Study on the Influence of EGR on the Combustion Performance of Biofuel Diesel at Different Ambient Simulated Pressures

Abstract

:1. Introduction

2. Experimental Equipment and Methods

3. Results and Discussions

3.1. Engine Performance

3.2. Economy

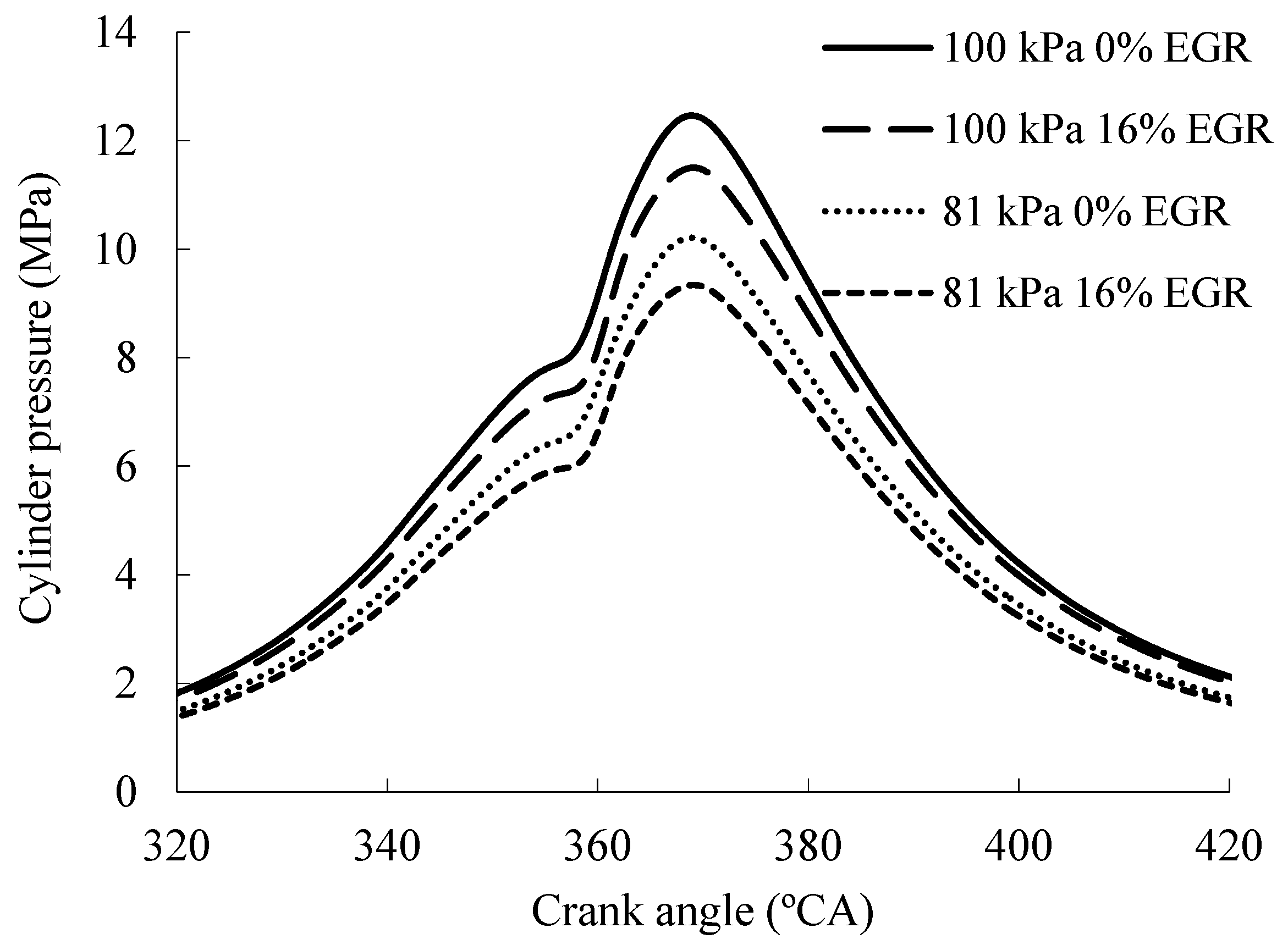

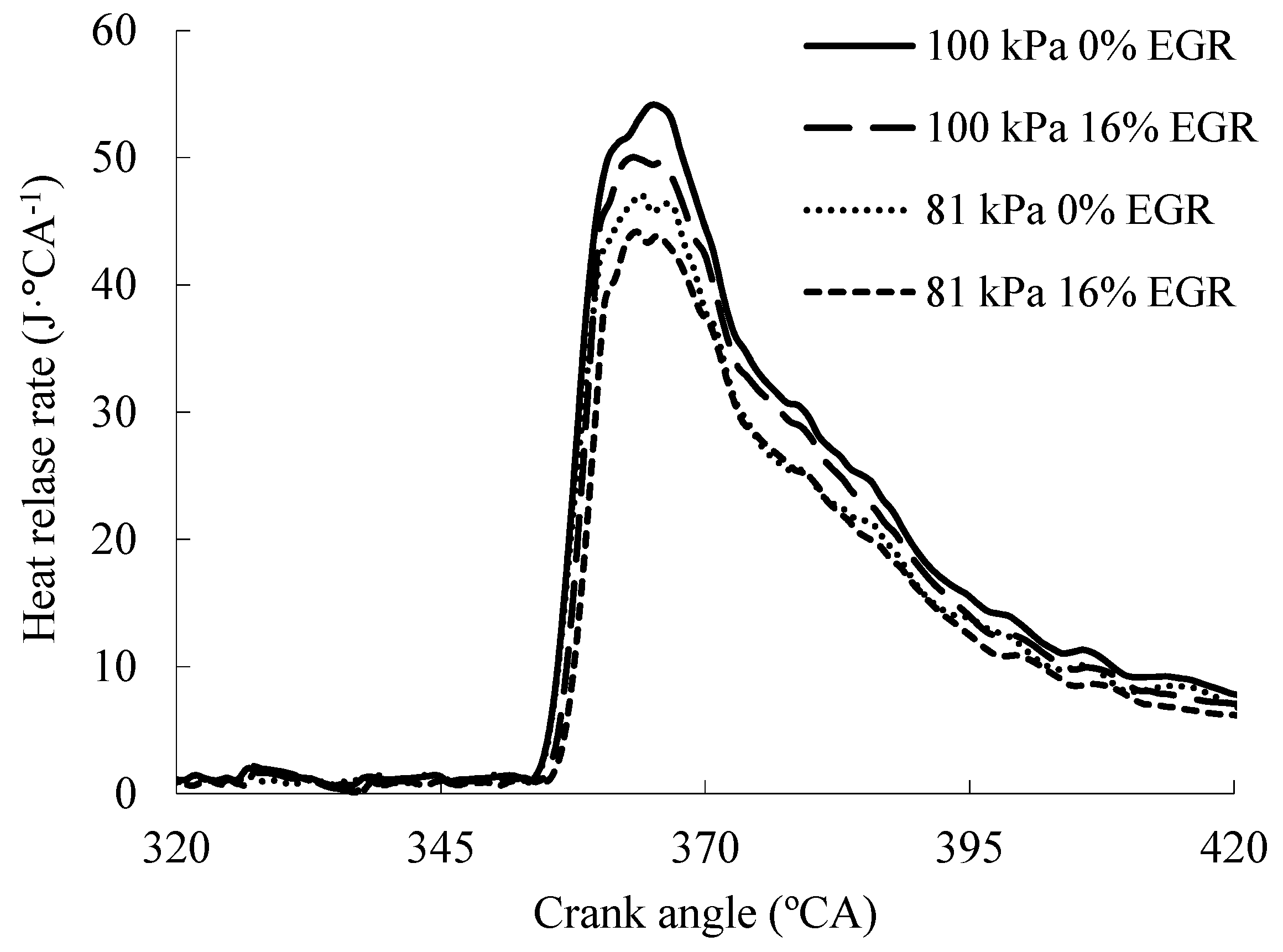

3.3. Cylinder Pressure and Heat Release Rate

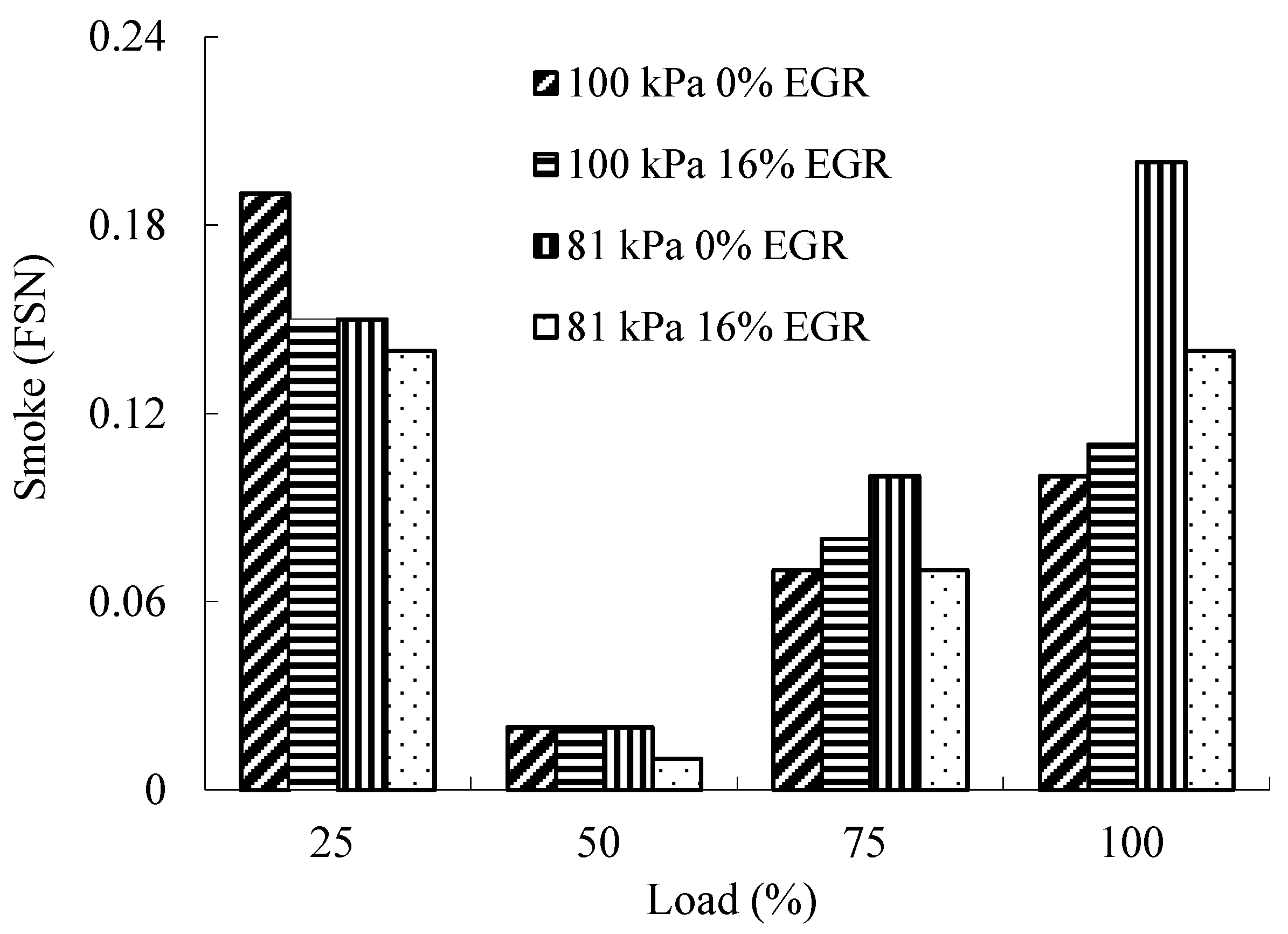

