Coal-Biomass Co-Firing Power Generation Technology: Current Status, Challenges and Policy Implications

Abstract

:1. Introduction

2. Current Status of Coal-Biomass Co-Firing Power Generation Technology

2.1. Policy Combing

2.2. Characteristics of Coal-Biomass Co-Firing Power Generation Technology

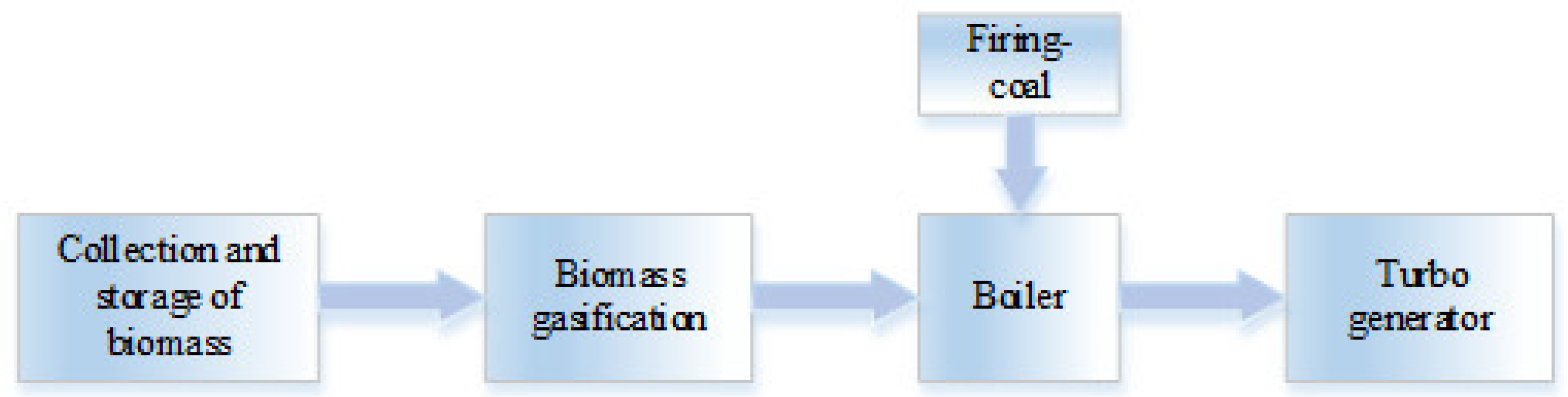

2.3. Types of Coal-Biomass Co-Firing Power Generation Technology

3. Economic Analysis

3.1. Model of LCOE

3.2. Parameters

3.3. Results

3.4. Sensitivity Analysis

4. Challenges of Coal-Biomass Co-Firing Power Generation Technology

5. Policy Implications

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Madanayake, B.N.; Gan, S.; Eastwick, C.; Ng, H.K. Biomass as an energy source in coal co-firing and its feasibility enhancement via pre-treatment techniques. Fuel Process. Technol. 2017, 159, 287–305. [Google Scholar] [CrossRef]

- Purohit, P.; Chaturvedi, V. Biomass pellets for power generation in India: A techno-economic evaluation. Environ. Sci. Pollut. Res. 2018, 25, 29614–29632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, J.P.; Huang, Q.; Lv, C.G.; Feng, Q.; Wang, F.J. Carbon emissions reductions oriented dynamic equilibrium strategy using biomass-coal co-firing. Energy Policy 2018, 123, 184–197. [Google Scholar] [CrossRef]

- Roni, M.S.; Chowdhury, S.; Mamun, S.; Marufuzzaman, M.; Lein, W.; Johnson, S. Biomass co-firing technology with policies, challenges, and opportunities: A global review. Renew. Sustain. Energy Rev. 2017, 78, 1089–1101. [Google Scholar] [CrossRef]

- Cutz, L.; Berndes, G.; Johnsson, F. A techno-economic assessment of biomass co-firing in Czech Republic, France, Germany and Polan. Biofuels Bioprod. Biorefining 2019, 13, 1289–1305. [Google Scholar] [CrossRef]

