Use of Off-ASTM Class F Fly Ash and Waste Limestone Powder in Mortar Mixtures Containing Waste Glass Sand

Abstract

:1. Introduction

2. Experimental Program

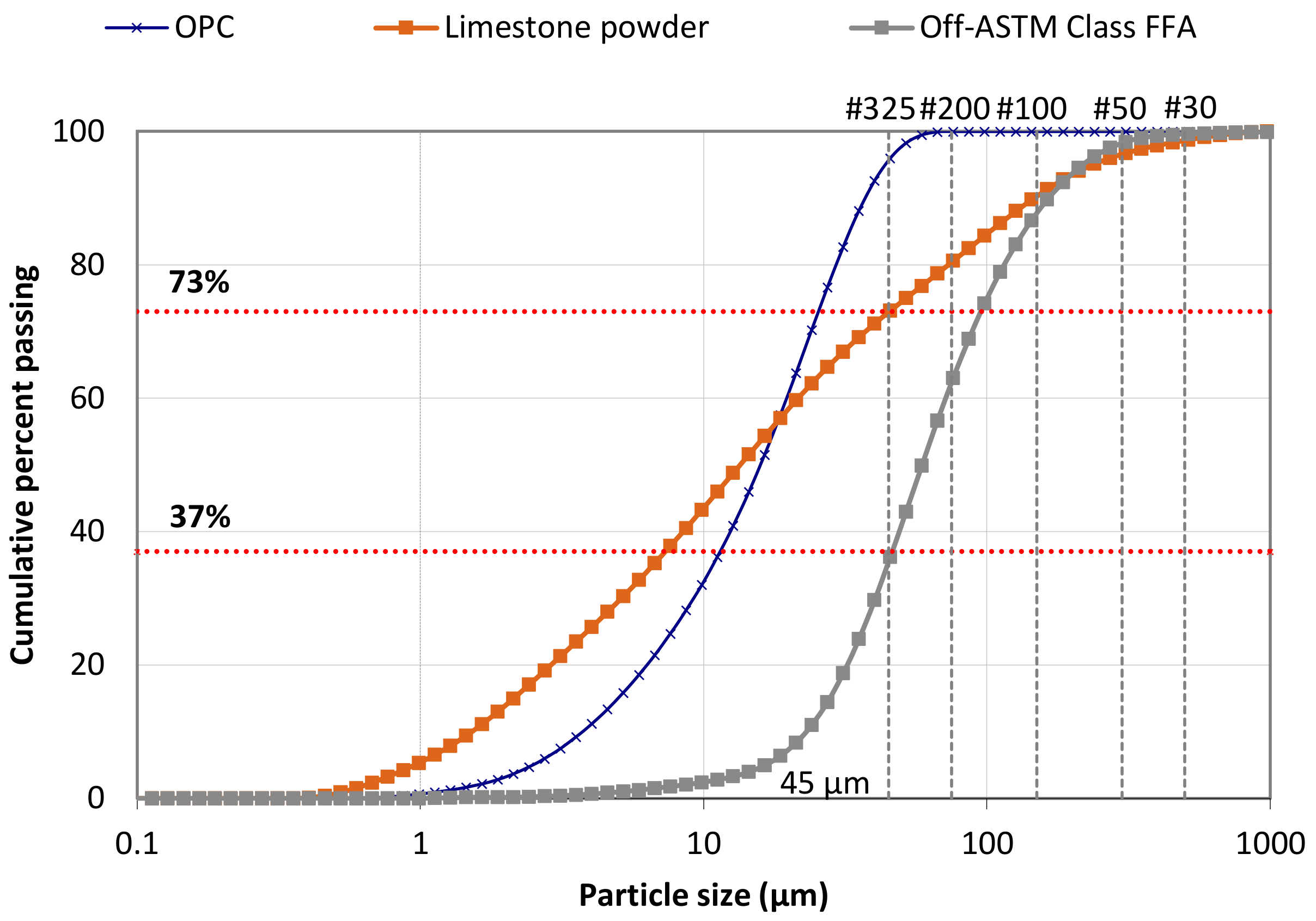

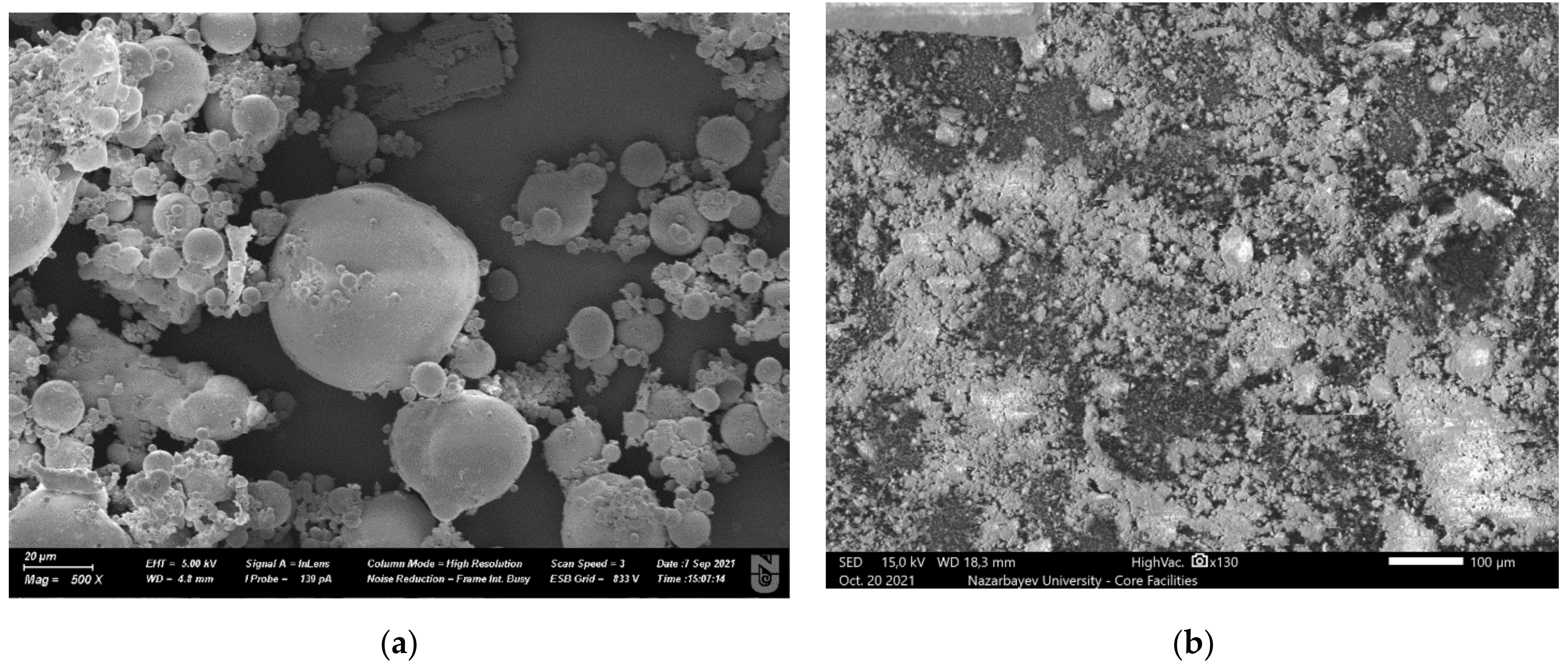

2.1. Materials

2.2. Mixture Proportions and ASR Test Method

