Inherent Safety Analysis and Sustainability Evaluation of a Vaccine Production Topology in North-East Colombia

Abstract

:1. Introduction

2. Materials and Methods

2.1. Inherent Safety Evaluation

2.2. Sustainability Evaluation

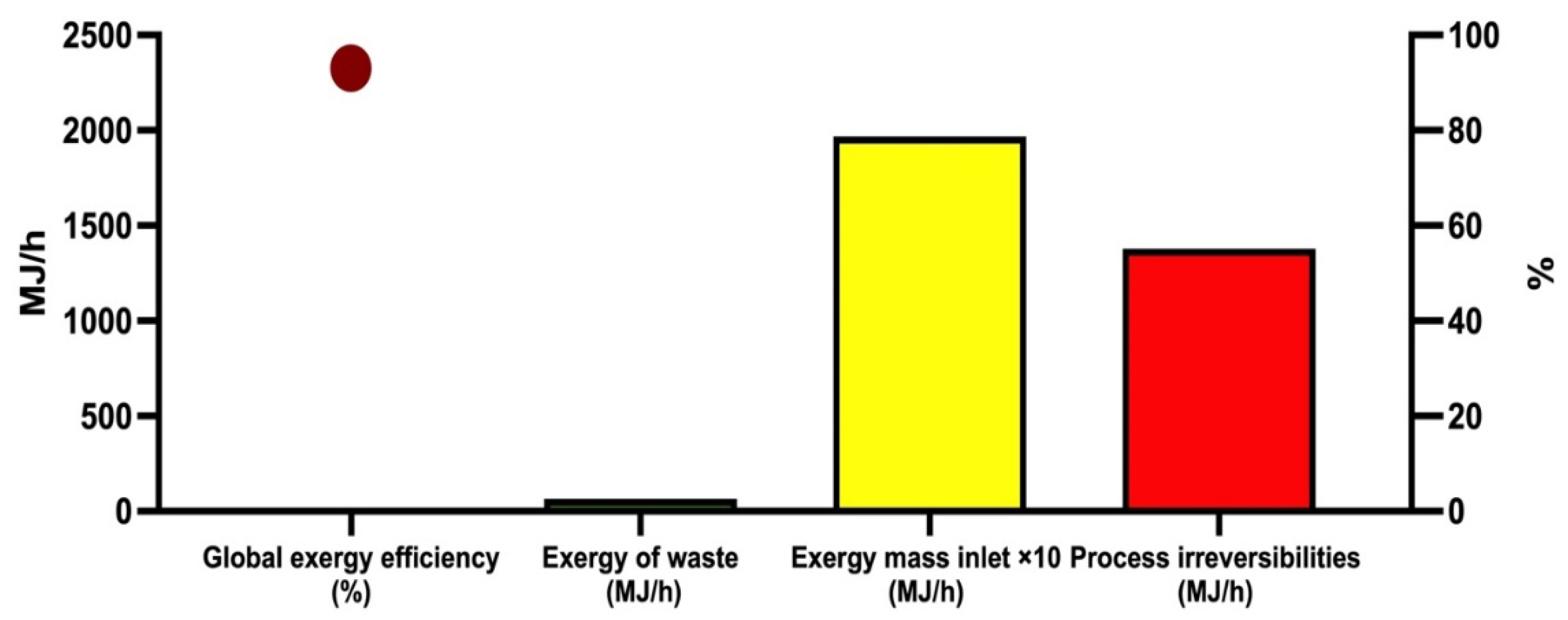

2.3. Exergy Indicators

