Innovation in Green Materials for the Non-Contact Stabilization of Sensitive Works of Art: Preliminary Assessment and the First Application of Ultra-Low Viscosity Hydroxypropyl Methylcellulose (HPMC) by Ultrasonic Misting to Consolidate Unstable Porous and Powdery Media

Abstract

:1. Introduction

2. Materials and Methods

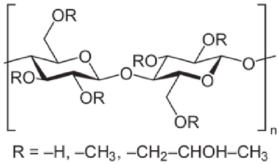

3. Novel Ultra-Low Viscosity (ULV) Cellulose Ethers for the Consolidation of Powdery Media

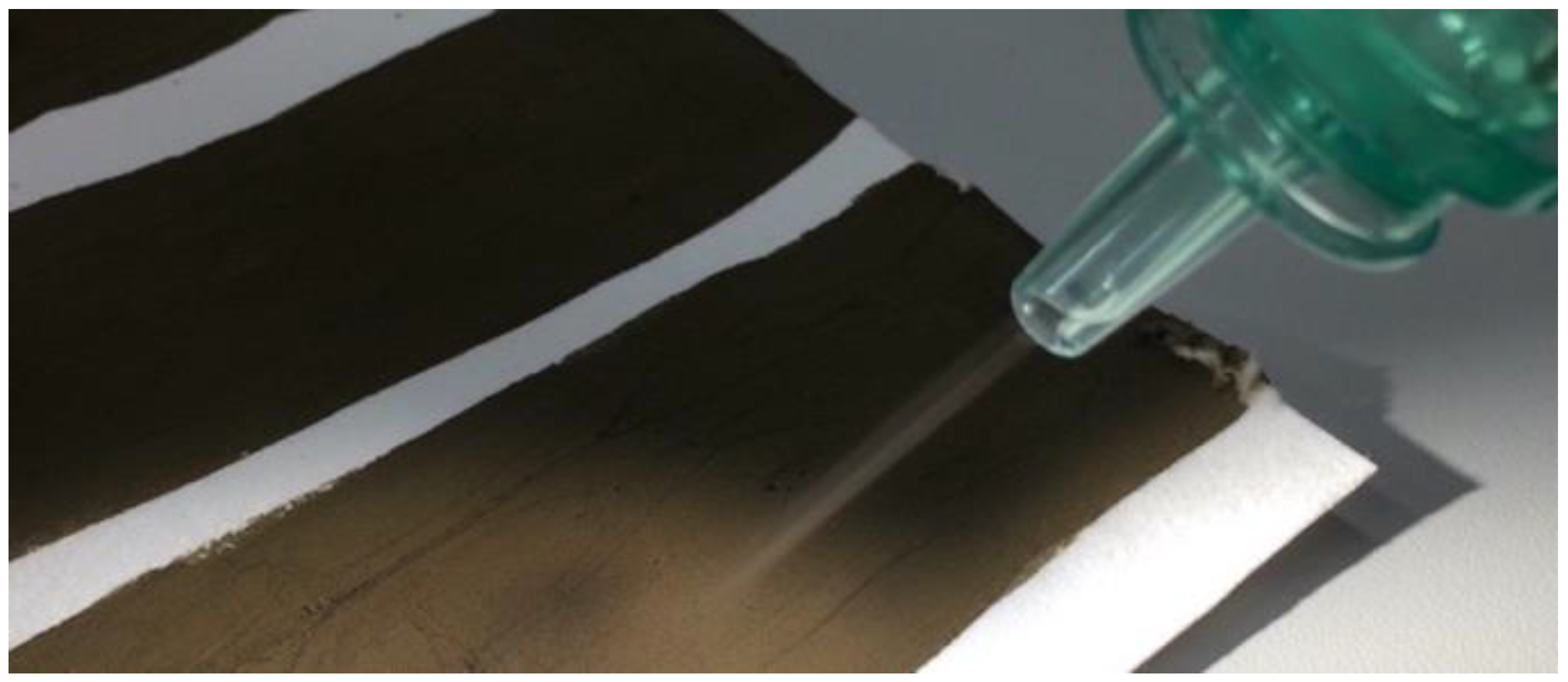

3.1. The Role of Ultra-Low Viscosity in the Consolidation of Media, Using Ultrasonic Misting

3.2. New Ultra-Low Viscosity HPMC Consolidation Medium for Ultrasonic Misting Treatments

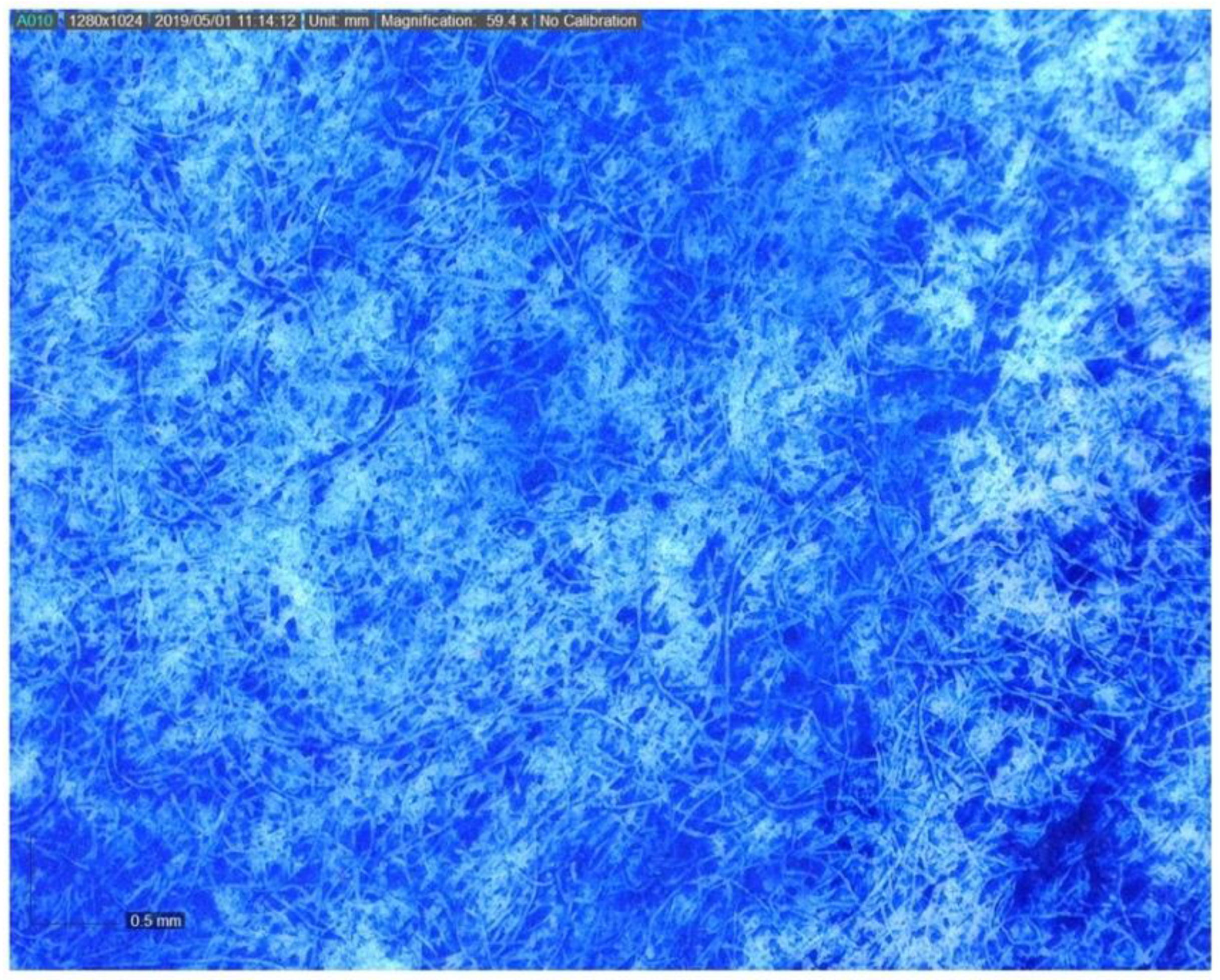

3.2.1. Ultra-Low Viscosity Hydroxypropyl Methylcellulose (ULV-HPMC) MOBS 3P4 (Pharmacoat 603®) and 6P4 (Pharmacoat 606®): Chemical and Physical Properties Relevant to Conservation

