Effects of Alternative Fertilization and Irrigation Practices on the Energy Use and Carbon Footprint of Canning Peach Orchards

Abstract

:1. Introduction

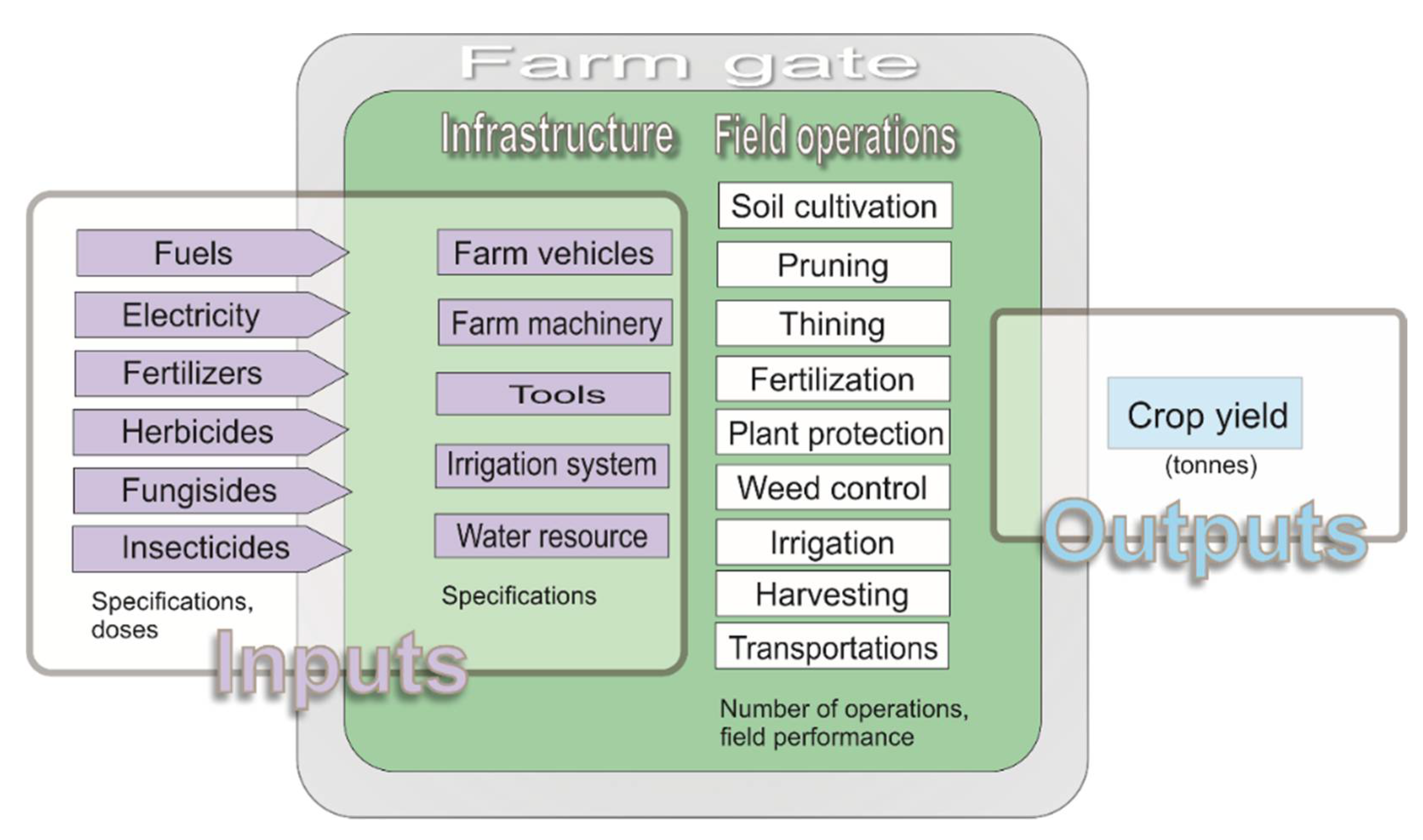

2. Materials and Methods

- Farmers’ traditional practices

- Alterative cultivation protocol comprising deficit irrigation (75% of ETc) and fertilization schemes combining balanced applications of surface granular fertilizers, foliar fertilizers and fertigation.

