Application of Granular and Non-Granular Organic Fertilizers in Terms of Energy, Environmental and Economic Efficiency

Abstract

:1. Introduction

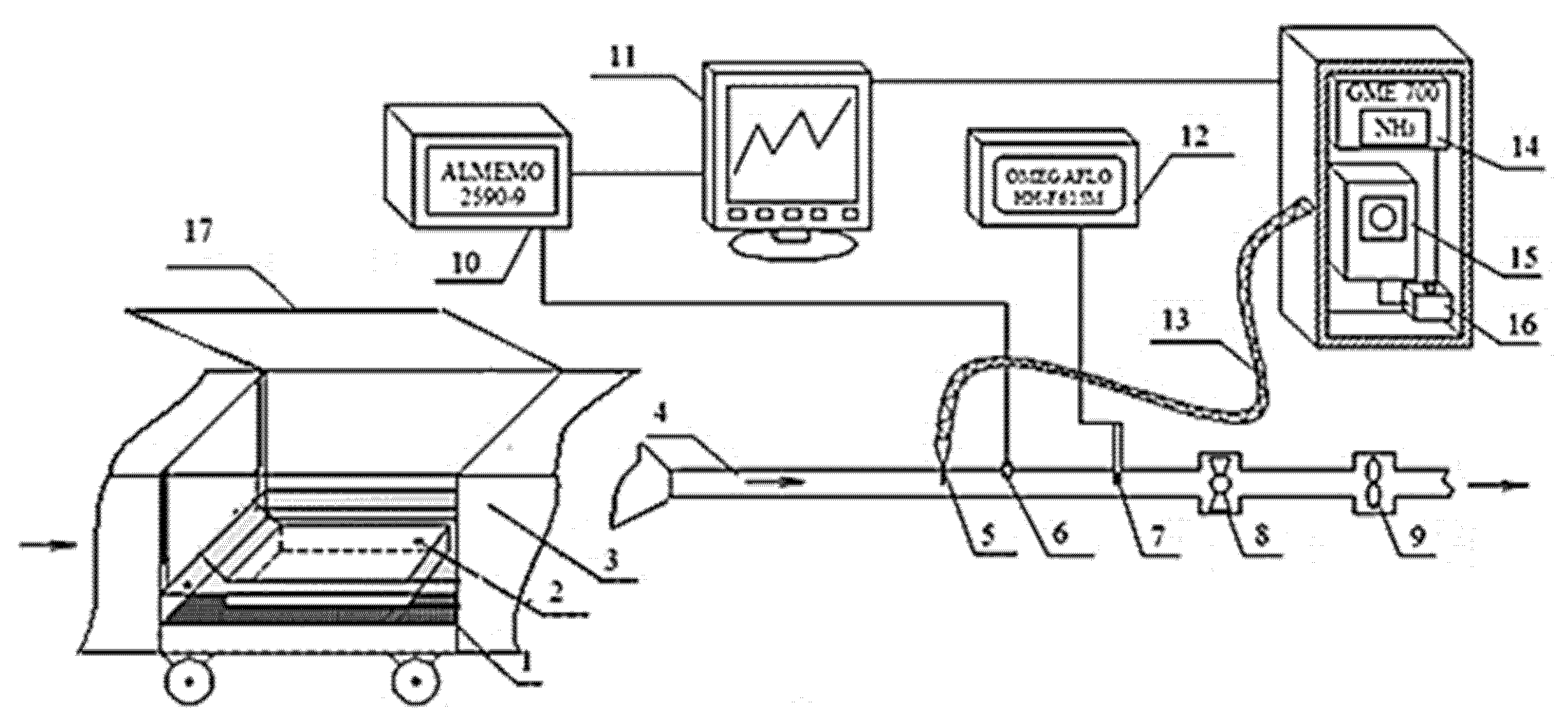

2. Materials and Methods

2.1. Energy Assessment of Organic Fertilizer Use

2.2. Assessment of Environmental Impact of Organic Fertilizers

2.3. Economic Assessment of Organic Fertilizer Use

2.4. Statistical Data Analysis

3. Results

3.1. Energy Assessment of Technological Operations of Organic Fertilizer Use

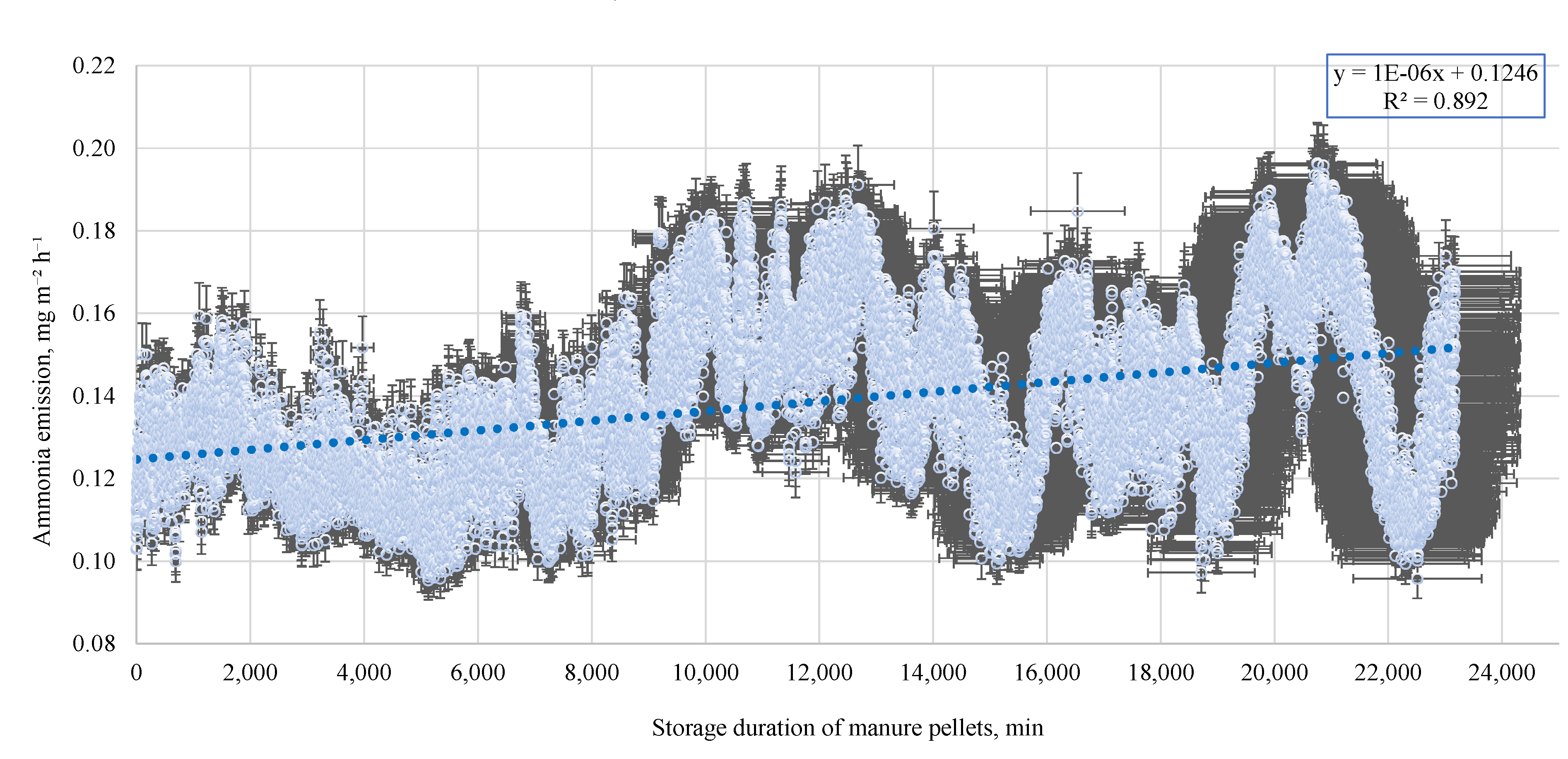

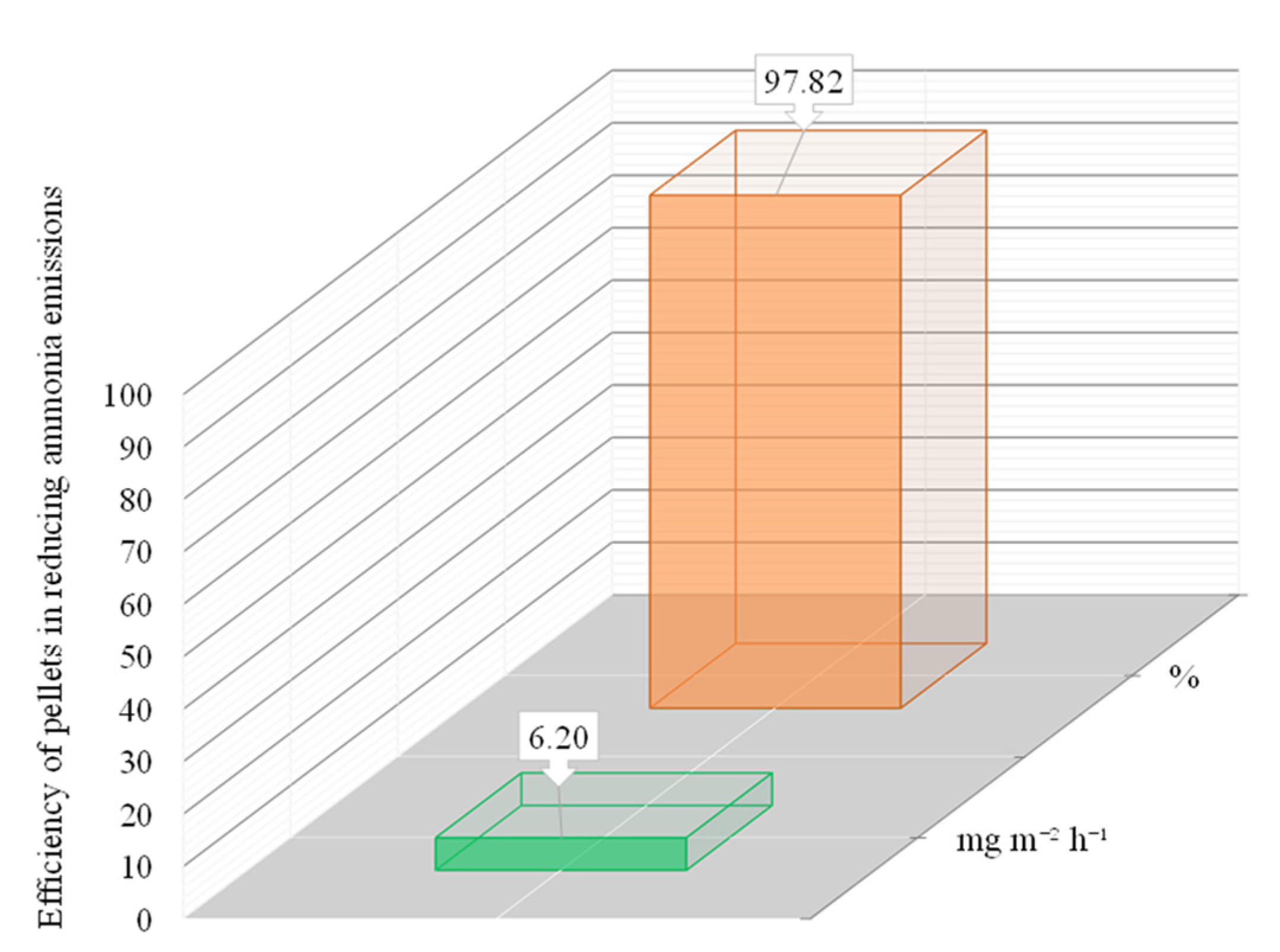

3.2. Environmental Impact Assessment

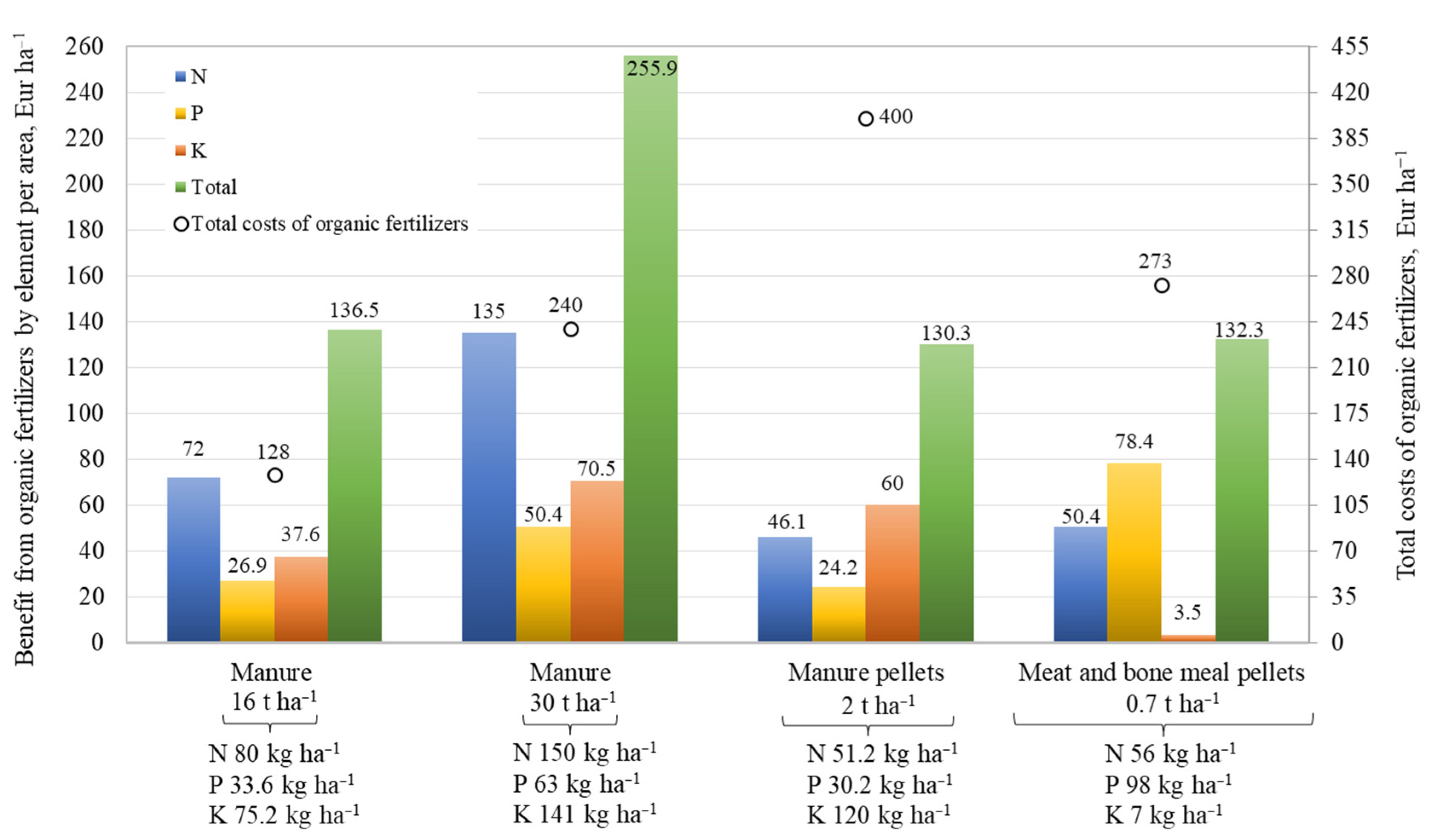

