Performance Measurement for the Recycling Production System Using Cooperative Game Network Data Envelopment Analysis

Abstract

:1. Introduction

2. Preliminaries

2.1. The Network Structure and Circular Process in the Recycling Production System

2.2. The Competitive Game DEA for Evaluating the Performance of the Recycling Production System

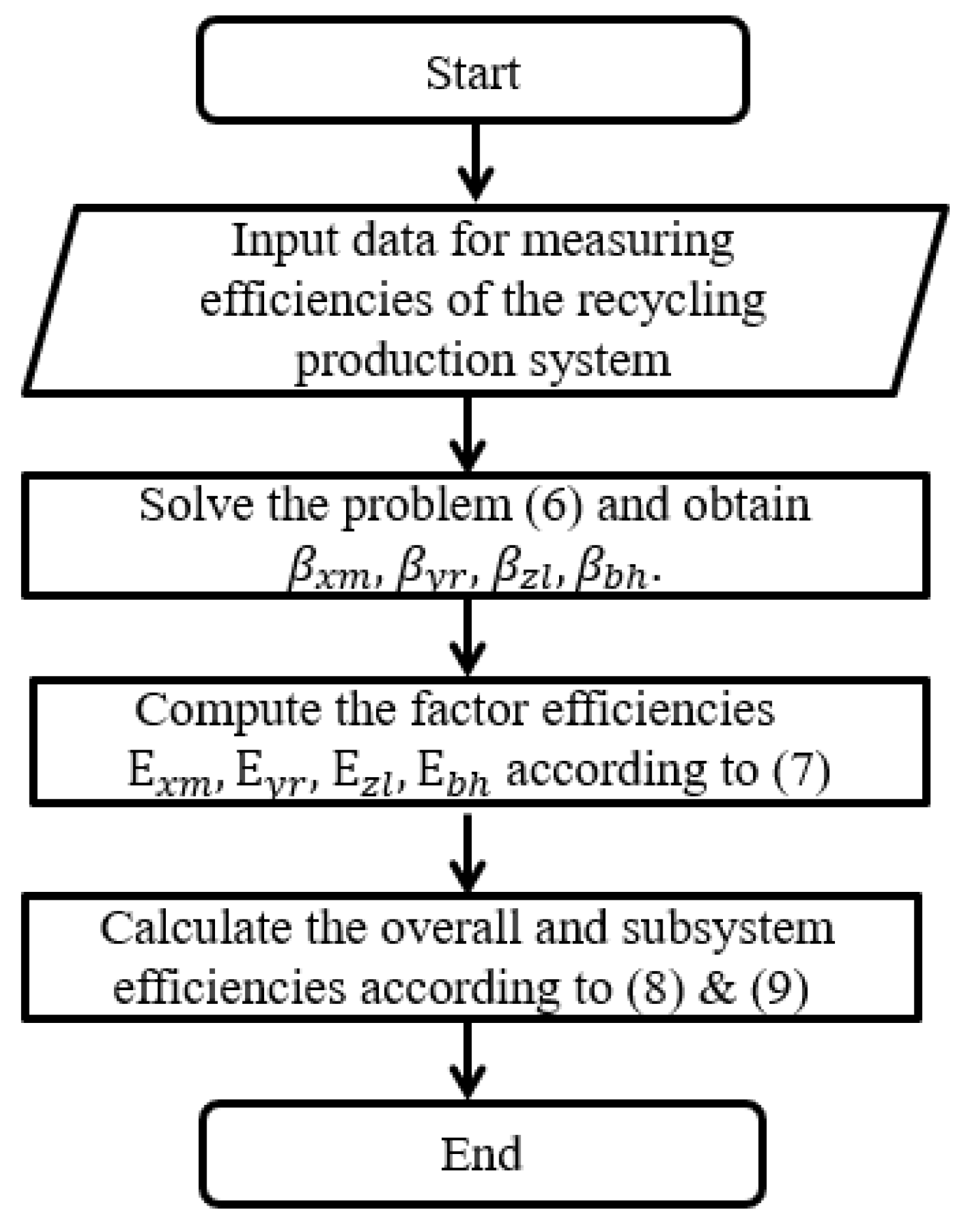

