Composting Old Bark and Wood Waste in Cold Weather Conditions

Abstract

:1. Introduction

- whether it is possible to compost old BWW from bark dumps during the cold period of the year using heaps in an open area;

- how strongly cold weather affects the process of composting old BWW;

- whether microbiological inoculation speeds up the composting process in cold weather conditions.

- old BWW with the use of mineral fertilizers;

- old BWW with the use of mineral fertilizers and a microbiological inoculum.

- The novelty and practical value of this study is twofold. To begin with, it is the first study to examine the possibility of composting old BWW from bark dumps with the addition of mineral fertilizers in cold weather conditions (up to −14 °C), and furthermore, it is the first to investigate the influence of an inoculum on the process of BWW composting in the aforementioned weather conditions.

2. Materials and Methods

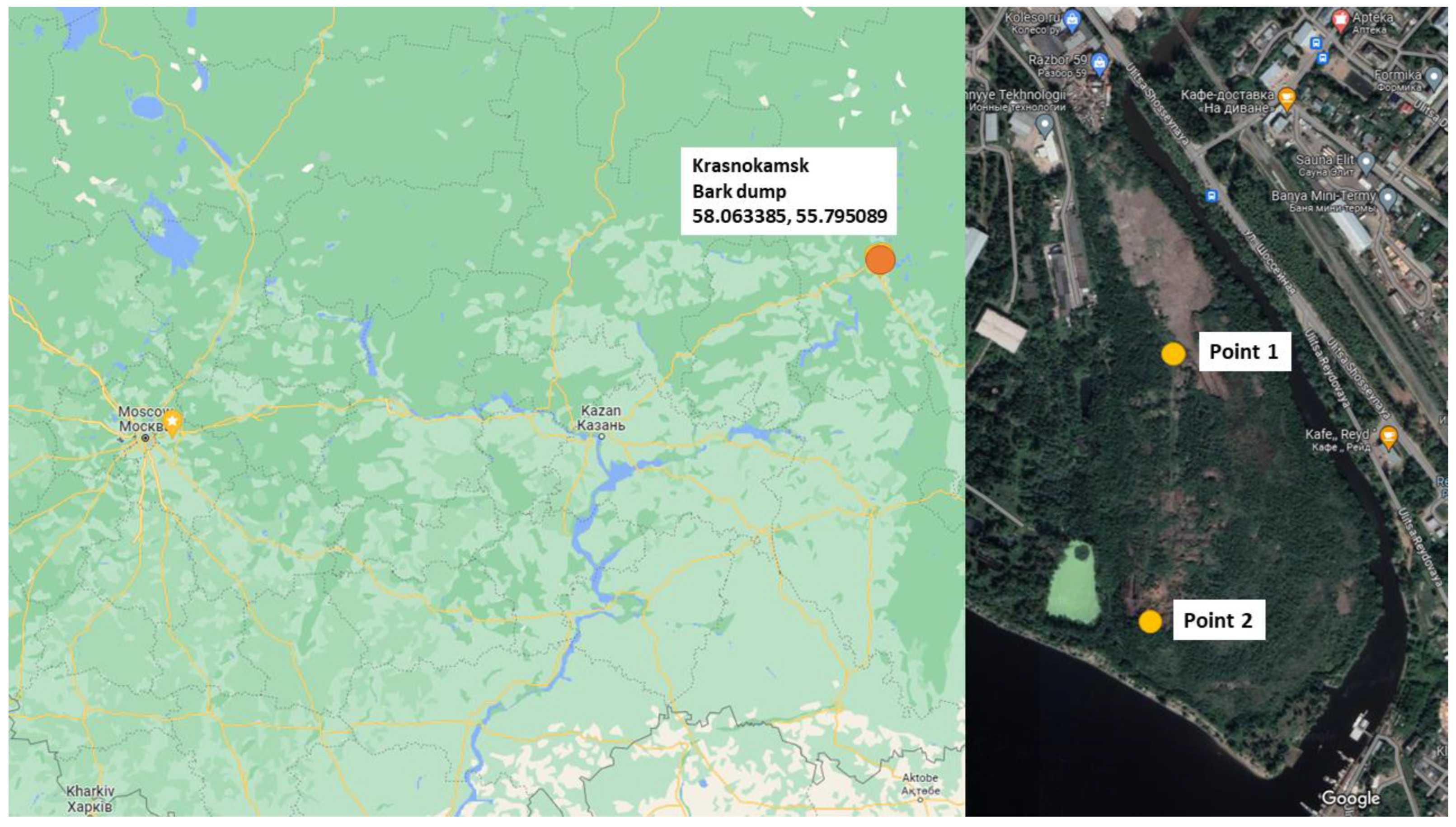

2.1. Object of Study

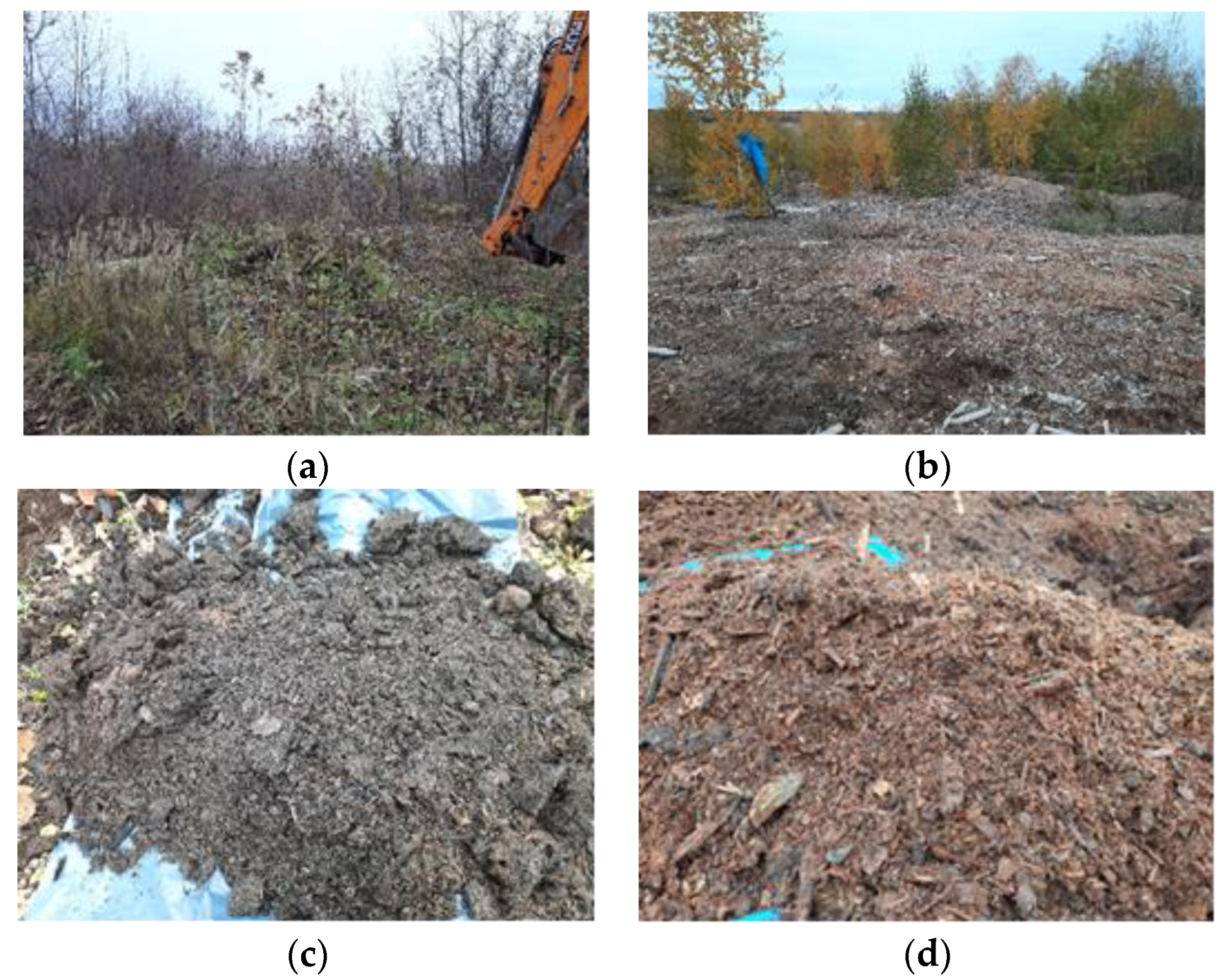

2.2. Field Composting

2.3. Old BWW Composting under Laboratory Conditions

2.4. Physicochemical and Microbiological Parameters

2.4.1. Temperature

2.4.2. Moisture Content

2.4.3. COD, BOD5, pH

2.4.4. LOI

2.4.5. AT4

2.4.6. Metals

2.4.7. Sanitary and Hygienic Indicators

2.5. Statistical Analysis

3. Results

3.1. Properties of Old BWW at the Beginning of Composting

