Is Price an Indicator of Garment Durability and Longevity?

Abstract

1. Introduction

2. Materials and Methods

2.1. Pre-Wash Assessment and Durability to Laundering

2.2. Perception Experiment

3. Results

3.1. Pre-Purchase Indicators of Quality

3.2. Durability to Laundering

3.2.1. Dimensional Stability

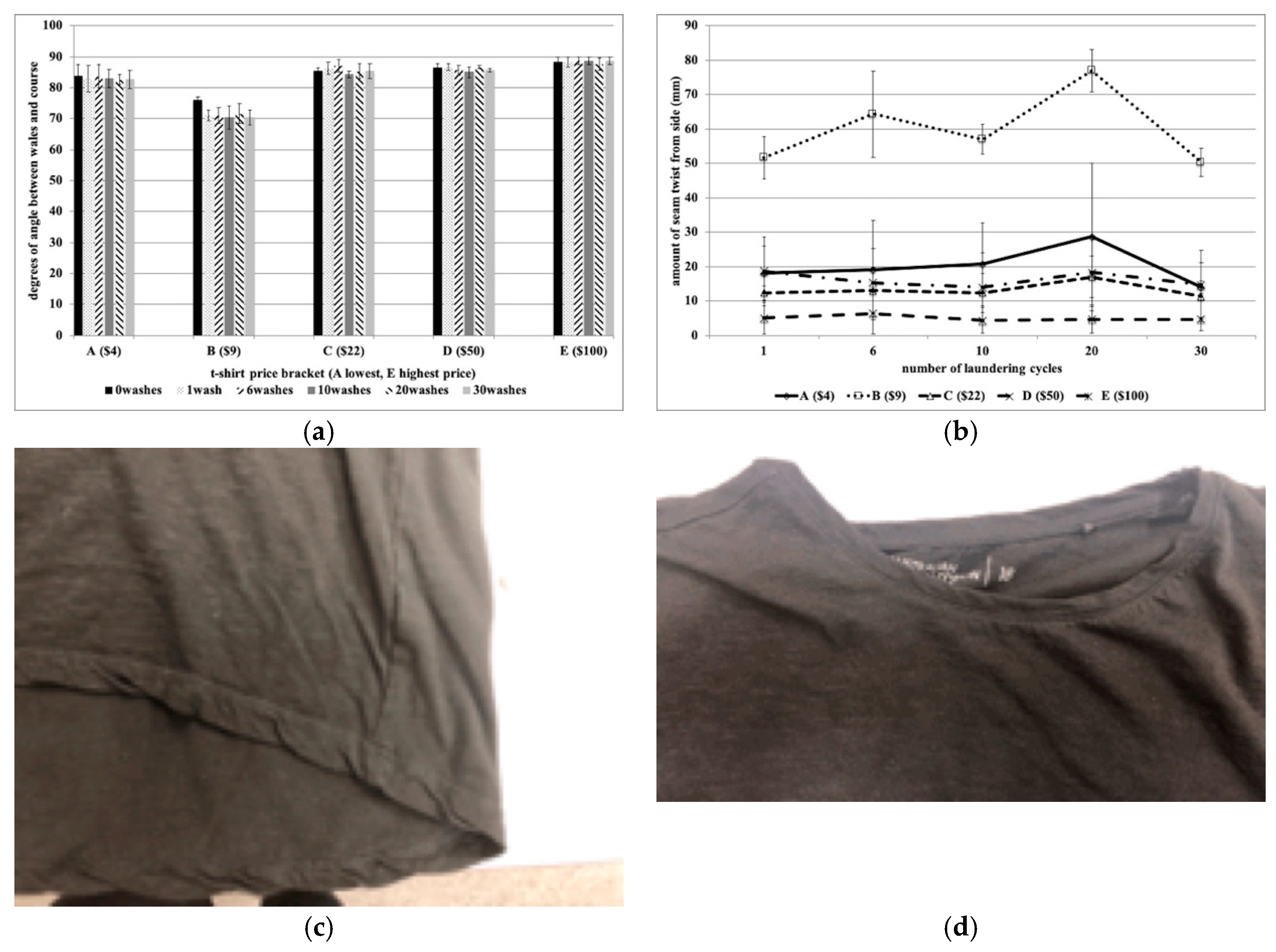

3.2.2. Spirality

3.2.3. Seam Twist

3.2.4. Seam Appearance and Integrity

3.2.5. Colour Difference

3.3. Survey Findings

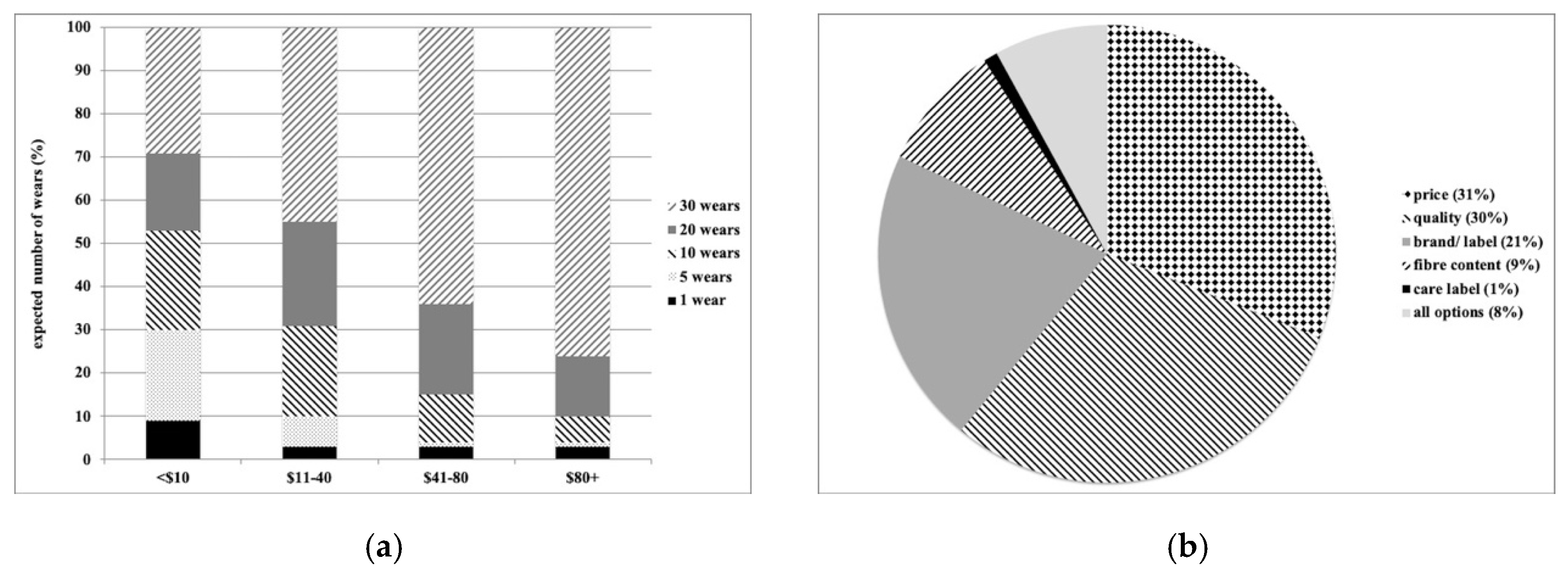

3.3.1. Purchase Price and Wear

3.3.2. Wear and Laundering

4. Discussion

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Joy, A.; Sherry, J.F., Jr.; Venkatesh, A.; Wang, J.; Chan, R. Fast fashion, sustainability, and the ethical appeal of luxury brands. Fash. Theory 2012, 16, 273–295. [Google Scholar] [CrossRef]

- Barnes, L.; Lea-Greenwood, G. Fast fashioning the supply chain: Shaping the research agenda. J. Fash. Mark. Manag. Int. J. 2006, 10, 259–271. [Google Scholar] [CrossRef]

- Niinimäki, K.; Hassi, L. Emerging design strategies in sustainable production and consumption of textiles and clothing. J. Clean. Prod. 2011, 19, 1876–1883. [Google Scholar] [CrossRef]

- Gabrielli, V.; Baghi, I.; Codeluppi, V. Consumption Practices of Fast Fashion Products: A Consumer-Based Approach. J. Fash. Mark. Manag. Int. J. 2013, 17, 206–224. [Google Scholar] [CrossRef]

- Morgan, L.R.; Birtwistle, G. An investigation of young fashion consumers’ disposal habits. Int. J. Consum. Stud. 2009, 33, 190–198. [Google Scholar] [CrossRef]

