Analysis and Comparison of Daylighting Technologies: Light Pipe, Optical Fiber, and Heliostat

Abstract

:1. Introduction

2. Daylighting Technologies

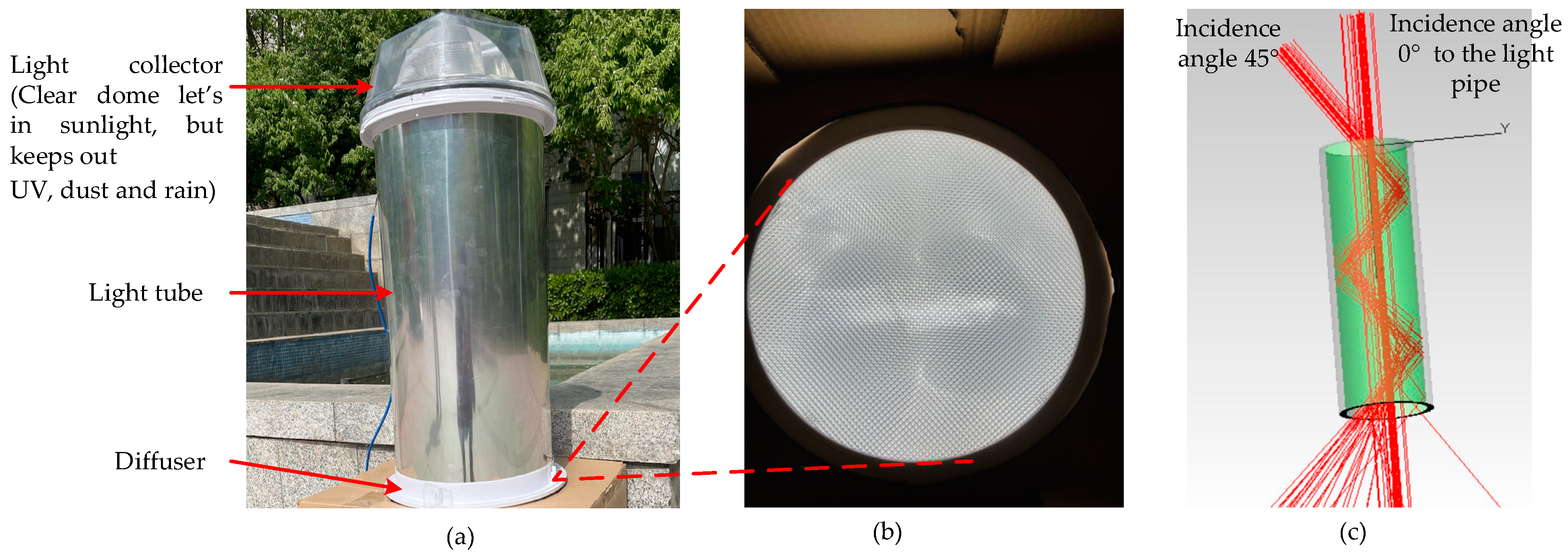

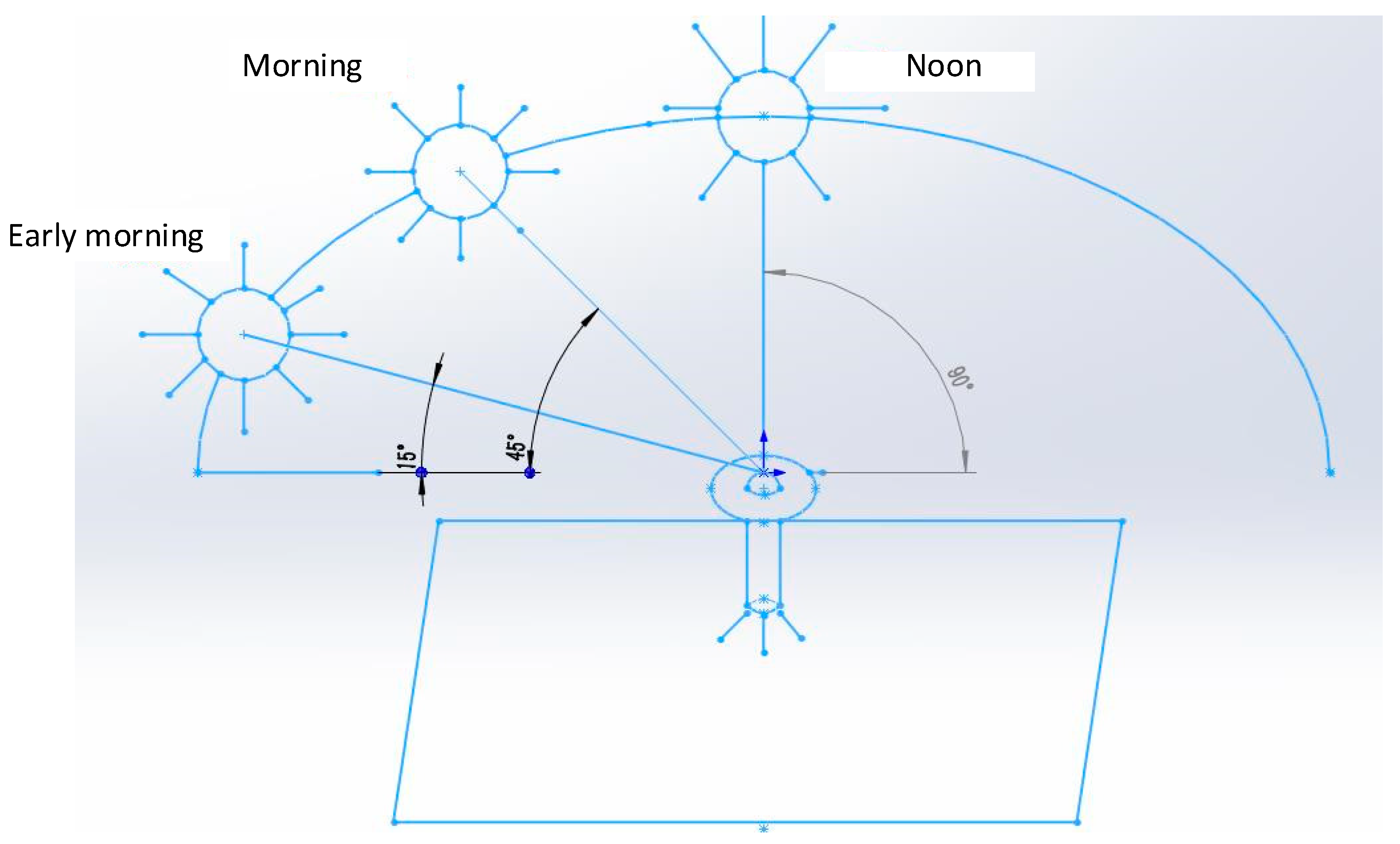

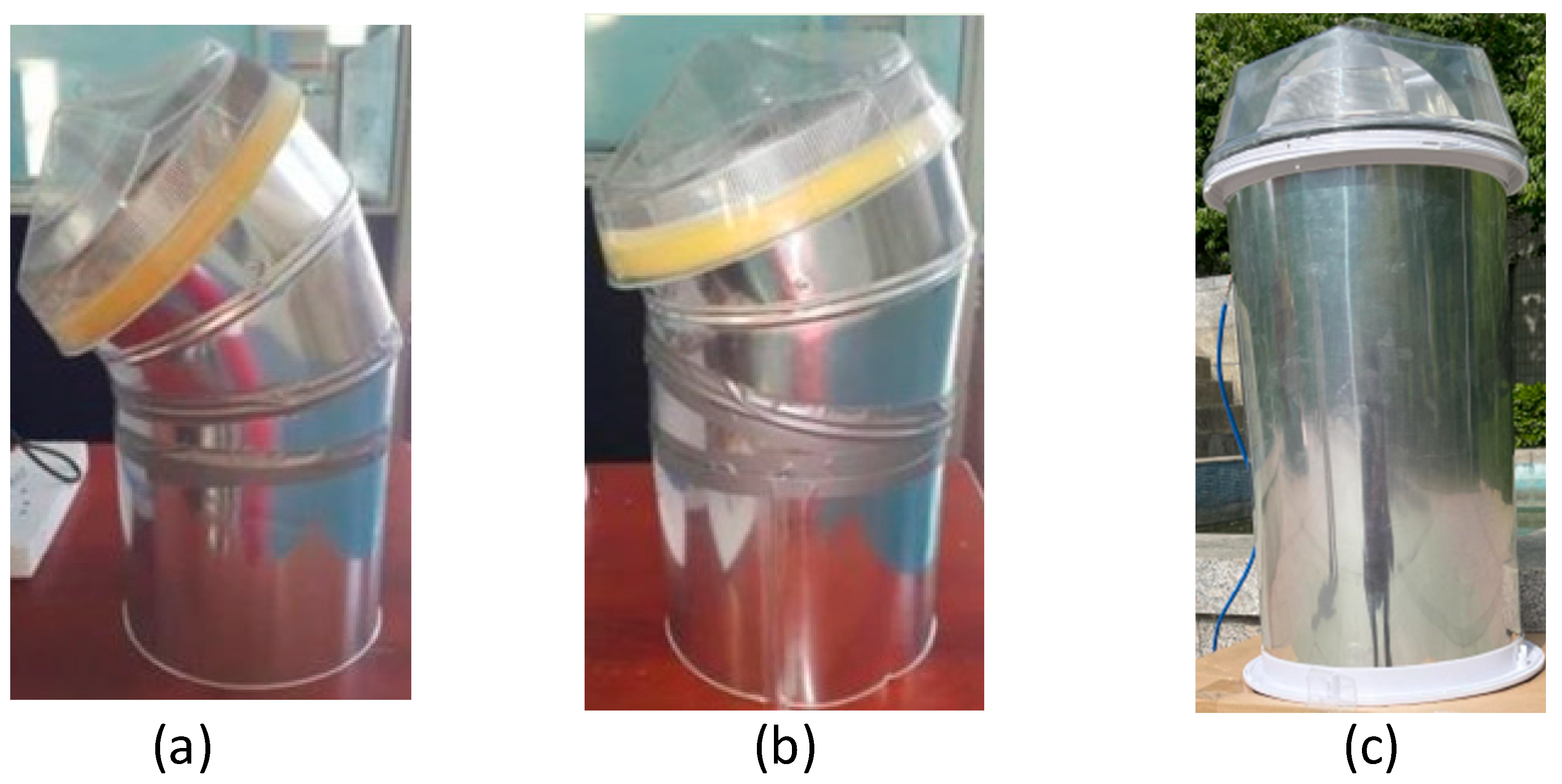

2.1. Light Pipe

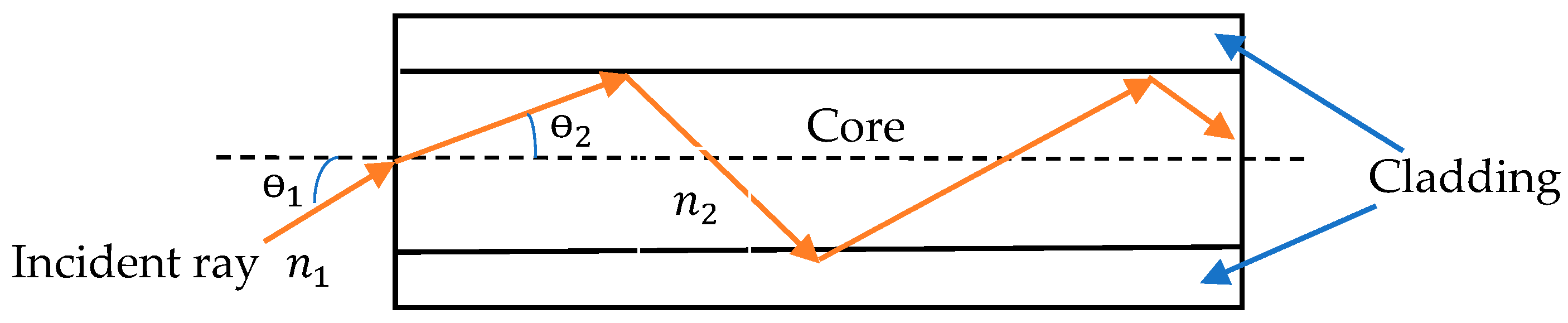

2.2. Optical Fiber

2.2.1. Concept

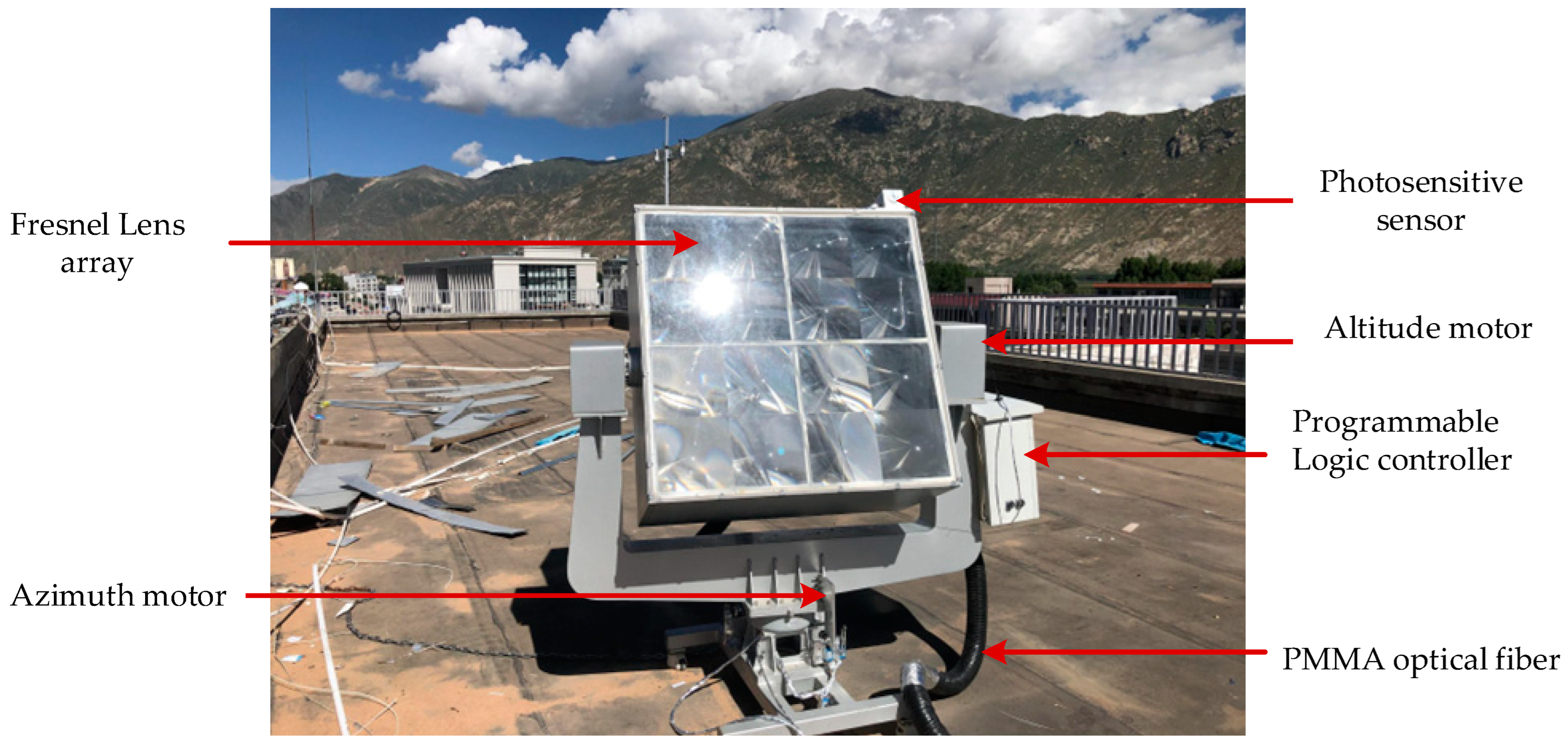

2.2.2. Primary Concentrator

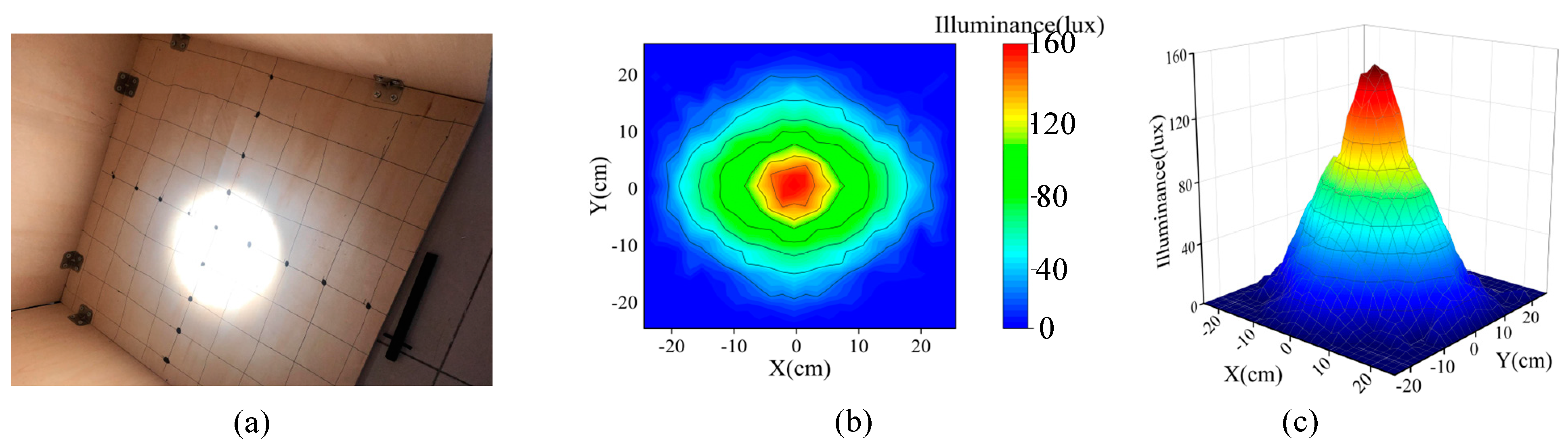

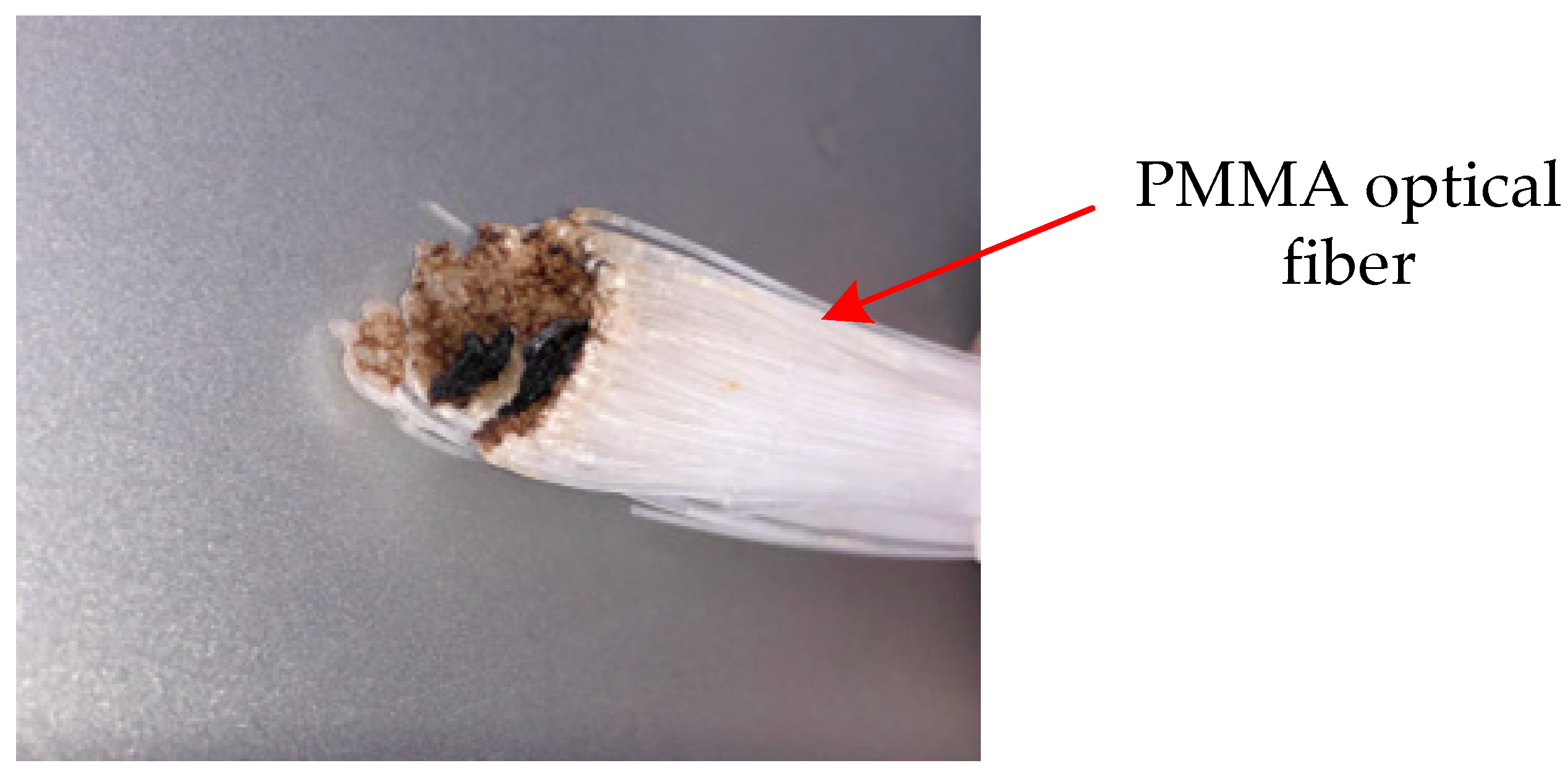

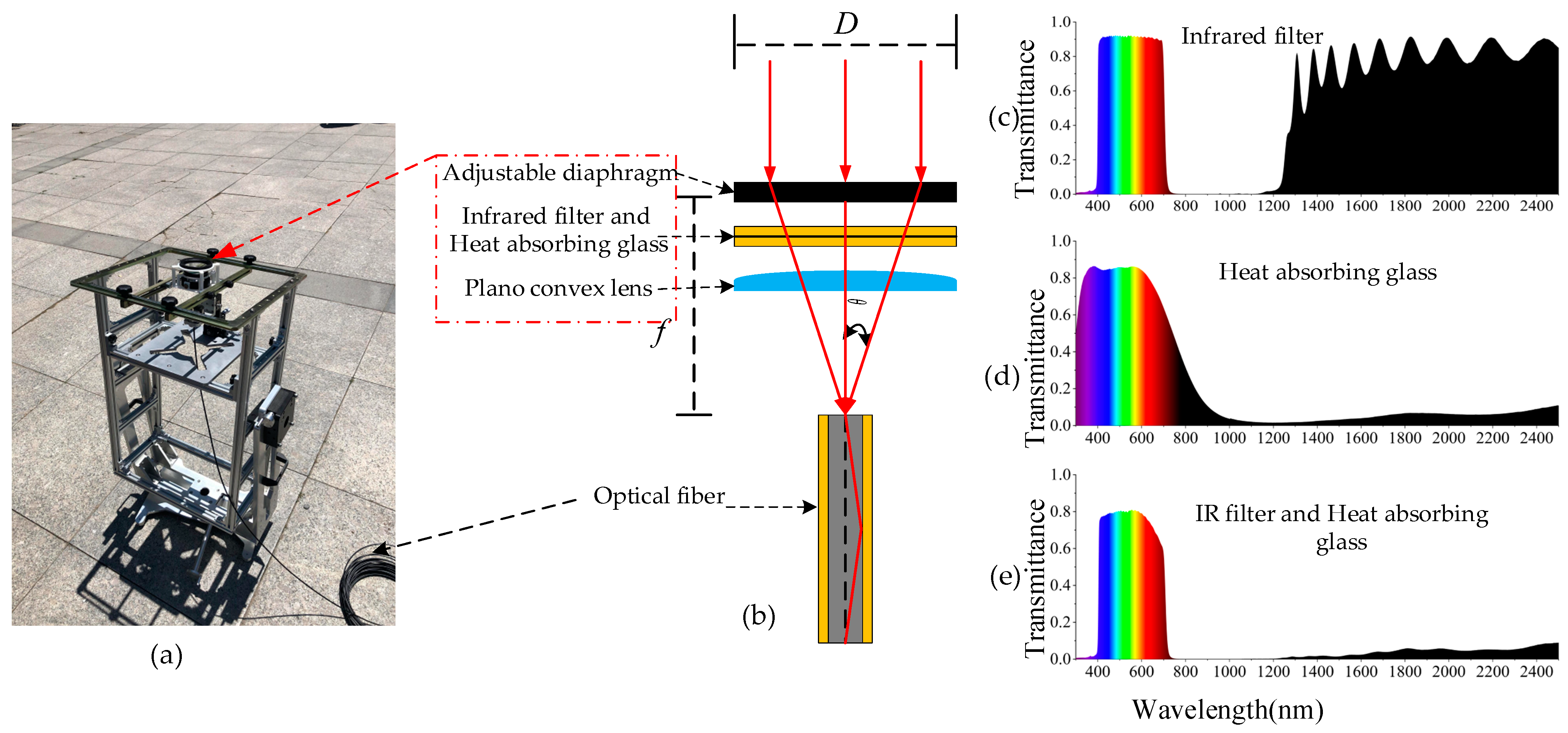

2.2.3. Secondary Optical Element

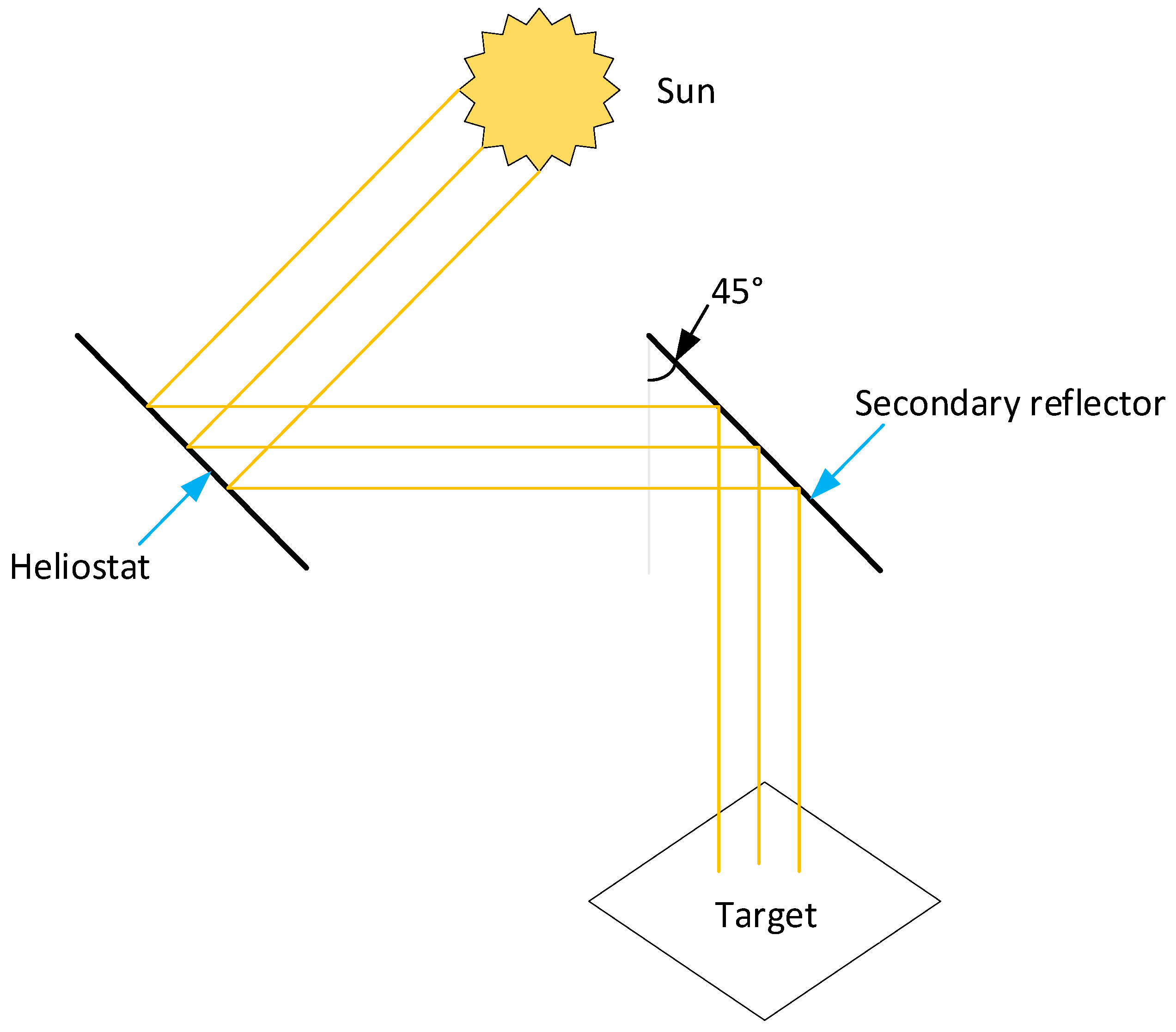

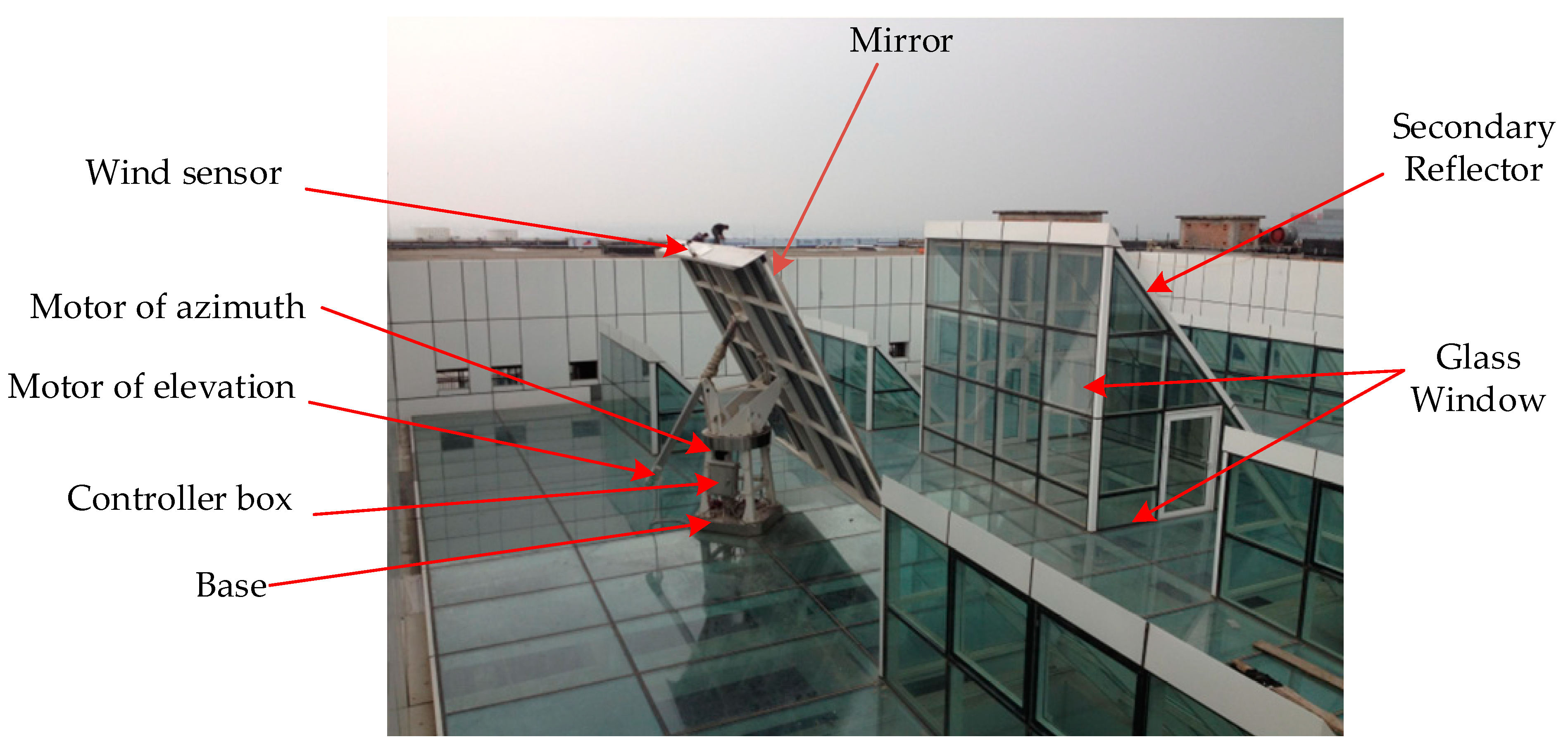

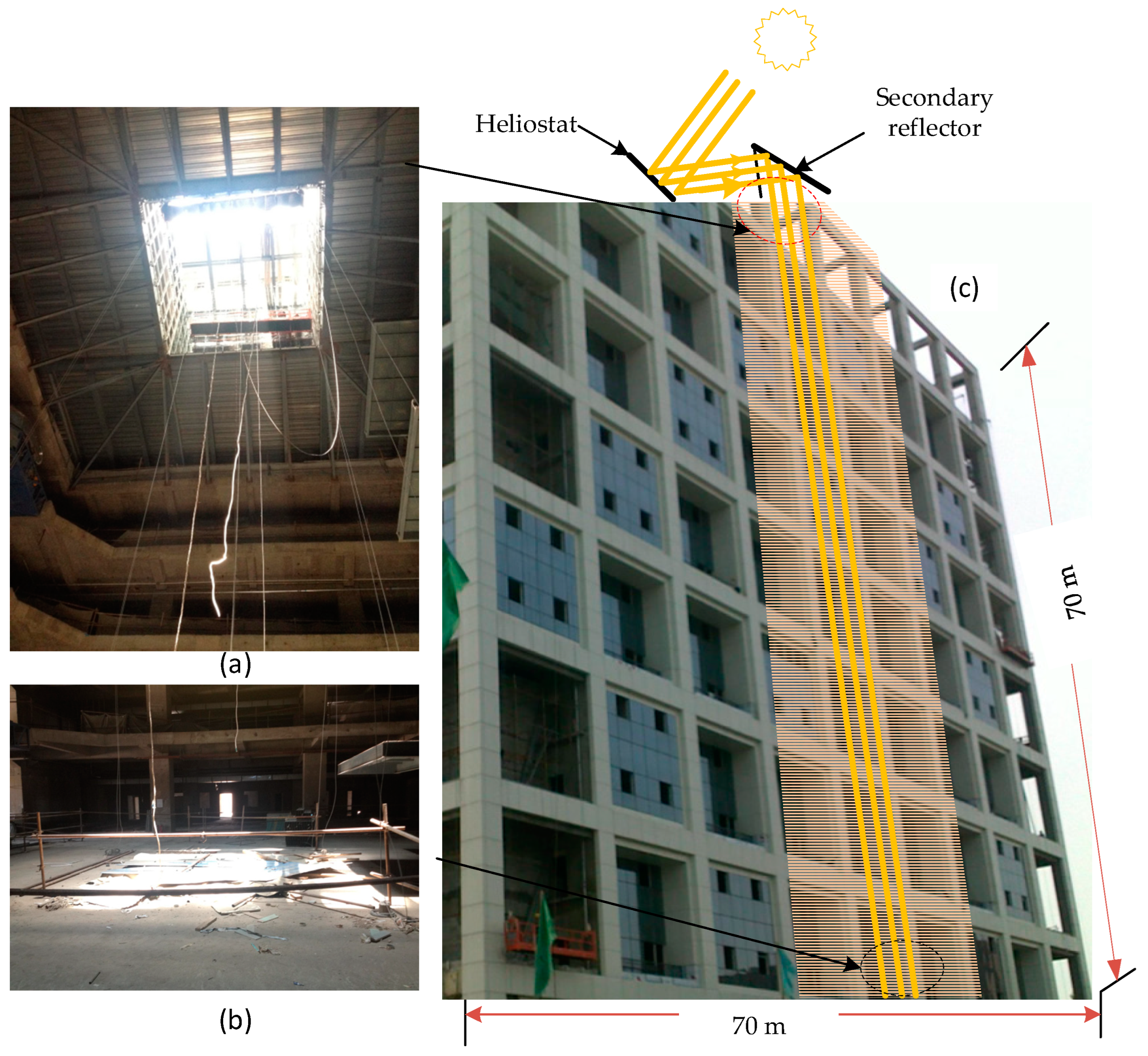

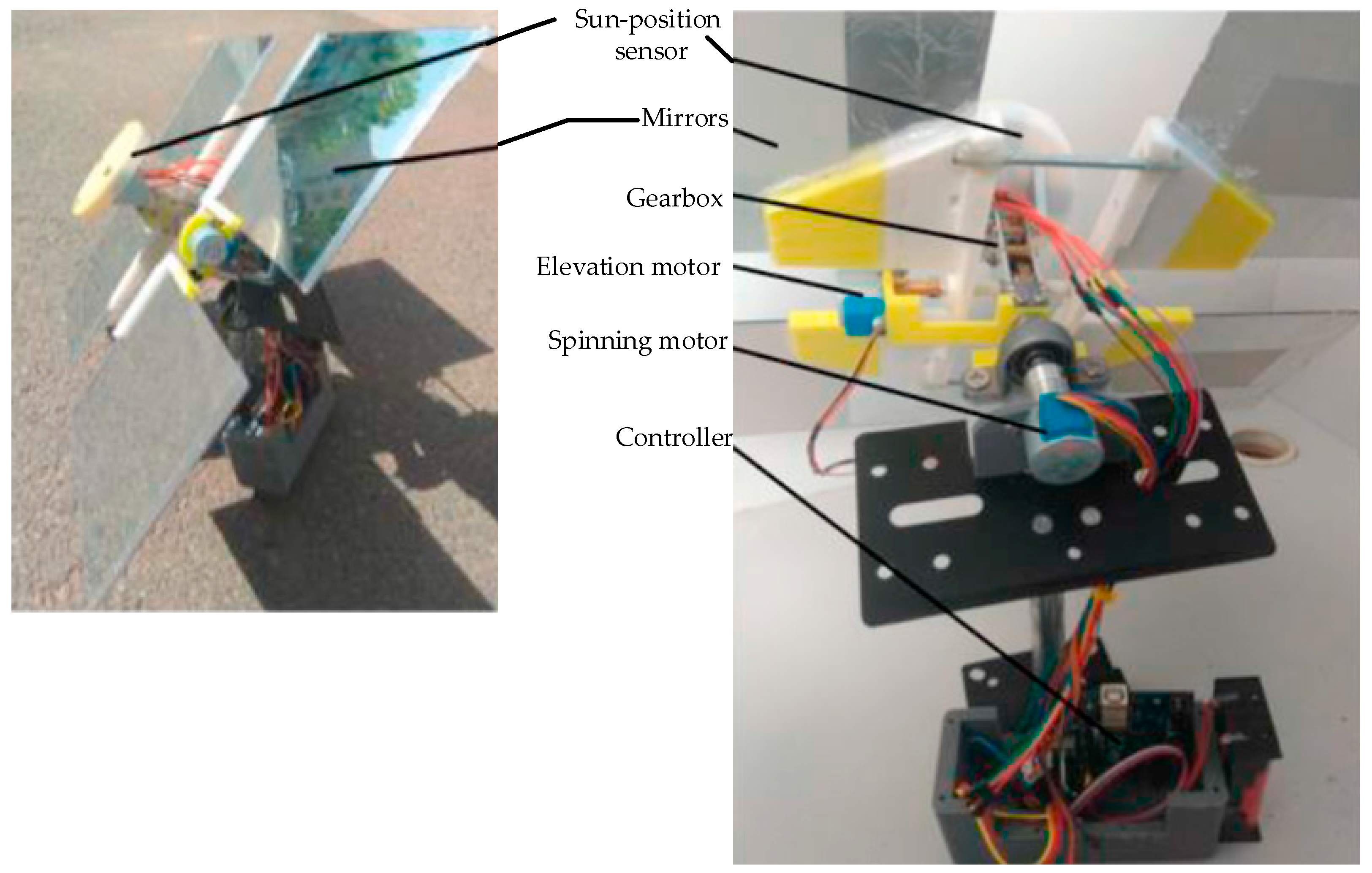

2.3. Heliostats

3. Comparison and Discussion

3.1. Installation

3.2. Efficiency

3.3. Cost

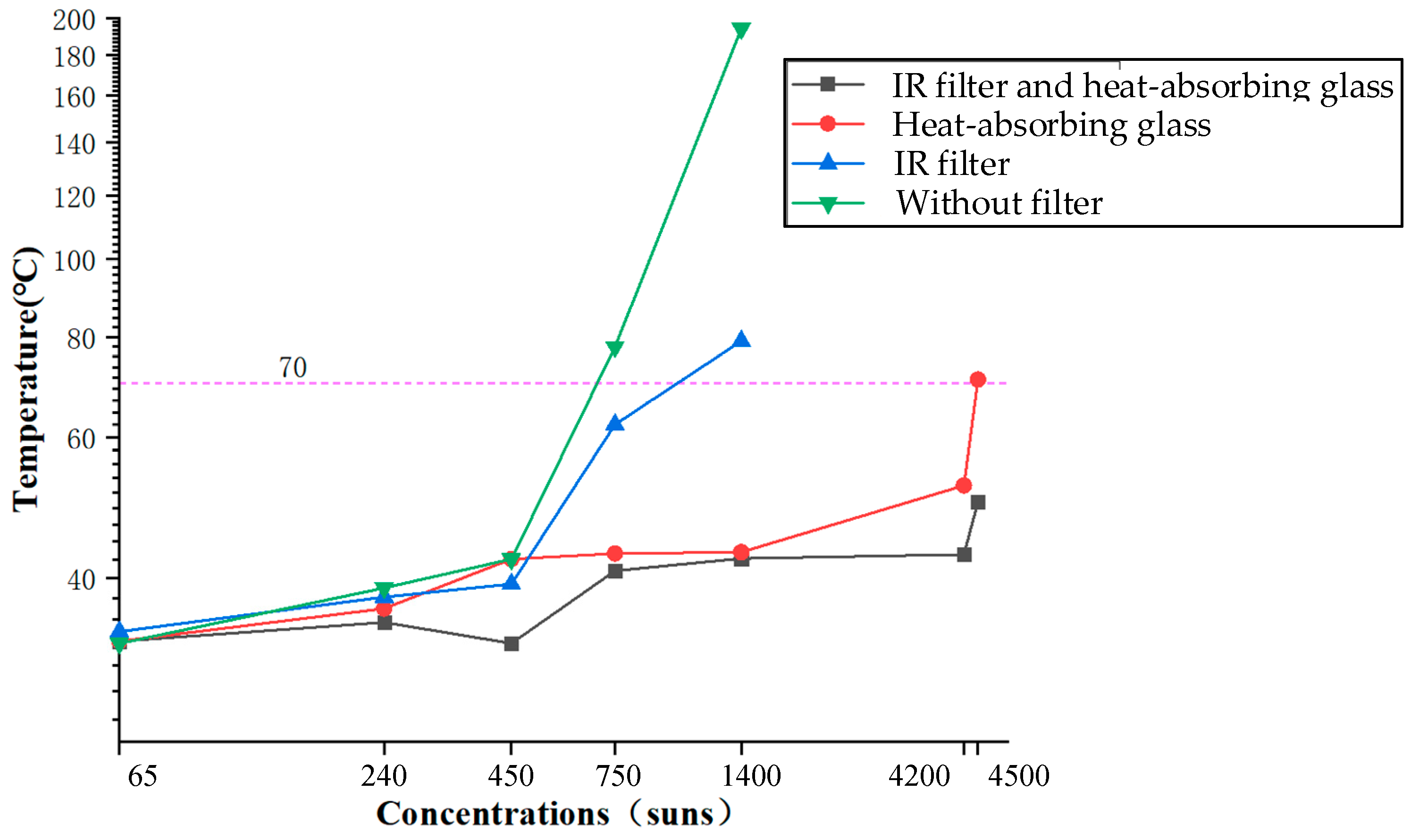

3.4. Spectrum

3.5. Hybrid Lighting System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ruck, N.; Aschehoug, Ø.; Aydinli, S. Daylight in Buildings: A Source Book on Daylighting Systems and Components; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2000.

