Development and Experimental Study of Smart Solar Assisted Yogurt Processing Unit for Decentralized Dairy Value Chain

Abstract

:1. Introduction

2. Material and Methods

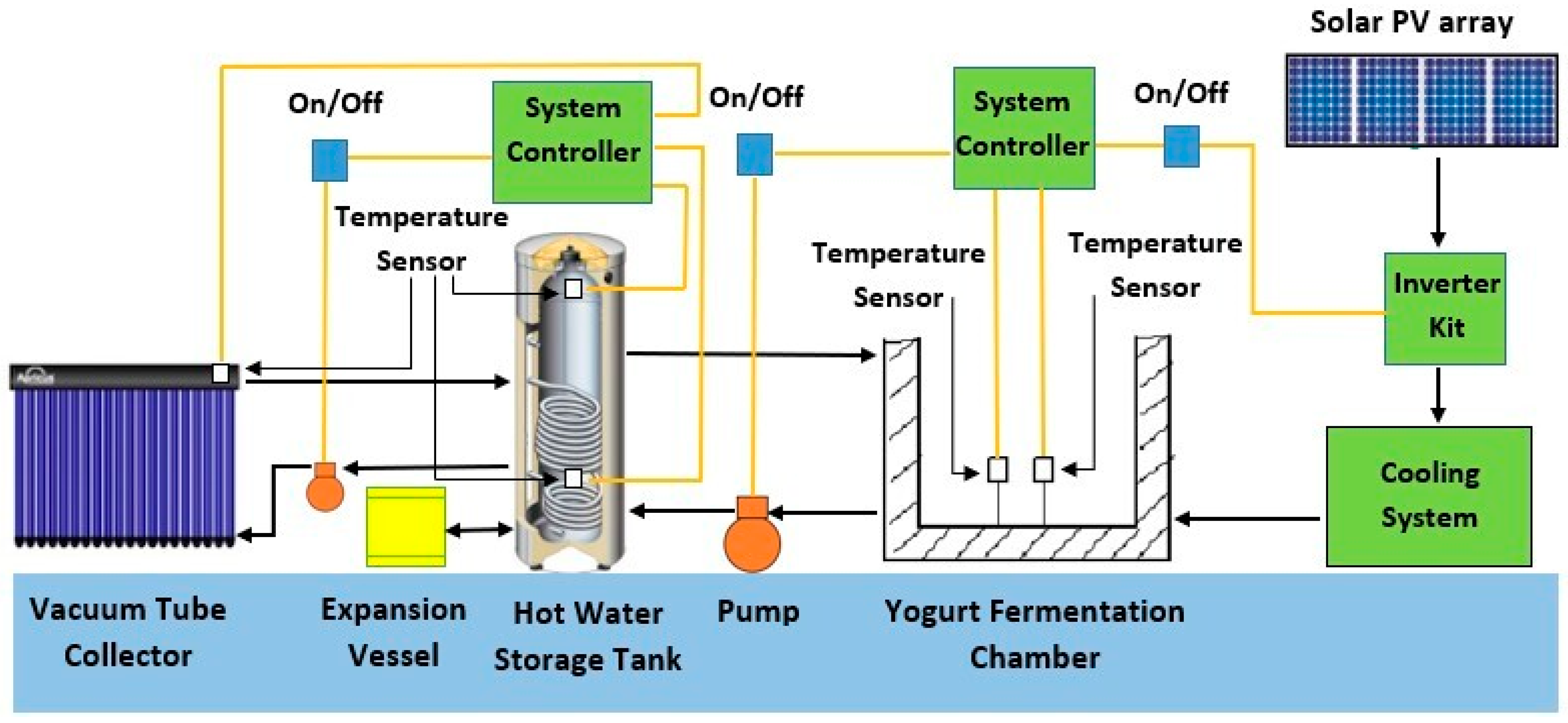

2.1. System Description

2.2. Sizing of Fermentation Chamber

2.3. Sizing of Refrigeration System

2.4. Photovoltaic System Design

2.5. Sizing of Evacuated Tube Collector (ETC)

2.6. Experiments

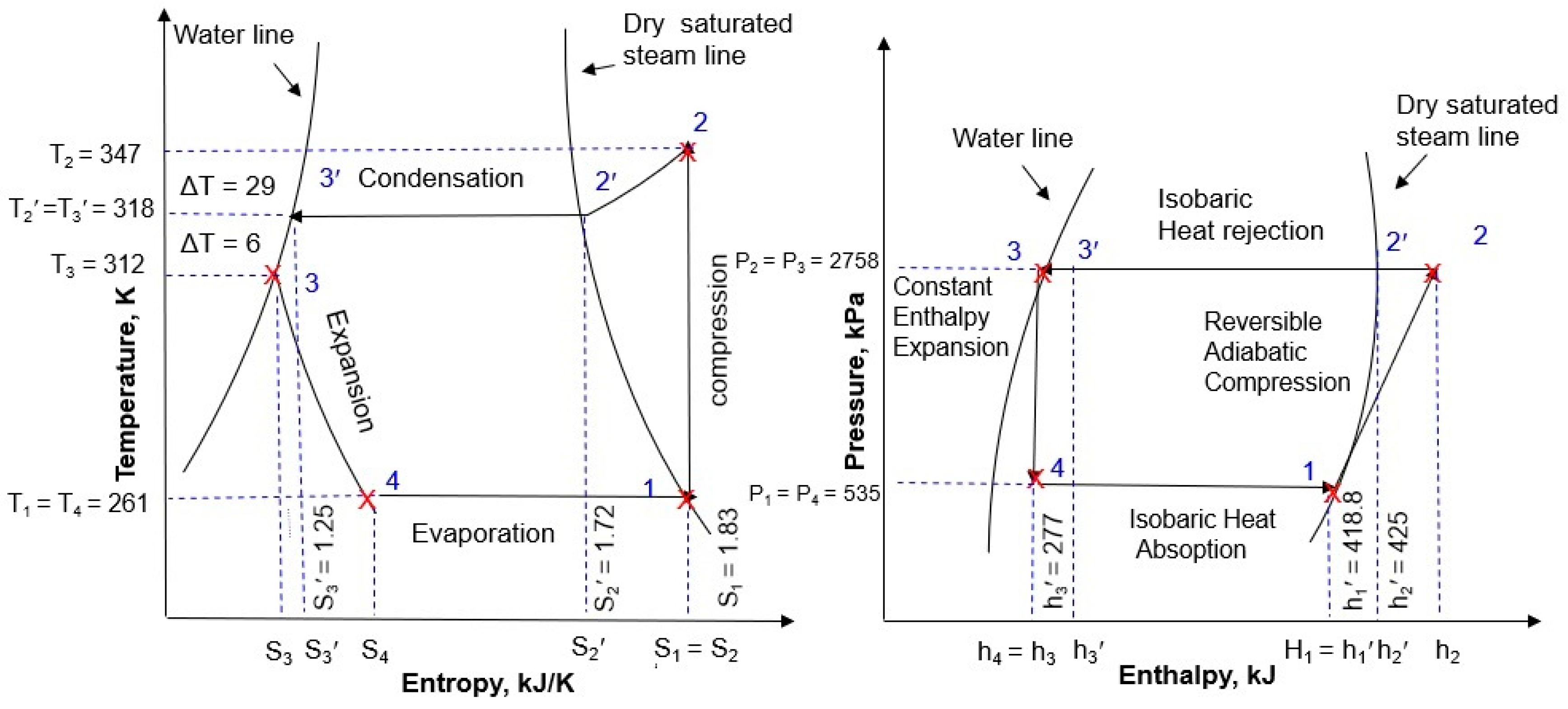

Thermodynamic Analysis for Efficient Refrigeration System

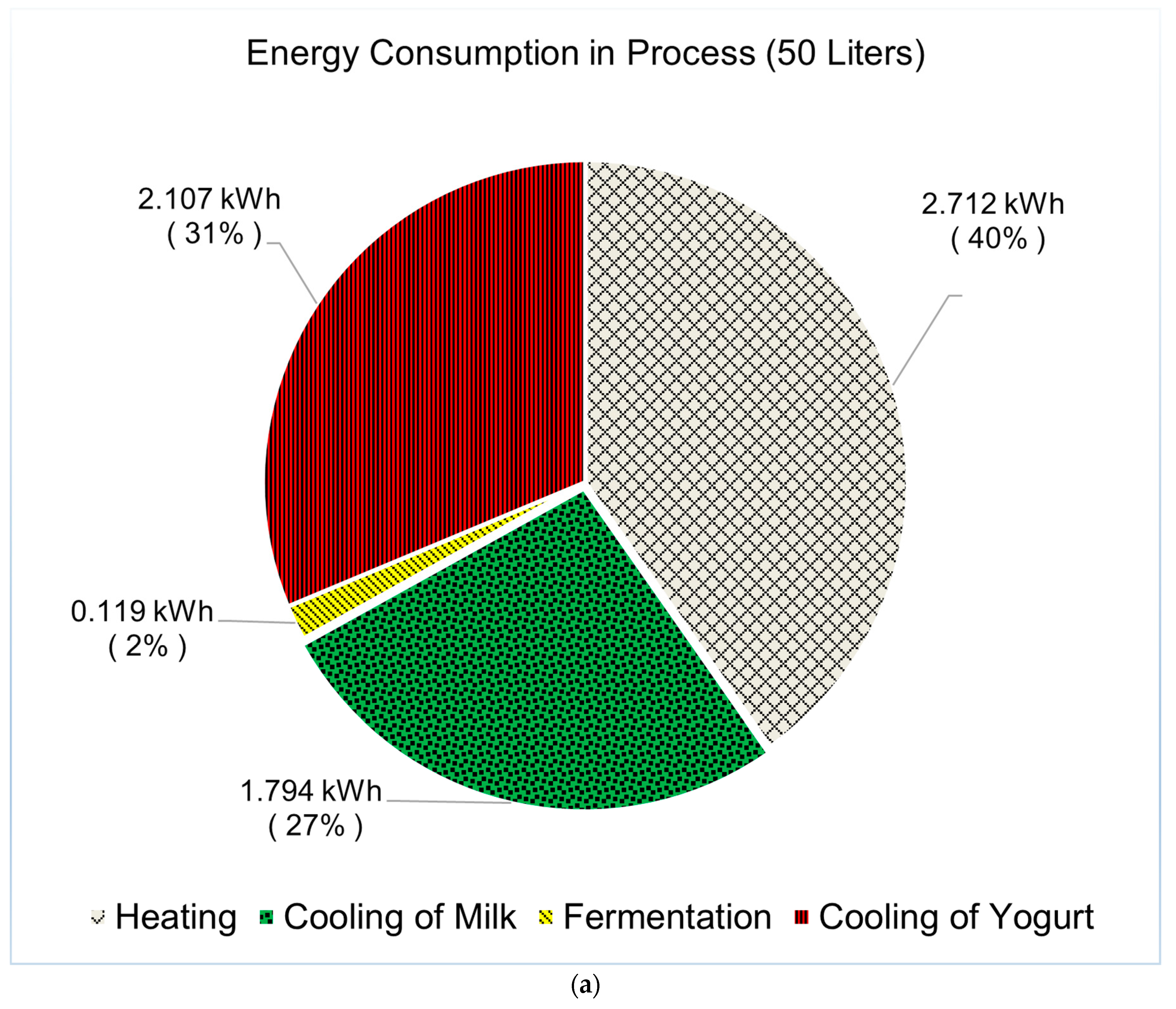

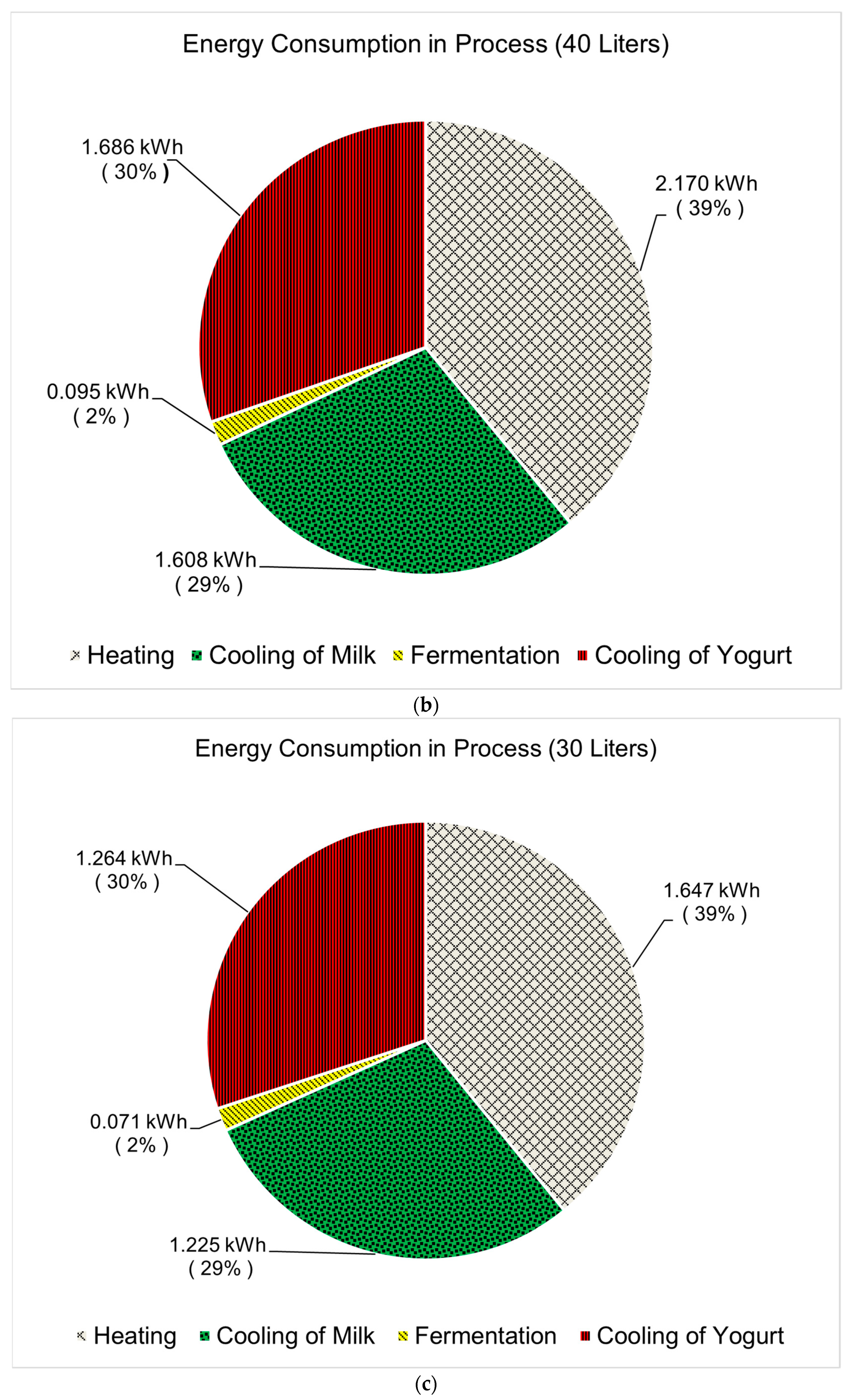

3. Results and Discussion

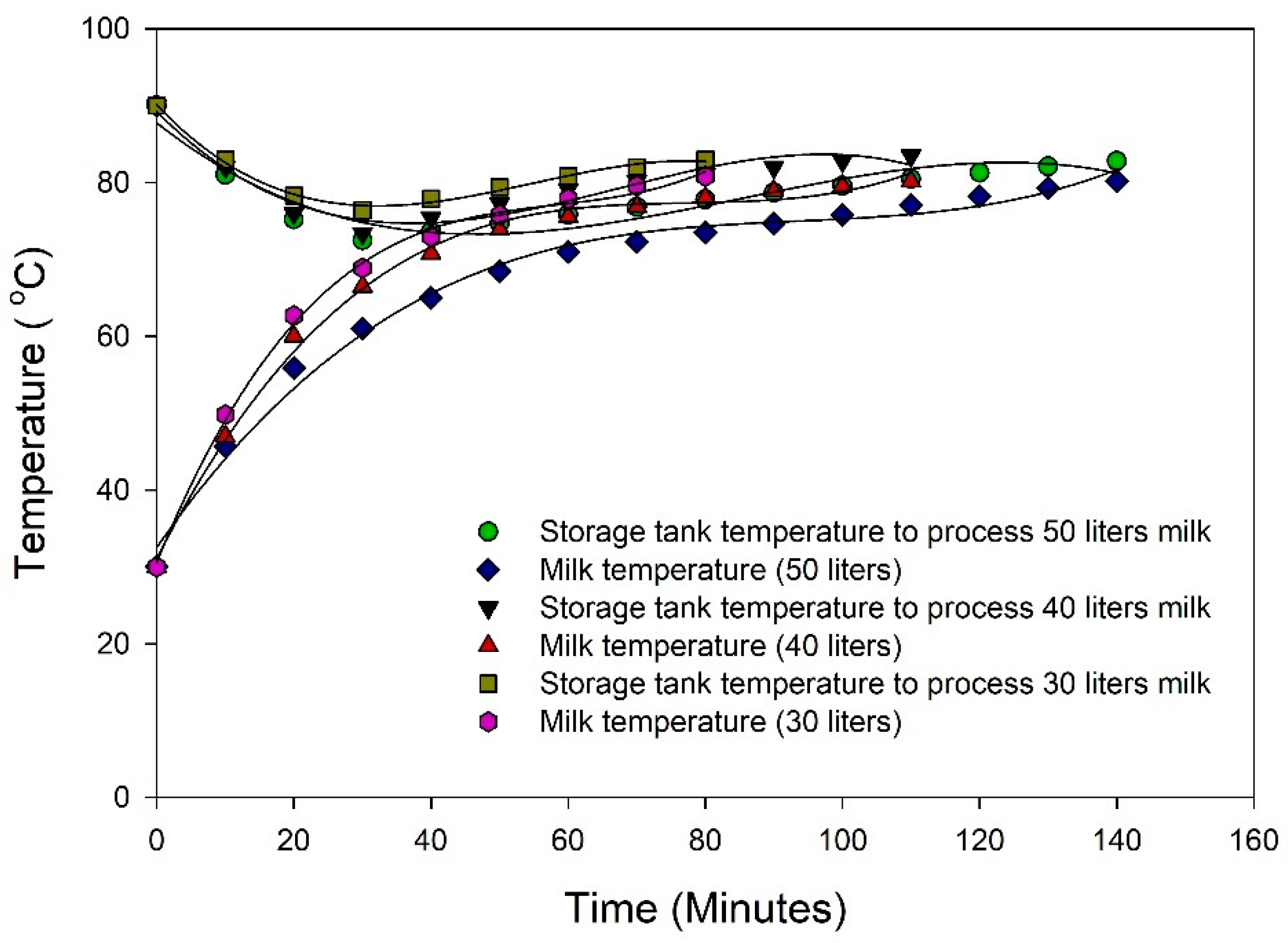

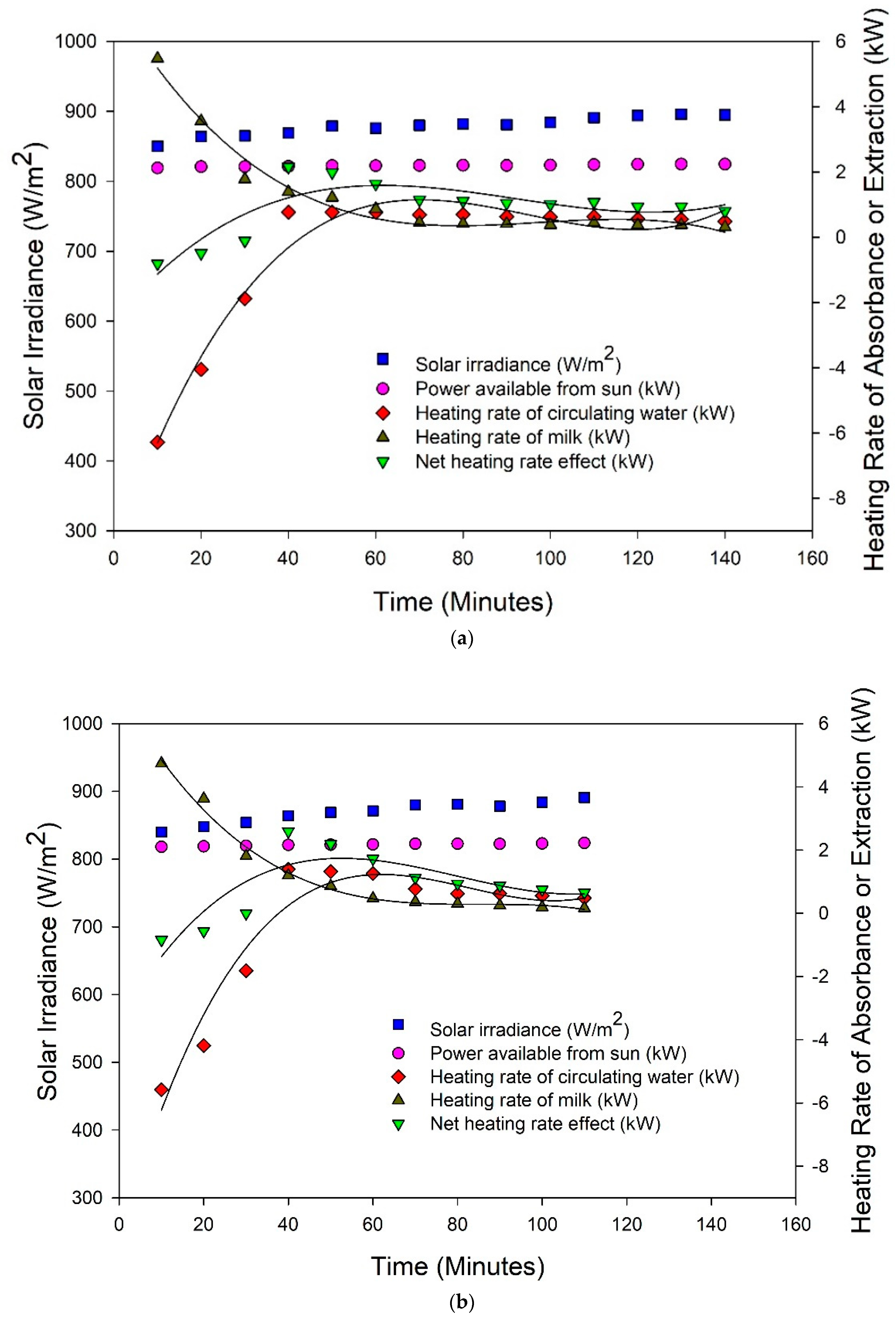

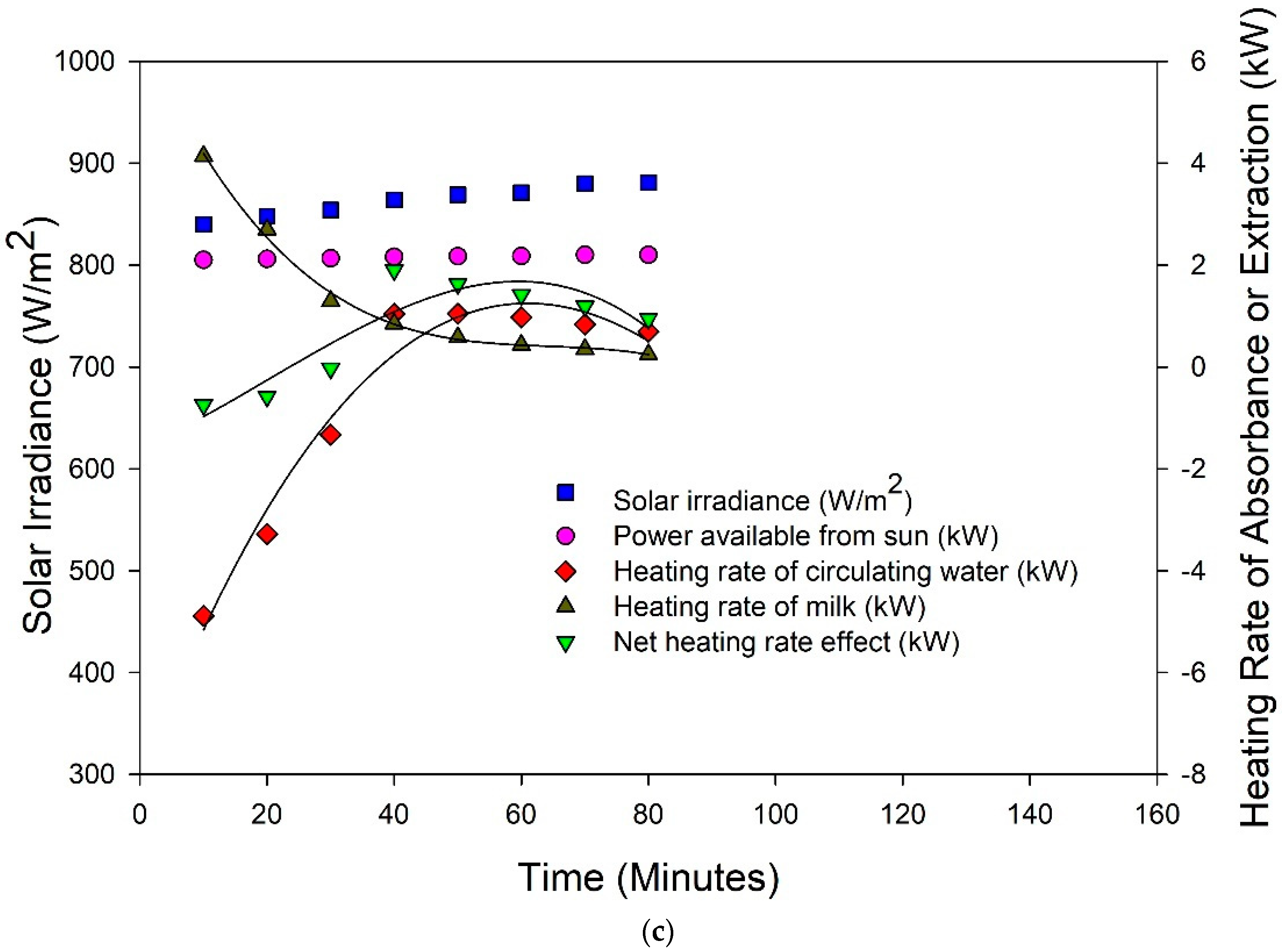

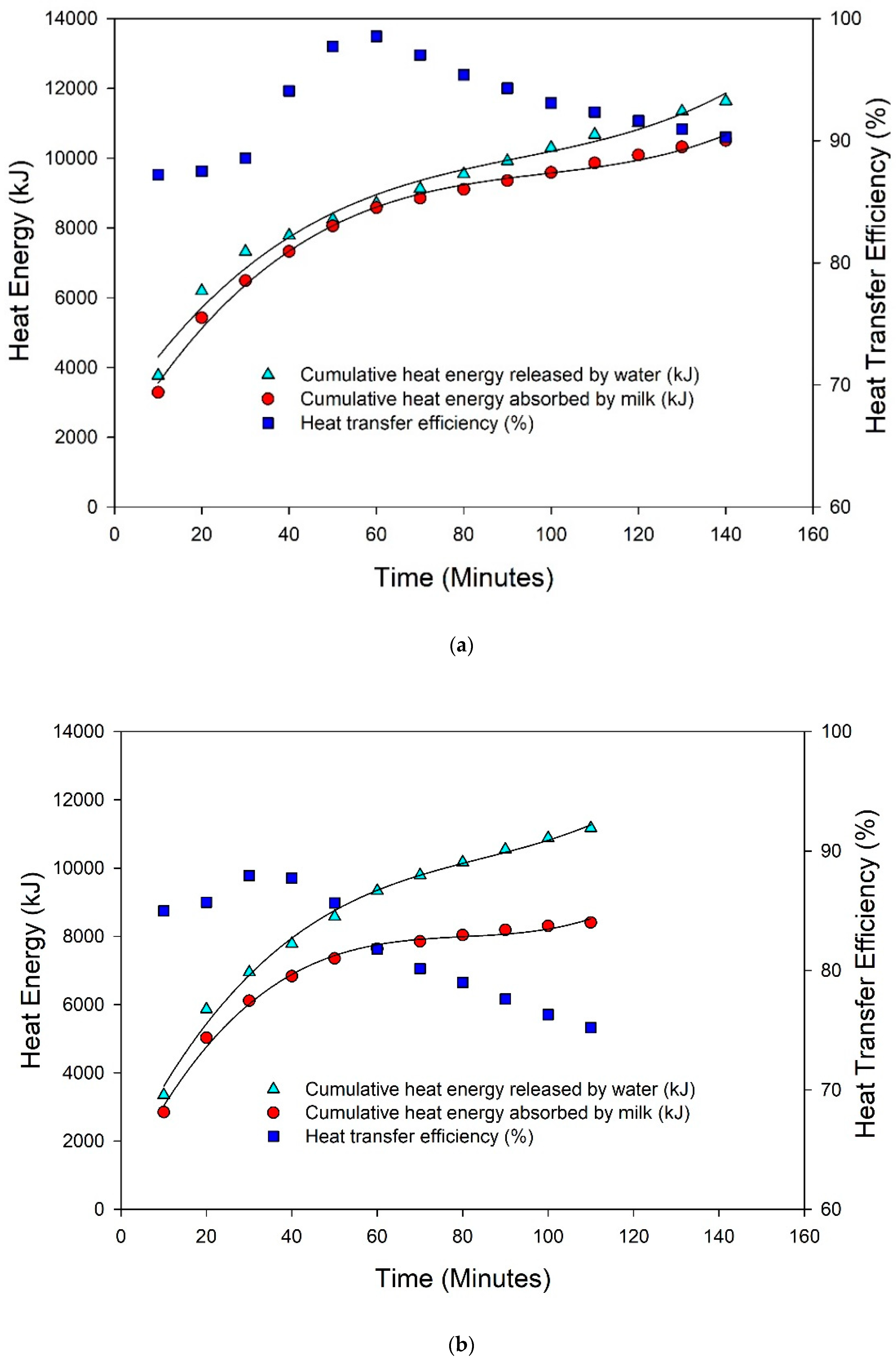

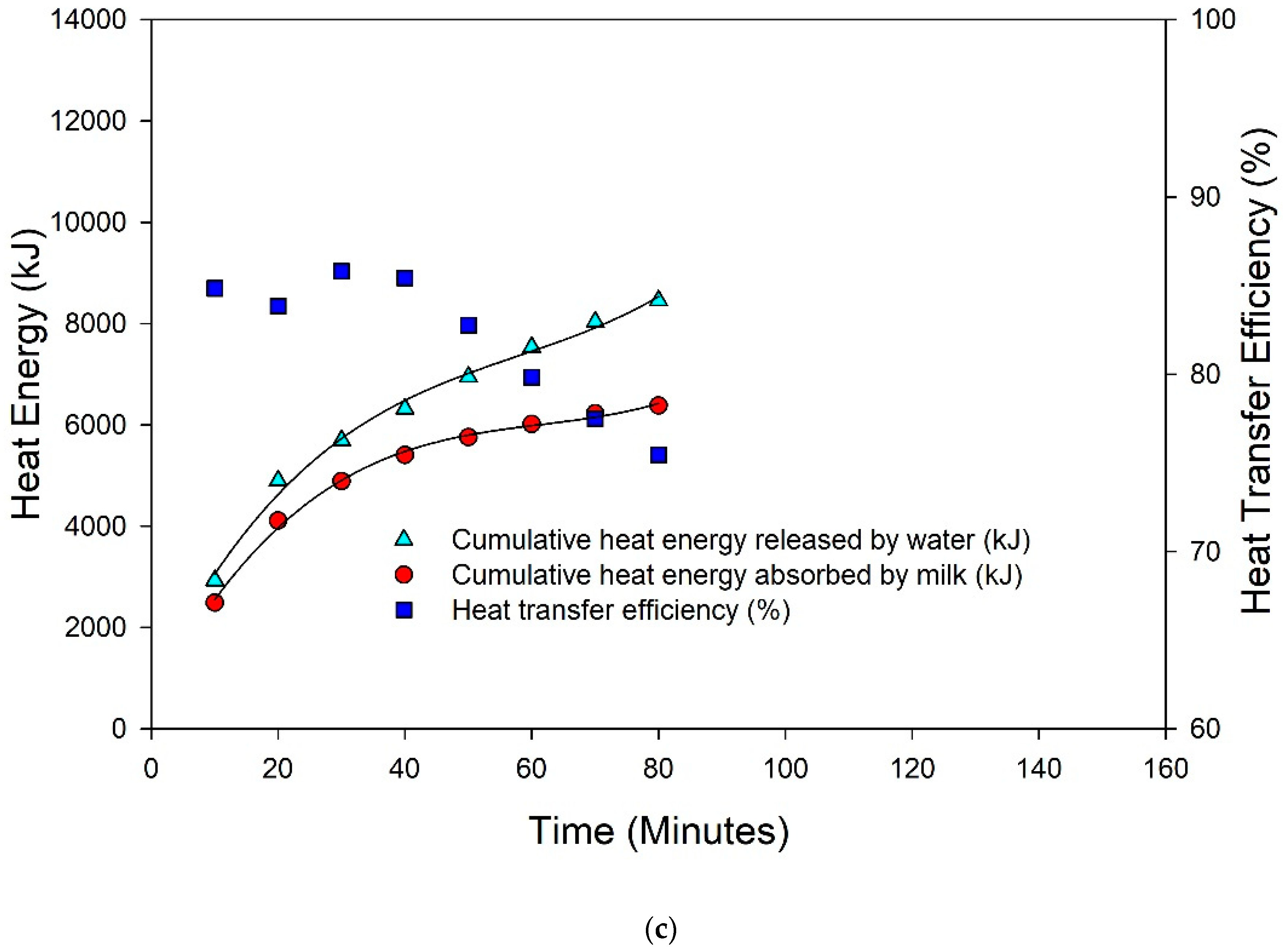

3.1. Heating of Raw Milk

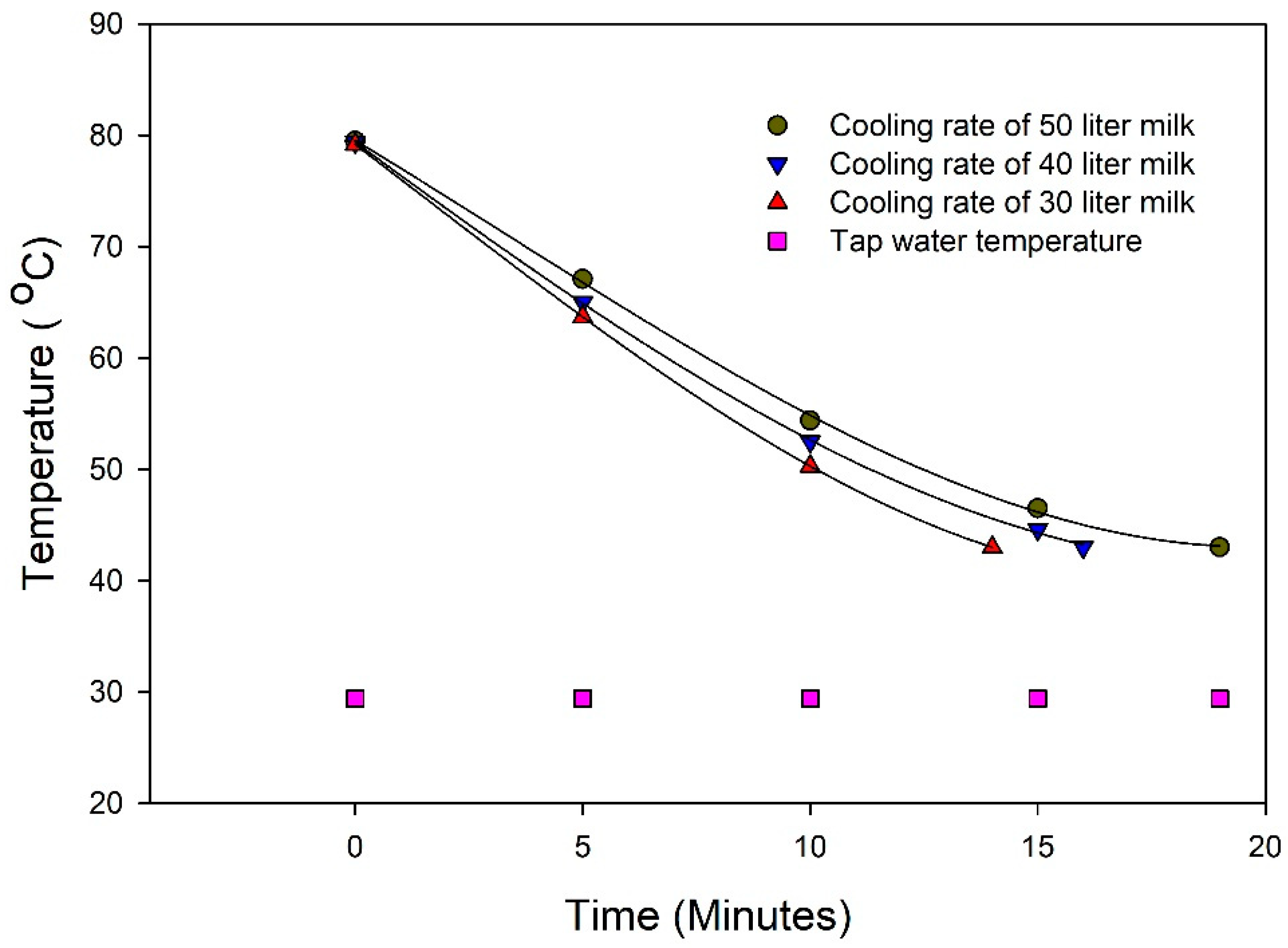

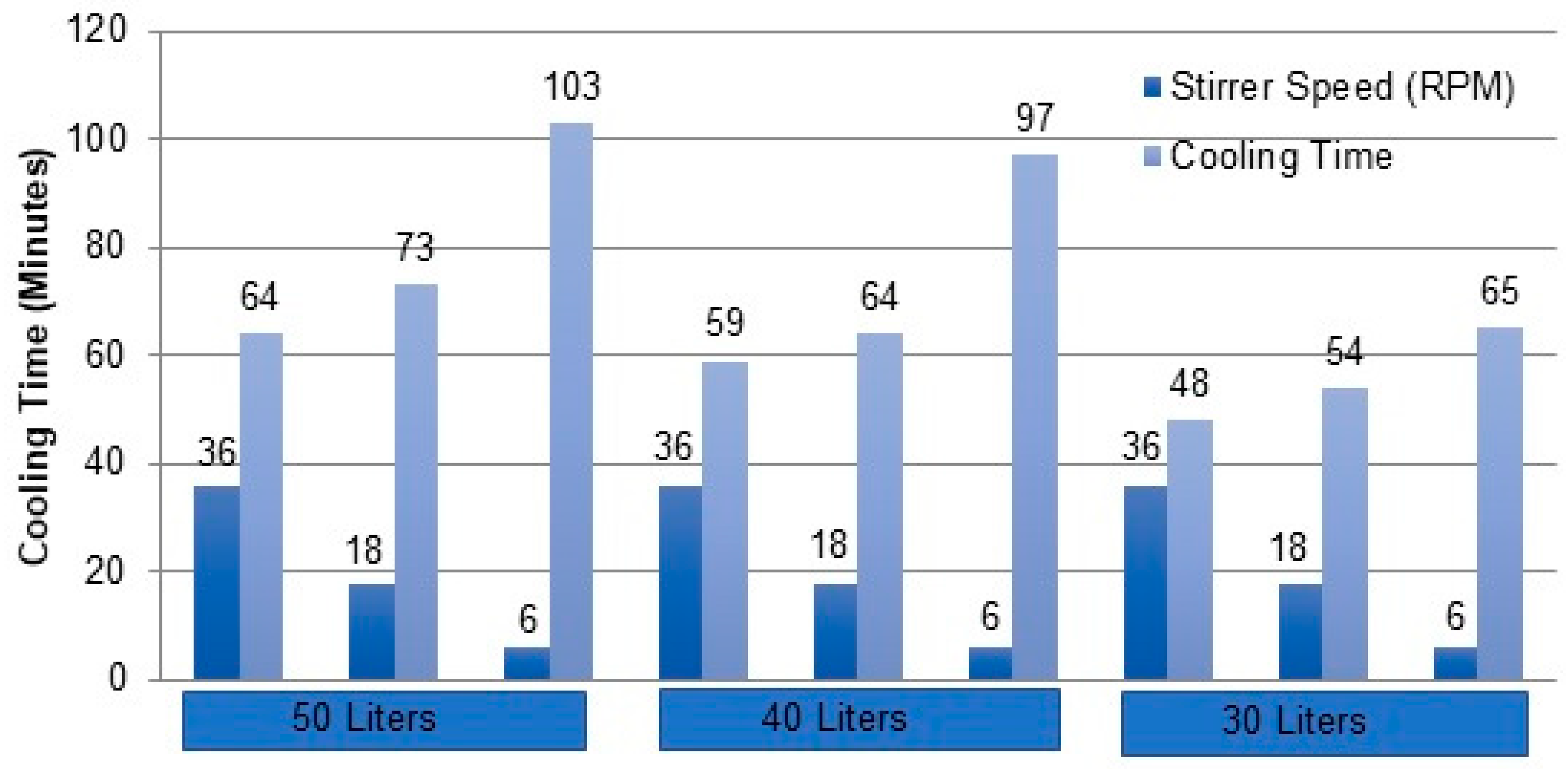

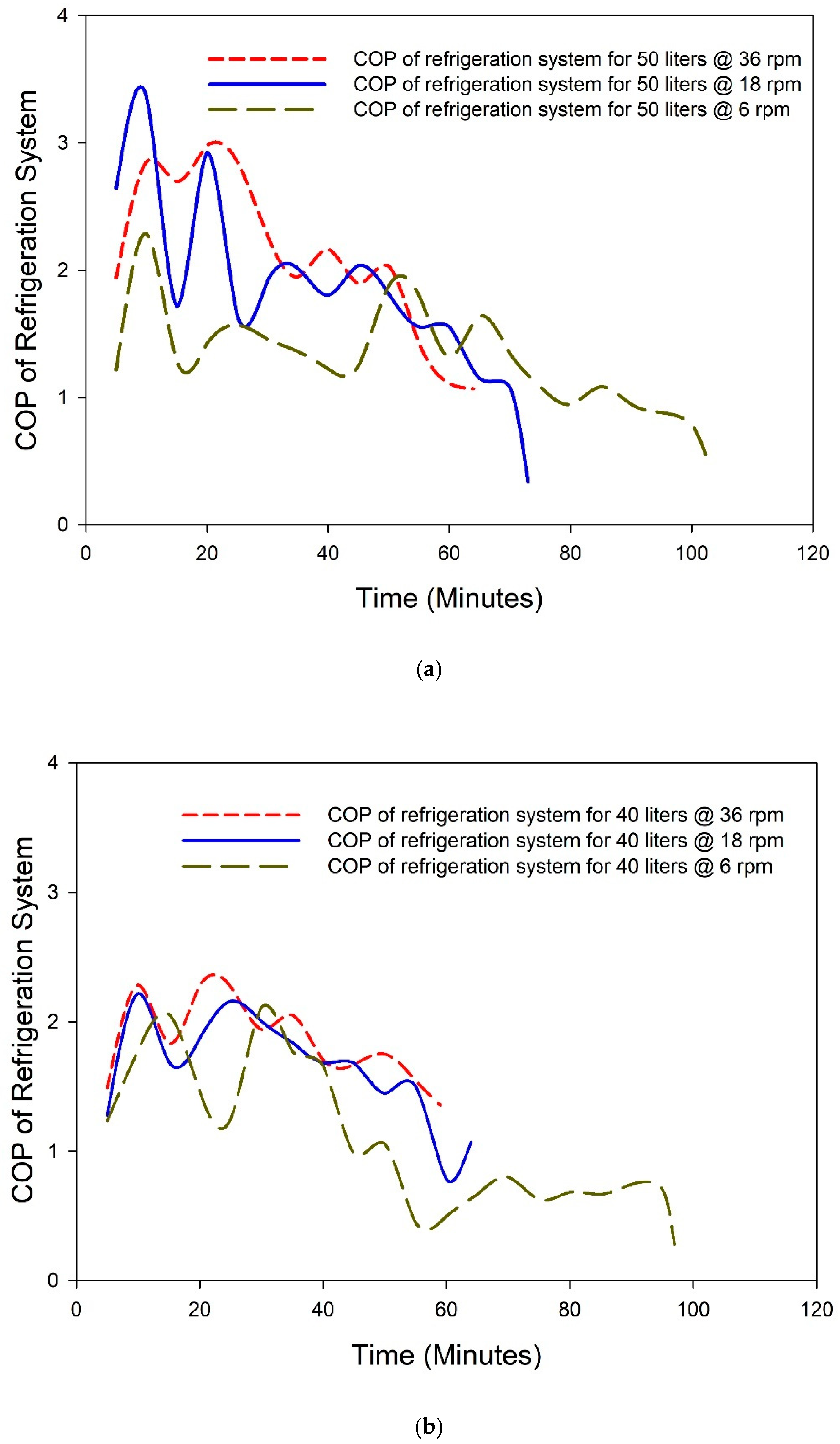

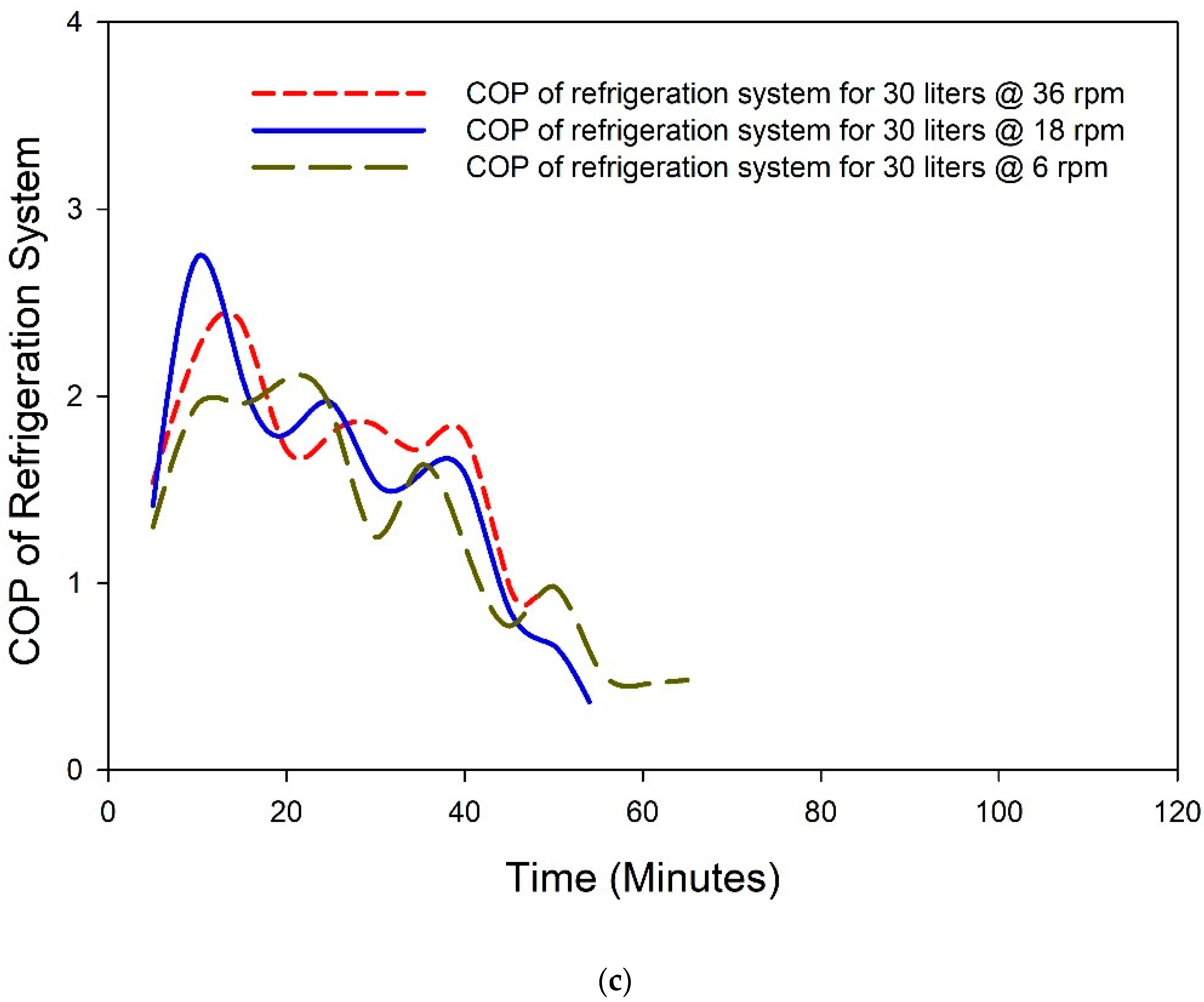

3.2. Cooling Process of Milk

3.3. Fermentation Process