3.3. Economic Assessment of Granular and Non-Granular Organic Fertilizer Use

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, Z.; Egidi, E.; Liu, H.; Kaur, S.; Singh, B.K. New frontiers in agriculture productivity: Optimised microbial inoculants and in situ microbiome engineering. Biotechnol. Adv. 2019, 37, 107371. [Google Scholar] [CrossRef] [PubMed]

- Borlaug, N. Fertilizer’s Role in World Food Production; The Fertilizer Institute: Washington, DC, USA, 2008; p. 20002. [Google Scholar]

- Schmitt, E.; Vries, W. Potential benefits of using Hermetia illucens frass as a soil amendment on food production and for environmental impact reduction. Curr. Opin. Green Sustain. Chem. 2020, 25, 100335. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Tabak, M.; Gródek-Szostak, Z.; Szeląg-Sikora, A.; Kuboń, M.; Komorowska, M. Assessment of the Efficiency of Nitrogen Slow-Release Fertilizers in Integrated Production of Carrot Depending on Fertilization Strategy. Sustainability 2020, 12, 1982. [Google Scholar] [CrossRef] [Green Version]

- Stewart, W.M.; Dibb, D.W.; Johnston, A.E.; Smyth, T.J. The Contribution of Commercial Fertilizer Nutrients to Food Production. Agron. J. 2005, 97, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Hazra, G. Different types of Eco-Friendly Fertilizers: An Overwiew. Sustain. Environ. 2016, 1, 54–70. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Guerrero, A.; Mouazen, A.M. Map-based variable-rate manure application in wheat using a data fusion approach. Soil Till. Res. 2021, 207, 104846. [Google Scholar] [CrossRef]

- Schmidt Rivera, X.C.; Bacenetti, J.; Fusi, A.; Niero, M. The influence of fertiliser and pesticide emissions model on life cycle assessment of agricultural products: The case of Danish and Italian barley. Sci. Total Environ. 2017, 592, 745–757. [Google Scholar] [CrossRef] [Green Version]

- Savci, S. An agricultural pollutant: Chemical fertilizer. Int. J. Environ. Sci. Dev. 2012, 3, 77–80. [Google Scholar] [CrossRef] [Green Version]