- Sahni, H.; Khan, B.M.; Barad, K. Constructing Customer Experience for Augmenting Apparel Products’ Attachment and Longevity. In Proceedings of the PLATE Conference, Nottingham, UK, 17–19 June 2015; Nottingham Trent University: Nottingham, UK, 2015; pp. 334–341. [Google Scholar]

- Watson, Z.M.; Yan, R. An Exploratory Study of the Decision Processes of Fast Fashion vs Slow Fashion Consumers. J. Fash. Mark. Manag. Int. J. 2013, 17, 141–159. [Google Scholar]

- Badgett, J.O. An Evaluation of the Quality of Mens 100% Cotton Jersey Knit T-Shirts Representing Three Retail Categories. Master’s Thesis, Univeristy of Kentucky, Lexington, KY, USA, 2017. [Google Scholar]

- Cooper, T.; Hughes, M.; Claxton, S. From rag trade to retail: Garment failure and the potential for sustainable fashion. In Proceedings of the PLATE Conference, Nottingham, UK, 17–19 June 2015; Nottingham Trent University: Nottingham, UK, 2015; pp. 73–80. [Google Scholar]

- Fowler, D.; Clodfelter, R. A Comparison of apparel quality: Outlet stores versus department stores. J. Fash. Mark. Manag. Int. J. 2001, 5, 57–66. [Google Scholar] [CrossRef]

- Bide, M. Testing textile durability. In Understanding and Improving the Durability of Textiles; Annis, P., Ed.; Woodhead: Cambridge, UK, 2012; pp. 126–142. [Google Scholar]

- Collett, M.; Cluver, B.; Chen, H.-L. Consumer perceptions of the limited lifespan of fast fashion apparel. Res. J. Text. Appar. 2013, 17, 61–68. [Google Scholar] [CrossRef]

- Keiser, J.S.; Garner, M.B. Beyond Design: The Synergy of Apparel Production Development, 3rd ed.; Bloomsbury Publishing Inc.: New York, NY, USA, 2012. [Google Scholar]

- Monitor, Cotton Incorporated Lifestyle. Price, Quality and Style: Consumers Seek Shopping Symmetry. Available online: https://lifestylemonitor.cottoninc.com/price-quality-and-style/ (accessed on 25 August 2019).

- Yuille, P. Exploring the Relationship between the Presumed Quality and Durability of Fast-Fashion Garments by the Generation-Y Consumer. In Proceedings of the PLATE Conference, Nottingham, UK, 17–19 June 2015; Nottingham Trent University: Nottingham, UK, 2015; pp. 415–421. [Google Scholar]

- Cooper, T. The Significance of Product Longevity. In Longer Lasting Products: Alternatives to the Throw Away Society; Cooper, T., Ed.; Farnham: Gower, UK, 2010; pp. 3–38. [Google Scholar]

- Oxborrow, L.; Claxton, S.; Cooper, T.; Hill, H. Product Development and Supply: Help or Hinderance to Clothing Longevity? In Proceedings of the PLATE Conference, Nottingham, UK, 17–19 June 2015; Nottingham Trent University: Nottingham, UK, 2015; pp. 264–269. [Google Scholar]

- Gwozdz, W.; Neilsen, K.S.; Muller, T. An environmental persepctive on clothing consumption: Consumer segments and their behavioural patterns. Sustainability 2017, 9, 762. [Google Scholar] [CrossRef]

- De Klerk, H.M.; Lubbe, S. Female consumers’ evaluation of apparel quality: Exploring the importance of aesthetics. J. Fash. Mark. Manag. Int. J. 2008, 12, 36–50. [Google Scholar] [CrossRef]

- Agins, T. The End of Fashion: How Marketing Changed the Clothing Business Forever; Harper Collins Publishers Inc.: New York, NY, USA, 2000. [Google Scholar]

- Farashahi, B.G.; Easter, E.; Annett-Hitchcock, K. Price and perceived product quality: A comparison of denim jeans in three price categories. J. Fash. Mark. Manag. Int. J. 2018, 22, 369–386. [Google Scholar] [CrossRef]

- Stamper, A.A.; Sharp, S.H.; Donnell, L.B. Evaluating Apparel Quality; Fairchild Fashion Group: New York, NY, USA, 1991. [Google Scholar]

