Production of Bioferments from Artichoke and Asparagus Waste with High Unicellular Protein and Carotenoid Content Using R. mucilaginosa

Abstract

:1. Introduction

2. Materials and Methods

2.1. Isolation and Biochemical Identification of R. mucilaginosa

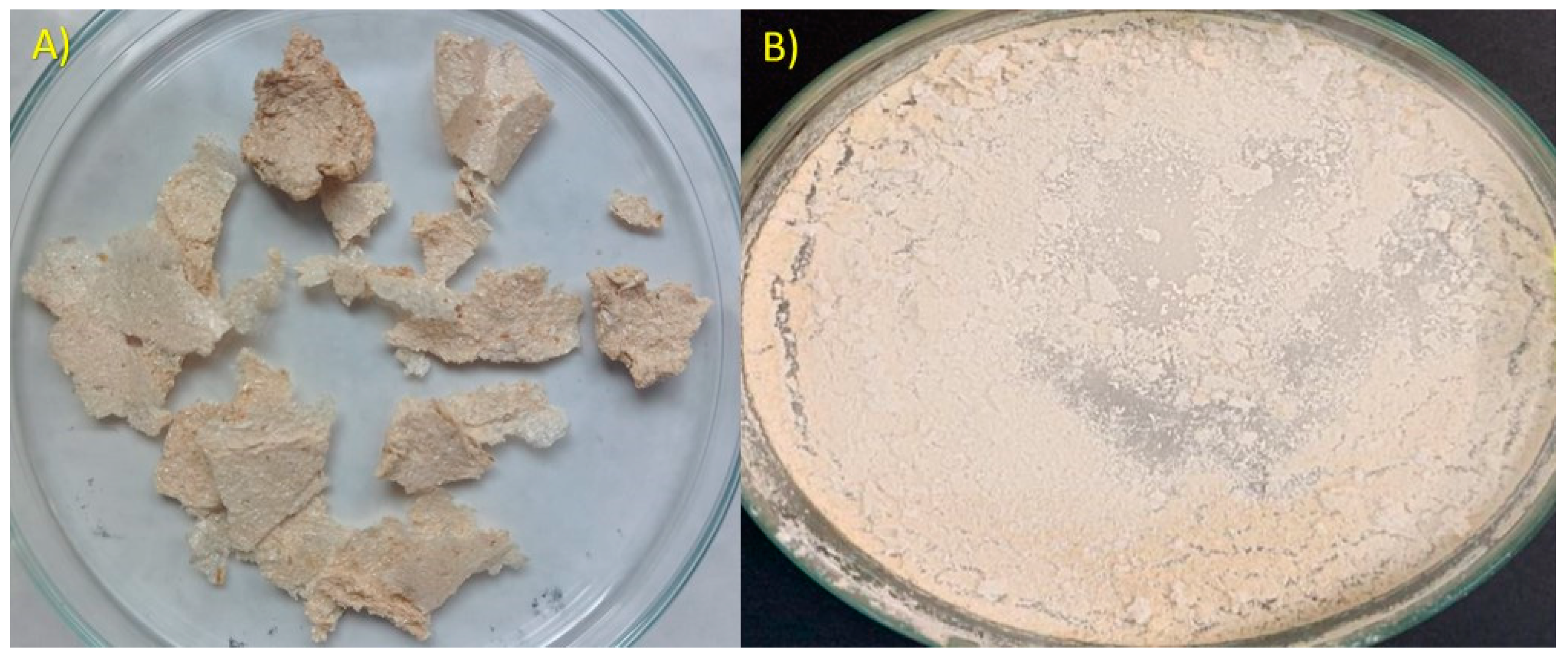

2.2. Conditioning and Pretreatment of Agro-Industrial Waste

2.3. Preparation of Microbial Culture

2.4. Fermentation of Agro-Industrial Wastes for the Production of Unicellular Protein and Carotenoids

2.5. Measurement of Unicellular Protein and Carotenoids

2.6. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Kharola, S.; Ram, M.; Goyal, N.; Mangla, S.K.; Nautiyal, O.P.; Rawat, A.; Kazancoglu, Y.; Pant, D. Barriers to Organic Waste Management in a Circular Economy. J. Clean. Prod. 2022, 362, 132282. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Senthil Kumar, P.; Varjani, S. Valorization of Agro-Industrial Wastes for Biorefinery Process and Circular Bioeconomy: A Critical Review. Bioresour. Technol. 2022, 343, 126126. [Google Scholar] [CrossRef] [PubMed]

