Sustainable Energy Progress via Integration of Thermal Energy Storage and Other Performance Enhancement Strategies in FPCs: A Synergistic Review

Abstract

:1. Introduction

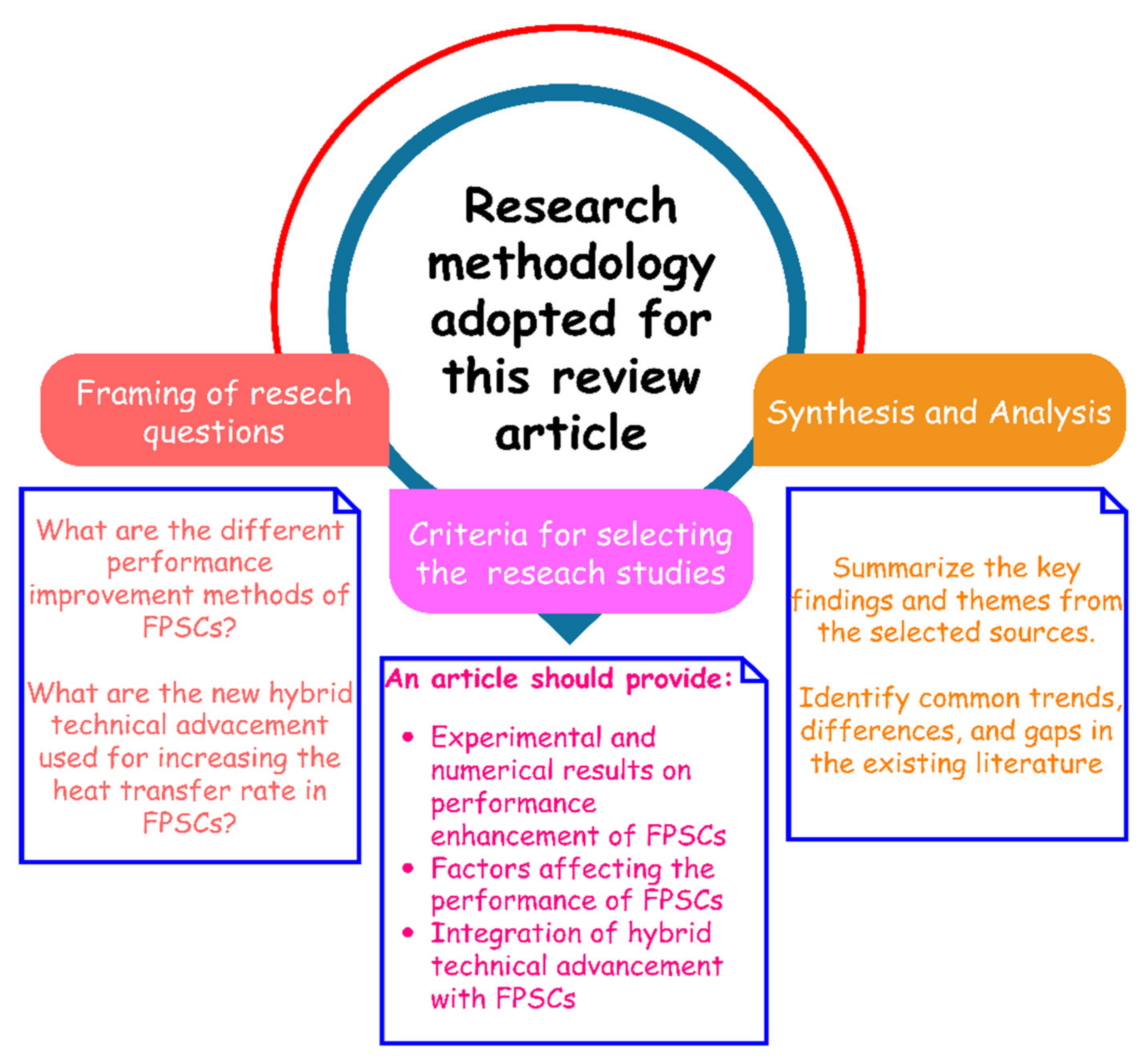

Novelty and Research Methodology of the Study

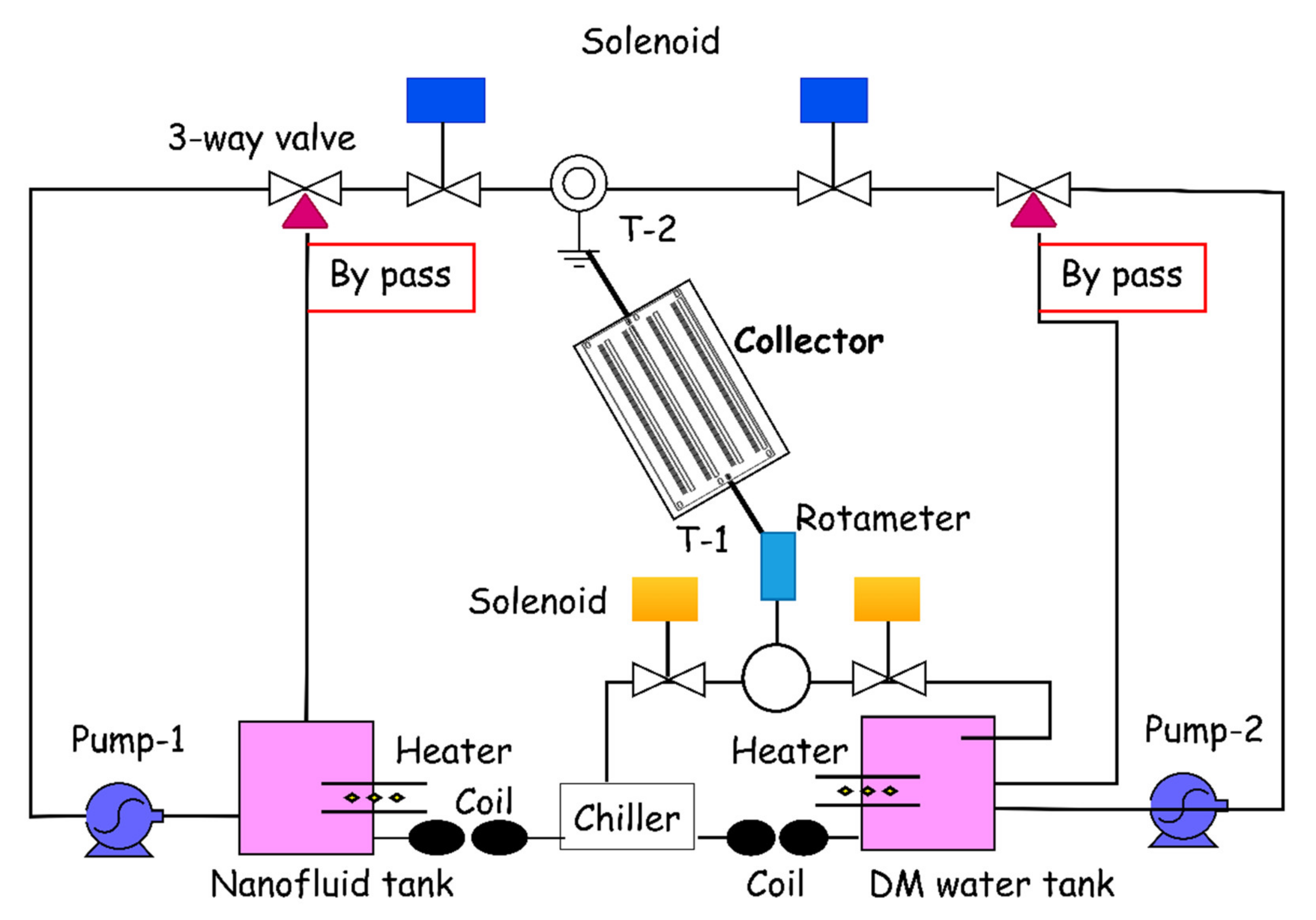

2. Flat Plate Collector: Construction and Working

- Absorber Plate

- Glazing Materials

- Riser and Header Tubes

- Collector Insulation

- Collector Support

- Collector Housing

2.1. Classification of Flat Plate Collectors

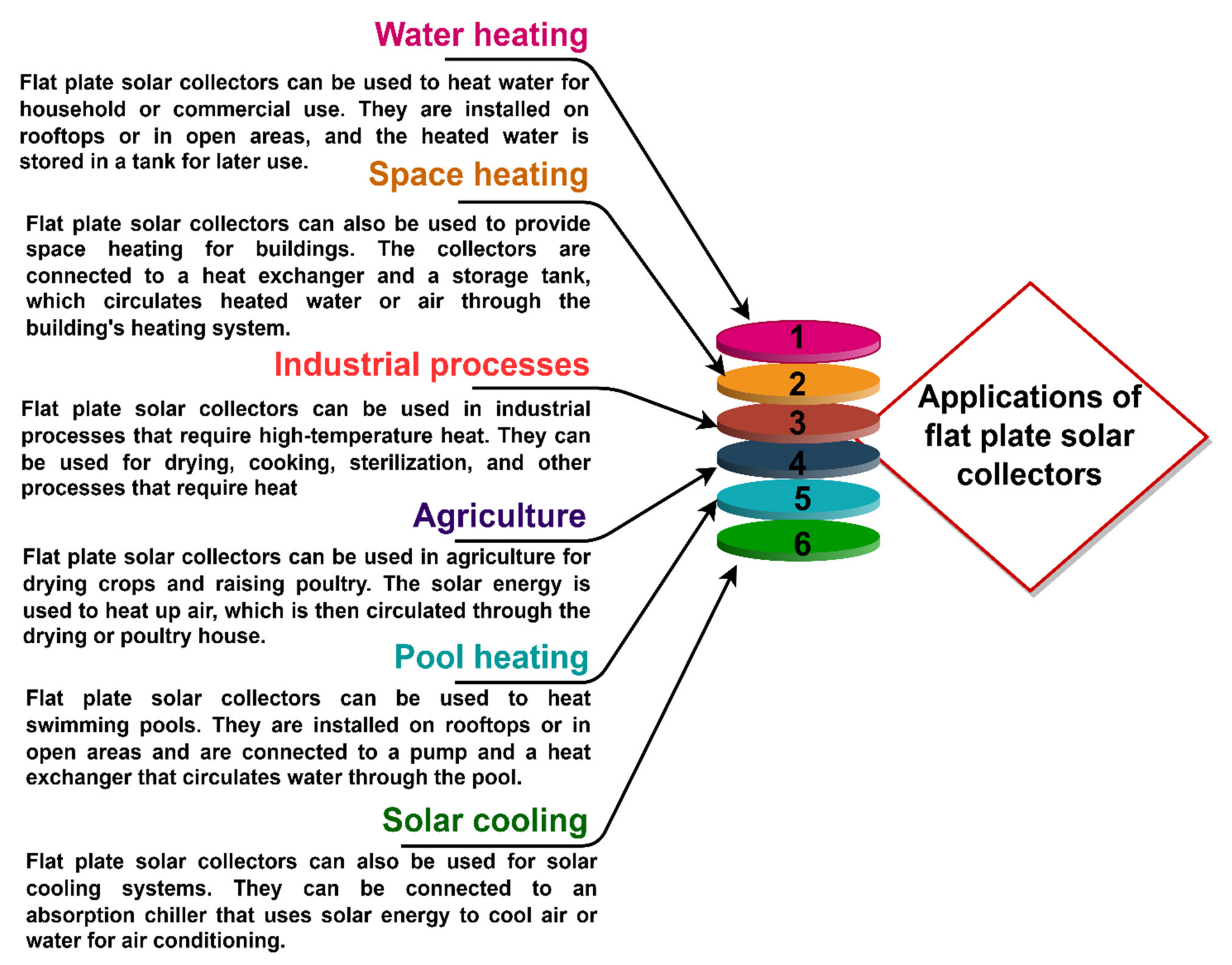

2.2. Merits, Demerits, and Applications

3. Thermodynamic Analysis of Flat Plate Collector

4. Performance Enhancement Techniques for FPC

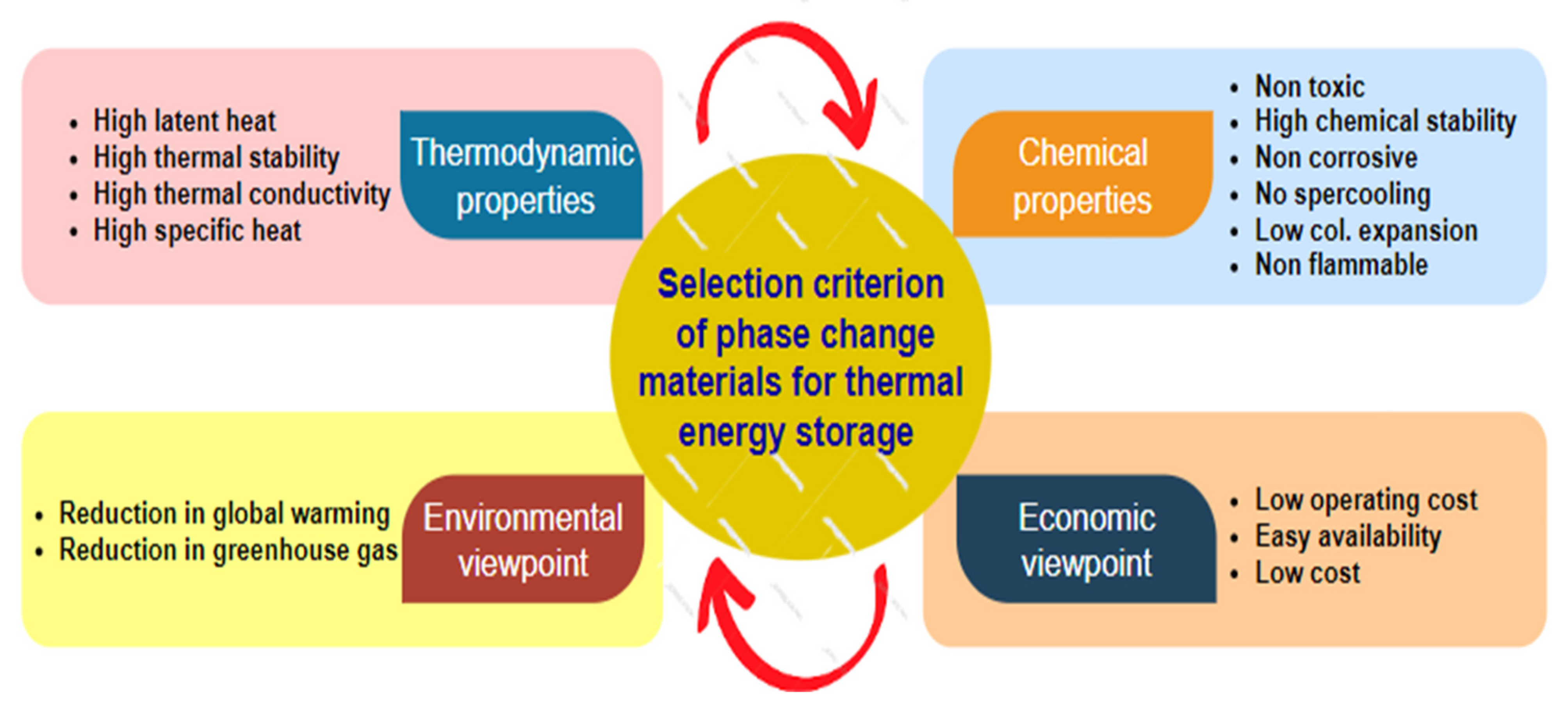

4.1. Utilization of Energy Storage Materials

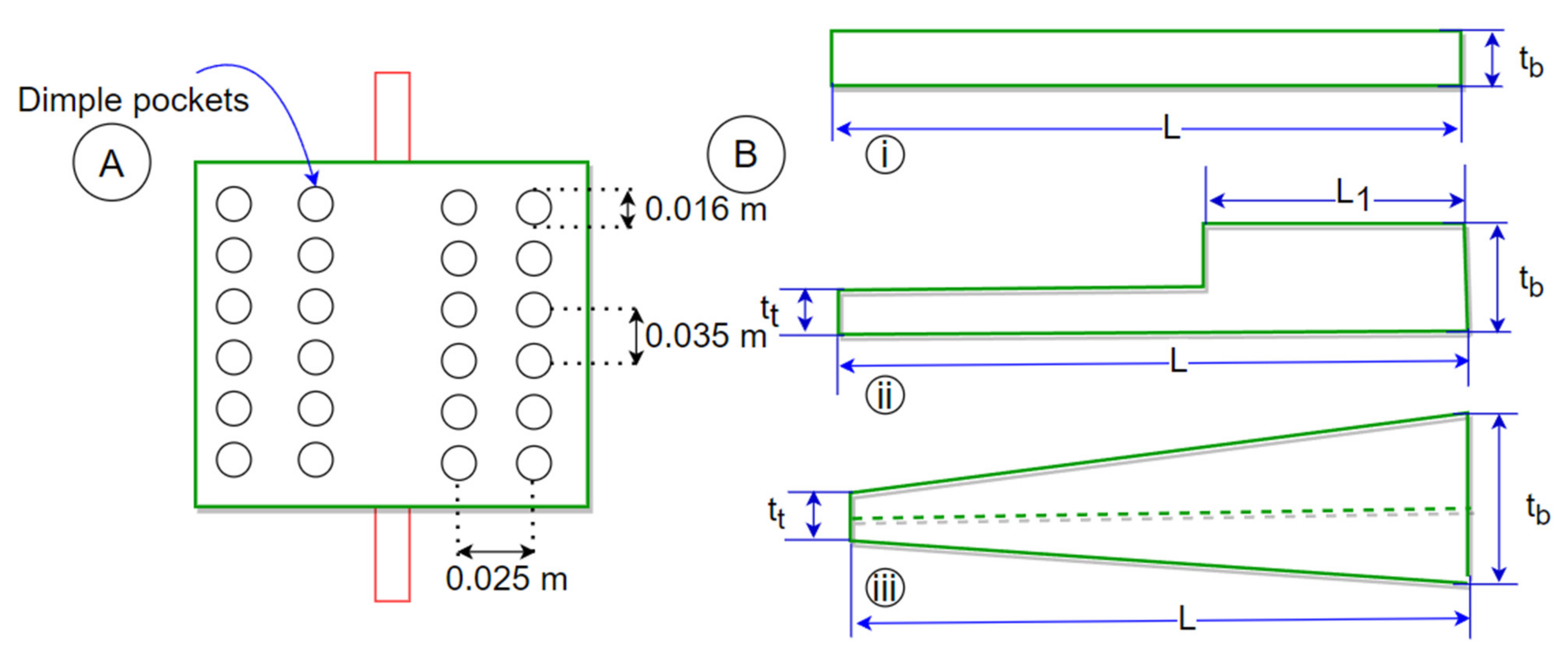

4.2. Modifications in Collector/Absorber Design

4.3. Use of Reflectors in FPCs

4.4. Impact of Nanofluids as the Working Fluid

4.5. Use of Other Methods

5. Discussion and Summary of Results

6. Current Challenges Associated with FPCs

- Temperature fluctuations: FPCs can experience overheating in high solar radiation and freezing in cold climates. Managing temperature fluctuations without complex thermal management systems is a challenge.

- Dust and soiling: The accumulation of dust, dirt, or bird droppings on the collector’s surface reduces its efficiency. Cleaning can be labor-intensive, particularly in remote installations.

- Space requirements: FPCs require a significant amount of space, making them less suitable for densely populated urban areas with limited rooftop or ground space.

- Cost: The initial cost of purchasing and installing FPCs can be high, deterring some potential users. Reducing the cost to make solar energy more accessible is an ongoing challenge.

- Durability and longevity: FPC components are exposed to weather conditions and UV radiation, potentially leading to degradation over time. Ensuring long-term durability and reliability is a challenge.

- Heat loss: Heat losses from the glazing and frame of the collector. Improving insulation and reducing thermal losses is an ongoing challenge.

- Environmental impact: The environmental impact of producing FPC components, particularly the glazing materials, should be considered. Reducing the environmental footprint of manufacturing is a challenge.