2.3. Mixing Procedure and Preparation of Testing Specimens

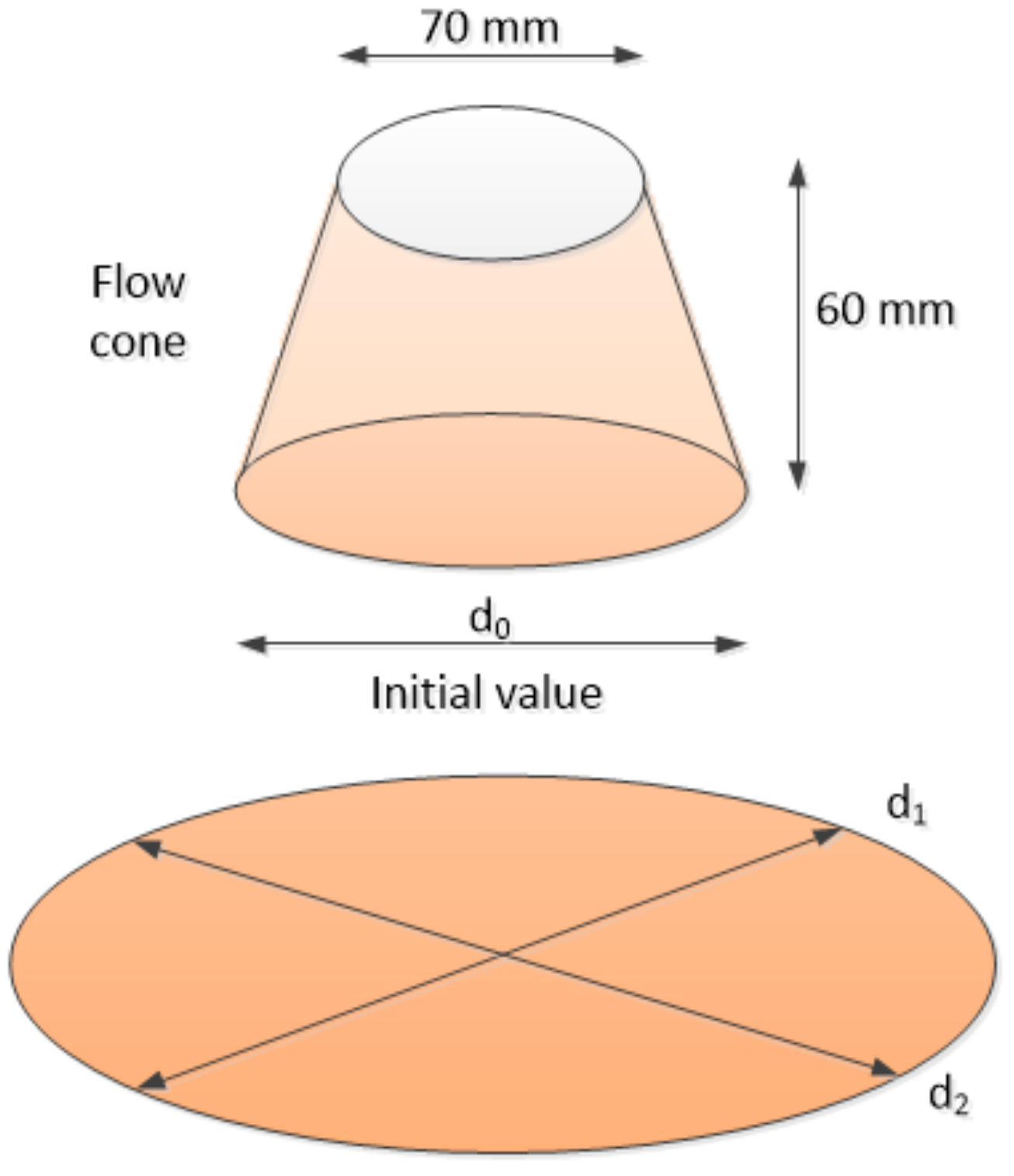

2.4. Test Procedures

3. Test Results and Discussion

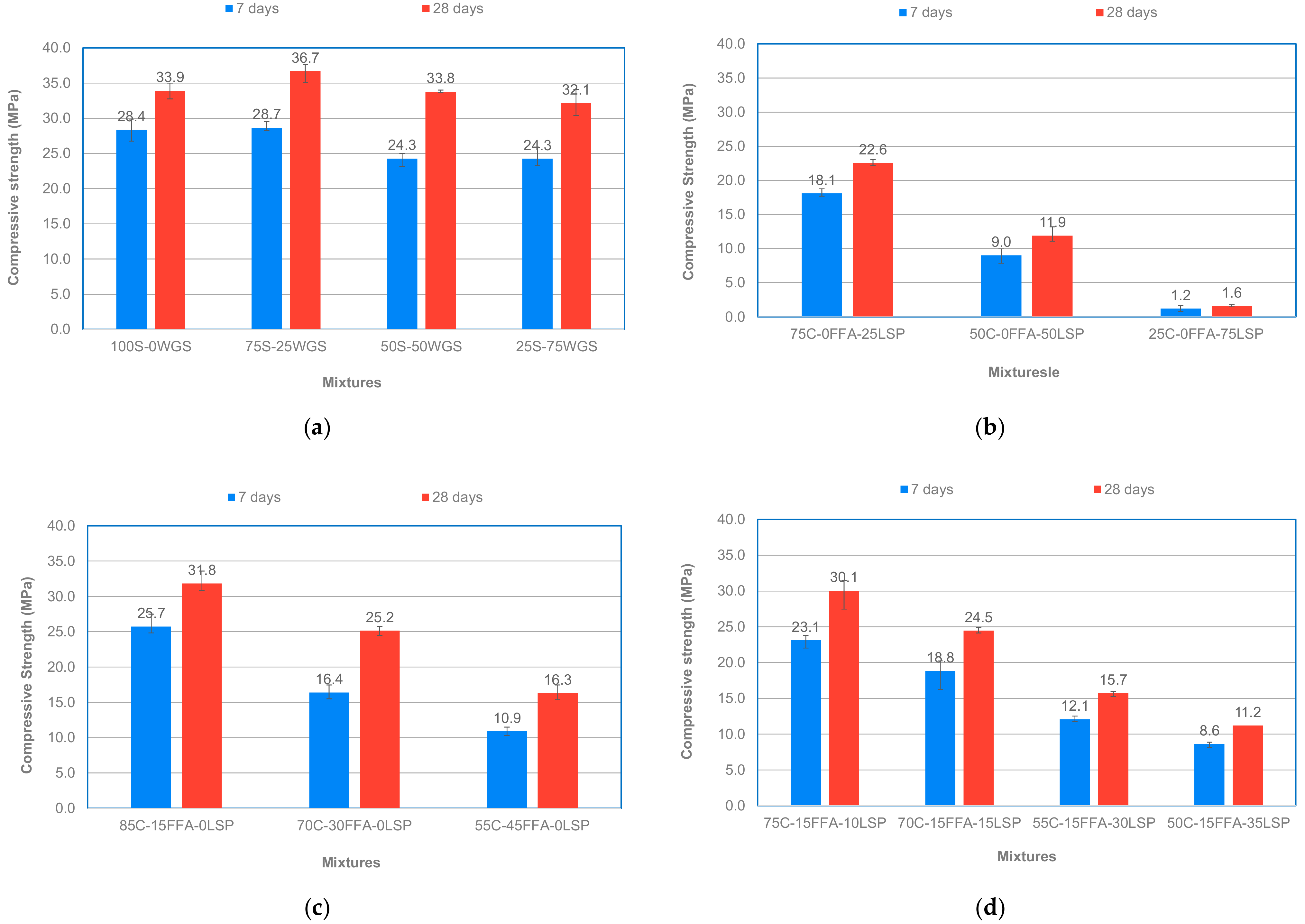

3.1. Compressive Strength Development

3.2. Relationship between Relative Flowability and 7-Day Compressive Strength