3.2.2. ULV-HPMC Stability, Optical Changes and Preliminary Accelerated Aging Testing

3.3. Experimental: Testing and Assessing ULV-HPMC Stability and Effectiveness

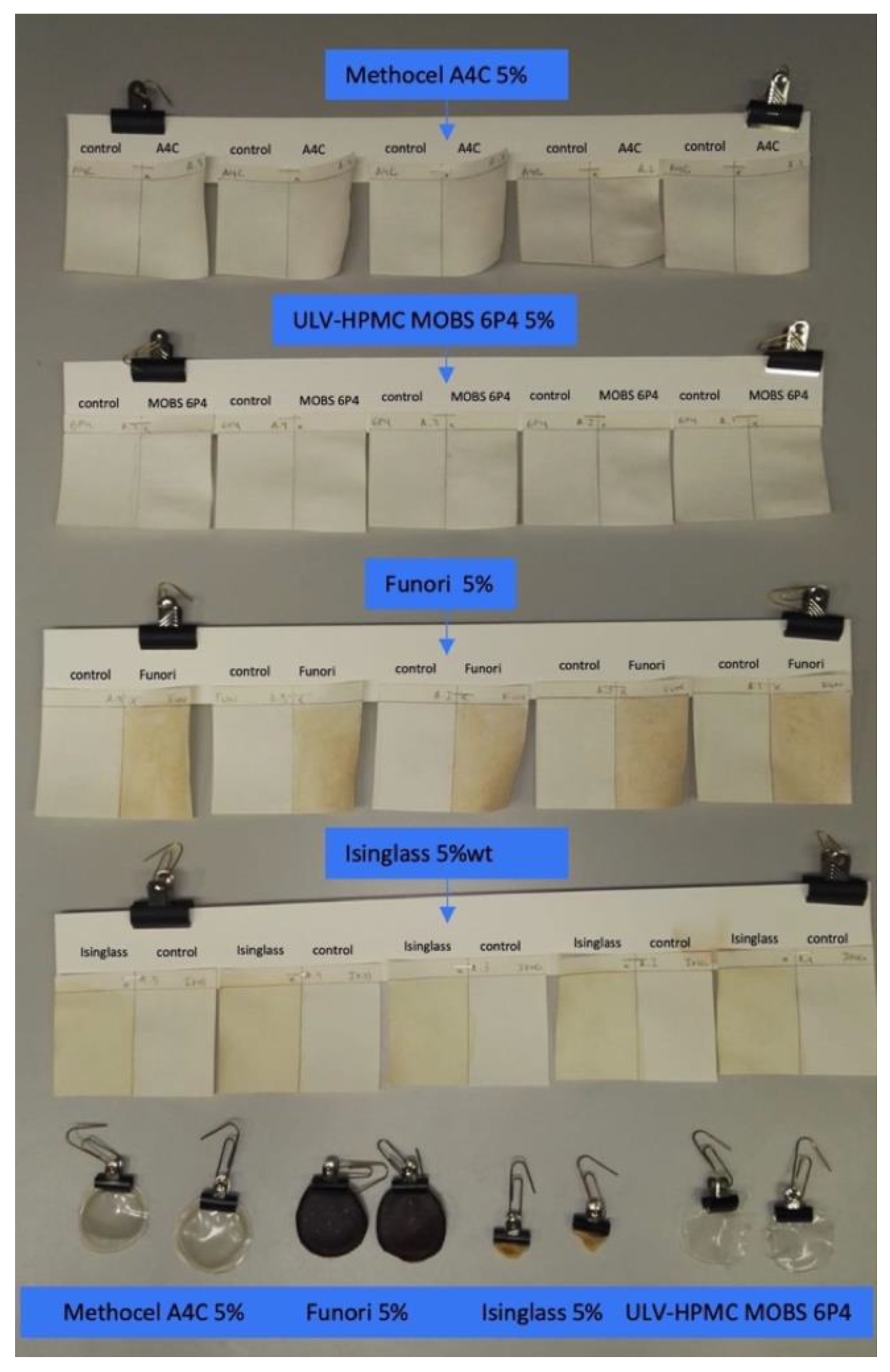

3.3.1. Hygro-Thermal Accelerated Aging

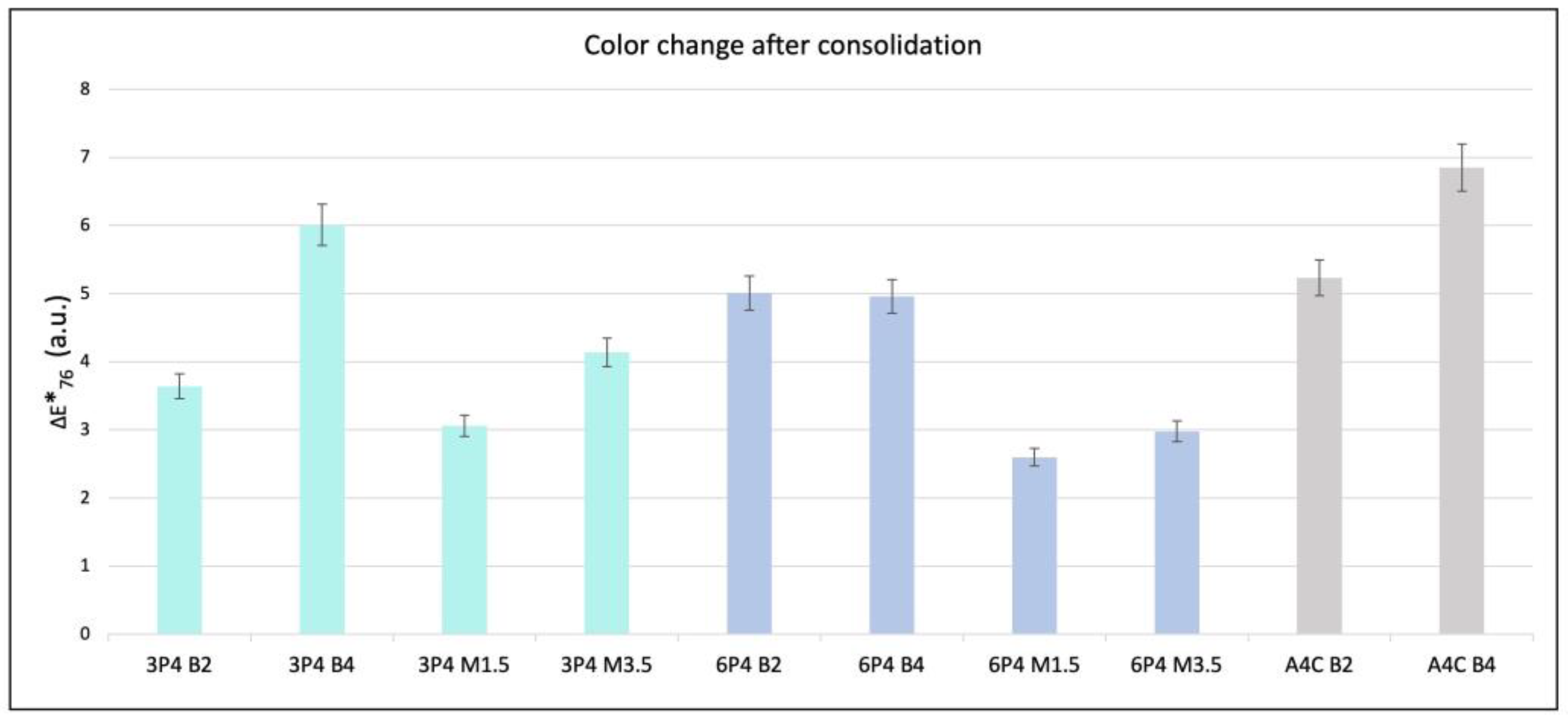

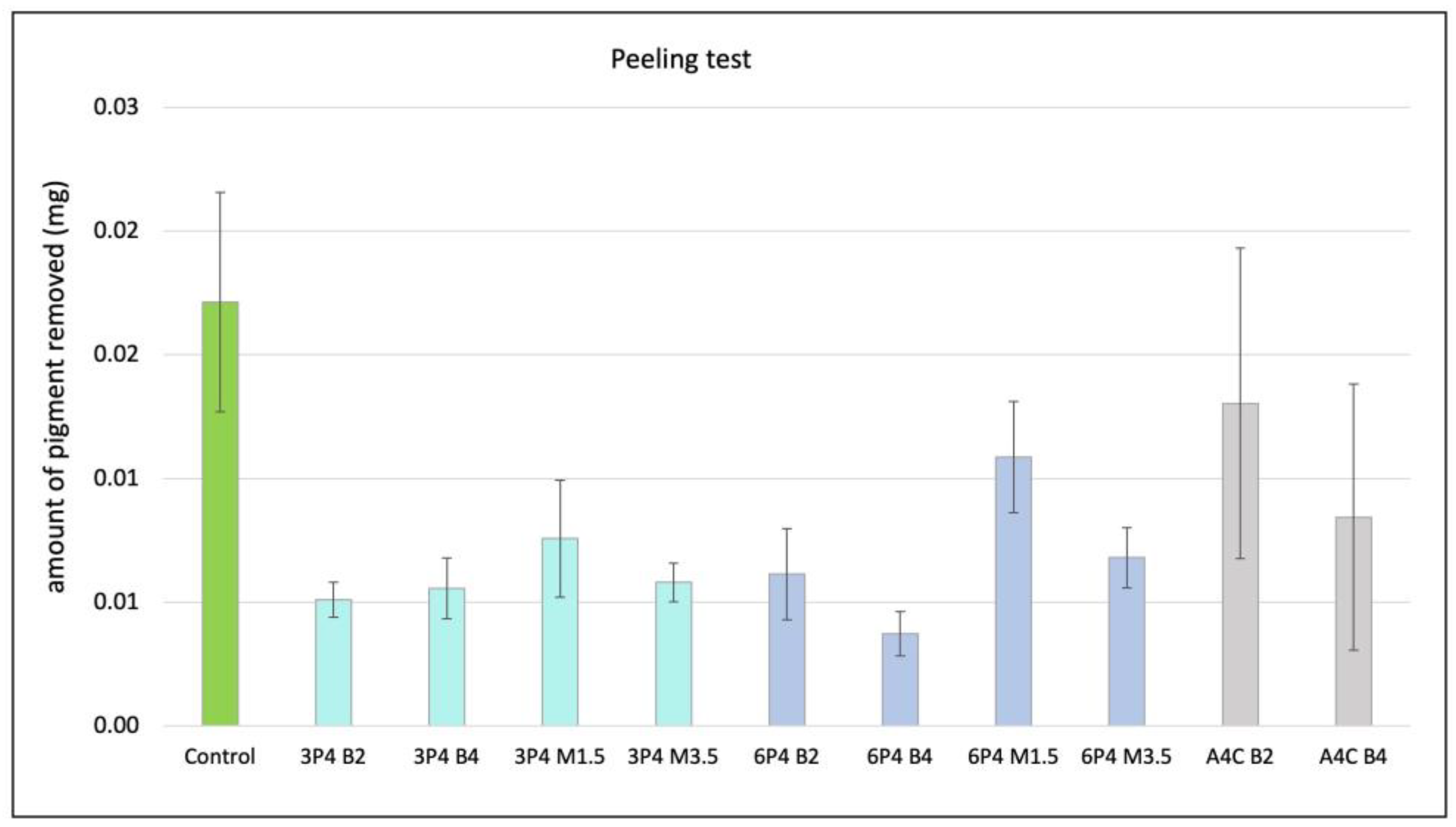