3. A Cooperative Game Network DEA Model for Efficiency Measurement of the Recycling Production System

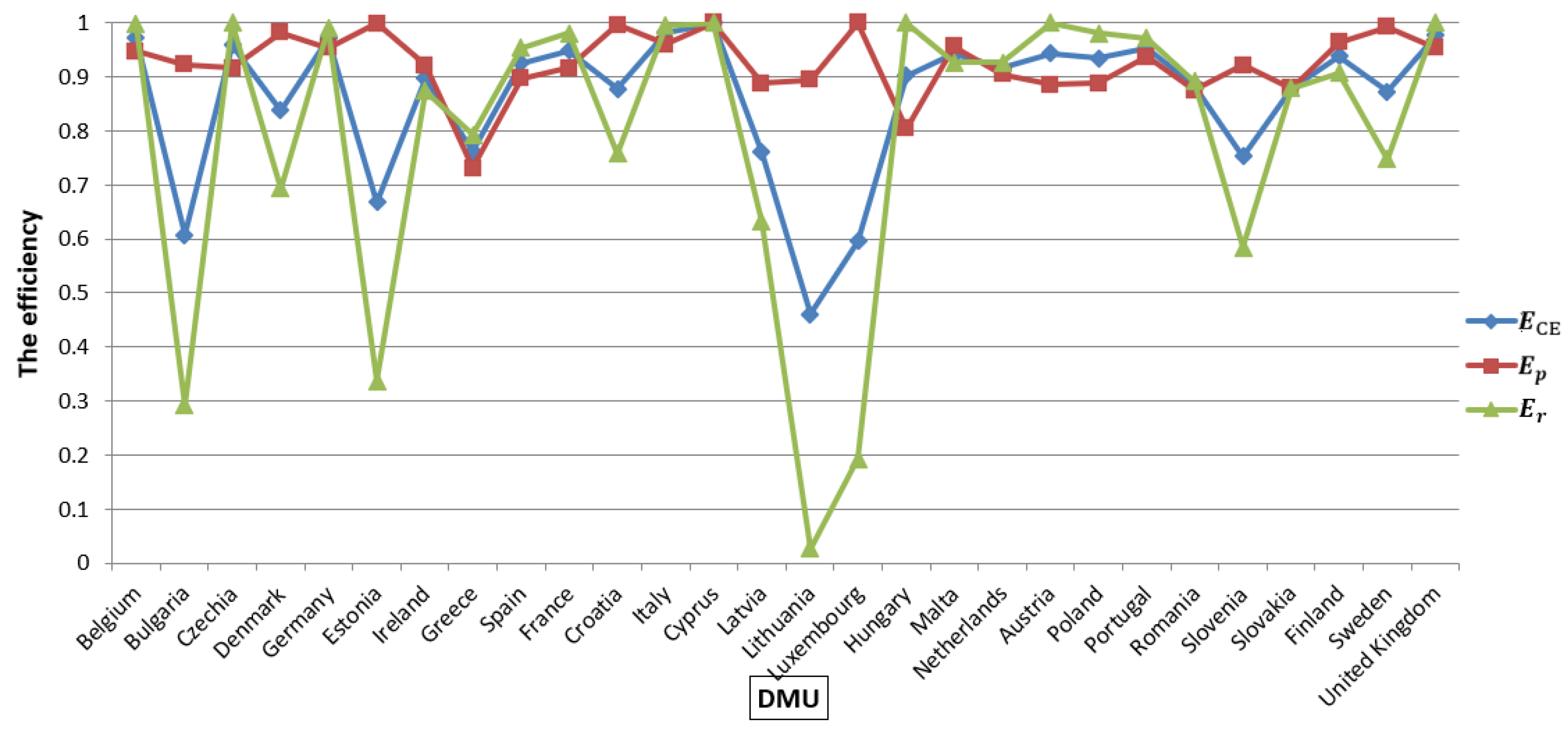

4. An Application to Assessing the Circular Economy of EU Countries

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Simon, B. What are the most significant aspects of supporting the circular economy in the plastic industry? Resour. Conserv. Recy. 2019, 141, 299–300. [Google Scholar] [CrossRef]

