar]

- Cirio, G.; Lopez-Moreno, J.; Otaduy, M.A. Efficient Simulation of Knitted Cloth Using Persistent Contacts. In Proceedings of the 14th ACM SIGGRAPH / Eurographics Symposium on Computer Animation; ACM: New York, NY, USA, 2015; pp. 55–61. [Google Scholar]

- Lomov, S.V.; Huysmans, G.; Verpoest, I. Hierarchy of Textile Structures and Architecture of Fabric Geometric Models. Text. Res. J. 2001, 71, 534–543. [Google Scholar] [CrossRef]

- Lomov, S.V. Modelling the Geometry of Textile Composite Reinforcements; WiseTex: Nairobi, Kenya, 2011. [Google Scholar]

- Lomov, S.V. WiseTex Software Suite; CMG: Beijing, China, 2005. [Google Scholar]

- TexGen. Available online: http://texgen.sourceforge.net/index.php/Main_Page (accessed on 23 November 2018).

- Neumüller, M.; Reichinger, A.; Rist, F.; Kern, C. 3D Printing for Cultural Heritage: Preservation, Accessibility, Research and Education. In 3D Research Challenges in Cultural Heritage: A Roadmap in Digital Heritage Preservation; Ioannides, M., Quak, E., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2014; pp. 119–134. ISBN 978-3-662-44630-0. [Google Scholar]

- Jung, T.H.; tom Dieck, M.C. Augmented reality, virtual reality and 3D printing for the co-creation of value for the visitor experience at cultural heritage places. J. Place Manag. Dev. 2017, 10, 140–151. [Google Scholar] [CrossRef]

- Scopigno, R.; Cignoni, P.; Pietroni, N.; Callieri, M.; Dellepiane, M. Digital Fabrication Techniques for Cultural Heritage: A Survey. Comput. Graph. Forum 2017, 36, 6–21. [Google Scholar] [CrossRef]

- Sabantina, L.; Kinzel, F.; Ehrmann, A.; Finsterbusch, K. Combining 3D printed forms with textile structures —Mechanical and geometrical properties of multi-material systems. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012005. [Google Scholar] [CrossRef]

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. IOP Conf. Ser. Mater. Sci. Eng. 2014, 62, 012018. [Google Scholar] [CrossRef] [Green Version]

- Pei, E.; Shen, J.; Watling, J. Direct 3D printing of polymers onto textiles: Experimental studies and applications. Rapid Prototyp. J. 2015, 21, 556–571. [Google Scholar] [CrossRef] [Green Version]

- Rivera, M.L.; Moukperian, M.; Ashbrook, D.; Mankoff, J.; Hudson, S.E. Stretching the Bounds of 3D Printing with Embedded Textiles; ACM: New York, NY, USA, 2017; pp. 497–508. [Google Scholar]

- Janne Kyttanen. Available online: https://www.jannekyttanen.com (accessed on 3 September 2020).

- Iris van Herpen. Available online: http://www.irisvanherpen.com:443/ (accessed on 3 September 2020).

- Noa Raviv. Available online: https://www.noaraviv.com/ (accessed on 3 September 2020).

- Silknow/Virtual-Loom. Available online: https://github.com/silknow/virtual-loom (accessed on 10 August 2020).

- Virtual Loom, Release History. Available online: https://silknow.eu/virtualLoom/ (accessed on 10 August 2020).

- Virtual Loom Tutorial. Available online: https://www.youtube.com/watch?time_continue=5&v=oaZqM3-Wli8&feature=emb_logo (accessed on 10 August 2020).

- ADASilk. Available online: https://ada.silknow.org/en (accessed on 10 August 2020).

- Lisena, P.; Meroño-Peñuela, A.; Kuhn, T.; Troncy, R. Easy Web API Development with SPARQL Transformer; Springer: Auckland, New Zealand, 2019. [Google Scholar]

- Palagi, E.; Gandon, F.; Troncy, R.; Giboin, A. A Survey of Definitions and Models of Exploratory Search; Springer International Publishing: Cham, Switzerland, 2017; p. 3. [Google Scholar]

- Mladenić, D.; Gaitán, M.; Troncy, R. SILKNOW–Multilingual Text Analysis for Silk Heritage. In Proceedings of the 25th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining (KDD ’19), Anchorage, AK, USA, 4–8 August 2019; Association for Computing Machinery: New York, NY, USA, 2019; pp. 1–2. [Google Scholar]

- Šajn, N. Environmental Impact of the Textile and Clothing Industry: What Consumers Need to Know; European Parliament: Strasbourg, France, 2019. [Google Scholar]

- King, L.; Stark, J.F.; Cooke, P. Experiencing the Digital World: The Cultural Value of Digital Engagement with Heritage. Herit. Soc. 2016, 9, 76–101. [Google Scholar] [CrossRef] [Green Version]

- Hogsden, C.; Poulter, E.K. The real other? Museum objects in digital contact networks. J. Mater. Cult. 2012. [Google Scholar] [CrossRef]

- Four-Leaf Folding Screen (Paravent) | French | The Met. Available online: https://www.metmuseum.org/art/collection/search/205091 (accessed on 16 August 2020).

- van der Hoeven, D. PHA: Promising, Versatile, Biodegradable. Available online: https://www.biobasedpress.eu/2016/08/pha-promising-versatile-biodegradable/ (accessed on 9 August 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez, M.; Casanova-Salas, P.; Twardo, P.; Twardo, P.; León, A.; Mladenic, D.; Massri, B.M.; Troncy, R.; Ehrhart, T.; Cicero, G.L.; et al. From Historical Silk Fabrics to Their Interactive Virtual Representation and 3D Printing. Sustainability 2020, 12, 7539. https://doi.org/10.3390/su12187539

Pérez M, Casanova-Salas P, Twardo P, Twardo P, León A, Mladenic D, Massri BM, Troncy R, Ehrhart T, Cicero GL, et al. From Historical Silk Fabrics to Their Interactive Virtual Representation and 3D Printing. Sustainability. 2020; 12(18):7539. https://doi.org/10.3390/su12187539

Chicago/Turabian StylePérez, Manolo, Pablo Casanova-Salas, Pawel Twardo, Piotr Twardo, Arabella León, Dunja Mladenic, Besher M. Massri, Raphaël Troncy, Thibault Ehrhart, Georgia Lo Cicero, and et al. 2020. "From Historical Silk Fabrics to Their Interactive Virtual Representation and 3D Printing" Sustainability 12, no. 18: 7539. https://doi.org/10.3390/su12187539

.jpg)