Scientometric Analysis and AHP for Hierarchizing Criteria Affecting Construction Equipment Operators’ Performance

Abstract

:1. Introduction

2. Literature Review

2.1. Scientometric Analysis

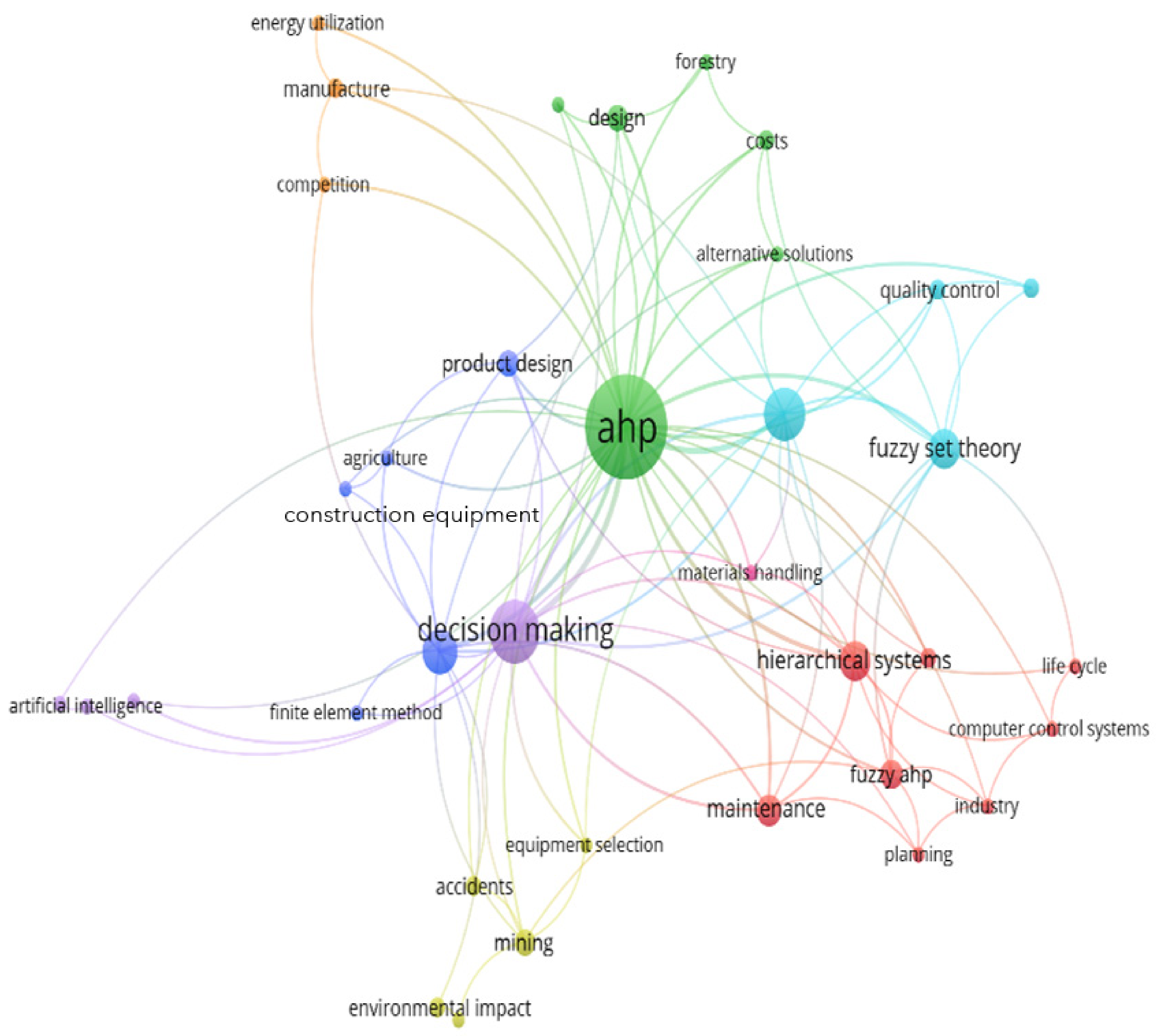

2.1.1. Text Data Co-Occurrence among the Titles and Their Abstracts

- The AHP is very popular among several MCDA methods with regard to the use of equipment. The term “equipment” includes construction equipment and general equipment (in industry, agriculture, manufacturing, etc.)

- By the way that the term “decision making” is linked with the other terms, it is related to issues such as maintenance, design, equipment selection, material handling, quality control, etc.

- The absence of the terms “production”, “productivity”, and “operator” can be explained by the fact that these terms are not defining the titles and the abstracts of the selected publications, which does not necessarily mean that they do not exist inside the rest of these documents.

- The fact that the last four clusters have fewer terms highlights the void inside the literature when it comes to relating construction equipment productivity with decision making in the industry sector and in material handling.

2.1.2. Keyword Co-Occurrence

- The average linkage weight (denser network) among the keywords is much stronger than among the titles and the text data of the abstracts; this is caused by the fact that the keywords are more or less used as common “de facto” terms.

- The clustering terms (visualized by different colors), in this case, are more distinct as their amount is greater, and they are used commonly.

- The term “decision making” is located at a close distance to “equipment selection” and “operator”, which clearly indicates the importance of the operator when it comes to selecting the proper equipment for certain projects. Equipment selection includes purchasing and fleet management.

