Active and Reactive Power Control of the Voltage Source Inverter in an AC Microgrid

Abstract

:1. Introduction

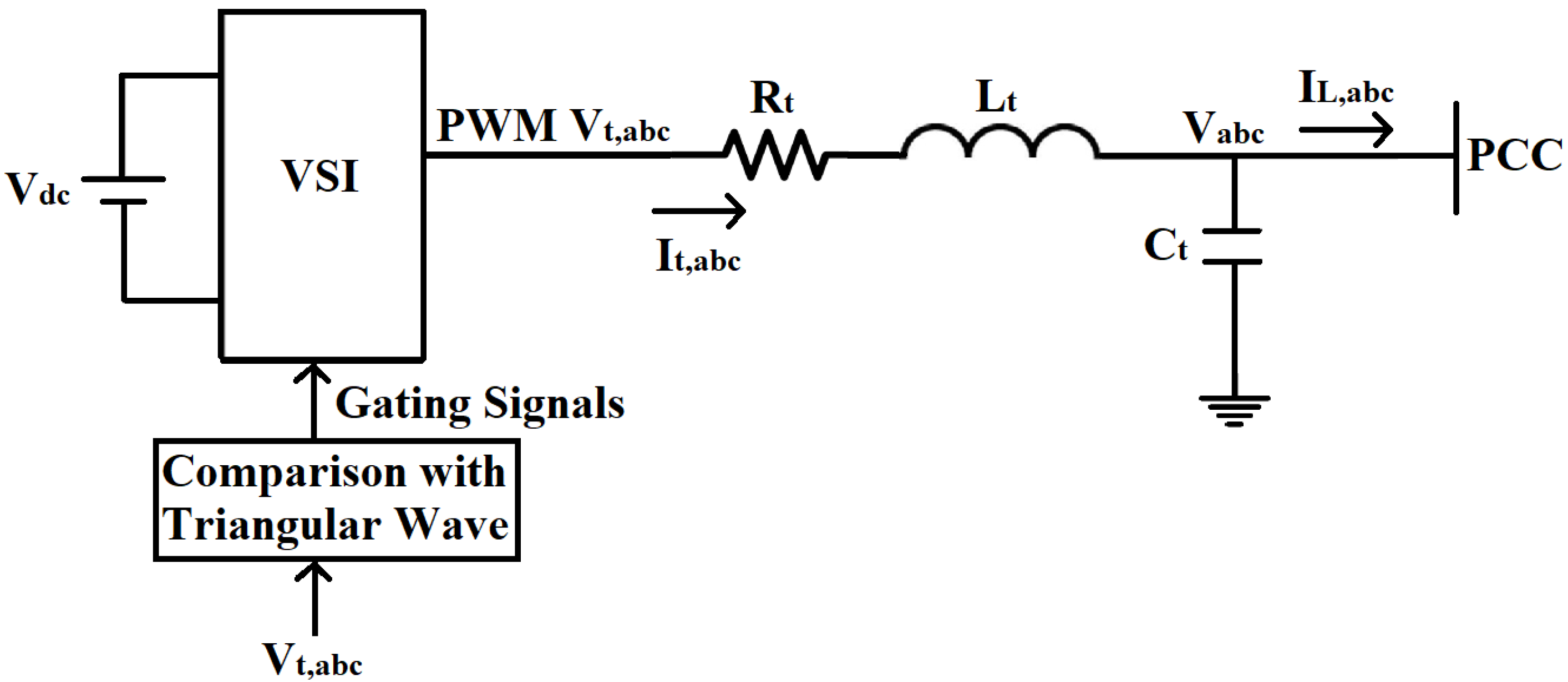

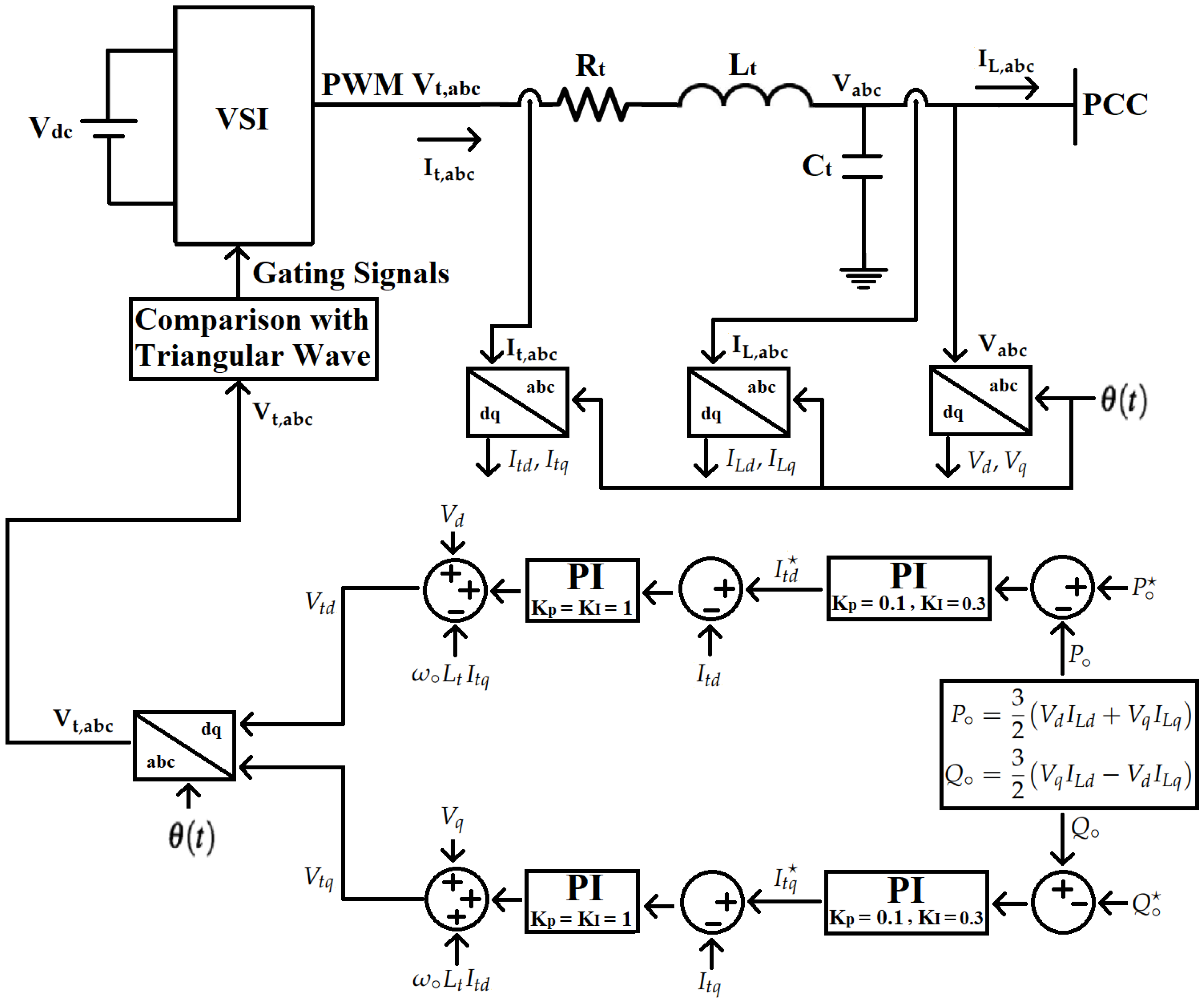

2. Problem Formulation

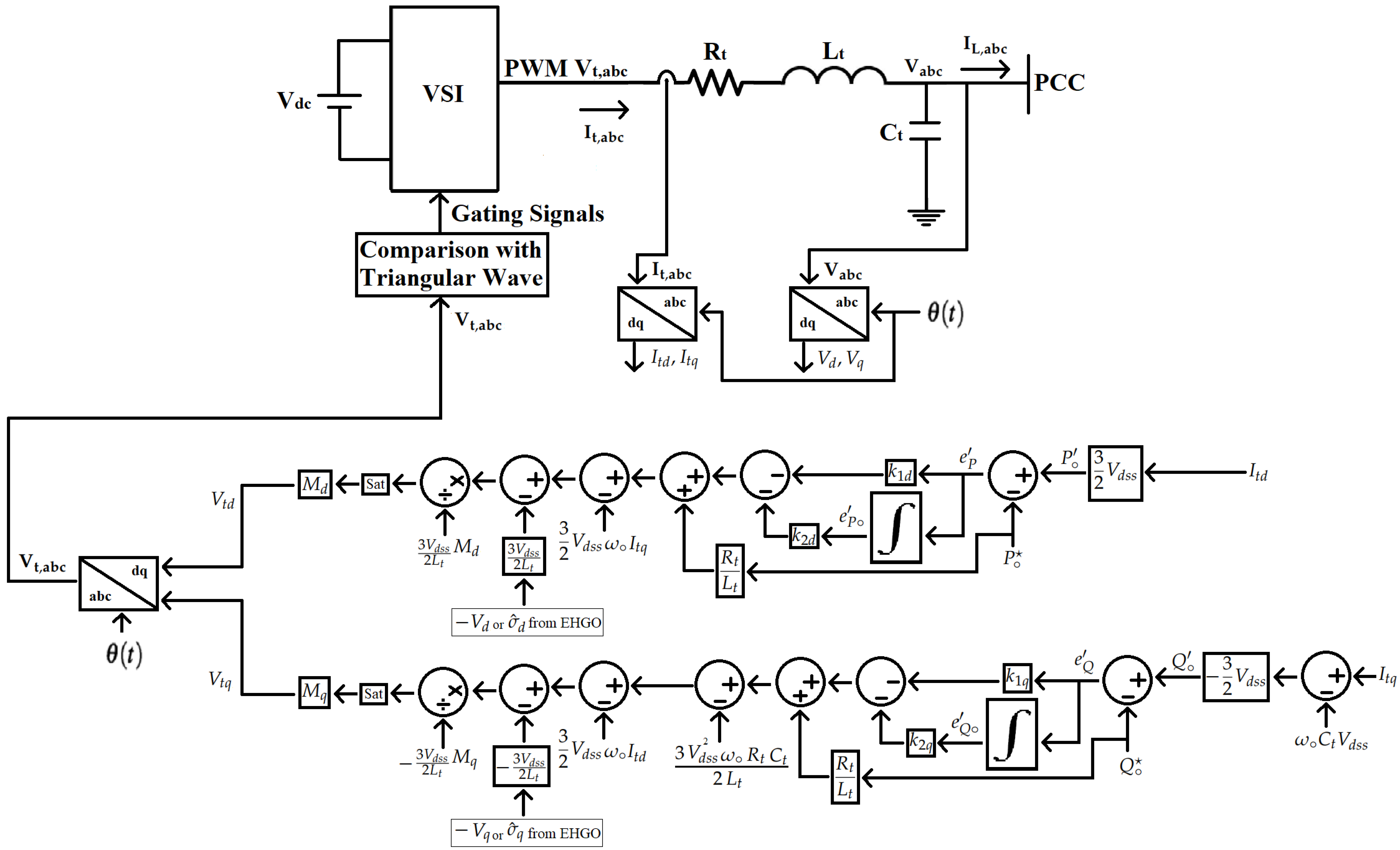

