Comparative Environmental Life Cycle and Cost Assessment of Electric, Hybrid, and Conventional Vehicles in Lithuania

Abstract

:1. Introduction

2. Methodology

2.1. Scope of Analysis and Life Cycle Impact Assessment Method for the LCA

2.2. Scope and Costs Assessment Method for the LCC

2.3. Inventory Analysis

Inventory Analysis Regarding Electricity Mix Production

3. Results and Discussion

3.1. Midpoint Results of the LCA

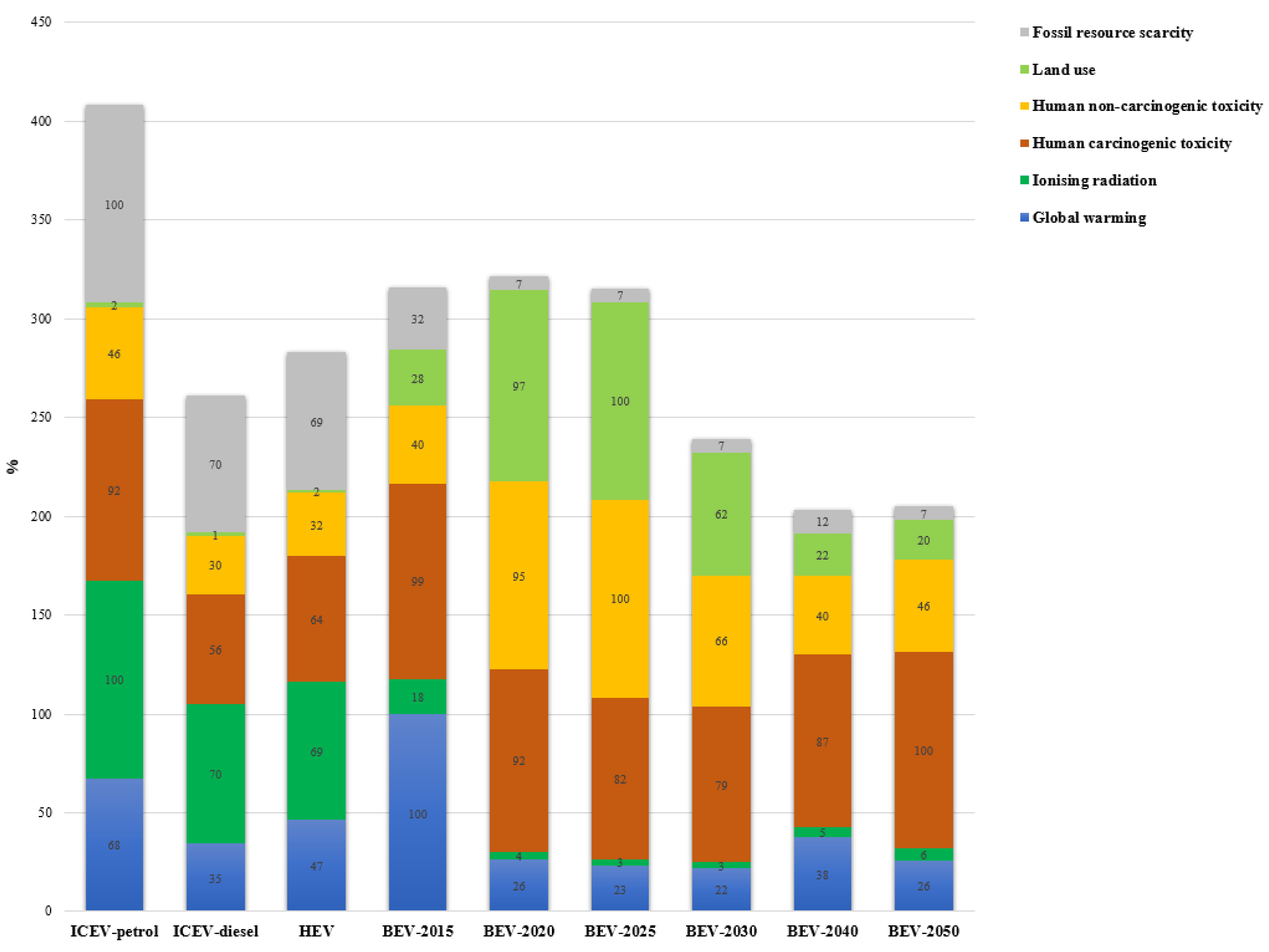

3.2. Comparative Well-to-Wheel Results of BEV (Electricity Mix Scenarios 2015–2050), HEV, and ICEVs at the Midpoint Level