- Ayoub, M. 100 Years of daylighting: A chronological review of daylight prediction and calculation methods. Sol. Energy 2019, 194, 360–390. [Google Scholar] [CrossRef]

- Görgülü, S.; Ekren, N. Energy saving in lighting system with fuzzy logic controller which uses light-pipe and dimmable ballast. Energy Build. 2013, 61, 172–176. [Google Scholar] [CrossRef]

- Rosemann, A.; Cox, G.; Friedel, P.; Mossman, M.; Whitehead, L. Cost-effective controlled illumination using daylighting and electric lighting in a dual-function prism light guide. Light. Res. Technol. 2008, 40, 77–88. [Google Scholar] [CrossRef]

- Doulos, L.T.; Kontadakis, A.; Madias, E.N.; Sinou, M.; Tsangrassoulis, A. Minimizing energy consumption for artificial lighting in a typical classroom of a Hellenic public school aiming for near Zero Energy Building using LED DC luminaires and daylight harvesting systems. Energy Build. 2019, 194, 201–217. [Google Scholar] [CrossRef]

- Wong, I.L. A review of daylighting design and implementation in buildings. Renew. Sustain. Energy Rev. 2017, 74, 959–968. [Google Scholar] [CrossRef] [Green Version]

- Chong, K.-K.; Onubogu, N.O.; Yew, T.-K.; Wong, C.-W.; Tan, W.-C. Design and construction of active daylighting system using two-stage non-imaging solar concentrator. Appl. Energy 2017, 207, 45–60. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Papinutto, M.; Boghetti, R.; Colombo, M.; Basurto, C.; Reutter, K.; Lalanne, D.; Kämpf, J.H.; Nembrini, J. Saving energy by max-imising daylight and minimising the impact on occupants: An automatic lighting system approach. Energy Build. 2022, 268, 112176. [Google Scholar] [CrossRef]

- Edwards, L.; Torcellini, P. Literature Review of the Effects of Natural Light on Building Occupants; National Renewable Energy Lab.: Golden, CO, USA, 2002; p. 58.

- Reinhart, C.; Selkowitz, S. Daylighting—Light, form, and people. Energy Build. 2006, 38, 715–717. [Google Scholar] [CrossRef] [Green Version]

- Costanzo, V.; Evola, G.; Marletta, L. A Review of Daylighting Strategies in Schools: State of the Art and Expected Future Trends. Buildings 2017, 7, 41. [Google Scholar] [CrossRef] [Green Version]

- Mathew, V.; Kurian, C.P.; Augustine, N. Optimizing Daylight Glare and Circadian Entrainment in a Daylight-Artificial Light Integrated Scheme. IEEE Access 2022, 10, 38174–38188. [Google Scholar] [CrossRef]