- Asmat-Campos, D.A.; Bravo Huivin, E.K.; Avalos-Vera, V.P. Valorización De Residuos Agroindustriales En Un Entorno De Economía Circular: Orujo De Uva Como Fuente De Compuestos Bioactivos Para Su Aplicación En Nanotecnología. In Proceedings of the 19th LACCEI International Multi-Conference for Engineering, Education, and Technology: “Prospective and Trends in Technology and Skills for Sustainable Social Development” “Leveraging Emerging Technologies to Construct the Future”; Latin American and Caribbean Consortium of Engineering Institutions: Boca Raton, FL, USA, 2021. [Google Scholar]

- Kammoun, M.; Ayeb, H.; Bettaieb, T.; Richel, A. Chemical characterisation and technical assessment of Agri-Food Residues, marine matrices, and wild grasses in the South Mediterranean Area: A Considerable Inflow for Biorefineries. Waste Manag. 2020, 118, 247–257. [Google Scholar] [CrossRef] [PubMed]

- Parasar, D.P.; Ramakrishnan, E.; Kabilan, S.; Kotoky, J.; Sarma, H.K. Characterization of β-Cryptoxanthin and Other Carotenoid Derivatives from Rhodotorula Taiwanensis, A Novel Yeast Isolated from Traditional Starter Culture of Assam. Chem. Biodivers. 2020, 17, e2000198. [Google Scholar] [CrossRef] [PubMed]

- Manimala, M.R.A.; Murugesan, R. Studies on Carotenoid Pigment Production by Yeast R. mucilaginosa Using Cheap Materials of Agro-Industrial Origin. Pharma Innov. 2017, 6, 80–82. [Google Scholar]

- Galal, G.F.; Ahmed, R.F. Using of Some Agro-Industrial Wastes for Improving Carotenoids Production from Yeast Rhodotorula glutinis 32 and Bacteria Erwinia Uredovora DSMZ 30080. Microbiol. Res. J. Int. 2020, 30, 15–25. [Google Scholar] [CrossRef]

- Costa, W.A.D.; Padilha, C.E.D.A.; Oliveira Júnior, S.D.D.; Silva, F.L.H.D.; Silva, J.; Ancântara, M.A.; Ferrari, M.; Santos, E.S.D. Oil-Lipids, Carotenoids and Fatty Acids Simultaneous Production by R. mucilaginosa CCT3892 Using Sugarcane Molasses as Carbon Source. Braz. J. Food Technol. 2020, 23, 1–11. [Google Scholar] [CrossRef]

- Cortes, A.G.; Vásquez, J.A.G.; Díaz, Y.C.A.; Castrillón, M.R. Effects of Cellular Stress on Pigment Production in R. mucilaginosa/Alborubescens AJB01 Strain from the Caribbean Region of Colombia. bioRxiv 2020. [Google Scholar] [CrossRef]

- Li, Z.; Li, C.; Cheng, P.; Yu, G. R. mucilaginosa—Alternative Sources of Natural Carotenoids, Lipids, and Enzymes for Industrial Use. Heliyon 2022, 8, e11505. [Google Scholar] [CrossRef]

- Ghilardi, C.; Sanmartin Negrete, P.; Carelli, A.A.; Borroni, V. Evaluation of Olive Mill Waste as Substrate for Carotenoid Production by R. mucilaginosa. Bioresour. Bioprocess. 2020, 7, 52. [Google Scholar] [CrossRef]

- Torres-Alvarez, D.; León-Buitimea, A.; Albalate-Ramírez, A.; Rivas-García, P.; Hernández-Núñez, E.; Morones-Ramírez, J.R. Conversion of Banana Peel into Diverse Valuable Metabolites Using an Autochthonous R. mucilaginosa Strain. Microb. Cell Fact. 2022, 21, 96. [Google Scholar] [CrossRef] [PubMed]