3.3. Endpoint Results of the LCA

3.4. Results of the Life Cycle Costing

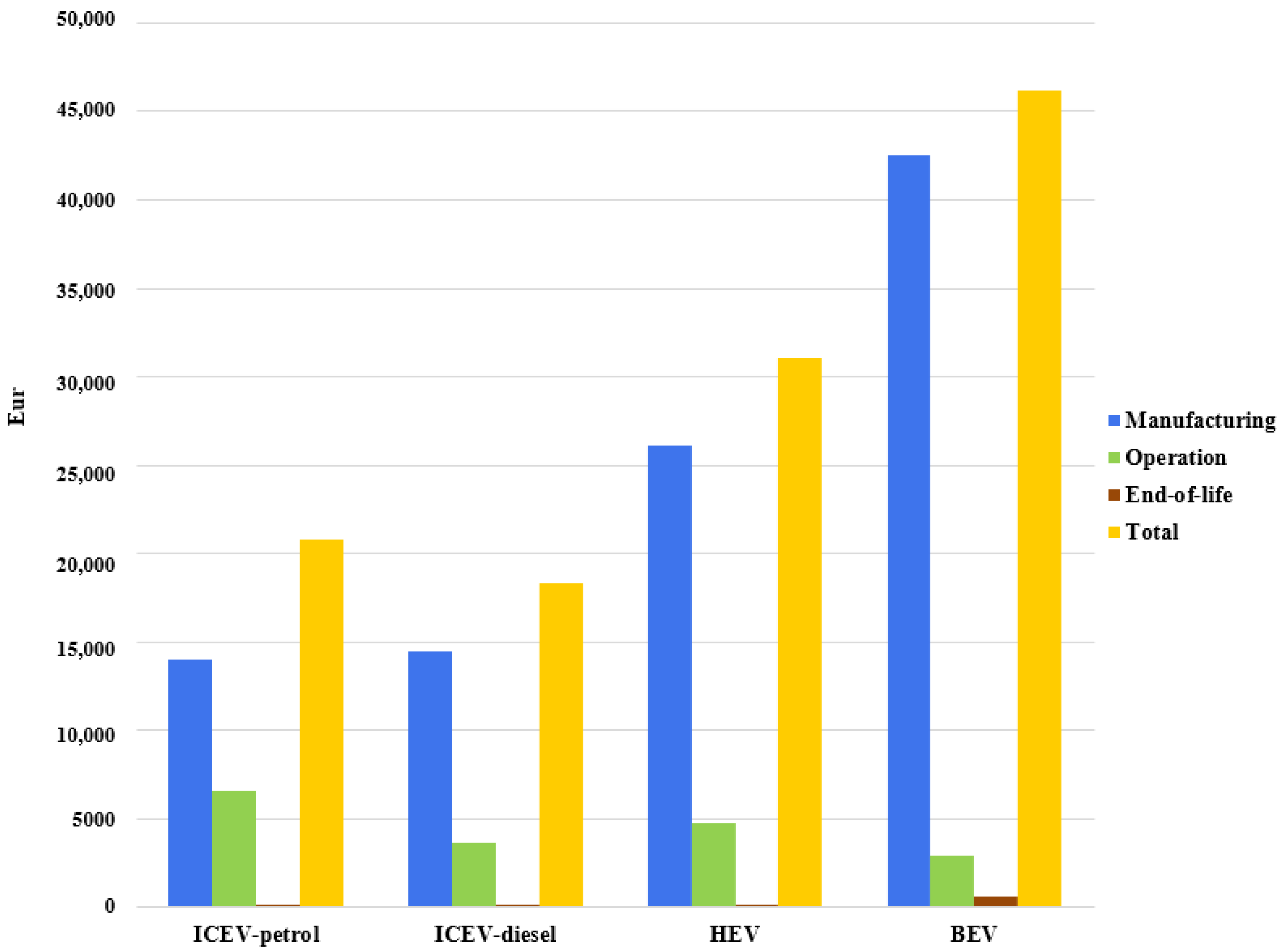

3.4.1. Results of the LCC from Consumer Side

3.4.2. Results of the LCC from Manufacturer Side

3.4.3. Electricity Production Costs for 2020 and 2040 Scenarios

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- European Commission. Climate strategies & Targets. 2018. Available online: https://ec.europa.eu/clima/policies/strategies (accessed on 26 November 2020).

- European Commission. Communication and Roadmap on the European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- EUROSTAT. Statistics Explained. Climate Change-Driving Forces. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Climate_change_-_driving_forces&oldid=461591#General_overview (accessed on 24 November 2020).

- Environmental Protection Agency. Lithuania‘s National Inventory Report 2020; Greenhouse Gas Emissions 1990–2018; Environmental Protection Agency: Vilnius, Lithuania, 2020.

- European Commission. The EU Environmental Implementation Review Country Report-LITHUANIA; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- State Enterprise “Regitra”. Statistics on Vehicles Registered in Lithuania. 2020. Available online: https://www.regitra.lt/lt/paslaugos/duomenu-teikimas/statistika/transporto-priemones-2 (accessed on 1 January 2021).

- European Environmental Agency. Electric Vehicles from Life Cycle and Circular Economy Perspectives; TERM 2018: Transport and Environment Reporting Mechanism (TERM) Report; European Environmental Agency: Copenhagen, Denmark, 2018.

- European Commission. Electrification of the Transport System; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Burchart-Korol, D.; Jursova, S.; Folęga, P.; Pustejovska, P. Life cycle impact assessment of electric vehicle battery charging in European Union countries. J. Clean. Prod. 2020, 257, 120476. [Google Scholar] [CrossRef]

