Evaluation of Soil–Structure Interaction in Structure Models via Shaking Table Test

Abstract

:1. Introduction

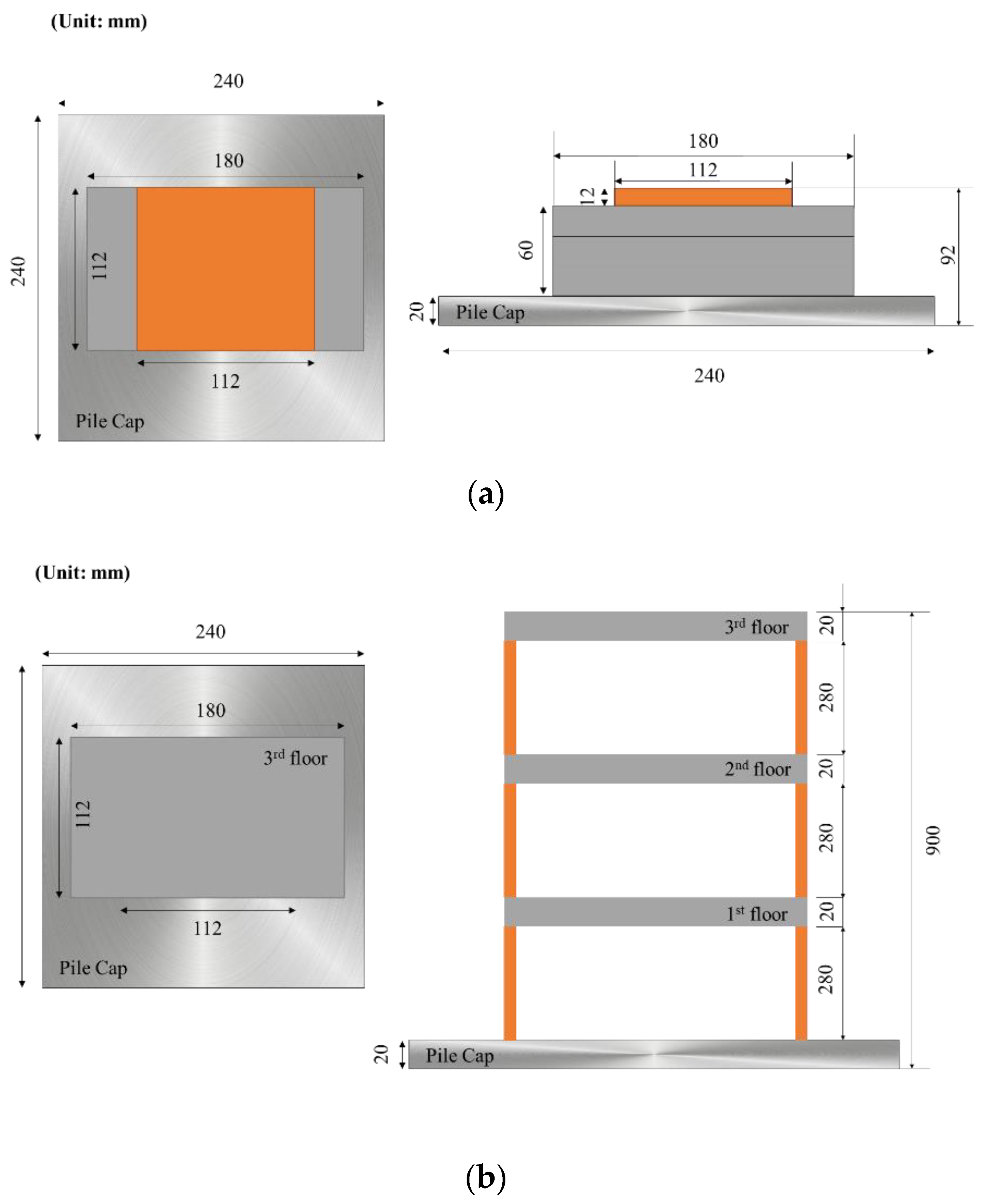

2. Model Test

2.1. Shaking Table Test

2.2. Test Model Similitude

2.3. Pile and Structure Properties

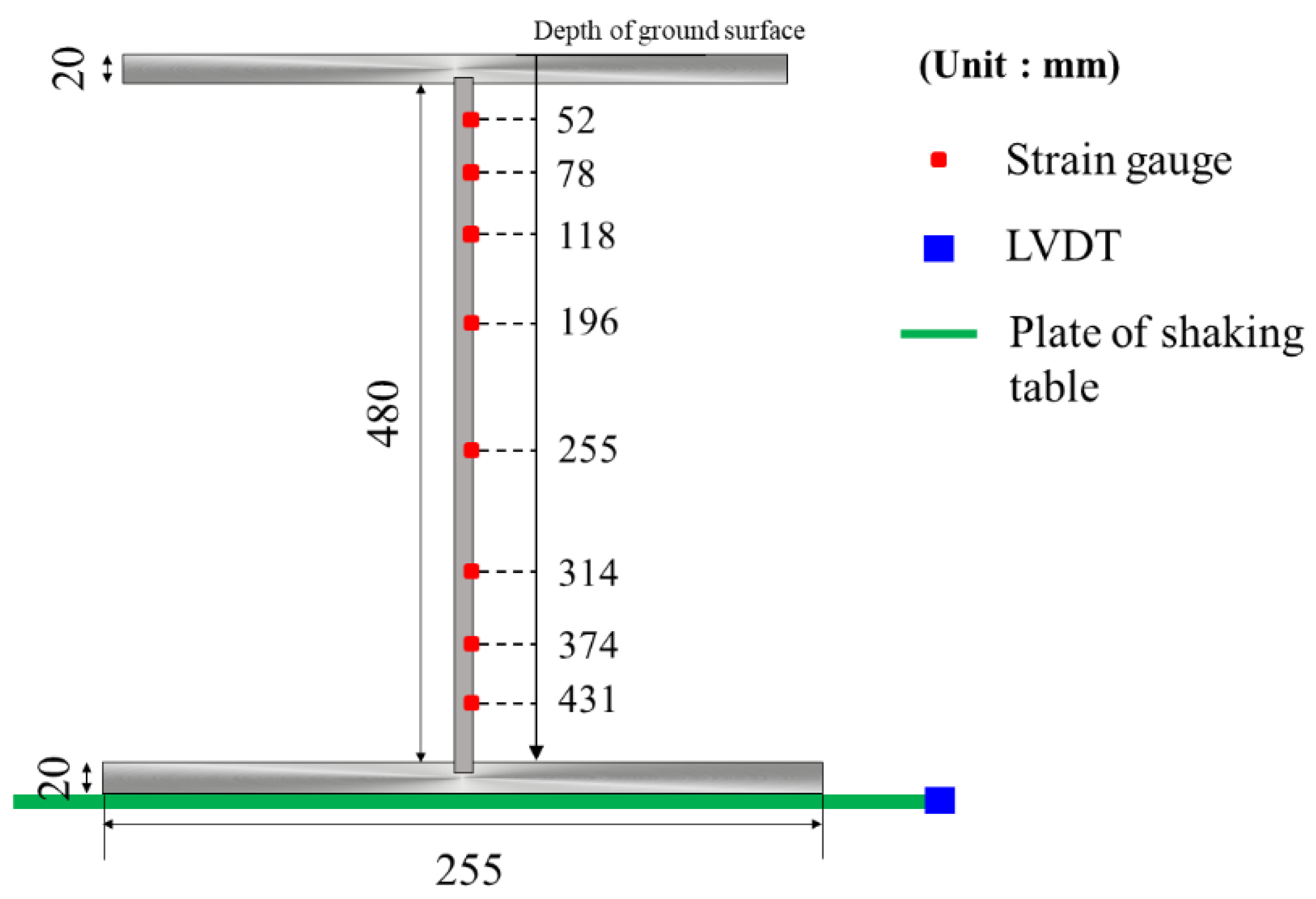

2.4. Types and Locations of Sensors

2.5. Test Soil

2.6. Test Program Settings

2.7. Dynamic p-y Curves

3. Numerical Analysis

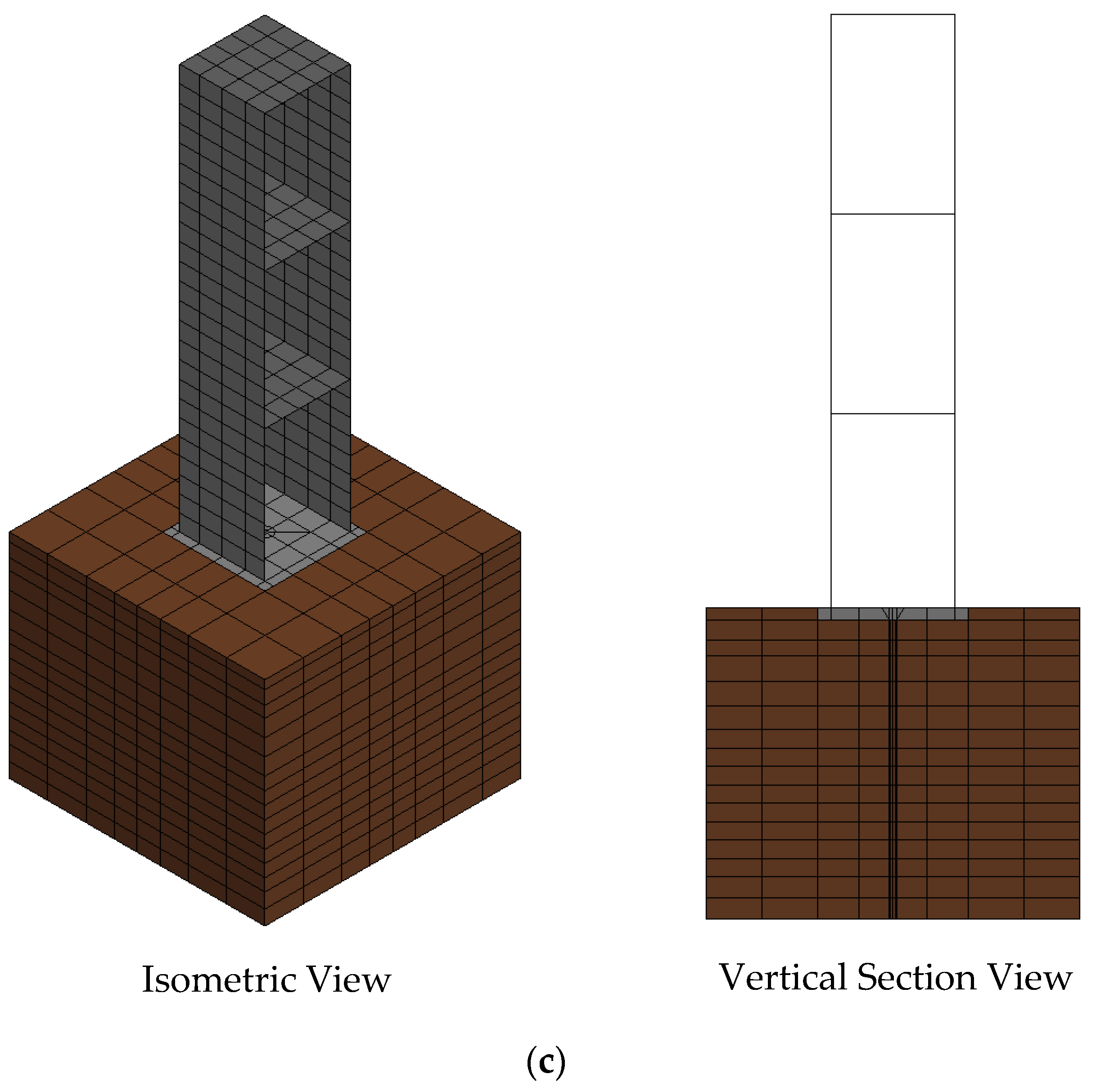