- Additionally, the “operator” is related with “safety”, “reliability”, “knowledge”, and “experience”, which are crucial factors for the operator’s performance and efficiency.

- The “decision making” cluster (green) lies very close to the “production” (red) and “AHP applications” (dark blue) clusters, indicating their strong relatedness.

- The “productivity” cluster (orange) also includes the “human factor”, a term which refers to the operators.

- The “industry” cluster (yellow) is the most distant; however, it includes heavily weighted terms as the construction industry is an essential part of the general term.

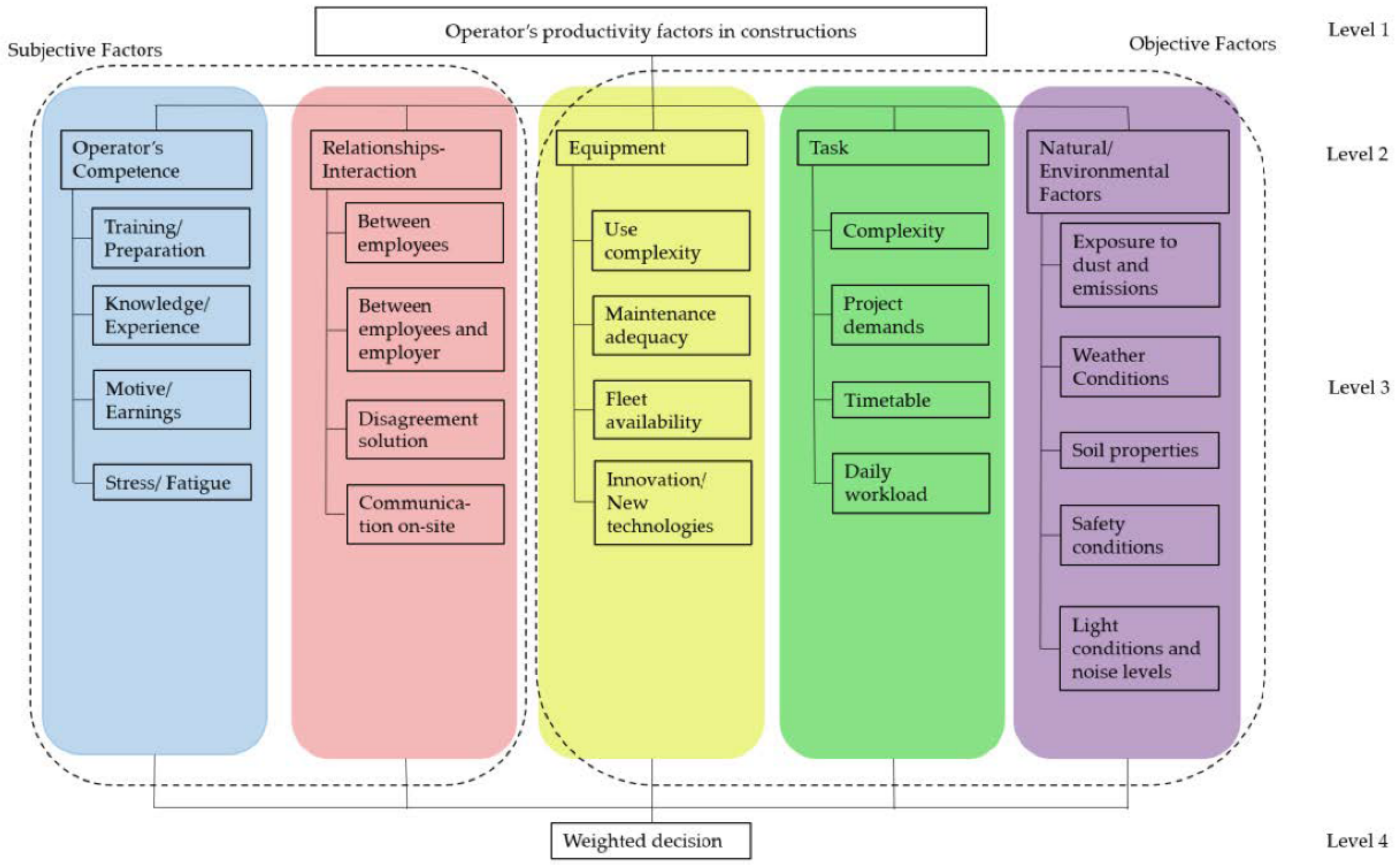

2.2. Criteria Selection

2.2.1. Operator’s Competence

2.2.2. Relationships and Interactions

2.2.3. Construction Equipment

2.2.4. Task

3. Materials and Methods

3.1. Research Process

3.2. Application of AHP

4. Results

4.1. Cumulative Evaluation

4.2. Sub-Criteria Evaluation

4.2.1. Equipment

4.2.2. Operator’s Competence

4.2.3. Task

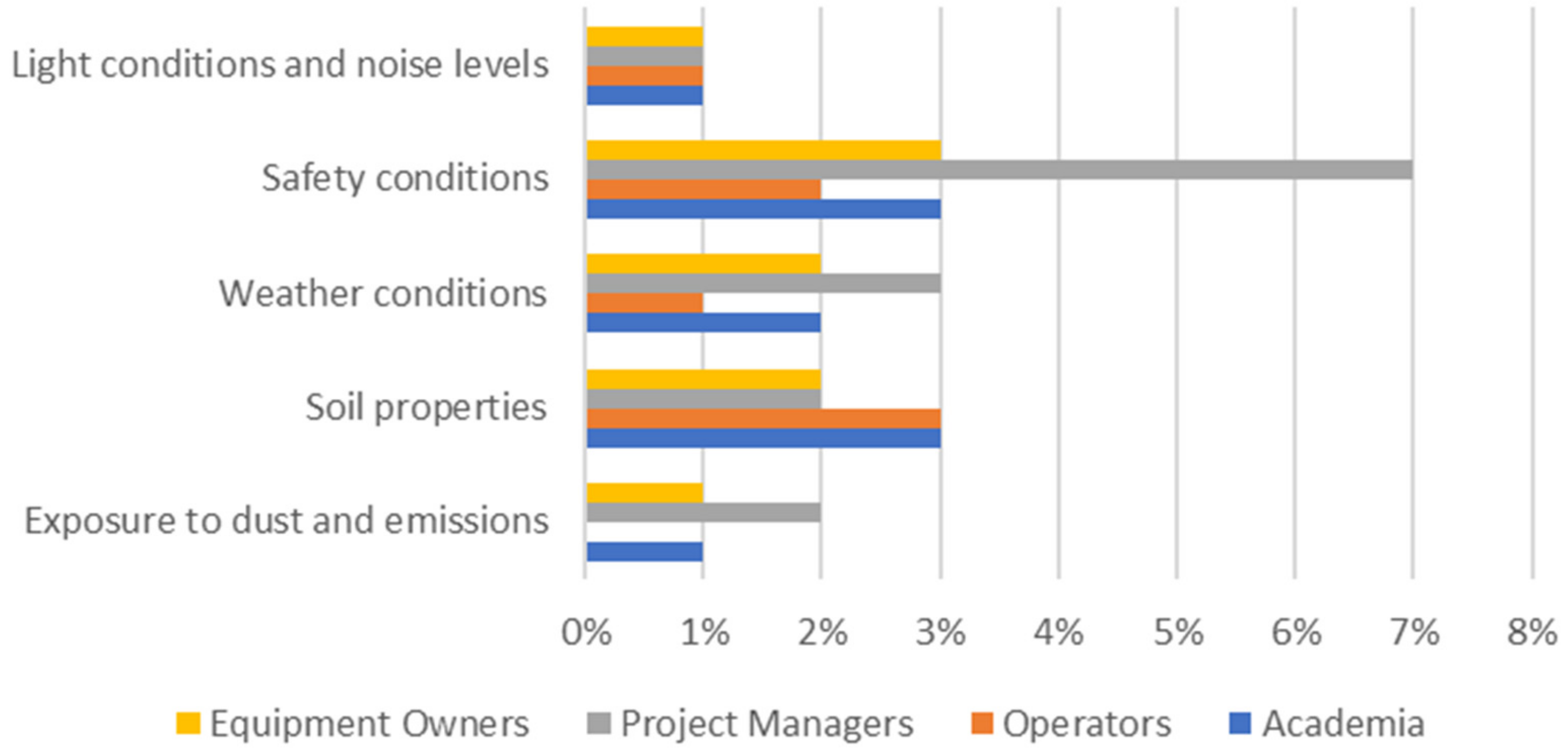

4.2.4. Natural/Environmental Factors

4.2.5. Relationships—Interaction

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gunduz, M.; Abu-Hijleh, A. Assessment of Human Productivity Drivers for Construction Labor through Importance Rating and Risk Mapping. Sustainability 2020, 12, 8614. [Google Scholar] [CrossRef]

- Yi, W.; Chan, A. Critical review of labor productivity research in construction journals. J. Manag. Eng. 2014, 30, 214–225. [Google Scholar] [CrossRef] [Green Version]