- Usmani, Z.; Sharma, M.; Diwan, D.; Tripathi, M.; Whale, E.; Jayakody, L.N.; Moreau, B.; Thakur, V.K.; Tuohy, M.; Gupta, V.K. Valorization of Sugar Beet Pulp to Value-Added Products: A Review. Bioresour. Technol. 2022, 346, 126580. [Google Scholar] [CrossRef]

- Pathak, N.; Singh, S.; Singh, P.; Singh, P.K.; Singh, R.; Bala, S.; Thirumalesh, B.V.; Gaur, R.; Tripathi, M. Valorization of Jackfruit Waste into Value Added Products and Their Potential Applications. Front. Nutr. 2022, 9, 1061098. [Google Scholar] [CrossRef] [PubMed]

- Ceballos-Garzón, A.; Cortes, G.; Morio, F.; Zamora-Cruz, E.L.; Linares, M.Y.; Ariza, B.E.; Valderrama, S.L.; Garzón, J.R.; Alvarez-Moreno, C.A.; Le Pape, P.; et al. Comparison between MALDI-TOF MS and MicroScan in the Identification of Emerging and Multidrug Resistant Yeasts in a Fourth-Level Hospital in Bogotá, Colombia. BMC Microbiol. 2019, 19, 106. [Google Scholar] [CrossRef] [PubMed]

- Sadh, P.K.; Duhan, S.; Duhan, J.S. Agro-Industrial Wastes and Their Utilization Using Solid State Fermentation: A Review. Bioresour. Bioprocess. 2018, 5, 1. [Google Scholar] [CrossRef]

- Hu, Z.; Que, Y.; Gao, Y.; Yin, Y.; Zhao, Y. Using Black Liquor from the Soda Pulping Process for Protein Production by Candida utilis. Bioresources 2015, 10, 3908–3921. [Google Scholar] [CrossRef]

- Roadjanakamolson, M.; Suntornsuk, W. Production of β-carotene-enriched rice bran using solid-state fermentation of Rhodotorula glutinis. J. Microbiol. Biotechnol. 2010, 20, 525–531. [Google Scholar] [PubMed]

- Mæhre, H.; Dalheim, L.; Edvinsen, G.; Elvevoll, E.; Jensen, I.-J. Protein Determination—Method Matters. Foods 2018, 7, 5. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, L.; Xia, Y.; Zhuang, X.; Chu, W. Isolation, Identification of Carotenoid-Producing Rhodotorula Sp. from Marine Environment and Optimization for Carotenoid Production. Mar. Drugs 2019, 17, 161. [Google Scholar] [CrossRef] [PubMed]

- Dyaa, A.; Soliman, H.; Abdelrazak, A.; Samra, B.N.; Khojah, E.; Ahmed, A.F.; El-Esawi, M.A.; Elsayed, A. Optimization of Carotenoids Production from Rhodotorula sp. Strain ATL72 for Enhancing Its Biotechnological Applications. J. Fungi 2022, 8, 160. [Google Scholar] [CrossRef]

- Al-Turki, A.I.; Al-Hassan, A.A.; Abd-El-Razik, M.M. Isolation and Characterization of Carotenoid Producing Yeasts from Qassim Region. J. Food Agric. Environ. 2016, 14, 20–23. [Google Scholar]

- El-Ziney, M.; Abu Zaid, E.; El-Naggar, M. Characterization of Carotenogenic Rhodotorula Strains Isolated from Delta Region, Egypt and Their Potential for Carotenoids Production. J. Pure Appl. Microbiol. 2018, 12, 587–599. [Google Scholar] [CrossRef]

- Nguyen Thanh, V.; Smit, M.S.; Moleleki, N.; Fell, J.W. Rhodotorula cycloclastica Sp. Nov., Rhodotorula retinophila Sp. Nov., and Rhodotorula terpenoidalis Sp. Nov., Three Limonene-Utilizing Yeasts Isolated from Soil. FEMS Yeast Res. 2004, 4, 857–863. [Google Scholar] [CrossRef] [PubMed]

- Flores, C.-L.; Gancedo, C. Construction and Characterization of a Saccharomyces Cerevisiae Strain Able to Grow on Glucosamine as Sole Carbon and Nitrogen Source. Sci. Rep. 2018, 8, 16949. [Google Scholar] [CrossRef] [PubMed]