3.2. Field Composting

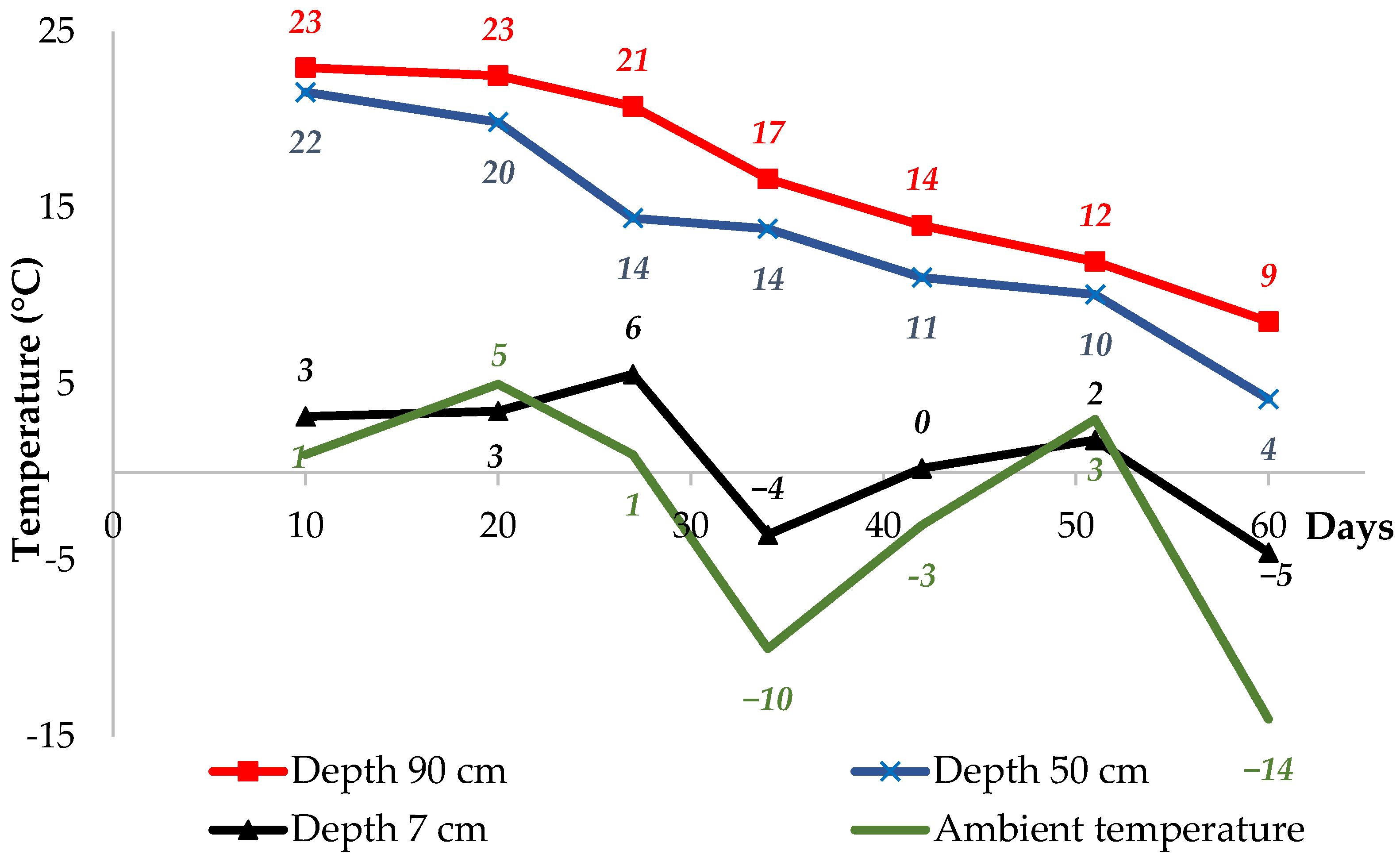

3.2.1. Temperature

- cooling of the heap due to an average daily decrease in the atmospheric temperature;

- the end of the thermophilic composting stage and the onset of the maturation phase, which is indicated by the equalization of the compost mixture temperature in the heap with the atmospheric temperature [42].

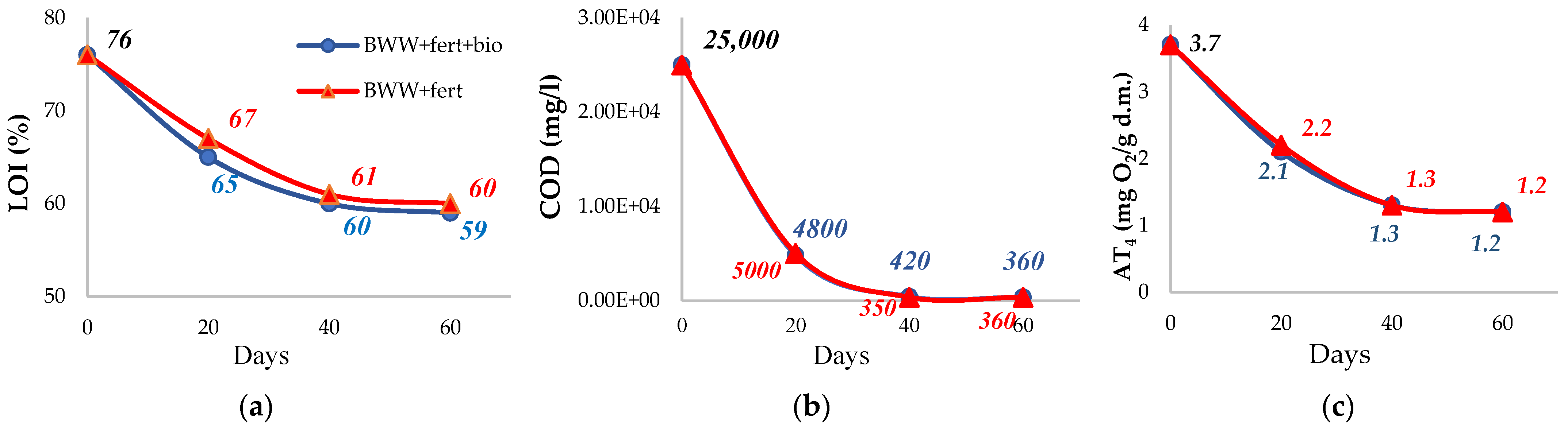

3.2.2. Compost Indicator Dynamics

3.3. Laboratory Composting

- BWW + fertilizers + inoculum, field composting;

- BWW + fertilizers + inoculum, laboratory composting;

- BWW + fertilizers, field composting;

- BWW + fertilizers, laboratory composting.