3.3.2. Assessment of Consolidation Treatment

4. Two Case Studies: Consolidation Treatments Using Novel ULV-HPMC Materials

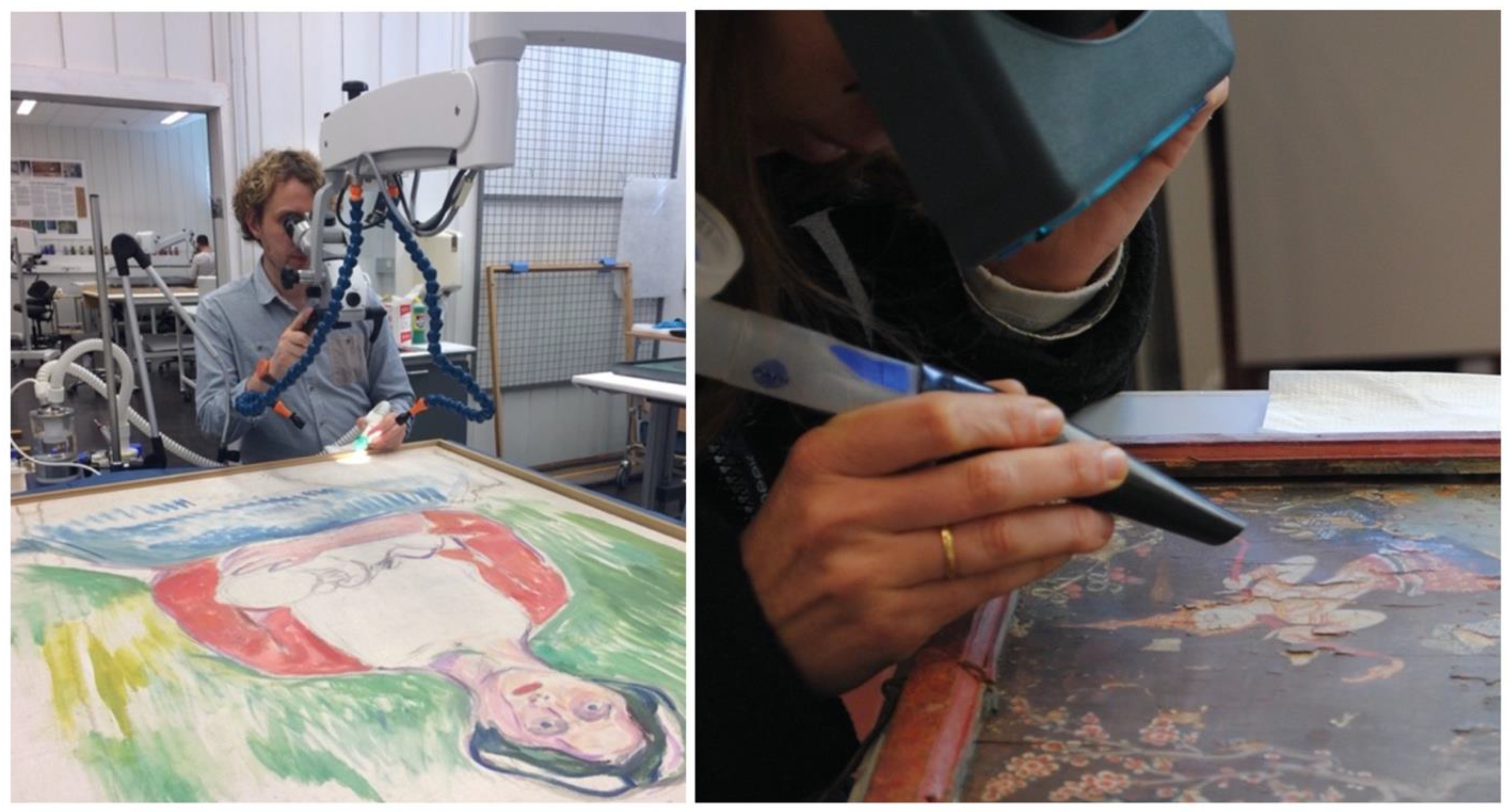

4.1. Edvard Munch’s Alma Mater Study

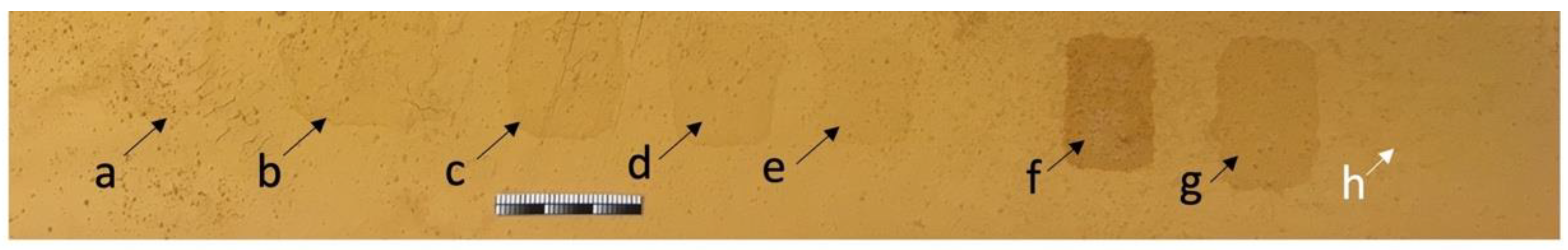

4.2. Two 19th C. Unvarnished Traditional Thai Thotsachat Gouache Paintings on Panel, Thai Thotsachat, 57.4 × 46.7 cm, Gouache and Gilding on Panel (IS.43-2005), Victoria & Albert Museum, London

5. Results and Discussion

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schellmann, N.C. Animal glues: A review of their key properties relevant to conservation. Stud. Conserv. 2007, 52 (Suppl. S1), 55–66. [Google Scholar] [CrossRef]