3.4. Cooling Process of Yogurt

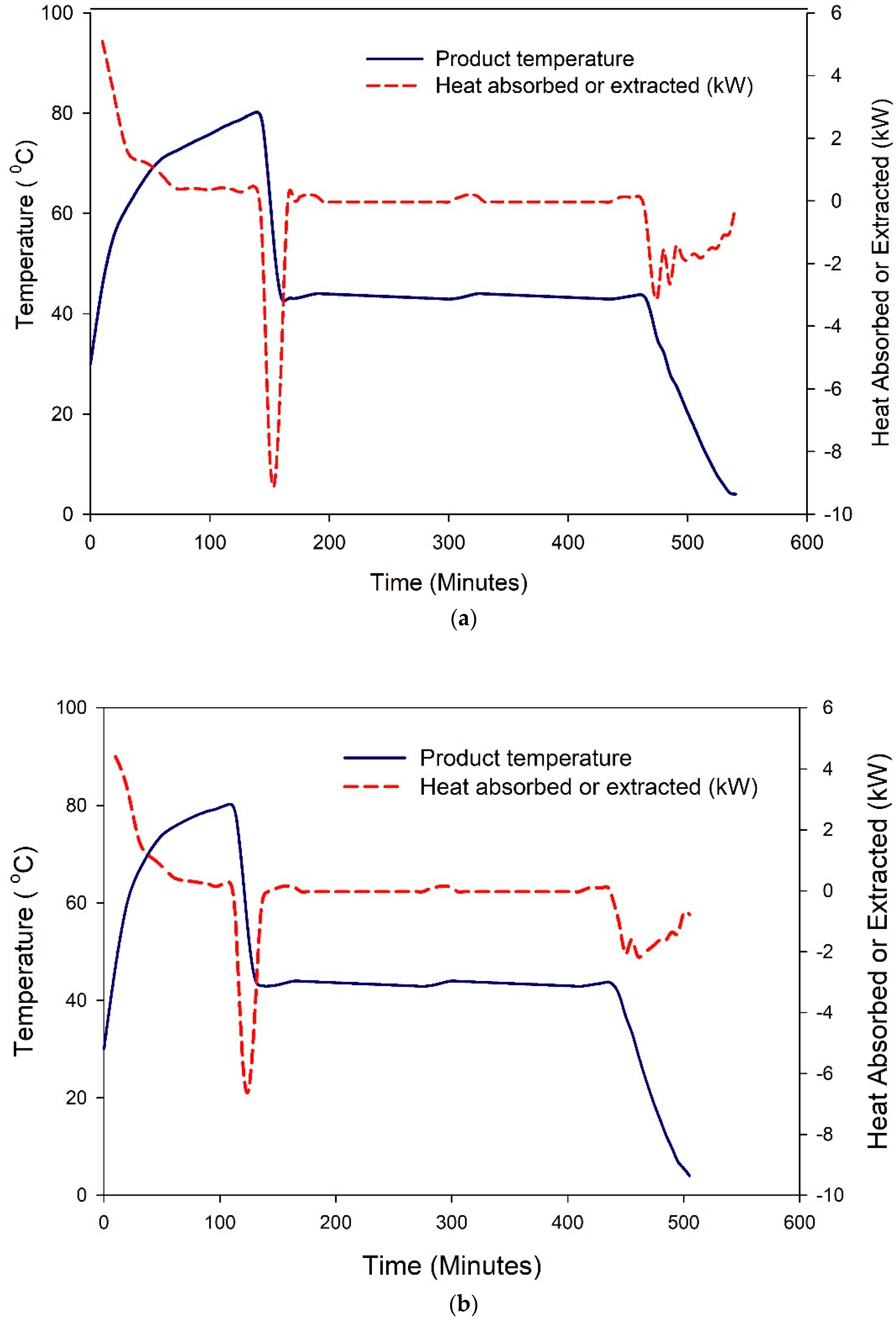

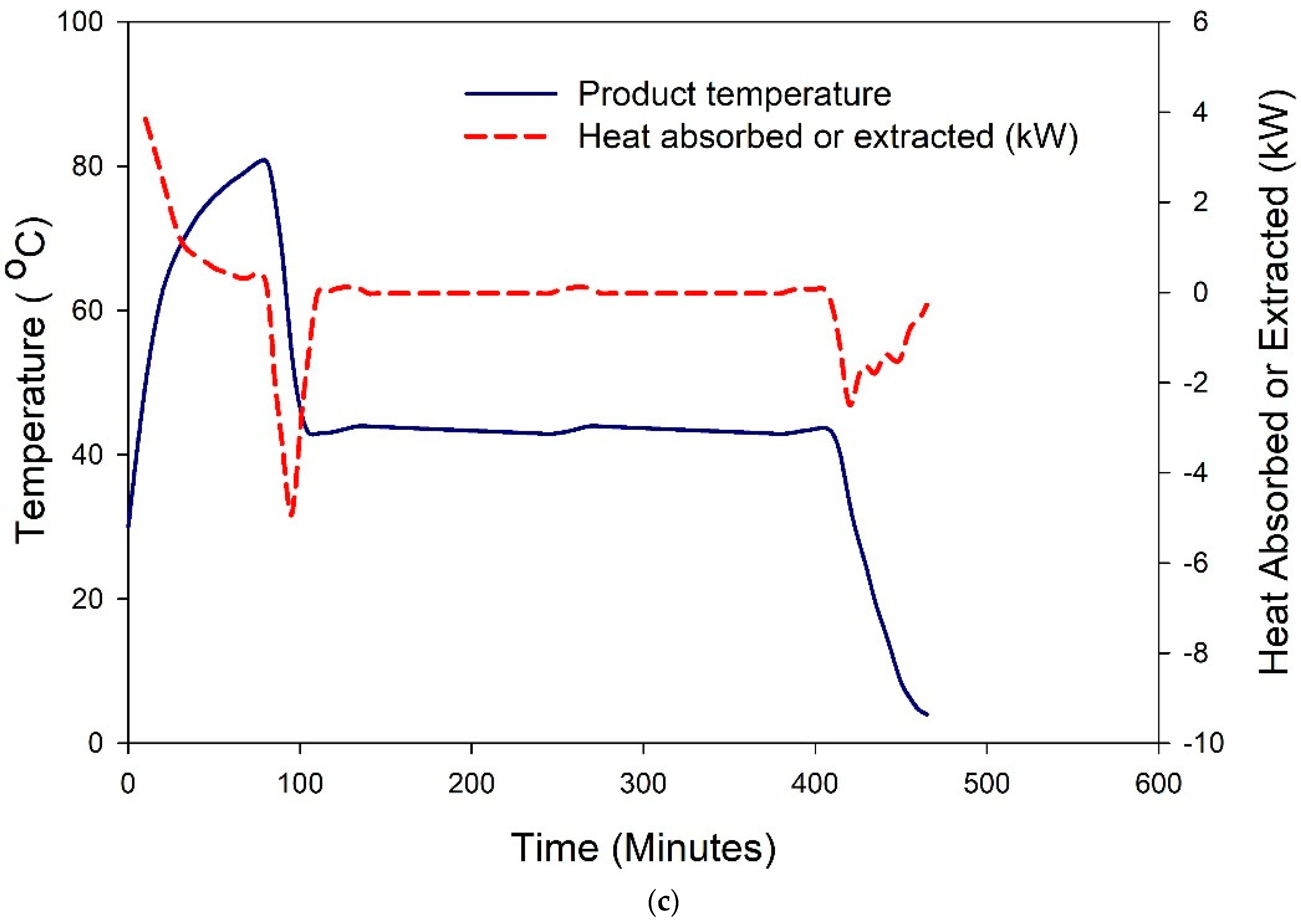

3.5. Thermal Profile of the Entire System

4. Conclusions

5. Directions for Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | |

| Ac | Surface area of evacuated tube collector (m2) |

| A | Heat transfer area area (m2) |

| CBat | Capacity of the battery bank (Ah) |

| Cp | Specific heat (kJ kg−1 k−1) |

| Cpg | Specific heat capacity of the refrigerant at constant pressure in gaseous state (kJ kg−1 k−1) |

| Cpl | Specific heat capacity of the refrigerant at constant pressure in the liquid state (kJ kg−1 k−1) |

| CIP | Clean-in-place |

| COP | Coefficient of performance |

| ETC | Evacuated tube collectors |

| d | Diameter (m) |

| Dd | Depth of discharge in fraction |

| GHI | Global Horizontal Irradiation) (W/m2) |

| Havg | Average global horizontal irradiance (kWh/(m2 d)) |

| h1 | Enthalpy of the refrigerant at the compressor inlet (kJ kg−1) |

| h2 | Enthalpy of the refrigerant at the compressor inlet (kJ kg−1) |