- Petroutsatou, K.; Marinelli, M. Construction Equipment, Operational Analysis and Economics of Civil. Engineering Projects, 2nd ed.; KRITIKI SA: Athens, Greece, 2018. [Google Scholar]

- Vorster, M. Construction Equipment Economics, 1st ed.; Pen Publications: Columbus, IN, USA, 2009. [Google Scholar]

- Petroutsatou, K.; Ladopoulos, I.; Vlachokostas, G. Comparative Evaluation of Fleet Management Software in the Greek Construction Industry. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1218. [Google Scholar] [CrossRef]

- Petroutsatou, K.; Sifniadis, A. Exploring the consequences of human multitasking in industrial automation projects: A tool to mitigate impacts-Part II. Organ. Technol. Manag. Constr. 2018, 10, 1770–1777. [Google Scholar] [CrossRef] [Green Version]

- Marinelli, M.; Petroutsatou, K.; Fragkakis, N.; Lambropoulos, S. Rethinking new public infrastructure value for money in recession times: The Greek case. Int. J. Constr. Manag. 2018, 18, 331–342. [Google Scholar] [CrossRef]

- Antunes, R.; Gonzalez, V.; Walsh, K.; Rojas, O. Dynamics of project-driven production systems in construction: Productivity function. J. Comput. Civil. Eng. 2017, 31, 4017053. [Google Scholar] [CrossRef]

- Liberda, M.; Ruwanpura, J.; Jergeas, G. Construction Productivity Improvement: A Study of Human, Management and External Issues. In Proceedings of the Construction Research Congress, Honolulu, HI, USA, 19–21 March 2003. [Google Scholar] [CrossRef]

- Ghoddousi, P.; Hosseini, M.R. A survey of the factors affecting the productivity of construction projects in Iran. Technol. Econ. Dev. Econ. 2012, 18, 99–116. [Google Scholar] [CrossRef] [Green Version]