3. Control Scheme

3.1. Controller Design for Active Power ()

3.2. Controller Design for Reactive Power ()

4. Stability Analyses

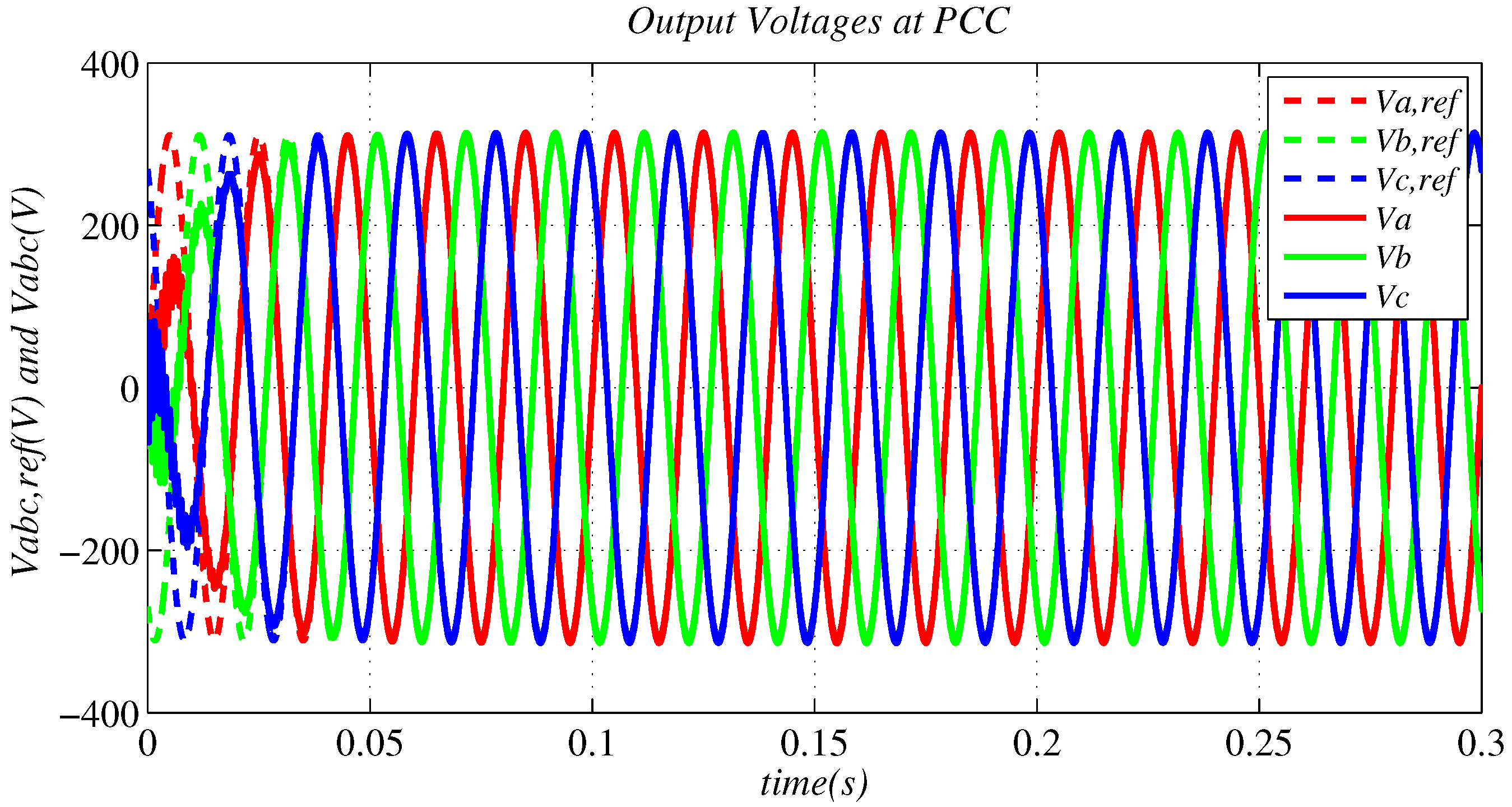

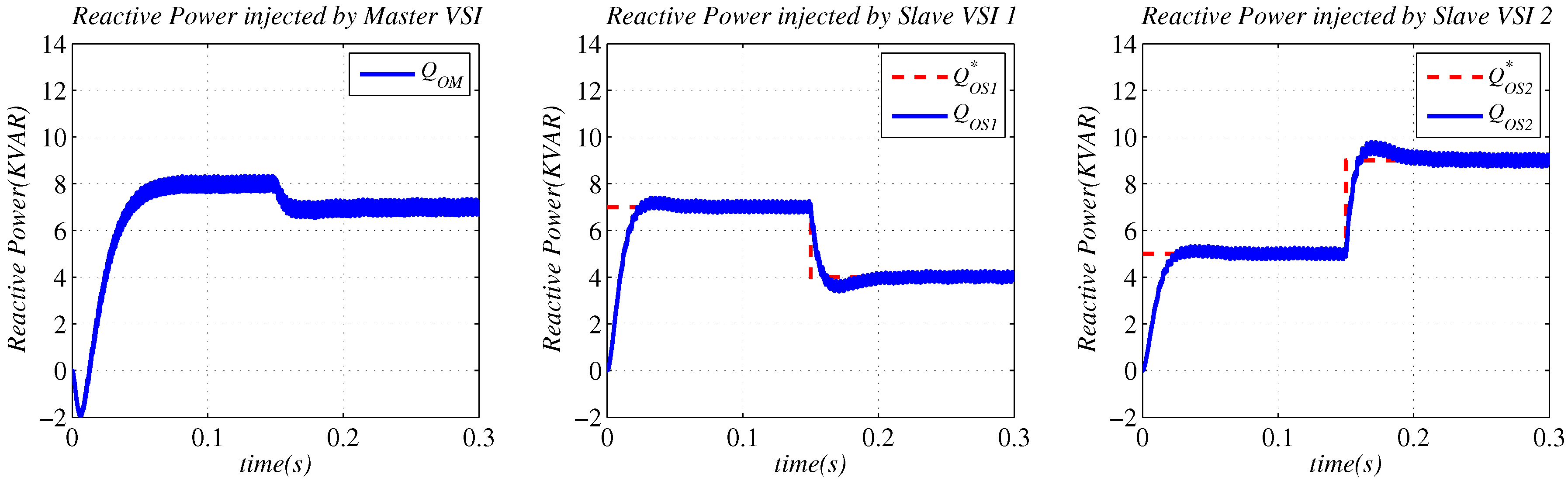

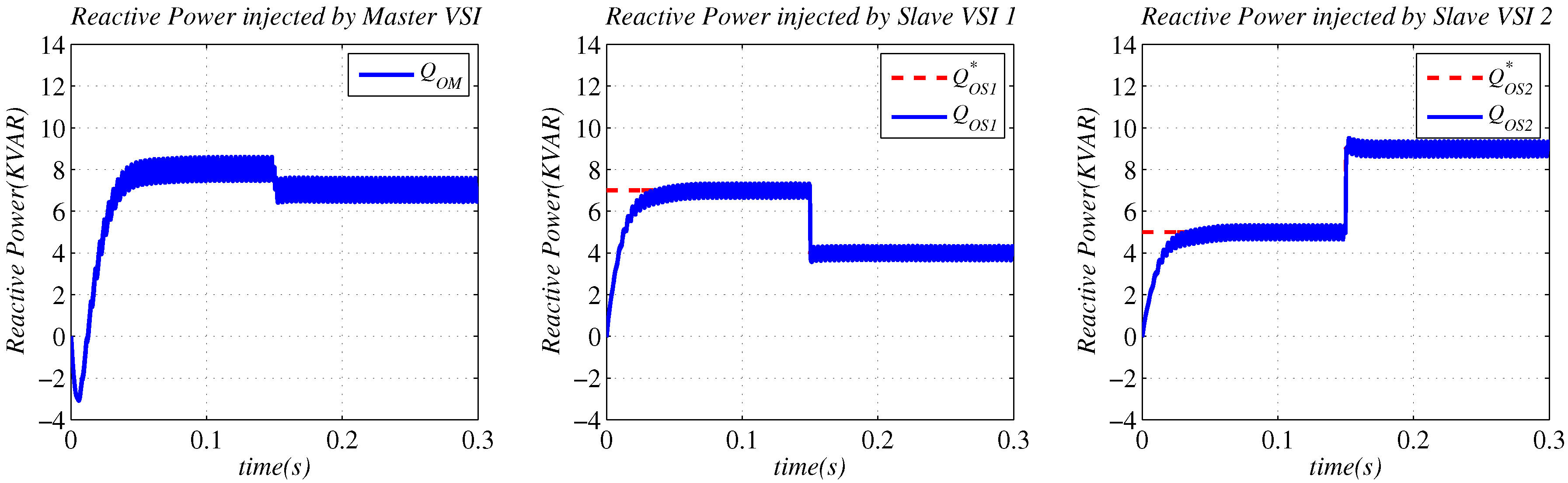

5. Simulation Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| VSI | voltage source inverter |

| PWM | pulse width modulated |

| PCC | point of common coupling |

| VCM | voltage control mode |

| PCM | power control mode |

| EHGO | extended high-gain observer |

References

- Deng, F.; Li, X.; Zhang, X.; Mattavelli, P. An Iterative Virtual Impedance Regulation Strategy in Islanded Microgrids for Enhanced Balanced, Unbalanced and Harmonic Current Sharing. IEEE Trans. Sustain. Energy 2022, 13, 514–526. [Google Scholar] [CrossRef]

- Bullich-Massagué, E.; Aragüés-Peñalba, M.; Prieto-Araujo, E.; Sumper, A.; Caire, R. Optimal feeder flow control for grid connected microgrids. Int. J. Electr. Power Energy Syst. 2019, 112, 144–155. [Google Scholar] [CrossRef]