- Fan, Y.; Fang, C. Circular economy development in China-current situation, evaluation and policy implications. Environ. Impact Assess. Rev. 2020, 84, 106441. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Chen, W.; Liu, W.J.; Geng, Y.; Ohnishi, S.; Sun, L.; Han, W.Y.; Tian, X.; Zhong, S.Z. Life cycle based emergy analysis on China’s cement production. J. Clean. Prod. 2016, 131, 1–8. [Google Scholar] [CrossRef]

- Sun, L.; Li, H.; Dong, L.; Fang, K.; Ren, J.Z.; Geng, Y.; Fujii, M.; Zhang, W.; Zhang, N.; Liu, Z. Eco-benefits assessment on urban industrial symbiosis based on material flows analysis and emergy evaluation approach: A case of Liuzhou city, China. Resour. Conserv. Recy. 2017, 119, 78–88. [Google Scholar] [CrossRef] [Green Version]

- Mikulcic, H.; Cabezas, H.; Vujanovic, M.; Duic, N. Environmental assessment of different cement manufacturing processes based on emergy and ecological footprint analysis. J. Clean. Prod. 2016, 130, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Castelli, L.; Pesenti, R.; Ukovich, W. DEA-like models for the efficiency evaluation of hierarchically structured units. Eur. J. Oper. Res. 2004, 154, 465–476. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S. Network DEA. Socio Econ. Plan. Sci. 2000, 4, 35–49. [Google Scholar] [CrossRef]

- Cook, W.D.; Liang, L.; Zhu, J. Measuring performance of two-stage network structures by DEA: A review and future perspective. Omega 2010, 38, 423–430. [Google Scholar] [CrossRef]

- Li, H.; Chen, C.; Cook, W.D.; Zhang, J.; Zhu, J. Two-stage network DEA: Who is the leader? Omega 2018, 74, 15–19. [Google Scholar] [CrossRef]

- Liang, L.; Yang, F.; Cook, W.D.; Zhu, J. DEA models for supply chain efficiency evaluation. Ann. Oper. Res. 2006, 145, 35–49. [Google Scholar] [CrossRef]

- Liang, L.; Cook, W.D.; Zhu, J. DEA models for two-stage processes: Game approach and efficiency decomposition. Nav. Res. Logist. 2008, 55, 643–653. [Google Scholar] [CrossRef]

- Sun, J.; Li, G.; Wang, Z. Technology heterogeneity and efficiency of China’s circular economic systems: A game meta-frontier DEA approach. Resour. Conserv. Recycl. 2019, 146, 337–347. [Google Scholar] [CrossRef]

- Ding, L.-L.; Lei, L.; Wang, L.; Zhang, L.; Calin, A.C. A novel cooperative game network DEA model for marine circular economy performance evaluation of China. Clean. Prod. 2020, 253, 120071. [Google Scholar] [CrossRef]

- Pearce, D.; Turner, R.K. Economics of Natural Resources and the Environment; The Johns Hopkins University Press: Baltimore, MD, USA, 1998. [Google Scholar]

- Wu, H.; Liu, Y.; Xia, Q.; Zhu, W. Measuring efficiency of recycling systems based on data envelopment analysis (DEA) network: A case from Chinese provincial circular economy. Environ. Eng. Manag. J. 2014, 13, 1089–1099. [Google Scholar]

- Zha, Y.; Liang, L. Two-stage cooperation model with input freely distributed among the stages. Eur. J. Oper. Res. 2010, 205, 332–338. [Google Scholar] [CrossRef]

- Tone, K.; Tsutsui, M. Dynamic DEA with network structure: A slacks-based measure approach. Omega 2014, 42, 124–131. [Google Scholar] [CrossRef] [Green Version]

- Färe, R.; Grosskopf, S.; Pasurka, S. Environmental production functions and environmental directional distance functions. Energy 2010, 32, 1055–1066. [Google Scholar] [CrossRef]

- Tone, K.; Tsutsui, M. Network DEA: A slacks-based measure approach. Eur. J. Oper. Res. 2009, 197, 243–252. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Yuan, Y.; Yang, R.; Ji, X.; Wu, J. Performance evaluation of Chinese port enterprises under significant environmental concerns: An extended DEA-based analysis. Transp. Policy 2017, 60, 75–86. [Google Scholar] [CrossRef]