- Hasan, A.; Baroudi, B.; Elmualim, A.; Rammeezdeen, R. Factors affecting construction productivity: A 30 year systematic review. Eng. Constr. Archit. Manag. 2018, 25, 916–937. [Google Scholar] [CrossRef]

- Hedman, R.; Subramaniyan, M.; Almstrom, P. Analysis of Critical Factors for Automatic Measurement of OEE. Procedia CIRP 2016, 57, 128–133. [Google Scholar] [CrossRef]

- He, Z.; Wang, G.; Chen, H.; Zou, Z.; Yan, H.; Liu, L. Measuring the Construction Project Resilience. Buildings 2022, 12, 56. [Google Scholar] [CrossRef]

- Zhu, Z.; Yuan, J.; Shao, Q.; Zhang, L.; Wang, G.; Li, X. Developing Key Safety Management Factors for Construction Projects in China: A Resilience Perspective. Int. J. Environ. Res. Public Health 2020, 17, 6167. [Google Scholar] [CrossRef]

- Johari, S.; Jha, K.N. How the Aptitude of Workers Affects Construction Labor Productivity. J. Manag. Eng. 2020, 36, 04020055. [Google Scholar] [CrossRef]

- Tangen, S. Demystifying productivity and performance. Int. J. Product. Perform. Manag. 2005, 54, 34–46. [Google Scholar] [CrossRef] [Green Version]

- Maqsoom, A.; Mubbasit, H.; Alqurashi, M.; Shaheen, I.; Alaloul, W.S.; Musarat, M.A.; Salman, A.; Aslam, B.; Zerouali, B.; Hussein, E.E. Intrinsic Workforce Diversity and Construction Worker Productivity in Pakistan: Impact of Employee Age and Industry Experience. Sustainability 2022, 14, 232. [Google Scholar] [CrossRef]

- Navon, R. Automated project performance control of construction projects. Autom. Constr. 2005, 14, 467–476. [Google Scholar] [CrossRef]

- Ofori, G.; Zhang, Z.; Ling, F. Key barriers to increase construction productivity: The Singapore case. Int. J. Constr. Manag. 2020. [Google Scholar] [CrossRef]

- Tijssen, R.; Van Raan, T. Mapping Changes in Science and Technology: Bibliometric Co-Occurrence Analysis of the R&D Literature. Eval. Rev. 1994, 18, 98–115. [Google Scholar] [CrossRef]

- Cobo, M.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science Mapping Software Tools: Review, Analysis, and Cooperative Study Among Tools. J. Am. Soc. Inf. Sci. Technol. 2011, 62, 1382–1402. [Google Scholar] [CrossRef]

- Jan van Eck, N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Zhong, B.; Wu, H.; Li, H.; Sepasgozar, S.; Luo, H.; He, L. A scientometric analysis and critical review of construction related ontology research. Autom. Constr. 2019, 101, 17–31. [Google Scholar] [CrossRef]

- Van Eck, N.; Waltman, L. VOSViewer Manual 2018. Available online: https://www.vosviewer.com/documentation/Manual_VOSviewer_1.6.8.pdf (accessed on 22 December 2021).

- Atkinson, R. Project management: Cost, time and quality, two best guesses and a phenomenon, its time to accept other success criteria. Int. J. Proj. Manag. 1999, 17, 337–342. [Google Scholar] [CrossRef]

- Holt, G.; Edwards, D. Analysis of interrelationships among excavator productivity modifying factors. Int. J. Product. Perform. Manag. 2015, 64, 853–869. [Google Scholar] [CrossRef]

- Yang, J.; Edwards, D.; Love, P.E.D. Measuring the impact of daily workload upon plant operator production performance using Artificial Neural Networks. Civ. Eng. Environ. Syst. 2004, 21, 279–293. [Google Scholar] [CrossRef]

- Dumitrescu, A.; Delsenicu, D. Risk assessment in manufacturing SMEs’ labor system. Procedia Manuf. 2018, 22, 912–915. [Google Scholar] [CrossRef]

- Du, Y.; Dorneich, M.; Steward, B.L. Virtual operator modeling method for excavator trenching. Autom. Constr. 2016, 70, 14–25. [Google Scholar] [CrossRef] [Green Version]

- Langer, T.H.; Iversen, T.; Andersen, N.; Mouritsen, O.; Hansen, M. Reducing whole-body vibration exposure in backhoe loaders by education of operators. Int. J. Ind. Ergon. 2012, 42, 304–311. [Google Scholar] [CrossRef] [Green Version]

- Naskoudakis, I.; Petroutsatou, K. A Thematic Review of Main Researches on Construction Equipment over the Recent Years. Procedia Eng. 2016, 164, 206–213. [Google Scholar] [CrossRef]

- Haggag, S.; Elnahas, S. Event-based detection of the digging operation states of a wheel loader earth moving equipment. Int. J. Heavy Veh. Syst. 2013, 20, 157–173. [Google Scholar] [CrossRef]

- Beleiu, I.; Crisan, E.; Nistor, R. Main factors Influencing Project Success. Int. Manag. Res. 2015, 11, 59–72. [Google Scholar]