3. Results and Discussion

3.1. Analysis of Input–Output Energy Use

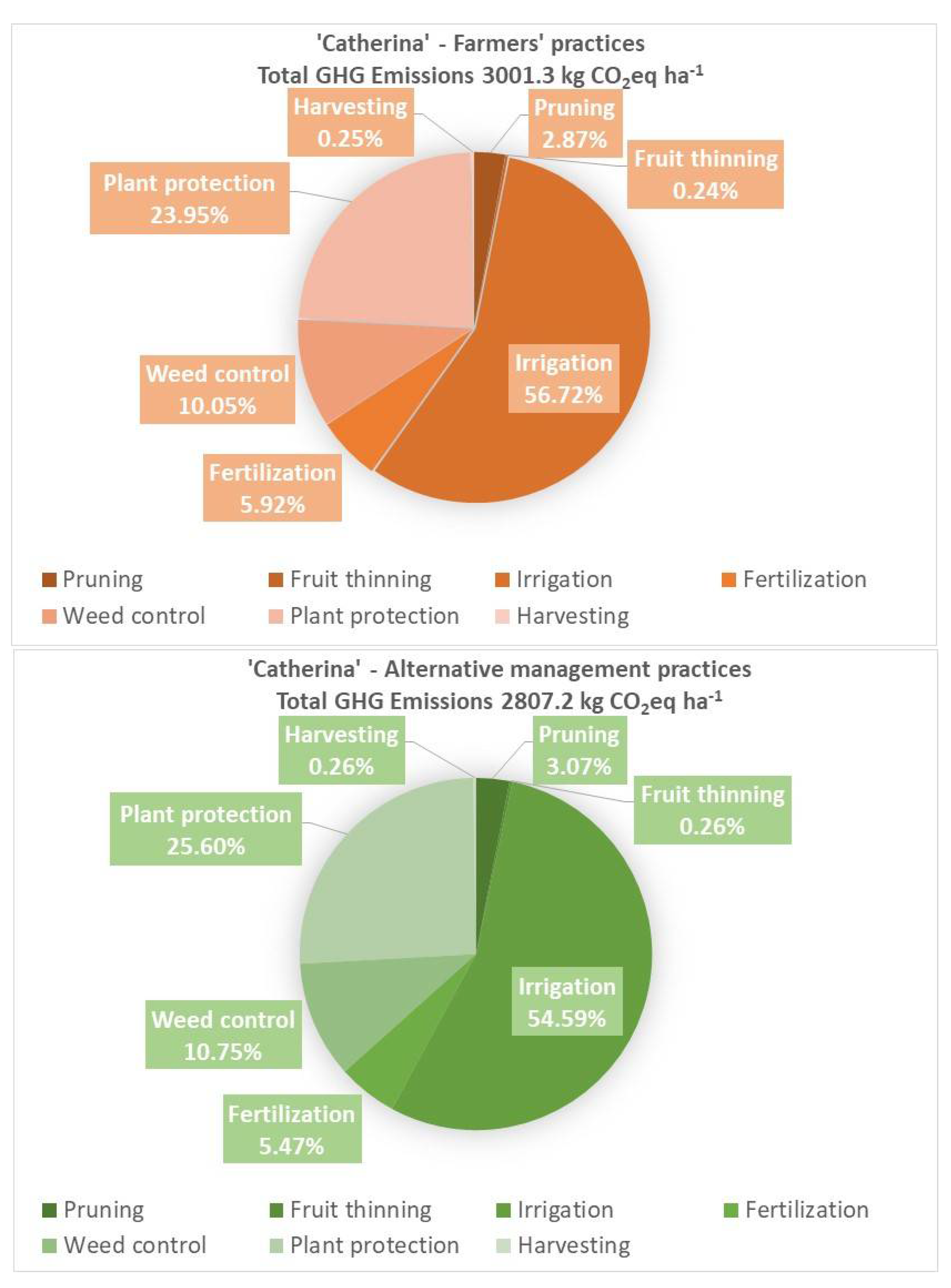

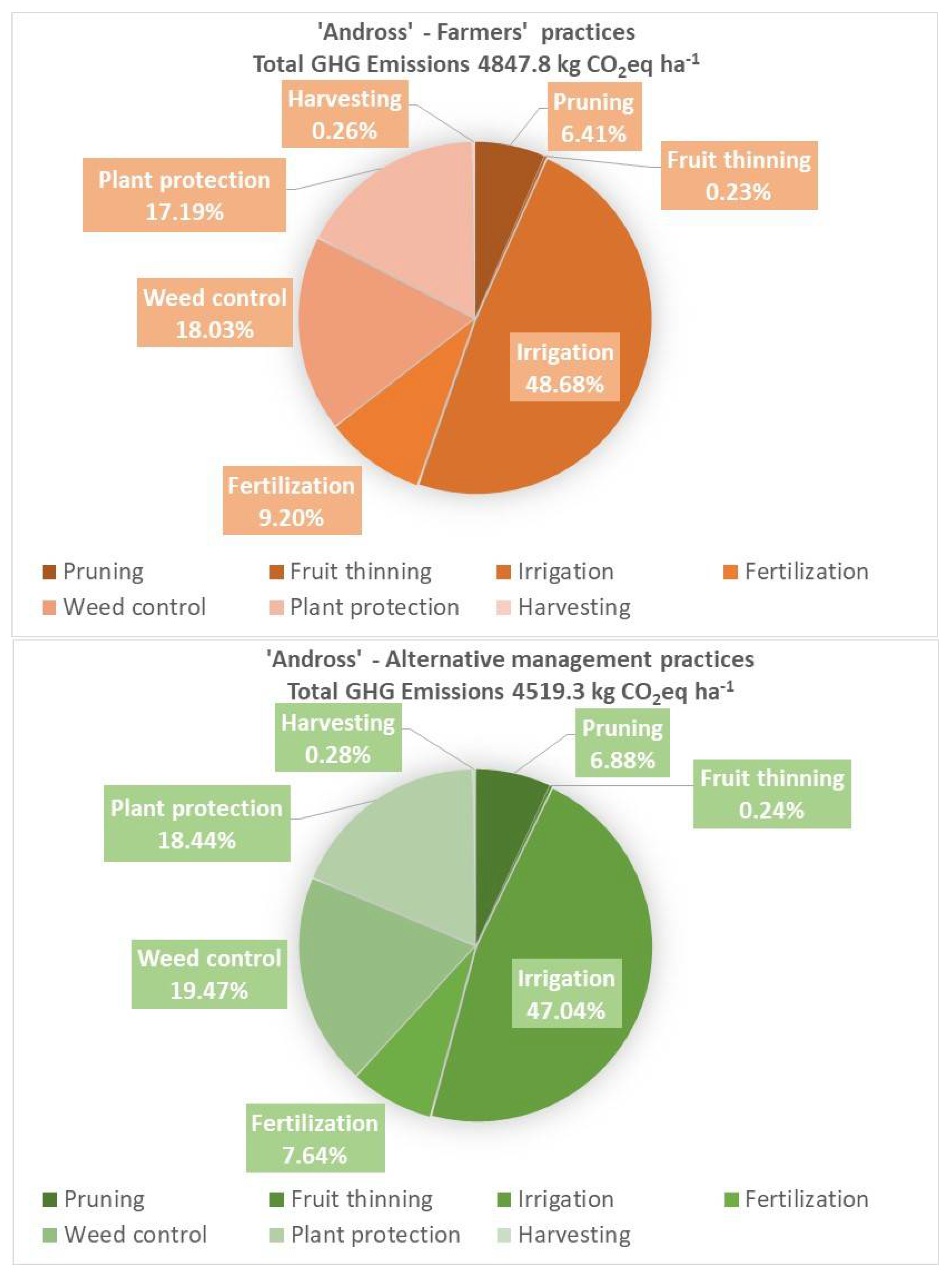

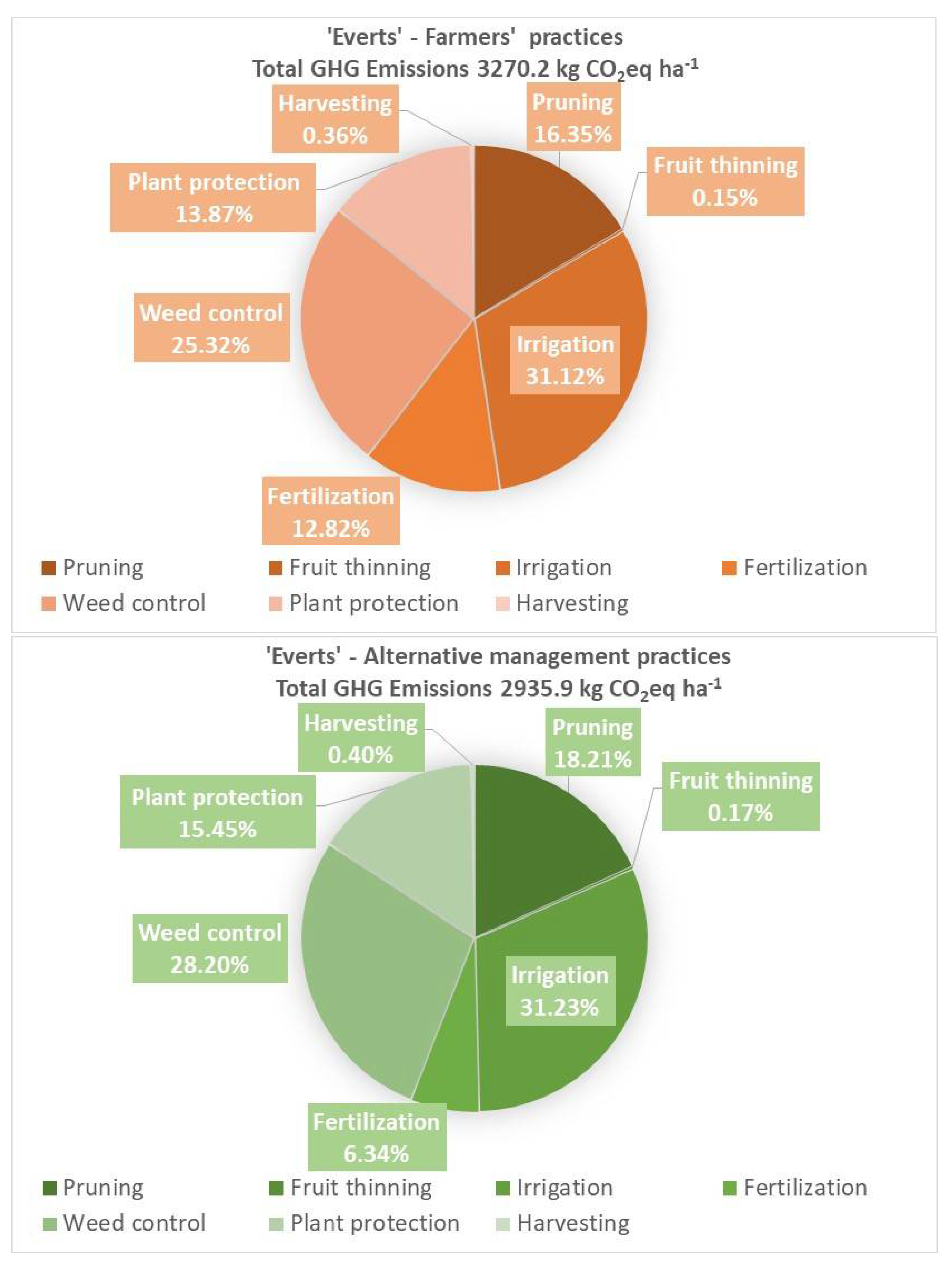

3.2. Analysis of GHG Emissions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Minagric. Data of Production and Processing of Clingstone Peach of Greece for the Periods 2006–2018. Available online: http://www.minagric.gr/images/stories/docs/agrotis/Oporokipeytika/stat_rodakino_2006eos2018.pdf (accessed on 3 July 2021).

