Review on the Application of Organic Fibers as Substitutes for Asbestos in Thin Fiber Cement Sheets from a Sri Lankan Perspective

Abstract

1. Introduction

2. Different Types of Organic Fibers

2.1. Fiber Availability and Production

2.2. Fiber Treatment

| Fiber Type | Treatment Method | References |

|---|---|---|

| Wood | Acetylation | [50] |

| Thermomechanical treatment | [37] | |

| Alkali treatment | [51] | |

| Fiber hybridization | [52] | |

| Silane treatment | [38] | |

| Banana | Hot-water immersion | [53] |

| Alkali treatment | [39,40] | |

| Fiber hybridization | [54] | |

| Bamboo | Acetylation | [43] |

| Alkali treatment | [41] | |

| Modified by glycerol | [42] | |

| Permanganate treatment | [44,55] | |

| Hot-water immersion | [41] | |

| Coconut coir | Hot-water immersion | [45,46] |

| Alkali treatment | [47,56] | |

| Permanganate treatment | [47] | |

| Fiber hybridization | [57] | |

| Peroxide treatment | [48] |

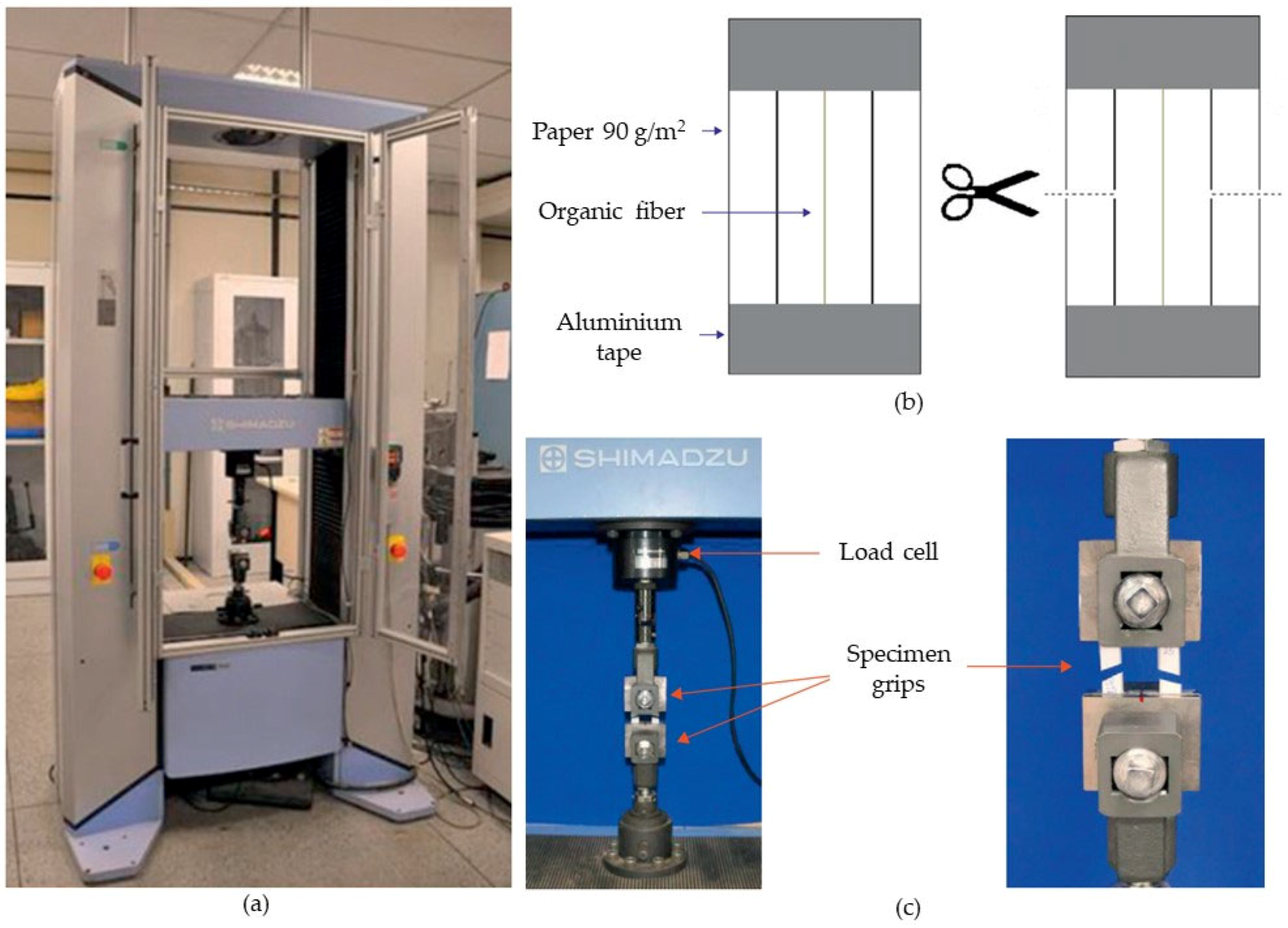

2.3. Physicomechanical Properties of Organic Fibers

3. Fiber Cement Composites

3.1. Composite Production

3.2. Mechanical Performance

3.3. Durability Performance

3.4. Energy Performance

3.5. Fire Resistance

4. Sustainability and Cost Analysis

5. Summary and Future Works

- It was found that, among treatment methods, alkali treatment can be identified as a more productive method for enhancing fiber–matrix adhesion and dimension stability. However, the effectiveness of the treatments varied depending on the fiber type.