- Beagle, E.; Belmont, E. Comparative life cycle assessment of biomass utilization for electricity generation in the European Union and the United States. Energy Policy 2019, 128, 267–275. [Google Scholar] [CrossRef]

- Kommalapati, R.R.; Hossan, I.; Botlaguduru, V.S.V.; Du, H.B.; Huque, Z. Life Cycle Environmental Impact of Biomass Co-Firing with Coal at a Power Plant in the Greater Houston Area. Sustainability 2018, 10, 2193. [Google Scholar] [CrossRef] [Green Version]

- Ali, U.; Akram, M.; Font-Palma, C.; Ingham, D.B.; Pourkashanian, M. Part-load performance of direct-firing and co-firing of coal and biomass in a power generation system integrated with a CO2 capture and compression system. Fuel 2017, 210, 873–884. [Google Scholar] [CrossRef]

- Hansen, K. Decision-making based on energy costs: Comparing levelized cost of energy and energy system costs. Energy Strategy Rev. 2019, 24, 68–82. [Google Scholar] [CrossRef]

- Giostri, A.; Binotti, M.; Macchi, E. Microalgae cofiring in coal power plants: Innovative system layout and energy analysis. Renew. Energy 2016, 95, 449–464. [Google Scholar] [CrossRef]

- Agbor, E.; Oyedun, A.O.; Zhang, X.; Kumar, A. Integrated techno-economic and environmental assessments of sixty scenarios for co-firing biomass with coal and natural gas. Appl. Energy 2016, 169, 433–449. [Google Scholar] [CrossRef]

- Dassanayake, G.D.M.; Kumar, A. Techno-economic assessment of triticale straw for power generation. Appl. Energy 2012, 98, 236–245. [Google Scholar] [CrossRef]

- Sun, Y. Techno-economic Analysis of Biomass Co-firing in Coal-fired Boiler. Master’s Thesis, Huazhong University of Science & Technology, Wuhan, China, May 2018. [Google Scholar]

- Gao, J.K.; Tong, Y.; Wang, S.C.; Sun, Y.; An, Y.D.; Yang, T.H. The current situation and future development tendency of biomass-coal coupling power generation system. Renew. Energy 2019, 37, 501–506. [Google Scholar]

- Mao, J.X. Co-firing biomass with coal for power generation. Distrib. Energy 2017, 2, 47–54. [Google Scholar]

- Chen, F. Research on Combustion Characteristics and Economic Analysis of Bagasse and Coal Combustion Power Generation. Master’s Thesis, Guangxi University, Nanning, China, June 2018. [Google Scholar]

- Kułazynski, M.; Jabłonski, S.; Kaczmarczyk, J.; Swia˛tek, L.; Pstrowska, K.; Łukaszewicz, M. Technological aspects of sunflower biomass and brown coal co-firing. J. Energy Inst. 2017, 91, 668–675. [Google Scholar] [CrossRef]

- Yu, B. Benefit and risk analysis of coal-fired biomass gasification coupled power generation project. Plant Maint. Eng. 2018, 20, 53–54. [Google Scholar]

- Lu, X.; Cao, L.; Wang, H.K.; Peng, W.; Xing, J.; Wang, S.X.; Cai, S.Y.; Shen, B.; Yang, Q.; Nielsen, C.P.; et al. Gasification of coal and biomass as a net carbon-negative power source for environment-friendly electricity generation in China. Proc. Natl. Acad. Sci. USA 2019, 116, 8206. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.T.; Li, K.Y.; Zhang, C.; Wang, A.J. Performance analysis of biomass gasification coupled with a coal-fired boiler system at various loads. Waste Manag. 2020, 105, 84–91. [Google Scholar] [CrossRef]

- Chen, H.R. Foresee 2019: Panoramic Map of China’s Biomass Energy Industry in 2019 (with Market Scale, Competition Pattern and Development Prospect). 2019. Available online: https://www.qianzhan.com/analyst/detail/220/190610-a91842e0.html (accessed on 11 March 2020).