- Farrokhabadi, M.; Cañizares, C.A.; Simpson-Porco, J.W.; Nasr, E.; Fan, L.; Mendoza-Araya, P.A.; Tonkoski, R.; Tamrakar, U.; Hatziargyriou, N.; Lagos, D.; et al. Microgrid stability definitions, analysis, and examples. IEEE Trans. Power Syst. 2019, 35, 13–29. [Google Scholar] [CrossRef]

- Chen, Z.; Pei, X.J.; Yang, M.; Peng, L. An adaptive virtual resistor (avr) control strategy for low-voltage parallel inverters. IEEE Trans. Power Electron. 2019, 34, 863–876. [Google Scholar] [CrossRef]

- Andishgar, M.H.; Gholipour, E.; Hooshm, R.A. An overview of control approaches of the inverter-based microgrids in islanding mode of operation. Renew. Sustain. Energy Rev. 2017, 80, 1043–1060. [Google Scholar] [CrossRef]

- Worku, M.Y.; Hassan, M.A.; Abido, M.A. Real Time-Based under Frequency Control and Energy Management of Microgrids. Electronics 2020, 9, 1487. [Google Scholar] [CrossRef]

- Hossain, M.A.; Pota, H.R.; Hossain, M.J.; Blaabjerg, F. Evolution of microgrids with converter-interfaced generations: Challenges and opportunities. Int. J. Electr. Power Energy Syst. 2019, 109, 160–186. [Google Scholar] [CrossRef]

- Zhou, Y.; Ho, C.N.-M. A review on microgrid architectures and control methods. In Proceedings of the 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia, Hefei, China, 22–26 May 2016; pp. 3149–3156. [Google Scholar]

- Guo, W.; Mu, L. Control principles of micro-source inverters used in the microgrid. Prot. Control Mod. Power Syst. 2016, 1, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Das, P.P.; Chattopadhayay, S.; Palma, M.l. A d–q voltage droop control method with dynamically phase-shifted phase-locked loop for inverter paralleling without any communication between individual inverters. IEEE Trans. Ind. Electron. 2017, 64, 4591–4600. [Google Scholar] [CrossRef]

- Zhong, Q.C.; Zeng, Y. Universal droop control of inverters with different types of output impedance. IEEE Access 2016, 4, 702–712. [Google Scholar] [CrossRef]

- Wai, R.J.; Zhang, Q.Q.; Wang, Y. A novel voltage stabilization and power sharing control method based on virtual complex impedance for an off-grid microgrid. IEEE Trans. Power Electron. 2019, 34, 1863–1880. [Google Scholar] [CrossRef]

- Amin, M.; Zhong, Q.C. Resynchronization of distributed generation based on the universal droop controller for seamless transfer between operation modes. IEEE Trans. Ind. Electron. 2020, 67, 7574–7582. [Google Scholar] [CrossRef] [Green Version]

- Rezaei, N.; Mazidi, M.; Gholami, M.; Mohiti, M. A new stochastic gain adaptive energy management system for smart microgrids considering frequency responsive loads. Energy Rep. 2020, 6, 914–932. [Google Scholar] [CrossRef]

- Saad, N.H.; El-Sattar, A.A.; Mansour, A.E.-A.M. A novel control strategy for grid connected hybrid renewable energy systems using improved particle swarm optimization. Ain Shams Eng. J. 2018, 9, 2195–2214. [Google Scholar] [CrossRef]

- Rocabert, J.; Luna, A.; Blaabjerg, F.; Rodríguez, P. Control of Power Converters in AC Microgrids. IEEE Trans. Power Electron. 2012, 27, 4734–4749. [Google Scholar] [CrossRef]

- Kothari, D.P.; Nagrath, I.J. Modern Power System Analysis; Tata McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Khan, H.S.; Memon, A.Y. Robust Output Feedback Control of the Voltage Source Inverter in an AC Microgrid. Energies 2022, 15, 5586. [Google Scholar] [CrossRef]

- Jabr, R.A. Economic Operation of Droop-Controlled AC Microgrids. IEEE Trans. Power Syst. 2022, 37, 3119–3128. [Google Scholar] [CrossRef]

- Chen, J.B.; Yue, D.; Dou, C.X.; Chen, L.; Weng, S.X.; Li, Y.M. A virtual complex impedance based P over dot droop method for parallel-connected inverters in low-voltage ac microgrids. IEEE Trans. Ind. Inform. 2021, 17, 1763–1773. [Google Scholar]