- Even though chrysotile fibers have a greater tensile strength (3060–4480 MPa) than organic fibers (under 1000 MPa), organic FC composites can be developed to carry high strength using different fiber lengths and contents. Moreover, except for bamboo and coconut coir, the flexural strength of the discussed FC composites was 20.1–23.5 MPa, which satisfies the SLS 9–1:2001 requirement.

- It is noteworthy that existing research needs more information to implement a durable FC product.

- The review found that organic FC composites can provide fire resistance comparable to asbestos-reinforced composites. Furthermore, using organic fibers in cement composites can provide similar benefits, such as enhanced thermal insulation (thermal conductivity, 0.1–0.9 W/m K) and improved energy efficiency.

- Using organic fibers in building materials can also help to ensure the industry’s sustainability by lowering the environmental impact of building material manufacturing and disposal.

- Cellulose fibers are utilized in the FC industry, with wood fiber and coconut fiber being less expensive than chrysotile asbestos fiber. Banana and bamboo fibers, extracted from agricultural waste and fast-growing trees, have limited cost analysis for their use in the FC industry.

- The durability of organic fibers is a pressing concern, as the organic nature of plant fibers combined with the alkaline composition of cementitious composites presents challenges. To address this issue, more effective pretreatment methods with minimal environmental impact must be explored to improve the use of organic fibers in FC thin sheets.

- In addition to exploring the durability of organic fibers, a life cycle assessment (LCA) of the development of organic-fiber-reinforced composites would promote their long-term sustainability.

- Moreover, limited cost analyses for using organic fibers in the FC industry currently exist, making further studies necessary to determine their cost-effectiveness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dias, C.M.R.; Savastano, H., Jr.; John, V.M. Exploring the Potential of Functionally Graded Materials Concept for the Development of Fiber Cement. Inorg. Fiber Compos. 2010, 24, 140–146. [Google Scholar] [CrossRef]

- Mobasher, B. Mechanics of Fiber and Textile Reinforced Cement Composites; CRC Press: Boca Raton, FL, USA, 2012; pp. 9–19. [Google Scholar]

- Rhino Products Limited Design Strip Ceiling. Available online: https://roofing.lk/product/design-strip-ceiling/ (accessed on 31 May 2022).

- Semenov, V.; Pligina, A.; Rozovskaya, T. The Use of the Chrysotile Cement Waste as the Secondary Aggregate for the Concrete. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Scientific Conference of Young Scientists: Advanced Materials in Construction and Engineering, Tomsk, Russia, 15–17 October 2014; Volume 71, p. 012041. [CrossRef]

- Masoud, M.A.; Rashad, A.M.; Sakr, K.; Shahien, M.G.; Zayed, A.M. Possibility of Using Different Types of Egyptian Serpentine as Fine and Coarse Aggregates for Concrete Production. Mater. Struct. 2020, 53, 87. [Google Scholar] [CrossRef]

- Masoud, M.A.; El-Khayatt, A.M.; Kansouh, W.A.; Sakr, K.; Shahien, M.G.; Zayed, A.M. Insights into the Effect of the Mineralogical Composition of Serpentine Aggregates on the Radiation Attenuation Properties of Their Concretes. Constr. Build. Mater. 2020, 263, 120141. [Google Scholar] [CrossRef]

- Kapush, I.; Zakrevskaya, L.N.; Gavrilenko, A. The Use of Chrysotile Asbestos in Concrete to Solve Economic Problems of Transport Infrastructure. In Networked Control Systems for Connected and Automated Vehicles; Springer: Berlin/Heidelberg, Germany, 2022; Volume 509, pp. 899–906. [Google Scholar]

- Thives, L.P.; Ghisi, E.; Juarez, J.; Vieira, A.S. Is Asbestos Still a Problem in the World? A Current Review. J. Environ. Manag. 2022, 319, 115716. [Google Scholar] [CrossRef] [PubMed]

- Virta, R.L. Worldwide Asbestos Supply and Consumption Trends from 1900 through 2003; U.S. Geological Survey: Reston, VA, USA, 2006.

- Bernstein, D.; Dunnigan, J.; Hesterberg, T.; Brown, R.; Velasco, J.A.L.; Barrera, R.; Hoskins, J.; Gibbs, A. Health Risk of Chrysotile Revisited. Crit. Rev. Toxicol. 2013, 43, 154–183. [Google Scholar] [CrossRef]

- World Health Organization Elimination of Asbestos-Related Diseases. Available online: https://www.who.int/publications/i/item/WHO-FWC-PHE-EPE-14.01 (accessed on 1 November 2022).