3.4. Compost Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Babich, O.O.; Kulikova, Y.V.; Sukhikh, S.A.; Kalashnikova, O.B.; Dolganyuk, V.F. Review of research in the field of development of technologies for direct production of liquid fuel from biomass. Herit. Sci. 2021, 80, 41–47. (In Russian) [Google Scholar]

- Veprikova, E.V.; Kuznetsova, S.A.; Chesnokov, N.V.; Kuznetsov, B.N. Obtaining of Organomineral Fertilizers on the Basis of Wood Bark (Review). J. Sib. Fed. Univ. Chem. 2016, 4, 414–429. [Google Scholar] [CrossRef]

- Maksimov, A.Y.; Maksimova, Y.G.; Shilova, A.V.; Kolesova, O.V.; Simonetti, J. Study of the properties and microbiological composition of bark and wood waste from the Krasnokamsk bark dump. Bull. PNRPU. Chem. Eng. Biotechnol. 2018, 4, 98–112. (In Russian) [Google Scholar]

- Giner-Santonja, G.; Suhr, M.; Klein, G.; Kourti, I.; Gonzalo, M.R.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Pulp, Paper and Board; Publications Office of the European Union: Luxembourg, 2015; pp. 185–504. [Google Scholar]

- Ministry of Natural Resources of Russia. On the State and Protection of the Environment of the Russian Federation in 2020. State-Donation Report; Ministry of Natural Resources of Russia: Moscow, Russia, 2021; pp. 245–318. (In Russian) [Google Scholar]

- Kulikova, Y.; Sukhikh, S.; Babich, O.; Yuliya, M.; Krasnovskikh, M.; Noskova, S. Feasibility of Old Bark and Wood Waste Recycling. Plants 2022, 11, 1549. [Google Scholar] [CrossRef] [PubMed]

- Metsämuuronen, S.; Sirén, H. Bioactive phenolic compounds, metabolism and properties: A review on valuable chemical compounds in Scots pine and Norway spruce. Phytochem. Rev. 2019, 18, 623–664. [Google Scholar] [CrossRef] [Green Version]

- Pozdin, B.I.; Sereda, T.G.; Kostarev, S.N. Environmentally safe technologies for processing waste from logging and wood processing industries into building materials. In Proceedings of the Ecology and Safety in the Technosphere: Modern Problems and Solutions, Tomsk, Russia, 23–25 November 2017. (In Russian). [Google Scholar]

- Kocheva, L.S.; Kachanova, A.V.; Karmanov, A.P. Utilization of bark-wood waste from timber processing enterprises. In Proceedings of the Political, Economic and Socio-Cultural Aspects of Regional Governance in the European North, Syktyvkar, Russia, 23–24 October 2014. (In Russian). [Google Scholar]

- Devyatlovskaya, A.N.; Zhuravleva, L.N.; Devyatlovsky, N.V. Utilization of wood bark of wood treatment enterprises. In Proceedings of the Forest Complex: State and Prospects of Development, Lesosibirsk, Russia, 1–30 November 2010. (In Russian). [Google Scholar]

- Li, J.; Bao, H.; Xing, W.; Yang, J.; Liu, R.; Wang, X.; Lv, L.; Tong, X.; Wu, F. Succession of fungal dynamics and their influence on physicochemical parameters during pig manure composting employing with pine leaf biochar. Bioresour Technol. 2020, 297, 122377. [Google Scholar] [CrossRef] [PubMed]

- Chaschin, A.; Gilev, V. Assessment of the capacity of the fertile layer of technogenically disturbed soils using the NDVI vegetation index. Socio-Ecol. Technol. 2020, 3, 290–305. (In Russian) [Google Scholar]

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L.I. Composting technology in waste stabilization: On the methods, challenges and future prospects. J. Env. Manage. 2017, 1, 140–157. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Chen, H.; Wang, Q.; Liu, T.; Duan, Y.; Awasthi, S.K.; Ren, X.; Tu, Z.; Li, J.; Zhao, J.; et al. Succession of bacteria diversity in the poultry manure composted mixed with clay: Studies upon its dynamics and associations with physicochemical and gaseous parameters. Bioresour Technol. 2018, 267, 618–625. [Google Scholar] [CrossRef] [PubMed]

- Williams, R.T.; Marks, P.J. Optimization of Composting for Explosives Contaminated Soil; Final Report; CETHA-TS-CR-91053; U.S. Army Corps of Engineers: Washington DC, USA, 1991. [Google Scholar]

- Qian, X.; Shen, G.; Wang, Z.; Guo, C.; Liu, Y.; Lei, Z.; Zhang, Z. Co-composting of livestock manure with rice straw, Characterization and establishment of maturity evaluation system. Waste Manag. 2014, 34, 530–535. [Google Scholar] [CrossRef] [Green Version]

- Proietti, P.; Calisti, R.; Gigliotti, G.; Nasini, L.; Regni, L.; Marchini, A. Composting optimization: Integrating cost analysis with the physical-chemical properties of materials to be composted. J. Clean. Prod. 2016, 137, 1086–1099. [Google Scholar] [CrossRef]

- Wang, K.; Li, W.; Li, Y.; Gong, X.; Wu, C.; Ren, N.-Q. The modelling of combined strategies to achieve thermophilic composting of sludge in cold region. Int. Biodeterior. Biodegrad. 2013, 85, 608–616. [Google Scholar] [CrossRef]

- Wang, L.; Wang, L.; Wang, D.; Li, J. Isolation and application of thermophilic and psychrophilic microorganisms in the composting process. Waste Biomass Valorization 2013, 5, 433–440. [Google Scholar] [CrossRef]