2.4. Economic Indicators

2.5. Environmental Indicators

3. Results

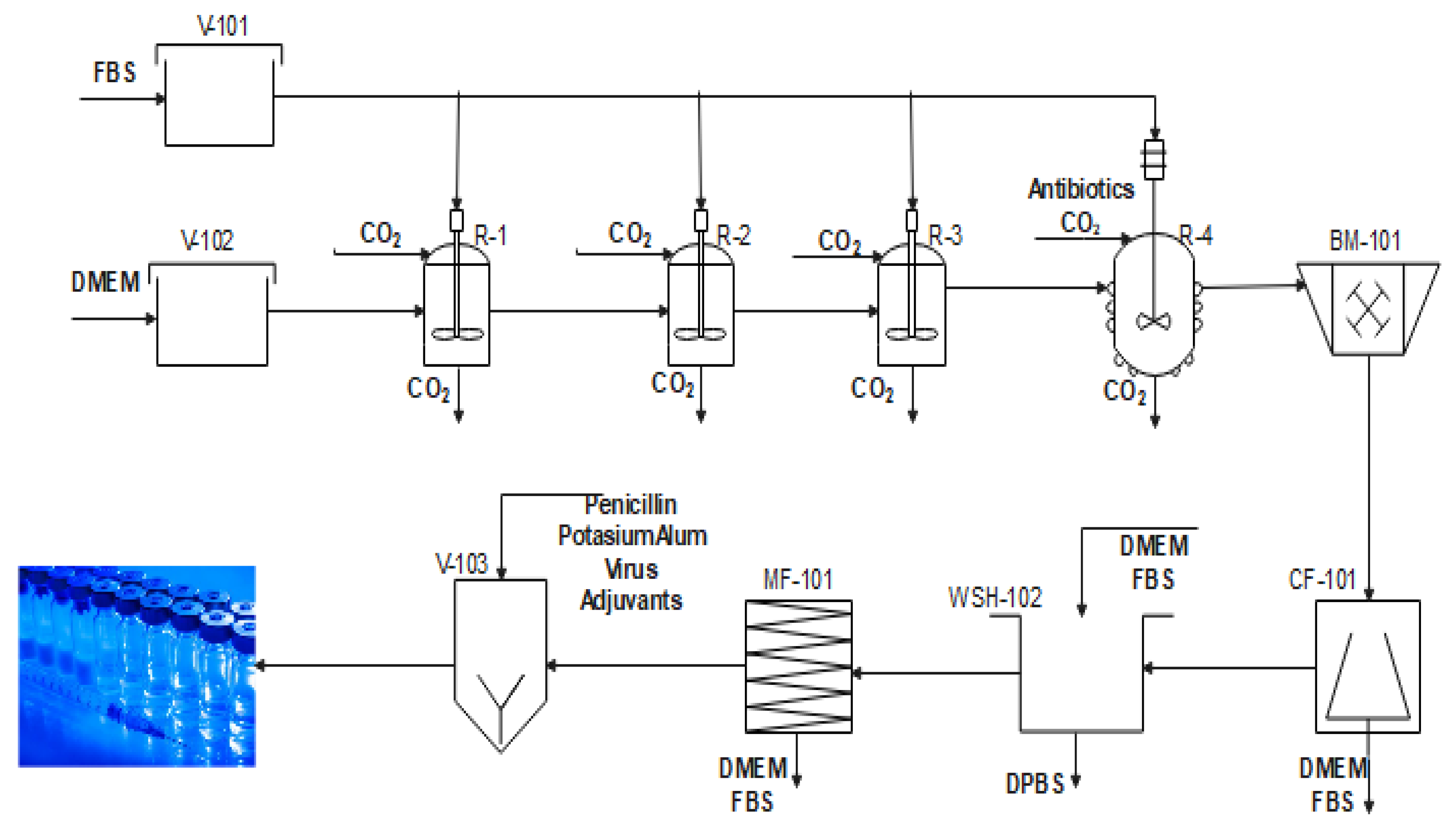

3.1. Process Description

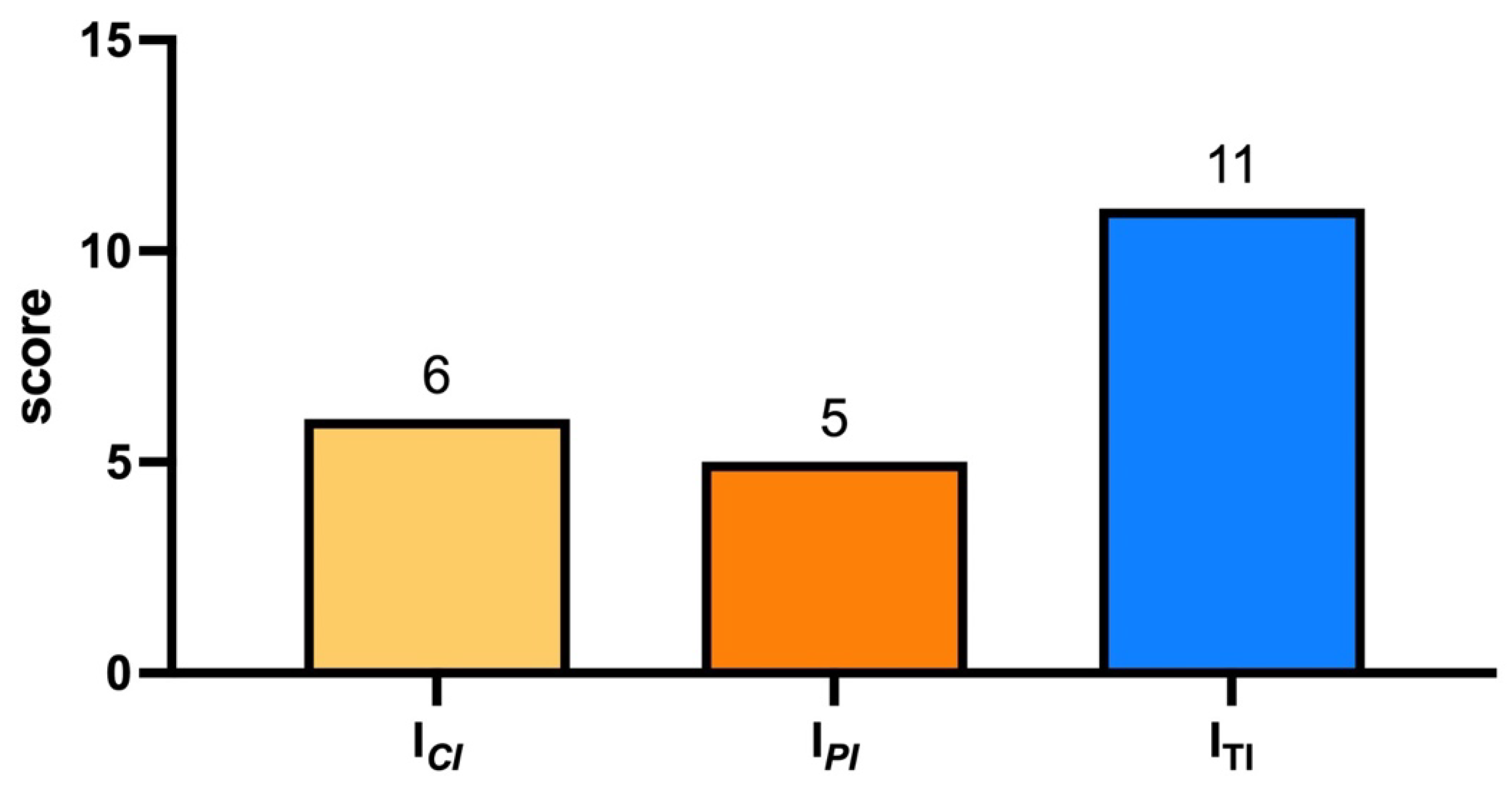

3.2. Inherent Safety Analysis

3.2.1. Chemical Inherent Safety Index

3.2.2. Process Inherent Safety Index