- NEA. Li Chuangjun, Deputy Director General, Introduced the Development of Renewable Energy in the First Three Quarters. 2019. Available online: http://www.nea.gov.cn/2019-10/29/c_138511525.htm (accessed on 11 March 2020).

- Zhang, Q.P. Application Analysis of Biomass and Coal-Fired Coupled Co-Combustion Power Generation Technology. 2018. Available online: http://www.china-nengyuan.com/tech/125253.html (accessed on 11 March 2020).

- Smith, J.S.; Safferman, S.I.; Saffron, C.M. Development and application of a decision support tool for biomass co-firing in existing coal-fired power plants. J. Clean Prod. 2019, 236, 117375. [Google Scholar] [CrossRef]

- Yi, Q.; Zhao, Y.J.; Huang, Y.; Wei, G.Q.; Hao, Y.H.; Feng, J.; Mohamed, U.; Pourkashanian, M.; Nimmo, W.; Li, W.Y. Life cycle energy-economic-CO2 emissions evaluation of biomass/coal, with and without CO2 capture and storage, in a pulverized fuel combustion power plant in the United Kingdom. Appl. Energy 2018, 225, 258–272. [Google Scholar] [CrossRef]

- Jiang, T.J. Coal-Biomass Co-Firing Power Generation- Application of Thermal Fuel Flexibility in China. 2017. Available online: http://news.bjx.com.cn/html/20180312/884758.shtml (accessed on 11 March 2020).

- Zhang, P.; Coal-Biomass Co-Firing Power Generation Ushers in Development Opportunities. China Science Daily 2018-02-01(006). Available online: http://news.sciencenet.cn/htmlnews/2018/2/401888.shtm (accessed on 12 March 2020).

- Jiang, S.H.; Coal-Biomass Co-Firing Power Generation Needs to be Supported by the Grid Price Policy. China Energy News 2018-07-30(017). Available online: http://paper.people.com.cn/zgnyb/html/2018-07/30/content_1871654.htm (accessed on 12 March 2020).

- NEA; MEP. The Notice on Carrying out Technical Transformation Pilot Work of Coal-biomass Co-firing Power Generation. 2017. Available online: http://zfxxgk.nea.gov.cn/auto84/201712/t20171204_3065.htm (accessed on 11 March 2020).

- NDRC. The 13th Five-Year Plan for Power Development. 2017. Available online: https://www.ndrc.gov.cn/fggz/fzzlgh/gjjzxgh/201706/t20170605_1196777.html (accessed on 11 March 2020).

- NDRC. The 13th Five-Year Plan for Energy Technology Innovation. 2017. Available online: https://www.ndrc.gov.cn/fggz/fzzlgh/gjjzxgh/201708/t20170809_1196881.html (accessed on 11 March 2020).

- NEA; MEE. Notice on Construction of Pilot Projects for Technical Transformation of Coal-biomass Co-firing Power Generation. 2018. Available online: http://zwgk.gd.gov.cn/006939756/201808/t20180814_777502.html (accessed on 11 March 2020).

- NDRC. Guide Catalogue for Industrial Structure Adjustment 2019. 2019. Available online: https://www.ndrc.gov.cn/xxgk/zcfb/fzggwl/201911/t20191105_1198077.html (accessed on 11 March 2020).

- Ge, S.Y. Feasibility Analysis of Biomass Electricity Generation Technology. Master’s Thesis, North China Electric Power University, Beijing, China, February 2009. [Google Scholar]

- Solid waste web of Polaris. Construction and Operation of Biomass Power Generation in 2019. 2020. Available online: http://huanbao.bjx.com.cn/news/20200311/1053022.shtml (accessed on 6 April 2020).