- Tamura, A.; Funakoshi, M.; Naw Awn, J.P.; Hasegawa, K.; Ishimine, A.; Koike, A.; Tannai, N.; Fujii, M.; Hattori, M.; Hirano, H.; et al. Potential Asbestos Exposure among Patients with Primary Lung Cancer in Japan. J. Occup. Health 2018, 60, 236–245. [Google Scholar] [CrossRef]

- Vimercati, L.; Cavone, D.; Caputi, A.; Delfino, M.C.; De Maria, L.; Ferri, G.M.; Serio, G. Malignant Mesothelioma in Construction Workers: The Apulia Regional Mesothelioma Register, Southern Italy. BMC Res. Notes 2019, 12, 636. [Google Scholar] [CrossRef]

- Kazan-Allen, L. Global Asbestos Panorama 2019. In Proceedings of the Asbestos Safety Conference, Perth, Australia, 19–20 May 2019. [Google Scholar]

- Coutts, R.S.P. A Review of Australian Research into Natural Fibre Cement Composites. Cem. Concr. Compos. 2005, 27, 518–526. [Google Scholar] [CrossRef]

- De Souza Castoldi, R.; de Souza, L.M.S.; Souto, F.; Liebscher, M.; Mechtcherine, V.; de Andrade Silva, F. Effect of Alkali Treatment on Physical–Chemical Properties of Sisal Fibers and Adhesion towards Cementbased Matrices. Constr. Build. Mater. 2022, 345, 128363. [Google Scholar] [CrossRef]

- Choi, Y.C. Hydration and Internal Curing Properties of Plant-based Natural Fiberreinforced Cement Composites. Case Stud. Constr. Mater. 2022, 17, 1690. [Google Scholar] [CrossRef]

- Do Amaral, L.M.; de Souza Rodrigues, C.; Poggiali, F.S.J. Hornification on Vegetable Fibers to Improve Fiber-Cement Composites: A Critical Review. J. Build. Eng. 2022, 48, 103947. [Google Scholar] [CrossRef]

- Santos, R.F.; Ribeiro, J.C.L.; de Carvalho, J.M.F.; Magalhães, W.L.E.; Pedroti, L.G.; Nalon, G.H.; de Lima, G.E.S. Nanofibrillated Cellulose and Its Applications in Cement-based Composites: A Review. Constr. Build. Mater. 2021, 288, 123122. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Brazilian Waste Fibres as Reinforcement for Cement-based Composites. Cem. Concr. Compos. 2000, 22, 379–384. [Google Scholar] [CrossRef]

- Nayak, L. The mineral fibre: Asbestos-Its manufacture, properties, toxic effects and substitutes. Nat. Environ. Pollut. Technol. 2016, 15, 477. [Google Scholar]

- Wickramatillake, B.A.; Fernando, M.A.; Frank, A.L. Prevalence of Asbestos-Related Disease Among Workers in Sri Lanka. Ann. Glob. Health 2019, 85, 108. [Google Scholar] [CrossRef]

- Peiris, D.; Weerasinghe, T.K. Study on Use of Environmentally Friendly Alternative Fiber Materials for Asbestos Roofing Sheets in Sri Lanka. OIDA Int. J. Sustain. Dev. 2019, 12, 11–18. [Google Scholar]

- Udawatthe, C.; Bibilegedara, D.; Perera, A.; Halwathura, R. Study on Usage of Chrysotile Fiber in Cement; University of Moratuwa: Moratuwa, Sri Lanka, 2018. [Google Scholar]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a Natural Source for Groundbreaking Applications in Materials Science: Today’s State. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated Cellulose—Its Barrier Properties and Applications in Cellulosic Materials: A Review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose Nanomaterials Review: Structure, Properties and Nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; Taylor & Francis: London, UK; New York, NY, USA, 2007; ISBN 9780415250481. [Google Scholar]

- Pachta, V.; Stefanidou, M.; Konopisi, S.; Papayianni, I. Technological Evolution of Historic Structural Mortars. J. Civ. Eng. Archit. 2014, 8, 846–854. [Google Scholar] [CrossRef]

- Coutts, R.S.P. Flax fibres as a reinforcement in cement mortars. Int. J. Cem. Compos. Lightweight Concr. 1983, 5, 257–262. [Google Scholar] [CrossRef]

- Ruwanpathiranal, N.D.; Amarasekera, H.S.; De Silva, M.P. Variation of Pinus Caribaea Wood Density with Height in Tree and Distance from Pith, in Different Site Classes. In Proceedings of International Forestry and Environment Symposium; Department of Forestry and Environmental Science, University of Sri Jayewardenepura: Sri Jayewardenepura Kotte, Sri Lanka, 1996. [Google Scholar]