Finite Element Models

4. Results and Discussion

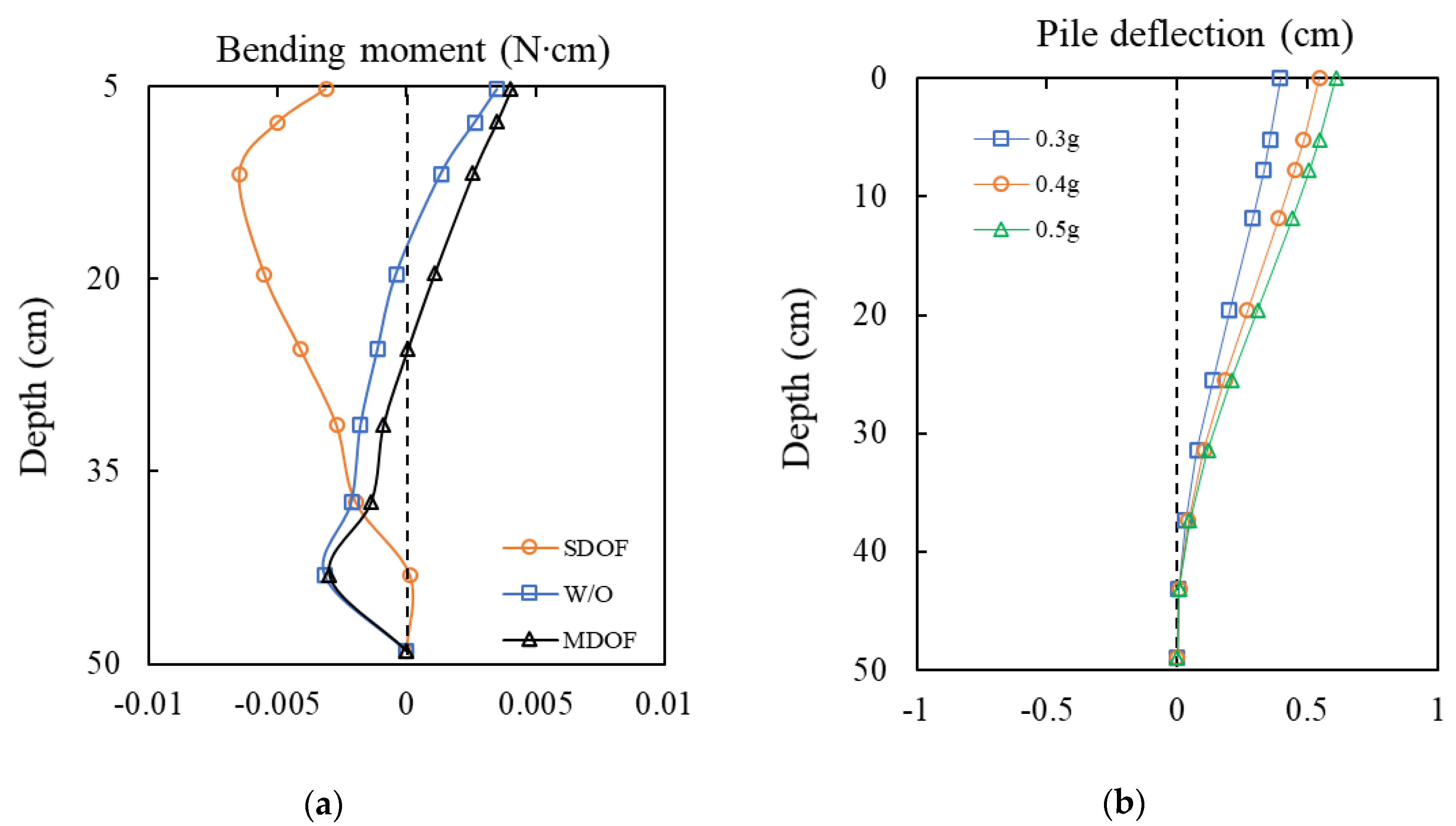

4.1. Bending Moment and Pile Displacement Distribution According to Depth

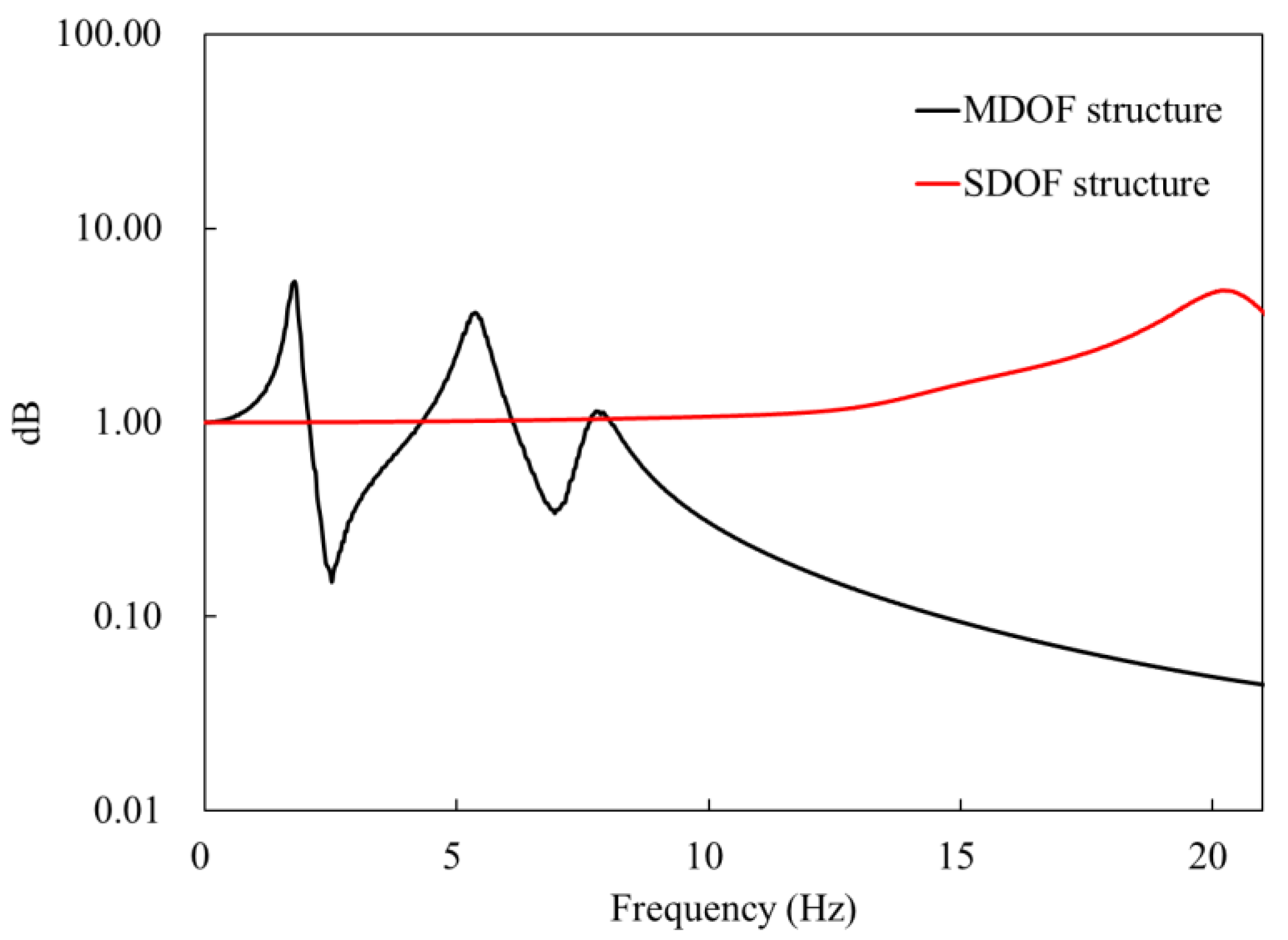

4.2. Natural Period According to Model Soil and Structure Mode

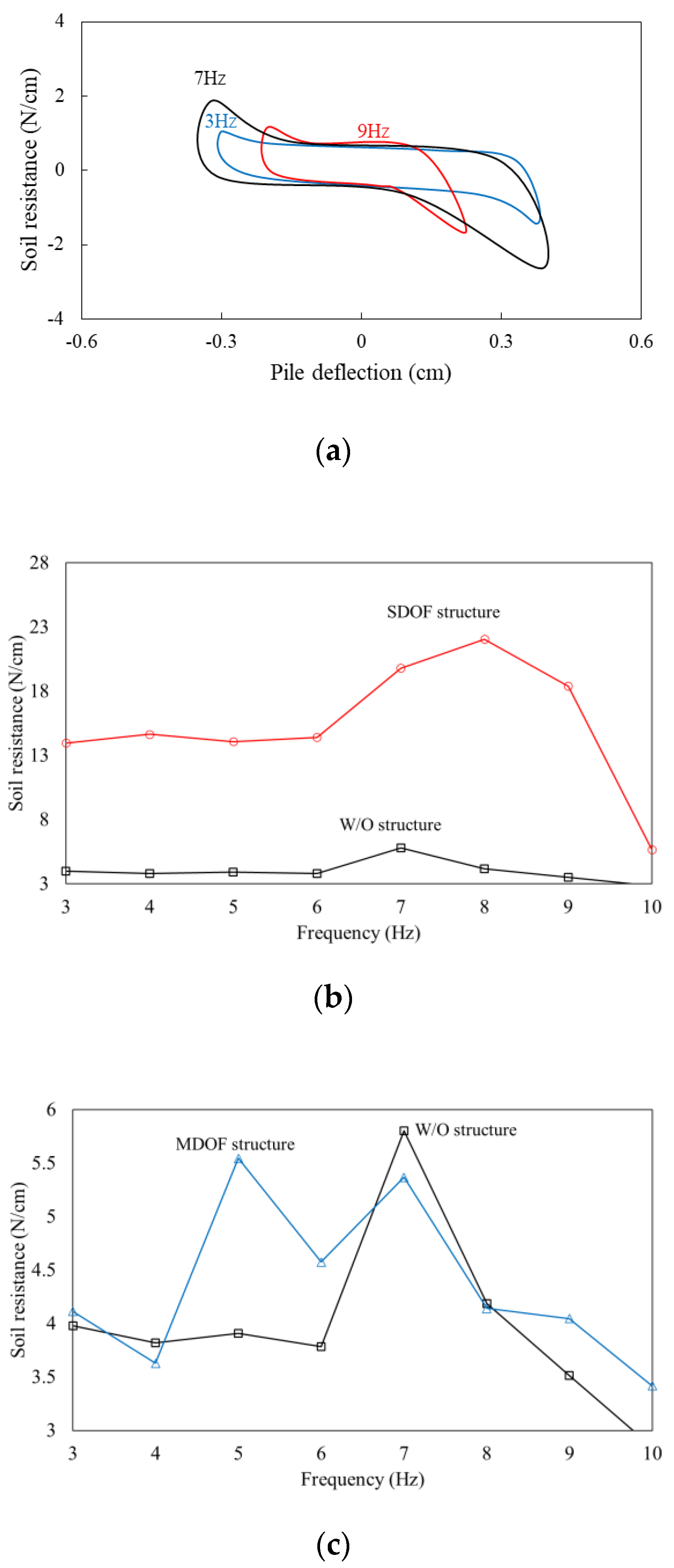

4.3. Soil–Structure Interaction Dynamic p-y Curve

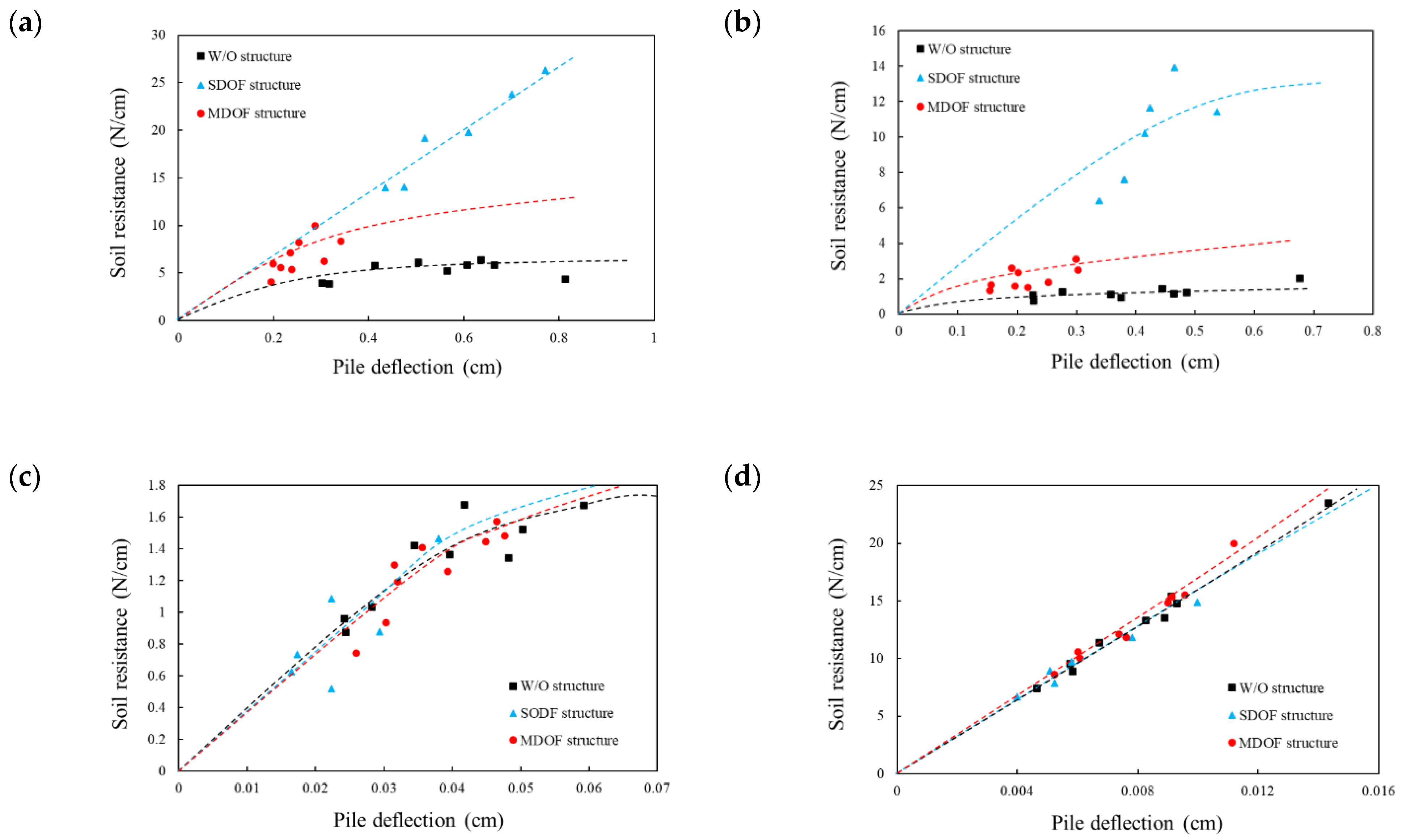

4.4. Validation Analysis

- For the ground used in the testing process, the properties of the soil varied by height; in the numerical analysis, by contrast, the ground had constant properties throughout. We believe that this introduced an error in the modeled maximum displacement arising from the lack of change in the ground stiffness with depth.

- We further note that the ground used in the experimental assessment was out of the elastic range when the vibration load was applied. For real field ground, the elastic range will be very small, but, for the convenience of analysis, the ground material model used in the numerical analysis was assumed to be an elastic body. This is also believed to have contributed to an error in the maximum displacement of the pile model.

4.5. Numerical Analysis Result

5. Conclusions

- (1)

- As the input acceleration increased, the bending moment and pile displacement increased, with the bending moments and pile displacements of the W/O and SDOF models found to be larger than those of the MDOF model. This difference was attributed to the change in the natural period of the upper structure with mode.

- (2)

- The natural frequency of the ground occurred at approximately 7 Hz and coincided with the largest ground reaction force and pile displacement. This phenomenon held for both the SDOF and MDOF models, although there were differences in soil resistance and displacement at other frequencies.