- Cheuk, A.N.; Leung, J.T.; Tse, P.W. Effective Architecture for Web-Based Maintenance System and Its Security. In Proceedings of the ASME 2005 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference: 20th Biennial Conference on Mechanical Vibration and Noise, Long Beach, CA, USA, 24–28 September 2005; Volume 1, pp. 601–606. [Google Scholar] [CrossRef]

- Bahnassi, H.; Hammad, A. Near Real-Time Motion Planning and Simulation of Cranes in Construction: Framework and System Architecture. J. Comput. Civil. Eng. 2012, 26, 54–63. [Google Scholar] [CrossRef] [Green Version]

- Lee, G.; Cho, J.; Ham, S.; Lee, T.; Lee, G.; Yun, S.-H.; Yang, H.-J. A BIM- and sensor-based tower crane navigation system for blind lifts. Autom. Constr. 2012, 26, 1–10. [Google Scholar] [CrossRef]

- Barati, K.; Shen, X. Modeling and optimizing fuel usage of on-road construction equipment. In Proceedings of the Construction Research Congress 2018: Sustainable Design and Construction and Education—Selected Papers from the Construction Research Congress, New Orleans, LA, USA, 2–4 April 2018; pp. 198–207. [Google Scholar] [CrossRef]

- Albrektsson, J.; Aslund, J. Fuel Optimal Control of an Articulated Hauler Utilising a Human Machine Interface. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 19–22 February 2018; pp. 175–180. [Google Scholar] [CrossRef]

- Kokot, G.; Ogierman, W. The numerical simulation of FOPS and ROPS tests using LS-DYNA. Mechanika 2019, 25, 383–390. [Google Scholar] [CrossRef] [Green Version]

- Petroutsatou, K.; Giannoulis, P. Analysis of construction machinery market: The case of Greece. Int. J. Constr. Manag. 2020. [Google Scholar] [CrossRef]

- Saaty, T. T. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef] [Green Version]

- Shapira, A.; Goldenberg, M. AHP-based equipment selection model for construction projects. J. Constr. Eng. Manag. 2005, 131, 1263–1273. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Castillo-Lopez, E.; Rodriguez-Hernandez, J.; Canteras-Jordana, J.C. A review of application of multi-criteria decision making methods in construction. Autom. Constr. 2014, 45, 151–162. [Google Scholar] [CrossRef]

- Saaty, T.; Ozdemir, M. The unknown in decision making. What to do about it. Eur. J. Oper. Res. 2006, 174, 349–359. [Google Scholar] [CrossRef]

- Nassar, K.; Thabet, W.; Beliveau, Y. A procedure for multi-criteria selection of building assemblies. Autom. Constr. 2003, 12, 543–560. [Google Scholar] [CrossRef]

- Transparent Choice AHP Software. Available online: https://www.transparentchoice.com/ahp-software (accessed on 8 April 2022).

- Petroutsatou, K.; Ladopoulos, I.; Nalmpantis, D. Hierarchizing the Criteria of Construction Equipment Procurement Decision Using the AHP Method. IEEE Trans. Eng. Manag. 2021, 1–12. [Google Scholar] [CrossRef]

- Saaty, T.L. How to Make a Decision: The Analytic Hierarchy Process. Interfaces 1994, 24, 19–43. [Google Scholar] [CrossRef] [Green Version]

- Tsafarakis, S.; Gkorezis, P.; Nalmpantis, D.; Genitsaris, E.; Andronikidis, A.; Altsitsiadis, E. Investigating the preferences of individuals on public transport innovations using the Maximum Difference Scaling Method. Eur. Transp. Res. Rev. 2019, 11, 3. [Google Scholar] [CrossRef]

- Wood, H.; Gidado, K. Project Complexity in Construction. In The International Construction Conference, Royal Institute of Chartered Surveyors, RICS COBRA; RICS Foundation UK: Dublin, Ireland, 2008. [Google Scholar]

- Tangkar, M.; Arditi, D. Innovation in the Construction Industry. Civ. Eng. Dimens. 2000, 2, 96–103. [Google Scholar] [CrossRef]

- Duffuaa, S.; Alfares, H. Methods and Approaches for Maintenance Capacity Planning. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 3–5 March 2015. [Google Scholar]

- Alabdulkarim, A.; Ball, P.; Tiwari, A. Rapid modeling of field maintenance using discrete event simulation. In Proceedings of the Winter Simulation Conference, Phoenix, AZ, USA, 11–14 December 2011. [Google Scholar] [CrossRef] [Green Version]

- Nepal, M.P.; Park, M. Downtime model development for construction equipment management. Eng. Constr. Archit. Manag. 2004, 11, 199–210. [Google Scholar] [CrossRef] [Green Version]

- Edwards, D.; Parn, E.; Sing, M.; Thwala, W.D. Risk of excavators overturning. Determining horizontal centrifugal force when slewing freely suspended loads. Eng. Constr. Archit. Manag. 2019, 26, 479–498. [Google Scholar] [CrossRef] [Green Version]

- Edwards, D.; Yang, J.; Wright, B.C. Establishing the link between plant operator performance and personal motivation. J. Eng. Des. Technol. 2007, 5, 173–187. [Google Scholar] [CrossRef]

- Jukic, D.; Carmichael, G. Emission and cost effects of training for construction equipment operators. Smart Sustain. Built Environ. 2016, 5, 96–110. [Google Scholar] [CrossRef]

- Edwards, D. An artificial intelligence approach for improving plant operator maintenance proficiency. J. Qual. Maint. Eng. 2002, 8, 239–252. [Google Scholar] [CrossRef]