3.3. Expansion Characteristics of Mortar Mixtures

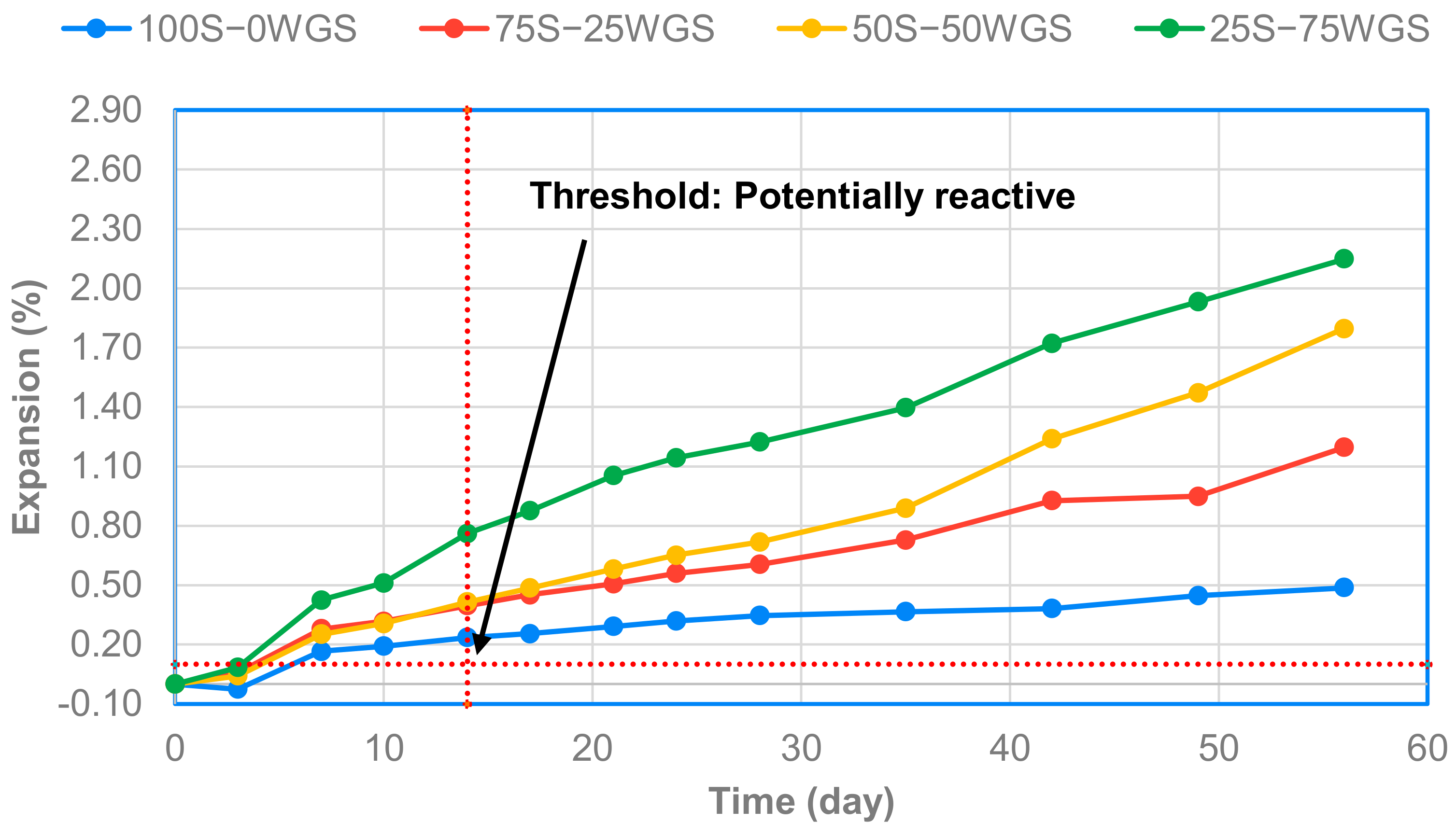

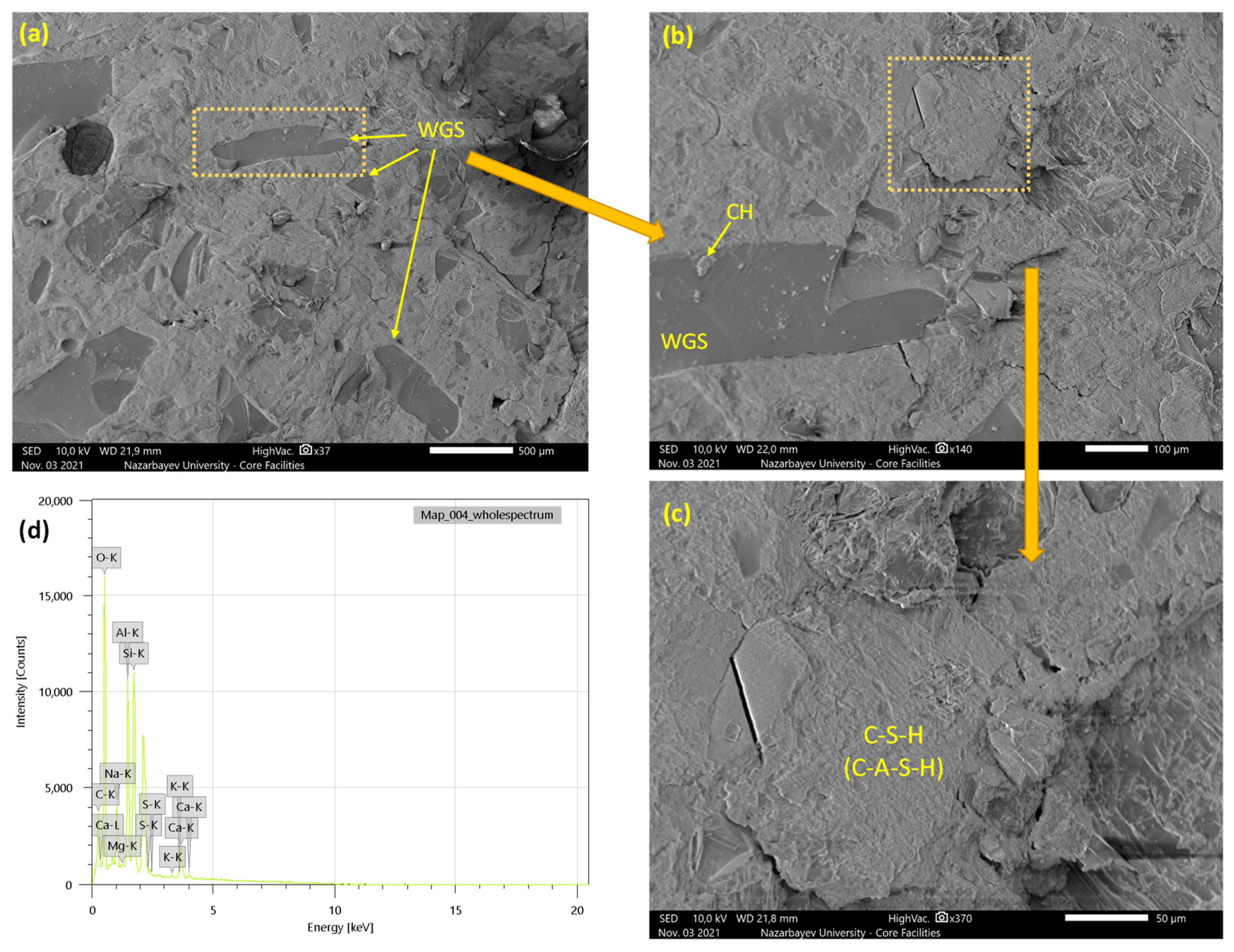

3.3.1. Expansion Characteristics of Control Mixtures

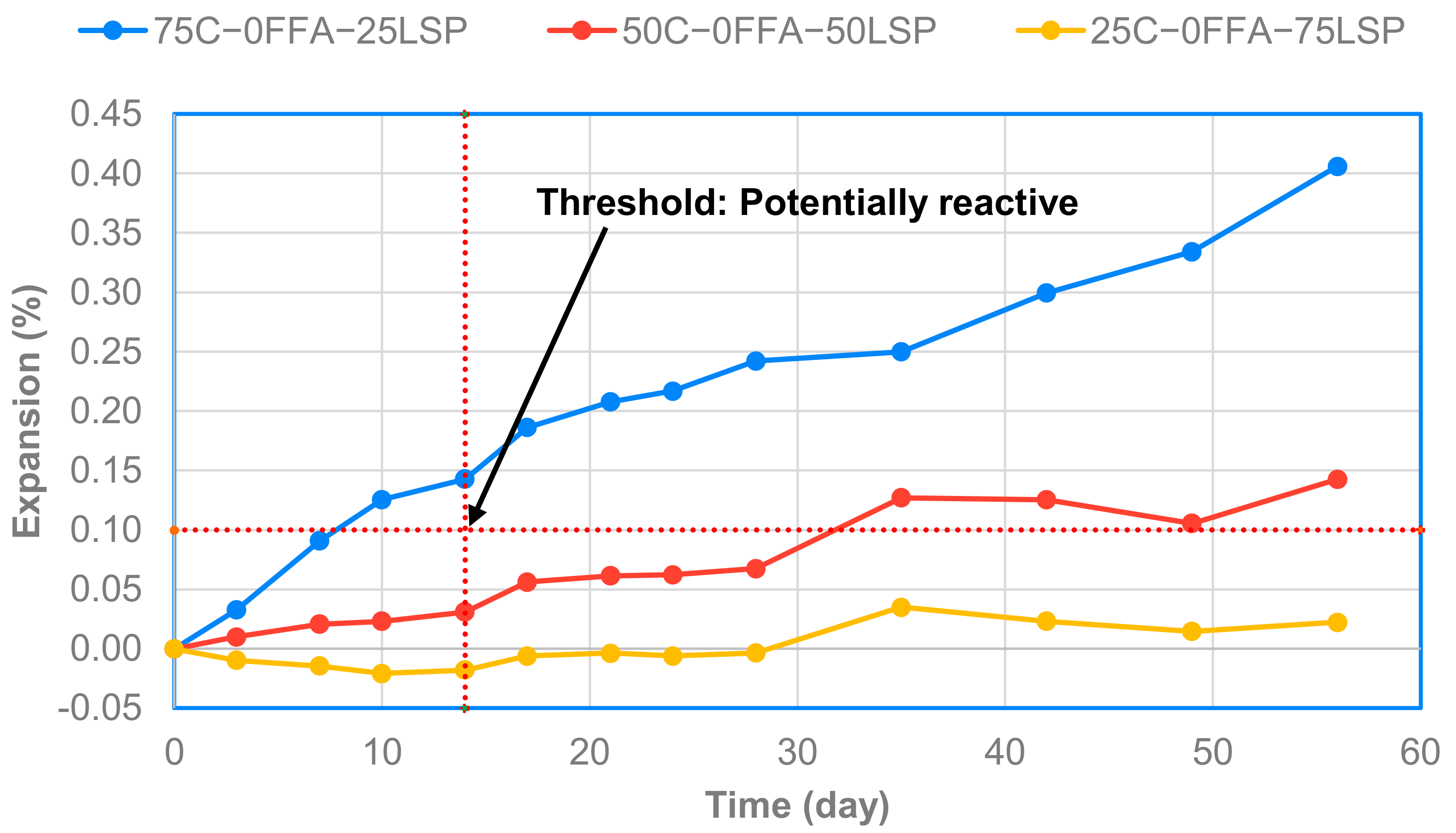

3.3.2. Expansion Characteristics of Binary LSP Mixtures

3.3.3. Expansion Characteristics of Binary FFA Mixtures

3.3.4. Expansion Characteristics of the Ternary Mixtures

3.4. Synergistic Effect of the Ternary Mixtures

4. Conclusions

- When the reactive river sand and waste glass sand are used together, the combination of 75S-25WGS had the lowest expansion value up to 56 days.

- As the ratio of LSP and FFA as a replacement of OPC increases, the compressive strength of the mortar mixture decreases.

- At 15% fixed FFA content, the addition of LSP led to lower compressive strength, and the reduction in compressive strength increased as the LSP content increased.