3.2.3. Total Inherent Safety Index

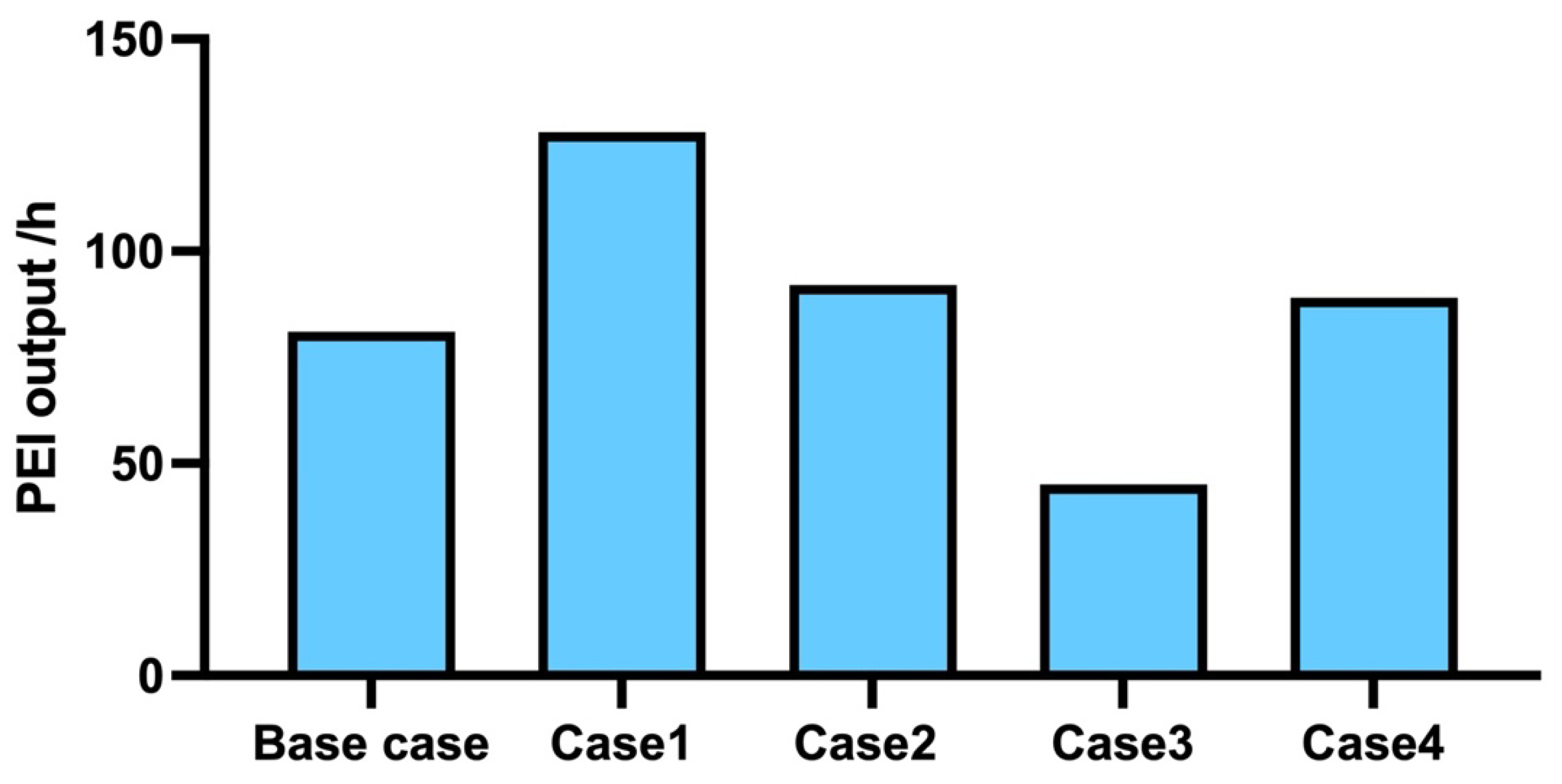

3.3. Sustainability Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moghadami, M. A Narrative Review of Influenza: A Seasonal and Pandemic Disease. Iran. J. Med. Sci. 2017, 42, 2–13. [Google Scholar]

- Paget, J.; Spreeuwenberg, P.; Charu, V.; Taylor, R.J.; Iuliano, A.D.; Bresee, J.; Simonsen, L.; Viboud, C. Global Mortality Associated with Seasonal Influenza Epidemics: New Burden Estimates and Predictors from the GLaMOR Project. J. Glob. Health 2019, 9, 1–12. [Google Scholar] [CrossRef]