7. Conclusions and Future Recommendations

7.1. Conclusions

- Energy storage materials (PCMs) can improve efficiency and prolong collector operational flexibility by eliminating overheating and frost issues in adverse conditions. So, PCMs and composite PCMs can increase the thermal output of FPCs.

- Absorber plate shape is a crucial design factor in improving FPC efficiency; generally, corrugated absorber plates outperform conventional absorbers due to augmented friction and turbulence.

- V-trough collector performance is increased by 18–19% due to the optimized combination of absorber type and tube inserts compared to a flat absorber collector. Regarding cost-effectiveness, a low flow rate is preferable for FPC-based air/water heaters of the serpentine type because the payback period is short.

- The use of different shapes, such as twisted tapes, turbulators, and fins, can improve the heat transfer rate (due to proper mixing of fluid) and thermal output of FPC-based solar air heaters.

- Nanoparticles in nanofluids boost the heat transmission rate due to their high conductivity and random fluid flow. By decreasing nanofluid viscosity, increased shear rate decreases the boundary layer at heat transfer surfaces, improving the heat transmission rate that will lead to improved thermal output of collectors.

- Hybrid nanofluids are effective heat transfer fluids that improve both the energy and exergy efficiency of FPCs compared to water-based mono nonfluids.

- Glass surfaces that possess superhydrophobic characteristics effectively minimize the likelihood of dust adherence, showcasing remarkable self-cleaning capabilities. Practical trials in specific regions are anticipated to introduce an enhanced approach for mitigating dust accumulation in photovoltaic systems.

7.2. Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Surface area (m2) |

| A | Absorptivity |

| Ac | Collector area (m2) |

| Side area of collector (m2) | |

| Cp | Specific heat (J/kg K) |

| Cb | Bond conduction (W/m2K) |

| D | Diameter of tube (mm) |

| FR | Heat removal factor |

| F | Collector fin efficiency (%) |

| F’ | efficiency factor of Collector |

| f | Friction factor |