- Scott, D.F.; Bruijnzeel, L.A.; Vertessy, R.A.; Calder, I.R. Hydrology|Impacts of Forest Plantations on Streamflow. In Encyclopedia of Forest Sciences; Academic Press: Cambridge, MA, USA, 2004; pp. 367–377. [Google Scholar] [CrossRef]

- Ranathilaka, M.B.; Lashmi, N.; Atukorala, W. Production and Marketing of Banana: Estimating the Profitability Using Walawa Region in Sri Lanka. J. Bus. Financ. Emerg. Mark. 2019, 2, 23–32. [Google Scholar] [CrossRef]

- Rohit, K.; Dixit, S. A Review—Future Aspect of Natural Fiber Reinforced Composite. Polym. Renew. Resour. 2016, 7, 43–59. [Google Scholar] [CrossRef]

- Rowell, R.M. Natural Fibres: Types and Properties. In Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008; pp. 3–66. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural FiberReinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Campbell, M.D.; Coutts, R.S.P. Wood Fibre reinforced Cement Composites. J. Mater. Sci. 1980, 15, 1962–1970. [Google Scholar] [CrossRef]

- Pehanich, J.L.; Blankenhorn, P.R.; Silsbee, M.R. Wood Fiber Surface Treatment Level Effects on Selected Mechanical Properties of Wood Fiber–Cement Composites. Cem. Concr. Res. 2004, 34, 59–65. [Google Scholar] [CrossRef]

- Jagadeesh, D.; Venkatachalam, R.; Nallakumarasamy, G. Characterisation of banana fiber-a review. J. Environ. Nanotechnol. 2015, 4, 23–26. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Dai, C. Development of Banana Fibers and Wood Bottom Ash Modified Cement Mortars. Constr. Build. Mater. 2020, 241, 118041. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Omoniyi, E.T.; Onuzulike, G. Effect of Microwave Assisted Alkali Pretreatment and Other Pretreatment Methods on Some Properties of Bamboo Fibre Reinforced Cement Composites. Constr. Build. Mater. 2020, 245, 118405. [Google Scholar] [CrossRef]

- Ban, Y.; Zhi, W.; Fei, M.; Liu, W.; Yu, D.; Fu, T.; Qiu, R. Preparation and Performance of Cement Mortar Reinforced by Modified Bamboo Fibers. Polymers 2020, 12, 2650. [Google Scholar] [CrossRef]

- Onyekwere, O.S.; Igboanugo, A.C.; Adeleke, T.B. Optimisation of Acetylation Parameters for Reduced Moisture Absorption of Bamboo Fibre Using Taguchi Experimental Design and Genetic Algorithm Optimisation Tools. Niger. J. Technol. 2019, 38, 104. [Google Scholar] [CrossRef]

- Sheng, K.; Qian, S.; Wang, H. Influence of Potassium Permanganate Pretreatment on Mechanical Properties and Thermal Behavior of Moso Bamboo Particles Reinforced PVC Composites. Polym. Compos. 2013, 35, 1460–1465. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Hirunlabh, J.; Khedari, J.; Charoenvai, S.; Zeghmati, B.; Cheul, S.U. Development of Coconut Coirbased Lightweight Cement Board. Constr. Build. Mater. 2007, 21, 277–288. [Google Scholar] [CrossRef]

- Moura, S.; Demori, R.; Leão, R.M.; Luis, C.; Ruth, S. The Influence of the Coconut Fiber Treated as Reinforcement in PHB (Polyhydroxybutyrate) Composites. Mater. Today Commun. 2019, 18, 191–198. [Google Scholar] [CrossRef]

- Arsyad, M. Sodium Hydroxide and Potassium Permanganate Treatment on Mechanical Properties of Coconut Fibers. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 5th International Symposium on Material, Mechatronics and Energy, Gowa, South Sulawesi, Indonesia, 6–8 November 2018; Volume 619, p. 012011.

- Brígida, A.I.S.; Calado, V.M.A.; Gonçalves, L.R.B.; Coelho, M.A.Z. Effect of Chemical Treatments on Properties of Green Coconut Fiber. Carbohydr. Polym. 2010, 79, 832–838. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials. Materials 2022, 15, 4362. [Google Scholar] [CrossRef]

- Tserki, V.; Panayiotou, C.; Zafeiropoulos, N.E. A Study of the Effect of Acetylation and Propionylation on the Interface of Natural Fibre Biodegradable Composites. Adv. Compos. Lett. 2005, 14, 65–71. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural Fiber Reinforced Composites: Sustainable Materials for Emerging Applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber Synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in Flexure and Direct Shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- ElMeligy, M.G.; Mohamed, S.H.; Mahani, R.M. Study Mechanical, Swelling and Dielectric Properties of Prehydrolysed Banana Fiber—Waste Polyurethane Foam Composites. Carbohydr. Polym. 2010, 80, 366–372. [Google Scholar] [CrossRef]