- Wu, J.; Chu, J.; Zhu, Q.; Yin, P.; Liang, L. DEA cross-efficiency evaluation based on satisfaction degree: An application to technology selection. Int. J. Prod. Res. 2016, 54, 5990–6007. [Google Scholar] [CrossRef]

| DMU | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| BE | 5004.72 | 109,635.23 | 36,332.6 | 46,000 | 63,150,004 | 2246 | 401,821,505.1 | 260,944,420.8 | 4,855,292,916 | 0 | 796,941,524 |

| BG | 4025.73 | 9889.20 | 9662.7 | 20,900 | 120,510,053 | 262.2 | 11,377,402,360 | 1,228,940.446 | 624,743,431 | 0 | 47,630,543 |

| CZ | 5387.52 | 48,753.81 | 24,880.6 | 34,200 | 25,380,325 | 489.1 | 421,402,923.7 | 8,969,823.401 | 1,256,506,220 | 736,788,139 | 114,365,359 |

| DK | 3024.43 | 62,642.40 | 14,449.5 | 49,300 | 20,981,701 | 73.2 | 611,036,025.7 | 453,589.4241 | 1,077,685,765 | 0 | 408,994,682 |

| DE | 43,294.64 | 696,913.18 | 216,447.3 | 49,800 | 400,049,839 | 5139 | 7,258,425,559 | 474,079,860.6 | 17,091,404,085 | 10,641,085,528 | 4,539,988,852 |

| EE | 694.11 | 5212.53 | 2818.3 | 30200 | 24,277,641 | 39.5 | 1,571,046,418 | 7207.720416 | 523,501,743 | 271,321,686 | 61,887,076 |

| IE | 2248.29 | 97,003.40 | 11,609.7 | 69,100 | 15,483,387 | 11.4 | 595,176,663.3 | 3,974,931.141 | 163,521,509 | 712,096,348 | 73,569,252 |

| EL | 4906.56 | 22,630.08 | 16,702.7 | 27,400 | 69,009,312 | 1045 | 6,101,405,554 | 2,254,867.174 | 223,834,033 | 559,291,350 | 14,145,383 |

| ES | 23,016.54 | 247,385.30 | 82,497.8 | 37,200 | 128,946,782 | 5561 | 6,917,730,969 | 1,630,152.259 | 4,782,727,890 | 729,903,060 | 462,686,172 |

| FR | 30,319.99 | 539,810.88 | 147,158.6 | 43,200 | 323,467,567 | 10,927 | 8,912,319,950 | 529,931,991.7 | 17,805,492,324 | 3,347,460,780 | 1,751,551,681 |

| HR | 1833.27 | 10,352.94 | 6639 | 23,800 | 5,280,553 | 3 | 252,644,927.4 | 8025.833542 | 248,979,558 | 21,330,946 | 5,091,818 |

| IT | 25,584.17 | 318,657.86 | 115,930.6 | 37,600 | 163,997,388 | 10,323.1 | 2,330,759,325 | 44,806,8861.9 | 12,940,757,588 | 16,749,969 | 663,403,006 |

| CY | 611.51 | 3610.62 | 1758 | 36,100 | 3,384,016 | 37.6 | 195,647,721.8 | 0 | 35,308,927 | 94,608,345 | 1,2836,602 |

| LV | 1008.67 | 5019.44 | 3820.3 | 26,200 | 2,531,726 | 86.5 | 5,151,4453.72 | 27,299.07299 | 181,524,359 | 2,877,570 | 17,228,886 |

| LT | 1481.03 | 8090.61 | 5108.4 | 6,645,689 | 146.3 | 376,219,111.1 | 265,115.2405 | 222,175,413 | 27,546,012 | 38,363,239 | |

| LU | 281.98 | 10,079.65 | 4038.9 | 105,400 | 136.6 | 394,682,009.3 | 447.388895 | 352,026,252 | 244,913,566 | 21,366,130 | |