- Gou, C.; Wang, Y.; Zhang, X.; Lou, Y.; Gao, Y. Inoculation with a psychrotrophic-thermophilic complex microbial agent accelerates onset and promotes maturity of dairy manure-rice straw composting under cold climate conditions. Bioresour. Technol. 2017, 243, 339–346. [Google Scholar] [CrossRef]

- Boutchich, G.; Tahiri, S.; Mahi, M.; Gallart-Mateu, D.; Guardia, M.; Aarfane, A.; Lhadi, E.; el Krati, M. Characterization of activated sludge from domestic sewage treatment plants and their management using composting and co-composting in aerobic silos. J. Mater. Environ. Sci. 2015, 6, 2206–2220. [Google Scholar]

- Naylor, L.; Kuter, G. Agitated Bed Composting: Past, Present, Future. Proc. Water Environ. Fed. 2005, 2, 375–385. [Google Scholar] [CrossRef]

- Webb, A.L. An innovative in-vessel tunnel composting system. Waste Resour. Manag. 2007, 160, 27–31. [Google Scholar] [CrossRef]

- Lindberg, C. Accelerated Composting in Tunnels. In The Science of Composting; de Bertoldi, M., Sequi, P., Lemmes, B., Papi, T., Eds.; Springer: Dordrecht, The Netherlands, 1996; pp. 1205–1206. [Google Scholar] [CrossRef]

- Kalamdhad, A.S.; Singh, Y.K.; Ali, M.; Khwairakpam, M.; Kazmi, A.A. Rotary drum composting of vegetable waste and tree leaves. Bioresour Technol. 2009, 100, 6442–6450. [Google Scholar] [CrossRef] [PubMed]

- Manyapu, V.; Shukla, S.; Kumar, S.; Rajendra, K. In-vessel composting: A rapid technology for conversion of biowaste into compost. Open Access Int. J. Sci. Eng. 2017, 2, 58–63. [Google Scholar]

- Liu, Z.; Wang, X.; Wang, F.; Bai, Z.; Chadwick, D.R.; Misselbrook, T.H.; Ma, L. The progress of composting technologies from static heap to intelligent reactor: Benefits and limitations. J. Clean. Prod. 2020, 270, 122328. [Google Scholar] [CrossRef]

- Al-Alawi, M.; El Fels, L.; Benjreid, R.; Szegi, T.; Hafidi, M.; Simon, B.; Gulyas, M. Evaluation of the performance of encapsulated lifting system composting technology with a GORE(R) cover membrane: Physico-chemical properties and spectroscopic analysis. Environ. Eng. Res. 2020, 25, 299–308. [Google Scholar] [CrossRef] [Green Version]

- McCartney, D.; Eftoda, G. Windrow composting of municipal biosolids in a cold climate. J. Environ. Eng. Sci. 2005, 4, 341–352. [Google Scholar] [CrossRef]

- Larney, F.J.; Alson, A.F.; Carcamo, A.A.; Chang, C. Physical changes during active and passive composting of beef feedlot manure in winter and summer. Bioresour. Technol. 2000, 75, 139–148. [Google Scholar] [CrossRef]

- Lynch, N.J.; Cherry, R.S. Winter composting using the passively aerated windrow system. Compost. Sci. Util. 2013, 4, 44–52. [Google Scholar] [CrossRef]

- Margesin, R.; Cimadom, J.; Schinner, F. Biological activity during composting of sewage sludge at low temperatures. Int. Biodeterior. Biodegrad. 2006, 57, 88–92. [Google Scholar] [CrossRef]

- Haug, R.T. The Practical Handbook of Compost Engineering; Lewis Publishers, CRC Press, Inc.: Boca Raton, FL, USA, 1996. [Google Scholar]

- Xi, B.D.; Zhang, G.J.; Liu, H.L. Process kinetics of inoculation composting of municipal solid waste. J. Hazard. Mater 2005, B124, 165–172. [Google Scholar] [CrossRef]

- Barrena, R.; Pagans, E.; Faltys, G.; Sanchez, A. Effect of inoculation dosing on the composting of source-selected organic fraction of municipal solid wastes. J. Chem. Technol. Biot. 2006, 81, 420–425. [Google Scholar] [CrossRef] [Green Version]

- Tiquia, S.M.; Tam, N.F.Y.; Hodgkiss, I.J. Effects of bacterial inoculum and moisture adjustment on composting pig manure. Environ. Pollut. 1997, 96, 161–171. [Google Scholar] [CrossRef]

- Bolta, S.V.; Mihelic, R.; Lobnik, F.; Lestan, D. Microbial community structure during composting with and without mass inocula. Compost. Sci. Util. 2003, 11, 6–15. [Google Scholar] [CrossRef]

- Acevedo, M.; Acevedo, L.; Restrepo-Sánchez, N.; Peláez, C. The inoculation of microorganisms in composting processes: Need or commercial strategy? Livest. Res. Rural. Dev. 2005, 17, 12. [Google Scholar]

- GOST R 54534-2011; Resources Saving. Sewage Sludge. Requirements for Recultivation of Disturbed Lands. Federal Agency for Technical Regulation and Metrology: Moscow, Russia, 2011. (In Russian)

- Jimenez, E.I.; Garcia, V.P. Evaluation of City Refuse Compost Maturity: A Review. Biol. Wastes 1989, 27, 115–142. [Google Scholar] [CrossRef] [Green Version]