- Sharp, F.; Lindsey, D.; Dols, J.; Coker, J. The use and environmental impact of daylighting. J. Clean. Prod. 2014, 85, 462–471. [Google Scholar] [CrossRef]

- Altomonte, S. Daylight for Energy Savings and Psycho-Physiological Well-Being in Sustainable Built Environments. J. Sustain. Dev. 2009, 1, 3. [Google Scholar] [CrossRef]

- Boubekri, M. Daylight, architecture and people’s health. In Environmental Health Risk; WIT Press: Boston, MA, USA, 2007; pp. 53–59. [Google Scholar]

- Konstantzos, I.; Sadeghi, S.A.; Kim, M.; Xiong, J.; Tzempelikos, A. The effect of lighting environment on task performance in buildings—A review. Energy Build. 2020, 226, 110394. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Xia, X.; Setunge, S.; Shi, L. A review of internal and external influencing factors on energy efficiency design of buildings. Energy Build. 2020, 216, 109944. [Google Scholar] [CrossRef]

- Li, D.H.; Lam, J.C. An investigation of daylighting performance and energy saving in a daylit corridor. Energy Build. 2003, 35, 365–373. [Google Scholar] [CrossRef]

- Mechergui, A.; Krarti, M. Lighting Energy Savings from Daylighting through Skylights for Warehouses. In Proceedings of the ASME 2007 Energy Sustainability Conference, Long Beach, CA, USA, 27–30 July 2007; pp. 619–625. [Google Scholar]

- Demers, C.; Potvin, A. On the Art of Daylighting Calculations, Statutes & Decisions the Laws of the Ussr & Its Successor States. PLEA 2013, 66, 22–28. [Google Scholar]

- Rayaz, S.; Rubab, S. Review of Advanced Daylighting Systems. Mater. Sci. Forum 2013, 760, 79–84. [Google Scholar] [CrossRef]

- Xue, P.; Mak, C.; Cheung, H. New static lightshelf system design of clerestory windows for Hong Kong. Build. Environ. 2014, 72, 368–376. [Google Scholar] [CrossRef]

- Mashaly, I.A.; Nassar, K.; El-Henawy, S.I.; Mohamed, M.W.; Galal, O.; Darwish, A.; Hassan, O.N.; Safwat, A.M. A prismatic daylight redirecting fenestration system for southern skies. Renew. Energy 2017, 109, 202–212. [Google Scholar] [CrossRef]

- Freewan, A.A.; Shao, L.; Riffat, S. Interactions between louvers and ceiling geometry for maximum daylighting performance. Renew. Energy 2009, 34, 223–232. [Google Scholar] [CrossRef]

- Eltaweel, A.; Su, Y. Parametric design and daylighting: A literature review. Renew. Sustain. Energy Rev. 2017, 73, 1086–1103. [Google Scholar] [CrossRef]