| HU | 4686.10 | 24,195.73 | 17,865.2 | 28,300 | 15,908,526 | 159.2 | 544,534,135.6 | 9,173,793.23 | 861,341,728 | 58,137,346 | 117,665,638 |

| MT | 212.81 | 2613.15 | 583.7 | 40,100 | 1,971,253 | 58.6 | 33,840,198.53 | 729,659.0766 | 37,642,029 | 124,913,458 | 0 |

| NL | 9050.42 | 154,915.44 | 49,517 | 52,800 | 141,027,997 | 3827 | 6,484,656,382 | 123,312,495 | 6,429,380,745 | 0 | 1,065,450,090 |

| AT | 4535.20 | 90,187.98 | 28,127.9 | 49,000 | 61,226,583 | 174.5 | 2,809,451,363 | 1,867,412 | 2,264,108,063 | 675,844,441 | 1,867,412 |

| PL | 18,393.55 | 84,961.32 | 66,652 | 28,300 | 181,990,641 | 372.7 | 5,095,006,125 | 63,893,549.64 | 8,399,307,294 | 4,036,605,469 | 604,251,699 |

| PT | 5207.27 | 31,296.05 | 16,114.8 | 29,600 | 14,734,417 | 425.5 | 510,697,523.8 | 3,546,142.319 | 640,596,720 | 140,172,510 | 178,428,819 |

| RO | 8939.35 | 43,109.53 | 22,280.2 | 22,900 | 177,557,398 | 508.3 | 1,670,2885,666 | 10,101,348.96 | 714,524,681 | 77,559,190 | 250,668,909 |

| SI | 996.96 | 7859.45 | 4875.5 | 32,900 | 5,517,787 | 42.1 | 38,252,271.38 | 4,285,174.818 | 332,376,636 | 150,325,015 | 26,539,590 |

| SK | 2762.41 | 19,021.79 | 10,418.4 | 32,000 | 10,606,352 | 319.7 | 50,6588,801 | 4,865,030.324 | 424,682,144 | 49,836,276 | 74,662,989 |

| FI | 2687.20 | 51,490.26 | 25,248.8 | 43,400 | 122,869,413 | 75 | 10,816,368,847 | 5,368,598.21 | 908,084,245 | 0 | 557,119,580 |

| SE | 5245.27 | 123,749.83 | 32,590.9 | 50,800 | 141,622,198 | 760.1 | 10,806,010,637 | 22,813,777.52 | 1,702,475,279 | 694,274,083 | 936,645,999 |

| UK | 33,693.49 | 437,140.07 | 133,688.5 | 43,800 | 277,272,474 | 13,601.3 | 10,410,809,602 | 735,540,574 | 13,457,214,835 | 2,175,093,717 | 948,588,194 |

| Cooperative | Game | Network | Competitive | Game | |

|---|---|---|---|---|---|

| DEA | Network | DEA | |||

| DMU | |||||

| Belgium | 0.9723 (4) | 0.9471 (12) | 0.9976 (6) | 0.9999 (4) | 1.0000 (1) |

| Bulgaria | 0.6073 (26) | 0.9230 (14) | 0.2917 (26) | 1.0000 (1) | 0.9996 (7) |

| Czechia | 0.9586 (6) | 0.9172 (17) | 1.0000 (1) | 0.4174 (20) | 1.0000 (1) |

| Denmark | 0.8379 (21) | 0.9820 (6) | 0.6937 (22) | 0.7913 (18) | 1.0000 (1) |

| Germany | 0.9721 (5) | 0.9545 (10) | 0.9897 (8) | 0.2953 (22) | 1.0000 (1) |

| Estonia | 0.6681 (25) | 0.9996 (3) | 0.3366 (25) | 1.0000 (1) | 1.0000 (1) |

| Ireland | 0.8978 (16) | 0.9220 (15) | 0.8736 (18) | 0.0004 (28) | 0.6504 (28) |