- Gracey, F.; Moon, D. Valuing our Clothes: The Evidence Base; WRAP: Banbury, UK, 2012. [Google Scholar]

- Cooper, T.; Claxton, S.; Hill, H.; Holbrook, K.; Hughes, M.; Knox, A.; Oxborrow, L. Clothing Longevity Protocol; WRAP: Banbury, UK, 2014. [Google Scholar]

- Roos, S.; Gustav, S.; Zamani, B.; Peters, G. Environmental Assessment of Swedish Fashion Consumption. Five Garments—Sustainable Futures; Mistra Future Fashion Consortium, Ed.; Mistra Future Fashion: Stockholm, Sweden, 2015. [Google Scholar]

- Firth, L. Every Time you Shop, Always Think. In Will I Wear This a Minimum of 30 Times? The Telegraph: London, UK, 2016. [Google Scholar]

- Fletcher, K. Durability, Fashion, Sustainability: The processes and practices of use. Fash. Pract. 2012, 4, 221–238. [Google Scholar] [CrossRef]

- Degenstein, L.; McQueen, R.H.; McNeill, L.S.; Hamlin, R.P.; Wakes, S.J.; Dunn, L.A. Impact of Physical Condition on Disposal Nad End-of-Life Extension of Clothing. Int. J. Consum. Stud. 2020, 11. [Google Scholar] [CrossRef]

- Taylor, M.A. Technology of Textile Properties, 3rd ed.; Forbes Publication: Hampshire, UK, 1990. [Google Scholar]

- Lakshmi, V.; Niharika, D.; Lahari, G. Impact of gender on consumer purchasing behavior. J. Bus. Manag. 2017, 19, 33–36. [Google Scholar]

- Mhlanga, O.; Machingambi, S. The Influence of demographic variables on customers’ expectations in restaurants in the Eastern Cape Province of South Africa. Afr. J. Hosp. Tour. Leis. 2016, 5, 1–21. [Google Scholar]

- International Organization for Standardization. Standard Atmospheres for Conditioning and Testing; ISO 139: 2005 Textiles; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

- International Organization for Standardization. Textiles—Determination of Thickness of Textiles and Textile Products; ISO 5084: 1996; International Organization for Standardization: Geneva, Switzerland, 1996. [Google Scholar]

- International Organization for Standardization. Textiles—Woven Fabrics—Construction—Methods of Analysis Part 2; Determination of threads per unit length; ISO 7211-2: 1994; International Organization for Standardization: Geneva, Switzerland, 1994. [Google Scholar]

- International Organization for Standardization. Textiles—Preparation, Marking and Measuring of Fabric Specimens and Garments in Tests for Determination of Dimensional Change; ISO 3759: 2011; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- International Organization for Standardization. Textiles—Domestic Washing and Drying Procedures for Textile Testing; ISO 6330: 2012; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- McQueen, R.H.; Batcheller, J.C.; Moran, L.J.; Zhang, H.; Hooper, P.M. Reducing laundering frequency to prolong the life of denim jeans. Int. J. Consum. Stud. 2017, 41, 36–45. [Google Scholar] [CrossRef]

- Miilunpalo, S.-M.; Räisänen, R. Clean Laundry for Pure Conscience—A Study of Laundry Practices among Finnish Consumers. Int. J. Consum. Stud 2019, 43, 153–165. [Google Scholar] [CrossRef]

- Claxton, S.; Cooper, T.; Hill, H.; Holbrook, K. Opportunities and Challenges of New Product Development and Testing for Logevity in Clothing. In Proceedings of the PLATE Conference, Nottingham, UK, 17–19 June 2015; Nottingham Trent University: Nottingham, UK, 2015; pp. 62–68. [Google Scholar]

- R Core Team. A Langauge and Environment for Statistical Computing. R Foundation for Statistical Computing. Available online: https://www.R-projects.org (accessed on 31 January 2019).

- Pinheiro, J.; Bates, D.; DebRoy, S.; Sarkar, D.; R Core Team. Nlme: Linear and Nonlinear Mixed Effects Models. R Package Version 3.1-137. Available online: https://CRAN.R-project.org/package=nlme> (accessed on 20 June 2019).

- Qualtrics. Qualtric Xm Online Survey Software. Available online: https://www.qualtrics.com/au (accessed on 20 June 2019).