- Allahkarami, S.; Sepahi, A.A.; Hosseini, H.; Razavi, M.R. Isolation and identification of carotenoid-producing Rhodotorula sp. from Pinaceae forest ecosystems and optimization of in vitro carotenoid production. Biotechnol. Rep. 2021, 32, e00687. [Google Scholar] [CrossRef]

- Bell, T.; Alamzad, R.; Graf, B.A. Effect of PH on the Chemical Stability of Carotenoids in Juice. Proc. Nutr. Soc. 2016, 75, E94. [Google Scholar] [CrossRef]

- Kot, A.M.; Błażejak, S.; Kieliszek, M.; Gientka, I.; Bryś, J. Simultaneous Production of Lipids and Carotenoids by the Red Yeast Rhodotorula from Waste Glycerol Fraction and Potato Wastewater. Appl. Biochem. Biotechnol. 2019, 189, 589–607. [Google Scholar] [CrossRef] [PubMed]

- Sharma, R.; Ghoshal, G. Optimization of Carotenoids Production by R. mucilaginosa (MTCC-1403) Using Agro-Industrial Waste in Bioreactor: A Statistical Approach. Biotechnol. Rep. 2020, 25, e00407. [Google Scholar] [CrossRef] [PubMed]

- Tarangini, K.; Mishra, S. Carotenoid Production by Rhodotorula Sp. on Fruit Waste Extract as a Sole Carbon Source and Optimization of Key Parameters. Iran. J. Chem. Chem. Eng. 2014, 33, 89–99. [Google Scholar] [CrossRef]

- Naghavi, F.; Hanachi, P.; Saboora, A. Effect of Temperature, PH, and Salinity on Carotenoid Production in Rodotorula mucilaginosa. Res. Biotechnol. 2014, 5, 1–4. [Google Scholar]

- Moreira, M.D.; Melo, M.M.; Coimbra, J.M.; Reis, K.C.D.; Schwan, R.F.; Silva, C.F. Solid Coffee Waste as Alternative to Produce Carotenoids with Antioxidant and Antimicrobial Activities. Waste Manag. 2018, 82, 93–99. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, J.E.S.; Sant’Ana, A.M.D.S.; Martini, M.; Sorce, C.; Andreucci, A.; de Melo, D.J.N.; da Silva, F.L.H. Rhodotorula glutinis Cultivation on Cassava Wastewater for Carotenoids and Fatty Acids Generation. Biocatal. Agric. Biotechnol. 2019, 22, 101419. [Google Scholar] [CrossRef]

- Magalhães, C.E.B.; Souza-Neto, M.S.; Astolfi-Filho, S.; Matos, I.T.S.R. Candida Tropicalis Able to Produce Yeast Single Cell Protein Using Sugarcane Bagasse Hemicellulosic Hydrolysate as Carbon Source. Biotechnol. Res. Innov. 2018, 2, 19–21. [Google Scholar] [CrossRef]

- Dias Rodrigues, T.V.; Amore, T.D.; Teixeira, E.C.; de Medeiros Burkert, J.F. Carotenoid Production by R. mucilaginosa in Batch and Fed-Batch Fermentation Using Agroindustrial Byproducts. Food Technol. Biotechnol. 2019, 57, 388–398. [Google Scholar] [CrossRef] [PubMed]

- Gualberto, N.C.; Nogueira, J.P.; de Souza da Silva, A.; Barbosa, P.F.; Santana Matos, C.M.; Rajan, M.; Santos Leite Neta, M.T.; Narain, N. Optimization of the Biotechnological Process Using R. mucilaginosa and Acerola (Malpighia emarginata L.) Seeds for the Production of Bioactive Compounds. Lebenson. Wiss. Technol. 2022, 160, 113190. [Google Scholar] [CrossRef]

