Medium-Term No-Tillage, Additional Compaction, and Chiseling as Affecting Clayey Subtropical Soil Physical Properties and Yield of Corn, Soybean and Wheat Crops

Abstract

:1. Introduction

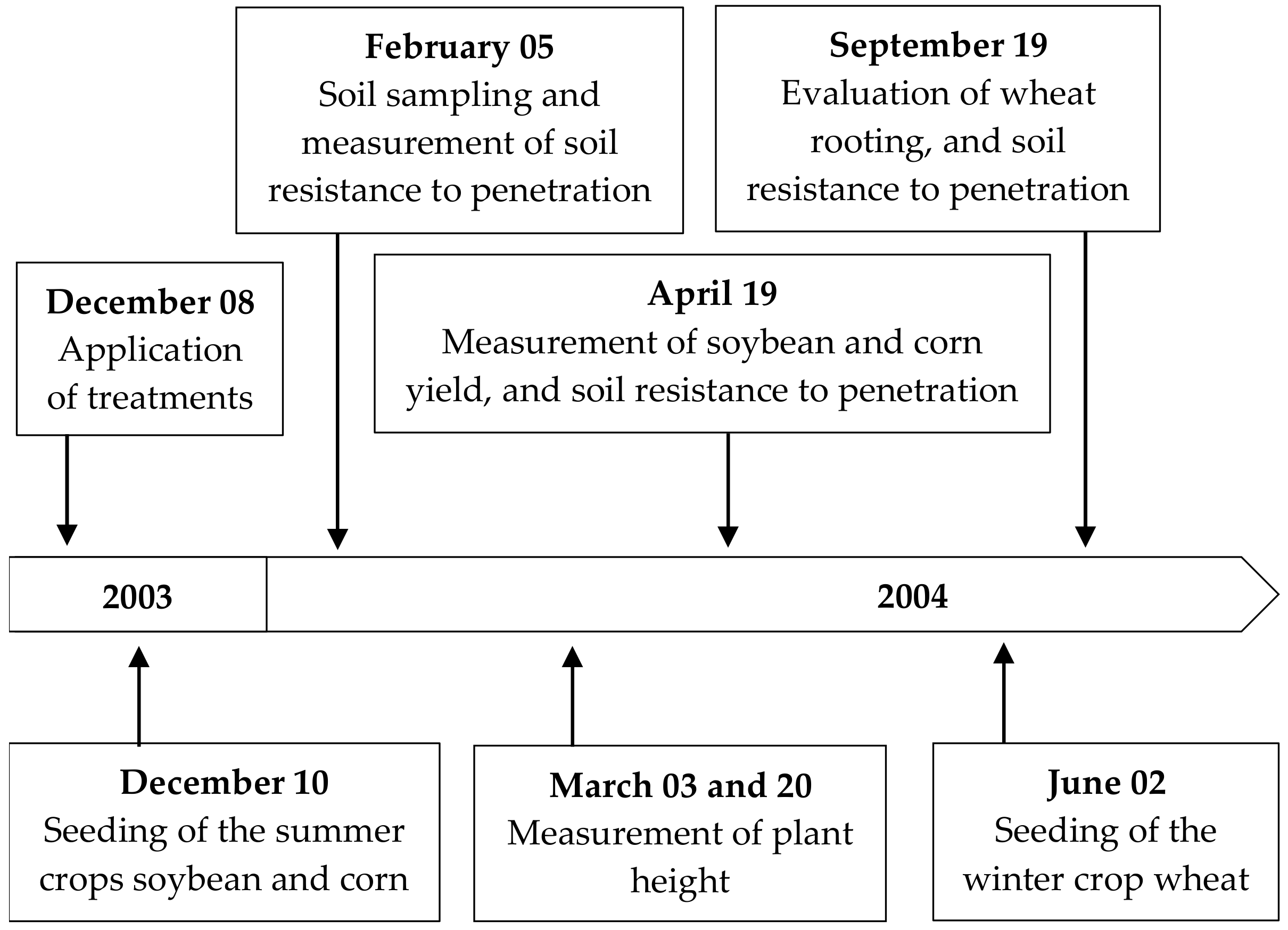

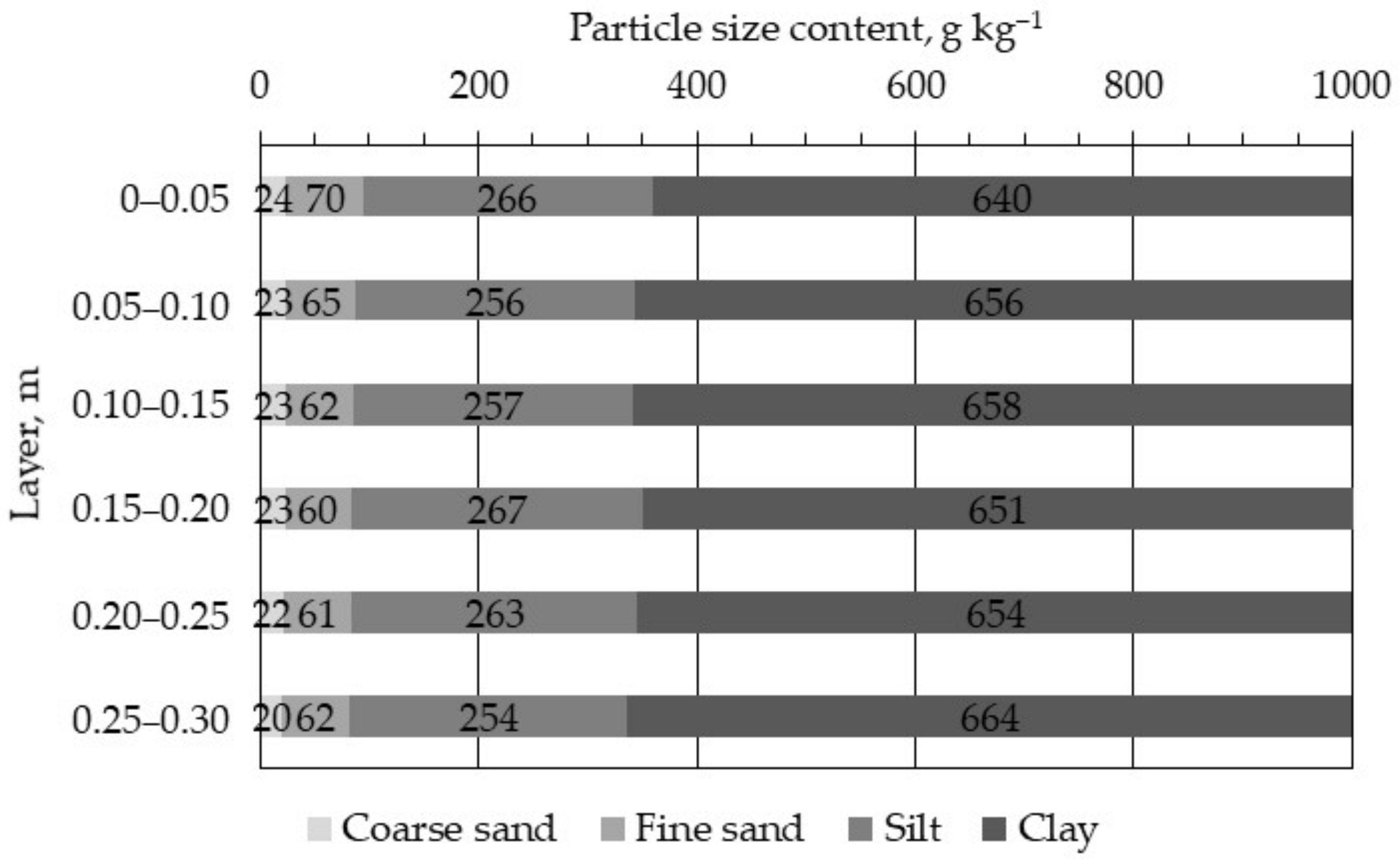

2. Materials and Methods

3. Results

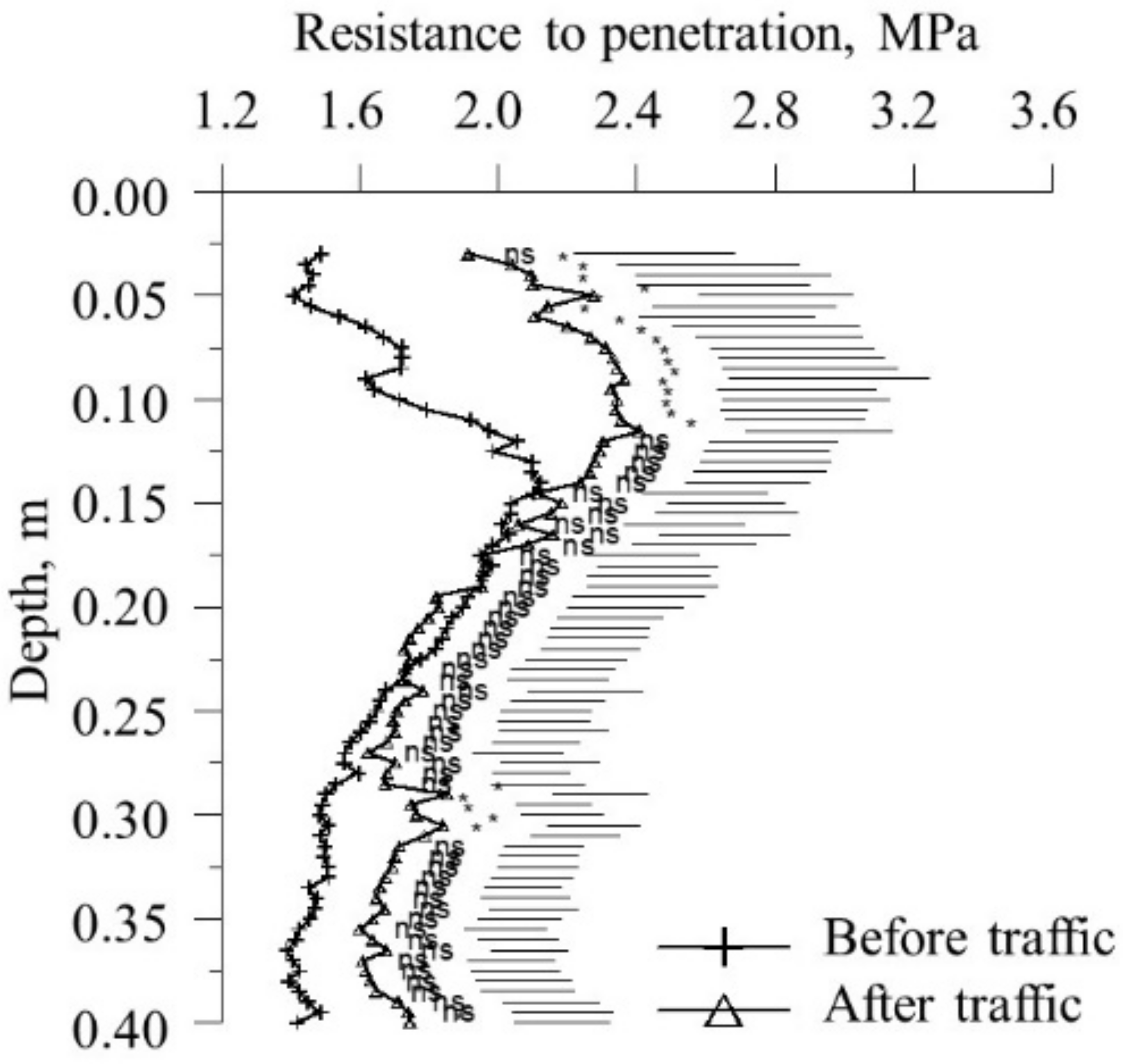

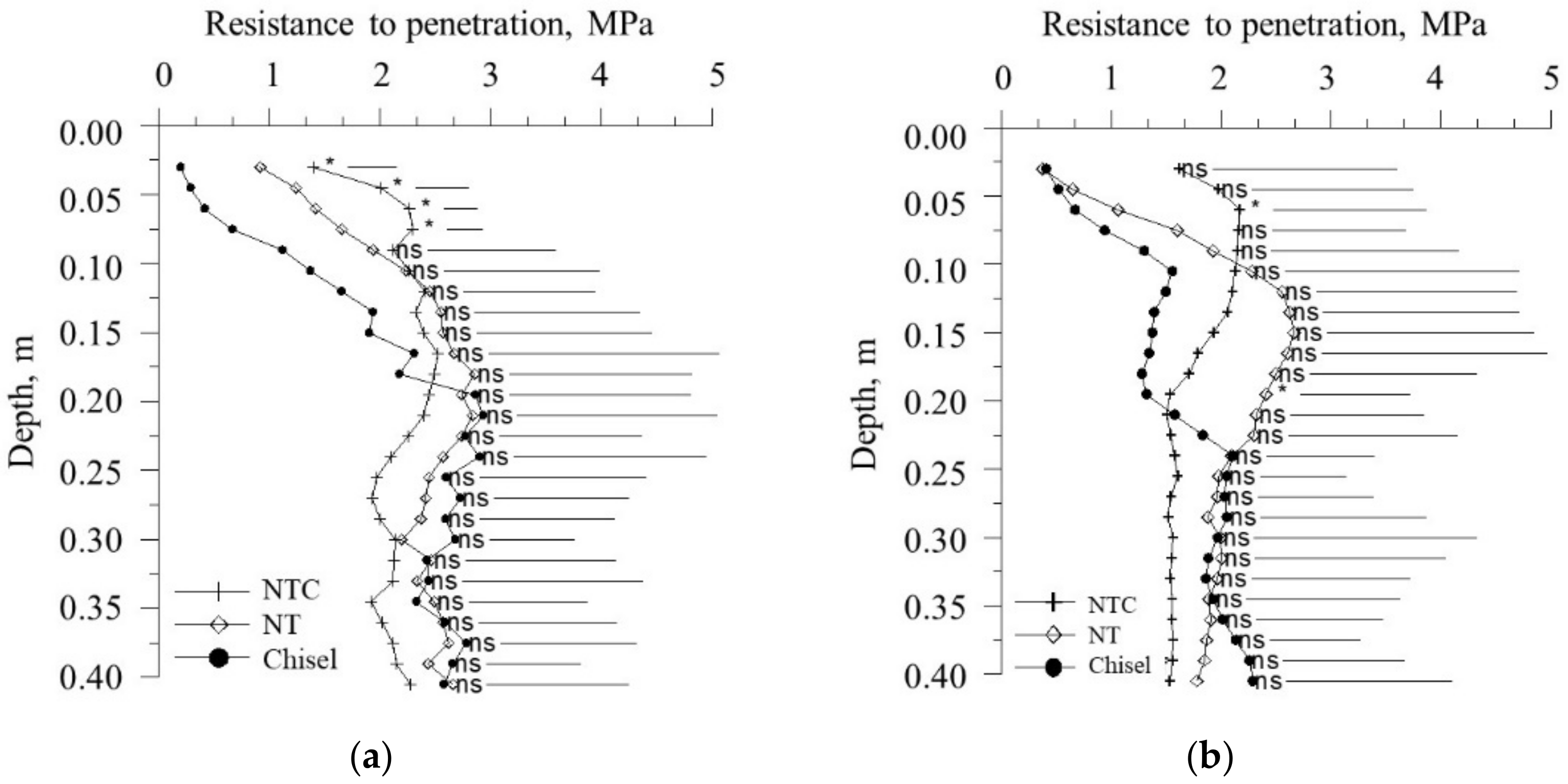

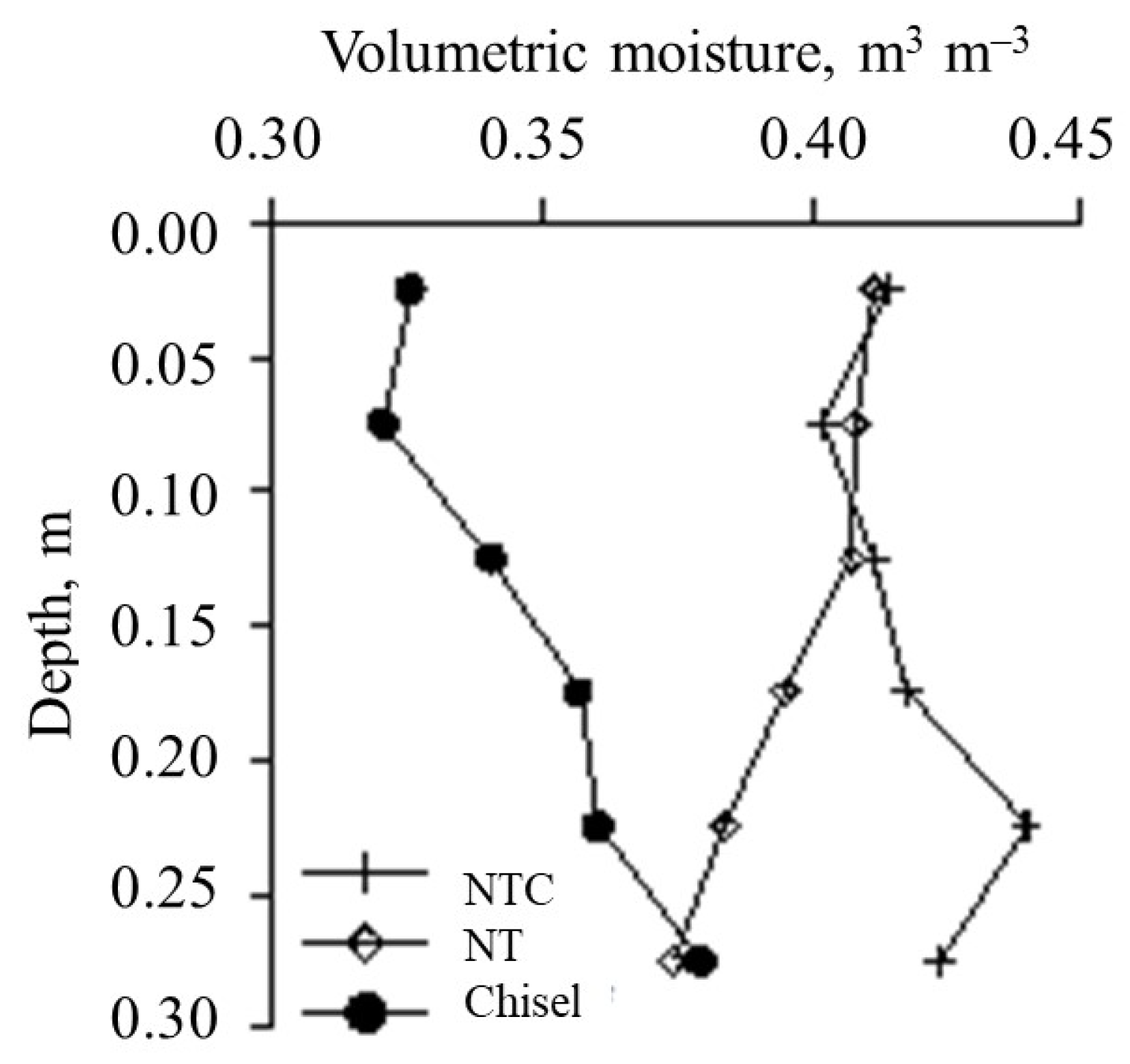

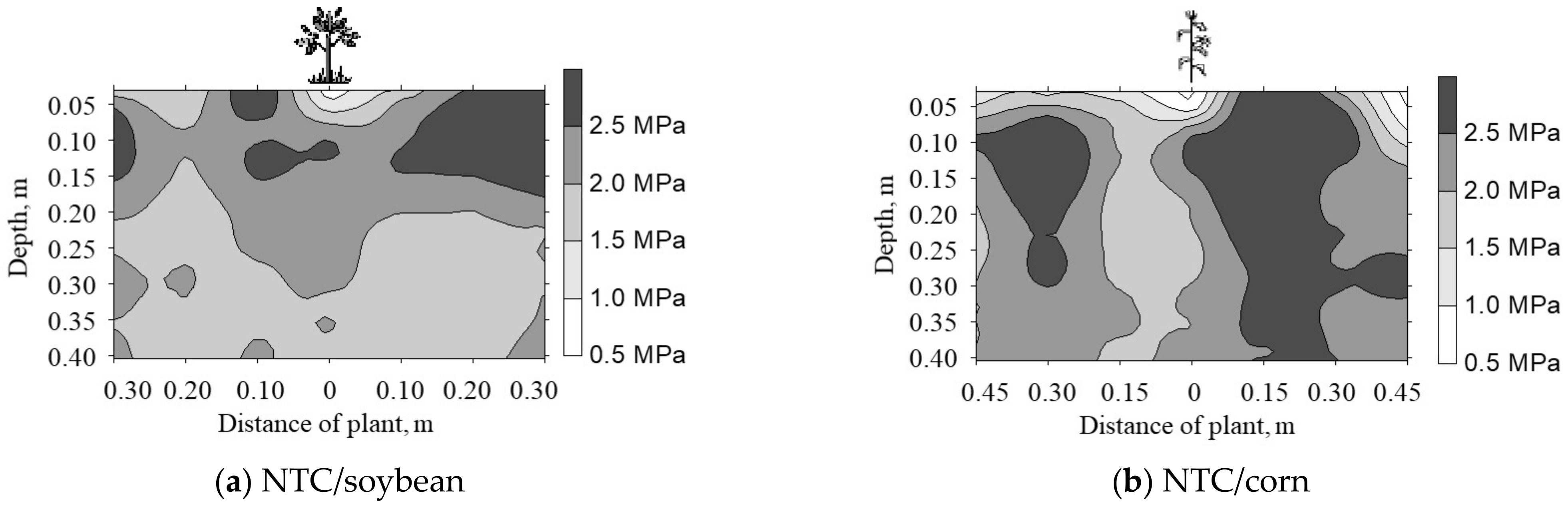

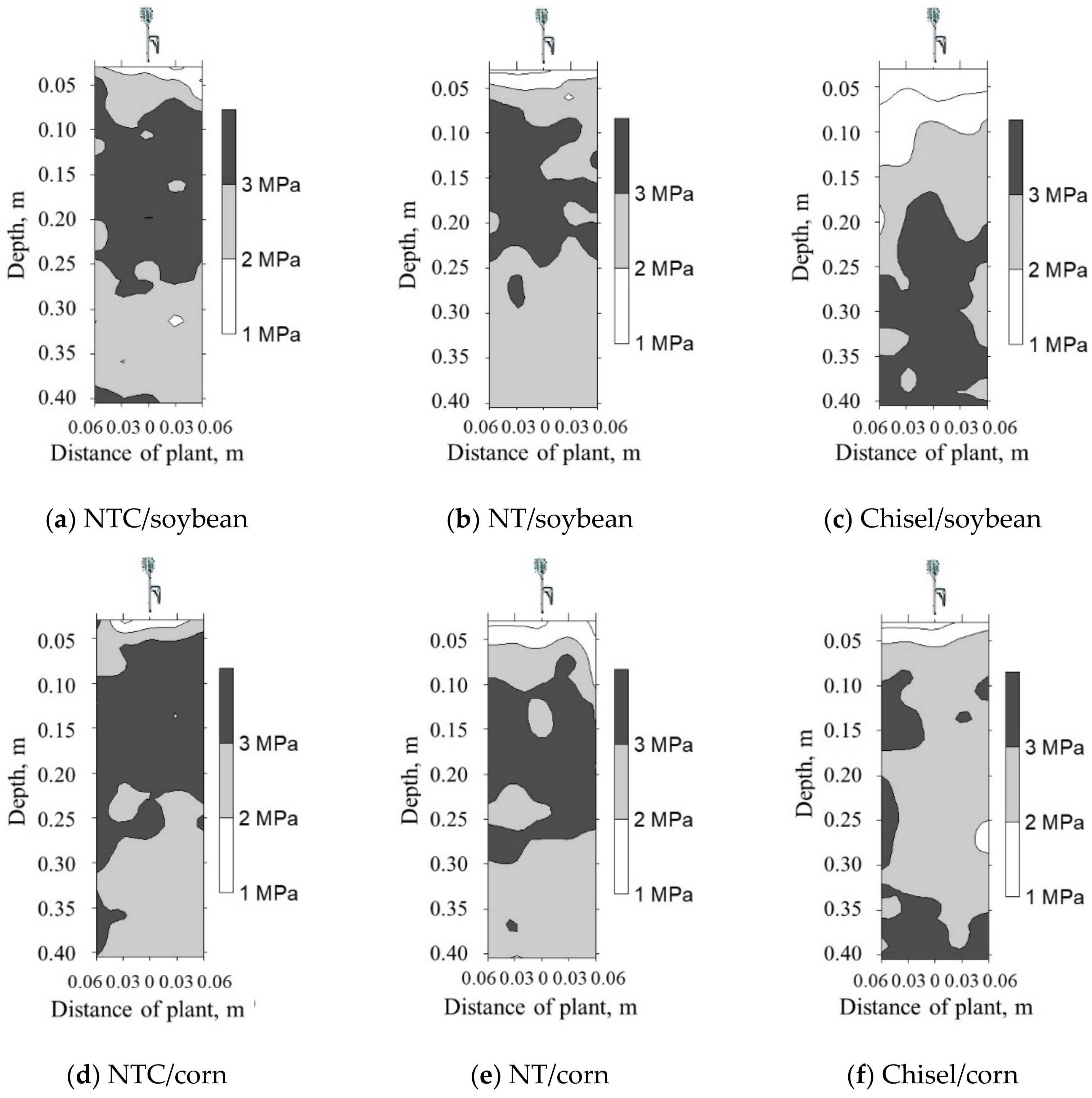

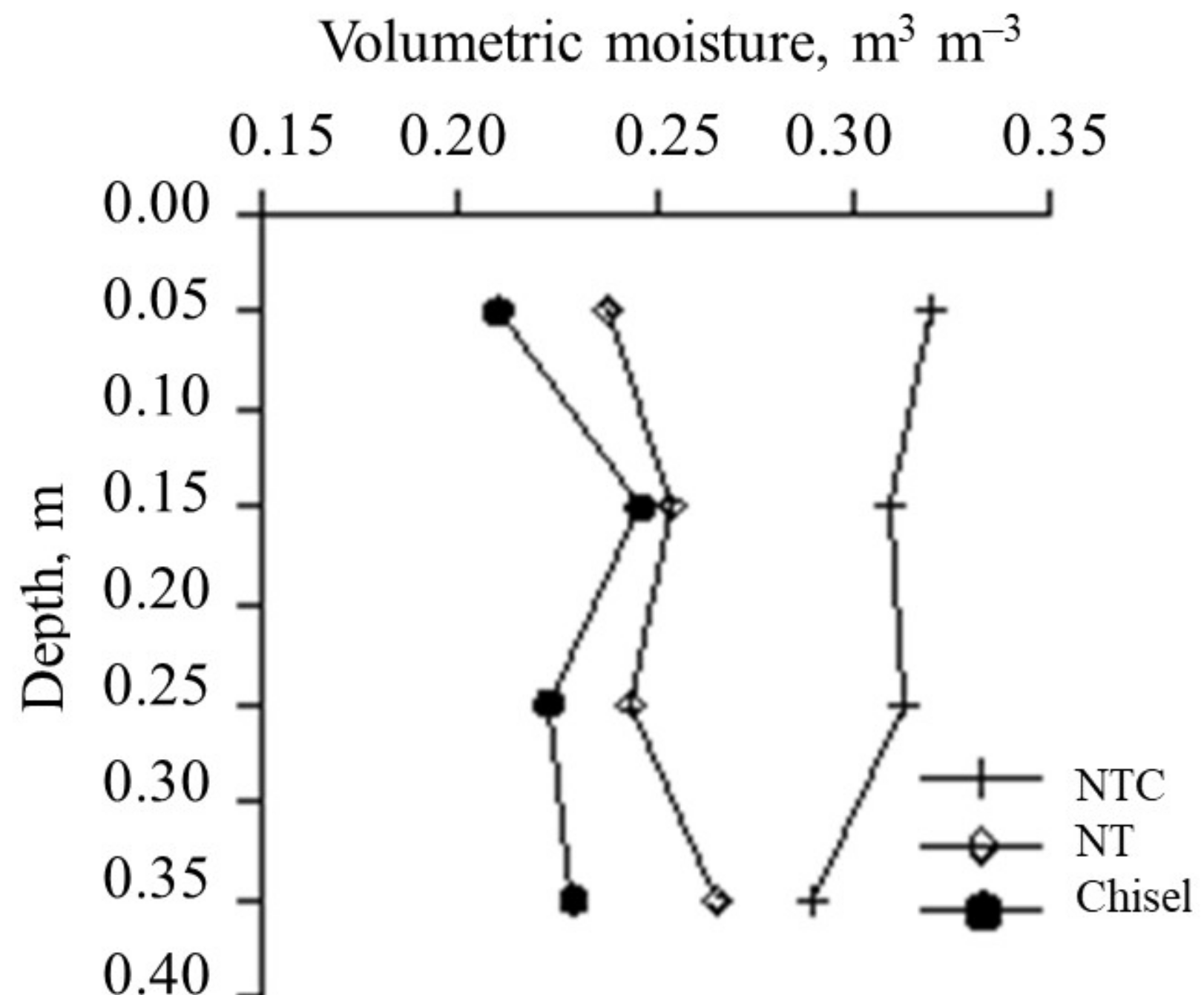

3.1. Soil Physical and Mechanical Properties

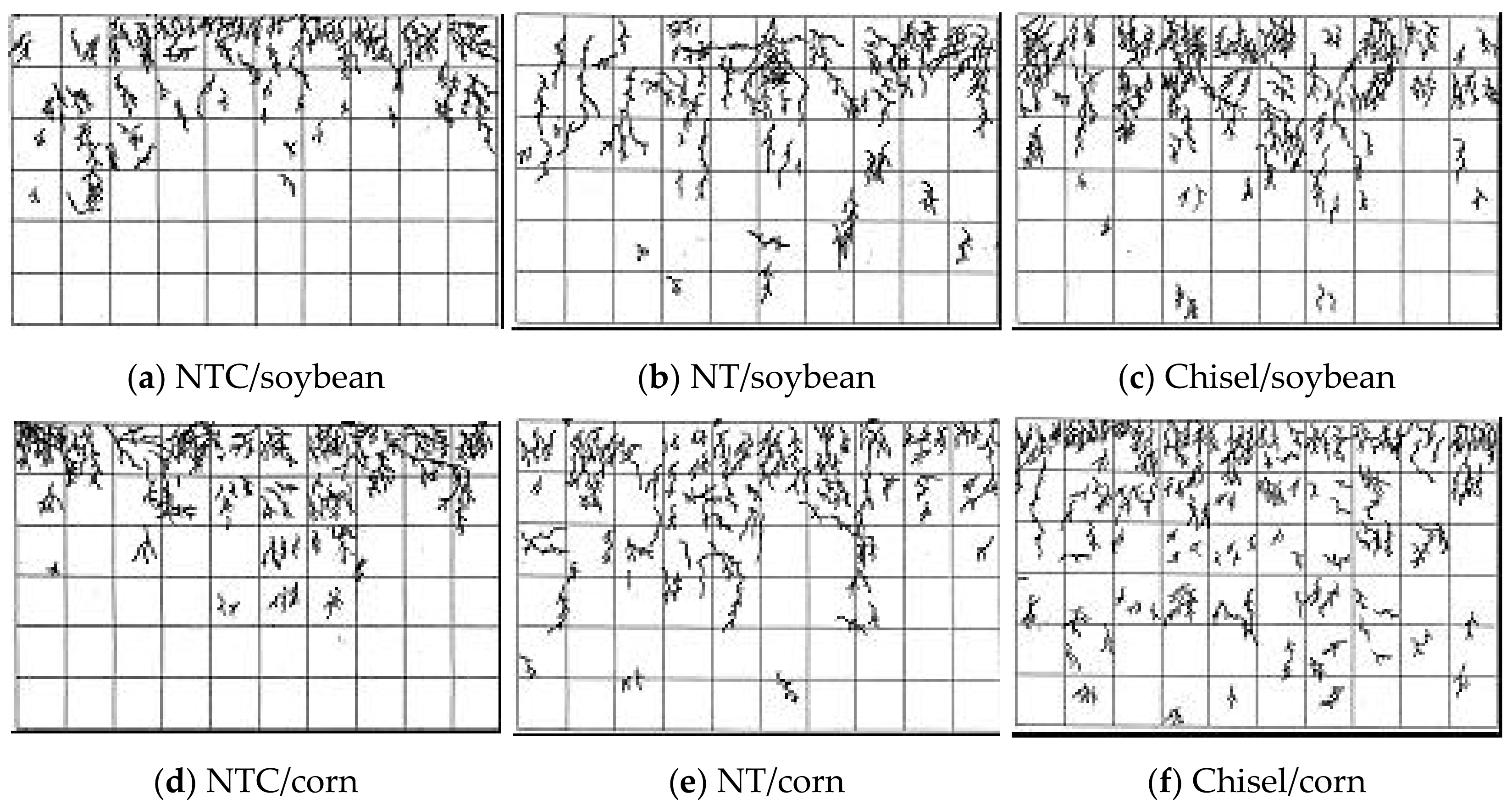

3.2. Growth and Yield of Soybean and Corn

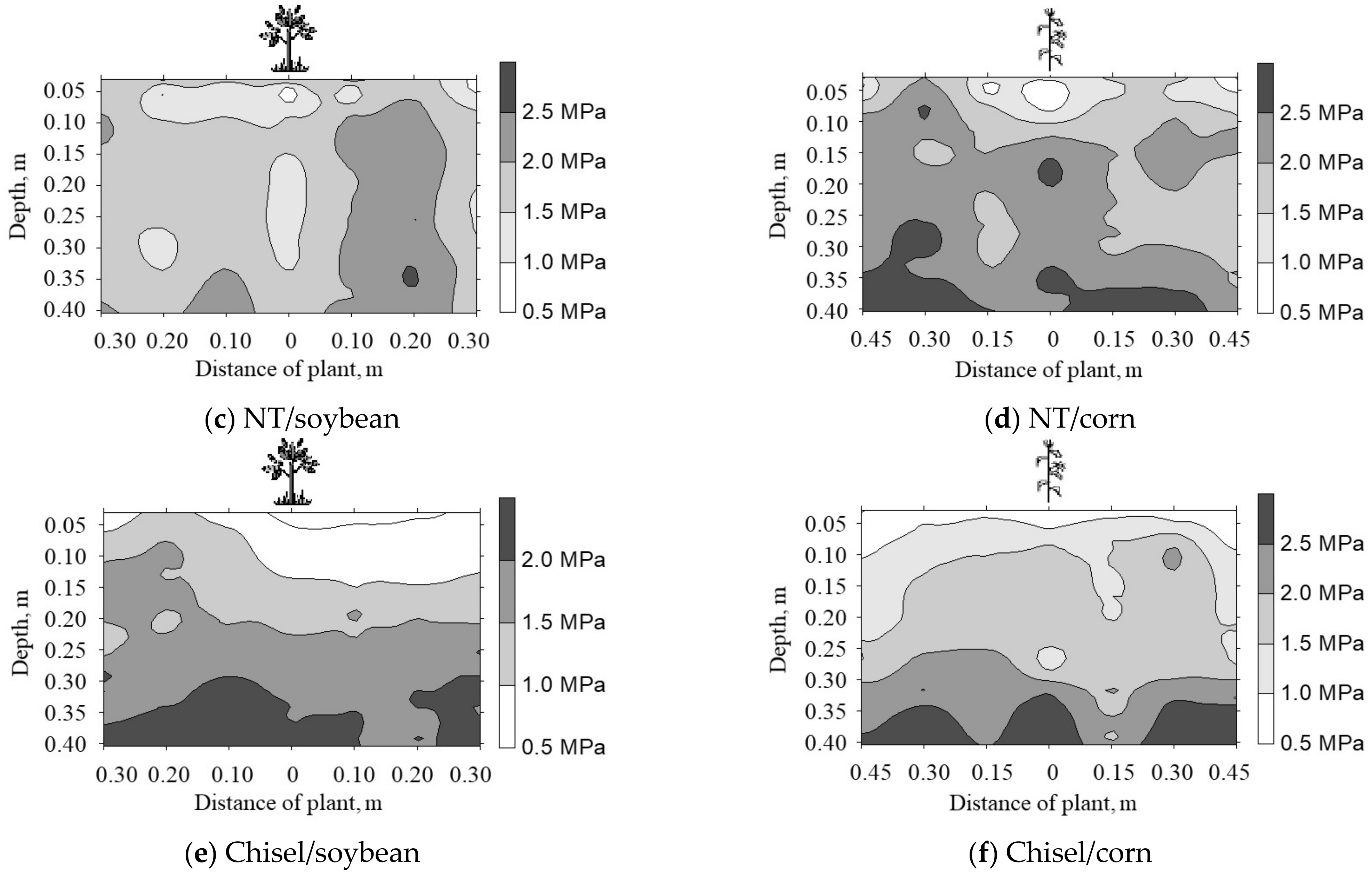

3.3. Wheat Crop

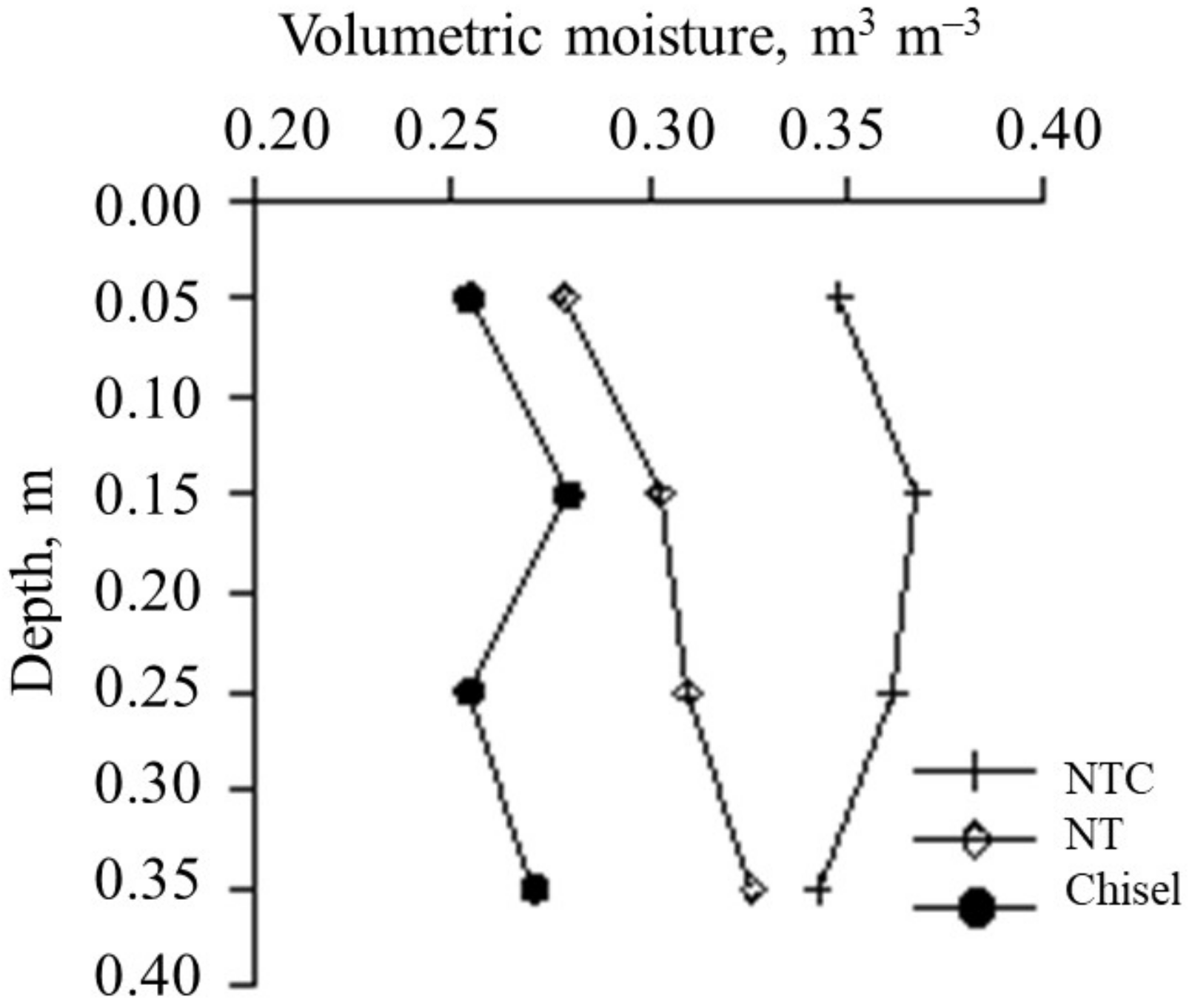

3.3.1. Soil Resistance to Penetration

3.3.2. Wheat Root Growth and Yield

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Botta, G.F.; Antille, D.L.; Nardon, G.F.; Rivero, D.; Bienvenido, F.; Contessotto, E.E.; Ezquerra-Canalejo, A.; Ressia, J.M. Zero and controlled traffic improved soil physical conditions and soybean yield under no-tillage. Soil Tillage Res. 2022, 215, 105235. [Google Scholar] [CrossRef]