- Raut, M.P.; William, S.M.P.P.; Bhattacharyya, J.K.; Chakrabarti, T.; Devotta, S. Microbial dynamics and enzyme activities during rapid composting of municipal solid waste–A compost maturity analysis perspective. Bioresour. Technol. 2008, 99, 6512–6519. [Google Scholar] [CrossRef]

- Tiquia, S.M. Microbiological parameters as indicators of compost maturity. J. Appl. Microbiol. 2005, 99, 816–828. [Google Scholar] [CrossRef]

- Turan, N.G.; Akdemir, A.; Ergun, O.N. Emission of volatile organic compounds during composting of poultry litter. Water Air Soil Pollut. 2007, 184, 177–182. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Pandey, A.K.; Khan, J.; Bundela, P.S.; Wong, J.W.C.; Selvam, A. Evaluation of thermophilic fungal consortium for organic municipal solid waste composting. Bioresour. Technol. 2014, 168, 214–221. [Google Scholar] [CrossRef] [PubMed]

- Luangwilai, T.; Sidhu, H.S.; Nelson, M.I.; Chen, X. Modelling the effects of moisture content in compost piles. In Proceedings of the CHEMECA 2011, Australian Chemical Engineering Conference Australia, Sydney, Australia, 18–21 September 2011. [Google Scholar]

- Mohammad, M.; Alam, M.; Kabbashi, N.A.; Ahsan, A. Effective composting of oil palm industrial waste by filamentous fungi, a review. Resour. Conserv. Recycl. 2012, 58, 69–78. [Google Scholar] [CrossRef]

- Makan, A.H.; Assobhei, O.; Mountadar, M. Effects of initial moisture content on in-vessel composting under air pressure of organic fraction of municipal solid wastes in Morocco. Iran. J. Environ. Health Sci. Eng. 2013, 10, 3. [Google Scholar] [CrossRef] [Green Version]

- Akdeniz, N. A systematic review of biochar use in animal waste composting. Waste Manag. 2019, 88, 291–300. [Google Scholar] [CrossRef]

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour. Technol. 2009, 100, 44–53. [Google Scholar] [CrossRef]

- Huang, G.F.; Wong, J.W.C.; Wu, Q.T.; Nagar, B.B. Effect of C/N on composting of pig manure with sawdust. Waste Manage. 2004, 24, 805–813. [Google Scholar] [CrossRef]

- Turan, N.G. The effects of natural zeolite on salinity level of poultry litter compost. Bioresour. Technol. 2008, 99, 2097–2101. [Google Scholar] [CrossRef]

- Chan, M.; Selvam, A.; Wong, J.W.C. Reducing nitrogen loss and salinity during ‘struvite’ food waste composting by zeolite amendment. Bioresour. Technol. 2016, 200, 838–844. [Google Scholar] [CrossRef]

- Matthiessen, M.K.; Larney, F.J.; Brent Selinger, L.; Olson, A.F. Influence of Loss-on-Ignition Temperature and Heating Time on Ash Content of Compost and Manure. Commun. Soil Sci. Plant Anal. 2005, 36, 2561–2573. [Google Scholar] [CrossRef]

- Water Quality–Determination of The Chemical Oxygen Demand. ISO 6060:1989. Available online: https://www.iso.org/standard/12260.html (accessed on 9 May 2023).

- PND F 14.1:2:3:4.123-97; Quantitative Chemical Analysis of Waters. Methodology for Measuring Biochemical Oxygen Demand after n-Days of Incubation in Surface Fresh, Underground (Ground), Drinking, Sewage and Treated Wastewater; Ministry of Environmental Protection and Natural Resources of the Russian Federation: Moscow, Russia, 1997. (In Russian)

- GOST 26483-85; Soils. Preparation of Salt Extract and Determination of Its pH by CINAO Method; Federal Agency for Technical Regulation and Metrology: Moscow, Russia, 1985. (In Russian)

- ASTM-D7348; Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues. ASTM International: West Conshohocken, PA, USA, 2021.

- Binner, E.; Bohm, K.; Lechner, P. Large scale study on measurement of respiration activity (AT4) by Sapromat and OxiTop. Waste Manag. 2012, 32, 1752–1759. [Google Scholar] [CrossRef]

- Mejias, L.; Komilis, D.; Gea, T.; Sánchez, A. The effect of airflow rates and aeration mode on the respiration activity of four organic wastes: Implications on the composting process. Waste Manag. 2017, 65, 22–28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- PND F 16.1:2.3:3.11-98; Quantitative Chemical Analysis of Soils. Methodology for Measuring the Mass Fraction (Gross Content) Selenium in Solid Bulk Materials by Fluorimetric Method with 2,3-diaminonaphthalene; Ministry of Environmental Protection and Natural Resources of the Russian Federation: Moscow, Russia, 1998. (In Russian)

- MU 2.1.7.2657-10; Entomological methods of studying the soil of populated areas for the presence of preimaginal stages of synanthropic flies. Federal Service for Supervision of Consumer Rights Protection and Human Well-Being: Moscow, Russia, 2010. (In Russian)

- MUK 4.2.3695-21; Methods of Microbiological Control of Soil. Federal Scientific Center of Hygiene named after F.F.Erisman" of the Federal Service for Supervision of Consumer Rights Protection and Human Well-Being: Moscow, Russia, 2021. (In Russian)