- Del Pero, F.; Delogu, M.; Pierini, M. Life Cycle Assessment in the automotive sector: A comparative case study of Internal Combustion Engine (ICE) and electric car. Procedia Struct. Integr. 2018, 12, 521–537. [Google Scholar] [CrossRef]

- Choi, H.; Shin, J.; Woo, J. Effect of electricity generation mix on battery electric vehicle adoption and its environmental impact. Energy Policy 2018, 121, 13–24. [Google Scholar] [CrossRef]

- Athanasopoulou, L.; Bikas, H.; Stavropoulos, P. Comparative Well-to-Wheel Emissions Assessment of Internal Combustion Engine and Battery Electric Vehicles. Procedia CIRP 2018, 78, 25–30. [Google Scholar] [CrossRef]

- Renewable Energy Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Renewable_energy_statistics (accessed on 24 November 2020).

- Ministry of Energy of the Republic of Lithuania. Statistics of Renewable Energy Resources. 2020. Available online: http://enmin.lrv.lt/lt/veiklos-sritys-3/atsinaujinantys-energijos-istekliai/statistika (accessed on 22 November 2020).

- Ministry of Energy of the Republic of Lithuania. National Energy Independence Strategy; Ministry of Energy of the Republic of Lithuania: Vilnius, Lithuania, 2018. [Google Scholar]

- National Energy and Climate Action Plan of the Republic of Lithuania for 2021–2030. Available online: https://am.lrv.lt/uploads/am/documents/files/KLIMATO%20KAITA/Integruotas%20planas/Final%20NECP.pdf (accessed on 1 January 2021).

- European Automobile Manufacturers Association. New Passenger Car Registrations by Fuel Type in the European Union. 2020. Available online: https://www.acea.be/uploads/press_releases_files/20201105_PRPC_fuel_Q3_2020_FINAL.pdf (accessed on 1 January 2021).