- Shi, Y.C. Overview of biomass energy development in China. Smart Power 2017, 45, 1–5. [Google Scholar]

- Fan, Y.; Long, W.D. Development status of biomass combined heat and power generation. Build Sci. 2009, 25, 1–6. [Google Scholar]

- Wang, Y.K.; Zhang, G.C.; Wang, X.X.; Deng, L.; Zhou, L.Y. Analysis of flexibility improvement of coal-fired power plant by biomass gasification coupled power generation. Therm. Power Gener. 2018, 47, 77–82. [Google Scholar]

- Jing, X.J.; Chen, Y.; Zhang, H.L.; Liu, S.G.; Yang, L. Biomass coupled power generation technology and power generation calculation methods. Therm. Power Gener. 2019, 48, 31–37. [Google Scholar]

- Li, D.K. Investigation of Biomass Co-fire in Finland and United Kingdom. Electr. Power Technol. 2010, 19, 2–8. [Google Scholar]

- Yuan, Z.H. A glimpse of biomass power generation technology in Europe. Renew. Energy 2004, 4, 65. [Google Scholar]

- Ji, J.R.; Wang, Y.J. Review of the Research Progress of Biomass Power Generation Technology Foreign Countries. Shanxi Sci. Technol. 2014, 29, 59–61. [Google Scholar]

- Ma, W.; Sheng, C.D. Application status of indirect biomass co-firing power generation technologies based on circulating fluidized bed gasification. Therm. Power Gener. 2019, 48, 1–7. [Google Scholar]

- Cory, K.; Schwabe, P. Wind Levelized Cost of Energy: A Comparison of Technical and Financing Input Variables; Technical Report: NREL/TP-6A2-46671; Alliance for Sustainable Energy, LLC: Golden, CO, USA, 2009. [Google Scholar]

- NREL. Simple Levelized Cost of Energy (LCOE) Calculator Documentation. 2010. Available online: http://www.nrel.gov/analysis/lcoe_documentation.html (accessed on 12 March 2020).

- Branker, K.; Pathak, M.J.M.; Pearce, J.M. A review of solar photovoltaic levelized cost of electricity. Renew. Sustain. Energ. Rev. 2011, 15, 4470–4482. [Google Scholar] [CrossRef] [Green Version]

- Levitt, A.C.; Kempton, W.; Smith, A.P.; Musial, W.; Firestone, J. Pricing offshore wind power. Energy Policy 2011, 39, 6408–6421. [Google Scholar] [CrossRef]

- E3: Energy+ Environmental Economics. Generation Cost Model for China. 2012. Available online: https://ethree.com/public_projects/generation_cost_model_for_china.php (accessed on 12 March 2020).

- Lin, L.; Zhang, B. Analysis and Diagnosis of High Coal Consumption of No.1 and No.2 Units of Hebei Jiantou Xuanhua Thermal Power Co., Ltd.; Xi’an Thermal Power Research Institute Co.: Xi’an, China, 2017; pp. 97–123. [Google Scholar]

- Jiang, H.; Xu, F.Y.; Bai, X.K.; Chang, D.F.; Li, X.; Wang, H.; Huang, J.S.; Li, Y.; Zhou, Y.X.; Xie, T.; et al. Flow algorithm for β ratio throat-tap nozzle which can control the system configuration easily. Therm. Power Gener. 2013, 42, 123–126. [Google Scholar]

- Yang, L.; Jiang, H.; Jing, X.J.; Zeng, L.F. Steady state detection method and application based on uncertainty theory. Therm. Power Gener. 2019, 48, 139–144. [Google Scholar]

- CREEI (China Renewable Energy Engineering Institute). Wind Farm Project Construction Standards; China Renewable Energy Engineering Institute: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Tan, Q.L.; Yang, H.P.; Zhang, X.P.; Deng, Y.M.; Wei, Y.M. Measurement Model and Empirical Analysis of Fuel Collection Cost for Biomass Power Generation. Forum Sci. Technol. China 2014, 5, 117–123. [Google Scholar]

- Xi, J.H. The dilemma of coal-fired coupled biomass. Energy 2018, 38–40. [Google Scholar]