- Chen, P.C.; Chiu, M.C.; Ma, H. Measuring the reduction limit of repeated recycling—A case study of the paper flow system. J. Clean. Prod. 2016, 132, 98–107. [Google Scholar] [CrossRef]

- Vergnoux, A.; Guiliano, M.; Le Drйau, Y.; Kister, J.; Dupuy, N.; Doumenq, P. Monitoring of the evolution of an industrial compost and prediction of some compost properties by NIR spectroscopy. Sci. Total Env. 2009, 407, 2390–2403. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, X.; Huang, Y.; Huang, H. Inoculation with nitrogen turnover bacterial agent appropriately increasing nitrogen and promoting maturity in pig manure composting. Waste Manag. 2015, 39, 78–85. [Google Scholar] [CrossRef]

- Barlaz, M.A. Forest Products Decomposition in Municipal Solid Waste Landfills. Waste Manag. 2006, 26, 321–333. [Google Scholar] [CrossRef]

- Hanson, J.L.; Yeşiller, N.; Oettle, N.K. Spatial and temporal temperature distributions in municipal solid waste landfills. J. Environ. Eng. 2010, 136, 804–814. [Google Scholar] [CrossRef] [Green Version]

- Grillo, R.J. Energy Recycling–Landfill Waste Heat Generation and Recovery. Curr. Sustain. Renew. Energy Rep. 2014, 1, 150–156. [Google Scholar] [CrossRef] [Green Version]

- Ximenes, F.A.; Gardner, W.D.; Cowie, A.L. The decomposition of wood products in landfills in Sydney, Australia. Waste Manag. 2008, 28, 2344–2354. [Google Scholar] [CrossRef] [PubMed]

- Kirk, T.K.; Cowling, E.B. Biological decomposition of solid wood. Adv. Chem. Ser. 1984, 207, 455–487. [Google Scholar] [CrossRef]

- Smailagić, A.; Ristivojević, P.; Dimkić, I.; Pavlović, T.; Dabić Zagorac, D.; Veljović, S.; Fotirić Akšić, M.; Meland, M.; Natić, M. Radical Scavenging and Antimicrobial Properties of Polyphenol Rich Waste Wood Extracts. Foods 2020, 9, 319. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| BWW Sample | LOI (%) | AT4 (mg O2/g) | pH | COD (mg/dm3) |

|---|---|---|---|---|

| Initial compost mix | 76 ± 3 | 3.7 ± 0.4 | 7.6 ± 0.3 | 25,000 ± 4000 |

| BWW, Point 1 | 65 ± 2 | 1.5 ± 0.2 | 7.4 ± 0.1 | 12,500 ± 1110 |

| BWW, Point 2 | 91 ± 3 | 4.7 ± 0.4 | 2.8 ± 0.2 | 6142 ± 250 |

| Number of Days | 10 | 20 | 27 | 34 | 42 | 51 | 60 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) Air | +1 | +5 | +1 | −10 | −3 | +3 | −14 | |||||||

| x | SD | x | SD | x | SD | x | SD | x | SD | x | SD | x | SD | |

| T (°C) in heap 1 (BWW + fertilizers + inoculum) | ||||||||||||||

| Depth 7 cm | 3.5 | 2.0 | 3.7 | 1.4 | 5.1 | 2.3 | −4.0 | 0.8 | −0.4 | 0.4 | 2.3 | 0.3 | −4.2 | 1.0 |

| Depth 50 cm | 22.4 | 0.7 | 20.2 | 2.3 | 14.3 | 2.3 | 13.3 | 0.4 | 10.4 | 0.5 | 10.0 | 0.5 | 5.0 | 1.7 |

| Depth 90 cm | 23.9 | 2.6 | 23.2 | 1.4 | 21.0 | 2.2 | 16.8 | 0.4 | 14.0 | 0.2 | 12.4 | 0.4 | 9.1 | 1.0 |

| T (°C) in heap 2 (BWW + fertilizers) | ||||||||||||||

| Depth 7 cm | 2.9 | 1.3 | 3.2 | 1.4 | 6.0 | 2.3 | −3.1 | 1.8 | 0.9 | 1.2 | 1.4 | 0.7 | −4.9 | 1.5 |

| Depth 50 cm | 20.8 | 2.7 | 19.6 | 1.5 | 14.5 | 2.8 | 14.4 | 0.96 | 11.2 | 1.5 | 9.2 | 0.9 | 5.3 | 0.8 |

| Depth 90 cm | 22.0 | 3.0 | 22.0 | 3.0 | 20.5 | 2.9 | 16.5 | 2.3 | 14.0 | 2.1 | 11.5 | 1.1 | 7.9 | 1.3 |