- Prabhakar, C.G.; Babu, A.; Kataraki Pramod, S.; Reddy, S. A Review on Natural Fibers and Mechanical Properties of Banyan and Banana Fibers Composites. Mater. Today Proc. 2021, 54, 348–358. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Pongwisuthiruchte, A.; Potiyaraj, P. Recent Advances of Natural Fibers Based Green Rubber Composites: Properties, Current Status, and Future Perspectives. J. Appl. Polym. Sci. 2021, 138, 50866. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Studies on the Durability of Natural Fibres and the Effect of Corroded Fibres on the Strength of Mortar. Nat. Fibre Reinf. Cem. Compos. 2005, 27, 575–582. [Google Scholar] [CrossRef]

- Islam, M.S.; Nur, H.; Hasan, M.; Talib, Z.A.; Jawaid, M.; Haafiz, M.K. Mohamad Physical, Mechanical and Biodegradable Properties of Kenaf/Coir Hybrid Fiber Reinforced Polymer Nanocomposites. Mater. Today Commun. 2015, 4, 69–76. [Google Scholar] [CrossRef]

- Mai, Y.W.; Hakeem, M.I. Slow Crack Growth in Cellulose Fibre Cements. J. Mater. Sci. 1984, 19, 501–508. [Google Scholar] [CrossRef]

- ASTM D3822; Standard Test Method for Tensile Properties of Single Textile Fibers. American Society for Testing and Materials: Conshohocken, PA, USA, 2001.

- ASTM C1557; Standard Test Method for Tensile Strength and Young’s Modulus of Fibers. American Society for Testing and Materials: Conshohocken, PA, USA, 2008.

- Hu, W.; Ton-That, M.-T.; Perrin-Sarazin, F.; Denault, J. An Improved Method for Single Fiber Tensile Test of Natural Fibers. Polym. Eng. Sci. 2009, 50, 819–825. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.D.F.M.; de Andrade Silva, F.; Toledo Filho, R.D. The Effect of Fiber Morphology on the Tensile Strength of Natural Fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Dharmaratne, P.; Galabada, H.; Jayasinghe, R.; Nilmini, R.; Halwatura, R. Characterization of Physical, Chemical and Mechanical Properties of Sri Lankan Coir Fibers. J. Ecol. Eng. 2021, 22, 55–65. [Google Scholar] [CrossRef]

- De Almeida Melo Filho, J.; de Andrade Silva, F.; Toledo Filho, R.D. Degradation Kinetics and Aging Mechanisms on Sisal Fiber Cement Composite Systems. Cem. Concr. Compos. 2013, 40, 30–39. [Google Scholar] [CrossRef]

- Coutts, R.S.P. Banana Fibres as Reinforcement for Building Products. J. Mater. Sci. Lett. 1990, 9, 1235–1236. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Z.; Yan, Y. Flexural Properties and Impact Behaviour Analysis of Bamboo Cellulosic Fibers Filled Cement Based Composites. Constr. Build. Mater. 2019, 220, 403–414. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, H.; Wang, G.; Yu, Z.; Shi, S.Q. Tensile Properties of Bamboo in Different Sizes. J. Wood Sci. 2015, 61, 552–561. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of Natural Fiber Cement Materials Containing Coconut Coir and Oil Palm Fibers for Residential Building Applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and Dynamic Properties of Coconut Fibre Reinforced Concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Rao, K.M.M.; Rao, K.M. Extraction and Tensile Properties of Natural Fibers: Vakka, Date and Bamboo. Compos. Struct. 2007, 77, 288–295. [Google Scholar] [CrossRef]

- Gao, X.; Zhu, D.; Fan, S.; Rahman, M.Z.; Guo, S.; Chen, F. Structural and Mechanical Properties of Bamboo Fiber Bundle and Fiber/Bundle Reinforced Composites: A Review. J. Mater. Res. Technol. 2022, 19, 1162–1190. [Google Scholar] [CrossRef]

- Ruslan, I.; Ruslan, B.; Evgenij, K. The Effect of Metal and Polypropylene Fiber on Technological and Physical Mechanical Properties of Activated Cement Compositions. Case Stud. Constr. Mater. 2022, 16, e00882. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic Fiber Reinforced Cementbased Composites: A Review of Recent Research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Correia, V.C.; Santos, S.F.; Tonoli, G.H.D.; Savastano, H.; Harries, K.A.; Sharma, B. Characterization of Vegetable Fibers and Their Application in Cementitious Composites. In Nonconventional and Vernacular Construction Materials; Woodhead Publishing: Cambridge, UK, 2016; pp. 83–110. ISBN 9780081008713. [Google Scholar]

- Cooke, A.M.; Akers, S.A.S. The Effect of Aluminous Additives on the Properties of Autoclaved Cellulose Fibre Cement. In Proceedings of the 11th International Inorganic-Bonded Fiber Composites Conference, Madrid, Spain, 5–7 November 2008. [Google Scholar]

