Acoustic Emission Waveform Characteristics of Red Sandstone Failure under Uniaxial Compression after Thermal Damage

Abstract

:1. Introduction

2. Specimen Preparation and Test System

3. Mechanical Properties and AE Response

4. Waveform Characteristics at Failure

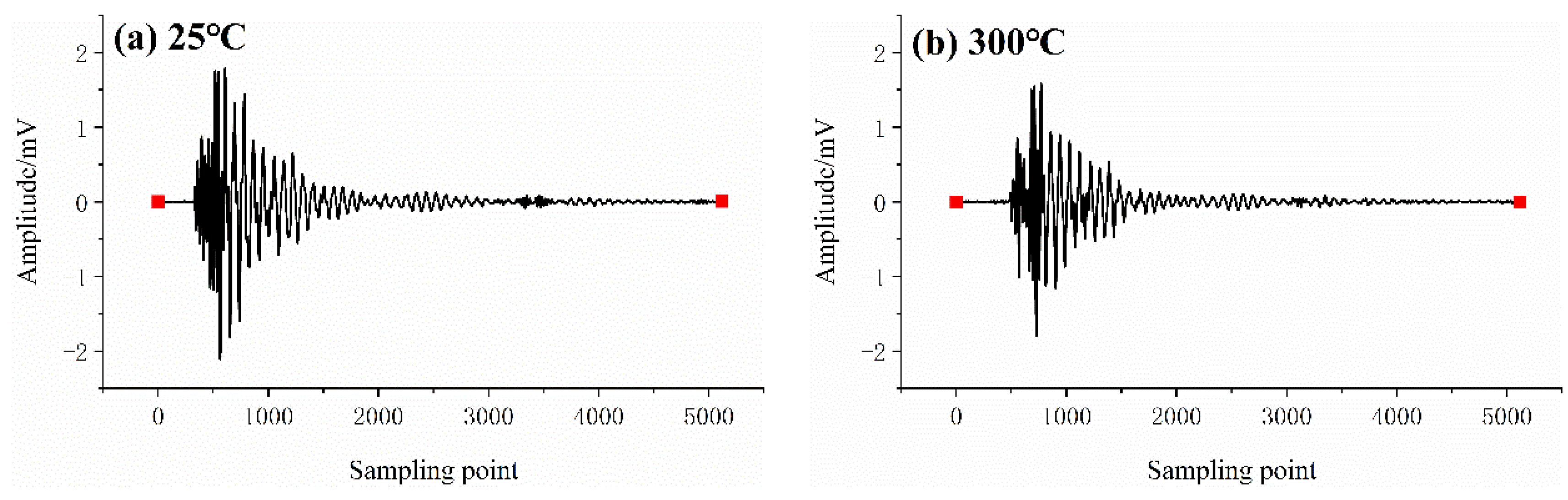

