New Evacuated Tube Solar Collector with Parabolic Trough Collector and Helical Coil Heat Exchanger for Usage in Domestic Water Heating

Abstract

:1. Introduction

2. Description of the ETSC

3. Mathematical Model

- -

- The energy loss occurring between the external cover of the solar collector and the surrounding area is similar to the thermal loss between the heat exchanger and the cover.

- -

- The heat transfer coefficient is assumed to be uniform along the tube.

- -

- The temperatures of the heat exchanger and HTF are practically equivalent.

- -

- The convective heat transfer coefficient between the surrounding environment and the glass tube is constant.

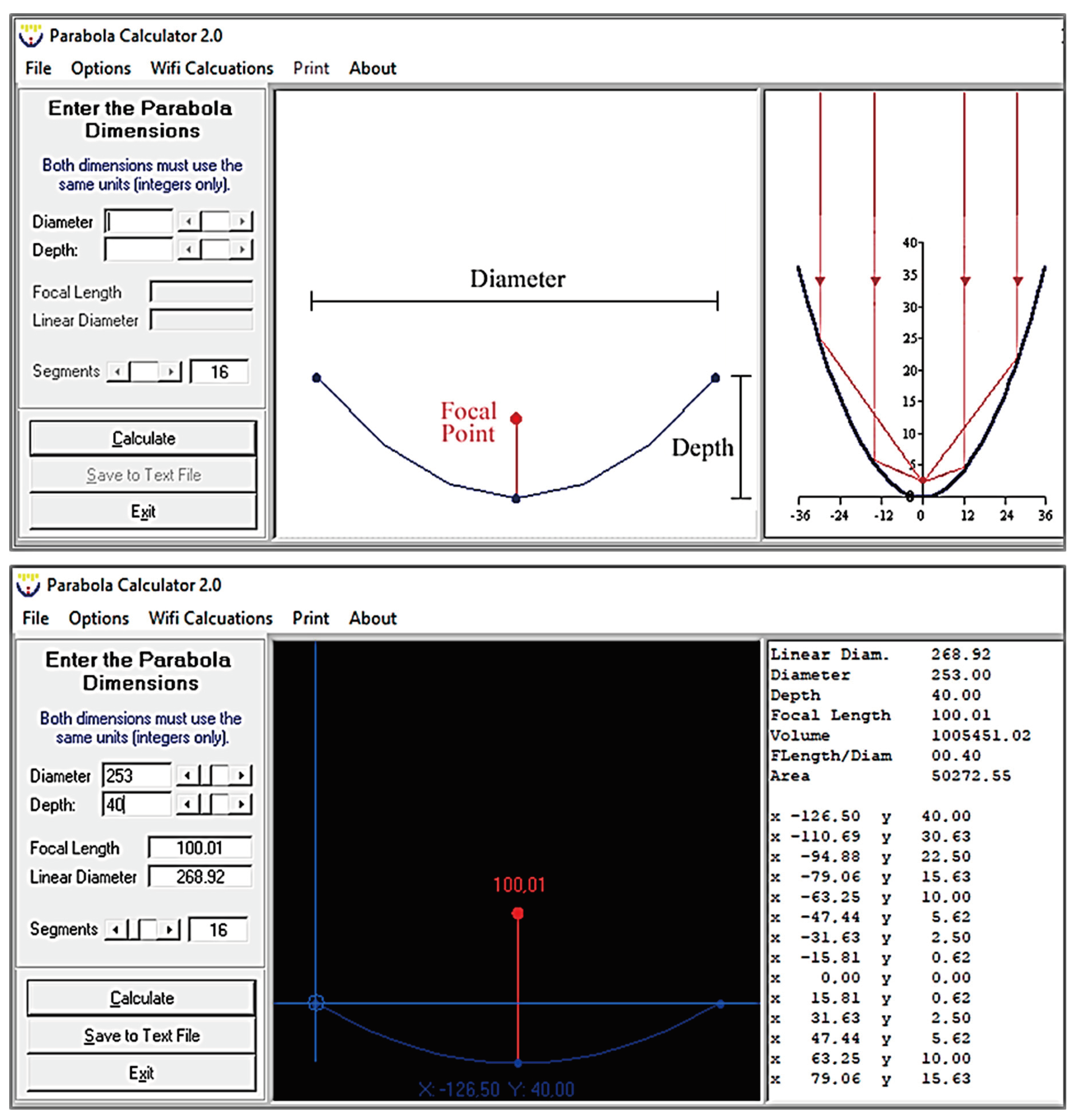

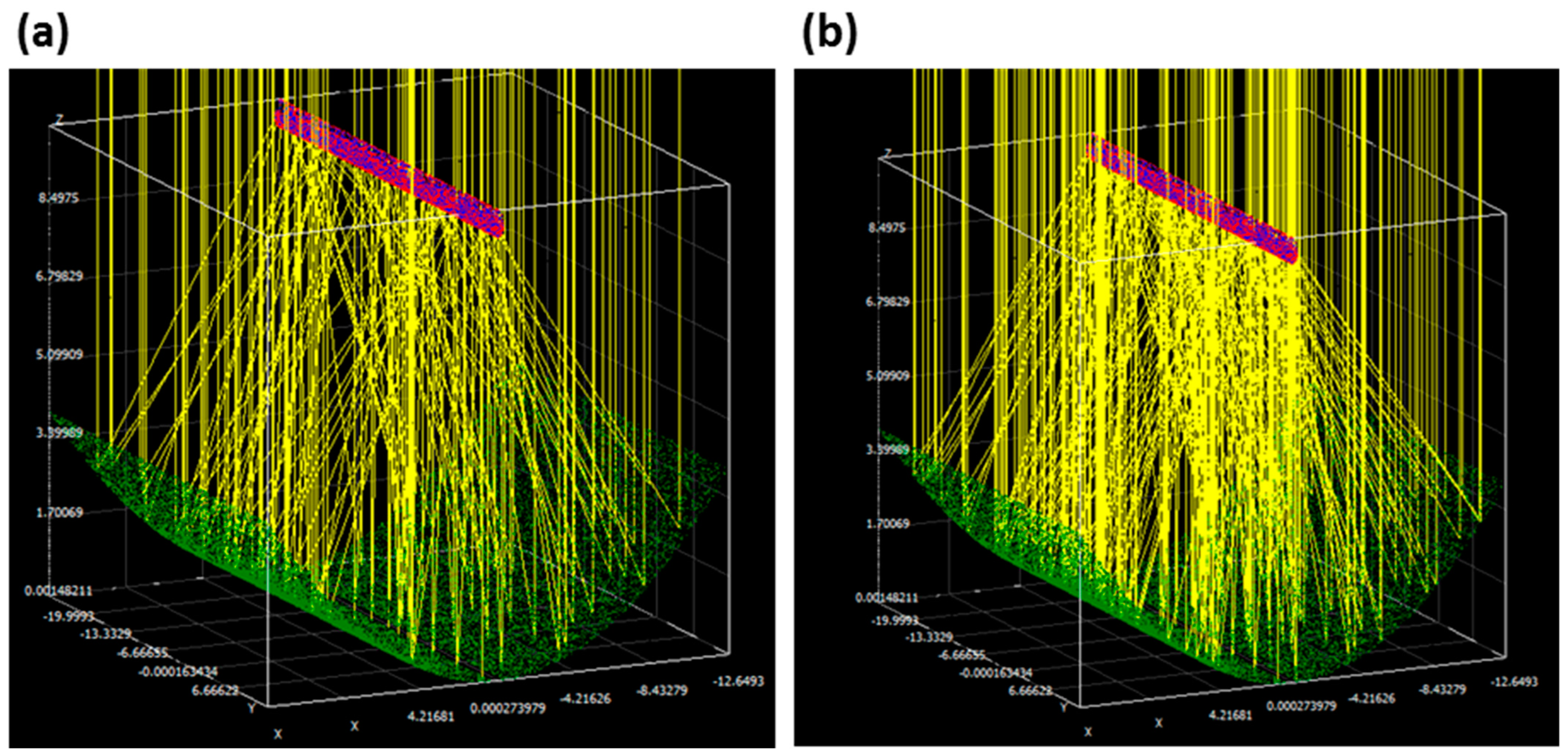

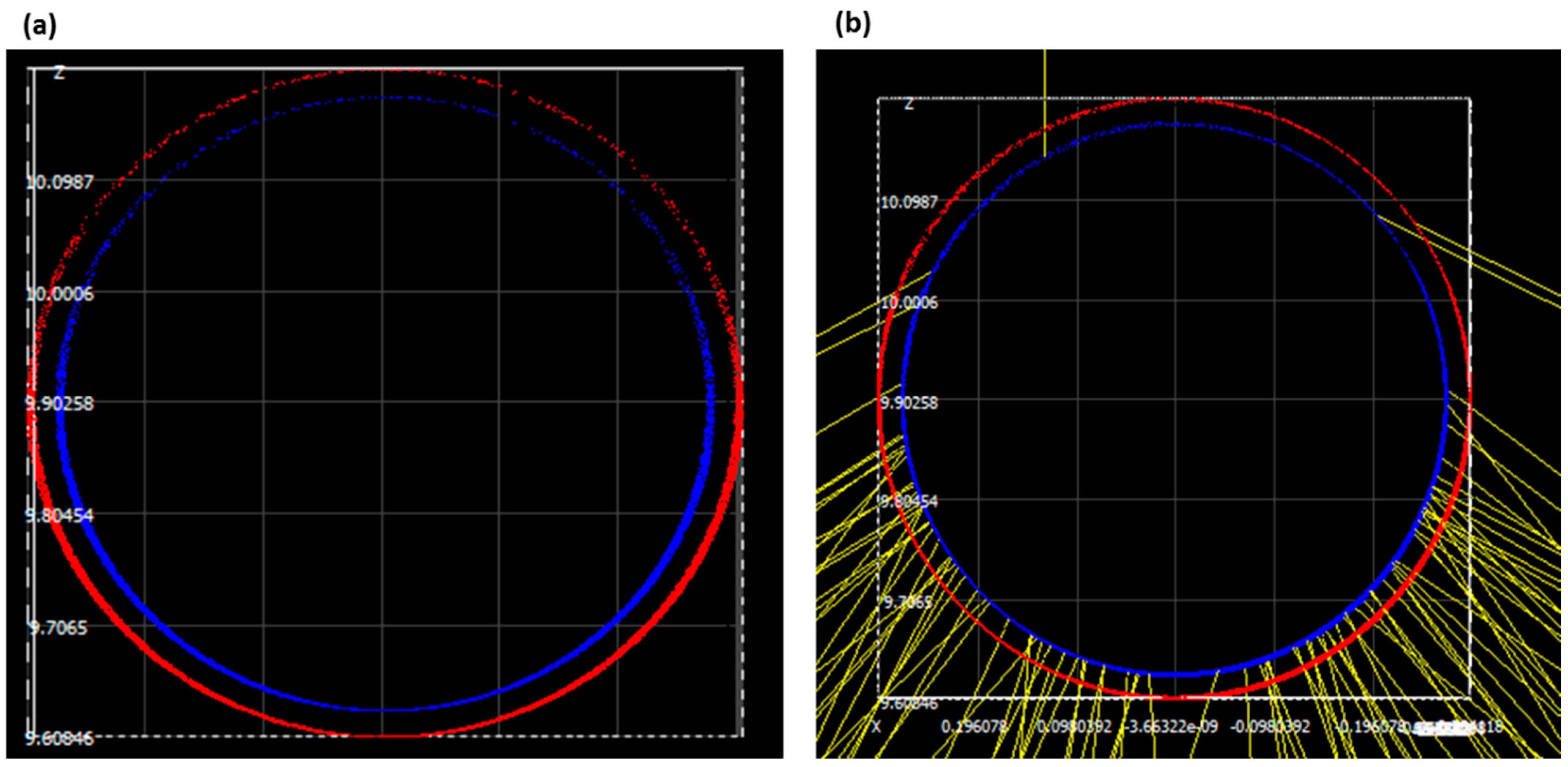

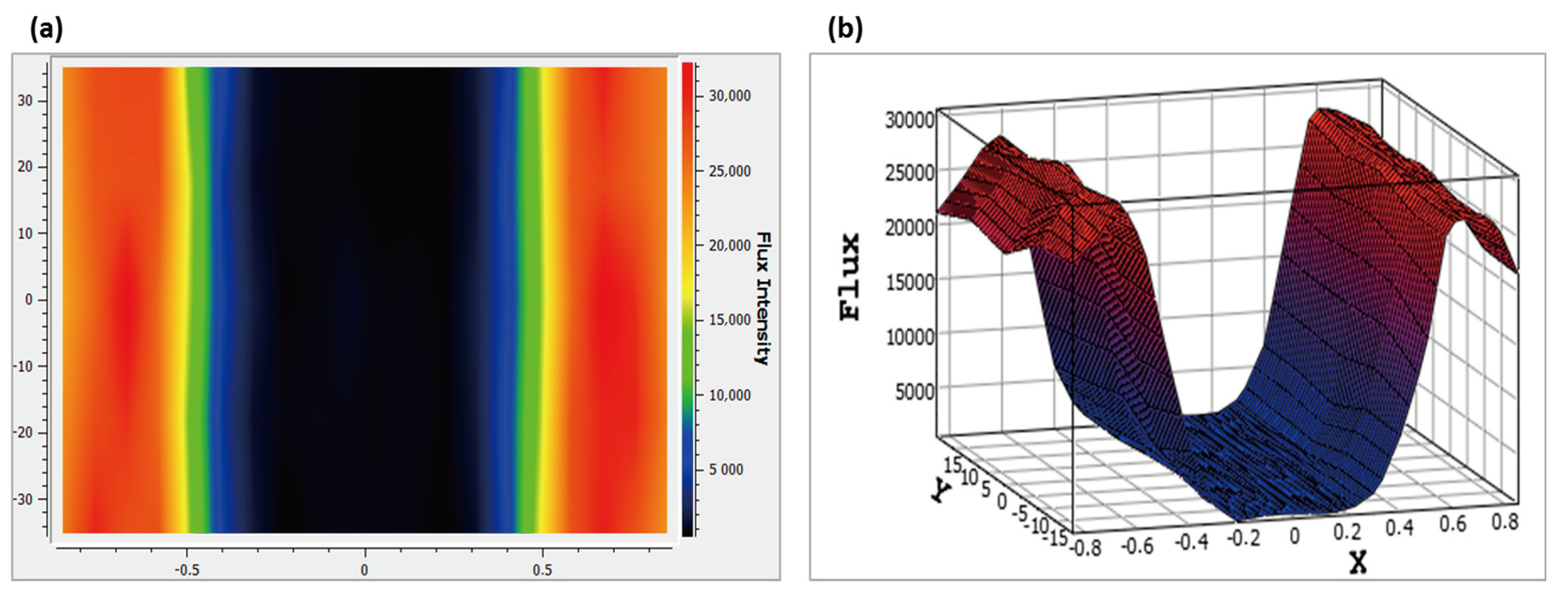