- Razi, R.; Iman-Eini, H.; Hamzeh, M. An impedance-power droop method for accurate power sharing in islanded resistive microgrids. IEEE J. Emerg. Sel. Top. Power Electron. 2020, 8, 3763–3771. [Google Scholar] [CrossRef]

- Elnady, A.; Suleiman, M.S. Comparative Analysis of Direct and Indirect Current Control of Master-Slave Scheme for Microgrid. In Proceedings of the 2022 International Conference on Power Energy Systems and Applications (ICoPESA), Singapore, 25–27 February 2022; pp. 83–89. [Google Scholar] [CrossRef]

- Parisio, A.; Rikos, E.; Glielmo, L.A. Model Predictive Control Approach to Microgrid Operation Optimization. IEEE Trans. Control Syst. Technol. 2014, 22, 1813–1827. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Teodorescu, R.; Liserre, M.; Timbus, A.V. Overview of Control and Grid Synchronization for Distributed Power Generation Systems. IEEE Trans. Ind. Electron. 2006, 53, 1398–1409. [Google Scholar] [CrossRef] [Green Version]

- Chattopadhyay, S.; Mitra, M.; Sengupta, S. Clarke and Park Transform. In Electric Power Quality Power Systems; Springer: Dordrecht, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Sadabadi, M.S.; Shafiee, Q.; Karimi, A. Plug-and-Play Voltage Stabilization in Inverter-Interfaced Microgrids via a Robust Control Strategy. IEEE Trans. Control. Syst. Technol. 2017, 25, 781–791. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, S.; Mekhilef, S.; Mokhlis, H. DQ-axis Synchronous Reference Frame based P-Q Control of Grid Connected AC Microgrid. In Proceedings of the 2020 IEEE International Conference on Computing, Power and Communication Technologies (GUCON), Greater Noida, India, 2–4 October 2020; pp. 842–847. [Google Scholar] [CrossRef]

- Worku, M.Y.; Hassan, M.A.; Abido, M.A. Real time energy management and control of renewable energy based microgrid in grid connected and island modes. Energies 2019, 12, 276. [Google Scholar] [CrossRef] [Green Version]

- Safa, A.; Berkouk, E.M.; Messlem, Y.; Gouichiche, A. A robust control algorithm for a multifunctional grid tied inverter to enhance the power quality of a microgrid under unbalanced conditions. Int. J. Electr. Power Energy Syst. 2018, 100, 253–264. [Google Scholar] [CrossRef]

- Ahmad, S.; Mekhilef, S.; Mokhlis, H.; Karimi, M.; Pourdaryaei, A.; Ahmed, T.; Jhuma, U.K.; Afzal, S. Fuzzy Logic-Based Direct Power Control Method for PV Inverter of Grid-Tied AC Microgrid without Phase-Locked Loop. Electronics 2021, 10, 3095. [Google Scholar] [CrossRef]

- Kaushal, J.; Basak, P. Power quality control based on voltage sag/swell, unbalancing, frequency, THD and power factor using artificial neural network in PV integrated AC microgrid. Sustain. Energy Grids Netw. 2020, 23, 100365. [Google Scholar] [CrossRef]

- Smadi, I.A.; Albatran, S.; Alsyouf, M.A. Optimal control of a compact converter in an AC microgrid. Electronics 2018, 7, 102. [Google Scholar] [CrossRef] [Green Version]

- Lou, G.; Gu, W.; Zhu, J.; Li, P.; Zhang, X. A novel control strategy for the seamless transfer of microgrids based on disturbance observer. Int. J. Electr. Power Energy Syst. 2020, 118, 105804. [Google Scholar] [CrossRef]

- Abadlia, I.; Adjabi, M.; Bouzeria, H. Sliding mode based power control of grid-connected photovoltaic-hydrogen hybrid system. Int. J. Hydrog. Energy 2017, 42, 28171–28182. [Google Scholar] [CrossRef]

- Alfaro, C.; Guzman, R.; de Vicuña, L.G.; Komurcugil, H.; Martín, H. Distributed Direct Power Sliding-Mode Control for Islanded AC Microgrids. IEEE Trans. Ind. Electron. 2022, 69, 9700–9710. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, D.; Xiao, D.; Li, M. Modeling and Stability Analysis of a Novel Voltage-Oriented Power Coordination Controlled Constant-Frequency AC Microgrid System. Electronics 2021, 10, 1935. [Google Scholar] [CrossRef]