3.4. Smoke and NOx Emission

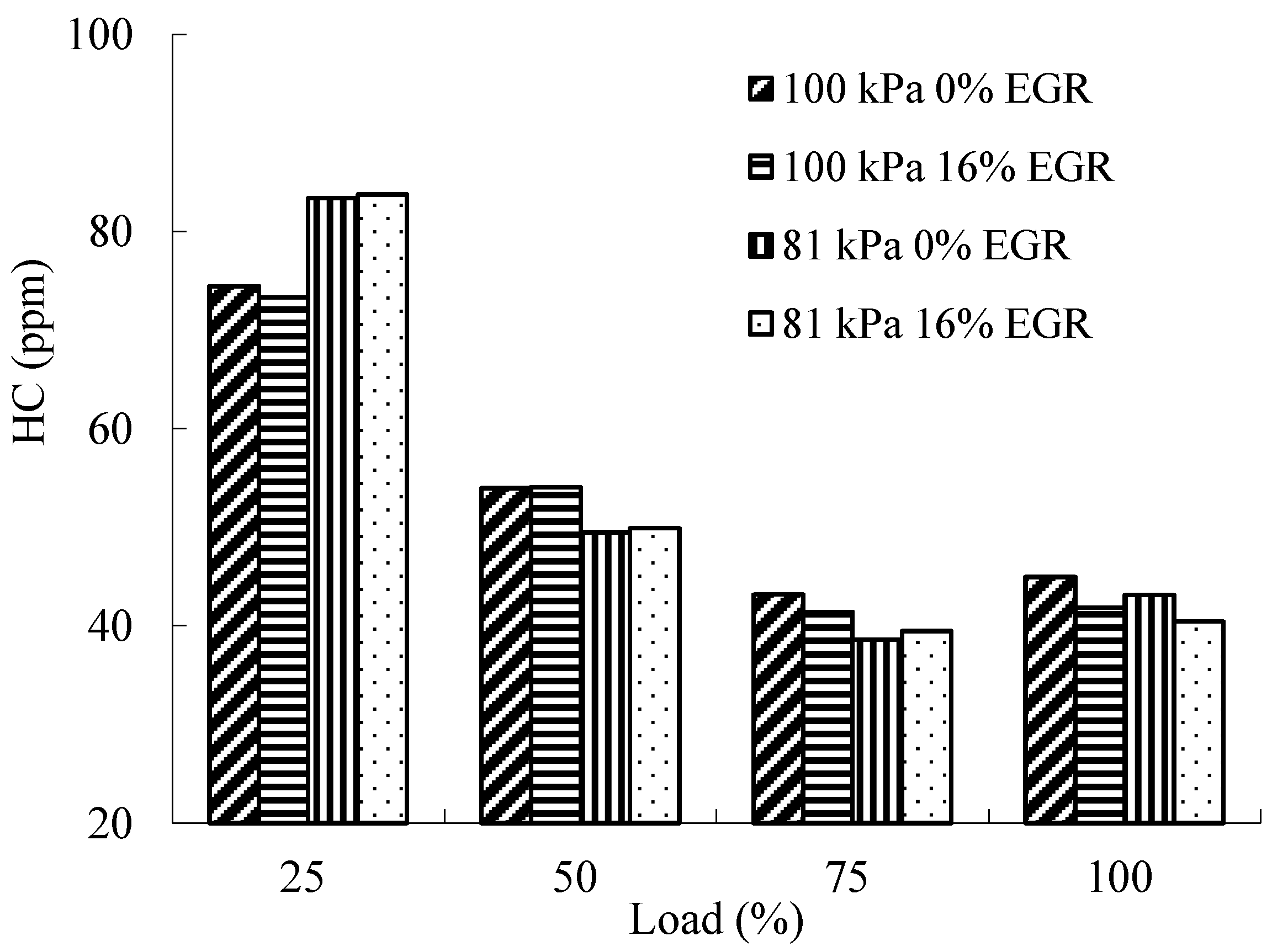

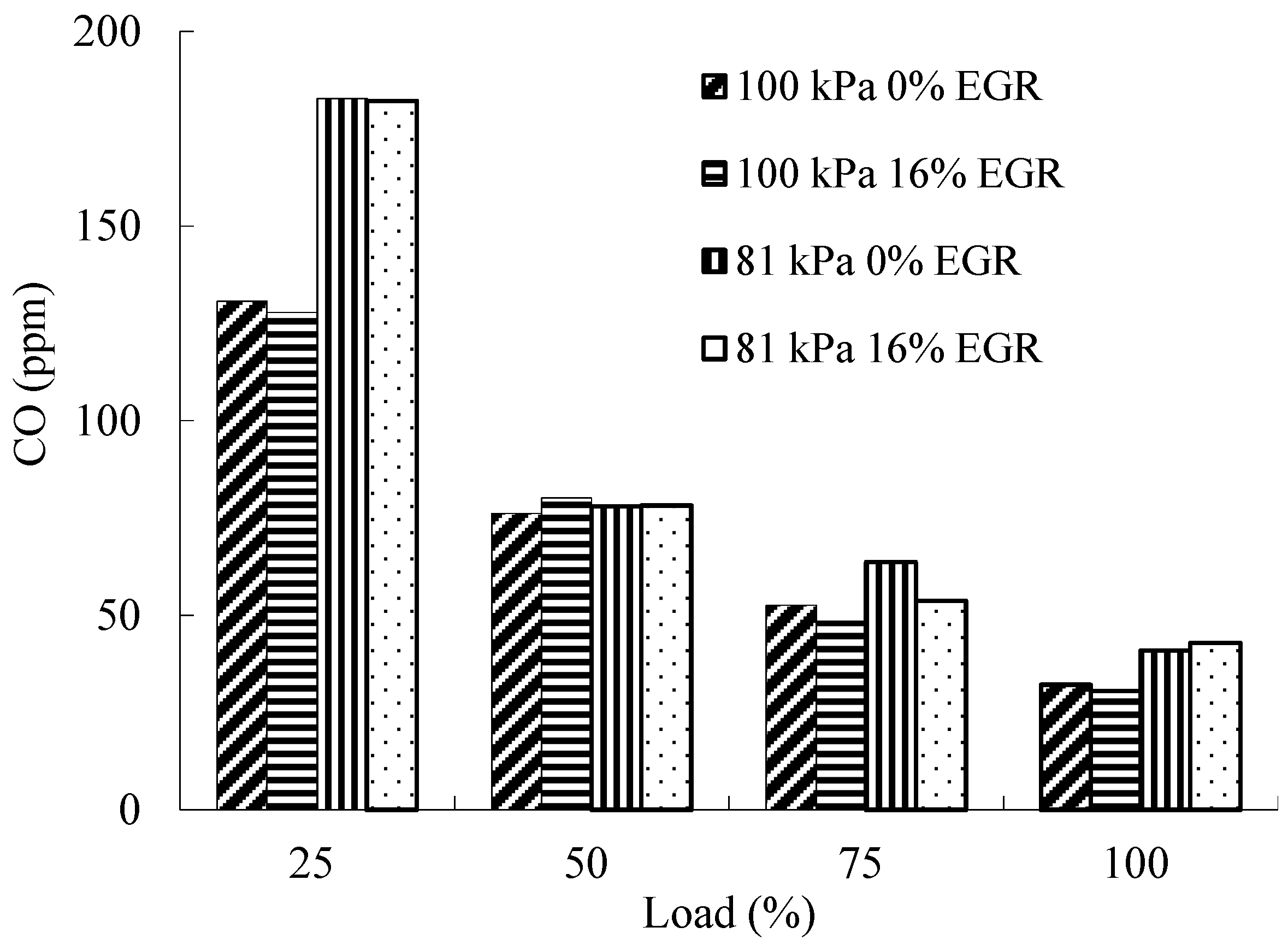

3.5. HC and CO Emission

4. Conclusions

- (1)

- As the atmospheric pressure increases, the diesel engine power performance of B15E5 fuel increases. At the same atmospheric pressure, the power performance deteriorates with the increase of EGR rate. With the increase of atmospheric pressure, the brake specific fuel consumption shows a downward trend and its decreasing amplitude is 1.5–11.7%. At the same atmospheric pressure, the brake specific fuel consumption increases with the increase of EGR rate and the diesel engine economy turns worse.