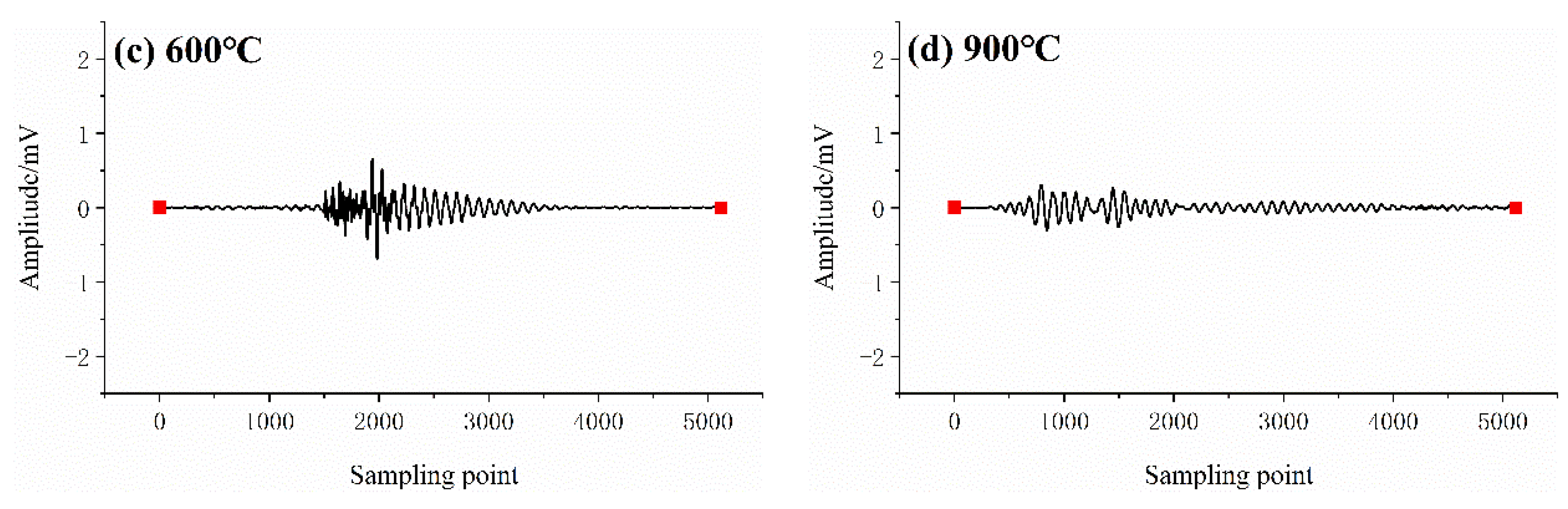

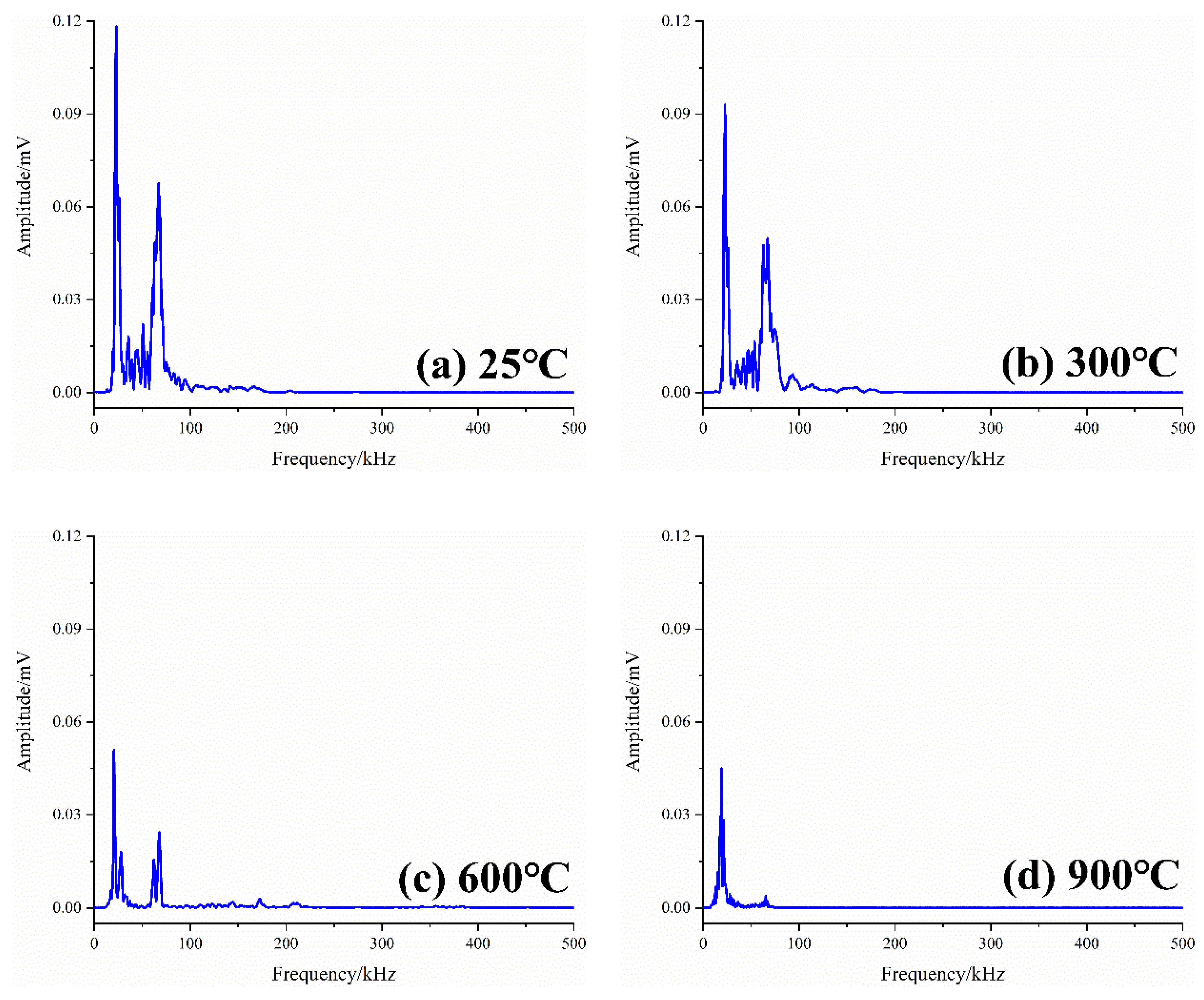

4.1. Original Waveform and FFT Analysis

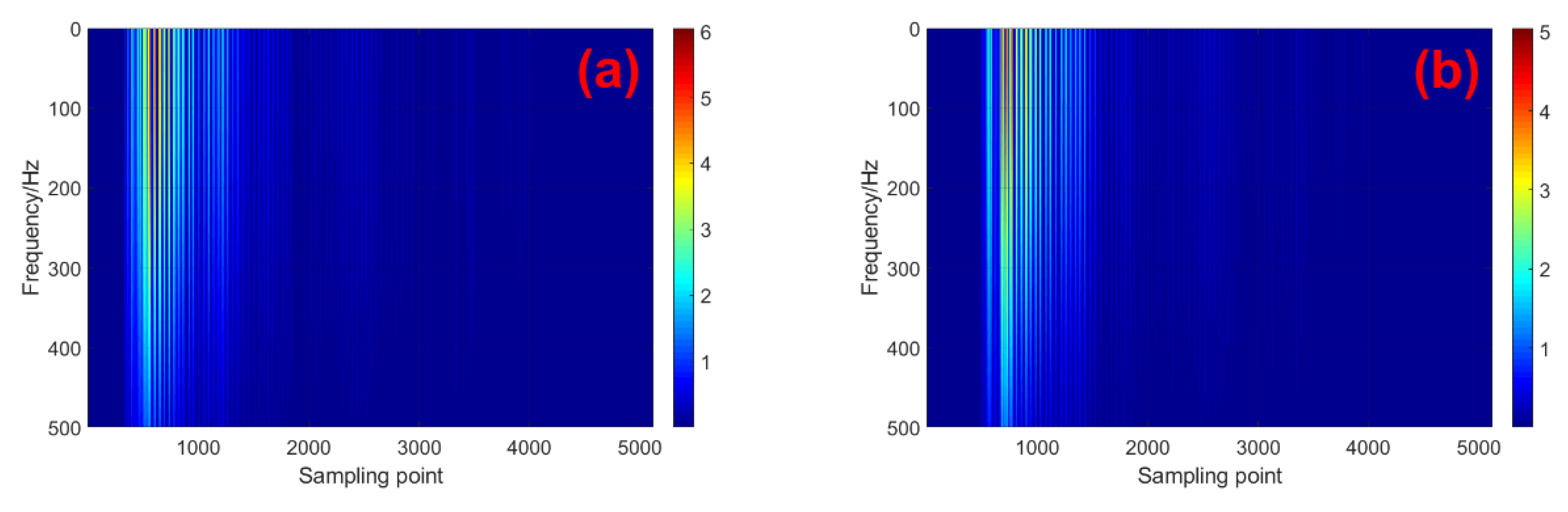