- The Environmental Projects Management Agency under the Ministry of Environment of the Republic of Lithuania. Promoting the Purchase of Electric Vehicles by Individuals. 2020. Available online: https://www.apva.lt/ (accessed on 17 December 2020).

- The Environmental Projects Management Agency under the Ministry of Environment of the Republic of Lithuania. Invitation to Purchase a Lower Pollution Car. 2020. Available online: https://www.apva.lt/ (accessed on 17 December 2020).

- The Environmental Projects Management Agency under the Ministry of Environment of the Republic of Lithuania. Business Support for the Purchase of New Electric Cars and Buses. 2020. Available online: https://www.apva.lt/ (accessed on 17 December 2020).

- Petrauskiene, K.; Dvarioniene, J.; Kaveckis, G.; Kliaugaite, D.; Chenadec, J.; Hehn, L.; Pérez, B.; Bordi, C.; Scavino, G.; Vignoli, A.; et al. Situation analysis of policies for electric mobility development: Experience from five European regions. Sustainability 2020, 12, 2935. [Google Scholar] [CrossRef] [Green Version]

- Hauschild, M.Z.; Rosenbaum, R.K.; Olsen, S.I. Life Cycle Assessment: Theory and Practice; Springer Nature: Cham, Switzerland, 2018. [Google Scholar]

- Kambanou, M.L. Life Cycle Costing: Understanding How It Is Practised and Its Relationship to Life Cycle Management—A Case Study. Sustainability 2020, 12, 3252. [Google Scholar] [CrossRef] [Green Version]

- Visentin, C.; Trentin, A.W.S.; Braun, B.A.; Thomé, A. Life cycle sustainability assessment: A systematic literature review through the application perspective, indicators, and methodologies. J. Clean. Prod. 2020, 270, 122509. [Google Scholar] [CrossRef]

- Fauzi, R.T.; Lavoie, P.; Sorelli, L.; Heidari, M.D.; Amor, B. Exploring the Current Challenges and Opportunities of Life Cycle Sustainability Assessment. Sustainability 2019, 11, 636. [Google Scholar] [CrossRef] [Green Version]

- Kara, S.; Li, W.; Sadjiva, N. Life Cycle Cost Analysis of Electrical Vehicles in Australia. Procedia CIRP 2017, 61, 767–772. [Google Scholar] [CrossRef]

- Prud’homme, R.; Koning, M. Electric vehicles: A tentative economic and environmental evaluation. Transp. Policy 2012, 23, 60–69. [Google Scholar] [CrossRef] [Green Version]

- Bubeck, S.; Tomaschek, J.; Fahl, U. Perspectives of electric mobility: Total cost of ownership of electric vehicles in Germany. Transp. Policy 2016, 50, 63–77. [Google Scholar] [CrossRef]

- Wu, G.; Inderbitzin, A.; Bening, C. Total cost of ownership of electric vehicles compared to conventional vehicles: A probabilistic analysis and projection across market segments. Energy Policy 2015, 80, 196–214. [Google Scholar] [CrossRef]

- Bekel, K.; Pauliuk, S. Prospective cost and environmental impact assessment of battery and fuel cell electric vehicles in Germany. Int. J. Life Cycle Assess. 2019, 24, 2220–2237. [Google Scholar] [CrossRef]

- Danielis, R.; Giansoldati, M.; Rotaris, L. A probabilistic total cost of ownership model to evaluate the current and future prospects of electric cars uptake in Italy. Energy Policy 2018, 119, 268–281. [Google Scholar] [CrossRef]

- Cox, B.; Bauer, C.; Beltran, A.M.; van Vuuren, D.P.; Mutel, C.L. Life cycle environmental and cost comparison of current and future passenger cars under different energy scenarios. Appl. Energy 2020, 269, 115021. [Google Scholar] [CrossRef]

- Gilmore, E.A.; Lave, L.B. Comparing resale prices and total cost of ownership for gasoline, hybrid and diesel passenger cars and trucks. Transp. Policy 2013, 27, 200–2008. [Google Scholar] [CrossRef]