| h | Coefficient of convective heat transfer (W/m2K) |

| hfi | Coefficient of convective heat transfer of water (W/m2K) |

| It | Solar radiation (W/m2) |

| k | Heat conductivity (W/mK) |

| kb | Heat conductivity of bond (W/mK) |

| L | Length (mm) |

| Flow rate (kg/s) | |

| N | Number of tubes |

| Ρ | Reflectivity |

| Q | Heat flow (W) |

| Qloss | Heat loss to surrounding (W) |

| Qu | Useful amount of heat W) |

| R | Thermal resistance (°C/mm) |

| Rg-a | Thermal resistance between glass to ambient (°C/mm) |

| Rp-g | Thermal resistance between absorber plate to glass (°C/mm) |

| Rp-b | Thermal resistance between absorber plate to back of collector (°C/mm) |

| Rb-a | Thermal resistance between back of collector to ambient (°C/mm) |

| r | Radius (mm) |

| T | Temperature (°C) |

| Tp | Temperature of absorber plate (°C) |

| Tfi | Temperature of inlet fluid (°C) |

| Tfo | Temperature of outlet fluid (°C) |

| To | Ambient temperature (°C) |

| U | Coefficient of Overall heat transfer (W/m2K) |

| Ut | Coefficient of top heat loss (W/m2K) |

| Ub | Heat loss coefficient at bottom (W/m2K) |

| Ue | Coefficient of side heat loss (W/m2K) |

| UL | Coefficient of Overall heat loss W/m2K) |

| V | velocity (m/s) |

| W | Width of tube (mm) |

| Xb | Thickness (mm) |

| Greek letters | |

| ∆ | Thickness (mm) |

| Expansion coefficient | |

| Emissivity of plate | |

| Emissivity of glass | |

| Efficiency of collector | |

| Ʈ | Transmissivity |

| plate thickness (m) | |

| ατ | Absorptivity and transmissivity product |

| Abbreviations | |

| CNT | Carbon nanotubes |

| EG | Expanded graphite |

| ETC | Evacuated tube collector |

| FPC | Flat plate collector |

| FPSC | Flat plate solar collector |

| HTF | Heat transfer fluid |

| HP | Heat pipe |

| HTC | Heat transfer coefficient |

| PCM | Phase change material |

| SDG | Sustainable development goals |

| SWH | Solar water heater |

| SAH | Solar air heater |

| TES | Thermal energy storage |

References

- Goel, V.; Hans, V.S.; Singh, S.; Kumar, R.; Pathak, S.K.; Singla, M.; Bhattacharyya, S.; Almatrafi, E.; Gill, R.S.; Saini, R.P. A Comprehensive Study on the Progressive Development and Applications of Solar Air Heaters. Sol. Energy 2021, 229, 112–147. [Google Scholar] [CrossRef]