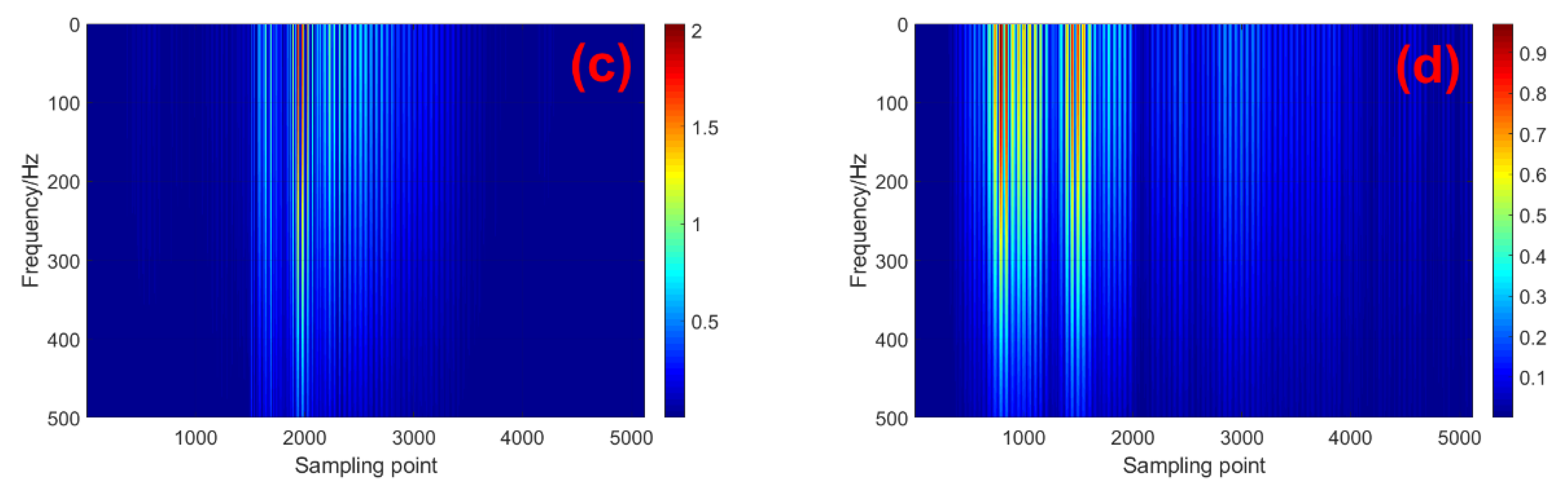

4.2. STFT Analysis

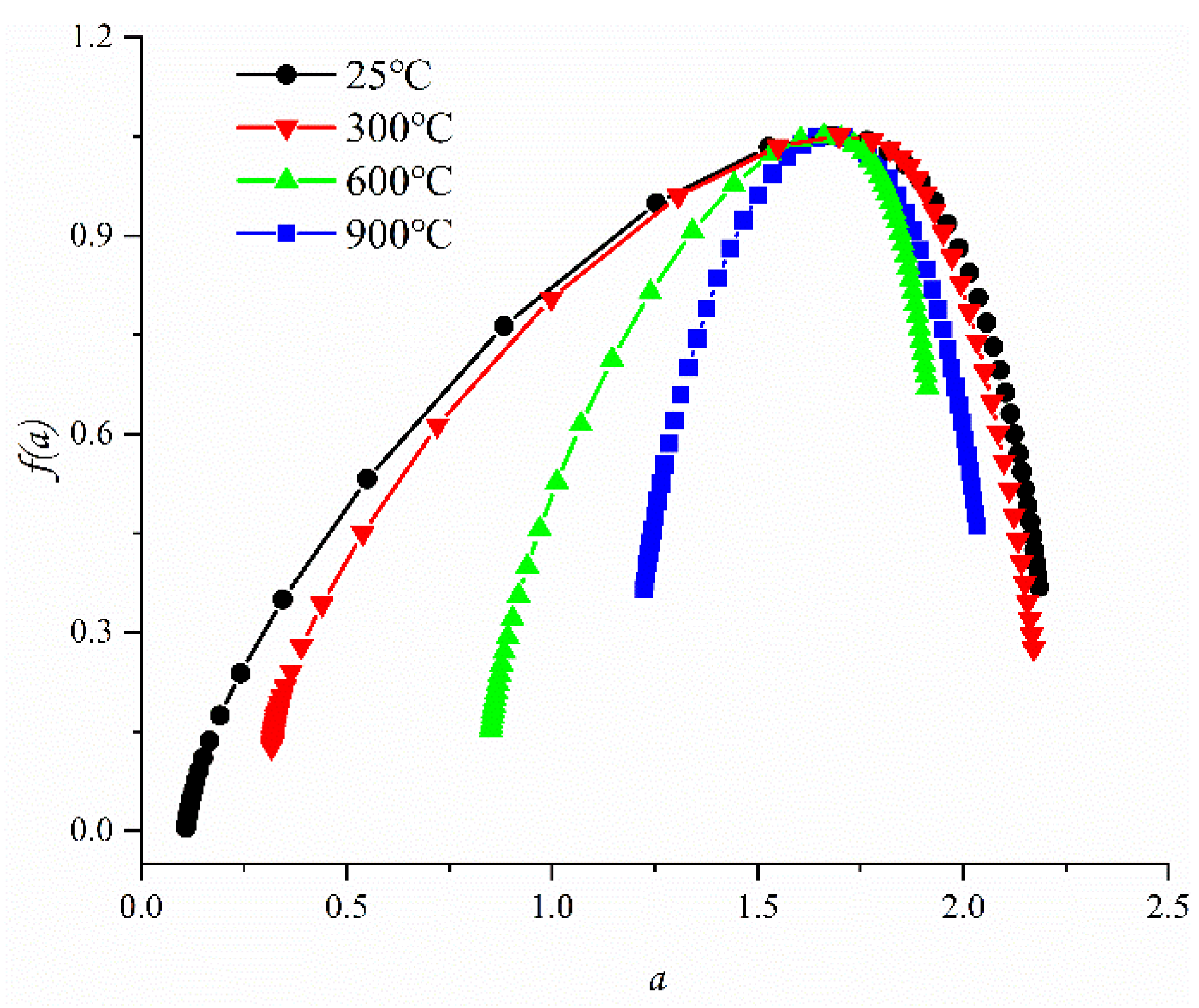

4.3. Multifractal Analysis

5. Conclusions

- (1)