- Ingram, D.L.; Fernandez, R. Life Cycle Assessment: A tool for determining the environmental impact of horticultural crop production. HortTechnology 2012, 22, 275–279. [Google Scholar] [CrossRef] [Green Version]

- Roussos, P.A. Climate change impacts on fruit trees and mitigation strategies of adverse effects. AgroLife Sci. J. 2020, 9, 269–276. [Google Scholar]

- Van der Werf, H.M.G.; Garnett, T.; Corson, M.S.; Hayashi, K.; Huisingh, D.; Cederberg, C. Towards eco-efficient agriculture and food systems: Theory, praxis and future challenges. J. Clean. Prod. 2014, 73, 1–9. [Google Scholar] [CrossRef]

- Platis, D.P.; Anagnostopoulos, C.D.; Tsaboula, A.D.; Menexes, G.C.; Kalburtji, K.L.; Mamolos, A.P. Energy analysis, and carbon and water footprint for environmentally friendly farming practices in agroecosystems and agroforestry. Sustainability 2019, 11, 1664. [Google Scholar] [CrossRef] [Green Version]

- Gündoğmuş, E. Does energy efficiency increase with orchard size? A case study from peach production. Energy Effic. 2014, 7, 833–839. [Google Scholar] [CrossRef]

- Strapatsa, A.V.; Nanos, G.D.; Tsatsarelis, C.A. Energy flow for integrated apple production in Greece. Agric. Ecosyst. Environ. 2006, 116, 176–180. [Google Scholar] [CrossRef]

- Guzmán, G.I.; Alonso, A.M. A comparison of energy use in conventional and organic olive oil production in Spain. Agric. Syst. 2008, 98, 167–176. [Google Scholar] [CrossRef]

- Kaltsas, A.M.; Mamolos, A.P.; Tsatsarelis, C.A.; Nanos, G.D.; Kalburtji, K.L. Energy budget in organic and conventional olive groves. Agric. Ecosyst. Environ. 2007, 122, 243–251. [Google Scholar] [CrossRef]

- Cerutti, A.K.; Bruun, S.; Beccaro, G.L.; Bounous, G. A review of studies applying environmental impact assessment methods on fruit production systems. J. Environ. Manag. 2011, 92, 2277–2286. [Google Scholar] [CrossRef]

- Ghatrehsamani, S.; Ebrahimi, R.; Kazi, S.N.; Badry, A.B.; Sadeghinezhad, E. Optimization model of peach production relevant to input energies—Yield function in Chaharmahalva Bakhtiari province, Iran. Energy 2016, 99, 315–321. [Google Scholar] [CrossRef]

- Aydin, B.; Aktürk, D. Energy use efficiency and economic analysis of peach and cherry production regarding good agricultural practices in Turkey: A case study in Çanakkale province. Energy 2018, 158, 967–974. [Google Scholar] [CrossRef]

- Litskas, V.D.; Mamolos, A.P.; Kalburtji, K.L.; Tsatsarelis, C.A.; Kiose-Kampasakali, E. Energy flow and greenhouse gas emissions in organic and conventional sweet cherry orchards located in or close to Natura 2000 sites. Biomass Bioenergy 2011, 35, 1302–1310. [Google Scholar] [CrossRef]

- Michos, M.C.; Mamolos, A.P.; Menexes, G.C.; Tsatsarelis, C.A.; Tsirakoglou, V.M.; Kalburtji, K.L. Energy inputs, outputs and greenhouse gas emissions in organic, integrated and conventional peach orchards. Ecol. Indic. 2012, 13, 22–28. [Google Scholar] [CrossRef]

- Aguilera, E.; Guzmán, G.; Alonso, A. Greenhouse gas emissions from conventional and organic cropping systems in Spain. II. Fruit tree orchards. Agron. Sustain. Dev. 2015, 35, 725–737. [Google Scholar] [CrossRef] [Green Version]

- Ingrao, C.; Matarazzo, A.; Tricase, C.; Clasadonte, M.T.; Huisingh, D. Life cycle assessment for highlighting environmental hotspots in Sicilian peach production systems. J. Clean. Prod. 2015, 92, 109–120. [Google Scholar] [CrossRef]

- Yan, M.; Cheng, K.; Yue, Q.; Yan, Y.; Rees, R.M.; Pan, G. Farm and product carbon footprints of China’s fruit production-life cycle inventory of representative orchards of five major fruits. Environ. Sci. Pollut. Res. 2016, 23, 4681–4691. [Google Scholar] [CrossRef]

- Vinyes, E.; Asin, L.; Alegre, S.; Gasol, C.M.; Munoz, P. Carbon footprint and profitability of two apple cultivation training systems: Central axis and Fruiting wall. Sci. Hortic. 2018, 229, 233–239. [Google Scholar] [CrossRef]

- Alluvione, F.; Moretti, B.; Sacco, D.; Grignani, C. EUE (energy use efficiency) of cropping systems for a sustainable agriculture. Energy 2011, 36, 4468–4481. [Google Scholar] [CrossRef]

- Gemtos, T.A.; Cavalaris, C.; Karamoutis, C.; Tagarakis, A.C.; Fountas, S. Energy analysis of three energy crops in Greece. Agric. Eng. Int. CIGR J. 2013, 15, 52–66. [Google Scholar]

- Fluck, R.C. Energy of human labor. In Energy in World Agriculture. Energy in Farm Production, 1st ed.; Fluck, R.C., Ed.; Elsevier: Amsterdam, The Netherlands, 1992; pp. 31–37. [Google Scholar] [CrossRef]

- Bowers, W. Agricultural field equipment. In Energy in World agriculture, Energy in Farm Production, 1st ed.; Fluck, R.C., Ed.; Elsevier: Amsterdam, The Netherlands, 1992; Volume 10, pp. 117–129. [Google Scholar] [CrossRef]

- Pimentel, D.L.; Hurd, E.; Belloti, A.L.; Forster, M.J.; Oka, J.N.; Sholes, O.D.; Whitman, R.J. Food production and the energy crisis. Science 1973, 182, 443–449. [Google Scholar] [CrossRef]

- Fluck, R.C. Energy sequestered in repairs and maintenance of agricultural machinery. Trans. ASAE 1985, 28, 738–744. [Google Scholar] [CrossRef]

- ASABE. Agricultural Machinery Management Data; ASABE D 497.5 FEB; ASABE: St. Joseph, MI, USA, 2006. [Google Scholar]

- Lockeretz, W. Energy inputs for nitrogen, phosphorus and potash fertilizers. Ιn Handbook of Energy Utilization in Agriculture; Pimentel, D., Ed.; CRC Press: New York, NY, USA, 1980; pp. 15–21. [Google Scholar]

- Tsatsarelis, C.A. Energy inputs and outputs for soft winter wheat production in Greece. Agric. Ecosyst. Environ. 1993, 43, 109–118. [Google Scholar] [CrossRef]

- Wells, C. Total Energy Indicators of Agricultural Sustainability: Dairy Farming Case Study; Technical Paper 2001/3; Ministry of Agriculture and Forestry: Wellington, New Zealand, 2001.