- Zabrodskyi, A.; Šarauskis, E.; Kukharets, S.; Juostas, A.; Vasiliauskas, G.; Andriušis, A. Analysis of the impact of soil compaction on the environment and agricultural economic losses in Lithuania and Ukraine. Sustainability 2021, 13, 7762. [Google Scholar] [CrossRef]

- Keller, T.; Sandina, M.; Colombia, T.; Horn, R.; Or, D. Historical increase in agricultural machinery weights enhanced soil stress levels and adversely affected soil functioning. Soil Tillage Res. 2019, 194, 104293. [Google Scholar] [CrossRef]

- Reichert, J.M.; Suzuki, L.E.A.S.; Reinert, D.J.; Horn, R.; Håkansson, I. Reference bulk density and critical degree-of-compactness for no-till crop production in subtropical highly weathered soils. Soil Tillage Res. 2009, 102, 242–254. [Google Scholar] [CrossRef]

- Suzuki, L.E.A.S.; Reichert, J.M.; Reinert, D.J. Degree of compactness, soil physical properties and yield of soybean in six soils under no-tillage. Soil Res. 2013, 51, 311–321. [Google Scholar] [CrossRef]

- Nunes, M.R.; Pauletto, E.A.; Denardin, J.E.; Suzuki, L.E.A.S.; van Es, H.M. Dynamic changes in compressive properties and crop response after chisel tillage in a highly weathered soil. Soil Tillage Res. 2019, 186, 183–190. [Google Scholar] [CrossRef]

- IBGE—Instituto Brasileiro de Geografia e Estatística. Produção Agrícola Municipal 2007; IBGE: Rio de Janeiro, Brazil, 2008. Available online: https://cidades.ibge.gov.br/brasil/rs/ijui/pesquisa/24/76693 (accessed on 28 December 2021).

- Derpsch, R.; Friedrich, T.; Kassam, A.; Hongwen, L. Current status of adoption of no-till farming in the world and some of its main benefits. Int. J. Agric. Biol. Eng. 2010, 3, 26–37. Available online: https://ijabe.org/index.php/ijabe/article/view/223/114 (accessed on 28 December 2021).

- IBGE—Instituto Brasileiro de Geografia e Estatística. Banco de Dados de Informações Ambientais: Pedologia; IBGE: Rio de Janeiro, Brazil, 2021. Available online: https://bdiaweb.ibge.gov.br/#/consulta/pedologia (accessed on 28 December 2021).