- Diacono, M.; Rubino, P.; Montemurro, F. Precision nitrogen management of wheat. Agron. Sustain. Dev. 2013, 33, 219–241. [Google Scholar] [CrossRef]

- Kazlauskas, M.; Bručienė, I.; Jasinskas, A.; Šarauskis, E. Comparative Analysis of Energy and GHG Emissions Using Fixed and Variable Fertilization Rates. Agronomy 2021, 11, 138. [Google Scholar] [CrossRef]

- Li, L.; Wu, W.; Giller, P.; O’Halloran, J.; Liang, L.; Peng, P.; Zhao, G. Life Cycle Assessment of a Highly Diverse Vegetable. Multi-Cropping System in Fengqiu County, China. Sustainability 2018, 10, 983. [Google Scholar] [CrossRef] [Green Version]

- Tubiello, F.N.; Salvatore, M.; Rossi, S.; Ferrara, A.; Fitton, N.; Smith, P. The FAOSTAT database of greenhouse gas emissions from agriculture. Environ. Res. Lett. 2013, 8, 015009. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.; Zhang, S.; Wang, Y. What could promote farmers to replace chemical fertilizers with organic fertilizers? J. Clean. Prod. 2018, 199, 82–890. [Google Scholar] [CrossRef]

- Czekała, W.; Jeżowska, A.; Chełkowski, D. The Use of Biochar for the Production of Organic Fertilizers. J. Ecol. Eng. 2019, 20, 1–8. [Google Scholar] [CrossRef]

- European Union Emission Inventory Report 1990–2016 under the UNECE Convention on Long-Range Transboundary Air Pollution (LRTAP). 2018. Available online: https://www.eea.europa.eu/publications/european-union-emission-inventory-report-1990-2016 (accessed on 12 November 2020).

- Fowler, D.; Coyle, M.; Skiba, U.; Sutton, M.A.; Cape, J.N.; Reis, S.; Sheppard, L.J.; Jenkins, A.; Grizzetti, B.; Galloway, J.N. The global nitrogen cycle in the twenty-first century. Philos. Trans. R. Soc. B Biol. Sci. 2013, 368, 20130164. [Google Scholar] [CrossRef]

- Goglio, P.; Smith, W.N.; Grant, B.B.; Desjardins, R.L.; McConkey, B.G.; Campbell, C.A.; Nemecek, T. Accounting for soil carbon changes in agricultural life cycle assessment (LCA): A Review. J. Clean. Prod. 2015, 104, 23–30. [Google Scholar] [CrossRef]

- Sharara, M.A.; Rungea, T.; Larson, R.; Primb, J.G. Techno-economic optimization of community-based manure processing. Agric. Syst. 2018, 161, 117–123. [Google Scholar] [CrossRef]

- Van Loon, J.; Speratti, A.B.; Govaerts, B. Precision for Smallholder Farmers: A Small-Scale-Tailored Variable Rate Fertilizer Application Kit. Agriculture 2018, 8, 48. [Google Scholar] [CrossRef] [Green Version]

- Atikur Rahman, K.M.; Zhang, D. Effects of Fertilizer Broadcasting on the Excessive Use of Inorganic Fertilizers and Environmental Sustainability. Sustainability 2018, 10, 759. [Google Scholar] [CrossRef] [Green Version]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Gródek-Szostak, Z.A.; Kuboń, M.; Komorowska, M. The Impact of a Controlled-Release Fertilizer on Greenhouse Gas Emissions and the Efficiency of the Production of Chinese Cabbage. Energies 2020, 13, 2063. [Google Scholar] [CrossRef] [Green Version]

- Lenerts, A.; Berzins, G.; Popluga, D. Nitrogen fertilizer use efficiency and GHG emissions in the Latvian grain sector. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 25–27 May 2016; pp. 224–229. [Google Scholar]

- Jensen, L.S.; Oelofse, M.; Hoeve, M.; Bruun, S. Environmental Impact Assessment on the Production and Use of Biobased Fertilizers. Biorefin. Inorg. 2020, 1, 329–362. [Google Scholar] [CrossRef]

- Česonienė, L.; Rutkovienė, V. Lysimetric research of nutrient losses from organic fertilizers. Agron. Res. 2009, 7, 224–232. [Google Scholar]

- Möller, K. Assessment of Alternative Phosphorus Fertilizers for Organic Farming: Meat and Bone Meal. IMPROVE-P Factsheet. 2015; pp. 1–8. Available online: https://orgprints.org/29505/1/moeller2015-factsheet-Meat-and-bone-meal.pdf (accessed on 14 March 2021).