- (2)

- Under the external characteristic conditions, with the increase of atmospheric pressure, the maximum cylinder pressure and peak heat release rate both increase; at the same atmospheric pressure, the maximum cylinder pressure and peak heat release rate of the diesel engine both decrease with the increase of EGR rate, and their location of crank angle is slightly delayed.

- (3)

- At partial load conditions, with the increase of load, the smoke emission decreased first and then increased. With the increase of atmospheric pressure, decrease of the smoke emission ranges from 6.6% to 40%, but the increase of NOx emission ranges from 1.2% to 8.5%; however, the emission of HC and CO decreases from 9.3% to 19.1% and from 2.9% to 16.6%, respectively. Both HC and CO emissions show a downward trend.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, D.; Huang, Z. Internal Combustion Engine Alternative Fuel Combustion; Xi’an Jiaotong University Press: Xi’an, China, 2007. [Google Scholar]

- Lin, C.Y.; Li, R.J. Engine performance and emission characteristics of marine fish-oil biodiesel produced from the discarded parts of marine fish. Fuel Process. Technol. 2009, 90, 883–888. [Google Scholar] [CrossRef]

- Yilmaz, N. Performance and emission characteristics of a diesel engine fuelled with biodiesel–ethanol and biodiesel–methanol blends at elevated air temperatures. Fuel 2012, 94, 440–443. [Google Scholar] [CrossRef]

- De Caro, P.S.; Mouloungui, Z.; Vaitilingom, G.; Berge, J.C. Interest of combining an additive with diesel–ethanol blends for use in diesel engines. Fuel 2001, 80, 565–574. [Google Scholar] [CrossRef]

- Shi, X.; Yu, Y.; He, H.; Shuai, S.; Wang, J.; Li, R. Emission characteristics using methyl soyate–ethanol–diesel fuel blends on a diesel engine. Fuel 2005, 84, 1543–1549. [Google Scholar] [CrossRef]

- Huang, Z.H.; Lu, H.B.; Jiang, D.M.; Zeng, K.; Liu, B.; Zhang, J.Q.; Wang, X.B. Study on combustion characteristics of a DI diesel engine operating on diesel/methanol blends. Trans. CSICE 2003, 21, 401–410. [Google Scholar]

- Sendzikiene, E.; Makareviciene, V.; Janulis, P. Influence of fuel oxygen content on diesel engine exhaust emissions. Renew. Energy 2006, 31, 2505–2512. [Google Scholar] [CrossRef]

- Boldaji, M.T.; Ebrahimzadeh, R.; Kheiralipour, K.; Borghei, A.M. Effect of some BED blends on the equivalence ratio, exhaust oxygen fraction and water and oil temperature of a diesel engine. Biomass Bioenergy 2011, 35, 4099–4106. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Shuai, S.; Chen, W. Study of oxygenated biomass fuel blends on a diesel engine. Fuel 2008, 87, 3462–3468. [Google Scholar] [CrossRef]

- Asadi, A.; Kadijani, O.N.; Doranehgard, M.H.; Bozorg, M.V.; Xiong, Q.; Shadloo, M.S.; Li, L.K. Numerical study on the application of biodiesel and bioethanol in a multiple injection diesel engine. Renew. Energy 2020, 150, 1019–1029. [Google Scholar] [CrossRef]

- Kim, H.Y.; Ge, J.C.; Choi, N.J. Effects of Ethanol–Diesel on the Combustion and Emissions from a Diesel Engine at a Low Idle Speed. Appl. Sci. 2020, 10, 4153. [Google Scholar] [CrossRef]

- Geng, L.M.; Cheng, Q.B.; Chen, Y.; Wei, Y.T. Combustion and emission characteristics of biodiesel-diesel-ethanol fuel blends. China J. Highw. Transp. 2018, 31, 236–242. [Google Scholar]