- Geiger, T.; Michel, F. Studies on the Polysaccharide Jun-Funori Used to Consolidate Matt Paint. Stud. Conserv. 2005, 50, 193–204. [Google Scholar] [CrossRef]

- Sandbakken, E.G.; Storevik Tveit, E. Preserving a Master: Edvard Munch and His Painted Sketches. J. Urban Cult. Res. 2012, 5, 86–104. [Google Scholar]

- Swider, J.R.; Smith, M. Funori: Overview of a 300-Year-Old Consolidant. J. Am. Inst. Conserv. 2005, 44, 117–126. [Google Scholar] [CrossRef]

- Feller, R.L.; Wilt, M. Evaluation of Cellulose Ethers for Conservation; Research in Conservation 3; The Getty Conservation Institute: Los Angeles, CA, USA, 1990. [Google Scholar]

- Raposo, A.; Alturki, H.A.; Alkutbe, R.; Raheem, D. Eating Sturgeon: An Endangered Delicacy. Sustainability 2023, 15, 3511. [Google Scholar] [CrossRef]

- Eggertsen, M.; Halling, C. Knowledge gaps and management recommendations for future paths of sustainable seaweed farming in the Western Indian Ocean. Ambio 2021, 50, 60–73. [Google Scholar] [CrossRef]

- Markevicius, T.; Angelova, L.; Pardo, L.P. Study of New Materials for Non-Contact Consolidation of Unprotected Matte Paint Media: Coupling Ultra-Low Viscosity Cellulose Ethers with Ultrasonic Misting Technique. In Proceedings of the Oral presentation at the Paintings Specialty Group, AIC’s 47th Annual Meeting, Uncasville, CT, USA, 17 May 2019. [Google Scholar]

- Michalski, S. A physical model of the consolidation process, particularly of paintings. In Proceedings of the Color and Conservation: Materials and Methods in the Conservation of Polychrome Artworks: Third International Conference, Milan, Italy, 10–11 November 2006; pp. 27–47. [Google Scholar]

- Michalski, S.; Dignard, C. Ultrasonic Misting, Part 1, Experiments on Appearance Change and Improvement in Bonding. J. Am. Inst. Conserv. 1997, 36, 109–126. [Google Scholar] [CrossRef]

- Hansen, F.; Walston, S.S.; Bishop, M. (Eds.) Matte Paint. Its History and Technology, Analysis, Properties, and Conservation Treatment; The Getty Conservation Institute: Los Angeles, CA, USA, 1993. [Google Scholar]

- Gagnon, A.M. Fabrication of an Ultrasonic Nebulizer: Rate of Flow and Performance Studies. Stud. Conserv. 2019, 64, 435–447. [Google Scholar] [CrossRef]

- Pataki, A. Consolidation of White Chalk with Aerosols. In Proceedings of the 14th Triennial Meeting of the ICOM Committee for Conservation, Den Haag, The Netherlands, 12–16 September 2005; pp. 223–230. [Google Scholar]

- Sommermeyer, B. Consolidation of Matte, Powdery Paint in Modern Art with the Ultrasonic Mister. In Proceedings of the 12th Triennial Meeting of the ICOM Committee for Conservation, Lyon, Poster Abstract, London, UK, 29 August–3 September 1999; p. 901. [Google Scholar]

- Kessler, A.; Blüher, A.; Banik, G. Aerosole für die Konsolidierung pudriger Malschichten auf Papier. In Studiengang Restaurierung von Graphik, Archiv und Bibliotheksgut, Projekte, Diplomarbeiten, Semesterarbeiten; Stuttgart, B.G., Ed.; Selbstverlag: Ebmatingen, Switzerland, 1998; p. 16. [Google Scholar]

- Michalski, S.; Dignard, C.; Van Handel, L.; Arnold, D. The Ultrasonic Mister. In Consolidation of Powdery Paint on Wooden Artifacts, in Painted Wood: History and Conservation, Part 6-Scientific Research; Getty Conservation Institute: Los Angeles, CA, USA, 1998; pp. 498–512. [Google Scholar]

- Dignard, C.; Douglas, R.; Guild, S.; Maheux, A.; Mc Williams, W. Ultrasonic Misting Part 2, Treatment application. J. Am. Inst. Conserv. 1997, 36, 127–141. [Google Scholar] [CrossRef]

- Arnold, D. Recent Advances in Mist Consolidation of Powdery Surfaces. In Proceedings of the 24th Annual Meeting American Institute for Conservation, Washington, DC, USA, 10–16 June 1996; p. 102. [Google Scholar]

- Weidner, M.K. Treatment of Water-Sensitive and Friable Media using Suction and Ultrasonic Mist. AIC Book Pap. Group Annu. 1993, 12, 75–84. [Google Scholar]

- Fair, J. Liquid-gas systems. In Perry’s Chemical Engineers Handbook, 6th ed.; McGraw Hill: New York, NY, USA, 1984; pp. 18–52. [Google Scholar]

- McCallion, O.N.M.; Tayler, K.M.G.; Thomas, M.; Taylor, A.J. Nebulization of fluids of different physicochemical properties with air-jet and ultrasonic nebulizers. Pharm Res. 1995, 12, 1682–1688. [Google Scholar] [CrossRef] [PubMed]

- Mercer, T.T. Production of therapeutic aerosols: Principles and techniques. Chest 1980, 80, 813–818. [Google Scholar]

- Andrina, A. Potentiality of Funori to restore physical breaks of deteriorated cellulosic fibers. CeROArt. Conservation, exposition, Restauration d’Objets d’Art; Association CeROArt asbl, 2014. Available online: https://doi.org/10.4000/ceroart.3899 (accessed on 29 July 2023).