| h3 | Enthalpy of the refrigerant after the condensation process outlets (kJ kg−1) |

| hf3 | Liquid enthalpy after condenser outlet (kJ kg−1) |

| h2′ | Enthalpy of the refrigerant at the dry saturated steam line after compression process |

| h3′ | Enthalpy of the refrigerant at the water line after condensation (kJ kg−1) |

| I | Current (A) |

| Ib | Solar irradiance (W/m2) |

| Le | Electric load (kWh/d) |

| m | Mass (kg) |

| m′ | Mass flow rate (kgs−1) |

| Nccd | Autonomy and taken as the number of continuous cloudy days |

| Pp | Peak power of the solar system (kWp) |

| P | Power required to run the refrigeration system (kW) |

| PU | Polyurethane |

| PV | Photovoltaic |

| PVC | Polyvinyl chloride |

| Qt | Total heat transfer through walls and bottom (kWh/d) |

| QR | Cooling load of the product (kWh/d) |

| RTD | Resistance Temperature Detector |

| SS | Stainless steel |

| SPE | Specific production energy (kJ/kg) |

| STC | Standard test conditions |

| Tc | Cold face temperature of fermentation chamber (°C). |

| Th | Hot face temperature of the fermentation chamber (°C) |

| TCF | Temperature correction factor (0.4% per °C) |

| T2 | Actual temperatures of the refrigerant at the compressor outlet (K) |

| T2′ | Saturation temperature at the compressor outlet (K) |

| T3 | Actual temperature of the refrigerant after condenser (K) |

| T3′ | Saturation temperature at the liquid line after condensation process (K) |

| TR | Capacity of refrigeration |

| ∆T | Change in temperature (K) |

| t | Time (sec) |

| U | Overall heat transfer coefficient (W/m2 °C) |

| VFD | Variable frequency drive |

| V | Voltage |

| V | Volume (m3) |

| Subscripts | |

| bat | Battery |

| inv | Inverter |

| r | Refrigerant |

| oc | Open circuit |

| mpp | Maximum power |

| Greek Symbols | |

| τ | Transmission coefficient, |

| α | Absorption coefficient |

| η | Efficiency (%) |

References

- Wang, L.; Bandyopadhyay, S.; Cosgrove-Davies, M.; Samad, H. Quantifying Carbon and Distributional Benefits of Solar Home System Programs in Bangladesh; Policy Research Working Paper 5545; The World Bank Environment Department: Washington, DC, USA, 2011. [Google Scholar] [CrossRef]