- Liu, S.; Shen, L.; Bi, Y.; Lei, J. Effect of BED oxygenated fuel on the PM and NOx emissions of a diesel engine at different altitude levels. Acta Sci. Circumstantiae 2018, 38, 1791–1796. [Google Scholar]

- Hosseinzadeh-Bandbafha, H.; Rafiee, S.; Mohammadi, P.; Ghobadian, B.; Lam, S.S.; Tabatabaei, M.; Aghbashlo, M. Exergetic, economic, and environmental life cycle assessment analyses of a heavy-duty tractor diesel engine fueled with diesel–biodiesel-bioethanol blends. Energy Convers. Manag. 2021, 241, 114300. [Google Scholar] [CrossRef]

- Liu, S.H.; Shen, L.Z.; Bi, Y.H.; Zhang, S.B. Effects of biomass on performance and emissions of diesel engine high-altitude hypoxic condition. Trans. Chin. Soc. Agric. Eng. 2014, 30, 53–59. [Google Scholar]

- Bi, Y.; Tang, C.; Shen, L.; Wen, W.; Wang, J.; Song, G. Effect of VNT and EGR coupling on performance of diesel engine fueled with oxygenated fuel under different atmospheric pressures. Trans. Chin. Soc. Agric. Eng. 2018, 34, 38–45. [Google Scholar]

- Wang, B.; Yan, W.S.; Shen, J.W.; Chen, H.; Ye, M. Effect of biodiesel/diesel blend fuel on combustion and emission characteristic of common rail diesel engine under different atmospheric pressures. Trans. CSICE 2013, 34, 58–63. [Google Scholar]

- Huang, H.; Li, Z.; Teng, W.; Huang, R.; Liu, Q.; Wang, Y. Effects of EGR rate on combustion and emission characteristics of blends of ethanol and biodiesel. J. Combust. Sci. Technol. 2019, 25, 237–243. [Google Scholar]

- Liang, Y.; Zhou, L.; Yao, G.; Ding, X.; Zhou, J.; You, S. Experiment study on performance of engine fueled with ethanol-biodiesel using EGR. Renew. Energy Resour. 2015, 33, 1736–1742. [Google Scholar]

- Tan, Z.F.; Bi, Y.H.; Di, Y.L.; Ouyang, W.B.; Shen, L.Z. Effects of EGR system under plateau environments on performance of diesel engine used biomass materials fuels. J. Cent. South Univ. For. Technol. 2015, 33, 109–113. [Google Scholar]

- Liu, S.; Shen, L.; Zhang, S. A research on the stability of BED blend fuel and its effects on the engine performance in plateau area. Automot. Eng. 2012, 34, 816–820. [Google Scholar]

- Zheng, W.; Hu, D.Z.; Wen, L.Q.; Yao, X.G.; Shen, Y.G.; Shen, L.Z. Effects of EGR on the economic performance and smoke intensity of diesel engines working at different altitude. Small Intern. Combust. Engine Motorcycle 2006, 35, 9–12. [Google Scholar]

- Cai, M.; Yang, X.; Sun, P. Study on the combustion process and emission of a turbocharged diesel engine with EGR. Small Intern. Combust. Engine Motorcycle 2008, 37, 68–71. [Google Scholar]

- Hu, Z.L.; Bian, Q.; Gao, B.; Gao, W.Z. Internal EGR technology and its Application in the diesel engine for small excavator. Small Intern. Combust. Engine Motorcycle 2013, 42, 1–4. [Google Scholar]

- Wang, Y.; Dong, R. Investigation of EGR system in MD&HD CR diesel engine. Chin. Intern. Combust. Engine Eng. 2011, 32, 6–11. [Google Scholar]

- Peng, H.; Cui, Y.; Shi, L.; Deng, K. Effects of EGR on combustion process of DI diesel engine during cold start. Trans. CSICE 2007, 25, 193–201. [Google Scholar] [CrossRef]