- Browne, K. Snowball sampling: Using social networks to research non-heterosexual women. Int. J. Soc. Res. Methodol. 2005, 8, 47–60. [Google Scholar] [CrossRef]

- Kadolph, S.J. Textiles, 11th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2011. [Google Scholar]

- Mikuž, M.; Turk, S.S.; Tavčer, P.F. Properties of Ink-Jet printed, ultraviolet cured pigment prints in comparison with screen-printed, thermo-cured pigment prints. Coloration Technol. 2010, 126, 249–255. [Google Scholar] [CrossRef]

- Van Der Merwe, D.; Bosman, M.; Ellis, S.; Van Der Colff, N.; Warnock, M. Consumers’ knowledge of textile label information: An exploratory investigation. Int. J. Consum. Stud. 2014, 38, 18–24. [Google Scholar] [CrossRef]

- Gwozdz, W.; Netter, S.; Bjartmarz, T.; Reisch, L. Survey Results on Fashion Consumption and Sustainabiltiy of Young Swedes; Report Mistra Future Fashion, Ed.; Copenhagen Business School: Copenhagen, Denmark, 2013. [Google Scholar]

- McLaren, A.; Oxborrow, L.; Cooper, T.; Goworek, H. Clothing Longevity Perspectives: Exploring Consumer Expectations, Consumption and Use. In Proceedings of the PLATE Conference, Nottingham, UK, 17–19 June 2015; Nottingham Trent University: Nottingham, UK, 2015; pp. 229–235. [Google Scholar]

- Anon. Consumers Don’t Read Care Labels; AATCC Review: Research Triangle Park, NC, USA, 2009; p. 20. [Google Scholar]

- Gwilt, A.; Pal, R. Conditional garment design for longevity. In Proceedings of the Product Lifetimes and the Environment, PLATE Conference, Delft, The Netherlands, 8–10 November 2017; p. 149. [Google Scholar]

| Sett | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mass/Area (g/m2) | sd | Thickness (mm) | sd | Spirality (Angle in Degrees) | sd | Courses (/cm) | sd | Wales (/cm) | sd | |

| A ($4) | 163.32 | 7.23 | 0.72 | 0.03 | 84 | 4 | 35 | 1.2 | 46 | 0.6 |

| B ($9) | 138.76 | 1.56 | 0.73 | 0.02 | 76 | 1 | 34 | 1 | 46 | 0.6 |

| C ($22) | 210.61 | 2.48 | 0.68 | 0.02 | 85 | 1 | 36 | 1 | 50 | 0.6 |

| D ($50) | 218.86 | 0.54 | 0.8 | 0.02 | 86 | 2 | 35 | 0.6 | 50 | 0.6 |

| E ($100) | 227.32 | 2.40 | 0.74 | 0.01 | 88 | 2 | 35 | 0.6 | 54 | 0.6 |

| Lengthwise % Change | Width-Wise % Change | Seam Twist (mm) | Spirality % Change | Colour Change ΔE | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Less Than +2% or −6% | Less Than +2% or −6% | Less Than 3% | ΔE* Less Than 1 | ||||||||||

| Mean | s.d. | Mean | s.d. | Mean | s.d. | Mean | s.d. | Mean | s.d. | ||||

| A ($4) | number of laundry cycles | 1 | −2.38 | 1.61 | −4.22 | 2.76 | 18 | 8 | 0.82 | 0.71 | 0.40 | 0.1 | 5 |

| 6 | −2.81 | 1.71 | −5.32 | 2.96 | 19 | 14 | 0.00 | 0.00 | 0.60 | 0.0 | 7 | ||

| 10 | 3.35 | 2.12 | −6.33 | 2.29 | 21 | 12 | 0.76 | 1.79 | 0.45 | 0.0 | 5 | ||

| 20 | −4.00 | 1.57 | −6.72 | 2.58 | 29 | 22 | 1.08 | 4.17 | 0.41 | 0.1 | 3 | ||

| 30 | −3.89 | 1.72 | −5.34 | 2.09 | 14 | 2 | 1.16 | 1.14 | 1.08 | 0.0 | 9 | ||

| B ($9) | number of laundry cycles | 1 | −5.59 | 1.74 | −2.02 | 0.20 | 52 | 6 | 6.57 | 2.61 | 0.22 | 0.0 | 9 |