4. Simulation of the Solar Radiation toward an ETSC Integrated with a Parabolic Trough Solar Collector

5. Results and Discussions

5.1. Simulation of the Solar Radiation

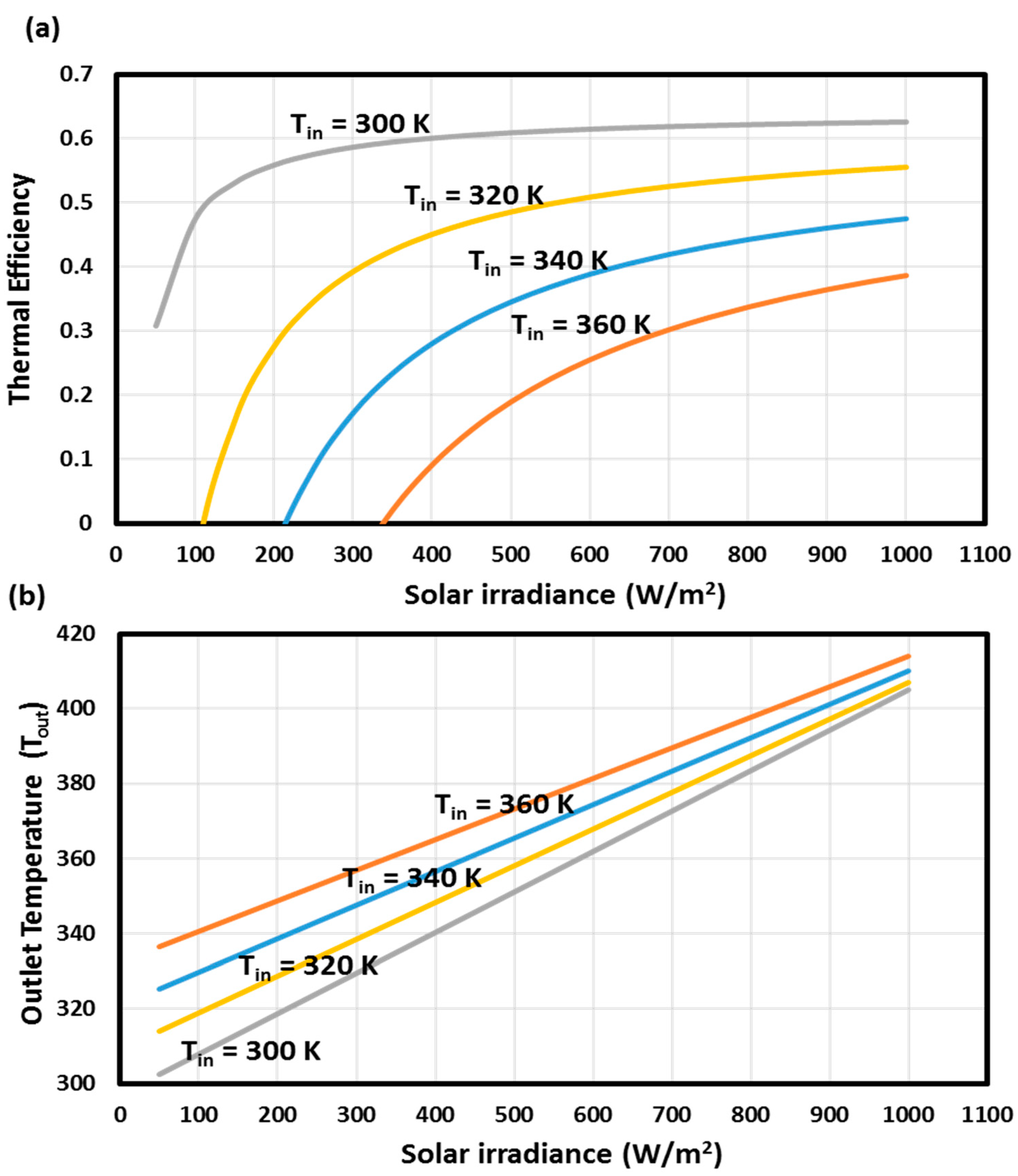

5.2. Effect of the Solar Irradiance

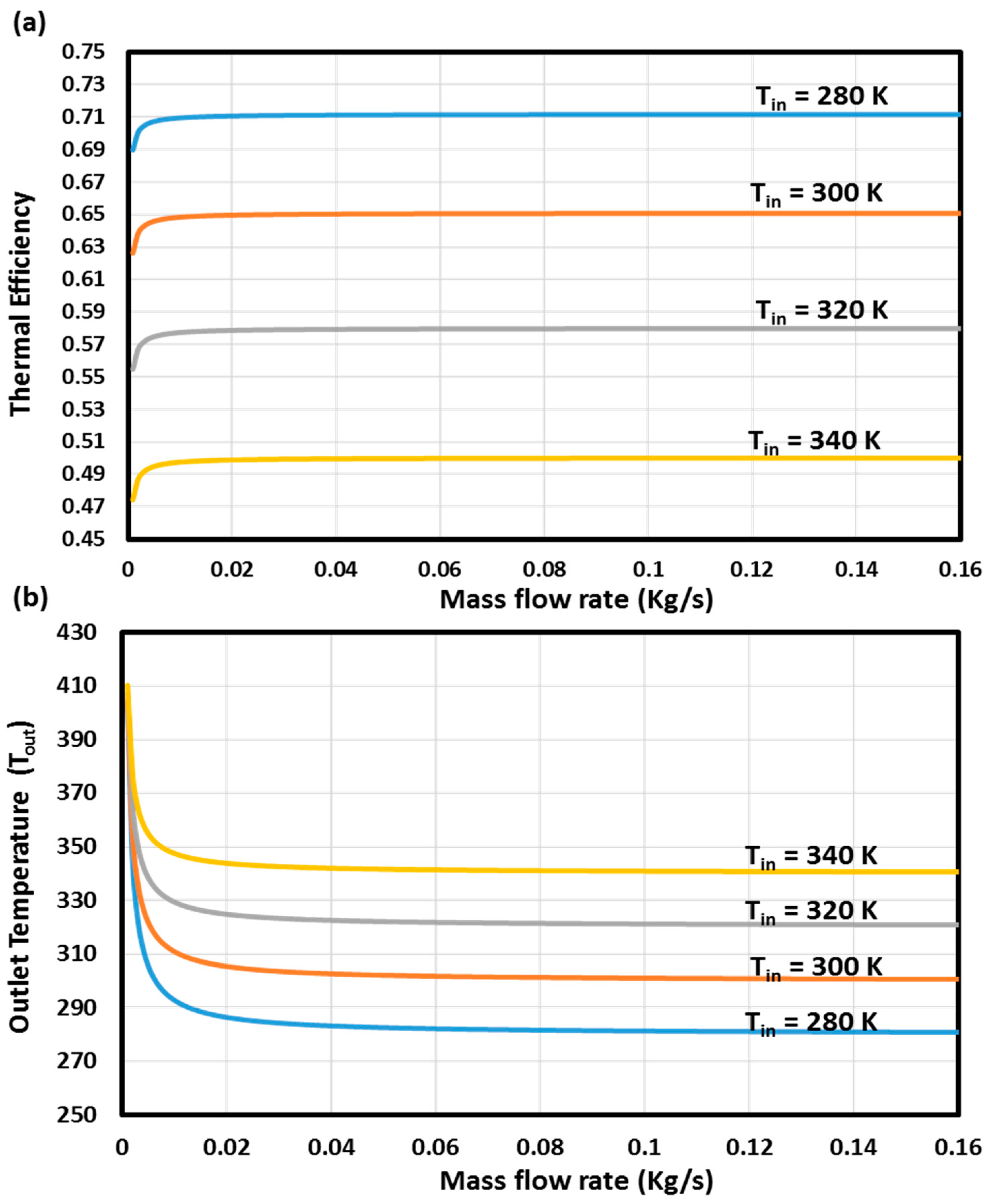

5.3. Effect of the Mass Flow Rate

5.4. Effect of the Heat Transfer Coefficient

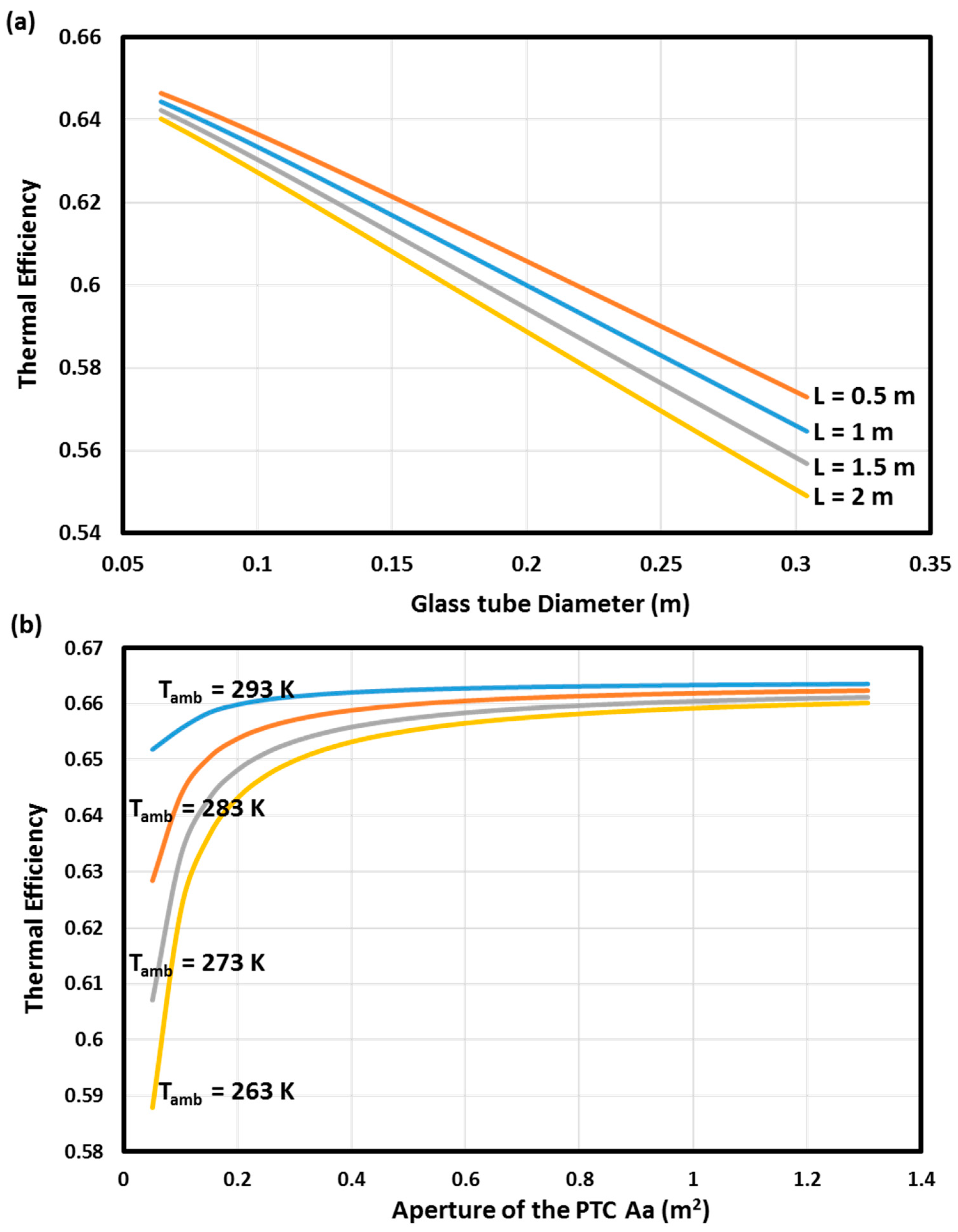

5.5. Effects of the Geometric Parameters

6. Conclusions

- -

- The ETSC provided a higher HTF temperature (reaching 418 K) by employing higher solar intensities of 1000 W/m2 and using a 300 K inlet HTF temperature.

- -

- The ETSC system achieved an efficiency of 72% by employing an inlet HTF temperature of 280 K.

- -

- The new ETSC performs better by employing lower mass flow rates and higher heat transfer coefficients.

- -

- The use of a lower ETSC length and a lower diameter of the glass tube resulted in great performance with a maximum of 65%.