- Pimentel, D. Handbook of Energy Utilization in Agriculture; CRC Press: New York, NY, USA, 1980. [Google Scholar]

- Fluck, R.C. Energy of agricultural products. In Energy in World Agriculture. Energy in Farm Production, 1st ed.; Fluck, R.C., Ed.; Elsevier: Amsterdam, The Netherlands, 1992; Volume 4, pp. 39–43. [Google Scholar] [CrossRef]

- Pimentel, D. Energy Inputs in Production Agriculture. In Energy in World Agriculture, Energy in Farm Production, 1st ed.; Fluck, R.C., Ed.; Elsevier: Amsterdam, The Netherlands, 1992; Volume 2, pp. 13–29. [Google Scholar] [CrossRef]

- Tzilivakis, J.; Warner, D.J.; May, M.; Lewis, K.A.; Jaggard, K. An assessment of the energy inputs and greenhouse gas emissions in sugar beet (Beta vulgaris) production in the UK. Agric. Syst. 2005, 85, 101–119. [Google Scholar] [CrossRef] [Green Version]

- Anaya, C.A.; Burgos, A.L. Energy consumption in the management of avocado orchards in Michoacán, Mexico. Rev. Chapingo Ser. Hortic. 2015, 21, 5–20. [Google Scholar] [CrossRef]

- Alonso, A.M.; Guzmán, G.J. Comparison of the efficiency and use of energy in organic and conventional farming in Spanish agricultural systems. J. Sustain. Agric. 2010, 34, 312–338. [Google Scholar] [CrossRef]

- Lal, R. Carbon emission from farm operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Soto-García, M.; Martínez-Alvarez, V. Energy and greenhouse-gas emissions in irrigated agriculture of SE (southeast) Spain. Effects of alternative water supply scenarios. Energy 2014, 77, 478–488. [Google Scholar] [CrossRef]

- Bascetincelik, A.; Yaldiz, O.; Ozturk, H.H.; Zeren, Y. Energy use in field crops of Turkey. In Proceedings of the International Congress of Agricultural Machinery and Energy, Kusadasi, Turkey, 11–14 October 1993. [Google Scholar]

- Tagliavini, M.; Marangoni, B. Major nutritional issues in deciduous fruit orchards of Northern Italy. HortTechnology 2002, 12, 26–31. [Google Scholar] [CrossRef] [Green Version]

- Lopez, G.; Arbones, A.; Del Campo, J.; Mata, M.; Vallverdu, X.; Girona, J.; Marsal, J. Responses of peach trees to regulated deficit irrigation during stage II of fruit development and summer pruning. Span. J. Agric. Res. 2008, 6, 479–491. [Google Scholar] [CrossRef] [Green Version]

- Crisosto, C.H.; Johnson, R.S.; Luza, J.G.; Crisosto, G.M. Irrigation regimes affect fruit soluble solids concentration and rate of water loss of ‘O’Henry’ peaches. HortScience 1994, 29, 1169–1171. [Google Scholar] [CrossRef] [Green Version]

- Behboudian, M.H.; Marsal, J.; Girona, J.; Lopez, G. Quality and yield responses of deciduous fruits to reduce irrigation. Hortic. Rev. 2011, 38, 149–189. [Google Scholar] [CrossRef]

- Royan, M.; Khojastehpour, M.; Emadi, B.; Mobtaker, H.G. Investigation of energy inputs for peach production using sensitivity analysis in Iran. Energy Conver. Manag. 2012, 64, 441–446. [Google Scholar] [CrossRef]

- Vinyes, E.; Gasol, C.M.; Asin, L.; Alegre, S.; Muñoz, P. Life cycle assessment of multiyear peach production. J. Clean. Prod. 2015, 104, 68–79. [Google Scholar] [CrossRef] [Green Version]

- Guo, C.; Wang, X.; Li, Y.; He, X.; Zhang, W.; Wang, J.; Shi, X.; Chen, X.; Zhang, Y. Carbon footprint analyses and potential carbon emission reduction in China’s major peach orchards. Sustainability 2018, 10, 2908. [Google Scholar] [CrossRef] [Green Version]

- Nikkhah, A.; Royan, M.; Khojastehpour, M.; Bacenetti, J. Environmental impacts modeling of Iranian peach production. Renew. Sust. Energ. Rev. 2017, 75, 677–682. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Maestre-Valero, J.F.; Almagro, M.; Boix-Fayos, C.; Martínez-Mena, M. Carbon emissions and economic assessment of farm operations under different tillage practices in organic rainfed almond orchards in semiarid Mediterranean conditions. Sci. Hortic. 2020, 261, 108978. [Google Scholar] [CrossRef]

- Fiore, A.; Dichio, B.; Celano, G.; Modarelli, A.; Palese, A.; Quinto, G.; Pergola, M.; Xiloyannis, C. A more comprehensive greenhouse gas accounting methodology for peach productive chain: Toward a certification of low-carbon fruits. Acta Hortic. 2015, 1084, 539–548. [Google Scholar] [CrossRef]