- Beinroth, F.H.; Eswaran, H.; Palmieri, F.; Reich, P.F. Properties, Classification, and Management of Oxisols. The Guy D. Smith Memorial Slide Set. 1996. Available online: https://www.icgc.cat/content/download/74051/637716/version/2/file/igc_iec_llibre08_7.pdf (accessed on 17 April 2022).

- De Maria, I.C.; Castro, O.M.; Dias, H.S. Atributos físicos do solo e crescimento radicular de soja em Latossolo Roxo sob diferentes métodos de preparo do solo. Rev. Bras. Ciênc. Solo 1999, 23, 703–709. [Google Scholar] [CrossRef]

- Sato, M.K.; Lima, H.V.; Oliveira, P.D.; Rodrigues, S. Critical soil bulk density for soybean growth in Oxisols. Int. Agrophys. 2015, 29, 441–447. [Google Scholar] [CrossRef] [Green Version]

- Carneiro, K.A.A.; Oliveira, F.P.; Araujo, M.C.S.P.; Fernandes, L.F.; Abrantes, E.G.; Vendruscolo, J. Influência da compactação do solo no crescimento de milho (Zea mays L.) em Latossolo Vermelho-Amarelo. Colloq. Agrar. 2018, 14, 88–98. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, L.E.A.S.; Reinert, D.J.; Alves, M.C.; Reichert, J.M. Critical limits for soybean and black bean root growth, based on macroporosity and penetrability, for soils with distinct texture and management systems. Sustainability 2022, 14, 2958. [Google Scholar] [CrossRef]

- Taylor, H.M.; Roberson, G.M.; Parker Junior, J.J. Soil strength-root penetration relations for medium to coarse-textured soil materials. Soil Sci. 1966, 102, 18–22. [Google Scholar] [CrossRef]

- Canarache, A. PENETR—A generalized semi-empirical model estimating soil resistance to penetration. Soil Tillage Res. 1990, 16, 51–70. [Google Scholar] [CrossRef]

- Beutler, A.N.; Centurion, J.F. Compactação do solo no desenvolvimento radicular e na produtividade da soja. Pesq. Agropecu. Bras. 2004, 39, 581–588. [Google Scholar]

- Beutler, A.N.; Centurion, J.F.; Centurion, M.A.P.C.; Silva, A.P. Efeito da compactação na produtividade de cultivares de soja em Latossolo Vermelho. Rev. Bras. Cienc. Solo 2006, 30, 787–794. [Google Scholar] [CrossRef] [Green Version]