- -

- A large PTC aperture area also provides higher efficiency, which reaches 66%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Inlet temperature (K) | |

| Outlet temperature (K) | |

| Mean fluid temperature (K) | |

| Ambient temperature (K) | |

| Cover temperature (K) | |

| Solar beam radiation (W/m2) | |

| Mass flow rate (Kg/s) | |

| Specific heat (J/Kg·K) | |

| Diameter of the absorber tube (m) | |

| Helical coil diameter (m) | |

| Outer diameter of the coil tube (m) | |

| Pitch of the helical coil tube (m) | |

| Heat transfer coefficient between the cover and the atmosphere (W/m2·K) | |

| Heat transfer coefficient between the HTF and the absorber (W/m2·K) | |

| Thermal conductivity (W/m·K) | |

| Area of the outer absorber tube (m2) | |

| Inner cover area (m2) | |

| Useful heat flow (W) | |

| Solar energy (W) | |

| Heat flow of the absorber tube (W) | |

| Heat losses (W) | |

| Nu | Nusselt number |

| Re | Reynolds number |

| Pr | Prandtl number |

| Greek symbols | |

| Dynamic viscosity (Kg/m·s) | |

| Emittance of the absorber tube | |

| Equivalent emittance | |

| Emittance of the cover | |

| Stefan-Boltzmann constant (W/m2·K4) | |

| Optical efficiency | |

| Thermal efficiency | |

| Abbreviations | |

| ETSC | Evacuated tube solar collector |

| PTC | Parabolic trough collector |

| HTF | Heat transfer fluid |

References

- Jebasingh, V.; Herbert, G.J. A review of solar parabolic trough collector. Renew. Sustain. Energy Rev. 2016, 54, 1085–1091. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Kannan, N.; Vakeesan, D. Solar energy for future world—A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pandey, A.; Sari, A. Global advancement on experimental and thermal analysis