- Staugaitis, G.; Masevičienė, A.; Mažeika, R.; Arbačiauskas, J. Granuliuotos organinės trąšos. Valstiečių laikraštis. 31-10-2016. Available online: https://valstietis.lt/archyvas/granuliuotos-organines-trasos-kas-tai/17784 (accessed on 28 May 2021).

- Zinkevičienė, R.; Jotautienė, E.; Juostas, A.; Comparetti, A.; Vaiciukevičius, E. Simulation of Granular Organic Fertilizer Application by Centrifugal Spreader. Agronomy 2021, 11, 247. [Google Scholar] [CrossRef]

- Ylivainio, K.; Uusitalo, R.; Turtola, E. Meat bone meal and fox manure as P sources for ryegrass (Lolium multiflorum) grown on a limed soil. Nutr. Cycl. Agroecosystems 2008, 81, 267–278. [Google Scholar] [CrossRef]

- Garcia, R.A.; Rosentrater, K.A. Concentration of key elements in North American meat & bone meal. Biomass Bioenergy 2008, 32, 887–891. [Google Scholar]

- Jeng, A.; Haraldsen, T.; Vagstad, N. Meat and bone meal as nitrogen fertilizer to cereals in Norway. Agric. Food Sci. 2004, 13, 268–275. [Google Scholar] [CrossRef] [Green Version]

- Prices of Mechanized Agricultural Services, Part 1, Main tillage; LIAE: Vilnius, Lithuania. 2018. Available online: https://www.laei.lt/?mt=leidiniai&metai=201 (accessed on 14 March 2021).

- Soni, P.; Taewichit, C.; Salokhe, V.M. Energy consumption and CO2 emissions in rainfed agricultural production systems of Northeast Thailand. Agric. Syst. 2013, 116, 25–36. [Google Scholar] [CrossRef]

- Šarauskis, E.; Romaneckas, K.; Jasinskas, A.; Kimbirauskienė, R.; Naujokienė, V. Improving energy efficiency and environmental mitigation through tillage management in faba bean production. Energy 2020, 209, 118453. [Google Scholar] [CrossRef]

- Kyttä, V.; Helenius, J.; Tuomisto, H.L. Carbon footprint and energy use of recycled fertilizers in arable farming. J. Clean. Prod. 2021, 287, 125063. [Google Scholar] [CrossRef]

- Fadare, D.A.; Bamiro, O.A.; Oni, A.O. Energy analysis for production of powdered and pelletised organic fertilizer in Nigeria. ARPN J. Eng. Appl. Sci. 2009, 4, 75–82. [Google Scholar]

- Polikaitis, S.; Žukas, J. (Eds.) Agronomist Manual; Mokslas: Vilnius, Lithuania, 1987; pp. 44–58. [Google Scholar]

- Apaeva, N.N.; Manishkin, S.G.; Kudryashova, L.V.; Yamalieva, A.M. An innovative approach to the use of the granulated organic fertilizers based on bird droppings on crops of spring wheat. IOP Conf. Ser. Earth Environ. Sci. 2020, 421, 22062. [Google Scholar] [CrossRef]

- Jotautienė, E.; Mieldazys, R.; Gaudutis, A.; Aboltins, A. Granulation of poultry manure and biochar for production of organic fertilizers. In Proceedings of the International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2021; pp. 431–436. [Google Scholar] [CrossRef]

- Klyosov, D.N.; Orekhovskaya, A.A. On the development of technology for obtaining organomineral fertilizers. Earth Env. Sci. 2021, 723, 032024. [Google Scholar] [CrossRef]

- Bručienė, I.; Aleliūnas, D.; Šarauskis, E.; Romaneckas, K. Influence of Mechanical and Intelligent Robotic Weed Control Methods on Energy Efficiency and Environment in Organic Sugar Beet Production. Agriculture 2021, 11, 449. [Google Scholar] [CrossRef]

- Šarauskis, E.; Masilionytė, L.; Juknevičius, D.; Buragienė, S.; Kriaučiūnienė, Z. Energy use efficiency, GHG emissions, and cost-effectiveness of organic and sustainable fertilisation. Energy 2019, 172, 1151–1160. [Google Scholar] [CrossRef]

- Apaeva, N.N.; Yamalieva, A.M.; Manishkin, S.G. Ecologized technology of spring wheat cultivation with application of granular organic fertilizers. Earth Environ. Sci. 2021, 624, 012217. [Google Scholar] [CrossRef]

- Chen, B.; Koziel, J.A.; Lee, M.; O’Brien, S.C.; Li, P.; Brown, R.C. Mitigation of Acute Hydrogen Sulfide and Ammonia Emissions from Swine Manure during Three-Hour Agitation Using Pelletized Biochar. Atmosphere 2021, 12, 825. [Google Scholar] [CrossRef]