- Snyder, C.S.; Bruulsema, T.W.; Jensen, T.L.; Fixen, P.E. Review of greenhouse gas emissions from crop production systems and fertilizer management effects. Agric. Ecosyst. Environ. 2009, 133, 247–266. [Google Scholar] [CrossRef]

- Vilarrasa-Nogué, M.; Teira-Esmatges, M.R.; Pascual, M.; Villar, J.M.; Rufat, J. Effect of N dose, fertilisation duration and application of a nitrification inhibitor on GHG emissions from a peach orchard. Sci. Total Environ. 2020, 699, 134042. [Google Scholar] [CrossRef]

- Xiloyannis, C.; Fiore, A.; Mininni, A.N.; Xylogiannis, E.; Montanaro, G.; Dichio, B. Effect of sustainable production systems on carbon and water footprint in fruit tree orchards. Acta Hortic. 2016, 1130, 19–24. [Google Scholar] [CrossRef]

| Farm | ‘Catherina’ | ‘Andross’ | ‘Everts’ |

|---|---|---|---|

| Soil type | Silty loam | Sandy loam | Clay loam |

| Sand (%) | 19.2 | 61.9 | 31.5 |

| Silt (%) | 57.3 | 27.0 | 39.0 |

| Clay (%) | 23.5 | 11.1 | 29.5 |

| pH | 7.84 | 7.92 | 7.58 |

| Electrical Conductivity (mmhos/cm) | 0.27 | 0.24 | 0.24 |

| CaCO3 (%) | 6.82 | 5.72 | 0.44 |

| Organic Matter (%) | 1.20 | 1.62 | 1.58 |

| P (mg kg−1) | 3 | 64 | 13 |

| K (mg kg−1) | 237 | 219 | 172 |

| Ca (mg kg−1) | 4005 | 3411 | 2523 |

| Mg (mg kg−1) | 587 | 721 | 787 |

| Zn (mg kg−1) | 0.78 | 2.52 | 1.82 |

| Fe (mg kg−1) | 8.02 | 7.66 | 9.72 |

| Mn (mg kg−1) | 7.88 | 3.86 | 12.5 |

| Item | Fuel Type | Fuel Consumption(L h−1) | Direct Energy Use (MJ h−1) |

|---|---|---|---|

| Vehicles | |||

| Farm tractor (75–95 hp) | Diesel | Depending on the specific tasks | |

| Farm car (half loaded) | Gasoline | 4.08 | 172.7 |

| Truck (half loaded) | Diesel | 4.2 | 200.7 |

| Machinery | |||

| Mower | Diesel | 10.83 | 517.5 |

| Pruning shredder | Diesel | 13.15 | 628.3 |

| Handheld weed mower | Gasoline | 1.62 | 68.6 |

| Fertilizer spreader | Diesel | 6.81 | 325.4 |

| Orchard sprayer | Diesel | 11.39 | 544.2 |

| Pruning shears (2 workers) with air compressor | Gasoline | 3.35 | 160.1 |

| Irrigation | |||

| Centrifugal pump with electric motor | Electricity | 92–231 1 | |

| Item | Mass 1 (kg) | Estimated Life (h) | Source | Indirect Energy Use (MJ h−1) |

|---|---|---|---|---|

| Vehicles | ||||

| Farm tractor (75–95 hp) | 3350–4240 | 16,000 | [25] | 18.1–22.3 |

| Farm car | 1200 | 7500 | Current estimations | 13.9 |

| Truck | 2000 | 7500 | Current estimations | 23.1 |

| Machinery | ||||

| Mower | 280–350 | 2000 | [25] | 12.1–15.2 |

| Pruning shredder | 850 | 1500 | [14] | 49.2 |

| Handheld weed mower | 10 | 1500 | [14] | 0.58 |

| Fertilizer spreader | 150–220 | 1200 | [25] | 10.8–14.5 |

| Orchard sprayer | 750–950 | 2000 | [25] | 32.5–41.2 |

| Aero-scissors (2 workers) with air compressor | 150–180 | 1500 | [14] | 8.7–10.4 |

| Irrigation | ||||

| Centrifugal pump with electric motor | 70–150 | 2160 | [20] adapted | 15.4–18.5 |

| Item | Energy Content (MJ kg−1) | Source |

|---|---|---|

| Nitrogen | 74.2 | [26,27] |

| Phosphate | 13.7 | [26,27] |

| Potassium | 9.7 | [26,27] |

| Sulphur | 5 | [28] |

| Calcium | 8.82 | [29] |

| Herbicides | 238 | [30] |

| Fungicides | 99 | [30] |

| Insecticides | 363 | [30] |

| Mineral oil | 43.2 | [31] |

| Lime sulphur | 1.3 | [32] |

| Bordeaux mixture | 2.35 | [33] adapted |

| Polyethylene pipes | 0.092 1 | [24,25] |

| Input | Unit | GHG Coefficient (kg CO2eq/unit) | Reference |

|---|---|---|---|

| Nitrogen | kg | 1.2 | [35] |

| Phosphate (P2O5) | kg | 0.2 | [35] |

| Potassium (K2O) | kg | 0.15 | [35] |

| Calcium | kg | 0.16 | [35] |

| Sulphur | kg | 0.3 | [28] |

| Herbicides | kg | 9.1 | [35] |

| Insecticides | kg | 5.1 | [35] |

| Fungicides | kg | 3.9 | [35] |

| Bordeaux mixture | kg | 1.2 | [28] |

| Lime sulphur | kg | 0.04 | [28] |

| Diesel | MJ | 0.0741 | [36] |

| Gasoline | MJ | 0.0693 | [28] |

| Machinery/tools | MJ | 0.08 | [28] |

| Electricity | MJ | 0.0581 | [28] |

| Water | m3 | 0.6 | [37] |

| ‘Catherina’ | ||||

|---|---|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |||

| Practice | Energy Input (MJ ha−1) | % of Total Energy Input | Energy Input (MJ ha−1) | % of Total Energy Input |