- Bai, C.X.; Liu, Z.C.; Han, Y.Q.; Li, K.; Liu, J.W. Effect of Stepped EGR on combustion process of a heavy-duty diesel engine. Trans. CSICE 2011, 29, 8–15. [Google Scholar]

- Shen, L.Z.; Bi, Y.H.; Zhang, W.; Lei, J.L.; Yan, W.S.; Yang, Y.Z.; Zhang, N. Combustion process of turbocharged and inter-cooled turbocharged diesel engine in different altitude regions. J. Combust. Sci. Technol. 2005, 11, 524–529. [Google Scholar]

- Du, D.; Gu, J. Study of the influence of EGR on soot formation in diffusion flames. J. Combust. Sci. Technol. 2002, 8, 529–532. [Google Scholar]

- Chen, S.H.; Wang, Z.; Yuan, Y.N.; Wang, L.; Zhang, X.C. The effect of EGR on cycle to cycle variation and combustion process of diesel engine. Automot. Eng. 2006, 28, 343–345. [Google Scholar]

- Jia, H.; Liu, S.; Yin, B.; Huang, C. Visualization of influence of EGR on combustion process and emission performance for light-duty diesel engine. Trans. Chin. Soc. Agric. Eng. 2012, 28, 44–49. [Google Scholar]

| Parameter Description | Details |

|---|---|

| Engine type | Four-stroke, in-line four cylinders, direct injection |

| Air intake system | Turbocharged, inter-cooled |

| Bore × Stroke | 95 mm × 105 mm |

| Displacement | 2.98 L |

| Compression ratio | 18:1 |

| Rated power | 81 kW at 3200 rpm |

| Peak torque | 360 Nm at 1800 rpm |

| Injection system | Bosch common-rail system CRS2–16 |

| Instrument | Measured Quantity | Range | Accuracy |

|---|---|---|---|

| WE31N hydrodynamic dynamometer | Engine torque | 0–400 Nm | ±0.2%full scale |

| Magnetic induction speed transducer | Engine speed | 0–7500 rpm | ±5 r/min |

| FCMA fuel consumption instrument | Fuel consumption | 0–40 kg/h | <±0.05%full scale |

| LFE300 air flow meter | Air volume flow rate | 0–800 m3/h | ±1.0%measure value |

| MEXA−7500DEGR | NOx | 0–10,000 ppm | 20 ppm |

| MEXA−7500DEGR | HC | 0–50,000 ppm | 10 ppm |

| MEXA−7500DEGR | CO | 0–5000 ppm | 5 ppm |

| AVL 415S | smoke | 0–10 FSN | ±0.001 FSN |

| AVL GH13P | Cylinder pressure | 0–250 bar | <±0.5%full scale |

| Fuel | Density (20 °C)/(g/cm3) | Cetane Number | Lower Heating Value (MJ/kg) | Oxygen Content in Weight (%) |

|---|---|---|---|---|

| diesel | 0.838 | 53.1 | 42.85 | 0.0 |

| biodiesel | 0.880 | 56.0 | 39.50 | 10.0 |

| alcohol | 0.789 | 8.00 | 26.78 | 34.8 |

| B15E15 | 0.837 | 51.3 | 41.80 | 3.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Z.; Wang, J.; Chen, W.; Shen, L.; Bi, Y. Study on the Influence of EGR on the Combustion Performance of Biofuel Diesel at Different Ambient Simulated Pressures. Sustainability 2021, 13, 7862. https://doi.org/10.3390/su13147862

Tan Z, Wang J, Chen W, Shen L, Bi Y. Study on the Influence of EGR on the Combustion Performance of Biofuel Diesel at Different Ambient Simulated Pressures. Sustainability. 2021; 13(14):7862. https://doi.org/10.3390/su13147862

Chicago/Turabian StyleTan, Zefei, Jun Wang, Wengang Chen, Lizhong Shen, and Yuhua Bi. 2021. "Study on the Influence of EGR on the Combustion Performance of Biofuel Diesel at Different Ambient Simulated Pressures" Sustainability 13, no. 14: 7862. https://doi.org/10.3390/su13147862