- Reichert, J.M.; Bervald, C.M.P.; Rodrigues, M.F.; Kato, O.R.; Reinert, D.J. Mechanized land preparation in eastern Amazon in fire-free forest-based fallow systems as alternatives to slash-and-burn practices: Hydraulic and mechanical soil properties. Agric. Ecosyst. Environ. 2014, 192, 47–60. [Google Scholar] [CrossRef]

- Fasinmirin, J.T.; Reichert, J.M. Conservation tillage for cassava (Manihot esculenta Crantz) production in the tropics. Soil Tillage Res. 2011, 113, 1–10. [Google Scholar] [CrossRef]

- Shaheb, M.R.; Venkatesh, R.; Shearer, S.A. A review on the effect of soil compaction and its management for sustainable crop production. J. Biosyst. Eng. 2021, 46, 417–439. [Google Scholar] [CrossRef]

- Santos, H.G.; Jacomine, P.K.T.; Anjos, L.H.; Oliveira, V.A.; Lumbreras, J.F.; Coelho, M.R.; Almeida, J.A.; Araujo Filho, J.C.; Oliveira, J.B.; Cunha, T.J.F. Sistema Brasileiro de Classificação de Solos; Embrapa: Brasília, Brazil, 2018; Available online: https://ainfo.cnptia.embrapa.br/digital/bitstream/item/199517/1/SiBCS-2018-pdf (accessed on 29 November 2021)ISBN -9788570358004.