- When a single FFA or LSP was used, a relatively replacement of OPC with FFA (30 or 45%) or LSP (75%) was required to control ASR expansion below the ASTM threshold value of 0.1% when the test period was extended to 56 days.

- The shortcoming of FFA or LSP needing high levels of replacement rate to control ASR expansion could be compensated by the ternary mixture with the combination of FFA and LSP.

- Ternary mortar mixture with 30% or 35% LSP at 15% fixed FFA content was more effective than other mixtures in inhibiting ASR expansion.

- Considering both the ASR mitigation effect and compressive strength development, the binary mixture 70C-30FFA-0LSP or ternary mixture 55C-15FFA-30LSP seems to be the best mixture in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mukangali, I.; Shon, C.S.; Kryzhanovskiy, K.; Zhang, D.C.; Kim, J.R. Effects of waste soda-lime glass sand and glass fiber on physical and mechanical properties of none-autoclaved aerated concrete. In Proceedings of the 9th International Conference on Material Science and Engineering Technology (ICMSET 2020), Kyoto, Japan, 9–12 October 2020. [Google Scholar] [CrossRef]

- OECD. Reform of the Mining Sector in Kazakhstan: Investment, Sustainability, Competitiveness, Global Relations Eurasia Competitiveness Programme. 2018. Available online: https://www.oecd.org/eurasia/countries/Kazakhstan_Mining_report_ENG.pdf (accessed on 10 December 2021).

- EY. Kazakhstan Mining Tax Guide, Ernst & Young Kazakhstan LLP—KZ. 2021. Available online: https://assets.ey.com/content/dam/ey-sites/ey-com/ru_kz/topics/mining-metals/ey-kazakhstan-mining-tax-guide_2021.pdf (accessed on 10 November 2021).

- International Energy Agency. Kazakhstan Energy Profile. 2021. Available online: https://iea.blob.core.windows.net/assets/a398cfb3-4f0b-4b8f-b82e-47b8d7b93d52/KazakhstanEnergyProfile.pdf (accessed on 10 December 2021).

- Massalimov, I.; Massalimov, B.; Akhmetshin, B.; Urakaev, F.; Burkitbaev, M. Conversion of limestone-limestone mining waste by impregnation with polysulfide solutions. Nanotechnologies Constr. A Sci. Internet-J. 2020, 12, 77–83. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Waste Glass Powder as Cement Replacement in Concrete. J. Adv. Concr. Technol. 2014, 12, 468–477. [Google Scholar] [CrossRef] [Green Version]

- Carsana, M.; Frassoni, M.; Bertolini, L. Comparison of ground waste glass with other supplementary cementitious materials. Cem. Concr. Compos. 2013, 45, 39–45. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- AlMesfer, N.; Ingham, J. Effect of Waste Glass on the Properties of Concrete. J. Mater. Civ. Eng. 2014, 26, 06014022. [Google Scholar] [CrossRef]

- Serpa, D.; Silva, A.S.; de Brito, J.; Pontes, J.; Soares, D. ASR of mortars containing glass. Constr. Build. Mater. 2013, 47, 489–495. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Use of waste glass as sand in mortar: Part II—Alkali–silica reaction and mitigation methods. Cem. Concr. Compos. 2013, 35, 118–126. [Google Scholar] [CrossRef]

- Lee, G.; Ling, T.-C.; Wong, Y.-L.; Poon, C.-S. Effects of crushed glass cullet sizes, casting methods and pozzolanic materials on ASR of concrete blocks. Constr. Build. Mater. 2011, 25, 2611–2618. [Google Scholar] [CrossRef]

- Saccani, A.; Bignozzi, M.C. ASR expansion behavior of recycled glass fine aggregates in concrete. Cem. Concr. Res. 2010, 40, 531–536. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Effect of particle size on alkali–silica reaction in recycled glass mortars. Constr. Build. Mater. 2014, 66, 275–285. [Google Scholar] [CrossRef]

- ASTM C1260-14. Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method); ASTM In-ternational: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Xie, Z.; Xiang, W.; Xi, Y. ASR Potentials of Glass Aggregates in Water-Glass Activated Fly Ash and Portland Cement Mortars. J. Mater. Civ. Eng. 2003, 15, 67–74. [Google Scholar] [CrossRef]

- Barros, S.V.A.; Marciano, J.E.A.; Ferreira, H.C.; Menezes, R.R.; Neves, G.A. Addition of quartzite residues on mortars: Analysis of the alkali aggregate reaction and the mechanical behavior. Constr. Build. Mater. 2016, 118, 344–351. [Google Scholar] [CrossRef]

- Turk, K.; Kina, C.; Bagdiken, M. Use of binary and ternary cementitious blends of F-Class fly-ash and limestone powder to mitigate alkali-silica reaction risk. Constr. Build. Mater. 2017, 151, 422–427. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H. A review on effects of limestone powder on the properties of concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- ASTM C1567-13. Standard Test Method for Determining the Potential Alkali-Silica Reactivity of Combinations of Ce-mentitious Materials and Aggregate (Accelerated Mortar-Bar Method); ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM C441/C441M-17. Standard Test Method for Effectiveness of Pozzolans or Ground Blast-Furnace Slag in Preventing Excessive Expansion of Concrete Due to the Alkali-Silica Reaction; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C1293-20. Standard Test Method for Determination of Length Change of Concrete Due to Alkali-Silica Reaction; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Wang, H.; Wu, D.; Mei, Z. Effect of fly ash and limestone powder on inhibiting alkali aggregate reaction of concrete. Constr. Build. Mater. 2019, 210, 620–626. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Abd Elrahman, M.; Sikora, P.; Rucinska, T.; Horszczaruk, E.; Stephan, D. Evaluation of the Effects of Crushed and Expanded Waste Glass Aggregates on the Material Properties of Lightweight Concrete Using Image-Based Approaches. Materials 2017, 10, 1354. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of Waste Glass Addition as a Replacement for Fine Aggregate on Properties of Mortar. Materials 2020, 13, 3189. [Google Scholar] [CrossRef]