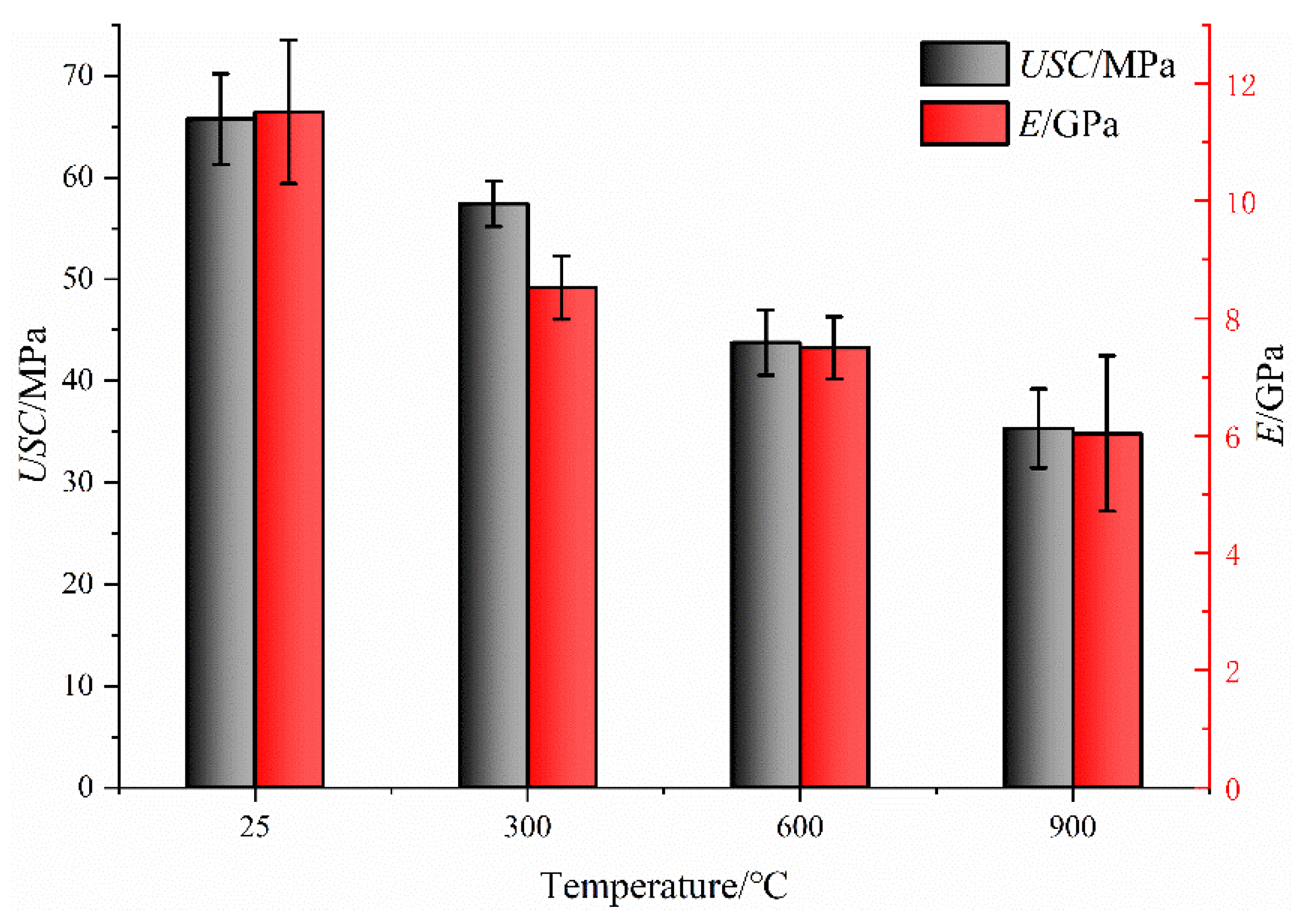

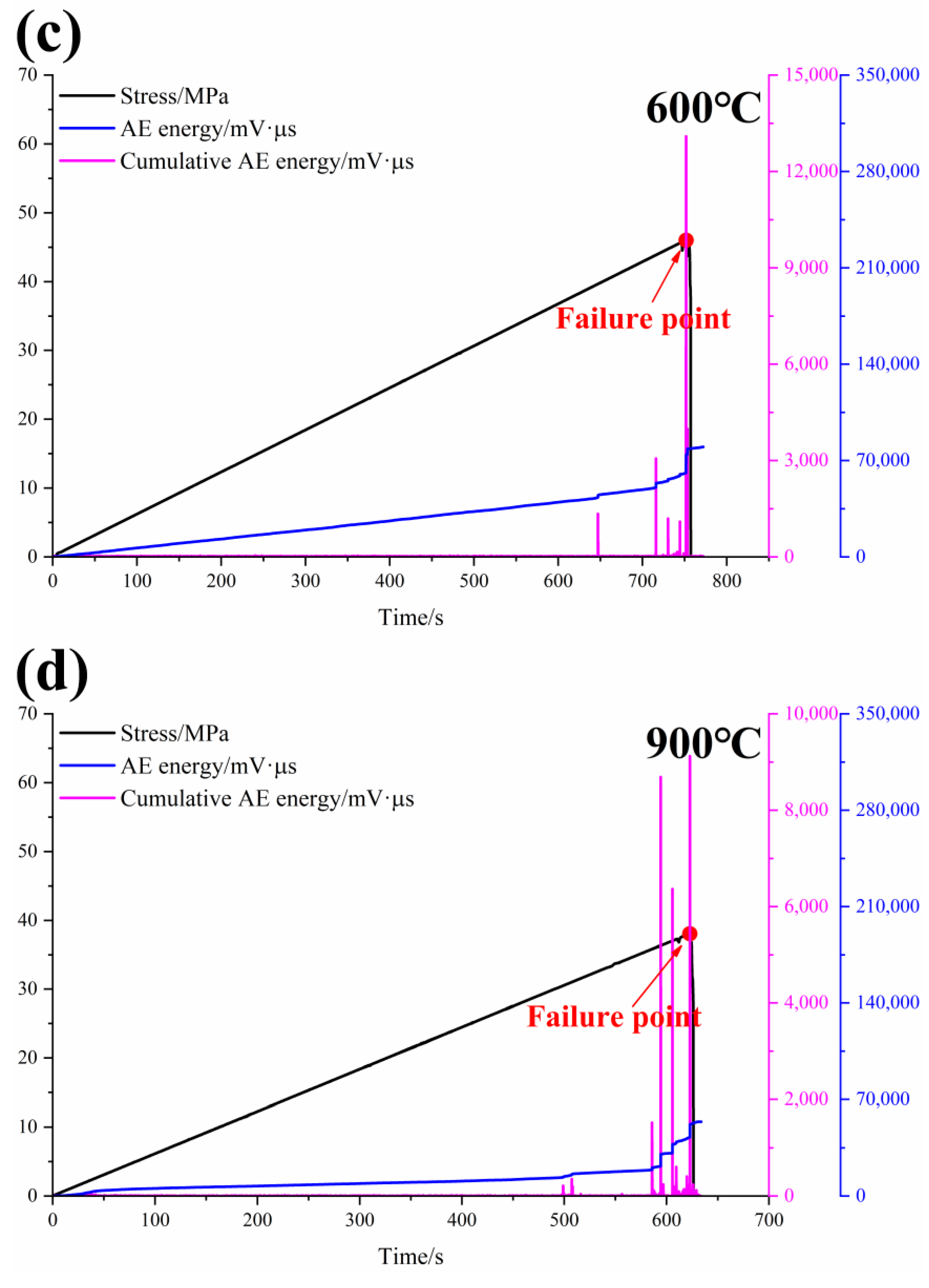

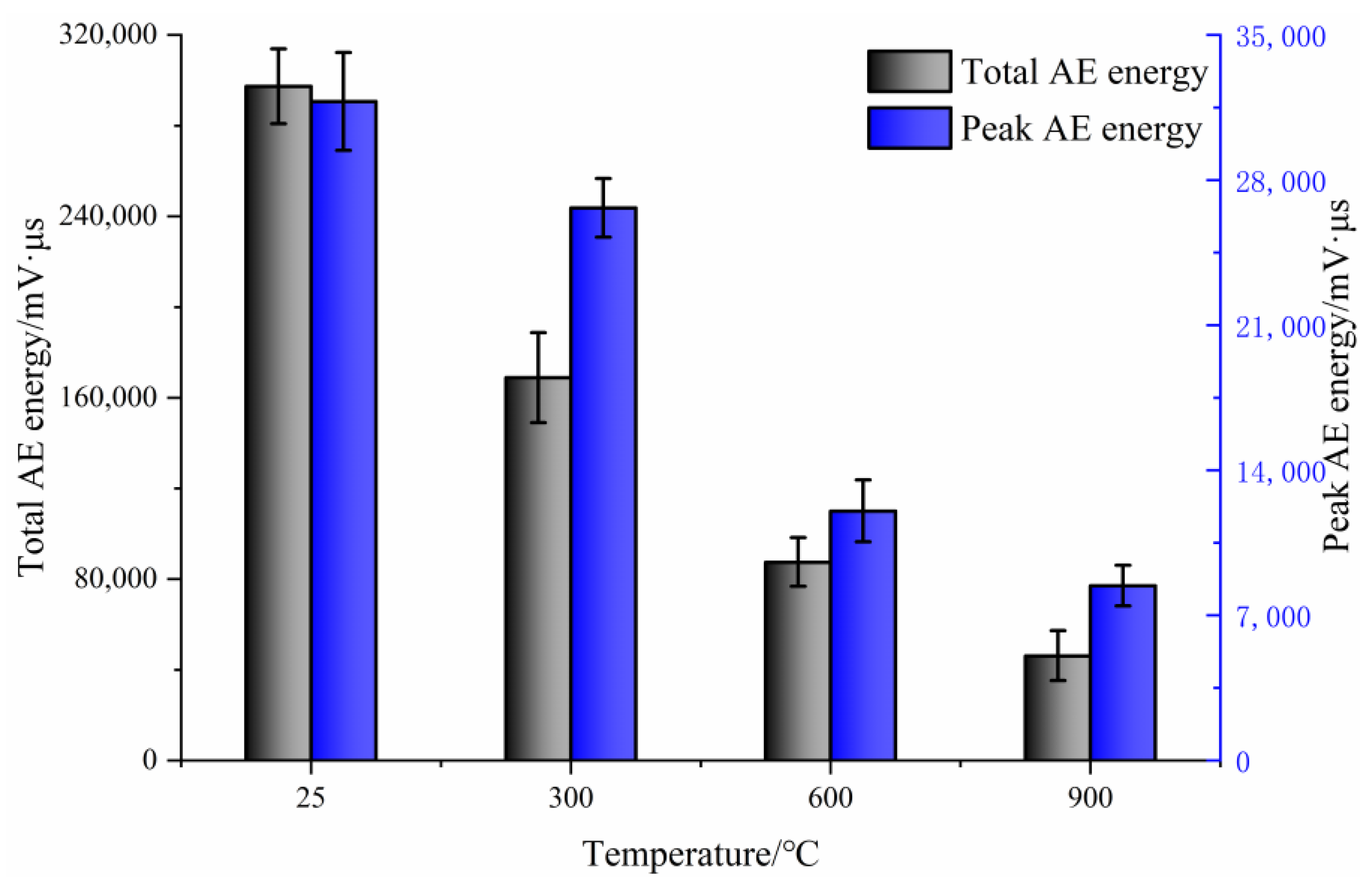

- When the heating temperature increases from 25 °C to 900 °C, the uniaxial compressive strength and elastic modulus of sandstone decrease by 46.27% and 47.57%, respectively. Moreover, with an increase in temperature, the AE energy level in the loading process tends to decay. Compared with the untreated samples, the total value and peak value of AE energy of the samples after the 900 °C treatment decrease by 84.45% and 73.47%, respectively.

- (2)

- The FFT analysis shows that with an increase in temperature, the dominant frequency and amplitude of the AE waveform of sandstone failure are decreased. The dominant frequency and amplitude of the samples treated at 900 °C are 23.22% and 66.67% lower, respectively, than those of the untreated samples. The STFT analysis also has basically consistent laws. In addition, STFT shows that the frequency range and intensity are gradually attenuated after the waveform reaches a peak. The attenuation of AE may be related to the decrease in elastic energy release and the increase in porosity.