- (3)

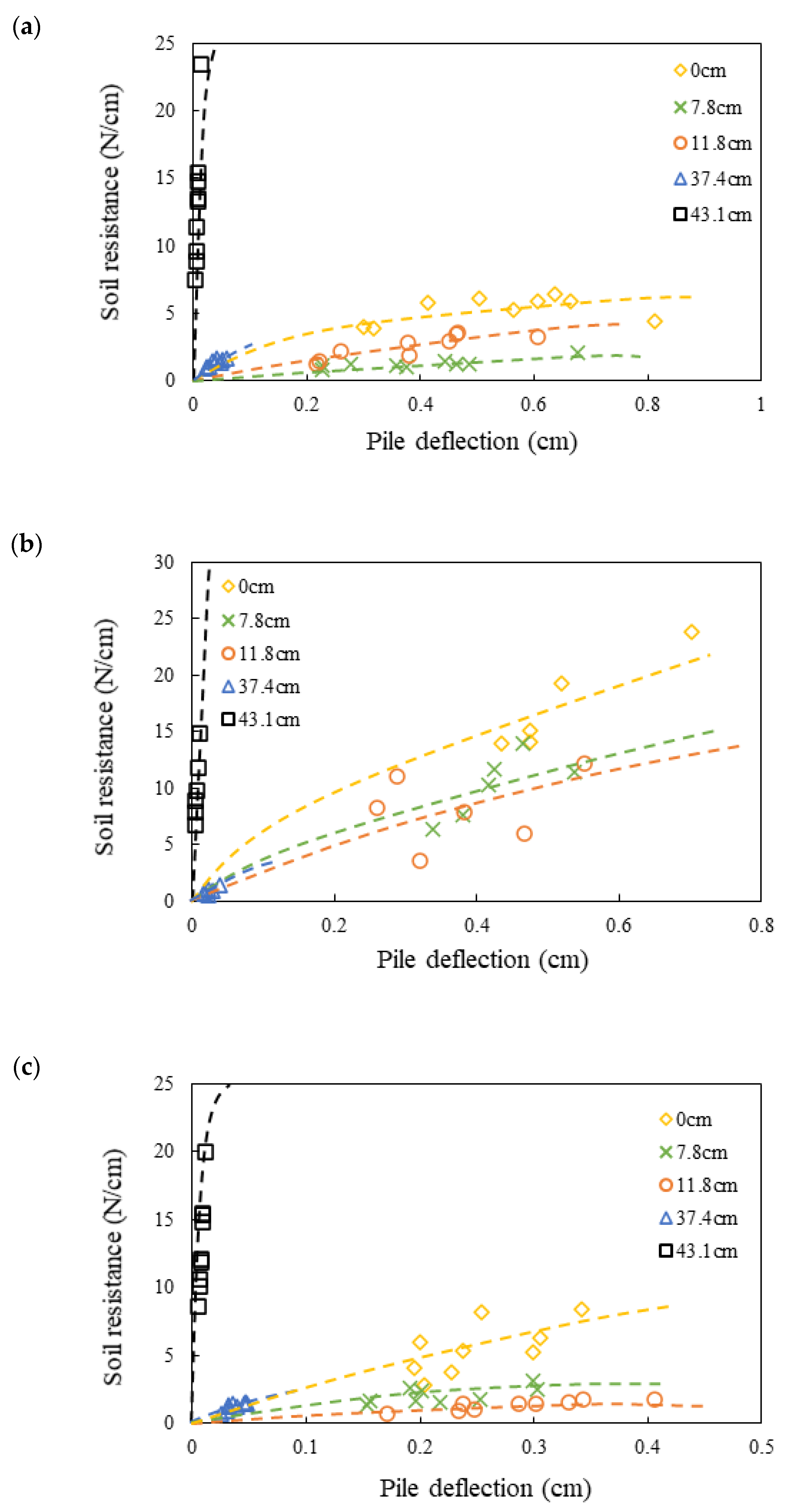

- An evaluation of the p-y backbone curves by depth revealed that as the depth increased, the soil resistance increased and the pile displacement decreased, although the pile displacement—and, therefore, the soil resistance—at the ground surface increased sharply in all three cases. This was attributed to the finding that the largest shear force was generated at the head as a result of the loading by the pile cap and upper structure at that position.

- (4)

- A comparison of the results by structure mode revealed that the differences according to mode narrowed as the depth increased. This was attributed to the fact that the ground–pile separation phenomenon occurs when the movement of the ground does not follow the movement of the pile at relatively large displacements in which the input acceleration increases at the top of the pile. As the ground deepens, this segregation phenomenon decreases and, presumably, the load is dispersed through the ground.

- (5)

- Numerical analysis of the model superstructures revealed differences between the natural periods and response spectrum energy distributions of SDOF and MDOF structures with the same weight. The natural frequency of the structure affects the ground and piles, and in order to consider the dynamic load when designing piles, the superstructure, ground, and earthquake waves must all be considered.

- (6)

- In order to remove the limitations of the indoor experiment and apply more accurate SSI, in situ tests and future studies examining the influence of the superstructure are required.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- USGS U.S. Geological Survey. 2020. Available online: https://www.usgs.gov/natural-hazards/earthquake-hazards/lists-maps-and-statistics (accessed on 16 December 2020).