- Aryal, A.; Ghahramani, A.; Becerik-Gerber, B. Monitoring fatigue in construction workers using physiological measurements. Autom. Constr. 2017, 82, 154–165. [Google Scholar] [CrossRef]

- Sneddon, A.; Mearns, K.; Flin, R. Stress, fatigue, situation awareness and safety in offshore drilling crews. Saf. Sci. 2013, 56, 80–88. [Google Scholar] [CrossRef]

- Dinakar, A. Delay Analysis in Construction Project. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 784–788. [Google Scholar]

- Petroutsatou, K.; Ladopoulos, I. Integrated Prescriptive Maintenance System (PREMSYS) for Construction Equipment Based on Productivity. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1218, 012006. [Google Scholar] [CrossRef]

- Izetbegović, J.; Nahod, M.-M. The impact of the additional workload on the productivity in construction projects. In Proceedings of the Creative Construction Conference, Prague, Czech, 21 June 2014. [Google Scholar]

- Choi, B.; Hwangb, S.; Leec, S.H. What drives construction workers’ acceptance of wearable technologies in the workplace?: Indoor localization and wearable health devices for occupational safety and health. Autom. Constr. 2017, 84, 31–41. [Google Scholar] [CrossRef]

- Barlow, J. Innovation and learning in complex offshore construction projects. Res. Policy 2000, 29, 973–989. [Google Scholar] [CrossRef]

- World Health Organization 2015. Available online: https://apps.who.int/iris/bitstream/handle/10665/154589/9789241508513_eng.pdf (accessed on 8 April 2022).

- Neitzel, R.; Daniell, W.; Sheppard, L.; Davies, H.; Seixas, N. Comparison of Perceived and Quantitative Measures of Occupational Noise Exposure. Ann. Occup. Hyg. 2008, 53, 41–54. [Google Scholar] [CrossRef]

- Duffy, S.; Choi, S.H.; Hollern, R.; Ronis, D. Factors Associated with Risky Sun Exposure Behaviors Among Operating Engineers. Am. J. Ind. Med. 2012, 55, 786–792. [Google Scholar] [CrossRef] [Green Version]

- Eger, T.; Salmoni, A.; Whissell, R. Factors influencing load–haul–dump operator line of sight in underground mining. Appl. Ergon. 2004, 35, 93–103. [Google Scholar] [CrossRef]

- Fang, D.; Huang, Y.; Guo, H.; Lim, H.W. LCB approach for construction safety. Saf. Sci. 2020, 128, 104761. [Google Scholar] [CrossRef]

- Elazouni, A.; Basha, I. Evaluating the performance of construction equipment operators in Egypt. J. Constr. Eng. Manag. 1996, 122, 109–114. [Google Scholar] [CrossRef] [Green Version]

- Parsakho, A.; Hosseini, S.A.; Jalilvand, H.; Lotfalian, M. Physical soil properties and slope treatments effects on hydraulic excavator productivity for forest road construction. Pak. J. Biol. Sci. 2008, 11, 1422–1428. [Google Scholar] [CrossRef] [Green Version]

- Devi, P.; Palaniappan, S. A study on energy use for excavation and transport of soil during building construction. J. Clean. Prod. 2017, 164, 543–556. [Google Scholar] [CrossRef]

- Luo, Q.; Huang, L.; Xue, X.; Chen, Z.; Zhou, F.; Wei, L.; Hue, J. Occupational health risk assessment based on dust exposure during earthwork construction. J. Build. Eng. 2021, 44, 103186. [Google Scholar] [CrossRef]

- Chen, X.; Guo, C.; Song, J.; Wang, X.; Cheng, J. Occupational health risk assessment based on actual dust exposure in a tunnel construction adopting roadheader in Chongqing, China. Build. Environ. 2019, 165, 106415. [Google Scholar] [CrossRef]

- Ahn, C.; Lee, S.H. Importance of Operational Efficiency to Achieve Energy Efficiency and Exhaust Emission Reduction of Construction Operations. J. Constr. Eng. Manag. 2013, 139, 404–413. [Google Scholar] [CrossRef]

- Havard, C.; Rorive, B.; Sobczak, A. Client, Employer and Employee: Mapping a Complex Triangulation. Eur. J. Ind. Relat. 2009, 15, 257–276. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, S. Safety Climate in Construction Site Environments. J. Constr. Eng. Manag. 2002, 128, 375–384. [Google Scholar] [CrossRef]

- Smithers, G.; Walker, D. The effect of the workplace on motivation and demotivation of construction professionals. Constr. Manag. Econ. 2000, 18, 833–841. [Google Scholar] [CrossRef]

| Boolean Operator | Terms | Description |

|---|---|---|

| construction equipment | The term that describes the main topic and the core search rule | |

| OR | machinery | Used for searching all machinery- and equipment-based publications, in order to exclude the irrelevant |

| OR | equipment | |

| AND | operator * | Term that specifies the distinctive topic, concerning operators |

| OR | product * | Term that specifies the distinctive topic, concerning productivity |

| AND | AHP | The applied Multi-Criteria Decision Analysis (MCDA) method |

| OR | Analytic * Hierarchy Process | Used to include references for AHP as Analytic or Analytical Hierarchy Process |

| NOT | medic * | All the terms concerning medical, health, and pharmaceutical issues |