- Mitropoulos, L.K.; Prevedouros, P.D.; Kopelias, P. Total cost of ownership and externalities of conventional, hybrid and electric vehicle. Transp. Res. Procedia 2017, 24, 267–274. [Google Scholar] [CrossRef]

- Mitropoulos, L.K.; Prevedouros, P.D. Life cycle emissions and cost model for urban light duty vehicles. Transp. Res. Part D 2015, 41, 147–159. [Google Scholar] [CrossRef]

- Traut, E.; Hendrickson, C.; Klampfl, E.; Liu, Y.; Michalek, J.J. Optimal design and allocation of electrified vehicles and dedicated charging infrastructure for minimum life cycle greenhouse gas emissions and cost. Energy Policy 2012, 51, 524–534. [Google Scholar] [CrossRef]

- ISO 14040. Environmental Management-Life Cycle Assessment-Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044. Environmental Management-Life Cycle Assessment-Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Nissan Leaf Representative in Lithuania. Nissan Leaf Technical Specifications and Price-List. 2020. Available online: https://www-europe.nissan-cdn.net/content/dam/Nissan/lt/brochures/lt_pricesandspec/LEAF_Klientų_kainininkai_MY19.pdf (accessed on 24 November 2020).

- Yang, Z.; Wang, B.; Jiao, K. Life cycle assessment of fuel cell, electric and internal combustion engine vehicles under different fuel scenarios and driving mileages in China. Energy 2020, 198, 117365. [Google Scholar] [CrossRef]

- Tagliaferri, C.; Evangelisti, S.; Acconcia, F.; Domenech, T.; Ekins, P.; Barletta, D.; Lettieri, P. Life cycle assessment of future electric and hybrid vehicles: A cradle-to-grave systems engineering approach. Chem. Eng. Res. Des. 2016, 112, 298–309. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Jursova, S.; Folęga, P.; Korol, J.; Pustejovska, P.; Blaut, A. Environmental life cycle assessment of electric vehicles in Poland and the Czech Republic. J. Clean. Prod. 2018, 202, 476–487. [Google Scholar] [CrossRef]

- National Institute for Public Health and the Environment. A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization; ReCiPe 2016 v1.1; RIVM: Bilthoven, The Netherlands, 2017.

- Swiss Centre for Life Cycle Inventories. Ecoinvent Database v3.5. 2019. Available online: https://www.ecoinvent.org/ (accessed on 10 November 2020).

- PRé Sustainability. SimaPro-LCA Software for Fact-Based Sustainability. 2020. Available online: https://simapro.com/ (accessed on 20 November 2020).

- GreenDelta. openLCA-Open Source Life Cycle Assessment Software. 2020. Available online: https://www.openlca.org/ (accessed on 21 November 2020).

- Electric Vehicle Database. Technical Specification of Nissan Leaf. 2019. Available online: https://ev-database.org/car/1106/Nissan-Leaf (accessed on 25 November 2020).

- Volkswagen Representative in Lithuania. Volkswagen Golf Technical Specifications and Price-List. 2020. Available online: https://www.volkswagen.lt/lt/models-and-configurator/golf-8.html#MOFA (accessed on 20 November 2020).

- JSC, Mototoja. Toyota Prius Technical Specifications and Price-List. 2020. Available online: https://www.mototoja.lt/toyota/lt/toyota-modeliai1126/toyota-modeliai2/car-14 (accessed on 18 November 2020).

- Lithuanian Energy Institute. Evaluation of the Implementation of Energy Policies listed in the National Energy Independence Strategy Project; Lithuanian Energy Institute: Kaunas, Lithuania, 2017. [Google Scholar]

- Statistics Lithuania. Electricity Prices for Household Consumers. 2020. Available online: https://osp.stat.gov.lt/statistiniu-rodikliu-analize#/ (accessed on 26 November 2020).