- De Silva, T.C.S.; Basnayake, T.; Herath, K.R.B. A Study of Finding Alternatives for Asbestos in Sri Lanka. IOSR J. Mech. Civ. Eng. 2020, 17, 21–28. [Google Scholar]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Ground Iron Blast Furnace Slag as a Matrix for Cellulosecement Materials. Cem. Concr. Compos. 2001, 23, 389–397. [Google Scholar] [CrossRef]

- Savastano, H.; Santos, S.F.; Radonjic, M.; Soboyejo, W.O. Fracture and Fatigue of Natural Fiberreinforced Cementitious Composites. Cem. Concr. Compos. 2009, 31, 232–243. [Google Scholar] [CrossRef]

- Correia, V.D.C.; Santos, S.F.; Mármol, G.; Aprigio, A.; Savastano, H. Potential of Bamboo Organosolv Pulp as a Reinforcing Element in Fiber–Cement Materials. Constr. Build. Mater. 2014, 72, 65–71. [Google Scholar] [CrossRef]

- Savastano, H.; Santos, S.F.; Agopyan, V.; Khatib, J.M. Sustainability of Vegetable Fibres in Construction. In Sustainability of Construction Materials; Woodhead Publishing: Cambridge, UK, 2009; pp. 55–81. [Google Scholar] [CrossRef]

- Savastano, H.; Warden, P.G.; Coutts, R.S.P. Microstructure and Mechanical Properties of Waste Fibre–Cement Composites. Nat. Fibre Reinf. Cem. Compos. 2005, 27, 583–592. [Google Scholar] [CrossRef]

- Soroushian, P.; Won, J.; Hassan, M. Durability Characteristics of CO2-cured Cellulose Fiber Reinforced Cement Composites. Constr. Build. Mater. 2012, 34, 44–53. [Google Scholar] [CrossRef]

- Adeniji, A.O.; Olorunnisola, A.O.; Savastano, H., Jr. Physico-Mechanical Properties and Weathering Performance of Coconut Husk Fibre-Reinforced Composite Roofing Tiles Produced with Selected Cement Admixtures. In Proceedings of 2nd World Conference on Byproducts of Palms and Their Applications, Kuala Lumpur, Malaysia; Springer Nature: Singapore, 2022; pp. 103–115. [Google Scholar] [CrossRef]

- Filho, T.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of Alkalisensitive Sisal and Coconut Fibres in Cement Mortar Composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Mohr, B.J.; Hood, K.L.; Kurtis, K.E. Mitigation of Alkali–Silica Expansion in Pulp Fiber–Mortar Composites. Cem. Concr. Compos. 2009, 31, 677–681. [Google Scholar] [CrossRef]

- Mohr, B.J.; Nanko, H.; Kurtis, K.E. Durability of Kraft Pulp Fiber–Cement Composites to Wet/Dry Cycling. Cem. Concr. Compos. 2005, 27, 435–448. [Google Scholar] [CrossRef]

- De Andrade Silva, F.; Mobasher, B.; Filho, R.D.T. Fatigue Behavior of Sisal Fiber Reinforced Cement Composites. Mater. Sci. Eng. A 2010, 527, 5507–5513. [Google Scholar] [CrossRef]

- Silva, F.D.A.; Mobasher, B.; Soranakom, C.; Filho, R.D.T. Effect of Fiber Shape and Morphology on Interfacial Bond and Cracking Behaviors of Sisal Fiber Cement Based Composites. Cem. Concr. Compos. 2011, 33, 814–823. [Google Scholar] [CrossRef]

- Agopyan, V.; Savastano, H.; John, V.M.; Cincotto, M.A. Developments on Vegetable Fibre–Cement Based Materials in São Paulo, Brazil: An Overview. Cem. Concr. Compos. 2005, 27, 527–536. [Google Scholar] [CrossRef]

- Zhu, W.H.; Tobias, B.C.; Coutts, R.S.P.; Langfors, G. Aircured Banana fibre reinforced Cement Composites. Cem. Concr. Compos. 1994, 16, 3–8. [Google Scholar] [CrossRef]

- Chakraborty, S.; Kundu, S.P.; Roy, A.; Basak, R.K.; Adhikari, B.; Majumder, S.B. Improvement of the Mechanical Properties of Jute Fibre Reinforced Cement Mortar: A Statistical Approach. Constr. Build. Mater. 2013, 38, 776–784. [Google Scholar] [CrossRef]

- Paramasivam, P.; Nathan, G.K.; Gupta, D. Coconut Fibre Reinforced Corrugated Slabs. Int. J. Cem. Compos. Lightweight Concr. 1984, 6, 19–27. [Google Scholar] [CrossRef]

- ISO 10904:2011; Fibre-Cement Corrugated Sheets and Fittings for Roofing and Cladding. 2011. Available online: https://www.iso.org/standard/46368.html (accessed on 20 January 2023).

- SLS 9–2: 2001; SLS 9: Specification for Asbestos Cement Products Part 2: Corrugated Sheets. Sri Lanka Standards Institution: Colombo, Sri Lanka, 2001.