- Kim, G.; Jeong, I.Y.; Kim, J.T. Visioning of prospective role of a daylighting system for sustainable feasibility in residential development. In Proceedings of the 8th International Symposium on Sustainable Healthy Buildings, Seoul, Republic of Korea, 19 September 2012. [Google Scholar]

- Whang, A.J.-W.; Yang, T.-H.; Deng, Z.-H.; Chen, Y.-Y.; Tseng, W.-C.; Chou, C.-H. A Review of Daylighting System: For Prototype Systems Performance and Development. Energies 2019, 12, 2863. [Google Scholar] [CrossRef] [Green Version]

- Mayhoub, M. Innovative daylighting systems’ challenges: A critical study. Energy Build. 2014, 80, 394–405. [Google Scholar] [CrossRef]

- Nielsen, M.D.; Mortensen, N.A.; Folkenberg, J.R. Reduced microdeformation attenuation in large-mode-area photonic crystal fibers for visible applications. Opt. Lett. 2003, 28, 1645–1647. [Google Scholar] [CrossRef] [Green Version]

- Tsangrassoulis, A.; Shading; Systems, D.; Boemi, S.-N.; Irulegi, O.; Santamouris, M. (Eds.) Energy Performance of Buildings: Energy Efficiency and Built Environment in Temperate Climates; Springer International Publishing: Cham, Switzerland, 2016; pp. 437–466. [Google Scholar]

- Zain-Ahmed, A.; Sopian, K.; Othman, M.; Sayigh, A.; Surendran, P. Daylighting as a passive solar design strategy in tropical buildings: A case study of Malaysia. Energy Convers. Manag. 2002, 43, 1725–1736. [Google Scholar] [CrossRef]

- Garcia-Hansen, V.; Esteves, A.; Pattini, A. Passive solar systems for heating, daylighting and ventilation for rooms without an equator-facing facade. Renew. Energy 2002, 26, 91–111. [Google Scholar] [CrossRef]

- Ochoa, C.E.; Capeluto, I.G. Evaluating visual comfort and performance of three natural lighting systems for deep office build-ings in highly luminous climates. Build. Environ. 2006, 41, 1128–1135. [Google Scholar] [CrossRef]

- Canziani, R.; Peron, F.; Rossi, G. Daylight and energy performances of a new type of light pipe. Energy Build. 2004, 36, 1163–1176. [Google Scholar] [CrossRef]

- Guo, M.; Wang, Z.; Liang, W.; Zhang, X.; Zang, C.; Lu, Z.; Wei, X. Tracking formulas and strategies for a receiver oriented dual-axis tracking toroidal heliostat. Sol. Energy 2010, 84, 939–947. [Google Scholar] [CrossRef]

- Ruck, N.; Oppenheim, D.; Roy, G.; Klinger, M.; de Herde, A.; Bodart, M.; Atif, M.; Love, J.; Carpenter, S. Daylight in Buildings, ECBCS Annex 29/SHC Task 21 Project Summary Report; AECOM Ltd.: UK, 2010; ISBN 978-0-9562808-2-4. [Google Scholar]

- Scartezzini, J.-L.; Courret, G. Anidolic daylighting systems. Sol. Energy 2002, 73, 123–135. [Google Scholar] [CrossRef]

- Köster, H. Daylighting Controls, Performance, and Global Impacts. In Encyclopedia of Sustainability Science and Technology; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- El-Hafeez, M.A.; Youssef, W.F.; El-Enein, U.A.; Elrayies, G.M. Daylight Transportation: A Green Lighting Technology to Save Energy. Port-Said Eng. Res. J. 2010, 14, 150–168. [Google Scholar]

- Zastrow, A.; Wittwer, V. Daylighting with Mirror Light Pipes and with Fluorescent Planar Concentrators. First Results Demonstr. Proj. Stuttg.-Hohenh. 1987, 692, 227–234. [Google Scholar]

- Ciugudeanu, C.; Beu, D. Passive Tubular Daylight Guidance System Survey. Procedia Technol. 2016, 22, 690–696. [Google Scholar] [CrossRef] [Green Version]

- Oakley, G.; Riffat, S.; Shao, L. Daylight performance of lightpipes. Sol. Energy 2000, 69, 89–98. [Google Scholar] [CrossRef]

- Malet-Damour, B.; Boyer, H.; Fakra, A.H.; Bojic, M. Light Pipes Performance Prediction: Inter Model and Experimental Confron-tation on Vertical Circular Light-guides. Energy Procedia 2014, 57, 1977–1986. [Google Scholar] [CrossRef]

- Baroncini, C.; Boccia, O.; Chella, F.; Zazzini, P. Experimental analysis on a 1:2 scale model of the double light pipe, an innovative technological device for daylight transmission. Sol. Energy 2010, 84, 296–307. [Google Scholar] [CrossRef]

- Kim, J.T.; Kim, G. Overview and new developments in optical daylighting systems for building a healthy indoor environment. Build. Environ. 2010, 45, 256–269. [Google Scholar] [CrossRef]

- Rosemann, A.; Kaase, H. Combined daylight systems for lightpipe applications. Int. J. Low-Carbon Technol. 2006, 1, 10–21. [Google Scholar] [CrossRef] [Green Version]

- Carter, D.J. Developments in tubular daylight guidance systems. Build. Res. Inf. 2004, 32, 220–234. [Google Scholar] [CrossRef]

- Rosemann, A.; Kaase, H. Lightpipe applications for daylighting systems. Sol. Energy 2005, 78, 772–780. [Google Scholar] [CrossRef]

- Khosravi, S.; Mossman, M.A.; Whitehead, L.A. Core Sunlighting System, a New Approach to Daylighting in Buildings. Energy Procedia 2014, 57, 1951–1960. [Google Scholar] [CrossRef] [Green Version]

- Kumar, N.; Patil, S. Solar day-lighting using optical fibers. In Proceedings of the 2012 International Conference on Fiber Optics and Photonics (PHOTONICS), Chennai, India, 9–12 December 2012; pp. 1–3. [Google Scholar]

- Lingfors, D.; Volotinen, T. Illumination performance and energy saving of a solar fiber optic lighting system. Opt. Express 2013, 21 (Suppl. S4), A642–A655. [Google Scholar] [CrossRef]

- Munaaim, M.A.C.; Al-Obaidi, K.M.; Ismail, M.R.; Rahman, A.M.A. Empirical Evaluation of the Effect of Heat Gain from Fiber Optic Daylighting System on Tropical Building Interiors. Sustainability 2014, 6, 9231–9243. [Google Scholar] [CrossRef] [Green Version]

- Lawless, S.; Gorthala, R. Development of a Fiber-Optic Hybrid Day-Lighting System for Mobile Shelter Applications. In PRO-Ceedings of the ASME 11th International Conference on Energy Sustainability; American Society of Mechanical Engineers: New York, NY, USA, 2017; Volume 2017, p. V001T009A004. [Google Scholar]

- Lawless, S.; Gorthala, R. Design and Development of a Fiber-Optic Hybrid Day-Lighting System. J. Sol. Energy Eng. 2018, 140, 021012. [Google Scholar] [CrossRef] [Green Version]

- Ullah, I.; Lv, H.; Whang, A.J.-W.; Su, Y. Analysis of a novel design of uniformly illumination for Fresnel lens-based optical fiber daylighting system. Energy Build. 2017, 154, 19–29. [Google Scholar] [CrossRef]

- Sapia, C. Daylighting in buildings: Developments of sunlight addressing by optical fiber. Sol. Energy 2013, 89, 113–121. [Google Scholar] [CrossRef]

- Ullah, I.; Shin, S. Development of optical fiber-based daylighting system with collimated illumination. In Proceedings of the 2012 17th Opto-Electronics and Communications Conference, Busan, Republic of Korea, 2–6 July 2012; pp. 596–597. [Google Scholar]

- Ullah, I.; Shin, S. Uniformly Illuminated Efficient Daylighting System. Smart Grid Renew. Energy 2013, 04, 161–166. [Google Scholar] [CrossRef]

- Mayhoub, M.S.; Carter, D. Towards hybrid lighting systems: A review. Light. Res. Technol. 2010, 42, 51–71. [Google Scholar] [CrossRef]

- Song, J.; Jin, Z.; Zhu, Y.; Zhou, Z.; Yang, Y. Development of a fiber daylighting system based on the parallel mechanism and direct focus detection. Sol. Energy 2015, 115, 484–493. [Google Scholar] [CrossRef]

- Osuna, R.; Morillo, R.; Jimenez, J.M. Control and operation stategies in PS10 tower plant. In Proceedings of the 13th Solar Paces, Seville, Spain, 20–23 June 2006. [Google Scholar]

- Han, H.; Kim, J.T. Application of high-density daylight for indoor illumination. Energy 2010, 35, 2654–2666. [Google Scholar] [CrossRef]

- Sedki, L.; Maaroufi, M. Performance Assessment of Installed Low Cost Solar Daylighting System via Optical Fiber. Energy Eng. 2017, 114, 37–55. [Google Scholar] [CrossRef]

- Sedki, L.; Maaroufi, M. Design of parabolic solar daylighting systems based on fiber optic wires: A new heat filtering device. Energy Build. 2017, 152, 434–441. [Google Scholar] [CrossRef]

- Kim, Y.; Jeong, H.J.; Kim, W.; Chun, W.; Han, H.J.; Sang, H.L. A comparative performance analysis on daylighting for two different types of solar concentrators: Dish vs. Fresnel lens. Energy 2017, 137, 449–456. [Google Scholar] [CrossRef]

- Tsangrassoulis, A.; Doulos, L.; Santamouris, M.; Fontoynont, M.; Maamari, F.; Wilson, M.; Jacobs, A.; Solomon, J.; Zimmerman, A.; Pohl, W.; et al. On the energy efficiency of a prototype hybrid daylighting system. Sol. Energy 2005, 79, 56–64. [Google Scholar] [CrossRef]

- Vu, N.-H.; Shin, S. Cost-effective optical fiber daylighting system using modified compound parabolic concentrators. Sol. Energy 2016, 136, 145–152. [Google Scholar] [CrossRef]