- Soil Survey Staff. Keys to Soil Taxonomy, 12th ed.; USDA—Natural Resources Conservation Service: Washington, DC, USA, 2014. Available online: https://www.nrcs.usda.gov/wps/portal/nrcs/detail/soils/survey/class/taxonomy/?cid=nrcs142p2_053580 (accessed on 8 December 2021).

- Climate-data.org. Clima Ijuí (Brasil). Available online: https://pt.climate-data.org/america-do-sul/brasil/rio-grande-do-sul/ijui-43847/ (accessed on 10 April 2022).

- Almeida, B.G.; Freitas, P.L.; Teixeira, W.G.; Viana, J.H.M.; Donagemma, G.K. Porosidade. In Manual de Métodos de Análise de Solo; Teixeira, P.C., Donagemma, G.K., Fontana, A., Teixeira, W.G., Eds.; Embrapa: Brasília, Brazil, 2017; pp. 82–94. Available online: http://www.infoteca.cnptia.embrapa.br/infoteca/handle/doc/1085209 (accessed on 15 April 2021).

- Blake, G.R.; Hartge, K.H. Bulk density. In Methods of Soil Analysis, Part 1: Physical and Mineralogical Methods, 2nd ed.; Klute, A., Ed.; American Society of Agronomy, Soil Science Society of America: Madison, WI, USA, 1986; pp. 363–375. [Google Scholar] [CrossRef]

- Klute, A. Water retention: Laboratory methods. In Methods of Soil Analysis: Physical and Mineralogical Methods; Klute, A., Ed.; American Society of Agronomy, Soil Science Society of America: Madison, WI, USA, 1986; pp. 635–660. [Google Scholar]

- Holtz, R.D.; Kovacs, W.D. An Introduction to Geotechnical Engineering; Prentice-Hall: Hoboken, NJ, USA, 1981. [Google Scholar]

- Gee, G.W.; Or, D. Particle-size analysis. In Methods of Soil Analysis, Part 4: Physical Methods, 5th ed.; Dane, J.H., Topp, C., Eds.; Soil Science Society of America: Madison, WI, USA, 2002; pp. 255–293. [Google Scholar]

- Suzuki, L.E.A.S.; Reichert, J.M.; Albuquerque, J.A.; Reinert, D.J.; Kaiser, D.R. Dispersion and flocculation of Vertisols, Alfisols and Oxisols in Southern Brazil. Geoderma Reg. 2015, 5, 64–70. [Google Scholar] [CrossRef]

- National Resource Conservation Service-NRCS/United States Department of Agriculture—USDA. Soil Texture Calculator. Available online: https://www.nrcs.usda.gov/wps/portal/nrcs/detail/?cid=nrcs142p2_054167 (accessed on 30 December 2021).

- Böhm, W. Methods of Studying Root Systems; Springer: Berlin, Germany, 1979. [Google Scholar]

- Vomocil, J.A.; Flocker, W.J. Effect of soil compaction on storage and movement of soil, air and water. Trans. ASAE 1966, 4, 242–246. [Google Scholar] [CrossRef]

- CEPEA—Centro de Estudos Avançados em Economia Aplicada. Indicador da soja CEPEA/ESALQ—Paraná. 2022. Available online: https://www.cepea.esalq.usp.br/br/indicador/soja.aspx (accessed on 16 April 2022).

- Carvalho, I.R.; Korcelski, C.; Pelissari, G.; Hanus, A.D.; Rosa, G.M. Demanda Hídrica das Culturas de Interesse Agronômico. Enciclopédia Biosf. 2013, 9, 969–985. [Google Scholar]

- CEPEA—Centro de Estudos Avançados em Economia Aplicada. Preço Médio do Trigo CEPEA/ESALQ-Rio Grande do Sul. 2022. Available online: https://www.cepea.esalq.usp.br/br/indicador/trigo.aspx (accessed on 16 April 2022).

- Moraes, M.T.; Debiasi, H.; Franchini, J.C.; Mastroberti, A.A.; Levien, R.; Leitner, D.; Schnepf, A. Soil compaction impacts soybean root growth in an Oxisol from subtropical Brazil. Soil Tillage Res. 2020, 200, 104611. [Google Scholar] [CrossRef]

- Braida, J.A.; Reichert, J.M.; Reinert, D.J.; Sequinatto, L. Elasticidade do solo em função da umidade e do teor de carbono orgânico. Rev. Bras. Ciênc. Solo 2008, 32, 477–485. [Google Scholar] [CrossRef]

- Horn, R.; Vossbrink, J.; Becker, S. Modern forestry vehicles and their impacts on soil physical properties. Soil Tillage Res. 2004, 79, 207–219. [Google Scholar] [CrossRef]

- Suzuki, L.E.A.S.; Reinert, D.J.; Reichert, J.M.; Lima, C.L.R. Estimativa da suscetibilidade à compactação e do suporte de carga do solo com base em propriedades físicas de solos do Rio Grande do Sul. Rev. Bras. Ciênc. Solo 2008, 32, 963–973. [Google Scholar] [CrossRef] [Green Version]

- Horn, R.; Fleige, H. A method for assessing the impact offload on mechanical stability and on physical properties of soils. Soil Tillage Res. 2003, 73, 89–99. [Google Scholar] [CrossRef]

- Horn, R.; Lebert, M. Soil compactability and compressibility. In Soil Compaction in Crop Production; Soane, B.D., van Ouwerkerk, C., Eds.; Elsevier: Amsterdan, The Netherlands, 1994; pp. 45–69. [Google Scholar]

- Powers, R.F.; Scott, D.A.; Sanchez, F.G.; Voldseth, R.A.; Page-Dumroese, D.; Elioff, J.D.; Stonef, D.M. The North American long-term soil productivity experiment: Findings from the first decade of research. For. Ecol. Manag. 2005, 220, 31–50. [Google Scholar] [CrossRef]

- Soracco, C.G.; Lozano, L.A.; Villarreal, R.; Palancar, T.C.; Collazo, D.J.; Sarli, G.O.; Filgueira, R.R. Effects of compaction due to machinery traffic on soil pore configuration. Rev. Bras. Ciênc. Solo 2015, 39, 408–415. [Google Scholar] [CrossRef] [Green Version]

- Boone, F.R.; Veen, B.W. Mechanisms of crop responses to soil compaction. In Soil Compaction in Crop Production; Soane, B.D., van Ouwerkerk, C., Eds.; Elsevier: Amsterdam, The Netherlands, 1994; pp. 237–264. [Google Scholar]

- Queiroz-Voltan, R.B.; Nogueira, S.S.S.; Miranda, M.A.C. Aspectos da estrutura da raiz e do desenvolvimento de plantas de soja em solos compactados. Pesq. Agropecu. Bras. 2000, 35, 929–938. [Google Scholar] [CrossRef] [Green Version]

- Unger, P.W.; Kaspar, T.C. Soil compaction and root growth: A review. Agron. J. 1994, 86, 759–766. [Google Scholar] [CrossRef]

- Lipiec, J.; Simota, C. Role of soil and climate factors in influencing crop responses to soil compaction in Central and Eastern Europe. In Soil Compaction in Crop Production; Soane, B.D., van Ouwerkerk, C., Eds.; Elsevier: Amsterdan, The Netherlands, 1994; pp. 365–390. [Google Scholar]

- Bergamaschi, H.; Dalmago, G.A.; Bergonci, J.I.; Bianchi, C.A.M.; Müller, A.G.; Comiran, F.; Heckler, B.M.M. Distribuição hídrica no período crítico do milho e produção de grãos. Pesq. Agropecu. Bras. 2004, 39, 831–839. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Gabrielle, B.; Makowski, D. A global dataset for crop production under conventional tillage and no tillage systems. Sci. Data 2021, 8, 33. [Google Scholar] [CrossRef] [PubMed]

- Flowers, M.D.; Lal, R. Axle load and tillage effects on soil physical properties and soybean grain yield on a mollic ochraqualf in northwest Ohio. Soil Tillage Res. 1998, 48, 21–35. [Google Scholar] [CrossRef]

- Nunes, M.R.; Denardin, J.E.; Pauletto, E.A.; Faganello, A.; Pinto, L.F.S. Mitigation of clayey soil compaction managed under no-tillage. Soil Tillage Res. 2015, 148, 119–126. [Google Scholar] [CrossRef] [Green Version]

- Derpsch, R.; Sidiras, N.; Roth, C.H. Results of studies made from 1977 to 1984 to control erosion by cover crops and no-tillage techniques in Paraná, Brazil. Soil Tillage Res. 1986, 8, 253–263. [Google Scholar] [CrossRef]

- Moraes, M.T.; Debiasi, H.; Franchini, J.C. Soybean and wheat response to cropping and tillage system after two decades in an oxisol under subtropical climate in Brazil. Rev. Sci. 2017, 18, 146–153. Available online: https://revistas.ufpr.br/agraria/article/view/51553/33602 (accessed on 31 December 2021).