- Augustyńska-Prejsnar, A.; Ormian, M.; Sokołowicz, Z.; Topczewska, J.; Lechowska, J. Environmental impacts of pig and poultry farms. Proc. Ecopole 2018, 12, 117–129. [Google Scholar] [CrossRef]

- Kopeć, M.; Gondek, K.; Orłowska, K.; Kulpa, Z. Wykorzystanie odpadów z ubojni drobiu do produkcji kompostu. Inżynieria Ekologiczna 2014, 37, 143–150. [Google Scholar]

- Staroń, P.; Kowalski, Z.; Banach, M. Physico-chemical properties of ash from thermal utilization of feathers, meat and bone meal and poultry litter. Przemysl Chemiczny 2014, 93, 568–569. [Google Scholar]

- Purnomo, C.W.; Indarti, S.; Wulandari, C.; Hinode, H.; Nakasaki, K. Slow release fertiliser production from poultry manure. Chem. Eng. Trans. 2017, 56, 1531–1536. [Google Scholar] [CrossRef]

- Fertilizers and Means to Improve Soil Properties for Use in Organic Farming. Available online: http://lodr.konskowola.pl/www_m/pdf/ekologia/wykaz_nawozow_ekologia_8.05.2018.pdf (accessed on 8 May 2018).

- Luostarinen, S.; Tampio, E.; Laakso, J.; Sarvi, M.; Ylivainio, K.; Riiko, K.; Sindhöj, E. Manure Processing as a Pathway to Enhance Nutrient Recycling. 2020. Available online: http://urn.kb.se/resolve?urn=urn:nbn:se:ri:diva-50954</div> (accessed on 12 July 2021).

- Marouani, E.; Ziadi, N.; Lévesque, V.; Benzina, N.K.; Bouslimi, B.; Koubaa, A. Mitigation of CO2, CH4 and N2O from Acidic Clayey Soil Amended with Fertilizer Pellets Based on Alkaline Organic Residues. Waste Biomass 2021, 12, 3813–3827. [Google Scholar] [CrossRef]

- Yang, X.; Duan, P.; Li, G.; Zhao, X.; Lin, Q.; Zhu, K. Spatial-heterogeneous granulation of organic amendments and chemical fertilizer stimulated N2O emissions from agricultural soil: An microcosm study. J. Environ. Manag. 2021, 277, 111437. [Google Scholar] [CrossRef]

- Mazeika, R.; Staugaitis, G.; Baltrusaitis, J. Engineered Pelletized Organo-Mineral Fertilizers (OMF) from Poultry Manure, Diammonium Phosphate and Potassium Chloride. ACS Sustain. Chem. Eng. 2016, 4, 2279–2285. [Google Scholar] [CrossRef]

- Rochette, P.; Angers, D.A.; Chantigny, M.H.; Gagnon, B.; Bertrand, N. N2O fluxes in soils of contrasting textures fertilized with liquid and solid dairy cattle manures. Can. J. Soil Sci. 2008, 88, 175–187. [Google Scholar] [CrossRef] [Green Version]

- Budiono, R.; Aziz, F.N.; Purbajanti, E.D.; Turkadze, T.; Adinurani, G.P. Effect and Effectivity of Granular Organic Fertilizer on Growth and Yield of Lowland Rice. In Proceedings of the 1st International Conference on Bioenergy and Environmentally Sustainable Agriculture Technology, Malang, Indonesia, 7 November 2019. [Google Scholar] [CrossRef]

- Samuel, A.D.; Bungau, S.; Tit, D.M.; Melinte, C.E.; Purza, L.; Badea, G.E. Effects of long term application of organic and mineral fertilizers on soil enzymes. Rev. Chim. 2018, 69, 2608–2612. [Google Scholar] [CrossRef]

- Bungau, S.; Behl, T.; Aleya, L.; Bourgeade, P.; Aloui-Sossé, B.; Purza, A.L.; Abid, A.; Samuel, A.D. Expatiating the impact of anthropogenic aspects and climatic factors on long term soil monitoring and management. Environ. Sci. Pollut. Res. 2021, 30528–30550. [Google Scholar] [CrossRef] [PubMed]