- Obianuju, O.N.; Chong, K.-K. High Acceptance Angle Optical Fiber Based Daylighting System Using Two-stage Reflective Non-imaging Dish Concentrator. Energy Procedia 2017, 105, 498–504. [Google Scholar] [CrossRef]

- Chen, W.; Abdul-Rahman, H.; Rao, S.P. A design of fluorescent fiber solar concentrator (FFSC) and outdoor testing for remote indoor day lighting. In Proceedings of the 5th International Conference on Responsive Manufacturing—Green Manufacturing (ICRM 2010), Ningbo, China, 11–13 January 2010; pp. 320–328. [Google Scholar]

- Chen, W.; Abdul-Rahman, H.; Rao, S.P. Development and Testing of a Fluorescent Fiber Solar Concentrator for Remote Day-lighting. J. Energy Eng. 2010, 136, 76–86. [Google Scholar]

- Lv, Y.; Xia, L.; Yan, J.; Bi, J. Design of a Hybrid Fiber Optic Daylighting and PV Solar Lighting System. Energy Procedia 2018, 145, 586–591. [Google Scholar] [CrossRef]

- Guo, M.; Wang, Z.; Zhang, J.; Sun, F.; Zhang, X. Accurate altitude–azimuth tracking angle formulas for a heliostat with mirror–pivot offset and other fixed geometrical errors. Sol. Energy 2011, 85, 1091–1100. [Google Scholar] [CrossRef]

- Chong, K.; Tan, M. Range of motion study for two different sun-tracking methods in the application of heliostat field. Sol. Energy 2011, 85, 1837–1850. [Google Scholar] [CrossRef]

- Song, J.; Luo, G.; Li, L.; Tong, K.; Yang, Y.; Zhao, J. Application of heliostat in interior sunlight illumination for large buildings. Renew. Energy 2018, 121, 19–27. [Google Scholar] [CrossRef]

- Peña-García, A.; Gil-Martín, L.M.; Hernández-Montes, E. Use of sunlight in road tunnels: An approach to the improvement of light-pipes’ efficacy through heliostats. Tunn. Undergr. Space Technol. 2016, 60, 135–140. [Google Scholar] [CrossRef]

- Guo, M.; Sun, F.; Wang, Z.; Zhang, J. Properties of a general azimuth–elevation tracking angle formula for a heliostat with a mirror-pivot offset and other angular errors. Sol. Energy 2013, 96, 159–167. [Google Scholar] [CrossRef]

- Wei, X.; Lu, Z.; Yu, W.; Zhang, H.; Wang, Z. Tracking and ray tracing equations for the target-aligned heliostat for solar tower power plants. Renew. Energy 2011, 36, 2687–2693. [Google Scholar] [CrossRef]

- Chen, Y.T.; Kribus, A.; Lim, B.H.; Lim, C.S.; Chong, K.K.; Karni, J.; Buck, R.; Pfahl, A.; Bligh, T.P. Comparison of Two Sun Tracking Methods in the Application of a Heliostat Field. J. Sol. Energy Eng. 2004, 126, 638–644. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Aziz, D.; Al-Qudah, E.A.; Yasien, H.Y.; Hamad, R. Improving the Day Lighting of Deep-Plan Buildings by Means of Light Piping Technique: The Case of Architectural Studios in the Department of Architecture, University of Jordan. Interna-Tional J. Civ. Eng. Technol. 2019, 10, 1755–1764. [Google Scholar]

- Omishore, A. Light pipe prototype testing. Electrotech. Rev. Prz. Elektrotechniczny 2018, 1, 109–114. [Google Scholar] [CrossRef] [Green Version]

- Obradovic, B.; Matusiak, B.S. Daylight Transport Systems for Buildings at High Latitudes. J. Daylighting 2019, 6, 60–79. [Google Scholar] [CrossRef]

- Ng, Y.F.; Hashim, M.S.M.; Din, M.A.Z.; Amin, N.A.M.; Kamarrudin, N.S.; Basha, M.H.; Tasyrif, M. Effect of various bending angles on a passive light pipe for eco-daylighting systems. J. Phys. Conf. Ser. 2017, 908, 012078. [Google Scholar] [CrossRef]

- Francini, F.; Fontani, D.; Sansoni, P. Transport of Light by Optical Fibers and Light Pipes. In Sustainable Indoor Lighting; Sansoni, P., Mercatelli, L., Farini, A., Eds.; Springer: London, UK, 2015; pp. 195–210. [Google Scholar]

- Edmonds, I.R.; Moore, G.I.; Smith, G.B.; Swift, P.D. Daylighting enhancement with light pipes coupled to laser-cut light-deflect-ing panels. Int. J. Light. Res. Technol. 1995, 27, 27–35. [Google Scholar] [CrossRef]

- Obradovic, B.; Matusiak, B.S. Daylight autonomy improvement in buildings at high latitudes using horizontal light pipes and light-deflecting panels. Sol. Energy 2020, 208, 493–514. [Google Scholar] [CrossRef]

- Diéguez’, A.P.; Gentile, N.; Von Wachenfelt, H.; Duboisb, M.-C.; Dubois, M.-C. Daylight Utilization with Light Pipe in Farm Animal Production: A Simulation Approach. J. Daylighting 2016, 3, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Ikuzwe, A.; Sebitosi, A. A novel design of a daylighting system for a classroom in rural South Africa. Sol. Energy 2015, 114, 349–355. [Google Scholar] [CrossRef]

- Peña-García, A.; Cabeza-Lainez, J. Daylighting of road tunnels through external ground-based light-pipes and complex reflec-tive geometry. Tunn. Undergr. Space Technol. 2023, 131, 104788. [Google Scholar] [CrossRef]

- Beltran, L.O.; Lee, E.S.; Papmichael, K.M.; Selkowitz, S.E. The Design and Evaluation of Three Advanced Daylighting Systems: Light Shelves, Light Pipes and Skylights; Lawrence Berkeley Lab.: Berkeley, CA, USA, 1994.

- Song, J.; Wu, Z.; Wang, J.; Zhang, K.; Wang, K.; Liu, K.; Duan, L.; Hou, H. Application of highly concentrated sunlight transmission and daylighting indoor via plastic optical fibers with comprehensive cooling approaches. Renew. Energy 2021, 180, 1391–1404. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Du, J. The potential of circadian lighting in office buildings using a fibre optics daylighting system in Beijing. Build. Environ. 2020, 182, 107118. [Google Scholar] [CrossRef]

- Yao, Q.; Cai, W.; Li, M.; Hu, Z.; Xue, P.; Dai, Q. Efficient circadian daylighting: A proposed equation, experimental validation, and the consequent importance of room surface reflectance. Energy Build. 2020, 210, 109784. [Google Scholar] [CrossRef]

- Casquero-Modrego, N. Optical fiber light scattering outdoor tests for interior daylighting. Energy Build. 2019, 198, 138–1488. [Google Scholar] [CrossRef]

- Ndujiuba, C.U.; John, S.N.; Onasoga, K. Optic Fibericity—The New Era Lighting. Int. J. Energy Eng. 2014, 4, 69–74. [Google Scholar]

- Yang, Z.; Li, L.; Wang, J.; Wang, W.; Song, J. Realization of high flux daylighting via optical fibers using large Fresnel lens. Sol. Energy 2019, 183, 204–211. [Google Scholar] [CrossRef]

- Vu, D.T.; Nghiem, V.T.; Tien, T.Q.; Hieu, N.M.; Minh, K.N.; Vu, H.; Shin, S.; Vu, N.H. Optimizing optical fiber daylighting system for indoor agriculture applications. Sol. Energy 2022, 247, 1–12. [Google Scholar] [CrossRef]

- Whang, A.J.-W.; Chen, Y.-Y.; Wu, B.-Y. Innovative design of cassegrain solar concentrator system for indoor illumination utiliz-ing chromatic aberration to filter out ultraviolet and infrared in sunlight. Sol. Energy 2009, 83, 1115–1122. [Google Scholar] [CrossRef]

- Kavitha, T.; Pappa, C.K.; Shobana, R.; Raj, A.A.; Ahilan, A.; Veerasamy, B.; Gnanamalar, A.J. Advanced day lighting system using fiber optics. Opt. Quantum Electron. 2023, 55, 525. [Google Scholar] [CrossRef]

- Blanc, P.; Espinar, B.; Geuder, N.; Gueymard, C.; Meyer, R.; Pitz-Paal, R.; Reinhardt, B.; Renné, D.; Sengupta, M.; Wald, L.; et al. Direct normal irradiance related definitions and applications: The circumsolar issue. Sol. Energy 2014, 110, 561–577. [Google Scholar] [CrossRef]

- Buie, D.; Monger, A. The effect of circumsolar radiation on a solar concentrating system. Sol. Energy 2004, 76, 181–185. [Google Scholar] [CrossRef]

- Buie, D.; Monger, A.; Dey, C. Sunshape distributions for terrestrial solar simulations. Sol. Energy 2003, 74, 113–122. [Google Scholar] [CrossRef]

- Wilbert, S.; Reinhardt, B.; DeVore, J.; Röger, M.; Pitz-Paal, R.; Gueymard, C.; Buras, R. Measurement of Solar Radiance Profiles With the Sun and Aureole Measurement System. J. Sol. Energy Eng. 2013, 135, 041002. [Google Scholar] [CrossRef]

- Gleckman, P.; O’Gallagher, J.; Winston, R. Concentration of sunlight to solar-surface levels using non-imaging optics. Nature 1989, 339, 198–200. [Google Scholar] [CrossRef]

- Rabl, A. Comparison of solar concentrators. Sol. Energy 1976, 18, 93–111. [Google Scholar] [CrossRef]

- Song, J.; Yang, Y.; Zhu, Y.; Jin, Z. A high precision tracking system based on a hybrid strategy designed for concentrated sunlight transmission via fibers. Renew. Energy 2013, 57, 12–19. [Google Scholar] [CrossRef]

- Gorthala, R.; Tidd, M.; Lawless, S. Design and development of a faceted secondary concentrator for a fiber-optic hybrid solar lighting system. Sol. Energy 2017, 157, 629–640. [Google Scholar] [CrossRef]