| NOT | Health | |

| NOT | pharma * |

| Cluster Number | Main Subject | Color | Terms Included |

|---|---|---|---|

| 1 | Hierarchization methods | Red | 8 |

| 2 | AHP | Green | 6 |

| 3 | Equipment | Dark Blue | 5 |

| 4 | Ore mining | Light Green | 5 |

| 5 | Decision Making | Purple | 4 |

| 6 | Construction Equipment | Sky Blue | 4 |

| 7 | Industry | Orange | 3 |

| 8 | Material Handling | Pink | 1 |

| Cluster Number | Main Subject | Color | Terms Included |

|---|---|---|---|

| 1 | Production | Red | 10 |

| 2 | Decision Making | Green | 10 |

| 3 | AHP Applications | Dark Blue | 7 |

| 4 | Industry | Yellow | 7 |

| 5 | Maintenance | Purple | 6 |

| 6 | Strategy and Indexes | Sky Blue | 4 |

| 7 | Productivity | Orange | 3 |

| Criterion | Source |

|---|---|

| Operator’s Competence | |

| Knowledge/Experience | Holt and Edwards, 2015 [26] |

| Yang, Edwards, and Love, 2004 [27] | |

| Dumitrescu and Delsenicu, 2018 [28] | |

| Du, Dorneich, and Steward, 2016 [29] | |

| Training/Preparation | Langer et al., 2012 [30] |

| Du, Dorneich, and Steward, 2016 [29] | |

| Naskoudakis and Petroutsatou, 2016 [31] | |

| Dumitrescu and Delsenicu, 2018 [28] | |

| Motive/Earnings | Yang, Edwards, and Love, 2004 [27] |

| Holt and Edwards, 2015 [26] | |

| Dumitrescu and Delsenicu, 2018 [28] | |

| Stress/Fatigue | Yang, Edwards, and Love, 2004 [27] |

| Haggag and Elnahas, 2013 [32] | |

| Relationships and Interaction | |

| Between employees | Dumitrescu and Delsenicu, 2018 [28] |

| Between employees and employer | Dumitrescu and Delsenicu, 2018 [28] |

| Disagreement resolution | Dumitrescu and Delsenicu, 2018 [28] |

| On-site communication | Beleiu, Crisan, and Nistor, 2015 [33] |

| Construction Equipment | |

| Use complexity | Dumitrescu and Delsenicu, 2018 [28] |

| Maintenance adequacy | Yang, Edwards, and Love, 2004 [27] |

| Cheuk, Leung, and Tse, 2005 [34] | |

| Naskoudakis and Petroutsatou, 2016 [31] | |

| Fleet availability | Naskoudakis and Petroutsatou, 2016 [31] |

| Innovation/New technologies | Bahnassi and Hammad, 2012 [35] |

| Lee et al., 2012 [36] | |

| Naskoudakis and Petroutsatou, 2016 [31] | |

| Barati and Shen, 2018 [37] | |

| Albrektsson and Aslund, 2019 [38] | |

| Task | |

| Complexity | Dumitrescu and Delsenicu, 2018 [28] |

| Project demands | Dumitrescu and Delsenicu, 2018 [28] |

| Timetable | Naskoudakis and Petroutsatou, 2016 [31] |

| Dumitrescu and Delsenicu, 2018 [28] | |

| Daily workload | Yang, Edwards, and Love, 2004 [27] |

| Haggag and Elnahas, 2013 [32] | |

| Natural/Environmental Factors | |

| Exposure to dust and emissions | Langer et al., 2012 [30] |

| Naskoudakis and Petroutsatou, 2016 [31] | |

| Dumitrescu and Delsenicu, 2018 [28] | |

| Kokot and Ogierman, 2019 [39] | |

| Weather conditions | Du, Dorneich, and Steward, 2016 [29] |

| Dumitrescu and Delsenicu, 2018 [28] | |

| Soil properties | Du, Dorneich, and Steward, 2016 [29] |

| Barati and Shen, 2018 [37] | |

| Safety conditions | Langer et al., 2012 [30] |

| Naskoudakis and Petroutsatou, 2016 [31] | |

| Dumitrescu and Delsenicu, 2018 [28] | |

| Kokot and Ogierman, 2019 [39] | |

| Petroutsatou and Giannoulis, 2020 [40] | |

| Light conditions and noise levels | Bahnassi and Hammad, 2012 [35] |

| Naskoudakis and Petroutsatou, 2016 [31] | |

| Dumitrescu and Delsenicu, 2018 [28] | |

| Expertise | Quantity | |

|---|---|---|

| 1 | Academia | 6 |

| 2 | Project Managers | 2 |

| 3 | Construction Equipment Operators | 3 |

| 4 | Construction Equipment Owners | 2 |

| Total | 13 |

| # | Criteria | Weight | |

|---|---|---|---|

| Local | Global | ||

| 1. | Equipment | 24% | 24% |

| 1.1 | Fleet availability | 37% | 9% |

| 1.2 | Maintenance adequacy | 42% | 10% |

| 1.3 | Innovation/New technologies | 12% | 3% |

| 1.4 | Use complexity | 9% | 2% |

| 2. | Operator’s competence | 41% | 41% |

| 2.1 | Stress/Fatigue | 15% | 6% |

| 2.2 | Knowledge/Experience | 52% | 21% |

| 2.3 | Training/Preparation | 19% | 8% |