- Gao, J.W.; Zhang, H.B.; Zong, X.Y. Optimization of straw purchase scheme and cost estimation on biomass power generation. Renew. Energy Resour. 2017, 35, 141–147. [Google Scholar]

- Chen, H.P.; Lu, G.W.; Yu, X.W.; Bin, Y.Y. Economic analysis of co-combustion biomass in a coal-fired boiler. Therm. Power Gener. 2013, 12, 40–44. [Google Scholar]

- Feng, Y.M. Problems and Countermeasures of raw material collection in biomass power plant. Chin. Hi-Tech Enterp. 2009, 3, 157–158. [Google Scholar]

- Wang, H.G.; Huang, Y.H.; Bao, H.H.; Ding, W.L.; Huang, W.S. Study on the factors influencing the farmers’ willingness of biomass utilization. J. Arid Land Resour. Environ. 2018, 32, 39–44. [Google Scholar]

| Policy | Issuer | Year | Objectives | Reference |

|---|---|---|---|---|

| The Notice on Carrying out Technical Transformation Pilot Work of Coal-biomass Co-firing Power Generation | NEA & Ministry of Environmental Protection (MEP) | 2017 | Promote the ultra-low emission requirements and new energy consumption standards of coal-fired power plants nationwide. Organize the construction of coal-biomass co-firing power generation technology transformation pilot project. | [29] |

| The 13th Five-Year Plan for Power Development | National Development and Reform Commission (NDRC) & NEA | 2017 | Demonstration and application of coal-biomass co-firing power generation should be carried out; a number of demonstration projects of coal-fired and agricultural and forestry waste residues coupled power generation should be arranged in Northeast and other major grain production areas. | [30] |

| The 13th Five-Year Plan for Energy Technology Innovation | NEA | 2017 | "Coal-biomass co-firing power generation technology" is regarded as the application and promotion project of clean coal-fired power generation plate, which requires "mastering coal-biomass co-firing power generation technology" and "studying the transformation technology of existing coal-fired power plants coupled with biomass power generation". | [31] |

| Notice on Construction of Pilot Projects for Technical Transformation of Coal-biomass Co-firing Power Generation | NEA & Ministry of Ecology and Environment | 2018 | If the 84 pilot projects could be successfully carried out, the total annual biomass consumption would be 13.27 million tons. 8.3 billion kilowatt hours of biomass power could be increased every year to replace 2.62 million tons of coal and reduce 7.33 million tons of CO2 emissions. The on grid price could be reduced by 0.05–0.1 yuan/kWh. | [32] |

| Guide catalogue for industrial structure adjustment 2019 | NDRC | 2019 | "Coal-biomass co-firing power generation" was listed in the guidance catalogue as a new encouraged industry. | [33] |

| Item | Pure Biomass-Fired Power Generation | Coal-Biomass Co-Firing Power Generation |

|---|---|---|

| Application situation [34] | Technology is mature and has been widely used. As of 2019, the installed capacity of biomass power generation in China has reached to 22.54 GW [35] | It has been widely used in Europe |

| In China, almost all of biomass power plants are pure burning. | China’s Jingmen power plant and Shiliquan power plant have carried out the transformation of coal-biomass co-firing power generation. | |

| Fuel [36] | Fuel cost is the most important part of the cost of biomass power generation in China, accounting for about 49%. | It can reduce the supply risk of the biomass fuel. The fuel adaptability is better, the available biomass fuel varieties are more diverse. |

| Unit type [37] | 1–50 MW, most are 10–30 MW high pressure parameter units | 100–1000 MW, most are 300–660 MW subcritical, supercritical and ultra-supercritical units |

| Efficiency [37] | Power supply efficiency is generally lower than 30% | Power supply efficiency is generally higher than 40% |

| Power generation investment [34] | Higher initial investment | Lower initial investment (Only a new biomass fuel treatment system is needed and the boiler burner is partially modified.) |

| Floor space | New requisition land is needed | There is no need to add additional land outside the plant walls. |

| Economical efficiency | Relatively weak, limited to the supply of biomass resources | More economical |