of evacuated tube collector with and without heat pipe systems and possible applications. Appl. Energy 2018, 228, 351–389. [Google Scholar] [CrossRef]

- Sabiha, M.A.; Saidur, R.; Mekhilef, S.; Mahian, O. Progress and latest developments of evacuated tube solar collectors. Renew. Sustain. Energy Rev. 2015, 51, 1038–1054. [Google Scholar] [CrossRef]

- Shafieian, A.; Khiadani, M.; Nosrati, A. A review of latest developments, progress, and applications of heat pipe solar collectors. Renew. Sustain. Energy Rev. 2018, 95, 273–304. [Google Scholar] [CrossRef]

- Priyanka, K.B. Thermal performance investigation of evacuated tube heat pipe solar collector integrated with parabolic Trough. IJARIIE 2017, 3, 2395–4396. [Google Scholar]

- Upadhyay, B.H.; Patel, A.J.; Ramana, P.V. A detailed review on solar parabolic trough collector. Int. J. Ambient. Energy 2019, 43, 176–196. [Google Scholar] [CrossRef]

- Odeh, S.D.; Abu-Mulaweh, H.I. Design and development of an educational solar tracking parabolic trough collector system. Glob. J. Eng. Educ. 2013, 15, 21–27. [Google Scholar]

- Abdulhamed, A.J.; Adam, N.M.; Ab-Kadir, M.Z.A.; Hairuddin, A.A. Review of solar parabolic-trough collector geometrical and thermal analyses, performance, and applications. Renew. Sustain. Energy Rev. 2018, 91, 822–831. [Google Scholar] [CrossRef]

- Haddock, C.; McKee, J.S.C. Solar energy collection, concentration, and thermal conversion—A review. Energy Sources 1991, 13, 461–482. [Google Scholar] [CrossRef]

- Hafez, A.; Attia, A.; Eltwab, H.; ElKousy, A.; Afifi, A.; AbdElhamid, A.; AbdElqader, A.; Fateen, S.-E.; El-Metwally, K.; Soliman, A.; et al. Design analysis of solar parabolic trough thermal collectors. Renew. Sustain. Energy Rev. 2018, 82, 1215–1260. [Google Scholar] [CrossRef]