| Pruning | 1566.2 | 2.7 | 1561.3 | 3.1 |

| Fruit thinning | 888.1 | 1.5 | 888.1 | 1.7 |

| Irrigation | 30,890.4 | 52.5 | 27,806.4 | 54.5 |

| Fertilization | 10,284.9 | 17.5 | 5598.9 | 11.0 |

| Weed control | 4554.8 | 7.7 | 4547.2 | 8.9 |

| Plant protection | 10,274.2 | 17.5 | 10,215.1 | 20.1 |

| Harvesting | 361.6 | 0.6 | 361.6 | 0.7 |

| Total energy input | 58,820.2 | 50,978.7 | ||

| ‘Andross’ | ||||

|---|---|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |||

| Practice | Energy Input (MJ ha−1) | % of Total Energy Input | Energy Input (MJ ha−1) | % of Total Energy Input |

| Pruning | 4615.3 | 5.2 | 4615.3 | 6.1 |

| Fruit thinning | 537.9 | 0.6 | 537.9 | 0.7 |

| Irrigation | 40,138.7 | 45.0 | 36,161.9 | 47.9 |

| Fertilization | 18,840.5 | 21.1 | 9099.9 | 12.1 |

| Weed control | 12,032.7 | 13.5 | 12,032.7 | 16.0 |

| Plant protection | 12,354.3 | 13.9 | 12,369.5 | 16.4 |

| Harvesting | 609.0 | 0.7 | 609.0 | 0.8 |

| Total energy input | 89,128.4 | 75,426.2 | ||

| ‘Everts’ | ||||

|---|---|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |||

| Practice | Energy Input (MJ ha−1) | % of Total Energy Input | Energy Input (MJ ha−1) | % of Total Energy Input |

| Pruning | 7371.9 | 10.9 | 7371.9 | 14.7 |

| Fruit thinning | 263.8 | 0.4 | 263.8 | 0.5 |

| Irrigation | 17,354.5 | 25.8 | 15,594.1 | 31.1 |

| Fertilization | 22,932.6 | 34.0 | 7402.5 | 14.8 |

| Weed control | 12,021.4 | 17.8 | 12,021.4 | 24.0 |

| Plant protection | 6684.2 | 9.9 | 6699.4 | 13.4 |

| Harvesting | 726.1 | 1.1 | 726.1 | 1.5 |

| Total energy input | 67,354.5 | 50,079.2 | ||

| ‘Catherina’ | ||||

|---|---|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |||

| Inputs | Energy Input (MJ ha−1) | % of Total Energy Input | Energy Input (MJ ha−1) | % of Total Energy Input |

| Fertilizers | ||||

| N | 9349.2 | 3554.2 | ||

| P | 247.4 | 113.1 | 10.0 | |

| K | 676.3 | 17.5 | 1009.6 | |

| Other fertilizers | 422.9 | |||

| Fungicides | 870.3 | 1.5 | 870.3 | 1.7 |

| Insecticides | 1503.4 | 2.6 | 1503.4 | 2.9 |

| Herbicides | 0 | 0 | 0 | 0 |

| Irrigation water | 2009.7 | 3.4 | 1808.7 | 3.5 |

| Tools | 80.1 | 0.1 | 80.1 | 0.2 |

| Human labour | 1560.7 | 2.6 | 1562.3 | 3.1 |

| Electricity | 27,720.0 | 47.1 | 24,948.0 | 48.9 |

| Fuels | 12,590.6 | 21.4 | 13,028.5 | 25.5 |

| Machinery | 2212.5 | 3.8 | 2149.1 | 4.2 |

| Total energy input | 58,820.2 | 51,050.3 | ||

| Outputs | ||||

| Yield (t ha−1) | 41.65 | 43.50 | ||

| Total energy output (MJ ha−1) | 140,360.5 | 146,595.0 | ||

| Energy indices | ||||

| Net energy (MJ) | 81,540.3 | 95,544.7 | ||

| Energy efficiency (MJ MJ−1) | 2.39 | 2.87 | ||

| Energy productivity (kg MJ−1) | 0.71 | 0.85 | ||

| Specific energy (MJ kg−1) | 1.41 | 1.17 | ||

| ‘Andross’ | ||||

|---|---|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |||

| Inputs | Energy Input (MJ ha−1) | % of Total Energy Input | Energy Input (MJ ha−1) | % of Total Energy Input |