- (3)

- Multifractal theory was introduced to analyze the waveform of failure. The multifractal characteristic ( and ) of the signal gradually decreases with an increase in temperature, and it provides new parameters for the waveform characteristic analysis, which has an engineering application value and is conducive to improving the accuracy of rock-failure monitoring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, M.C.; Xie, H.P.; Peng, S.P.; Jiang, Y.D. Study on rock mechanics in deep mining engineering. Chin. J. Rock. Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Kong, X.G.; He, D.; Liu, X.F.; Wang, E.Y.; Li, S.G.; Liu, T.; Ji, P.F.; Deng, D.Y.; Yang, S.R. Strain characteristics and energy dissipation laws of gas-bearing coal during impact fracture process. Energy 2022, 242, 123028. [Google Scholar] [CrossRef]

- Kong, X.G.; Li, S.G.; Wang, E.Y.; Wang, X.; Zhou, Y.X.; Ji, P.F.; Shuang, H.Q.; Li, S.R.; Wei, Z.Y. Experimental and numerical investigations on dynamic mechanical responses and failure process of gas-bearing coal under impact load. Soil Dyn. Earthq. Eng. 2021, 142, 106579. [Google Scholar] [CrossRef]

- Kong, X.G.; Li, S.G.; Wang, E.Y.; Ji, P.F.; Wang, X.; Shuang, H.Q.; Zhou, Y.X. Dynamics behaviour of gas-bearing coal subjected to SHPB tests. Compos. Struct. 2021, 256, 113088. [Google Scholar] [CrossRef]

- Han, S.B.; Hu, X.D.; Zhou, F.J.; Qiu, Y.; Li, M.H.; Huang, G.P. Influence of temperature on the interaction of metal veins and hydraulic fractures in shale formations: Experiment and simulation. J. Pet. Sci. Eng. 2021, 200, 108372. [Google Scholar] [CrossRef]

- Kong, B.; Wang, E.Y.; Li, Z.H.; Wang, X.R.; Liu, J.; Li, N. Fracture mechanical behavior of sandstone subjected to high-temperature treatment and its acoustic emission characteristics under uniaxial compression conditions. Rock Mech. Rock Eng. 2016, 49, 4911–4918. [Google Scholar] [CrossRef]

- Giordano, M.; Calabro, A.; Esposito, C.; Damore, A.; Nicolais, L. An acoustic-emission characterization of the failure modes in polymer-composite materials. Compos. Sci. Technol. 1998, 58, 1923–1928. [Google Scholar] [CrossRef]

- Brotons, V.; Tomas, R.; Ivorra, S.; Alarcon, J.C. Temperature influence on the physical and mechanical properties of a porous rock: San Julian’s calcarenite. Eng. Geol. 2013, 167, 117–127. [Google Scholar] [CrossRef]

- Ozguven, A.; Ozcelik, Y. Investigation of some property changes of natural building stones exposed to fire and high heat. Constr. Build. Mater. 2013, 38, 813–821. [Google Scholar] [CrossRef]

- Ozguven, A.; Ozcelik, Y. Effects of high temperature on physico-mechanical properties of Turkish natural building stones. Eng. Geol. 2014, 183, 127–136. [Google Scholar] [CrossRef]

- Zhu, D.; Jing, H.W.; Yin, Q.; Han, G.S. Experimental study on the damage of granite by acoustic emission after cyclic heating and cooling with circulating water. Processes 2018, 6, 101. [Google Scholar] [CrossRef] [Green Version]

- Chmel, A.; Shcherbakov, I. Temperature dependence of acoustic emission from impact fractured granites. Tectonophysics 2014, 632, 218–223. [Google Scholar] [CrossRef]

- Chmel, A.; Shcherbakov, I. Microcracking in impact-damaged granites heated up to 600 °C. J. Geophys. Eng. 2015, 12, 485–491. [Google Scholar] [CrossRef]

- Sun, Q.; Lu, C.; Cao, L.W.; Li, W.C.; Geng, J.S.; Zhang, W.Q. Thermal properties of sandstone after treatment at high temperature. Int. J. Rock. Mech. Min. Sci. 2016, 85, 60–66. [Google Scholar] [CrossRef]

- Zuo, J.P.; Xie, H.P.; Zhou, H.W.; Peng, S.P. SEM investigation on thermal cracking behaviour of PingDingShan sandstone at elevated temperatures. Geophys. J. Int. 2010, 181, 593–603. [Google Scholar]

- Hueckel, T.; Peano, A.; Pellegrini, R. A thermo-plastic constitutive law for brittle-plastic behavior of rocks at high temperatures. Pure. Appl. Geophys. 1994, 143, 483–510. [Google Scholar] [CrossRef]

- Han, G.S.; Jing, H.W.; Su, H.J.; Liu, R.C.; Yin, Q.; Wu, J.Y. Effects of thermal shock due to rapid cooling on the mechanical properties of sandstone. Environ. Earth Sci. 2019, 78, 146. [Google Scholar] [CrossRef]

- Wang, X.R.; Wang, E.Y.; Liu, X.F.; Zhou, X. Failure mechanism of fractured rock and associated acoustic behaviors under different loading rates. Eng. Fract. Mech. 2021, 247, 107674. [Google Scholar] [CrossRef]