- Karlsson, E.A.; Ciuoderis, K.; Freiden, P.J.; Seufzer, B.; Jones, J.C.; Johnson, J.; Parra, R.; Gongora, A.; Cardenas, D.; Barajas, D.; et al. Prevalence and Characterization of Influenza Viruses in Diverse Species in Los Llanos, Colombia. Emerg. Microbes Infect. 2013, 2, 1–10. [Google Scholar] [CrossRef]

- García-Corzo, J.; Niederbacher-Velasquez, J.; González-Rugéles, C.; Rodríguez-Villamizar, L.; Machuca-Pérez, M.; Torres-Prieto, A. Etiología viral de infección respiratoria aguda en niños menores de 5 años en las provincias Comunera y García Rovira de Santander. Rev. Univ. Ind. Santander 2016, 48, 240–245. [Google Scholar] [CrossRef]

- Gasparini, R.; Amicizia, D.; Lai, P.L.; Panatto, D. Influenza Vaccination: From Epidemiological Aspects and Advances in Research to Dissent and Vaccination Policies. J. Prev. Med. Hyg. 2016, 57, E1–E4. [Google Scholar]

- Contreras-Ropero, J.E.; Ruiz-Roa, S.L.; García-Martínez, J.B.; Urbina-Suarez, N.A.; López-Barrera, G.L.; Barajas-Solano, A.F.; Zuorro, A. A Simulation Analysis of an Influenza Vaccine Production Plant in Areas of High Humanitarian Flow. A Preliminary Study for the Region of Norte de Santander (Colombia). Appl. Sci. 2022, 12, 183. [Google Scholar] [CrossRef]

- González-Delgado, A.D.; García-Martínez, J.B.; Barajas-Solano, A.F. Evaluation of Algae-Based Biodiesel Production Topologies via Inherent Safety Index (ISI). Appl. Sci. 2021, 11, 2854. [Google Scholar] [CrossRef]

- Rasouli, A.; Hosseini, S.M.; Bahadori, M.K.; Ravangard, R. Characteristics of Occupational Injuries in a Pharmaceutical Company in Iran. Bull. Emerg. Trauma 2018, 6, 155–161. [Google Scholar] [CrossRef]

- Meramo-Hurtado, S.; Ceballos-Arrieta, N.; Cortes-Caballero, J.; Leon-Pulido, J.; Gonzalez-Quiroga, A.; Gonzalez-Delgado, Á.D. Inherent Safety Assessment of Industrial-Scale Production of Chitosan Microbeads Modified with TiO2 Nanoparticles. Biomolecules 2021, 11, 568. [Google Scholar] [CrossRef]

- Zuorro, A.; Moreno-Sader, K.A.; González-Delgado, Á.D. Inherent Safety Analysis and Sustainability Evaluation of Chitosan Production from Shrimp Exoskeleton in Colombia. Water 2021, 13, 553. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Jiang, P.; Van Fan, Y.; Bokhari, A.; Wang, X.-C. COVID-19 Pandemics Stage II—Energy and Environmental Impacts of Vaccination. Renew. Sustain. Energy Rev. 2021, 150, 111400. [Google Scholar] [CrossRef]

- Dias, F.P.F.; Fernandes, I.T.; Bueno, A.V.; Rocha, P.A.C.; de Oliveira, M.L.M. Exergy Analysis of Glycerol Steam Reforming in a Heat Recovery Reactor. Int. J. Hydrogen Energy 2021, 46, 8995–9007. [Google Scholar] [CrossRef]

- Kang, Q.; Tan, T. Exergy and CO2 Analyses as Key Tools for the Evaluation of Bio-Ethanol Production. Sustainability 2016, 8, 76. [Google Scholar] [CrossRef]

- Herrera-Rodriguez, T.; Parejo-Palacio, V.; González-Delgado, A. Technoeconomic sensibility analysis of industrial agar production from red algae. Chem. Eng. Trans. 2018, 70, 2029–2034. [Google Scholar] [CrossRef]