- Andrade, I.; Pena, R.; Blasco-Gimenez, R.; Riedemann, J.; Jara, W.; Pesce, C. An Active/Reactive Power Control Strategy for Renewable Generation Systems. Electronics 2021, 10, 1061. [Google Scholar] [CrossRef]

- Go, S.-I.; Choi, J.-H. Design and dynamic modelling of pv-battery hybrid systems for custom electromagnetic transient simulation. Electronics 2020, 9, 1651. [Google Scholar] [CrossRef]

- Shan, Y.; Hu, J.; Liu, H. A Holistic Power Management Strategy of Microgrids Based on Model Predictive Control and Particle Swarm Optimization. IEEE Trans. Ind. Inform. 2022, 18, 5115–5126. [Google Scholar] [CrossRef]

- Burbano-Benavides, D.S.; Ortiz-Sotelo, O.D.; Revelo-Fuelagán, J.; Candelo-Becerra, J.E. Design of an On-Grid Microinverter Control Technique for Managing Active and Reactive Power in a Microgrid. Appl. Sci. 2021, 11, 4765. [Google Scholar] [CrossRef]

- Mousavi, S.Y.M.; Jalilian, A.; Savaghebi, M.; Guerrero, J.M. Coordinated control of multifunctional inverters for voltage support and harmonic compensation in a grid-connected microgrid. Electr. Power Syst. Res. 2018, 155, 254–264. [Google Scholar] [CrossRef] [Green Version]

- Sedaghati, R.; Shakarami, M.R. A novel control strategy and power management of hybrid PV/FC/SC/battery renewable power system-based grid-connected microgrid. Sustain. Cities Soc. 2019, 44, 830–843. [Google Scholar] [CrossRef]

- Etemadi, A.H.; Davison, E.J.; Iravani, R. A Generalized Decentralized Robust Control of Islanded Microgrids. IEEE Trans. Power Syst. 2014, 29, 3102–3113. [Google Scholar] [CrossRef]

- Babazadeh, M.; Karimi, H. A Robust Two-Degree-of-Freedom Control Strategy for an Islanded Microgrid. IEEE Trans. Power Deliv. 2013, 28, 1339–1347. [Google Scholar] [CrossRef]

- Khalil, H.K. High-gain observers in nonlinear feedback control. In Proceedings of the 2008 International Conference on Control, Automation and Systems, Seoul, Republic of Korea, 14–17 October 2008; pp. xlvii–lvii. [Google Scholar] [CrossRef]

| Electrical Parameters | Values |

|---|---|

| DC voltage source () | 1000 V |

| PWM carrier frequency | 12.8 KHz |

| Nominal voltage of the system (phase-to-neutral) | |

| Nominal frequency of the system | rad/s |

| Resistance of the VSI output filter | 0.2 |

| Inductance of the VSI output filter | 1 mH |

| Capacitance of the VSI output filter | 20 |

| Required Power Sharing | Values |

|---|---|

| Active power of the Load () | 20 KW |

| Reactive power of the Load () | 20 KVAR |

| Active power of the Slave VSI 1 () | 7 KW ( s), 4 KW ( s) |

| Reactive power of the Slave VSI 1 () | 7 KVAR ( s), 4 KVAR ( s) |

| Active power of the Slave VSI 2 () | 5 KW ( s), 9 KW ( s) |

| Reactive power of the Slave VSI 2 () | 5 KVAR ( s), 9 KVAR ( s) |

| Active power of the Master VSI () | |

| Reactive power of the Master VSI () |

| Parameters | Values |

|---|---|

| and | 0 |

| and | 10,000 |

| 500 | |

| 250 | |

| and | 2 |

| and |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, H.S.; Memon, A.Y. Active and Reactive Power Control of the Voltage Source Inverter in an AC Microgrid. Sustainability 2023, 15, 1621. https://doi.org/10.3390/su15021621

Khan HS, Memon AY. Active and Reactive Power Control of the Voltage Source Inverter in an AC Microgrid. Sustainability. 2023; 15(2):1621. https://doi.org/10.3390/su15021621

Chicago/Turabian StyleKhan, Hamid Saeed, and Attaullah Y. Memon. 2023. "Active and Reactive Power Control of the Voltage Source Inverter in an AC Microgrid" Sustainability 15, no. 2: 1621. https://doi.org/10.3390/su15021621