- ASTM C109/C109M-20b. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM C1437-13. Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Shon, C.-S.; Kim, Y.-S. Evaluation of West Texas natural zeolite as an alternative of ASTM Class F fly ash. Constr. Build. Mater. 2013, 47, 389–396. [Google Scholar] [CrossRef]

- ASTM C490/C490M-17. Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Olofinnade, O.M.; Ede, A.N.; Ndambuki, J.M.; Ngene, B.U.; Akinwumi, I.I.; Ofuyatan, O. Strength and microstructure of eco-concrete produced using waste glass as partial and complete replacement for sand. Cogent Eng. 2018, 5. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Jia, H.; Zeng, R.; Wu, Y.; Lao, L. A quantitative study on physical and chemical effects of limestone powder on properties of cement pastes. Constr. Build. Mater. 2019, 204, 58–69. [Google Scholar] [CrossRef]

- Shon, C.-S.; Abdigaliyev, A.; Bagitova, S.; Chung, C.-W.; Kim, D. Determination of air-void system and modified frost resistance number for freeze-thaw resistance evaluation of ternary blended concrete made of ordinary Portland cement/silica fume/class F fly ash. Cold Reg. Sci. Technol. 2018, 155, 127–136. [Google Scholar] [CrossRef]

- Marsh, B.K.; Day, R.L. Pozzolanic and cementitious reactions of fly ash in blended cement pastes. Cem. Concr. Res. 1988, 18, 301–310. [Google Scholar] [CrossRef]

- Lin, W.-T.; Cheng, A.; Černý, R. Effect of limestone powder on strength and permeability of cementitious mortars. MATEC Web Conf. 2020, 322, 01009. [Google Scholar] [CrossRef]

- Rajabipour, F.; Giannini, E.; Dunant, C.; Ideker, J.; Thomas, M.D. Alkali–silica reaction: Current understanding of the reaction mechanisms and the knowledge gaps. Cem. Concr. Res. 2015, 76, 130–146. [Google Scholar] [CrossRef]

- Rajabipour, F.; Maraghechi, H.; Fischer, G. Investigating the Alkali-Silica Reaction of Recycled Glass Aggregates in Concrete Materials. J. Mater. Civ. Eng. 2010, 22, 1201–1208. [Google Scholar] [CrossRef]

- Chen, C.; Yang, W. Mitigation of Alkali-Silica reaction in mortar with limestone addition and carbonation. In Proceedings of the 3rd Inter-national Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 18–21 August 2013. [Google Scholar]

- Ouyang, X.; Koleva, D.; Ye, G.; Van Breugel, K. Insights into the mechanisms of nucleation and growth of C–S–H on fillers. Mater. Struct. 2017, 50, 213. [Google Scholar] [CrossRef]

- Shon, C.-S.; Zollinger, D.G.; Sarkar, S.L. Evaluation of modified ASTM C 1260 accelerated mortar bar test for alkali–silica reactivity. Cem. Concr. Res. 2002, 32, 1981–1987. [Google Scholar] [CrossRef]

- Lee, J.-C.; Jang, B.-K.; Shon, C.-S.; Kim, J.-H.; Chung, C.-W. Potential use of borosilicate glass to make neutron shielding mortar: Enhancement of thermal neutron shielding and strength development and mitigation of alkali-silica reaction. J. Clean. Prod. 2018, 210, 638–645. [Google Scholar] [CrossRef]

- Wang, Y.; Burris, L.; Hooton, R.D.; Shearer, C.R.; Suraneni, P. Effects of unconventional fly ashes on cementitious paste properties. Cem. Concr. Compos. 2021, 125, 104291. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Hou, X.; Struble, L.J.; Kirkpatrick, R. Formation of ASR gel and the roles of C-S-H and portlandite. Cem. Concr. Res. 2004, 34, 1683–1696. [Google Scholar] [CrossRef]

- Chen, J.; Kwan, A.; Jiang, Y. Adding limestone fines as cement paste replacement to reduce water permeability and sorptivity of concrete. Constr. Build. Mater. 2014, 56, 87–93. [Google Scholar] [CrossRef]

| Test Attribute | Measured Properties | Specification/References | Test Period |

|---|---|---|---|

| Material characterization | Chemical composition | ASTM C 618/C 311 | |

| Particle size distribution | Mastersizer 3000 using the technique of laser diffraction | ||

| Scanning electron microscope (SEM)-Morphology | JSM-IT200(LA) | ||

| Basic fresh and hardened properties | Flowability | ASTM C1437 | |

| Compressive strength | ASTM C 109 | 7 and 28 days | |

| ASR characteristics | ASR expansion | ASTM C 1260/C 1567 | Periodically up to 56 day |