- Pandey, K.M.; Chaurasiya, R. A Review on Analysis and Development of Solar Flat Plate Collector. Renew. Sustain. Energy Rev. 2017, 67, 641–650. [Google Scholar] [CrossRef]

- Pathak, S.K.; Tyagi, V.V.; Chopra, K.; Rejikumar, R.; Pandey, A.K. Integration of Emerging PCMs and Nano-Enhanced PCMs with Different Solar Water Heating Systems for Sustainable Energy Future: A Systematic Review. Sol. Energy Mater. Sol. Cells 2023, 254, 112237. [Google Scholar] [CrossRef]

- Kumar Pathak, S.; Tyagi, V.V.; Chopra, K.; Kumar Sharma, R. Recent Development in Thermal Performance of Solar Water Heating (SWH) Systems. Mater. Today Proc. 2022, 63, 778–785. [Google Scholar] [CrossRef]

- Vengadesan, E.; Senthil, R. A Review on Recent Developments in Thermal Performance Enhancement Methods of Flat Plate Solar Air Collector. Renew. Sustain. Energy Rev. 2020, 134, 110315. [Google Scholar] [CrossRef]

- Saxena, A.; Varun; El-Sebaii, A.A. A Thermodynamic Review of Solar Air Heaters. Renew. Sustain. Energy Rev. 2015, 43, 863–890. [Google Scholar] [CrossRef]

- Kosky, P.; Balmer, R.T.; Keat, W.D.; Wise, G. Exploring Engineering: An Introduction to Engineering and Design; Academic Press: Cambridge, MA, USA, 2012; p. 491. [Google Scholar]

- Gawande, V.B.; Dhoble, A.S.; Zodpe, D.B. Effect of Roughness Geometries on Heat Transfer Enhancement in Solar Thermal Systems—A Review. Renew. Sustain. Energy Rev. 2014, 32, 347–378. [Google Scholar] [CrossRef]

- Chang, W.; Wang, Y.; Li, M.; Luo, X.; Ruan, Y.; Hong, Y.; Zhang, S. The Theoretical and Experimental Research on Thermal Performance of Solar Air Collector with Finned Absorber. Energy Procedia 2015, 70, 13–22. [Google Scholar] [CrossRef]

- Singh, S.; Chander, S.; Saini, J.S. Thermo-Hydraulic Performance Due to Relative Roughness Pitch in V-down Rib with Gap in Solar Air Heater Duct—Comparison with Similar Rib Roughness Geometries. Renew. Sustain. Energy Rev. 2015, 43, 1159–1166. [Google Scholar] [CrossRef]

- Priyam, A.; Chand, P. Thermal and Thermohydraulic Performance of Wavy Finned Absorber Solar Air Heater. Sol. Energy 2016, 130, 250–259. [Google Scholar] [CrossRef]

- Chauhan, R.; Singh, T.; Thakur, N.S.; Kumar, N.; Kumar, R.; Kumar, A. Heat Transfer Augmentation in Solar Thermal Collectors Using Impinging Air Jets: A Comprehensive Review. Renew. Sustain. Energy Rev. 2018, 82, 3179–3190. [Google Scholar] [CrossRef]

- Ravi, R.K.; Saini, R.P. A Review on Different Techniques Used for Performance Enhancement of Double Pass Solar Air Heaters. Renew. Sustain. Energy Rev. 2016, 56, 941–952. [Google Scholar] [CrossRef]

- Ho, C.D.; Tien, Y.E.; Chang, H. Performance Improvement of a Double-Pass V-Corrugated Solar Air Heater under Recycling Operation. Int. J. Green Energy 2016, 13, 1547–1555. [Google Scholar] [CrossRef]

- Al-Manea, A.; Al-Rbaihat, R.; Kadhim, H.T.; Alahmer, A.; Yusaf, T.; Egab, K. Experimental and Numerical Study to Develop TRANSYS Model for an Active Flat Plate Solar Collector with an Internally Serpentine Tube Receiver. Int. J. Thermofluids 2022, 15, 100189. [Google Scholar] [CrossRef]

- Abuşka, M.; Şevik, S. Energy, Exergy, Economic and Environmental (4E) Analyses of Flat-Plate and V-Groove Solar Air Collectors Based on Aluminium and Copper. Sol. Energy 2017, 158, 259–277. [Google Scholar] [CrossRef]

- Wenceslas Koholé, Y.; Cyrille Vincelas Fohagui, F.; Tchuen, G. Flat-Plate Solar Collector Thermal Performance Assessment via Energy, Exergy and Irreversibility Analysis. Energy Convers. Manag. X 2022, 15, 100247. [Google Scholar] [CrossRef]

- Kousik Suraparaju, S.; Ramasamy, D.; Kumar Natarajan, S. Augmentation of Freshwater Productivity in a Single-Slope Solar Still Using Ball Marbles. Environ. Sci. Pollut. Res. 2021, 28, 65974–65986. [Google Scholar] [CrossRef]

- Sekhar, Y.R.; Sharma, K.V.; Karupparaj, R.T.; Chiranjeevi, C. Heat Transfer Enhancement with Al2O3 Nanofluids and Twisted Tapes in a Pipe for Solar Thermal Applications. In Proceedings of the Procedia Engineering; Elsevier: Amsterdam, The Netherlands, 2013; Volume 64, pp. 1474–1484. [Google Scholar]

- Babar, O.A.; Arora, V.K.; Nema, P.K.; Kasara, A.; Tarafdar, A. Effect of PCM Assisted Flat Plate Collector Solar Drying of Green Chili on Retention of Bioactive Compounds and Control of Aflatoxins Development. Sol. Energy 2021, 229, 102–111. [Google Scholar] [CrossRef]

- Kumar, Y.; Verma, M.; Ghritlahre, H.K.; Verma, P. Recent Developments in the Thermal Performance of Flat Plate Solar Water Heaters with Reflectors—A Review. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 9448–9475. [Google Scholar] [CrossRef]

- Sankar, S.S.K.; Murugan, A.; Rahman, A.; Illyas, M.; Ramalingam, R.D.; Marquez, F.P.G.; Athikesavan, M.M. Recent Advancements in Flat Plate Solar Collector Using Phase Change Materials and Nanofluid: A Review. Environ. Sci. Pollut. Res. 2023, 30, 88366–88386. [Google Scholar] [CrossRef]

- Eltaweel, M.; Abdel-Rehim, A.A.; Attia, A.A.A. A Comparison between Flat-Plate and Evacuated Tube Solar Collectors in Terms of Energy and Exergy Analysis by Using Nanofluid. Appl. Therm. Eng. 2021, 186, 116516. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar Thermal Collectors and Applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A.; McGowan, J. Solar Engineering of Thermal Processes. Am. J. Phys. 1998, 53, 382. [Google Scholar] [CrossRef]

- Kiliç, F.; Menlik, T.; Sözen, A. Effect of Titanium Dioxide/Water Nanofluid Use on Thermal Performance of the Flat Plate Solar Collector. Sol. Energy 2018, 164, 101–108. [Google Scholar] [CrossRef]

- Hill, J.E.; Kusuda, T. Method of Testing for Rating Solar Collectors Based on Thermal Performance; National Science Foundation: Washington, DC, USA, 1974.