| Greece | 0.7620 (22) | 0.7306 (28) | 0.7935 (19) | 0.9985 (7) | 0.9930 (15) |

| Spain | 0.9251 (13) | 0.8967 (20) | 0.9535 (12) | 0.1901 (25) | 0.9849 (18) |

| France | 0.9484 (8) | 0.9162 (18) | 0.9806 (10) | 0.0652 (27) | 0.9475 (25) |

| Croatia | 0.8773 (19) | 0.9964 (4) | 0.7583 (20) | 0.9918 (11) | 0.9697 (22) |

| Italy | 0.9819 (2) | 0.9609 (8) | 0.9948 (7) | 0.2311 (23) | 0.9609 (23) |

| Cyprus | 1.0000 (1) | 1.0000 (1) | 1.0000 (1) | 0.9691 (14) | 0.9797 (19) |

| Latvia | 0.7606 (23) | 0.8888 (22) | 0.6323 (23) | 0.8972 (16) | 0.9338 (27) |

| Lithuania | 0.4608 (28) | 0.8945 (21) | 0.0268 (28) | 0.9180 (15) | 0.9947 (14) |

| Luxembourg | 0.5961 (27) | 1.0000 (1) | 0.1922 (27) | 0.9998 (5) | 0.9351 (26) |

| Hungary | 0.9023 (15) | 0.8047 (27) | 0.9999 (5) | 0.3370 (21) | 0.9969 (12) |

| Malta | 0.9417 (10) | 0.9565 (9) | 0.9269 (14) | 0.9933 (9) | 0.9579 (24) |

| Netherlands | 0.9161 (14) | 0.9049 (19) | 0.9271 (13) | 0.9993 (6) | 0.9988 (8) |

| Austria | 0.9430 (9) | 0.8860 (24) | 1.0000 (1) | 0.9965 (8) | 0.9965 (13) |

| Poland | 0.9347 (12) | 0.8879 (23) | 0.9816 (9) | 0.9817 (12) | 0.9925 (16) |

| Portugal | 0.9542 (7) | 0.9366 (13) | 0.9718 (11) | 0.1420 (26) | 0.9909 (17) |

| Romania | 0.8840 (17) | 0.8760 (26) | 0.8920 (16) | 0.9794 (13) | 0.9978 (11) |

| Slovenia | 0.7530 (24) | 0.9215 (16) | 0.5846 (24) | 0.9926 (10) | 0.9979 (10) |

| Slovakia | 0.8792 (18) | 0.8796 (25) | 0.8789 (17) | 0.2240 (24) | 0.9792 (20) |

| Finland | 0.9385 (11) | 0.9637 (7) | 0.9079 (15) | 1.0000 (1) | 1.0000 (1) |

| Sweden | 0.8729 (20) | 0.9932 (5) | 0.7482 (21) | 0.7069 (19) | 0.9777 (21) |

| United Kingdom | 0.9771 (3) | 0.9542 (11) | 1.0000 (1) | 0.8728 (17) | 0.9987 (9) |

| Average | 0.8615 | 0.9251 | 0.7976 0.7139 | 0.9726 |

| DMU | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Belgium | 0.9471 | 0.9972 | 0.9981 | 0.9992 | 0.9489 | 0.9976 | 0.9993 | 0.9968 | 0.9998 |

| Bulgaria | 0.9229 | 0.9972 | 0.9827 | 0.9975 | 0.9299 | 0.2917 | 0.2944 | 0.9817 | 0.9997 |

| Czechia | 0.9172 | 0.9704 | 0.9707 | 0.9844 | 0.9406 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| Denmark | 0.9820 | 0.9977 | 0.9983 | 0.9992 | 0.9836 | 0.6937 | 0.6939 | 0.9995 | 1.0000 |

| Germany | 0.9545 | 0.9997 | 1.0000 | 0.9998 | 0.9547 | 0.9897 | 0.9900 | 0.9994 | 1.0000 |

| Estonia | 0.9996 | 0.9999 | 0.9999 | 1.0000 | 0.9997 | 0.3365 | 0.3366 | 0.9996 | 1.0000 |

| Ireland | 0.9220 | 0.9951 | 0.9793 | 0.9866 | 0.9341 | 0.8737 | 0.9821 | 0.7793 | 0.9999 |

| Greece | 0.7306 | 0.9915 | 0.9916 | 0.9868 | 0.7380 | 0.7936 | 0.7993 | 0.9858 | 0.9998 |