| Parameter | Value |

|---|---|

| Fuel | Electricity |

| Car body | Hatchback |

| Height | 1530 mm |

| Length | 4490 mm |

| Width | 1788 mm |

| Battery capacity | 40 kWh |

| Battery weight | 296 kg |

| Vehicle weight without battery | 1249 kg |

| Vehicle energy consumption (WLTP) | 20.6 kWh/100 km |

| Parameter | Value | Value | Value |

|---|---|---|---|

| Fuel | Petrol | Diesel | Petrol/electricity |

| Engine | 1.5 TSI ACT (150 Hp), 1498 cm3 | 2.0 TDI (115 Hp), 1968 cm3 | 1.8 (99 Hp) 1798 cm3 |

| Car body | Hatchback | Hatchback | Hatchback |

| Length | 4284 mm | 4284 mm | 4540 mm |

| Width | 1789 mm | 1789 mm | 1760 mm |

| Height | 1456 mm | 1456 mm | 1490 mm |

| Kerb weight | 1265 kg | 1305 kg | 1375 kg |

| Fuel consumption (combined) (WLTP) | 6.2–6.5 L/100 km | 4.1 L/100 km | 4.2–4.6 L/100 km |

| Emission standard | EURO 6 | EURO 6 | EURO 6 |

| Unit, % | 2015 | 2020 | 2025 | 2030 | 2040 | 2050 |

|---|---|---|---|---|---|---|

| Waste | 2.28 | 6.63 | 4.16 | 2.50 | 1.79 | 1.28 |

| Biogas | 3.51 | 4.79 | 1.75 | 0.57 | 0.97 | 1.13 |

| Biomass | 5.85 | 24.12 | 25.18 | 15.56 | 4.97 | 4.49 |

| Natural gas | 41.73 | 10.33 | 10.67 | 11.09 | 19.90 | 7.28 |

| Hydro | 20.55 | 6.97 | 5.28 | 4.44 | 6.34 | 5.72 |

| Wind | 14.56 | 36.76 | 38.58 | 52.40 | 34.86 | 33.61 |

| Solar | 1.76 | 5.96 | 11.71 | 11.83 | 30.00 | 45.57 |

| Geothermal | 5.19 | 4.45 | 2.68 | 1.60 | 1.17 | 0.93 |

| Oil | 4.57 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Total Consumer Life Cycle Costs | ||||||||

|---|---|---|---|---|---|---|---|---|

| Passenger Vehicle | Manufacturing Phase | Operation Phase | End-of-Life Phase | Revenues | Total Costs, Eur/150,000 km | Total Cost, Eur/km | ||

| Acquisition Price, Eur | Registration Tax, Eur | Fuel Price, Eur/150,000 km | Maintenance, Eur/150,000 km | Deregistration Tax, Eur | Compensation | |||

| ICEV-petrol | 22,328 | 21.68 | 10,954 | 1186 | 2.9 | 0 | 34,492 | 0.23 |

| ICEV-diesel | 23,831 | 21.68 | 6581 | 1072 | 2.9 | 0 | 31,508 | 0.21 |

| HEV | 28,190 | 21.68 | 7590 | 2034 | 2.9 | 0 | 37,839 | 0.25 |

| BEV | 31,880 | 21.68 | 4017 | 817 | 2.9 | −4000 | 32,739 | 0.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrauskienė, K.; Galinis, A.; Kliaugaitė, D.; Dvarionienė, J. Comparative Environmental Life Cycle and Cost Assessment of Electric, Hybrid, and Conventional Vehicles in Lithuania. Sustainability 2021, 13, 957. https://doi.org/10.3390/su13020957

Petrauskienė K, Galinis A, Kliaugaitė D, Dvarionienė J. Comparative Environmental Life Cycle and Cost Assessment of Electric, Hybrid, and Conventional Vehicles in Lithuania. Sustainability. 2021; 13(2):957. https://doi.org/10.3390/su13020957

Chicago/Turabian StylePetrauskienė, Kamilė, Arvydas Galinis, Daina Kliaugaitė, and Jolanta Dvarionienė. 2021. "Comparative Environmental Life Cycle and Cost Assessment of Electric, Hybrid, and Conventional Vehicles in Lithuania" Sustainability 13, no. 2: 957. https://doi.org/10.3390/su13020957