- SLS 9–1: 2001; SLS 9: Specification for Asbestos Cement Products Part 1: Flat Sheets. Sri Lanka Standards Institution: Colombo, Sri Lanka, 2001.

- Wei, J.; Meyer, C. Degradation Mechanisms of Natural Fiber in the Matrix of Cement Composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Sudin, R.; Swamy, N. Bamboo and Wood Fibre Cement Composites for Sustainable Infrastructure Regeneration. J. Mater. Sci. 2006, 41, 6917–6924. [Google Scholar] [CrossRef]

- Baghban, M.H.; Mahjoub, R. Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review. Appl. Sci. 2020, 10, 357. [Google Scholar] [CrossRef]

- Cooke, A.M. Durability of Autoclaved Cellulose Fiber Cement Composites. In Proceedings of the 7th Inorganic-Bonded Wood and Fiber Conference, Aalborg, Denmark, 21–24 September 2000. [Google Scholar]

- Gheni, A.; Aljaberi, Z.; ElGawady, M.; Myers, J. Energy Efficiency and Thermal Characterization of Eco-Friendly Wood Fiber Masonry Blocks. In Proceedings of the 16th International Brick and Block Masonry Conference, Padova, Italy, 26–30 June 2016; pp. 895–902. [Google Scholar]

- Khedari, J.; Charoenvai, S.; Hirunlabh, J. New Insulating Particleboards from Durian Peel and Coconut Coir. Build. Environ. 2003, 38, 435–441. [Google Scholar] [CrossRef]

- Khedari, J.; Nankongnab, N.; Hirunlabh, J.; Teekasap, S. New Lowcost Insulation Particleboards from Mixture of Durian Peel and Coconut Coir. Build. Environ. 2004, 39, 59–65. [Google Scholar] [CrossRef]

- Gnanachelvam, S.; Mahendran, M.; Ariyanayagam, A. Elevated Temperature Thermal Properties of Advanced Materials Used in LSF Systems. Fire Mater. 2021, 46, 12–28. [Google Scholar] [CrossRef]

- Bentchikon, M.; Guidoum, A.; Scrivener, K.L.; Silhadi, K.; Hanini, S. Effect of Cellulose Fiber on the Thermal and Mechanical Properties of Cement Paste. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Building and structures, Barcelona, Spain, 8–11 November 2004; pp. 725–730. [Google Scholar]

- Dirisu, J.; Joseph, O.; Babalola, P.O.; Oyedepo, S.O.; Fayomi, O.S.I.; Oluwasegun, K.M.; Nduka, U.; Ajayi, O.O.; Ajibero, M. Utilization of Waste Materials for Eco-Friendly Building Ceilings: An Overview. Key Eng. Mater. 2022, 917, 285–295. [Google Scholar] [CrossRef]

- Taiwo, A.S.; Egbodion, E.O.; Adediran, A.A.; Shittu, S.A.; Balogun, S.O.; Adesina, O.S. Mechanical properties and water-absorption characteristics of selected natural fibers as a replacement for asbestos. Mater. Technol. 2021, 55, 97–104. [Google Scholar]

- Rabi, J.A.; Sérgio, S.; Henrique, G.; Savastano, H., Jr. Agricultural Wastes as Building Materials: Properties, Performance and Applications. In Building Materials: Properties, Performance and Applications; Nova Science Publishers: New York, NY, USA, 2009. [Google Scholar]

- Singh, S.; Chourasia, A.; Bisht, R.S.; Yadav, S. Thermal and Acoustic Performance of Cement Fibreboard and Bamboo Buildings. Indian J. Eng. Mater. Sci. 2021, 28, 462–471. [Google Scholar]

- Ali, M. Coconut fibre: A versatile material and its applications in engineering. J. Civ. Eng. Constr. Technol. 2011, 2, 189–197. [Google Scholar]

- Luisito, J.P. How to Make Coconut Fiber Cement Board (CFB). Available online: https://businessdiary.com.ph/2933/coconut-fiber-cement-board-cfb/ (accessed on 20 November 2022).

- Muszynski, L.; Gulas, S. Fire resistance and performance of alternative concrete wall systems. J. Constr. Educ. 2001, 6, 146–154. [Google Scholar]

- Adamczak-Bugno, A.; Świt, G.; Krampikowska, A.; Proverbio, E. Analysis of the Significance of Changes in the Number and Energy Parameters of Acoustic Emission Signals on the Assessment of the Strength of Fibre–Cement Boards. Materials 2022, 15, 5757. [Google Scholar] [CrossRef] [PubMed]

- Schabowicz, K.; Sulik, P.; Gorzelańczyk, T.; Zawiślak, Ł. Assessment of the Destruction of a Fibre Cement Board Subjected to Fire in a Large-Scale Study. Materials 2022, 15, 2929. [Google Scholar] [CrossRef]

- Schabowicz, K.; Sulik, P.; Zawiślak, Ł. Reduction of Load Capacity of Fiber Cement Board Facade Cladding under the Influence of Fire. Materials 2021, 14, 1769. [Google Scholar] [CrossRef]

- Thongcharoen, N.; Khongtong, S.; Srivaro, S.; Wisadsatorn, S.; Chub-uppakarn, T.; Chaowana, P. Development of Structural Insulated Panels Made from Wood-Composite Boards and Natural Rubber Foam. Polymers 2021, 13, 2497. [Google Scholar] [CrossRef]

- ASTM D3801-10; Standard Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in a Vertical Position. ASTM International: West Conshohocken, PA, USA, 2010.