- Derkach, S.R.; Voron’ko, N.G.; Kuchina, Y.A.; Kolotova, D.S. Modified Fish Gelatin as an Alternative to Mammalian Gelatin in Modern Food Technologies. Polymers 2020, 12, 3051. [Google Scholar] [CrossRef] [PubMed]

- Shin-Etsu, Hypromellose USP Pharmacoat, Film Coating Material and Binder, Cellulose and Pharmaceutical Excipient Department Technical Sheet, Tokyo. 2018. Available online: https://www.metolose.jp/en/pharmaceutical/tc-5.html (accessed on 19 September 2022).

- Manufacturers Technical Data Sheet. Available online: https://www.gusmerenterprises.com/wp-content/uploads/2015/05/Cryofine-for-Beer-Clarification.pdf (accessed on 10 July 2023).

- Kokubo, H.; Obara, S.; Nishiyama, Y. Application of Extremely Low Viscosity Methylcellulose (MC) for Pellet Film Coating. Chem. Pharm. Bull. 1998, 46, 1803–1806. [Google Scholar] [CrossRef]

- Sahoo, C.K.; Rao, S.R.M.; Sudhakar, M. HPMC: A biomedical polymer in pharmaceutical dosage forms. J. Chem. Pharm. Sci. 2015, 8, 875–881. [Google Scholar]

- Pal, K.; Paulson, A.T.; Rousseau, D. Biopolymers in Controlled-Release Delivery Systems, in Plastics Design Library. In Handbook of Biopolymers and Biodegradable Plastics; Ebnesajjad, S., Ed.; William Andrew Publishing: Norwich, NY, USA, 2013; pp. 329–363. [Google Scholar]

- Hollie, F.B.; Sheskey, P.J.; Garcia-Todd, P.; Felton, L.A. Novel low-molecular-weight hypromellose polymeric films for aqueous film coating applications. Drug Dev. Ind. Pharm. 2011, 37, 1439–1445. [Google Scholar] [CrossRef]

- Perfetti, G.; Alphazan, T.; Wildeboer, W.J.; Meesters, G.M.H. Thermo-physical characterization of Pharmacoat® 603, Pharmacoat® 615 and Mowiol® 4-98. J. Therm. Anal. Calorim. 2012, 109, 203–215. [Google Scholar] [CrossRef]

- Dow, Methocel Cellulose Ethers in Aqueous Systems for Tablet Coating, The Dow Chemical Company Technical Leaflet, 2002.

- Otoni, C.G.; Marcos, L.M.; Lorevice, V.; de Moura, M.R.; Mattoso, L.H. On the effects of hydroxyl substitution degree and molecular weight on mechanical and water barrier properties of hydroxypropyl methylcellulose films. Carbohydr. Polym. 2018, 185, 105–111. [Google Scholar] [CrossRef]

- Baker, C. The Role Viscosity Grade Plays when Choosing Methylcellulose as a Sizing Agent. In Institute of Paper Conservation Conference Papers, Manchester; Institute of Paper Conservation: London, UK, 1992; pp. 219–221. [Google Scholar]

- Direct communication with Shin-Etsu representative Frank Schneider, SE Tylose GmbH & Co. KG, 2 May 2019.

- Pretzel, B. Now You See It, Now You Don’t: Lighting Decisions for the Ardabil Carpet Based on the Probability of Visual Perception and Rates of Fading. In Proceedings of the ICOM-CC 15th Triennial Conference, New Delhi, India, 22–26 September 2008; p. 762. [Google Scholar]

- Fan, T.F. Evaluation of Funori stability in preparation methods. In Adhesives and Consolidants in Paintings Conservation; Archetype Publications Ltd.: London, UK, 2012; pp. 53–60. [Google Scholar]

- Pataki-Hundt, A.; Hummert, E. Colour Stability of Natural Adhesives—Light Aging of Adhesive Films and Colour Changes of Pigment Layers after Aerosol Application. Restaurator. Int. J. Preserv. Libr. Arch. Mater. 2016, 37, 138. [Google Scholar]

- Van Boekel, M.A.J.S. Kinetic aspects of the Maillard reaction: A critical review. Mol. Nutr. 2001, 45, 150–159. [Google Scholar]

- Elzoghby, A.O.; Elgohary, M.M.; Kamel, N.M. Advances in Protein Chemistry and Structural Biology. In Protein and Peptide Nanoparticles for Drug Delivery; Donev, R., Ed.; Academic Press: Cambridge, MA, USA, 2015; Volume 98, pp. 169–218. [Google Scholar]

- Sakac, M.; Gyura, J.; Misan, A.; Seres, Z.; Dokic, L. Influence of pH and temperature on non-enzymatic browning reaction between affined C sugar and amino acids. Food Feed. Res. J. Inst. Food Technol. Novi Sad 2012, 39, 103–109. [Google Scholar]