- Li, H.R.; Qiao, Y.F.; Shen, R.X.; He, M.C.; Cheng, T.; Xiao, Y.M.; Tang, J. Effect of water on mechanical behavior and acoustic emission response of sandstone during loading process: Phenomenon and mechanism. Eng. Geol. 2021, 294, 106386. [Google Scholar] [CrossRef]

- Shen, R.X.; Li, H.R.; Wang, E.Y.; Li, D.X.; Hou, Z.H.; Zhang, X.; Han, X. Mechanical behavior and AE and EMR characteristics of natural and saturated coal samples in the indirect tensile process. J. Geophys. Eng. 2019, 16, 753–763. [Google Scholar] [CrossRef]

- Li, H.R.; Shen, R.X.; Qiao, Y.F.; He, M.C. Acoustic emission signal characteristics and its critical slowing down phenomenon during the loading process of water-bearing sandstone. J. Appl. Geophys. 2021, 194, 104458. [Google Scholar] [CrossRef]

- Li, H.R.; Qiao, Y.F.; Shen, R.X.; He, M.C. Electromagnetic radiation signal monitoring and multi-fractal analysis during uniaxial compression of water-bearing sandstone. Measurement 2022, 196, 111245. [Google Scholar] [CrossRef]

- Kong, B.; Wang, E.Y.; Li, Z.H.; Wang, X.R.; Chen, L.; Kong, X.G. Nonlinear characteristics of acoustic emissions during the deformation and fracture of sandstone subjected to thermal treatment. Int. J. Rock Mech. Min. Sci. 2016, 90, 43–52. [Google Scholar] [CrossRef]

- Masera, D.; Bocca, P.; Grazzini, A. Frequency analysis of acoustic emission signal to monitor damage evolution in masonry structures. J. Phys. Conf. Ser. 2011, 305, 12134–12143. [Google Scholar] [CrossRef]

- Li, D.X.; Wang, E.Y.; Kong, X.G.; Ali, M.; Wang, D.M. Mechanical behaviors and acoustic emission fractal characteristics of coal specimens with a pre-existing flaw of various inclinations under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2019, 116, 38–51. [Google Scholar] [CrossRef]

- Wu, Z.X.; Liu, X.X.; Liang, Z.Z.; You, X.; Yu, M. Experimental study of fractal dimension of AE serials of different rocks under uniaxial compression. Rock. Soil. Mech. 2012, 33, 3561–3569. [Google Scholar]

- Yavuz, H.; Demirdag, S.; Caran, S. Thermal effect on the physical properties of carbonate rocks. Int. J. Rock. Mech. Min. Sci. 2010, 47, 94–103. [Google Scholar] [CrossRef]

- Hajpál, M. Changes in sandstones of historical monuments exposed to fire or high temperature. Fire. Technol. 2002, 38, 373–382. [Google Scholar] [CrossRef]

- Ito, K.; Enoki, M. Acquisition and analysis of continuous acoustic emission waveform for classification of damage sources in ceramic fiber mat. Mater. Trans. 2007, 48, 1221–1226. [Google Scholar] [CrossRef] [Green Version]

| Sample NO. | P-Wave Velocity (km/s) | USC (MPa) | E (GPa) | Total AE Energy (mV·μs) | Peak AE Energy (mV·μs) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Value | Mean | Value | Mean | Value | Mean | Value | Mean | Value | Mean | |

| S25-1 | 3.52 | 3.51 | 62.58 | 65.74 | 10.65 | 11.52 | 308,982 | 297,311.5 | 30,120 | 31,788 |

| S25-2 | 3.51 | 68.89 | 12.38 | 285,641 | 33,456 | |||||

| S300-1 | 2.84 | 2.82 | 55.83 | 57.4 | 8.9 | 8.52 | 182,911 | 168,878.5 | 25,657 | 26,657.5 |

| S300-2 | 2.81 | 58.98 | 8.14 | 154,846 | 27,658 | |||||

| S600-1 | 2.38 | 2.36 | 46.03 | 43.76 | 7.87 | 7.5 | 79,938 | 87,521 | 13,093 | 12,037 |

| S600-2 | 2.34 | 41.48 | 7.12 | 95,104 | 10,981 | |||||

| S900-1 | 2.03 | 2.01 | 38.07 | 35.32 | 6.97 | 6.04 | 54,006 | 46,231 | 9125 | 8433 |

| S900-2 | 1.98 | 32.57 | 5.1 | 38,456 | 7741 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Guo, W. Acoustic Emission Waveform Characteristics of Red Sandstone Failure under Uniaxial Compression after Thermal Damage. Sustainability 2022, 14, 13285. https://doi.org/10.3390/su142013285

Zhang H, Guo W. Acoustic Emission Waveform Characteristics of Red Sandstone Failure under Uniaxial Compression after Thermal Damage. Sustainability. 2022; 14(20):13285. https://doi.org/10.3390/su142013285

Chicago/Turabian StyleZhang, Herui, and Weihong Guo. 2022. "Acoustic Emission Waveform Characteristics of Red Sandstone Failure under Uniaxial Compression after Thermal Damage" Sustainability 14, no. 20: 13285. https://doi.org/10.3390/su142013285