- Awe, G.O.; Reichert, J.M.; Timm, L.C.; Wendroth, O.O. Temporal processes of soil water status in a sugarcane field under residue management. Plant Soil 2015, 387, 395–411. [Google Scholar] [CrossRef]

- Lipiec, J.; Tarkiewicz, S.; Kossowski, J.; Hakansson, I. Soil physical properties and growth of spring barley related to the degree of compactness of two soils. Soil Tillage Res. 1991, 19, 307–317. [Google Scholar] [CrossRef]

- Jamali, H.; Nachimuthu, G.; Palmer, B.; Hodgson, D.; Hundt, A.; Nunn, C.; Braunack, M. Soil compaction in a new light: Know the cost of doing nothing—A cotton case study. Soil Tillage Res. 2021, 213, 105158. [Google Scholar] [CrossRef]

- Pedrotti, A.; Dias Junior, M.S. Compactação do solo: Como evitá-la. Agropecu. Catarin. 1996, 9, 50–52. [Google Scholar]

- Agomoh, I.V.; Drury, C.F.; Yang, X.; Phillips, L.A.; Reynolds, W.D. Crop rotation enhances soybean yields and soil health indicators. Soil Water Manag. Conserv. 2021, 85, 1185–1195. [Google Scholar] [CrossRef]

- Santos, H.P.; Lhamby, J.C.B.; Lima, M.R. Efeito de métodos de preparo do solo no inverno e de rotação de culturas no rendimento de grãos de soja. Pesq. Agropecu. Gaúcha 2001, 7, 69–76. [Google Scholar]

- Chan, K.Y.; Oates, A.; Swan, A.D.; Hayes, R.C.; Dear, B.S.; Peoples, M.B. Agronomic consequences of tractor wheel compaction on a clay soil. Soil Tillage Res. 2006, 89, 13–21. [Google Scholar] [CrossRef]

- Canalli, L.B.S.; da Costa, G.V.; Volsi, B.; Leocádio, A.L.M.; Neves, C.S.V.J.; Telles, T.S. Production and profitability of crop rotation systems in southern Brazil. Semin. Ciênc. Agrár. 2020, 41, 2541–2554. [Google Scholar] [CrossRef]

- Radford, B.J.; Bridge, B.J.; Davis, R.J.; Mcgarry, D.; Pillai, U.P.; Rickman, J.F.; Walsh, P.A.; Yule, D.F. Changes in the properties of a Vertisol and responses of wheat after compaction with harvester traffic. Soil Tillage Res. 2000, 54, 155–170. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, D.Z. Long-term effects of returning wheat straw to croplands on soil compaction and nutrient availability under conventional tillage. Plant Soil Environ. 2013, 59, 280–286. [Google Scholar] [CrossRef] [Green Version]

| Treatment | VM | SD | BDfinal | Def | PCS | CI |

|---|---|---|---|---|---|---|

| m3 m−3 | % | Mg m−3 | cm | kPa | ||

| NTC | 0.38 a | 86.08 a | 1.67 ab | 0.272 b | 130.4 ab | 0.17 b |

| NT | 0.37 a | 77.84 a | 1.65 b | 0.380 b | 167.1 a | 0.27 b |

| Chisel | 0.32 b | 58.34 b | 1.69 a | 0.703 a | 101.1 b | 0.49 a |

| Layer (m) | Treatments | Average | ||

|---|---|---|---|---|

| NTC | NT | Chisel | ||

| Total porosity (m3 m−3) | ||||

| 0–0.05 | 0.496 B | 0.520 AB | 0.573 A | 0.530 |

| 0.05–0.10 | 0.466 B | 0.466 B | 0.544 A | 0.492 |

| 0.10–0.15 | 0.460 A | 0.464 A | 0.530 A | 0.484 |

| 0.15–0.20 | 0.483 A | 0.482 A | 0.505 A | 0.490 |

| 0.20–0.25 | 0.497 A | 0.494 A | 0.513 A | 0.501 |

| 0.25–0.30 | 0.510 A | 0.510 A | 0.488 A | 0.503 |

| Average | 0.485 | 0.489 | 0.526 | |

| Macroporosity (m3 m−3) | ||||

| 0–0.05 | 0.052 B | 0.091 B | 0.219 A | 0.120 |

| 0.05–0.10 | 0.020 B | 0.038 B | 0.163 A | 0.073 |

| 0.10–0.15 | 0.017 B | 0.033 B | 0.150 A | 0.066 |

| 0.15–0.20 | 0.031 B | 0.049 AB | 0.093 A | 0.057 |

| 0.20–0.25 | 0.021 A | 0.061 A | 0.094 A | 0.058 |

| 0.25–0.30 | 0.043 A | 0.086 A | 0.051 A | 0.060 |

| Average | 0.031 | 0.059 | 0.128 | |

| Microporosity (m3 m−3) | ||||

| 0–0.05 | 0.444 A | 0.429 A | 0.354 B | 0.409 |

| 0.05–0.10 | 0.446 A | 0.429 A | 0.381 B | 0.419 |

| 0.10–0.15 | 0.442 A | 0.431 A | 0.380 B | 0.418 |

| 0.15–0.20 | 0.453 A | 0.433 AB | 0.413 B | 0.433 |

| 0.20–0.25 | 0.476 A | 0.433 B | 0.419 B | 0.443 |

| 0.25–0.30 | 0.467 A | 0.424 B | 0.437 AB | 0.443 |

| Average | 0.455 | 0.430 | 0.397 | |

| Summer Crop | Treatments | ||

|---|---|---|---|

| NTC | NT | Chisel | |

| Heights, cm | |||

| Corn | 125 C | 193 A | 169 B |

| Soybean (1st evaluation) | 43 B | 57 A | 52 A |

| Soybean (2nd evaluation) | 46 B | 59 A | 54 A |

| Yield, kg ha−1 | |||

| Corn | 3306 A | 4328 A | 3603 A |

| Soybean | 1769 B | 2700 A | 2129 B |

| Crops Sequence | Treatments | ||

|---|---|---|---|

| NTC | NT | Chisel | |

| kg ha−1 | |||

| Soybean | 2382 | 2551 | 2399 |

| Corn | 2287 | 2082 | 2257 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suzuki, L.E.A.S.; Reinert, D.J.; Alves, M.C.; Reichert, J.M. Medium-Term No-Tillage, Additional Compaction, and Chiseling as Affecting Clayey Subtropical Soil Physical Properties and Yield of Corn, Soybean and Wheat Crops. Sustainability 2022, 14, 9717. https://doi.org/10.3390/su14159717

Suzuki LEAS, Reinert DJ, Alves MC, Reichert JM. Medium-Term No-Tillage, Additional Compaction, and Chiseling as Affecting Clayey Subtropical Soil Physical Properties and Yield of Corn, Soybean and Wheat Crops. Sustainability. 2022; 14(15):9717. https://doi.org/10.3390/su14159717

Chicago/Turabian StyleSuzuki, Luis Eduardo Akiyoshi Sanches, Dalvan José Reinert, Marlene Cristina Alves, and José Miguel Reichert. 2022. "Medium-Term No-Tillage, Additional Compaction, and Chiseling as Affecting Clayey Subtropical Soil Physical Properties and Yield of Corn, Soybean and Wheat Crops" Sustainability 14, no. 15: 9717. https://doi.org/10.3390/su14159717