- Liu, K.; Zou, L.; Li, Y.; Wang, K.; Wang, H.; Song, J. Measurement and Analysis of Light Leakage in Plastic Optical Fiber Daylight-ing System. Sustainability 2023, 15, 3155. [Google Scholar] [CrossRef]

- Feuermann, D.; Gordon, J.M.; Huleihil, M. Light leakage in optical fibers: Experimental results, modeling and the consequences for solar concentrators. Sol. Energy 2002, 72, 195–204. [Google Scholar] [CrossRef]

- Song, J.; Luo, G.; Tong, K.; Li, L.; Yang, Y. A note on dispersion phenomenon in the fiber daylighting system with the Fresnel lens. Sol. Energy 2018, 161, 6–8. [Google Scholar] [CrossRef]

- Ashby, M.F. Materials Selection in Mechanical Design, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2005; p. 519. ISBN 978-0-7506-6168-3. [Google Scholar]

- Song, J.; Zhu, Y.; Tong, K.; Yang, Y.; Reyes-Belmonte, M. A note on the optic characteristics of daylighting system via PMMA fibers. Sol. Energy 2016, 136, 32–34. [Google Scholar] [CrossRef]

- Wang, K.; Wang, Q.; Zou, L.; Su, Y.; Liu, K.; Li, W.; Zhang, K.; Wang, H.; Song, J. Study on thermal protection and temperature of PMMA plastic optical fiber for concentrated sunlight transmission in daylighting. Sol. Energy 2023, 253, 127–136. [Google Scholar] [CrossRef]

- Yu, S.; Shi, L.; Zhang, L.; Liu, Z.; Tu, Y. A solar optical reflection lighting system for threshold zone of short tunnels: Theory and practice. Tunn. Undergr. Space Technol. 2023, 131, 104839. [Google Scholar] [CrossRef]

- Fernández-Ahumada, L.M.; Osuna-Mérida, M.; López-Sánchez, J.; Gómez-Uceda, F.J.; López-Luque, R.; Varo-Martínez, M. Use of Polar Heliostats to Improve Levels of Natural Lighting inside Buildings with Little Access to Sunlight. Sensors 2022, 22, 5996. [Google Scholar] [CrossRef]

- Luo, G.; Li, L.; Wang, J.; Wang, W.; Song, J.; Yang, Y. A heliostat integrated with a sun-position sensor for daylighting. Energy Procedia 2019, 158, 394–399. [Google Scholar] [CrossRef]

- Sedki, M.M.L. Feasibility Study of Low Cost Solar Energy Day Lighting System via Optical Fiber: A Case study of Rabat City in Morocco. In Proceedings of the 2015 3rd International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 10–13 December 2015. [Google Scholar]

- Fraas, L.M.; Pyle, W.R.; Ryason, P.R. Concentrated and piped sunlight for indoor illumination. Appl. Opt. 1983, 22, 578–582. [Google Scholar] [CrossRef] [PubMed]

- Ge, A.; Qiu, P.; Cai, J.; Wang, W.; Wang, J. Hybrid daylight/light-emitting diode illumination system for indoor lighting. Appl. Opt. 2014, 53, 1869–1873. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, J.; Pei, J.; Cao, X.; Chen, Q.; Jiang, Y. Experimental and simulation study on the performance of daylighting in an industrial building and its energy saving potential. Energy Build. 2014, 73, 184–191. [Google Scholar] [CrossRef]

- Krarti, M.; Erickson, P.M.; Hillman, T.C. A simplified method to estimate energy savings of artificial lighting use from daylight-ing. Build. Environ. 2005, 40, 747–754. [Google Scholar] [CrossRef]

- Lam, J.C.; Li, D.H.; Cheung, S. An analysis of electricity end-use in air-conditioned office buildings in Hong Kong. Build. Environ. 2003, 38, 493–498. [Google Scholar] [CrossRef]

- Mayhoub, M.; Carter, D. A feasibility study for hybrid lighting systems. Build. Environ. 2012, 53, 83–94. [Google Scholar] [CrossRef]

- Tsuei, C.H.; Sun, W.S.; Kuo, C.C. Hybrid sunlight/LED illumination and renewable solar energy saving concepts for indoor lighting. Opt. Express 2010, 18 (Suppl. S4), A640–A653. [Google Scholar] [CrossRef]

| DTT | Reference | Concentrator | Tracking | Structure | Length | Fiber Material | Collecting Area | Concentration Ratio | Type |

|---|---|---|---|---|---|---|---|---|---|

| Light Pipe | [41] | FPC | No | 6.5 m | PMMA | 0.29 m2 | – | Experiment | |

| [42] | Flat concentrator | No | 2.5 m | Acrylic | 0.36 | Experiment | |||

| [43] | No | No | – | 2.77–4 m | 0.0855 m2 | – | Experiment | ||

| [44] | No | No | – | 1 m | 0.049 m2 | – | Experiment | ||

| [45] | No | No | – | 3 m | 0.196 m2 | – | Experiment | ||

| [46] | No | No | – | 1.3 m | 0.332 m2 | – | Experiment | ||

| [47,48,49] | Fresnel lens | Yes | A–E | 12.5 m | 6.20 m2 | <100 | Experiment | ||

| [50] | Linear Fresnel lens | Yes | – | 15 m | 0.6 m2 | – | Simulation | ||

| Optical Fiber | [51] | Fresnel lens | Yes | A–E | 1 m | PMMA | – | – | Experiment |

| [52,53] | Fresnel lens | Yes | A–E | 10 m | PMMA | – | – | Experiment | |

| [54,55] | Fresnel lens | Yes | A–E | 6.7–11 m | Plastic | – | – | Experiment | |

| [56] | Fresnel lens | Yes | A–E | – | plastic | 0.09 m2 | 585 | Simulation | |

| [57] | Parabolic collector | Yes | – | 10 m | Plastic | 4.48 m2 | |||

| Flat optical reflector | |||||||||

| [58,59] | parabolic reflector | Yes | A–E | – | Silica + plastic | 0.09 m2 | – | Experiment | |

| Fresnel/dish | 0.0804 m2 | – | |||||||

| [60] | Fresnel lens | Yes | P–M | <20 m | PMMA | 0.48 m2 | <1634 | Experiment | |

| [61] | Fresnel lens | Yes | P–M | 10 m | PMMA | 0.48 m2 | 2500 | Experiment | |

| [29,62] | Convex lens | Yes | A–E | 200 m | Silica | – | 10,000 | Experiment | |

| [63] | Parabolic dish | Yes | A–E | 5 m | 0.07 m2 | – | Experiment | ||

| [64] | Parabolic dish | Yes | A–E | 3 m | PMMA | 0.785 m2 | 600 | Experiment | |

| [65] | Parabolic dish | Yes | A–E | 6 m | PMMA | 0.785 m2 | 976 | Experiment | |

| [66] | Fresnel lens | Yes | A–E | 10 m | PMMA | 0.073 m2 | – | Experiment | |

| [67] | Fresnel lens | Yes | A–E | 10 m | Liquid+ PMMA | 0.785 m2 | 3906 | Experiment | |

| [68] | Funnel concentrator | Yes | A–E | 5 m | Plastic | 0.000314 m2 | 100 | Experiment | |

| [7,69] | Mirrors | Yes | A–E | 10 m | PMMA | 0.2 m2 | <100 | Experiment | |

| [70,71] | Flat concentrator | No | A–E | 1 m | PMMA | 1.44 m2 | 25 | Experiment | |

| [72] | Fresnel lens | Yes | A–E | 2.5 m | PMMA | 0.0254 m2 | 400 | Experiment | |

| Heliostat | [46] | No | Yes | A–E | 12 m | 0.442 m2 | [73,74] | Experiment | |

| [27] | No | Yes | A–E | >26 m | 8.03 m2 | – | Experiment | ||

| [75] | No | Yes | A–E | 70 m | 22.95 m2 | – | Experiment | ||

| [76] | No | Yes | A–E | 1.85 m | 0.016 m2 | – | Experiment | ||

| [77] | No | Yes | S–E | 20 m | 0.1 m2 | [78,79] | Experiment |

| Light Pipe Length | Internal Average Irradiance (W/m2) | ||

|---|---|---|---|

| At Noon 15° | In the Morning 45° | In the Morning 90° | |

| 500 mm | 23.6 | 109.8 | 473 |

| 700 mm | 20 | 105.6 | 472 |

| 2000 mm | 12.8 | 68.4 | 447 |

| The Incidence Angle of The Sun | 15° | 45° | 90° | |

|---|---|---|---|---|

| Light Pipe Length | ||||

| 500 mm | 5.90% | 18.30% | 47.30% | |

| 700 mm | 5.50% | 17.60% | 47.20% | |

| 2000 mm | 3.20% | 11.40% | 44.70% | |

| Parameters | Light Pipes | Optical Fiber | Heliostat |

|---|---|---|---|

| Materials used | Al/Ag | PMMA | Mirrors |

| Spectrum | Natural spectrum | Very close to the natural spectrum | Natural spectrum |

| Transmission efficiency (%) | 44.7 | 18 | 23 |

| Transmission distance (m) | 2 | 20 | 70 |

| Photo effect (lm/w) | 150 | 220 | 110 |

| Color rendering index (CRI) | 98.9 | 89.1 | 98.3 |

| Daylighting Technologies | Advantages | Disadvantages |

|---|---|---|

Light pipes |

|

|

Plastic Optical fiber |

|

|

Heliostat |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Dessie, B.B.; Gao, L. Analysis and Comparison of Daylighting Technologies: Light Pipe, Optical Fiber, and Heliostat. Sustainability 2023, 15, 11044. https://doi.org/10.3390/su151411044

Song J, Dessie BB, Gao L. Analysis and Comparison of Daylighting Technologies: Light Pipe, Optical Fiber, and Heliostat. Sustainability. 2023; 15(14):11044. https://doi.org/10.3390/su151411044

Chicago/Turabian StyleSong, Jifeng, Bizuayehu Bogale Dessie, and Longyu Gao. 2023. "Analysis and Comparison of Daylighting Technologies: Light Pipe, Optical Fiber, and Heliostat" Sustainability 15, no. 14: 11044. https://doi.org/10.3390/su151411044