| Number of Days | Depth of Heap, cm | T °C | F-Stat | p-Value | |

|---|---|---|---|---|---|

| x | SD | ||||

| 10 | 7 | 3 | 2 | 0.2 | 0.68 |

| 50 | 22 | 2 | 1 | 0.37 | |

| 90 | 23 | 3 | 0.7 | 0.45 | |

| 20 | 7 | 3 | 1 | 0.2 | 0.70 |

| 50 | 20 | 2 | 0.2 | 0.72 | |

| 90 | 23 | 2 | 0.4 | 0.60 | |

| 27 | 7 | 6 | 2 | 0.2 | 0.67 |

| 50 | 14 | 2 | 0.01 | 0.90 | |

| 90 | 21 | 2 | 0.07 | 0.80 | |

| 34 | 7 | −4 | 1 | 0.6 | 0.48 |

| 50 | 14 | 1 | 3.2 | 1.50 | |

| 90 | 17 | 2 | 0.04 | 0.86 | |

| 42 | 7 | 0 | 1 | 3.5 | 0.14 |

| 50 | 11 | 1 | 0.8 | 0.14 | |

| 90 | 14 | 1 | 0.003 | 0.96 | |

| 51 | 7 | 2 | 1 | 3.9 | 0.12 |

| 50 | 10 | 1 | 0.2 | 0.70 | |

| 90 | 12 | 1 | 1.6 | 0.30 | |

| 60 | 7 | −5 | 1 | 0.4 | 0.58 |

| 50 | 4 | 2 | 2.8 | 0.17 | |

| 90 | 9 | 1 | 1.8 | 0.25 | |

| Number of Days | 0 | 20 | 40 | 60 |

|---|---|---|---|---|

| Heap 1 (BWW + fertilizers + inoculum) | ||||

| pH | 7.6 ± 0.1 | 7.7 ± 0.1 | 7.9 ± 0.0 | 7.6 ± 0.5 |

| Moisture content (%) | 65 ± 1 | 63 ± 0 | 66 ± 0 | 67 ± 1 |

| Heap 2 (BWW + fertilizers) | ||||

| pH | 7.6 ± 0.1 | 7.5 ± 0.1 | 7.9 ± 0.0 | 7.7 ± 2 |

| Moisture content (%) | 65 ± 1 | 60 ± 2 | 64 ± 1 | 65 ± 0 |

| LOI (%) | COD (mg/L) | AT4 (mg O2/g) | ||||

|---|---|---|---|---|---|---|

| x | SD | x | SD | x | SD | |

| Laborotory composting | ||||||

| Compost No. 1 (BWW + fertilizers + inoculum) | 57 | 7 | 283 | 66 | 0.9 | 0.1 |

| Compost No. 2(BWW + fertilizers) | 59 | 8 | 300 | 59 | 1 | 0.1 |

| Field composting | ||||||

| Heap 1 (BWW + fertilizers + inoculum) | 59 | 5 | 360 | 60 | 1.2 | 0.3 |

| Heap 2 (BWW + fertilizers) | 60 | 9 | 360 | 50 | 1.2 | 0.4 |

| F-Stat | p-Value | |

|---|---|---|

| LOI | 0.07 | 1 |

| COD | 1.1 | 0.40 |

| AT4 | 2 | 0.18 |

| Index | Normative Value | Compost No. 1 BWW + Fert + Bio | Compost No. 2 BWW + Fert | Corresponds to Norm |

|---|---|---|---|---|

| Mass fraction of dry matter (%) | >45 | 38.5 ± 2.7 | 35.4 ± 2.5 | + |

| Ash con tent (%) | >65 (35–65) * | 48 ± 2 | 49 ± 2 | |

| Salt extract pH | 5.0–8.5 | 6.7 ± 0.1 | 6.5 ± 0.1 | + |

| Mercury (mg/kg) | <30 | 0.40 ± 0.02 | 0.43 ± 0.02 | + |

| Chromium (mg/kg) | <2000 | 38 ± 8 | 34 ± 7 | + |

| Plumbum (mg/kg) | <1000 | 33 ± 8 | 28 ± 7 | + |

| Cadmium (mg/kg) | <60 | 0.62 ± 0.31 | 0.46 ± 0.23 | + |

| Nickel (mg/kg) | <800 | 13 ± 5 | 11 ± 4 | + |

| Copper (mg/kg) | <1500 | 240 ± 50 | 210 ± 40 | + |

| Zinc (mg/kg) | <7000 | 190 ± 40 | 140 ± 30 | + |

| Arsenic (mg/kg) | <40 | 1.4 ± 0.7 | 1.6 ± 0.8 | + |

| COD water extract (mg/dm3) | <700 | 360 ± 60 | 360 ± 50 | + |

| BOD5 water extract (mg O2/dm3) | <500 | 170 ± 50 | 160 ± 50 | + |

| Pathogenic microorganisms, incl. Salmonella (cells/g) | Absence | Not found | Not found | + |

| Viable helminth eggs and protozoan cysts | Absence | Not found | Not found | + |

| Presence of viable larvae and pupae of synanthropic flies | Absence | Not found | Not found | + |

| Escherichia coli bacteria, index | <1000 | 10 | Less than 1 | + |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Margina, Y.; Troegubov, A.; Kulikova, Y.; Sliusar, N. Composting Old Bark and Wood Waste in Cold Weather Conditions. Sustainability 2023, 15, 10768. https://doi.org/10.3390/su151410768

Margina Y, Troegubov A, Kulikova Y, Sliusar N. Composting Old Bark and Wood Waste in Cold Weather Conditions. Sustainability. 2023; 15(14):10768. https://doi.org/10.3390/su151410768

Chicago/Turabian StyleMargina, Yuliya, Aleksandr Troegubov, Yuliya Kulikova, and Natalia Sliusar. 2023. "Composting Old Bark and Wood Waste in Cold Weather Conditions" Sustainability 15, no. 14: 10768. https://doi.org/10.3390/su151410768