- Thakur, A.K.; Singh, R.; Gehlot, A.; Kaviti, A.K.; Aseer, R.; Suraparaju, S.K.; Natarajan, S.K.; Sikarwar, V.S. Advancements in Solar Technologies for Sustainable Development of Agricultural Sector in India: A Comprehensive Review on Challenges and Opportunities. Environ. Sci. Pollut. Res. 2022, 29, 43607–43634. [Google Scholar] [CrossRef]

- Kenisarin, M.M. Thermophysical Properties of Some Organic Phase Change Materials for Latent Heat Storage. A Review. Sol. Energy 2014, 107, 553–575. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. Enhanced Thermophysical Properties of Organic PCM through Shape Stabilization for Thermal Energy Storage in Buildings: A State of the Art Review. Energy Build. 2021, 236, 110799. [Google Scholar] [CrossRef]

- Carmona, M.; Palacio, M. Thermal Modelling of a Flat Plate Solar Collector with Latent Heat Storage Validated with Experimental Data in Outdoor Conditions. Sol. Energy 2019, 177, 620–633. [Google Scholar] [CrossRef]

- Vestlund, J.; Rönnelid, M.; Dalenbäck, J.O. Thermal Performance of Gas-Filled Flat Plate Solar Collectors. Sol. Energy 2009, 83, 896–904. [Google Scholar] [CrossRef]

- Vengadesan, E.; Bharathwaj, D.; Kumar, B.S.; Senthil, R. Experimental Study on Heat Storage Integrated Flat Plate Solar Collector for Combined Water and Air Heating in Buildings. Appl. Therm. Eng. 2022, 216, 119105. [Google Scholar] [CrossRef]

- Henshall, P.; Eames, P.; Arya, F.; Hyde, T.; Moss, R.; Shire, S. Constant Temperature Induced Stresses in Evacuated Enclosures for High Performance Flat Plate Solar Thermal Collectors. Sol. Energy 2016, 127, 250–261. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Said, Z. Investigation and Optimization of a Solar-Assisted Pumped Thermal Energy Storage System with Flat Plate Collectors. Energy Convers. Manag. 2021, 237, 114137. [Google Scholar] [CrossRef]

- Mukherjee, A.; Majumdar, R.; Saha, S.K.; Subramaniam, C.; Kumar, L. Performance Evaluation of an Open Thermochemical Energy Storage System Integrated with Flat Plate Solar Collector. Appl. Therm. Eng. 2020, 173, 115218. [Google Scholar] [CrossRef]

- Fan, R.; Xu, B.; Shi, L.; Zheng, N.; Sun, Z. A Scalable Phase Change Material-Based System Enhanced by Multi-Walled Carbon Nanotubes and Fins for Efficient Solar Water Heating Applications. J. Energy Storage 2023, 72, 108791. [Google Scholar] [CrossRef]

- Alptekin, E.; Ezan, M.A. A Systematic Assessment on a Solar Collector Integrated Packed-Bed Single/Multi-Layered Latent Heat Thermal Energy Storage System. J. Energy Storage 2021, 37, 102410. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Chen, Y.; Kang, W.; Liu, Y. Experimental Study on Performance Test of Serpentine Flat Plate Collector with Different Pipe Parameters and A New Phase Change Collector. Energy Procedia 2019, 158, 738–743. [Google Scholar] [CrossRef]

- Mohamed, M.M.; Mahmoud, N.H.; Farahat, M.A. Energy Storage System with Flat Plate Solar Collector and Water-ZnO Nanofluid. Sol. Energy 2020, 202, 25–31. [Google Scholar] [CrossRef]

- Younes, M.M.; Abdullah, A.S.; Omara, Z.M.; Essa, F.A. Enhancement of Discs’ Solar Still Performance Using Thermal Energy Storage Unit and Reflectors: An Experimental Approach. Alex. Eng. J. 2022, 61, 7477–7487. [Google Scholar] [CrossRef]

- Dissa, A.O.; Ouoba, S.; Bathiebo, D.; Koulidiati, J. A Study of a Solar Air Collector with a Mixed “Porous” and “Non-Porous” Composite Absorber. Sol. Energy 2016, 129, 156–174. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, M.; Peng, D. Heat Transfer Performance Analysis of a Solar Flat-Plate Collector with an Integrated Metal Foam Porous Structure Filled with Paraffin. Appl. Therm. Eng. 2010, 30, 1967–1973. [Google Scholar] [CrossRef]

- Abuşka, M.; Şevik, S.; Kayapunar, A. Comparative Energy and Exergy Performance Investigation of Forced Convection Solar Air Collectors with Cherry Stone/Powder. Renew. Energy 2019, 143, 34–46. [Google Scholar] [CrossRef]

- Saedodin, S.; Zamzamian, S.A.H.; Nimvari, M.E.; Wongwises, S.; Jouybari, H.J. Performance Evaluation of a Flat-Plate Solar Collector Filled with Porous Metal Foam: Experimental and Numerical Analysis. Energy Convers. Manag. 2017, 153, 278–287. [Google Scholar] [CrossRef]

- Sakhaei, S.A.; Valipour, M.S. Thermal Behavior of a Flat Plate Solar Collector with Simultaneous Use of Helically Heat Collecting Tubes and Phase Change Materials. Sustain. Energy Technol. Assess. 2021, 46, 101279. [Google Scholar] [CrossRef]

- Badiei, Z.; Eslami, M.; Jafarpur, K. Performance Improvements in Solar Flat Plate Collectors by Integrating with Phase Change Materials and Fins: A CFD Modeling. Energy 2020, 192, 116719. [Google Scholar] [CrossRef]

- Sajawal, M.; Rehman, T.U.; Ali, H.M.; Sajjad, U.; Raza, A.; Bhatti, M.S. Experimental Thermal Performance Analysis of Finned Tube-Phase Change Material Based Double Pass Solar Air Heater. Case Stud. Therm. Eng. 2019, 15, 100543. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Lin, S.C. Performance Evaluation of a Solar Water Heater Integrated with a PCM Nanocomposite TES at Various Inclinations. Sol. Energy 2014, 109, 82–92. [Google Scholar] [CrossRef]

- Manjunath, M.; Karanth, V.; Sharma, Y. A Comparative CFD Study on Solar Dimple Plate Collector with Flat Plate Collector to Augment the Thermal Performance. World Acad. Sci. Eng. Technol. 2012, 2012, 969–975. [Google Scholar]

- Kundu, B. Performance Analysis and Optimization of Absorber Plates of Different Geometry for a Flat-Plate Solar Collector: A Comparative Study. Appl. Therm. Eng. 2002, 22, 999–1012. [Google Scholar] [CrossRef]

- Pandya, H.; Behura, A.K. Experimental Study of V-Through Solar Water Heater for Tilt Angle and Glass Transmissivity. Energy Procedia 2017, 109, 377–384. [Google Scholar] [CrossRef]

- Kim, S.; Jeong, H.; Park, J.Y.; Baek, S.Y.; Lee, A.; Choi, S.H. Innovative Flat-Plate Solar Collector (FPC) with Coloured Water Flowing through a Transparent Tube. RSC Adv. 2019, 9, 24192–24202. [Google Scholar] [CrossRef]

- Garcia, R.P.; del Oliveira, S.R.; Scalon, V.L. Thermal Efficiency Experimental Evaluation of Solar Flat Plate Collectors When Introducing Convective Barriers. Sol. Energy 2019, 182, 278–285. [Google Scholar] [CrossRef]

- Alomar, O.R.; Abd, H.M.; Mohamed Salih, M.M. Efficiency Enhancement of Solar Air Heater Collector by Modifying Jet Impingement with V-Corrugated Absorber Plate. J. Energy Storage 2022, 55, 105535. [Google Scholar] [CrossRef]

- Hellstrom, B.; Adsten, M.; Nostell, P.; Karlsson, B.; Wackelgard, E. The Impact of Optical and Thermal Properties on the Performance of Flat Plate Solar Collectors. Renew. Energy 2003, 28, 331–344. [Google Scholar] [CrossRef]

- Balaji, K.; Ganesh Kumar, P.; Sakthivadivel, D.; Vigneswaran, V.S.; Iniyan, S. Experimental Investigation on Flat Plate Solar Collector Using Frictionally Engaged Thermal Performance Enhancer in the Absorber Tube. Renew. Energy 2019, 142, 62–72. [Google Scholar] [CrossRef]

- Amori, K.E.; Jabouri, N.S. Thermal Performance of Solar Hot Water Systems Using a Flat Plate Collector of Accelerated Risers. J. Eng. Res. 2012, 9, 1–10. [Google Scholar] [CrossRef]

- Vengadesan, E.; Senthil, R. Experimental Study on the Thermal Performance of a Flat Plate Solar Water Collector with a Bifunctional Flow Insert. Sustain. Energy Technol. Assess. 2022, 50, 101829. [Google Scholar] [CrossRef]

- Moss, R.W.; Shire, G.S.F.; Henshall, P.; Eames, P.C.; Arya, F.; Hyde, T. Design and Fabrication of a Hydroformed Absorber for an Evacuated Flat Plate Solar Collector. Appl. Therm. Eng. 2018, 138, 456–464. [Google Scholar] [CrossRef]

- Kizildag, D.; Castro, J.; Kessentini, H.; Schillaci, E.; Rigola, J. First Test Field Performance of Highly Efficient Flat Plate Solar Collectors with Transparent Insulation and Low-Cost Overheating Protection. Sol. Energy 2022, 236, 239–248. [Google Scholar] [CrossRef]