- ASCE. Minimum Design Loads for Buildings and Other Structures; ASCE: Reston, VA, USA, 2013. [Google Scholar]

- Hyun-Sung, L.; Sang-Seom, C.J. Information, Analysis of Dynamic Behavior of a Single Pile in Dry Sand by 1g Shaking Table Tests. J. Korean Geotech. Soc. 2017, 33, 17–28. [Google Scholar]

- Seoongho, K.; Kwangkuk, A.; Hongsig, K. Dynamic Behavior of Group Piles according to Pile Cap Embedded. J. Korean GEO-Environ. Soc. 2018, 19, 35–41. [Google Scholar] [CrossRef]

- American Petroleum Institute (API). Recommended Practice for Planning, Designing, and Constructing Fixed Offshore Platforms–Working Stress Design; API: Washington, DC, USA, 2010. [Google Scholar]

- Matlock, H. Correlation for Design of Laterally Loaded Piles in Soft Clay. All Days 1970. [Google Scholar] [CrossRef]

- Reese, L.C.; Cox, W.R.; Koop, F.D. Analysis of Laterally Loaded Piles in Sand. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–7 May 1974. [Google Scholar]

- O’Neill, M.W.; Murchison, J.M. An Evaluation of p-y Relationships in Sands; University of Houston: Houston, TX, USA, 1983. [Google Scholar]

- Angelides, D.C.; Roësset, J.M. Nonlinear Lateral Dynamic Stiffness of Piles. J. Geotech. Eng. Div. 1981, 107, 1443–1460. [Google Scholar] [CrossRef]

- Lim, H.; Jeong, S. Simplified p-y curves under dynamic loading in dry sand. Soil Dyn. Earthq. Eng. 2018, 113, 101–111. [Google Scholar] [CrossRef]

- Yoo, M.-T.; Choi, J.-I.; Han, J.-T.; Kim, M.-M. Dynamic P-Y Curves for Dry Sand from Centrifuge Tests. J. Earthq. Eng. 2013, 17, 1082–1102. [Google Scholar] [CrossRef]

- Rovithis, E.; Kirtas, E.; Pitilakis, K. Experimental p-y loops for estimating seismic soil-pile interaction. Bull. Earthq. Eng. 2009, 7, 719–736. [Google Scholar] [CrossRef]

- Iai, S. Similitude for Shaking Table Tests on Soil-Structure-Fluid Model in 1g Gravitational Field. Soils Found. 1989, 29, 105–118. [Google Scholar] [CrossRef] [Green Version]

- Myungjae, L.; Mintaek, Y.; Jeongjun, P.; Kyungchan, M. Evaluation of Lateral Pile Behavior under Cyclic Loading by Centrifuge Tests. J. Korean Geotech. Soc. 2019, 35, 39–48. [Google Scholar]

- Kwon, S.Y.; Yoo, M. Evaluation of Dynamic Soil-Pile-Structure Interactive Behavior in Dry Sand by 3D Numerical Simulation. Appl. Sci. 2019, 9, 2612. [Google Scholar] [CrossRef] [Green Version]

- Van Ngo, L.; Kim, J.-M.; Lim, J.; Lee, C. Foundation-soil-foundation Interaction of Shallow Foundations Using Geo Centrifuge: Experimental Approach. J. Korean Geotech. Soc. 2018, 34, 25–35. [Google Scholar]

- Liang, F.; Liang, X.; Zhang, H.; Wang, C. Seismic Response from Centrifuge Model Tests of a Scoured Bridge with a Pile-Group Foundation. J. Bridg. Eng. 2020, 25, 04020054. [Google Scholar] [CrossRef]

- Choi, Y.; Ahn, J. Evaluation of p-y Curves and p-multiplier of Pile Groups Corresponding to Sand Properties Change Based on 3D Numerical Analysis. J. Korean Soc. Hazard Mitig. 2020, 20, 207–217. [Google Scholar] [CrossRef]

- Hokmabadi, A.S.; Fatahi, B.; Samali, B. Assessment of soil–pile–structure interaction influencing seismic response of mid-rise buildings sitting on floating pile foundations. Comput. Geotech. 2014, 55, 172–186. [Google Scholar] [CrossRef]

- Al-Abboodi, I.; Sabbagh, T.T. Numerical Modelling of Passively Loaded Pile Groups. Geotech. Geol. Eng. 2019, 37, 2747–2761. [Google Scholar] [CrossRef] [Green Version]

- Bao, X.; Morikawa, Y.; Kondo, Y.; Nakamura, K.; Zhang, F. Shaking table test on reinforcement effect of partial ground improvement for group-pile foundation and its numericalsimulation. Soils Found. 2012, 52, 1043–1061. [Google Scholar] [CrossRef] [Green Version]

- Mitropoulou, C.C.; Kostopanagiotis, C.; Kopanos, M.; Ioakim, D.; Lagaros, N.D. Influence of soil–structure interaction on fragility assessment of building structures. Structures 2016, 6, 85–98. [Google Scholar] [CrossRef]

- Forcellini, D. Analytical fragility curves of shallow-founded structures subjected to Soil-Structure Interaction (SSI) effects. Soil Dyn. Earthq. Eng. 2021, 141, 106487. [Google Scholar] [CrossRef]

- Finn, W.D.L. A Study of Piles during Earthquakes: Issues of Design and Analysis. Bull. Earthq. Eng. 2005, 3, 141–234. [Google Scholar] [CrossRef]

- Ko, Y.-Y.; Yang, H.-H. Deriving seismic fragility curves for sheet-pile wharves using finite element analysis. Soil Dyn. Earthq. Eng. 2019, 123, 265–277. [Google Scholar] [CrossRef]

- Yang, C.-S.W.; Desroches, R.; Rix, G.J. Numerical Fragility Analysis of Vertical-Pile-Supported Wharves in the Western United States. J. Earthq. Eng. 2012, 16, 579–594. [Google Scholar] [CrossRef]

- Broms, B.B. Lateral Resistance of Piles in Cohesive Soils. J. Soil Mech. Found. Div. 1964, 90, 27–63. [Google Scholar] [CrossRef]

- Davisson, M.T. Lateral Load Capacity of Piles. In Proceedings of the 49th Annual Meeting of the Highway Research Board, Washington, DC, USA, 12–16 January 1970; pp. 104–112. [Google Scholar]

- Meymand, P.J. Shaking Table Scale Model Tests of Nonlinear Soil-Pile-Superstructure Interaction in Soft Clay. Ph.D. Thesis, University of California, Berkeley, CA, USA, 1994; p. 75. [Google Scholar]

- Applied Technology Council. Tentative Provisions for the Development of Seismic Regulations for Buildings; ATC-3-06 (NBS SP-510) U.S Government Printing Office: Washington, DC, USA, 1978.