- Bansa, H. Accelerated Aging of Paper: Some Ideas on its Practical Benefit. Restaur. Int. J. Preserv. Libr. Arch. Mater. 2012, 23, 106–117. [Google Scholar]

- Singer, B.; Aslaksby, T.; Trond, E.; Topalova Casadiego, B.; Tveit Storevik, E. Investigation of Materials Used by Edvard Munch. Stud. Conserv. 2010, 55, 274–292. [Google Scholar] [CrossRef]

- Ferrer, J.S.; Syversen, T.; Markevicius, T. The Challenge of the ‘Kill-or-Cure’ Remedy. The Munch Museum’s Authenticity Problem Owing to the Interpretation and Preservation of Edvard Munch Paintings. Aesthetic Investig. 2019, 2, 123–143. [Google Scholar] [CrossRef]

- Markevicius, T.; Ferrer, J.S.; Syversen, T. Kill-or-Cure Remedy in Edvard Munch Paintings: Authenticity Challenges Distinguishing Intended Weathering from Decay by the Ravages of Time. In Proceedings of the Encore Conference ‘The Impact of Conservation-Restoration Education on the Development of the Profession’, Turin, Italy, 2020; pp. 146–167. [Google Scholar]

- Feller, R.L.; Kunz, N. The Effect of Pigment Volume Concentration Paint on the Lightness and Darkness of Porous Paints; AIC Preprints: Washington, DC, USA, 1981; pp. 66–74. [Google Scholar]

- Kobara, H.; Tamiya, M.; Wakisaka, A.; Fukazu, T.; Matsuura, K. Relationship between the size of mist droplets and ethanol condensation efficiency at ultrasonic atomization on ethanol–water mixtures. AIChE J. 2010, 56, 810–814. [Google Scholar] [CrossRef]

- Gray, C.J. Conservation of a Thai Painting: Testing a New Consolidant for Underbound Matt Paint, Online Publication, December 9, 2020 Publications. Available online: https://www.vam.ac.uk/blog/caring-for-our-collections/conservation-of-a-thai-painting-testing-a-new-consolidant-for-underbound-matt-pain (accessed on 11 July 2023).

- Hummert, E.; Henniges, U.; Potthast, A. Stabilization treatments with aerosols: Evaluating the penetration behavior of gelatin and methylcellulose. Restaur. Int. J. Preserv. Libr. Arch. Mater. 2013, 34, 134–171. [Google Scholar]

- Proietti, N.; Di Tullio, V.; Presciutti, F.; Gentile, G.B.; Brunetti, G.; Capitani, D. A multi-analytical study of ancient Nubian detached mural paintings. Microchem. J. 2016, 124, 719–725. [Google Scholar] [CrossRef]

- Blümich, B.; Blümler, P.; Eidmann, G.; Guthausen, A.; Haken, R.; Schmitz, U.; Saito, K.; Zimmer, G. The NMR-mouse: Construction, excitation, and applications. Magn. Reson. Imaging 1998, 16, 479–484. [Google Scholar] [CrossRef]

- Blümich, B.; Anders, J. When the MOUSE leaves the house? Magn. Reson. 2021, 2, 149–160. [Google Scholar] [CrossRef]

| Aging Method and Consolidant | ΔE*76 Aged vs. Unaged Paper | ΔE*76 Unaged Coating vs. Unaged Paper | ΔE*76 Aged Consolidant vs. Aged Paper |

|---|---|---|---|

| Ambient: MOBS 6P4 | 0.14 | 0.15 | 0.47 |

| Ambient: Methocel A4C | 0.18 | 0.29 | 0.54 |

| Ambient: Isinglass | 0.59 | 0.98 | 0.48 |

| Ambient: Funori | 0.17 | 1.86 | 1.92 |

| Chamber: MOBS 6P4 | 5.53 | 0.16 | 0.30 |

| Chamber: Methocel A4C | 5.79 | 0.36 | 1.25 |

| Chamber: Isinglass | 5.73 | 0.98 | 7.91 |

| Chamber: Funori | 5.83 | 2.01 | 14.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markevicius, T. Innovation in Green Materials for the Non-Contact Stabilization of Sensitive Works of Art: Preliminary Assessment and the First Application of Ultra-Low Viscosity Hydroxypropyl Methylcellulose (HPMC) by Ultrasonic Misting to Consolidate Unstable Porous and Powdery Media. Sustainability 2023, 15, 14699. https://doi.org/10.3390/su152014699

Markevicius T. Innovation in Green Materials for the Non-Contact Stabilization of Sensitive Works of Art: Preliminary Assessment and the First Application of Ultra-Low Viscosity Hydroxypropyl Methylcellulose (HPMC) by Ultrasonic Misting to Consolidate Unstable Porous and Powdery Media. Sustainability. 2023; 15(20):14699. https://doi.org/10.3390/su152014699

Chicago/Turabian StyleMarkevicius, Tomas. 2023. "Innovation in Green Materials for the Non-Contact Stabilization of Sensitive Works of Art: Preliminary Assessment and the First Application of Ultra-Low Viscosity Hydroxypropyl Methylcellulose (HPMC) by Ultrasonic Misting to Consolidate Unstable Porous and Powdery Media" Sustainability 15, no. 20: 14699. https://doi.org/10.3390/su152014699