- Anirudh, K.; Dhinakaran, S. Numerical Analysis of the Performance Improvement of a Flat-Plate Solar Collector Using Conjugated Porous Blocks. Renew. Energy 2021, 172, 382–391. [Google Scholar] [CrossRef]

- Ammar, M.; Mokni, A.; Mhiri, H.; Bournot, P. Performance Optimization of Flat Plate Solar Collector through the Integration of Different Slats Arrangements Made of Transparent Insulation Material. Sustain. Energy Technol. Assess. 2021, 46, 101237. [Google Scholar] [CrossRef]

- Nejlaoui, M.; Alghafis, A.; Sadig, H. Six Sigma Robust Multi-Objective Design Optimization of Flat Plate Collector System under Uncertain Design Parameters. Energy 2021, 239, 121883. [Google Scholar] [CrossRef]

- Channa Keshava Naik, N.; Shashi Shekar, K.S. Evaluation and Comparison of Performance of a Solar Pebble Absorber Collector with a Conventional Flat Plate Collector. Mater. Today Proc. 2022, 52, 266–273. [Google Scholar] [CrossRef]

- Kansara, R.; Pathak, M.; Patel, V.K. Performance Assessment of Flat-Plate Solar Collector with Internal Fins and Porous Media through an Integrated Approach of CFD and Experimentation. Int. J. Therm. Sci. 2021, 165, 106932. [Google Scholar] [CrossRef]

- Yehualashet, K.N.; Fatoba, O.; Asfaw, S.M. Experimental Study and Numerical Analysis of Thermal Performance of Corrugated Plate Solar Collector. Mater. Today Proc. 2022, 62, 2849–2856. [Google Scholar] [CrossRef]

- Fan, M.; You, S.; Gao, X.; Zhang, H.; Li, B.; Zheng, W.; Sun, L.; Zhou, T. A Comparative Study on the Performance of Liquid Flat-Plate Solar Collector with a New V-Corrugated Absorber. Energy Convers. Manag. 2019, 184, 235–248. [Google Scholar] [CrossRef]

- Sivakumar, S.; Velmurugan, C.; Dhas, D.S.E.J.; Solomon, A.B.; Dev Wins, K.L. Effect of Nano Cupric Oxide Coating on the Forced Convection Performance of a Mixed-Mode Flat Plate Solar Dryer. Renew. Energy 2020, 155, 1165–1172. [Google Scholar] [CrossRef]

- Nazari, M.; Jafarmadar, S.; Khalilarya, S. Exergy and Thermoeconomic Analyses of Serpentine Tube Flat-Plate Solar Water Heaters Coated with CuO Nanostructures. Case Stud. Therm. Eng. 2022, 35, 102072. [Google Scholar] [CrossRef]

- Selikhov, Y.; Klemeš, J.J.; Kapustenko, P.; Arsenyeva, O. The Study of Flat Plate Solar Collector with Absorbing Elements from a Polymer Material. Energy 2022, 256, 124677. [Google Scholar] [CrossRef]

- Alkhafaji, M.H.; Freegah, B.; Alhamdo, M.H. Study the Influence of Adding Fins to the Plate of the Solar Collector on Thermal Performance under Natural Phenomena. Int. Commun. Heat Mass Transf. 2022, 135, 106058. [Google Scholar] [CrossRef]

- Sharma, H.K.; Kumar, S.; Verma, S.K. Comparative Performance Analysis of Flat Plate Solar Collector Having Circular &trapezoidal Corrugated Absorber Plate Designs. Energy 2022, 253, 124137. [Google Scholar] [CrossRef]

- Bollentin, J.W.; Wilk, R.D. Modeling the Solar Irradiation on Flat Plate Collectors Augmented with Planar Reflectors. Sol. Energy 1995, 55, 343–354. [Google Scholar] [CrossRef]

- Rönnelid, M.; Karlsson, B. The use of corrugated booster reflectors for solar collector fields. Sol. Energy 1999, 65, 343–351. [Google Scholar] [CrossRef]

- El-Assal, B.; Irshad, K.; Ali, A. Effect of Side Reflectors on the Performance of Flat Plate Solar Collector: A Case Study for Asir Region, Saudi Arabia. Arab. J. Sci. Eng. 2019, 45, 1035–1050. [Google Scholar] [CrossRef]

- Rajashekaraiah, T.; Mura, M.J.; Sharasthantra, R.; Sharma, G.S. Optimizing the Efficiency of Solar Flat Plate Collector with Trapezoidal Reflector. AIP Conf. Proc. 2019, 2080, 030008. [Google Scholar] [CrossRef]

- Singhal, A.; Bhatt, A.; Raval, T. Performance Enhancement of Solar Flat Plate Collector with Aluminium Foil Reflectors and Trapezoidal Glass Cover. ARPN J. Eng. Appl. Sci. 2019, 14, 2948–2953. [Google Scholar]

- Rachedi, M.Y.; Bechki, D.; Marif, Y.; Boughali, S.; Bouguettaia, H. A Novel Model for Optimizing Tilts of Four Reflectors on a Flat Plate Thermal Collector: Case Study in Ouargla Region. Case Stud. Therm. Eng. 2022, 32, 101872. [Google Scholar] [CrossRef]

- Bhowmik, H.; Amin, R. Efficiency Improvement of Flat Plate Solar Collector Using Reflector. Energy Rep. 2017, 3, 119–123. [Google Scholar] [CrossRef]

- Ramesh, C.; Vijayakumar, M.; Alshahrani, S.; Navaneethakrishnan, G.; Palanisamy, R.; Natrayan, L.; Saleel, C.A.; Afzal, A.; Shaik, S.; Panchal, H. Performance Enhancement of Selective Layer Coated on Solar Absorber Panel with Reflector for Water Heater by Response Surface Method: A Case Study. Case Stud. Therm. Eng. 2022, 36, 102093. [Google Scholar] [CrossRef]

- Baccoli, R.; Frattolillo, A.; Mastino, C.; Curreli, S.; Ghiani, E. A Comprehensive Optimization Model for Flat Solar Collector Coupled with a Flat Booster Bottom Reflector Based on an Exact Finite Length Simulation Model. Energy Convers. Manag. 2018, 164, 482–507. [Google Scholar] [CrossRef]

- Murugan, M.; Vijayan, R.; Saravanan, A.; Jaisankar, S. Performance Enhancement of Centrally Finned Twist Inserted Solar Collector Using Corrugated Booster Reflectors. Energy 2019, 168, 858–869. [Google Scholar] [CrossRef]

- Momeni, S.; Menbari, A.; Alemrajabi, A.A.; Mohammadi, P. Theoretical Performance Analysis of New Class of Fresnel Concentrated Solar Thermal Collector Based on Parabolic Reflectors. Sustain. Energy Technol. Assess. 2019, 31, 25–33. [Google Scholar] [CrossRef]

- Nikolić, N.; Lukić, N. Theoretical and Experimental Investigation of the Thermal Performance of a Double Exposure Flat-Plate Solar Collector. Sol. Energy 2015, 119, 100–113. [Google Scholar] [CrossRef]

- Rachedi, M.Y.; Bechki, D.; Marif, Y.; Bouguettaia, H. Solar Flat Plate Collector Enhanced by Two Reflectors: Optimum Tilts of Reflectors. Electr. Eng. Electromech. 2022, 2022, 67–70. [Google Scholar] [CrossRef]

- Housseyn Karoua, M.D.A.M. An Experimental Study of a New Solar Air Heater with a Linear Fresnel Reflector. In Proceedings of the 2016 International Renewable and Sustainable Energy Conference (IRSEC), Marrakesh, Morocco, 14–17 November 2016; IEEE: Piscataway, NJ, USA, 2016. ISBN 9781509057139. [Google Scholar]

- Pathak, S.K.; Kumar, R.; Goel, V.; Pandey, A.K.; Tyagi, V.V. Recent Advancements in Thermal Performance of Nano-Fluids Charged Heat Pipes Used for Thermal Management Applications: A Comprehensive Review. Appl. Therm. Eng. 2022, 216, 119023. [Google Scholar] [CrossRef]

- Pathak, S.K.; Sharma, P.O.; Goel, V.; Bhattacharyya, S.; Aybar, H.; Meyer, J.P. A Detailed Review on the Performance of Photovoltaic/Thermal System Using Various Cooling Methods. Sustain. Energy Technol. Assess. 2022, 51, 101844. [Google Scholar] [CrossRef]