- Asif, M.; Khatib, J.M. Sustainability of Timber, Wood and Bamboo in Construction. In Sustainability of Construction Materials; Woodhead Publishing: Cambridge, UK, 2009; pp. 31–54. [Google Scholar] [CrossRef]

- Ince, C.; Tayançlı, S.; Derogar, S. Recycling Waste Wood in Cement Mortars towards the Regeneration of Sustainable Environment. Constr. Build. Mater. 2021, 299, 123891. [Google Scholar] [CrossRef]

- Kochova, K.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Using Alternative Waste Coir Fibres as a Reinforcement in Cementfibre Composites. Constr. Build. Mater. 2020, 231, 117121. [Google Scholar] [CrossRef]

- Pearl Industries Chrysotile Raw Asbestos Fiber. Available online: https://www.indiamart.com/proddetail/chrysotile-raw-asbestos-fiber-23141500855.html (accessed on 3 February 2023).

- Cellulose Fibers—Cellulose Fibers Buyers, Suppliers, Importers, Exporters and Manufacturers—Latest Price and Trends. Available online: https://connect2india.com/Cellulose-Fibers (accessed on 3 February 2023).

- Agrielite Impex Private Limited Natural Coconut Coir Fiber. Available online: https://www.indiamart.com/proddetail/natural-coconut-coir-fiber-23176536597.html (accessed on 3 February 2023).

- Banana Fiber. Available online: http://naturalfibercompany.com/product/banana-fiber (accessed on 5 February 2023).

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Wan, F.N.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef] [PubMed]

- Ho, M.; Wang, H.; Lee, J.; Ho, C.; Lau, K.; Leng, J.; Hui, D. Critical Factors on Manufacturing Processes of Natural Fibre Composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

| Fiber Type | Critical Fiber Length (mm) | Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation to Break (%) | References |

|---|---|---|---|---|---|

| Chrysotile fiber | 1.0–5.0 | 3060–4480 | 160 | - | [28] |

| Wood (pinus radiata) | 2.0–4.5 | 500–1000 | 7–70 | 0.5–1.4 | [28,37] |

| Banana | 2.7–5.5 | 600 | 17–18 | 3 | [65,70,71] |

| Bamboo | 2.1–2.9 | 540–630 | 11–17 | 2 | [66,67,71] |

| Coconut coir | 5.0–10.0 | 94–159 | 1.2–1.8 | 20–67 | [63,68,69] |

| Fiber | Fiber Content (w/w) (%) | Density (kg/m3) | Flexural Strength (MPa) | Modulus of Elasticity (MPa) | Fracture Toughness (kJ/m2) | References |

|---|---|---|---|---|---|---|

| Chrysotile fiber | 8 | 2100 | 25.4 | 14.73 | - | [28] |

| Softwood | 8 | 1540 | 23.5 | 10.3 | 1.32 | [20] |

| Banana | 12 | 1580 | 20.1 | 7.04 | 1.01 | [20,81] |

| Bamboo | 12 | - | 11.5 | - | 2.20 | [66] |

| Coconut coir | 2.5 | 1250 | 10.18 | - | - | [68,76] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deegoda, I.; Buddika, S.; Yapa, H.; Navaratnam, S.; Zhang, G. Review on the Application of Organic Fibers as Substitutes for Asbestos in Thin Fiber Cement Sheets from a Sri Lankan Perspective. Sustainability 2023, 15, 10235. https://doi.org/10.3390/su151310235

Deegoda I, Buddika S, Yapa H, Navaratnam S, Zhang G. Review on the Application of Organic Fibers as Substitutes for Asbestos in Thin Fiber Cement Sheets from a Sri Lankan Perspective. Sustainability. 2023; 15(13):10235. https://doi.org/10.3390/su151310235

Chicago/Turabian StyleDeegoda, Isuru, Samith Buddika, Hiran Yapa, Satheeskumar Navaratnam, and Guomin Zhang. 2023. "Review on the Application of Organic Fibers as Substitutes for Asbestos in Thin Fiber Cement Sheets from a Sri Lankan Perspective" Sustainability 15, no. 13: 10235. https://doi.org/10.3390/su151310235

APA StyleDeegoda, I., Buddika, S., Yapa, H., Navaratnam, S., & Zhang, G. (2023). Review on the Application of Organic Fibers as Substitutes for Asbestos in Thin Fiber Cement Sheets from a Sri Lankan Perspective. Sustainability, 15(13), 10235. https://doi.org/10.3390/su151310235

_Zhang.png)