- Zuorro, A.; Moreno-Sader, K.A.; González-Delgado, Á.D. Economic Evaluation and Techno-Economic Sensitivity Analysis of a Mass Integrated Shrimp Biorefinery in North Colombia. Polymers 2020, 12, 2397. [Google Scholar] [CrossRef]

- Cassiani-Cassiani, D.; Meza-González, D.; González-Delgado, A. Environmental evaluation of agar production from macroalgae Gracilaria sp. Chem. Eng. Trans. 2018, 70, 2005–2010. [Google Scholar] [CrossRef]

- Herrera-Aristizábal, R.; Salgado-Dueñas, J.; Peralta-Ruiz, Y.; González-Delgado, A. Environmental evaluation of a palm-based biorefinery under North-Colombian condition. Chem. Eng. Trans. 2017, 57, 193–198. [Google Scholar] [CrossRef]

- Luján-Ornelas, C.; Güereca, L.P.; Franco-García, M.-L.; Heldeweg, M. A Life Cycle Thinking Approach to Analyse Sustainability in the Textile Industry: A Literature Review. Sustainability 2020, 12, 10193. [Google Scholar] [CrossRef]

- Meramo-Hurtado, S.I.; Sanchez-Tuiran, E.; Ponce-Ortega, J.M.; El-Halwagi, M.M.; Ojeda-Delgado, K.A. Synthesis and Sustainability Evaluation of a Lignocellulosic Multifeedstock Biorefinery Considering Technical Performance Indicators. ACS Omega 2020, 5, 9259–9275. [Google Scholar] [CrossRef]

- Heikkilä, A. Inherent Safety in Process Plant Design: An Index-Based Approach; VTT Technical Research Centre of Finland: Espoo, Finland, 1999. [Google Scholar]

- Moreno Sader, K.; León Pulido, J.; González-Delgado, A. Evaluación de la producción de aceite crudo de palma y palmiste en el norte de Colombia mediante el análisis de exergía asistido por computador. Rev. ION 2021, 34, 31–41. [Google Scholar] [CrossRef]

- González-Delgado, A.D.; Barajas-Solano, A.F.; Leon-Pulido, J. Evaluating the Sustainability and Inherent Safety of a Crude Palm Oil Production Process in North-Colombia. Appl. Sci. 2021, 11, 1046. [Google Scholar] [CrossRef]

- Zuorro, A.; Moreno-Sader, K.A.; González-Delgado, Á.D. Evaluating the Feasibility of a Pilot-Scale Shrimp Biorefinery via Techno-Economic Analysis. J. Clean. Prod. 2021, 320, 128740. [Google Scholar] [CrossRef]

- Zamfir, M.; Manea, M.D.; Ionescu, L. Return on Investment—Indicator for Measuring the Profitability of Invested Capital. Valahian J. Econ. Stud. 2016, 7, 79–86. [Google Scholar] [CrossRef]

- Young, D.M.; Cabezas, H. Designing Sustainable Processes with Simulation: The Waste Reduction (WAR) Algorithm. Comput. Chem. Eng. 1999, 23, 1477–1491. [Google Scholar] [CrossRef]

- Yan, W.; Wang, T.; Zhao, L.; Sun, C. Modified DMEM Xenic Culture Medium for Propagation, Isolation and Maintenance of Balantioides Coli. Acta Trop. 2021, 214, 105762. [Google Scholar] [CrossRef]

- Kurzweil, P.; Müller, A.; Wahler, S. The Ecological Footprint of COVID-19 mRNA Vaccines: Estimating Greenhouse Gas Emissions in Germany. Int. J. Environ. Res. Public Health 2021, 18, 7425. [Google Scholar] [CrossRef]

- Gonzalez-Delgado, A.; Moreno-Sader, K.; Baldiris-Navarro, I. Inherent safety assessment of a valorization alternative for shrimp wastes under the concept of biorefinery. Prospectiva 2021, 19, 1–10. [Google Scholar]

- Merck. Safety Data Sheet for Urea 818710; 2021; Available online: https://www.merckmillipore.com/CO/es/product/msds/MDA_CHEM-818710 (accessed on 7 August 2022).