- Verma, S.K.; Tiwari, A.K.; Chauhan, D.S. Performance Augmentation in Flat Plate Solar Collector Using MgO/Water Nanofluid. Energy Convers. Manag. 2016, 124, 607–617. [Google Scholar] [CrossRef]

- Choudhary, S.; Sachdeva, A.; Kumar, P. Investigation of the Stability of MgO Nanofluid and Its Effect on the Thermal Performance of Flat Plate Solar Collector. Renew. Energy 2020, 147, 1801–1814. [Google Scholar] [CrossRef]

- Mondragón, R.; Sánchez, D.; Cabello, R.; Llopis, R.; Juliá, J.E. Flat Plate Solar Collector Performance Using Alumina Nanofluids: Experimental Characterization and Efficiency Tests. PLoS ONE 2019, 14, e0212260. [Google Scholar] [CrossRef]

- Alim, M.A.; Abdin, Z.; Saidur, R.; Hepbasli, A.; Khairul, M.A.; Rahim, N.A. Analyses of Entropy Generation and Pressure Drop for a Conventional Flat Plate Solar Collector Using Different Types of Metal Oxide Nanofluids. Energy Build. 2013, 66, 289–296. [Google Scholar] [CrossRef]

- Nasrin, R.; Parvin, S.; Alim, M.A. Heat Transfer by Nanofluids Through a Flat Plate Solar Collector. Procedia Eng. 2014, 90, 364–370. [Google Scholar] [CrossRef]

- Yousefi, T.; Veisy, F.; Shojaeizadeh, E.; Zinadini, S. An Experimental Investigation on the Effect of MWCNT-H2O Nanofluid on the Efficiency of Flat-Plate Solar Collectors. Exp. Therm. Fluid Sci. 2012, 39, 207–212. [Google Scholar] [CrossRef]

- Hordy, N.; Rabilloud, D.; Meunier, J.L.; Coulombe, S. High Temperature and Long-Term Stability of Carbon Nanotube Nanofluids for Direct Absorption Solar Thermal Collectors. Sol. Energy 2014, 105, 82–90. [Google Scholar] [CrossRef]

- Goudarzi, K.; Nejati, F.; Shojaeizadeh, E.; Asadi Yousef-abad, S.K. Experimental Study on the Effect of PH Variation of Nanofluids on the Thermal Efficiency of a Solar Collector with Helical Tube. Exp. Therm. Fluid Sci. 2015, 60, 20–27. [Google Scholar] [CrossRef]

- Bamisile, O.; Cai, D.; Adun, H.; Adedeji, M.; Dagbasi, M.; Dika, F.; Huang, Q. A Brief Review and Comparative Evaluation of Nanofluid Application in Solar Parabolic Trough and Flat Plate Collectors. Energy Rep. 2022, 8, 156–166. [Google Scholar] [CrossRef]

- Xu, L.; Khalifeh, A.; Khandakar, A.; Vaferi, B. Numerical Investigating the Effect of Al2O3-Water Nanofluids on the Thermal Efficiency of Flat Plate Solar Collectors. Energy Rep. 2022, 8, 6530–6542. [Google Scholar] [CrossRef]

- Chavez Panduro, E.A.; Finotti, F.; Largiller, G.; Lervåg, K.Y. A Review of the Use of Nanofluids as Heat-Transfer Fluids in Parabolic-Trough Collectors. Appl. Therm. Eng. 2022, 211, 118346. [Google Scholar] [CrossRef]

- Sundar, L.S.; Ramana, E.V.; Said, Z.; Sekhar, Y.R.; Chandra Mouli, K.V.V.; Sousa, A.C.M. Heat transfer, energy, and exergy efficiency enhancement of nanodiamond/water nanofluids circulate in a flat plate solar collector. J. Enhanc. Heat Transf. 2021, 28, 57–99. [Google Scholar] [CrossRef]

- Ajeena, A.M.; Víg, P.; Farkas, I. A Comprehensive Analysis of Nanofluids and Their Practical Applications for Flat Plate Solar Collectors: Fundamentals, Thermophysical Properties, Stability, and Difficulties. Energy Rep. 2022, 8, 4461–4490. [Google Scholar] [CrossRef]

- Saffarian, M.R.; Moravej, M.; Doranehgard, M.H. Heat Transfer Enhancement in a Flat Plate Solar Collector with Different Flow Path Shapes Using Nanofluid. Renew. Energy 2020, 146, 2316–2329. [Google Scholar] [CrossRef]

- Akram, N.; Sadri, R.; Kazi, S.N.; Ahmed, S.M.; Zubir, M.N.M.; Ridha, M.; Soudagar, M.; Ahmed, W.; Arzpeyma, M.; Tong, G.B. An Experimental Investigation on the Performance of a Flat-Plate Solar Collector Using Eco-Friendly Treated Graphene Nanoplatelets–Water Nanofluids. J. Therm. Anal. Calorim. 2019, 138, 609–621. [Google Scholar] [CrossRef]

- Elshazly, E.; Abdel-Rehim, A.A.; El-Mahallawi, I. 4E Study of Experimental Thermal Performance Enhancement of Flat Plate Solar Collectors Using MWCNT, Al2O3, and Hybrid MWCNT/Al2O3 Nanofluids. Results Eng. 2022, 16, 100723. [Google Scholar] [CrossRef]

- Noghrehabadi, A.; Hajidavaloo, E.; Moravej, M. Experimental Investigation of Efficiency of Square Flat-Plate Solar Collector Using SiO2/Water Nanofluid. Case Stud. Therm. Eng. 2016, 8, 378–386. [Google Scholar] [CrossRef]

- Said, Z.; Sharma, P.; Sundar, L.S.; Li, C.; Tran, D.C.; Khoa Pham, N.D.; Nguyen, X.P. Improving the Thermal Efficiency of a Solar Flat Plate Collector Using MWCNT-Fe3O4/Water Hybrid Nanofluids and Ensemble Machine Learning. Case Stud. Therm. Eng. 2022, 40, 102448. [Google Scholar] [CrossRef]

- Mirzaei, M.; Hosseini, S.M.S.; Moradi Kashkooli, A.M. Assessment of Al2O3 Nanoparticles for the Optimal Operation of the Flat Plate Solar Collector. Appl. Therm. Eng. 2018, 134, 68–77. [Google Scholar] [CrossRef]

- Verma, S.K.; Tiwari, A.K.; Tiwari, S.; Chauhan, D.S. Performance Analysis of Hybrid Nanofluids in Flat Plate Solar Collector as an Advanced Working Fluid. Sol. Energy 2018, 167, 231–241. [Google Scholar] [CrossRef]

- Ashour, A.F.; El-Awady, A.T.; Tawfik, M.A. Numerical Investigation on the Thermal Performance of a Flat Plate Solar Collector Using ZnO & CuO Water Nanofluids under Egyptian Weathering Conditions. Energy 2022, 240, 122743. [Google Scholar] [CrossRef]

- Tong, Y.; Lee, H.; Kang, W.; Cho, H. Energy and Exergy Comparison of a Flat-Plate Solar Collector Using Water, Al2O3 Nanofluid, and CuO Nanofluid. Appl. Therm. Eng. 2019, 159, 113959. [Google Scholar] [CrossRef]

- Akram, N.; Montazer, E.; Kazi, S.N.; Soudagar, M.E.M.; Ahmed, W.; Zubir, M.N.M.; Afzal, A.; Muhammad, M.R.; Ali, H.M.; Márquez, F.P.G.; et al. Experimental Investigations of the Performance of a Flat-Plate Solar Collector Using Carbon and Metal Oxides Based Nanofluids. Energy 2021, 227, 120452. [Google Scholar] [CrossRef]

- Mausam, K.; Pare, A.; Ghosh, S.K.; Tiwari, A.K. Thermal Performance Analysis of Hybrid-Nanofluid Based Flat Plate Collector Using Grey Relational Analysis (GRA): An Approach for Sustainable Energy Harvesting. Therm. Sci. Eng. Prog. 2023, 37, 101609. [Google Scholar] [CrossRef]

- Hariri, N.G.; Almadani, I.K.; Osman, I.S. A State-of-the-Art Self-Cleaning System Using Thermomechanical Effect in Shape Memory Alloy for Smart Photovoltaic Applications. Materials 2022, 15, 5704. [Google Scholar] [CrossRef]