| 6 | −7.50 | 2.82 | −1.80 | 1.99 | 64 | 13 | 6.56 | 3.93 | 0.43 | 0.1 | 3 | ||

| 10 | −8.53 | 2.85 | −3.33 | 0.98 | 57 | 4 | 7.45 | 4.98 | 0.57 | 0.0 | 2 | ||

| 20 | −7.85 | 3.44 | −2.54 | 1.24 | 77 | 6 | 5.70 | 4.23 | 0.62 | 0.0 | 7 | ||

| 30 | −8.59 | 2.69 | −1.12 | 1.69 | 50 | 4 | 7.43 | 4.19 | 1.01 | 0.0 | 7 | ||

| C ($22) | number of laundry cycles | 1 | −3.61 | 0.54 | −0.75 | 0.20 | 12 | 2 | 1.16 | 1.16 | 0.40 | 0.0 | 6 |

| 6 | −4.72 | 0.34 | −1.22 | 0.3 | 13 | 7 | 1.95 | 1.33 | 0.85 | 0.1 | 1 | ||

| 10 | −4.72 | 0.63 | −2.15 | 0.77 | 12 | 6 | 1.95 | 1.33 | 0.70 | 0.2 | 4 | ||

| 20 | −4.48 | 1.10 | −2.20 | 0.43 | 17 | 6 | 2.33 | 1.15 | 0.66 | 0.1 | 8 | ||

| 30 | −5.24 | 0.95 | −0.98 | 1.28 | 11 | 10 | 2.33 | 1.15 | 0.95 | 0.1 | 2 | ||

| D ($50) | number of laundry cycles | 1 | −0.55 | 0.55 | −2.23 | 1.48 | 19 | 11 | 1.93 | 1.79 | 0.33 | 0.1 | 2 |

| 6 | −1.10 | 0.48 | −2.99 | 0.42 | 15 | 8 | 2.32 | 0.04 | 0.58 | 0.0 | 7 | ||

| 10 | −1.09 | 0.31 | −4.38 | 1.52 | 14 | 2 | 2.31 | 1.16 | 0.68 | 0.1 | 5 | ||

| 20 | −1.28 | 0.79 | −3.42 | 1.34 | 18 | 7 | 1.16 | 1.18 | 0.40 | 0.0 | 6 | ||

| 30 | −2.07 | 0.29 | −4.06 | 2.22 | 15 | 2 | 1.54 | 0.64 | 0.94 | 0.1 | 0 | ||

| E ($100) | number of laundry cycles | 1 | −1.28 | 0.78 | −2.73 | 1.21 | 5 | 5 | 0.00 | 0.00 | 0.40 | 0.1 | 6 |

| 6 | −1.86 | 0.95 | −3.23 | 1.58 | 6 | 6 | 0.38 | 0.66 | 0.75 | 0.1 | 1 | ||

| 10 | −1.69 | 0.87 | −3.94 | 0.53 | 4 | 4 | 0.38 | 0.66 | 0.98 | 0.0 | 3 | ||

| 20 | −1.63 | 0.89 | −3.87 | 0.88 | 5 | 4 | 0.76 | 1.31 | 0.63 | 0.0 | 6 | ||

| 30 | −1.80 | 0.89 | −2.41 | 0.55 | 5 | 1 | 0.38 | 0.66 | 1.25 | 0.2 | 7 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wakes, S.; Dunn, L.; Penty, D.; Kitson, K.; Jowett, T. Is Price an Indicator of Garment Durability and Longevity? Sustainability 2020, 12, 8906. https://doi.org/10.3390/su12218906

Wakes S, Dunn L, Penty D, Kitson K, Jowett T. Is Price an Indicator of Garment Durability and Longevity? Sustainability. 2020; 12(21):8906. https://doi.org/10.3390/su12218906

Chicago/Turabian StyleWakes, Sarah, Linda Dunn, Dahna Penty, Kayla Kitson, and Tim Jowett. 2020. "Is Price an Indicator of Garment Durability and Longevity?" Sustainability 12, no. 21: 8906. https://doi.org/10.3390/su12218906

APA StyleWakes, S., Dunn, L., Penty, D., Kitson, K., & Jowett, T. (2020). Is Price an Indicator of Garment Durability and Longevity? Sustainability, 12(21), 8906. https://doi.org/10.3390/su12218906