- Fuqiang, W.; Ziming, C.; Jianyu, T.; Yuan, Y.; Yong, S.; Linhua, L. Progress in concentrated solar power technology with parabolic trough collector system: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 79, 1314–1328. [Google Scholar] [CrossRef]

- Tagle-Salazar, P.D.; Nigam, K.D.P.; Rivera-Solorio, C.I. Parabolic trough solar collectors: A general overview of technology, industrial applications, energy market, modeling, and standards. Green Process. Synth. 2020, 9, 595–649. [Google Scholar] [CrossRef]

- Pandey, S.; Mishra, S.K.; Sharma, A.; Verma, A.K.; Yadav, L. Performance analysis of evacuated tube type solar air heater with parabolic trough type collector. Int. J. Energy Water Resour. 2021, 6, 337–351. [Google Scholar] [CrossRef]

- Tzivanidis, C.; Bellos, E.; Korres, D.; Antonopoulos, K.; Mitsopoulos, G. Thermal and optical efficiency investigation of a parabolic trough collector. Case Stud. Therm. Eng. 2015, 6, 226–237. [Google Scholar] [CrossRef] [Green Version]

- Elarem, R.; Alqahtani, T.; Mellouli, S.; Aich, W.; Ben Khedher, N.; Kolsi, L.; Jemni, A. Numerical study of an Evacuated Tube Solar Collector incorporating a Nano-PCM as a latent heat storage system. Case Stud. Therm. Eng. 2021, 24, 100859. [Google Scholar] [CrossRef]

- Bassem, S.; Jalil, J.M.; Ismael, S.J. Investigation of Thermal Performance of Evacuated Tube with Parabolic Trough Collector with and without Porous Media. IOP Conf. Ser. Earth Environ. Sci. 2022, 961, 012045. [Google Scholar] [CrossRef]

- Naik, B.K.; Premnath, S.; Muthukumar, P. Performance comparison of evacuated U-tube solar collector integrated parabolic reflector with conventional evacuated U-tube solar collector. Sādhanā 2021, 46, 137. [Google Scholar] [CrossRef]

- Abo-Elfadl, S.; Hassan, H.; El-Dosoky, M. Energy and exergy assessment of integrating reflectors on thermal energy storage of evacuated tube solar collector-heat pipe system. Sol. Energy 2020, 209, 470–484. [Google Scholar] [CrossRef]

- Rezaeian, M.; Dehaj, M.S.; Mohiabadi, M.Z.; Salarmofrad, M.; Shamsi, S. Experimental investigation into a parabolic solar collector with direct flow evacuated tube. Appl. Therm. Eng. 2021, 189, 116608. [Google Scholar] [CrossRef]

- Dawood, M.M.K.; Nabil, T.; Kabeel, A.; Shehata, A.I.; Abdalla, A.M.; Elnaghi, B.E. Experimental study of productivity progress for a solar still integrated with parabolic trough collectors with a phase change material in the receiver evacuated tubes and in the still. J. Energy Storage 2020, 32, 102007. [Google Scholar] [CrossRef]

- Shah, S.F.; Manzoor, S.; Mazoor, A.; Iqbal, A.; Asif, M.; Jafry, A.T. Modelling and Experimental Analysis of a Novel Evacuated Tubes based Parabolic Trough Solar Collector for Water Heating Applications. In Proceedings of the 2021 International Conference on Emerging Power Technologies (ICEPT), Topi, Pakistan, 10–11 April 2021. [Google Scholar] [CrossRef]

- Fathabadi, H. Impact of utilizing reflector, single-axis and two-axis sun trackers on the performance of an evacuated tube solar collector. Int. J. Green Energy 2020, 17, 742–755. [Google Scholar] [CrossRef]

- Feliński, P.; Sekret, R. Effect of a low cost parabolic reflector on the charging efficiency of an evacuated tube collector/storage system with a PCM. Sol. Energy 2017, 144, 758–766. [Google Scholar] [CrossRef]

- Nabil, T.; Dawood, M.M.K. Numerical and experimental investigation of parabolic trough collector with focal evacuated tube and different working fluids integrated with single slope solar still. Heat Transf. 2020, 50, 2007–2032. [Google Scholar] [CrossRef]

- Xu, L.; Wang, Z.; Yuan, G.; Li, X.; Ruan, Y. A new dynamic test method for thermal performance of all-glass evacuated solar air collectors. Sol. Energy 2012, 86, 1222–1231. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A.; Daniil, I. The use of gas working fluids in parabolic trough collectors—An energetic and exergetic analysis. Appl. Therm. Eng. 2016, 109, 1–14. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Assessment of the thermal enhancement methods in parabolic trough collectors. Int. J. Energy Environ. Eng. 2017, 9, 59–70. [Google Scholar] [CrossRef] [Green Version]

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. A detailed working fluid investigation for solar parabolic trough collectors. Appl. Therm. Eng. 2016, 114, 374–386. [Google Scholar] [CrossRef]

- Abed, N.; Afgan, I. An extensive review of various technologies for enhancing the thermal and optical performances of parabolic trough collectors. Int. J. Energy Res. 2020, 44, 5117–5164. [Google Scholar] [CrossRef] [Green Version]