| Power Plant/Commissioning Time. | Capacity of Coal-Fired Unit | Coupling Form | Biomass Fuel | Co-Combustion Ratio of Heat | Technical Characteristics |

|---|---|---|---|---|---|

| Shiliquan Power Plant/2005 | 400t/h high temperature and high pressure boiler | Direct co-firing | Wheat-straw, corn stalk | 18.6% (Design), 5%~8% (Reality) | Adopt the independent burning system of BWE company in Denmark to achieve co-combustion, and the fuel entering the boiler needs to be pretreated. |

| Baoji No.2 Power Generation Co., Ltd/2010 | 300 MW boiler | Direct co-firing | Straw, molding biomass | 6.76%~21.90% | Through a set of pulverizing system, biomass fuel is burned separately |

| Datang Changshan thermal power plant/2018 | 660 MW | Indirect co-firing | Straw, rice husk, waste wood, et al. | 3% | Using micro positive pressure of circulating fluidized bed(CFB) and gasifier system to gasify the original burner |

| Huadian Xiangyang power plant/2018 | 600 MW | Indirect co-firing | 50% rice husk, straw, 50% biomass briquette | 1.8% | Adopt CFB negative pressure gasifier system |

| Changyuan Jingmen Power Plant/2016 | 640 MW | Indirect co-firing | Rice husk, straw | 1.7% | Biomass CFB gasification unit |

| Finnish Kymijarvi power plant/1998 | 167 MW/240 MW | Indirect co-firing | Wood based biomass, waste recycling fuel | 15%~30% | Atmospheric air gasification, FW CFB vaporizer |

| Finnish Vaskiluoto power plant/2014 | 560 MW (240 MW/170 MW) | Indirect co-firing | Dry wood based biomass | 25% | Atmospheric air gasification, Valmet CFB vaporizer,800~900 °C |

| British Tibury power plant/2004 | 712 MW | Direct co-firing | Forest tree, wood pellet | ~100% | Using biomass to break in biomass burner |

| British Fiddlers Ferry power plant/1995 | 4*500 MW | Direct co-firing | Pressed waste wood pellet fuel, olive core and other biomass | 20% | After grinding, biomass particles are directly sent to the boiler for combustion |

| Cost Name | Value | Cost Name | Value |

|---|---|---|---|

| Maintenance rate | 2% | Staff Salaries (yuan/year) | 80,000 |

| Insurance rate | 0.25% | Number of Staff | 120 |

| Discount rate | 8% | Welfare and labor insurance coefficient | 60% |

| Design and installation rate | 10% | Annual growth rate of employees’ wages | 6% |

| Depreciable lives (year) | 20 | Denitration efficiency | 99% |

| Education surcharges (%) | 1% | Decarburization efficiency | 80% |

| Income tax (%) | 25% | Heat contained in one kilowatt hour | 3600 kJ |

| Value added tax (%) | 17% | Bank loan interest rate (%) | 6% |

| Property tax (%) | 1% | Years of bank loan (year) | 20 |

| Deduction proportion of property tax (%) | 30% | Internal recovery rate after tax | 8% |

| Urban maintenance and construction tax (%) | 5% | Annual utilization hours | 5000 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Yang, K.; Zhou, J.; Zhao, G. Coal-Biomass Co-Firing Power Generation Technology: Current Status, Challenges and Policy Implications. Sustainability 2020, 12, 3692. https://doi.org/10.3390/su12093692

Xu Y, Yang K, Zhou J, Zhao G. Coal-Biomass Co-Firing Power Generation Technology: Current Status, Challenges and Policy Implications. Sustainability. 2020; 12(9):3692. https://doi.org/10.3390/su12093692

Chicago/Turabian StyleXu, Yan, Kun Yang, Jiahui Zhou, and Guohao Zhao. 2020. "Coal-Biomass Co-Firing Power Generation Technology: Current Status, Challenges and Policy Implications" Sustainability 12, no. 9: 3692. https://doi.org/10.3390/su12093692