- Wu, Y.; Du, J.; Liu, G.; Ma, D.; Jia, F.; Klemeš, J.J.; Wang, J. A Review of Self-Cleaning Technology to Reduce Dust and Ice Accumulation in Photovoltaic Power Generation Using Superhydrophobic Coating. Renew. Energy 2022, 185, 1034–1061. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, J.; Wen, M.; Yao, M.; Wang, F.; Huang, F.; Zhang, Q.; Cheng, Y.-B.; Zhong, J. Supporting Information for Sequentially Reinforced Additive Coating for Transparent and Durable Superhydrophobic Glass. Am. Chem. Soc. 2018, 34, 11316–11324. [Google Scholar] [CrossRef]

- Deng, X.; Mammen, L.; Butt, H.J.; Vollmer, D. Candle Soot as a Template for a Transparent Robust Superamphiphobic Coating. Science 2012, 335, 67–70. [Google Scholar] [CrossRef]

- Bin Ishak, M.A.A.; Ibrahim, A.; Sopian, K.; Fauzan, M.F.; Rahmat, A.A.; Yusaidi, N.J. Performance and Economic Analysis of a Reversed Circular Flow Jet Impingement Bifacial PVT Solar Collector. Int. J. Renew. Energy Dev. 2023, 12, 780–788. [Google Scholar] [CrossRef]

- Alami, A.H.; Aokal, K. Enhancement of Spectral Absorption of Solar Thermal Collectors by Bulk Graphene Addition via High-Pressure Graphite Blasting. Energy Convers. Manag. 2018, 156, 757–764. [Google Scholar] [CrossRef]

- El-Mahallawi, I.S.; Abdel-Rehim, A.A.; Khattab, N.; Rafat, N.H.; Badr, H. Effect of Nano-Graphite Dispersion on the Thermal Solar Selective Absorbance of Polymeric-Based Coating Material. In Energy Technology 2018: Carbon Dioxide Management and Other Technologies; Proceedings of the Minerals, Metals and Materials Series; Springer International Publishing: Cham, Switzerland, 2018; pp. 523–533. [Google Scholar]

- Sarasar, M.B.; Saedodin, S.; Rostamian, S.H.; Doostmohammadi, M.; Khaledi, O. The Effect of Vortex Generator Insert and TiO2/Water Nanofluid on Thermal Efficiency and Heat Transfer of Flat Plate Solar Collector. Sustain. Energy Technol. Assess. 2022, 53, 102617. [Google Scholar] [CrossRef]

| Type of PCM | Name of PCM | Latent Heat (kJ/kg) | Melting Temperature (°C) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|

| Organic PCMs | Paraffin waxes | 150–250 | 0–90 | 0.20 |

| Palmitic acid | 222 | 61 | 0.21 | |

| PEG6000 | 127.3 | 60 | 0.29 | |

| Lauric acid | 212 | 44 | 0.22 | |

| Acetic acid | 192 | 17 | 0.26 | |

| Capric acid | 139.8 | 29.60 | - | |

| Stearic acid | 244.21 | 67 | 0.28 | |

| Myristic acid | 228 | 56 | 0.22 | |

| Eicosane | 247 | 36.3 | - | |

| Hexadecane | 236 | 18 | 0.24 | |

| Inorganic PCMs | Sodium sulphate | 252 | 32.4 | - |

| KF·4H2O | 231 | 18.5 | - | |

| Salt hydrate | 259 | 38 | 1.46 | |

| LiNO3·2H2O | 296 | 30 | - | |

| FeBr3·6H2O | 105 | 21 | - | |

| Eutectics PCMs | Capric + Stearic acid | 24.7 | 178.6 | - |

| Capric + Palmitic | 22.1 | 220 | - | |

| Methyl stearate + Cetyl-stearate | 22.3 | 180 | - | |

| Triethylolethane + urea | 29.8 | 218 | - | |

| Methly-stearate + Cetylpalmitate | 28.2 | 189 | - |

| Researcher | Setup Location | Working Fluid | Performance Methods | Key Outputs |

|---|---|---|---|---|

| Absuka et al. [44] | - | Air | Use of PCM as TES |

|

| Saedodin et al. [45] | Karaj, Iran | Water | Porous metal foam as energy storage |

|

| Sakhaei and Vaipour et al. [46] | Semnan, Iran | Water | Use of corrugated absorber and PCM |

|

| Badiei et al. [47] | Shiraz, Iran | Water | Use of PCM with fins |

|

| Sajawal et al. [48] | Taxila, Pakistan | Air | Use of PCM (RT44HC) with fins |

|

| Al-Kayiem and Lin [49] | Universiti Teknologi PETRONAS (Malaysia) | Water | Paraffin and paraffin with nanoparticle |

|

| Researcher | Setup Location | Working Fluid | Performance Methods | Key Outputs |

|---|---|---|---|---|

| Fan et al. [68] | - | Water | V-corrugated absorber with mini channels |

|

| Sivakumar et al. [69] | Coimbatore, India | Air | CuO nanoparticle coated surface for absorption |

|

| Nazari et al. [70] | Urmia, Iran | Water | Coated of CuO on absorber plate |

|

| Selikhov et al. [71] | - | Air | Polymer material coating |

|

| Alkhafaji et al. [72] | Baghdad—Iraq | Water | Addition of fins |

|

| Sharma et al. [73] | India | Water | Circular & trapezoidal corrugated absorber plate |

|

| Researcher | Setup Location | Working Fluid | Performance Improvement Methods | Key Outputs |

|---|---|---|---|---|

| Ramesh et al. [81] | Tamilnadu, India | Water | Reflector with absorber coating |

|

| Nilolic and Lukic [85] | Kragujevac, Serbia | Working fluid (water/air) | Flat plate reflective surface |

|

| Pandya and Behura [52] | Jaipur, India | Water | V-trough for reflection |

|

| Rachedi et al. [86] | Southern Algeria | Water | V-trough concentrators |

|

| Housseyn Karoua [87] | - | Air | Linear Fresnel reflector |

|

| Researcher | Setup Location | Working Fluid | Performance Methods | Key Outputs |

|---|---|---|---|---|

| Noghrehabadi et al. [106] | Ahvaz, Iran | Water + nanoparticles | Use of nanofluid as HTF |

|

| Saied et al. [107] | - | Water + nanoparticles | Use of hybrid nanofluid (MWCNT+Fe3O4/Water) |

|

| Mirzaei et al. [108] | Rafsanjan, Iran | Nanofluid + water | Al2O3 as heat transfer fluid |

|

| Verma et al. [109] | Mathura India | Water + hybrid nanoparticles | Use of hybrid nanofluids |

|

| Ashour et al. [110] | Egypt | Water | Use of nanofluids (ZnO and CuO) |

|

| Tong et al. [111] | Gwangju, Korea | Water + nanoparticles | Use of nanofluid as HTF |

|

| Akram et al. [112] | Kuala Lumpur, Malaysia | Water + nanoparticles | Use of different nanofluids |

|

| Mausam et al. [113] | Mathura, India | Cu+MWCNT+DI water | Use of hybrid nanofluids |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pathak, S.K.; Tazmeen, T.; Chopra, K.; Tyagi, V.V.; Anand, S.; Abdulateef, A.M.; Pandey, A.K. Sustainable Energy Progress via Integration of Thermal Energy Storage and Other Performance Enhancement Strategies in FPCs: A Synergistic Review. Sustainability 2023, 15, 13749. https://doi.org/10.3390/su151813749

Pathak SK, Tazmeen T, Chopra K, Tyagi VV, Anand S, Abdulateef AM, Pandey AK. Sustainable Energy Progress via Integration of Thermal Energy Storage and Other Performance Enhancement Strategies in FPCs: A Synergistic Review. Sustainability. 2023; 15(18):13749. https://doi.org/10.3390/su151813749

Chicago/Turabian StylePathak, Sudhir Kumar, Tagamud Tazmeen, K. Chopra, V. V. Tyagi, Sanjeev Anand, Ammar M. Abdulateef, and A. K. Pandey. 2023. "Sustainable Energy Progress via Integration of Thermal Energy Storage and Other Performance Enhancement Strategies in FPCs: A Synergistic Review" Sustainability 15, no. 18: 13749. https://doi.org/10.3390/su151813749