| Fertilizers | ||||

| N | 14,927.4 | 4429.9 | ||

| P | 518.4 | 18.7 | 191.5 | 8.4 |

| K | 1160.1 | 1263.2 | ||

| Other fertilizers | 7.4 | 438.1 | ||

| Fungicides | 754.8 | 0.8 | 754.8 | 1.0 |

| Insecticides | 1958.1 | 2.2 | 1958.1 | 2.6 |

| Herbicides | 535.2 | 0.6 | 535.2 | 0.7 |

| Irrigation water | 2116.8 | 2.4 | 1905.1 | 2.5 |

| Tools | 90.1 | 0.1 | 90.1 | 0.1 |

| Human labour | 1625.4 | 1.8 | 1627.5 | 2.2 |

| Electricity | 30,744.0 | 34.5 | 27,669.6 | 36.7 |

| Fuels | 24,334.5 | 27.3 | 24,842.5 | 32.9 |

| Machinery | 10,356.3 | 11.6 | 9721.0 | 12.9 |

| Total energy input | 89,128.4 | 75,426.2 | ||

| Outputs | ||||

| Yield (t ha−1) | 48.0 | 51.5 | ||

| Total energy output (MJ ha−1) | 161,760.0 | 173,550.0 | ||

| Energy indices | ||||

| Net energy (MJ) | 72,631.6 | 98,123.8 | ||

| Energy efficiency (MJ MJ−1) | 1.81 | 2.30 | ||

| Energy productivity (kg MJ−1) | 0.54 | 0.68 | ||

| Specific energy (MJ kg−1) | 1.86 | 1.46 | ||

| ‘Everts’ | ||||

|---|---|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |||

| Inputs | Energy Input (MJ ha−1) | % of Total Energy Input | Energy Input (MJ ha−1) | % of Total Energy Input |

| Fertilizers | ||||

| N | 21,748.0 | 5194.0 | ||

| P | 32.4 | 34.0 | 191.5 | 14.3 |

| K | 57.2 | 1263.2 | ||

| Other fertilizers | 1060.0 | 504.7 | ||

| Fungicides | 660.7 | 1.0 | 660.7 | 1.3 |

| Insecticides | 1632.0 | 2.4 | 1632.0 | 3.3 |

| Herbicides | 1713.6 | 2.5 | 1713.6 | 3.4 |

| Irrigation water | 963.9 | 1.4 | 867.5 | 1.7 |

| Tools | 78.1 | 0.1 | 78.1 | 0.2 |

| Human labour | 1021.4 | 1.5 | 1022.2 | 2.0 |

| Electricity | 13,248.0 | 19.7 | 11,880.0 | 23.8 |

| Fuels | 18,685.8 | 27.8 | 18,891.9 | 37.7 |

| Machinery | 6453.4 | 9.6 | 6179.9 | 12.3 |

| Total energy input | 67,354.5 | 50,079.2 | ||

| Outputs | ||||

| Yield (t ha−1) | 35.0 | 37.80 | ||

| Total energy output (MJ ha−1) | 117,950.0 | 127,386.0 | ||

| Energy indices | ||||

| Net energy (MJ) | 50,595.5 | 77,306.8 | ||

| Energy efficiency (MJ MJ−1) | 1.75 | 2.54 | ||

| Energy productivity (kg MJ−1) | 0.52 | 0.75 | ||

| Specific energy (MJ kg−1) | 1.92 | 1.32 | ||

| ‘Catherina’ | ||

|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |

| Practice | GHG Emissions (kg CO2eq ha−1) | GHG Emissions (kg CO2eq ha−1) |

| Pruning | 86.2 | 86.2 |

| Fruit thinning | 7.2 | 7.2 |

| Irrigation | 1702.3 | 1532.3 |

| Fertilization | 177.8 | 153.6 |

| Weed control | 301.7 | 301.7 |

| Plant protection | 718.7 | 718.7 |

| Harvesting | 7.4 | 7.4 |

| Total GHG emissions | 3001.3 | 2807.2 |

| Yield (t ha−1) | 41.65 | 43.50 |

| kg CO2eq kg−1 | 0.0721 | 0.0645 |

| ‘Andross’ | ||

|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |

| Practice | GHG Emissions (kg CO2eq ha−1) | GHG Emissions (kg CO2eq ha−1) |

| Pruning | 310.8 | 310.8 |

| Fruit thinning | 11.0 | 11.0 |

| Irrigation | 2359.9 | 2126.0 |

| Fertilization | 445.8 | 345.4 |

| Weed control | 874.2 | 879.9 |

| Plant protection | 833.4 | 833.4 |

| Harvesting | 12.8 | 12.8 |

| Total GHG emissions | 4847.8 | 4519.3 |

| Yield (t ha−1) | 48.00 | 51.50 |

| kg CO2eq kg−1 | 0.101 | 0.0878 |

| ‘Everts’ | ||

|---|---|---|

| Farmers’ Practices | Alternative Management Practices | |

| Practice | GHG Emissions (kg CO2eq ha−1) | GHG Emissions (kg CO2eq ha−1) |

| Pruning | 534.7 | 534.7 |

| Fruit thinning | 5.0 | 5.0 |

| Irrigation | 1017.8 | 917.1 |

| Fertilization | 419.3 | 186.1 |

| Weed control | 828.0 | 828.0 |

| Plant protection | 453.5 | 453.5 |

| Harvesting | 11.8 | 11.8 |

| Total GHG emissions | 3270.2 | 2935.9 |

| Yield (t ha−1) | 35.00 | 37.80 |

| kg CO2eq kg−1 | 0.0934 | 0.0777 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maletsika, P.; Cavalaris, C.; Giouvanis, V.; Nanos, G.D. Effects of Alternative Fertilization and Irrigation Practices on the Energy Use and Carbon Footprint of Canning Peach Orchards. Sustainability 2022, 14, 8583. https://doi.org/10.3390/su14148583

Maletsika P, Cavalaris C, Giouvanis V, Nanos GD. Effects of Alternative Fertilization and Irrigation Practices on the Energy Use and Carbon Footprint of Canning Peach Orchards. Sustainability. 2022; 14(14):8583. https://doi.org/10.3390/su14148583

Chicago/Turabian StyleMaletsika, Persefoni, Chris Cavalaris, Vasileios Giouvanis, and George D. Nanos. 2022. "Effects of Alternative Fertilization and Irrigation Practices on the Energy Use and Carbon Footprint of Canning Peach Orchards" Sustainability 14, no. 14: 8583. https://doi.org/10.3390/su14148583