- Bellos, E.; Tzivanidis, C. Analytical Expression of Parabolic Trough Solar Collector Performance. Designs 2018, 2, 9. [Google Scholar] [CrossRef] [Green Version]

- Ma, L.; Lu, Z.; Zhang, J.; Liang, R. Thermal performance analysis of the glass evacuated tube solar collector with U-tube. Build. Environ. 2010, 45, 1959–1967. [Google Scholar] [CrossRef]

- Mangal, D.; Lamba, D.K.; Gupta, T.; Jhamb, K. Acknowledgement of Evacuated Tube Solar Water Heater Over Flat Plate Solar Water Heater. Int. J. Eng. 2010, 4, 279–284. [Google Scholar]

- Mahdi, Q.S.; Fattah, S.A.; juma Abd, F. Experimental and Numerical Investigation to Evaluate the Performance of Helical Coiled Tube Heat Exchanger. J. Eng. Dev. 2014, 18, 89–110. [Google Scholar]

- Moawed, M. Experimental study of forced convection from helical coiled tubes with different parameters. Energy Convers. Manag. 2011, 52, 1150–1156. [Google Scholar] [CrossRef]

- Riyandwita, B.W.; Awwaluddin, M.; Hastuty, S. Performance evaluation of helical coil heat exchanger with annulus shell side using computational fluid dynamics. AIP Conf. Proc. 2019, 2180, 020039. [Google Scholar] [CrossRef]

- Liu, X.; Huang, J.; Mao, Q. Sensitive Analysis for the Efficiency of a Parabolic Trough Solar Collector Based on Orthogonal Experiment. Int. J. Photoenergy 2015, 2015, 151874. [Google Scholar] [CrossRef] [Green Version]

- Macedo-Valencia, J.; Ramírez-Ávila, J.; Acosta, R.; Jaramillo, O.; Aguilar, J. Design, Construction and Evaluation of Parabolic Trough Collector as Demonstrative Prototype. Energy Procedia 2014, 57, 989–998. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.; Lohani, R.B. Sensitivity Analysis of Parabolic Trough Collector in SolTrace. In Proceedings of the 2019 IEEE 1st International Conference on Energy, Systems and Information Processing (ICESIP), Chennai, India, 4–6 July 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Cheng, Z.D.; He, Y.L.; Cui, F.Q.; Du, B.C.; Zheng, Z.J.; Xu, Y. Comparative and Sensitive Analysis for Parabolic Trough Solar Collectors with A DetailedMonte Carlo Ray-Tracing Optical Model. Appl. Energy 2014, 115, 559–572. [Google Scholar] [CrossRef]

- Said, S.; Mellouli, S.; Alqahtani, T.; Algarni, S.; Ajjel, R.; Ghachem, K. An Experimental Comparison of the Performance of Various Evacuated Tube Solar Collector Designs. Sustainability 2023, 15, 5533. [Google Scholar] [CrossRef]

- Chopra, K.; Pathak, A.K.; Tyagi, V.; Pandey, A.; Anand, S.; Sari, A. Thermal performance of phase change material integrated heat pipe evacuated tube solar collector system: An experimental assessment. Energy Convers. Manag. 2019, 203, 112205. [Google Scholar] [CrossRef]

- Siuta-Olcha, A.; Cholewa, T.; Dopieralska-Howoruszko, K. Experimental studies of thermal performance of an evacuated tube heat pipe solar collector in Polish climatic conditions. Environ. Sci. Pollut. Res. 2020, 28, 14319–14328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Parabolic trough Solar Collector | Evacuated Tube Solar Collector | ||

|---|---|---|---|

| Focal length (mm) | 100.01 | Glass diameter (mm) | 58 |

| Diameter (mm) | 253 | Inner pipe diameter (mm) | 54 |

| Depth (mm) | 40 | Length (mm) | 700 |

| Length (mm) | 700 | ||

| Rim angle | 60° | ||

| PTC | Glass Tube | Absorber Tube | |

|---|---|---|---|

| Reflectivity | 0.96 | 0 | 0.96 |

| Refraction | 1 | 1 | 0.1 |

| Transmissivity | 0.95 | 0.95 | 1 |

| Slope error (mrad) | 3 | 0.0001 | 0.0001 |

| Speculiarity error (mrad) | 0.5 | 0.0001 | 0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Said, S.; Mellouli, S.; Alqahtani, T.; Algarni, S.; Ajjel, R. New Evacuated Tube Solar Collector with Parabolic Trough Collector and Helical Coil Heat Exchanger for Usage in Domestic Water Heating. Sustainability 2023, 15, 11497. https://doi.org/10.3390/su151511497

Said S, Mellouli S, Alqahtani T, Algarni S, Ajjel R. New Evacuated Tube Solar Collector with Parabolic Trough Collector and Helical Coil Heat Exchanger for Usage in Domestic Water Heating. Sustainability. 2023; 15(15):11497. https://doi.org/10.3390/su151511497

Chicago/Turabian StyleSaid, Sana, Sofiene Mellouli, Talal Alqahtani, Salem Algarni, and Ridha Ajjel. 2023. "New Evacuated Tube Solar Collector with Parabolic Trough Collector and Helical Coil Heat Exchanger for Usage in Domestic Water Heating" Sustainability 15, no. 15: 11497. https://doi.org/10.3390/su151511497