| Spain | 0.8967 | 0.9487 | 0.9471 | 0.9753 | 0.9369 | 0.9534 | 0.9996 | 0.9076 | 1.0000 |

| France | 0.9162 | 0.9963 | 0.9409 | 0.9984 | 0.9363 | 0.9806 | 1.0000 | 0.9612 | 1.0000 |

| Croatia | 0.9964 | 0.9975 | 0.9982 | 0.9978 | 0.9986 | 0.7582 | 0.7831 | 0.9365 | 1.0000 |

| Italy | 0.9690 | 0.9989 | 0.9984 | 0.9993 | 0.9701 | 0.9949 | 0.9967 | 0.9965 | 0.9998 |

| Cyprus | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| Latvia | 0.8888 | 0.8970 | 0.9504 | 0.9323 | 0.9592 | 0.6323 | 0.7941 | 0.5926 | 0.9986 |

| Lithuania | 0.8948 | 0.8846 | 0.9663 | 0.9340 | 0.9640 | 0.0268 | 0.0322 | 0.6666 | 0.9999 |

| Luxembourg | 0.9998 | 0.9999 | 0.9999 | 1.0000 | 0.9999 | 0.1923 | 0.1923 | 0.9997 | 1.0000 |

| Hungary | 0.8047 | 0.8840 | 0.9840 | 0.9361 | 0.8608 | 0.9999 | 1.0000 | 0.9998 | 1.0000 |

| Malta | 0.9565 | 0.9600 | 0.9741 | 0.9869 | 0.9823 | 0.9270 | 0.9974 | 0.8589 | 0.9999 |

| Netherlands | 0.9049 | 0.9887 | 0.9905 | 0.9990 | 0.9115 | 0.9237 | 0.9747 | 0.9034 | 0.9995 |

| Austria | 0.8860 | 0.9875 | 0.9429 | 0.9732 | 0.9154 | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| Poland | 0.8879 | 0.9987 | 0.9960 | 0.9990 | 0.8898 | 0.9815 | 0.9823 | 0.9991 | 0.9993 |

| Portugal | 0.9366 | 0.9731 | 0.9909 | 0.9857 | 0.9526 | 0.9718 | 1.0000 | 0.9435 | 1.0000 |

| Romania | 0.8760 | 0.9790 | 0.9818 | 0.9950 | 0.8891 | 0.8920 | 0.9030 | 0.9762 | 0.9995 |

| Slovenia | 0.9215 | 0.9188 | 0.9569 | 0.8977 | 0.9968 | 0.5845 | 0.9958 | 0.1745 | 0.9995 |

| Slovakia | 0.8796 | 0.8457 | 0.9149 | 0.8833 | 0.9981 | 0.8789 | 0.9822 | 0.7898 | 0.9998 |

| Finland | 0.9637 | 0.9976 | 0.9973 | 0.9983 | 0.9659 | 0.9079 | 0.9199 | 0.9742 | 0.9997 |

| Sweden | 0.9932 | 0.9953 | 0.9942 | 0.9973 | 0.9976 | 0.7498 | 0.7856 | 0.9095 | 0.9994 |

| United Kingdom | 0.9542 | 0.9582 | 0.9338 | 0.9926 | 0.9924 | 0.9999 | 1.0000 | 0.9999 | 1.0000 |

| Average | 0.9251 | 0.9699 | 0.9778 | 0.9798 | 0.9481 | 0.7976 | 0.8368 | 0.9047 | 0.9998 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.-C.; Hu, C.-F. Performance Measurement for the Recycling Production System Using Cooperative Game Network Data Envelopment Analysis. Sustainability 2021, 13, 11060. https://doi.org/10.3390/su131911060

Huang H-C, Hu C-F. Performance Measurement for the Recycling Production System Using Cooperative Game Network Data Envelopment Analysis. Sustainability. 2021; 13(19):11060. https://doi.org/10.3390/su131911060

Chicago/Turabian StyleHuang, Huang-Chu, and Cheng-Feng Hu. 2021. "Performance Measurement for the Recycling Production System Using Cooperative Game Network Data Envelopment Analysis" Sustainability 13, no. 19: 11060. https://doi.org/10.3390/su131911060