- Shahid, H.; Shafique, O.; Shokat, A. Dairy Industry of Pakistan. Eur. J. Bus. Manag. 2012, 4, 1–4. [Google Scholar]

- Charad, J.; Lanctuit, H. Nestlé Dairy Factories in Pakistan: Losses Across the Value Chain—A Case Study; The Food Loss & Waste Protocol: Washington, DC, USA, 2017. [Google Scholar]

- Tamang, J.P. Ethnic Fermented Foods and Alcoholic Beverages of Asia; Chapter 5 Ethnic Fermented Foods in Pakistan; Springer: Delhi, India, 2016. [Google Scholar] [CrossRef]

- Singh, G.; Chopra, K.; Tyagi, V.; Pandey, A.; Ma, Z.; Ren, H. A comprehensive energy, exergy and enviroeconomic (3-E) analysis with carbon mitigation for multistage evaporation assisted milk powder production unit. Sustain. Energy Technol. Assess. 2020, 43, 100925. [Google Scholar] [CrossRef]

- Munir, M.T.; Yu, W.; Young, B.R. Can Exergy Be a Useful Tool for the Dairy Industry? Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2014; Volume 33. [Google Scholar] [CrossRef]

- Brush, A.; Eric, M.; Ernst, W. Energy Efficiency Improvement and Cost Saving Opportunities, An ENERGY STAR® Guide for Energy and Plant Managers. In Energy Analysis Department Environmental Energy Technologies Division Lawrence Berkeley National Laboratory; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2011. [Google Scholar]

- Von Keyserlingk, M.A.G.; Martin, N.P.; Kebreab, E.; Knowlton, K.F.; Grant, R.J.; Stephenson, M.; Sniffen, C.J.; Harner, J.R., III; Wright, A.D.; Smith, S.I. Invited review: Sustainability of the US dairy industry. J. Dairy Sci. 2013, 96, 5405–5425. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tahir, Z.; Asim, M. Surface measured solar radiation data and solar energy resource assessment of Pakistan: A review. Renew. Sustain. Energy Rev. 2018, 81, 2839–2861. [Google Scholar] [CrossRef]

- Michael, M.B.; Akinlabi, E.T.; Jen, T.C. A Review of Solar Thermal Systems Utilization for Industrial Process Heat Applications. Lect. Notes Eng. Comput. Sci. 2016, 2226, 859–863. [Google Scholar]

- Amjad, W.; Waseem, M.; Munir, A.; Ghafoor, A.; Asghar, F.; Gilani, G.A. Solar Assisted Dehydrator for Decentralized Controlled and Homogeneous Multi-Product Drying. J. Sol. Energy Eng. Trans. ASME 2021, 143, 11011. [Google Scholar] [CrossRef]

- Ismail, M.I.; Yunus, N.A.; Hashim, H. Integration of Solar Heating Systems for Low-Temperature Heat Demand in Food Processing Industry—A Review. Renew. Sustain. Energy Rev. 2021, 147, 111192. [Google Scholar] [CrossRef]

- Khan, K.S.; Amjad, W.; Munir, A.; Hensel, O. Improved Solar Milk Chilling System Using Variable Refrigerant Flow Technology (VRF). Sol. Energy 2020, 197, 317–325. [Google Scholar] [CrossRef]

- Desai, D.D.; Raol, J.B.; Patel, S.; Chauhan, I. Application of Solar Energy for Sustainable Dairy Development. Eur. J. Sustain. Dev. 2013, 2, 131–140. [Google Scholar] [CrossRef]

- Mekhilef, S.; Saidur, R.; Safari, A. A Review on Solar Energy Use in Industries. Renew. Sustain. Energy Rev. 2011, 15, 1777–1790. [Google Scholar] [CrossRef]

- Anderson, T.N.; Duke, M. Solar Energy Use for Energy Savings in Dairy Processing Plants. IPENZ Eng. TreNz 2007, 2008, 1–9. Available online: https://hdl.handle.net/10289/3204 (accessed on 20 September 2021).