- Yuan, B.; Chen, R.; Teng, J.; Wang, Y.; Chen, W.; Peng, T.; Feng, Z.; Yu, Y.; Dong, J. Effect of Sand Relative Density on Response of a Laterally Loaded Pile and Sand Deformation. J. Chem. 2015, 2015, 1–6. [Google Scholar] [CrossRef] [Green Version]

| Classification | Scaling Factor [13] | Model Pile | Prototype Pile |

|---|---|---|---|

| Material | n/a | Aluminum 6061 | Concrete |

| Pile length (cm) | λ | 49 | 1298.5 |

| Diameter (cm) | λ | 1.2 | 50 |

| Thickness (cm) | λ | 0.2 | 10 |

| Elastic modulus (GPa) | λ | 72.5 | 27 |

| Classification | Sand | Clay |

|---|---|---|

| Short pile | ||

| Immediate pile | - | |

| Long pile | ||

| , | ||

| Index | Sample | |

|---|---|---|

| Sieve analysis | D10 | 0.17 |

| D30 | 0.47 | |

| D60 | 1.1 | |

| Cu | 6.47 | |

| CC | 1.18 | |

| Passing No. 4 sieve (%) | 100 | |

| Passing No. 200 sieve (%) | 2.42 | |

| USCS | SP | |

| Specific gravity | 2.59 | |

| Unit weight (g/cm3) | 1.67 | |

| Case | Input Acceleration (g) | Input Frequency (Hz) |

|---|---|---|

| W/O structure | 0.3, 0.4, 0.5 | 3–10 |

| SDOF structure | 0.3, 0.4 | 3–10 |

| MDOF structure | 0.3, 0.4, 0.5 | 3–10 |

| Material | Modulus of Elasticity (N/mm2) | Poisson’s Ratio | Unit of Weight (ton/m3) |

|---|---|---|---|

| Soil | 106.40 | 0.33 | 1.600 |

| Structure/Mass structure | 210,000.00 | 0.30 | 7.850 |

| Pile | 68,900.00 | 0.33 | 2.700 |

| Element Type | Number of Element | ||

|---|---|---|---|

| Mass type | Mass | Solid (8 node) | 120 |

| Basement | Solid (8 node) | 104 | |

| Pile | Shell (4 node) | 120 | |

| Soil | Solid (8 node) | 1068 | |

| Two-story building type | Structure | Shell (4 node) | 168 |

| Basement | Solid (8 node) | 104 | |

| Pile | Shell (4 node) | 120 | |

| Soil | Solid (8 node) | 1068 | |

| Three-story building type | Structure | Shell (4 node) | 252 |

| Basement | Solid (8 node) | 104 | |

| Pile | Shell (4 node) | 120 | |

| Soil | Solid (8 node) | 1068 | |

| Height (mm) | SDOF | MDOF | ||||

|---|---|---|---|---|---|---|

| Experiment (mm) | Analysis (mm) | Difference (%) | Experiment (mm) | Analysis (mm) | Difference (%) | |

| 0.0 | 3.262 | 0.835 | 25.594 | 2.243 | 0.637 | 28.383 |

| −52.0 | 2.968 | 0.824 | 27.772 | 2.104 | 0.633 | 30.065 |

| −78.0 | 2.770 | 0.801 | 28.910 | 1.992 | 0.623 | 31.256 |

| −118.0 | 2.422 | 0.744 | 30.723 | 1.779 | 0.595 | 33.463 |

| −196.0 | 1.682 | 0.578 | 34.379 | 1.286 | 0.500 | 38.915 |

| −255.0 | 1.137 | 0.424 | 37.267 | 0.898 | 0.394 | 43.912 |

| −314.0 | 0.652 | 0.269 | 41.197 | 0.532 | 0.272 | 51.122 |

| −344.0 | 0.263 | 0.196 | 74.537 | 0.222 | 0.209 | 93.956 |

| −431.0 | 0.048 | 0.043 | 89.826 | 0.041 | 0.050 | 121.371 |

| −480.0 | 0.000 | 0.000 | 100.000 | 0.000 | 0.000 | 100.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, S.; Park, G.; Yoon, H.; Han, J.-H.; Jung, J. Evaluation of Soil–Structure Interaction in Structure Models via Shaking Table Test. Sustainability 2021, 13, 4995. https://doi.org/10.3390/su13094995

Ahn S, Park G, Yoon H, Han J-H, Jung J. Evaluation of Soil–Structure Interaction in Structure Models via Shaking Table Test. Sustainability. 2021; 13(9):4995. https://doi.org/10.3390/su13094995

Chicago/Turabian StyleAhn, Seongnoh, Gun Park, Hyungchul Yoon, Jae-Hyeok Han, and Jongwon Jung. 2021. "Evaluation of Soil–Structure Interaction in Structure Models via Shaking Table Test" Sustainability 13, no. 9: 4995. https://doi.org/10.3390/su13094995