| 2.4 | Motive/Earnings | 14% | 6% |

| 3. | Task | 15% | 15% |

| 3.1 | Project demands | 34% | 5% |

| 3.2 | Daily workload | 18% | 3% |

| 3.3 | Complexity | 14% | 2% |

| 3.4 | Timetable | 34% | 5% |

| 4. | Natural/Environmental Factors | 10% | 10% |

| 4.1 | Exposure to dust and emissions | 9% | 1% |

| 4.2 | Soil properties | 26% | 2% |

| 4.3 | Weather conditions | 21% | 2% |

| 4.4 | Safety conditions | 34% | 3% |

| 4.5 | Light conditions and noise levels | 10% | 1% |

| 5. | Relationships—Interaction | 11% | 11% |

| 5.1 | Disagreement solution | 24% | 3% |

| 5.2 | Between employees | 19% | 2% |

| 5.3 | Between employees and employer | 26% | 3% |

| 5.4 | On-site communication on site | 32% | 3% |

| # | Criteria | Academia (6) | Project Managers (2) | Operators (3) | Owners (2) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Weight | Weight | Weight | Weight | ||||||

| Local | Global | Local | Global | Local | Global | Local | Global | ||

| 1. | Equipment | 20% | 20 | 25% | 25% | 28% | 28% | 24% | 24 |

| 1.1 | Fleet availability | 28% | 6% | 43% | 11% | 43% | 12% | 42% | 10 |

| 1.2 | Maintenance adequacy | 48% | 10% | 42% | 10% | 40% | 11% | 25% | 6 |

| 1.3 | Innovation/New technologies | 11% | 2% | 9% | 2% | 10% | 3% | 24% | 6 |

| 1.4 | Use complexity | 12% | 2% | 5% | 1% | 6% | 2% | 9% | 2 |

| 2. | Operator’s competence | 41% | 41% | 26% | 26% | 51% | 51% | 38% | 38 |

| 2.1 | Stress/Fatigue | 20% | 8% | 10% | 3% | 10% | 5% | 15% | 6 |

| 2.2 | Knowledge/ Experience | 44% | 18% | 58% | 15% | 61% | 31% | 54% | 21 |

| 2.3 | Training/ Preparation | 25% | 10% | 15% | 4% | 13% | 7% | 16% | 6 |

| 2.4 | Motive/Earnings | 11% | 5% | 18% | 5% | 17% | 8% | 16% | 6 |

| 3. | Task | 18% | 18% | 24% | 24% | 8% | 8% | 11% | 11 |

| 3.1 | Project demands | 26% | 5% | 24% | 5% | 44% | 4% | 48% | 5 |

| 3.2 | Daily workload | 22% | 4% | 11% | 3% | 18% | 1% | 12% | 1 |

| 3.3 | Complexity | 13% | 2% | 9% | 2% | 11% | 1% | 26% | 3 |

| 3.4 | Timetable | 39% | 7% | 56% | 14% | 27% | 2% | 15% | 2 |

| 4. | Natural/ Environmental Factors | 9% | 9% | 15% | 15% | 7% | 7% | 8% | 8 |

| 4.1 | Exposure to dust and emissions | 11% | 1% | 14% | 2% | 5% | 0% | 9% | 1 |

| 4.2 | Soil properties | 27% | 3% | 10% | 2% | 40% | 3% | 21% | 2 |

| 4.3 | Weather conditions | 20% | 2% | 18% | 3% | 21% | 1% | 24% | 2 |

| 4.4 | Safety conditions | 31% | 3% | 47% | 7% | 26% | 2% | 37% | 3 |

| 4.5 | Light conditions and noise levels | 11% | 1% | 10% | 1% | 9% | 1% | 9% | 1 |

| 5. | Relationships—Interaction | 12% | 12% | 11% | 11% | 6% | 6% | 18% | 18 |

| 5.1 | Disagreement solution | 23% | 3% | 29% | 3% | 30% | 2% | 14% | 3 |

| 5.2 | Between employees | 22% | 3% | 25% | 3% | 16% | 1% | 9% | 2 |

| 5.3 | Between employees and employer | 21% | 3% | 25% | 3% | 30% | 2% | 30% | 6 |

| 5.4 | On-site communication | 34% | 4% | 22% | 2% | 24% | 1% | 47% | 9 |

| Evaluators | Equipment | Operator’s Competence | Task | Natural/ Environmental Factors | Relationships— Interaction |

|---|---|---|---|---|---|

| Academia | 20% | 41% | 18% | 9% | 12% |

| Project Managers | 25% | 26% | 24% | 15% | 11% |

| Operators | 28% | 51% | 8% | 7% | 6% |

| Owners | 24% | 38% | 11% | 8% | 18% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petroutsatou, K.; Ladopoulos, I.; Tsakelidou, K. Scientometric Analysis and AHP for Hierarchizing Criteria Affecting Construction Equipment Operators’ Performance. Sustainability 2022, 14, 6836. https://doi.org/10.3390/su14116836

Petroutsatou K, Ladopoulos I, Tsakelidou K. Scientometric Analysis and AHP for Hierarchizing Criteria Affecting Construction Equipment Operators’ Performance. Sustainability. 2022; 14(11):6836. https://doi.org/10.3390/su14116836

Chicago/Turabian StylePetroutsatou, Kleopatra, Ilias Ladopoulos, and Konstantina Tsakelidou. 2022. "Scientometric Analysis and AHP for Hierarchizing Criteria Affecting Construction Equipment Operators’ Performance" Sustainability 14, no. 11: 6836. https://doi.org/10.3390/su14116836