- Zahira, R.; Akif, H.; Amin, N.; Azam, M.; Haq, Z.U. Fabrication and Performance Study of a Solar Milk Pasteurizer. Pak. J. Agric. Sci. 2009, 46, 162–168. [Google Scholar]

- Fathey Mohamed Atia, M.; Mostafa, M.M.; El-Nono, A.M.; Abdel-Salam, F.M. Solar Energy Utilization for Milk Pasteurization. Misr J. Agric. Eng. 2011, 28, 729–744. [Google Scholar]

- Wayua, F.O.; Okoth, M.W.; Wangoh, J. Design and Performance Assessment of a Flat-Plate Solar Milk Pasteurizer for Arid Pastoral Areas of Kenya. J. Food Process. Preserv. 2013, 37, 120–125. [Google Scholar] [CrossRef]

- Yaseen, M.U.; Ashraf, M.; Munir, A. Development and performance evaluation of solar assisted milk pasteurizer by using vacuum tube collector. Pak. J. Agric. Sci. 2019, 56, 693–700. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Liu, K.; Yu, H.; Cheng, K. Design of high-performance water-in-glass evacuated tube solar water heaters by a high-throughput screening based on machine learning: A combined modeling and experimental study. Sol. Energy 2017, 142, 61–67. [Google Scholar] [CrossRef]

- Ben Taher, M.; Benseddik, Z.; Afass, A.; Smouh, S.; Ahachad, M.; Mahdaoui, M. Energy life cycle cost analysis of various solar water heating systems under Middle East and North Africa region. Case Stud. Therm. Eng. 2021, 27, 101262. [Google Scholar] [CrossRef]

- Mohammed, A.K.; Hamakhan, I.A. Analysis of energy savings for residential electrical and solar water heating systems. Case Stud. Therm. Eng. 2021, 27, 101347. [Google Scholar] [CrossRef]

- Cengel, Y.A. Heat Transference a Practical Approach; MacGraw-Hill: New York, NY, USA, 2004; Volume 4, p. 874. [Google Scholar]

- Ghafoor, A.; Munir, A. Design and Economics Analysis of an Off-Grid PV System for Household Electrification. Renew. Sustain. Energy Rev. 2015, 42, 496–502. [Google Scholar] [CrossRef]

- Vendan, S.P.; Shunmuganathan, L.P.A.; Manojkumar, T.; Thanu, C.S. Study on Design of an Evacuated Tube Solar Collector for High Temperature Steam Generation. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 539–541. [Google Scholar]

- Thornton, B.; Wagner, A. Prepared for the General Services Administration by Pacific Northwest National Laboratory Variable Refrigerant Flow Systems. 2012. Available online: https://www.gsa.gov/cdnstatic/GPG_VRFTechnologyReport_20121220.pdf (accessed on 22 August 2021).

- Alsagri, A.S. Photovoltaic and Photovoltaic Thermal Technologies for Refrigeration Purposes: An Overview. Arab. J. Sci. Eng. 2022, 1–34. [Google Scholar] [CrossRef] [PubMed]

- Neri, I. Second law of thermodynamics at stopping times. Phys. Rev. Lett. 2020, 124, 40601. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Component of Solar PV System | Attributes | Rating | Unit |

|---|---|---|---|

| PV Module Model (TSPP-6U (60)-250W) | Power Output Tolerance | ±3.00 | % |

| Temperature Coefficient | −0.0047 | %/°C | |

| Open Circuit Voltage (Voc) at STC | 37.30 | V | |

| Short Circuit Current (Isc) at STC | 8.50 | A | |

| Peak Power Watts (Wp) at STC | 250.00 | W | |

| Maximum Power Voltage (Vmpp) at STC | 30.90 | V | |

| Maximum Power Current (Impp) at STC | 8.00 | A | |

| Efficiency of Module | 0.155 | % | |

| Dimension of solar panel | 1650 × 1000 × 40 | mm3 | |

| Inverter Model ((Premier-PW-24DC) | Maximum Input Current | 50.00 | A |

| Maximum input DC Voltage to controller | 60.00 | V | |

| Operated Voltage Range | 30–32 | V | |

| Output Voltage to battery | 24.00 | V | |

| Max. Power can be connected | 3.00 | kW | |

| Battery bank (Lithium-ion Battery) | Nominal Voltage | 12.00 | V |

| Nominal capacity | 150.00 | Ah | |

| Depth of discharge | 0.60 | ||

| Charging current | 100.00 | A | |

| Continuous discharging current | 100.00 | A | |

| Discharging working temperature | −20~60 °C | °C | |

| Charging working temperature | 0–45 | °C | |

| Dimensions | 479 × 482 × 132 | mm3 | |

| Efficiency of battery | 0.95 | % | |

| Cell combination | 36,130,170 8S2P + Smart BMS |

| Parameter | Milk Quantity | Y0 | A | b | C | R2 |

|---|---|---|---|---|---|---|

| Storage tank temperature | 50 | 87.7742 | −0.7063 | 0.0104 | −0.000040523 | 0.8903 |

| 40 | 89.2370 | −0.8957 | 0.0167 | −0.000082776 | 0.9315 | |

| 30 | 90.1101 | −0.9468 | 0.0208 | −0.0001 | 0.9907 | |

| Milk temperature | 50 | 32.5390 | 1.2812 | −0.0133 | 0.000047356 | 0.9905 |

| 40 | 31.0960 | 1.7573 | −0.0225 | 0.000096685 | 0.9957 | |

| 30 | 30.6020 | 2.1874 | −0.0358 | 0.0002 | 0.9978 | |

| Heating rate of circulating water (kW) | 50 | −9.7531 | 0.3859 | −0.0044 | 0.000015318 | 0.9648 |

| 40 | −10.3078 | 0.4659 | −0.0060 | 0.000024359 | 0.9377 | |

| 30 | −8.1497 | 0.3307 | −0.0033 | 0.0000059915 | 0.9672 | |

| Heating rate of milk (kW) | 50 | 7.1966 | −0.2242 | 0.0024 | −0.0000081955 | 0.9751 |

| 40 | 6.9267 | −0.2331 | 0.0027 | −0.000010638 | 0.9896 | |

| 30 | 6.5691 | −0.2777 | 0.0042 | −0.000021992 | 0.9956 | |

| Net heating rate effect | 50 | −2.5565 | 0.1617 | −0.0020 | 0.0000071226 | 0.7301 |

| 40 | −3.3811 | 0.2328 | −0.0033 | 0.000013721 | 0.7165 | |

| 30 | −1.5806 | 0.0530 | 0.0010 | −0.000016001 | 0.8302 | |

| Cumulative heat released by water (kJ) | 50 | 2577.6611 | 189.5369 | −1.7670 | 0.0063 | 0.9830 |

| 40 | 1312.5611 | 254.9214 | −2.6405 | 0.0104 | 0.9943 | |

| 30 | 888.2421 | 250.5796 | −3.5952 | 0.0207 | 0.9936 | |

| Cumulative heat absorbed by milk | 50 | 1624.8781 | 212.2518 | −2.0089 | 0.0068 | 0.9950 |

| 40 | 759.2427 | 257.3700 | −3.1228 | 0.0129 | 0.9939 | |

| 30 | 534.7397 | 235.4172 | −3.5727 | 0.0194 | 0.9967 | |

| Cooling rate of milk | 50 | 79.5733 | −2.4785 | −0.0311 | 0.0032 | 0.9995 |

| 40 | 79.4196 | −3.0165 | 0.0122 | 0.0022 | 0.9998 | |

| 30 | 79.2000 | −3.1207 | −0.0148 | 0.0038 | 1.0000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Husnain, S.N.; Amjad, W.; Munir, A.; Hensel, O. Development and Experimental Study of Smart Solar Assisted Yogurt Processing Unit for Decentralized Dairy Value Chain. Sustainability 2022, 14, 4285. https://doi.org/10.3390/su14074285

Husnain SN, Amjad W, Munir A, Hensel O. Development and Experimental Study of Smart Solar Assisted Yogurt Processing Unit for Decentralized Dairy Value Chain. Sustainability. 2022; 14(7):4285. https://doi.org/10.3390/su14074285

Chicago/Turabian StyleHusnain, Syed Nabeel, Waseem Amjad, Anjum Munir, and Oliver Hensel. 2022. "Development and Experimental Study of Smart Solar Assisted Yogurt Processing Unit for Decentralized Dairy Value Chain" Sustainability 14, no. 7: 4285. https://doi.org/10.3390/su14074285