- Samuel, A.D.; Bungau, S.; Fodor, I.K.; Tit, D.M.; Blidar, C.F.; David, A.T.; Melinte, C.E. Effects of liming and fertilization on the dehydrogenase and catalase activities. Rev. Chim. 2019, 70, 3464–3468. [Google Scholar] [CrossRef]

| Technological Operation | Tractor Power (kW) | Working Width (m) | Labor (h ha−1) | Fuel Consumption (L ha−1) |

|---|---|---|---|---|

| Manure loading into an organic fertilizer spreader | 65 | - | 0.67 | 0.80 |

| Manure transportation and spreading (16 t ha−1) | 138 | 12–14 | 0.33 | 6.20 |

| Manure transportation and spreading (30 t ha−1) | 138 | 12–14 | 0.44 | 7.90 |

| Total (16 t ha−1): | - | - | 1.00 | 7.00 |

| Total (30 t ha−1): | - | - | 1.11 | 8.70 |

| Manure pellet loading into an organic fertilizer spreader | 65 | - | 0.11 | 0.13 |

| Manure pellet transportation and spreading (2.0 t ha−1) | 138 | 12–14 | 0.14 | 2.63 |

| Total: | - | - | 0.25 | 2.76 |

| Loading of meat and bone meal pellets into an organic fertilizer spreader | 65 | - | 0.04 | 0.05 |

| Meat and bone meal pellet transportation and spreading (0.7 t ha−1) | 138 | 12–14 | 0.13 | 2.44 |

| Total: | - | - | 0.17 | 2.49 |

| Organic Fertilizers (Fertilization Rate) | Energy Inputs, MJ ha−1 | Total | ||

|---|---|---|---|---|

| Labor | Fuel | Machinery | MJ ha−1 | |

| Manure (16 t ha−1) | 1.96 | 277.2 | 357.2 | 636.4 |

| Manure (30 t ha−1) | 2.18 | 344.5 | 396.5 | 743.2 |

| Manure pellets (2.0 t ha−1) | 0.49 | 109.3 | 89.3 | 199.1 |

| Meat and bone meal pellets (0.7 t ha−1) | 0.33 | 98.6 | 60.7 | 159.6 |

| Organic Fertilizers (Fertilization Rate) | Energy Equivalent, MJ kg−1 | Energy Inputs for Fertilizers, MJ ha−1 | Energy Inputs for Technological Operations, MJ ha−1 | Total, MJ ha−1 | Percentage, % |

|---|---|---|---|---|---|

| Manure (30 t ha−1) | 0.47 | 14,100 | 743.2 | 14,843.2 | 100.00 |

| Manure (16 t ha−1) | 0.47 | 7520 | 636.4 | 8156.4 | 54.95 |

| Manure pellets (2.0 t ha−1) | 2.37 * | 4740 | 199.1 | 4939.1 | 33.28 |

| Meat and bone meal pellets (0.7 t ha−1) | 5.68 ** | 3976 | 159.6 | 4135.6 | 27.86 |

| Organic Fertilizers (Fertilization Rate) | Loading, EUR ha−1 | Transportation, EUR ha−1 | Spreading, EUR ha−1 | Total Costs, EUR ha−1 |

|---|---|---|---|---|

| Manure (16 t ha−1) | 4.64 | 22.24 | 26.30 | 53.18 |

| Manure (30 t ha−1) | 8.70 | 41.70 | 35.21 | 85.61 |

| Manure pellets (2.0 t ha−1) | 0.58 | 2.78 | 3.29 | 6.65 |

| Meat and bone meal pellets (0.7 t ha−1) | 0.20 | 0.97 | 1.15 | 2.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šarauskis, E.; Naujokienė, V.; Lekavičienė, K.; Kriaučiūnienė, Z.; Jotautienė, E.; Jasinskas, A.; Zinkevičienė, R. Application of Granular and Non-Granular Organic Fertilizers in Terms of Energy, Environmental and Economic Efficiency. Sustainability 2021, 13, 9740. https://doi.org/10.3390/su13179740

Šarauskis E, Naujokienė V, Lekavičienė K, Kriaučiūnienė Z, Jotautienė E, Jasinskas A, Zinkevičienė R. Application of Granular and Non-Granular Organic Fertilizers in Terms of Energy, Environmental and Economic Efficiency. Sustainability. 2021; 13(17):9740. https://doi.org/10.3390/su13179740

Chicago/Turabian StyleŠarauskis, Egidijus, Vilma Naujokienė, Kristina Lekavičienė, Zita Kriaučiūnienė, Eglė Jotautienė, Algirdas Jasinskas, and Raimonda Zinkevičienė. 2021. "Application of Granular and Non-Granular Organic Fertilizers in Terms of Energy, Environmental and Economic Efficiency" Sustainability 13, no. 17: 9740. https://doi.org/10.3390/su13179740