- Solórzano-Álvarez, E.; Pérez-Tortolo, J.; Rodriguez-Dueñnas, J. Biological risk assessment for the production of inactivated vaccines for animal use. VacciMonitor 2020, 29, 93–102. [Google Scholar]

- Zhang, E. Improving Energy Efficiency in a Pharmaceutical Manufacturing Environment—Production Facility; Massachusetts Institute of Technology: Cambridge, MA, USA, 2010. [Google Scholar]

- Munira, S. Viability of Local Vaccine Production in Developing Countries: An Economic Analysis of Cost Structures, Revenue Sizes, Market Shares and Vaccine Prices; Australian National University: Canberra, Australia, 2017. [Google Scholar]

- Ledley, F.; Shonka, S.; Vaughan, G.; Galkina, E. Profitability of large pharmaceutical companies compared with other large public companies. JAMA 2020, 323, 838–843. [Google Scholar]

- Hasija, V.; Patial, S.; Raizada, P.; Thakur, S.; Singh, P.; Mustansar, C. The environmental impact of mass coronavirus vaccinations: A point of view on huge COVID-19 vaccine waste across the globe during ongoing vaccine campaigns. Sci. Total Environ. 2022, 813, 151881. [Google Scholar] [CrossRef]

| Symbols | Score | |

| Chemical reactivity (main reaction) | 0-4 | |

| Chemical reactivity (side reactions) | 0-4 | |

| Chemical interactions | 0-4 | |

| Flammability | 0-4 | |

| Explosiveness | 0-4 | |

| Toxic exposure | 0-6 | |

| Corrosiveness | 0-2 | |

| Symbols | Score | |

| Inventory | 0-5 | |

| Temperature | 0-4 | |

| Pressure | 0-4 | |

| Equipment safety | 0-4 (ISBL); 0-3 (OSBL) | |

| Safe process structure | 0-5 |

| Value of Weighting Factor | Meaning |

|---|---|

| Lower relevance than economic parameter | |

| Equal relevance as an economic parameter | |

| Higher relevance than economic parameter |

| Stream | T °C | P (atm) | Mass Flow (kg/h) |

|---|---|---|---|

| Inlet R-1 | 100.00 | 1.00 | 0.19 |

| Outlet R-4 | 39.62 | 1.00 | 3.24 |

| Inlet WSH-102 | 25.00 | 1.00 | 0.89 |

| Inlet MF-101 | 25.00 | 1.00 | 0.76 |

| Outlet MF-101 (waste) | 25.00 | 1.00 | 0.38 |

| Inlet V-103 (main stream) | 25.00 | 1.00 | 0.37 |

| Outlet V-103 (product) | 25.00 | 1.00 | 840.32 |

| Aspect | Index | |||

|---|---|---|---|---|

| Energy | Exergy efficiency | 93% | 100% | 0.4 |

| Safety | ) | 11 | 11 | 0.5 |

| Environmental | 5% | 50% | 0.6 |

| Criteria | Base Case | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|---|

| Environmental | 0.4 | 0.5 | 1 | 0.5 | 1 |

| Energy | 0.5 | 1 | 0.5 | 0.5 | 1 |

| Safety | 0.6 | 0.5 | 0.5 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Delgado, Á.D.; García-Martínez, J.B.; Barajas-Solano, A.F. Inherent Safety Analysis and Sustainability Evaluation of a Vaccine Production Topology in North-East Colombia. Sustainability 2022, 14, 9985. https://doi.org/10.3390/su14169985

González-Delgado ÁD, García-Martínez JB, Barajas-Solano AF. Inherent Safety Analysis and Sustainability Evaluation of a Vaccine Production Topology in North-East Colombia. Sustainability. 2022; 14(16):9985. https://doi.org/10.3390/su14169985

Chicago/Turabian StyleGonzález-Delgado, Ángel Darío, Janet B. García-Martínez, and Andrés F. Barajas-Solano. 2022. "Inherent Safety Analysis and Sustainability Evaluation of a Vaccine Production Topology in North-East Colombia" Sustainability 14, no. 16: 9985. https://doi.org/10.3390/su14169985