| Composition | OPC | Off-ASTM Clsss F Fly Ash | LSP | ASTM Clsss F Fly Ash |

|---|---|---|---|---|

| SiO2 | 21.55 | 49.34 | 15.28 | |

| Al2O3 | 5.55 | 17.55 | 4.22 | |

| Fe2O3 | 4.70 | 19.07 | 13.75 | |

| ∑(SiO2 + Al2O3 + Fe2O3) | 31.80 | 85.96 | 33.25 | min. 70 |

| CaO | 65.91 | 3.38 | 58.80 | |

| MgO | 1.46 | 0.06 | 0.26 | |

| SO3 | 1.90 | 0.08 | 0.07 | max. 5 |

| a Na2Oequiv. | 0.65 | - | - | |

| b Na2Oequiv. | - | 1.04 | 2.02 | |

| Loss on Ignition (LOI) | 0.49 | 0.2 | - | max. 5 |

| Physical properties | ||||

| c Fineness | c 3680 | - | - | |

| d Fineness (%) | 63 | max. 34 | ||

| Specific gravity | 3.14 | - | - | |

| Pozzolanic activity/cement (7- and 28-d) (%) | 57 (7-d) 68 (28-d) | min. 75 | ||

| Initial set time (min.) | 150 | - | - | |

| Final set time (min.) | 270 | - | - | |

| Mixture | Aggregate Content (%) | Cementitious Materials (%) | |||

|---|---|---|---|---|---|

| Sand | WGS | Cement | FFA | LSP | |

| 100S-0WGS | 100 | 0 | 100 | 0 | 0 |

| 75S-25WGS | 75 | 25 | 100 | 0 | 0 |

| 50S-50WGS | 50 | 50 | 100 | 0 | 0 |

| 25S-75WGS | 25 | 75 | 100 | 0 | 0 |

| 75C-0FFA-25LSP | 75 | 25 | 75 | 0 | 25 |

| 50C-0FFA-50LSP | 75 | 25 | 50 | 0 | 50 |

| 25C-0FFA-75LSP | 75 | 25 | 25 | 0 | 75 |

| 85C-15FFA-0LSP | 75 | 25 | 85 | 15 | 0 |

| 70C-30FFA-0LSP | 75 | 25 | 70 | 30 | 0 |

| 55C-45FFA-0LSP | 75 | 25 | 55 | 45 | 0 |

| 75C-15FFA-10LSP | 75 | 25 | 75 | 15 | 10 |

| 70C-15FFA-15LSP | 75 | 25 | 70 | 15 | 15 |

| 55C-15FFA-30LSP | 75 | 25 | 55 | 15 | 30 |

| 50C-15FFA-35LSP | 75 | 25 | 50 | 15 | 35 |

| Mixture | 1 Expansion Threshold (%) | Expansion Reduction (%) | 2 Strength Activity Index (%) | |||||

|---|---|---|---|---|---|---|---|---|

| 14-Day | 28-Day | 56-Day | 14-Day | 28-Day | 56-Day | 7-Day | 28-Day | |

| 100S-0WGS | 0.24 | 0.35 | 0.49 | |||||

| 75S-25WGS | 0.40 | 0.61 | 1.20 | 100 | 100 | |||

| 50S-50WGS | 0.41 | 0.72 | 1.80 | |||||

| 25S-75WGS | 0.76 | 1.22 | 2.15 | |||||

| 75C-0FFA-25LSP | 0.14 | 0.24 | 0.41 | 63.9 | 60.0 | 66.1 | 63.09 | 61.50 |

| 50C-0FFA-50LSP | 0.03 | 0.07 | 0.14 | 92.2 | 88.9 | 88.1 | 31.41 | 32.38 |

| 25C-0FFA-75LSP | -0.02 | 0.00 | 0.02 | 104.5 | 100.6 | 98.1 | 4.19 | 4.32 |

| 85C-15FFA-0LSP | 0.09 | 0.20 | 0.31 | 76.4 | 66.7 | 73.8 | 89.73 | 86.78 |

| 70C-30FFA-0LSP | 0.01 | 0.02 | 0.02 | 97.9 | 97.3 | 98.6 | 57.21 | 68.54 |

| 55C-45FFA-0LSP | 0.02 | 0.05 | 0.07 | 94.9 | 91.7 | 94.0 | 38.04 | 44.48 |

| 75C-15FFA-10LSP | 0.06 | 0.14 | 0.22 | 85.5 | 76.6 | 81.3 | 80.65 | 81.92 |

| 70C-15FFA-15LSP | 0.04 | 0.11 | 0.18 | 90.7 | 81.4 | 84.6 | 65.63 | 66.67 |

| 55C-15FFA-30LSP | 0.01 | 0.05 | 0.06 | 96.3 | 93.4 | 95.2 | 42.17 | 42.84 |

| 50C-15FFA-35LSP | 0.01 | 0.02 | 0.02 | 102.4 | 96.5 | 98.5 | 30.08 | 30.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shon, C.-S.; Tugelbayev, A.; Shaimakhanov, R.; Karatay, N.; Zhang, D.; Kim, J.R. Use of Off-ASTM Class F Fly Ash and Waste Limestone Powder in Mortar Mixtures Containing Waste Glass Sand. Sustainability 2022, 14, 75. https://doi.org/10.3390/su14010075

Shon C-S, Tugelbayev A, Shaimakhanov R, Karatay N, Zhang D, Kim JR. Use of Off-ASTM Class F Fly Ash and Waste Limestone Powder in Mortar Mixtures Containing Waste Glass Sand. Sustainability. 2022; 14(1):75. https://doi.org/10.3390/su14010075

Chicago/Turabian StyleShon, Chang-Seon, Aidyn Tugelbayev, Ramazan Shaimakhanov, Nariman Karatay, Dichuan Zhang, and Jong R. Kim. 2022. "Use of Off-ASTM Class F Fly Ash and Waste Limestone Powder in Mortar Mixtures Containing Waste Glass Sand" Sustainability 14, no. 1: 75. https://doi.org/10.3390/su14010075