| Rapid Yeast Test ID | Result |

|---|---|

| Hydroxyproline | + |

| Isoleucine | + |

| Proline | + |

| Tyrosine | + |

| Glycine | − |

| Glycylglycine | + |

| Glycylarginine | − |

| Glycylproline | + |

| Arginylarginine | + |

| Lysylalanine | − |

| Seriltyrosine | + |

| Urease | + |

| Indosylphosphate | − |

| Histidine | − |

| Sucrose 1 | − |

| Sucrose 2 | + |

| Glucopyranoside | − |

| Fucopyranoside | − |

| Cellobiose | − |

| Galactosan | − |

| Glucosamine | + |

| Treatment | Ranges | Total Protein (mg/g Dry Residue Ferment) | FTC (μg/g) | CVC (μg/L) | Dry Biomass Yield (%) | p-Value |

|---|---|---|---|---|---|---|

| pH | 5 | 25.97 ± 0.68 | 71.36 ± 35.85 | 388.88 ± 148.39 | 17.86 ± 5.65 | |

| 6.6 | 25.37 ± 1.56 | 159.26 ± 48.58 | 431.37 ± 80.99 | 38.42 ± 16.42 | <0.05 | |

| 7.1 | 24.45 ± 1.41 | 152.39 ± 59.57 | 478.76 ± 106.76 | 31.07 ± 5.61 | ||

| 8.1 | 23.55 ± 0.42 | 61.66 ± 17.22 | 549.02 ± 160.27 | 11.27 ± 0.21 | ||

| Initial culture medium ratio (mL/g) | 10 | 17.02 ± 0.01 | 31.12 ± 1.15 | 552.29 ± 10.20 | 5.63 ± 0.10 | |

| 20 | 17.56 ± 0.42 | 46.50 ± 16.88 | 668.30 ± 118.09 | 6.82 ± 1.20 | <0.05 | |

| 30 | 18.15 ± 0.40 | 43.1 ± 6.83 | 648.69 ± 51.49 | 6.62 ± 0.53 | ||

| 40 | 18.12 ± 0.34 | 47.42 ± 14.11 | 676.47 ± 104.33 | 6.90 ± 1.06 |

| Treatment | Ranges | Total Protein (mg/g Dry Residue Ferment) | FTC (μg/g) | CVC (μg/L) | Dry Biomass Yield (%) | p-Value |

|---|---|---|---|---|---|---|

| pH | 5 | 20.10 ± 0.33 | 222.04 ± 66.74 | 1143.79 ± 487.67 | 23.03 ± 3.58 | <0.05 |

| 6.6 | 20.02 ± 0.45 | 475.19 ± 100.45 | 983.66 ± 219.79 | 45.08 ± 10.83 | ||

| 7.1 | 20.22 ± 0.53 | 254.69 ± 19.51 | 748.37 ± 51.02 | 33.37 ± 1.99 | ||

| 8.1 | 19.64 ± 0.45 | 72.88 ± 29.78 | 1088.24 ± 184.52 | 6.25 ± 2.40 | ||

| Initial culture medium ratio (mL/g) | 10 | 18.53 ± 0.19 | 21.40 ± 20.62 | 707.52 ± 115.83 | 2.87 ± 2.51 | |

| 20 | 18.90 ± 0.1 | 13.35 ± 7.72 | 797.39 ± 46.33 | 1.72 ± 1.1 | ||

| 30 | 19.20 ± 0.15 | 44.53 ± 8.72 | 673.2 ± 89.90 | 6.58 ± 0.45 | <0.05 | |

| 40 | 20.03 ± 0.23 | 58.29 ± 27.26 | 637.25 ± 106.38 | 8.90 ± 2.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De La Cruz-Noriega, M.; Benites, S.M.; Rojas-Flores, S.; Quiñones-Cerna, C.; Terrones Rodríguez, N.; Robles-Castillo, H.; Huanes-Carranza, J.; Mendoza-Villanueva, K. Production of Bioferments from Artichoke and Asparagus Waste with High Unicellular Protein and Carotenoid Content Using R. mucilaginosa. Sustainability 2023, 15, 15102. https://doi.org/10.3390/su152015102

De La Cruz-Noriega M, Benites SM, Rojas-Flores S, Quiñones-Cerna C, Terrones Rodríguez N, Robles-Castillo H, Huanes-Carranza J, Mendoza-Villanueva K. Production of Bioferments from Artichoke and Asparagus Waste with High Unicellular Protein and Carotenoid Content Using R. mucilaginosa. Sustainability. 2023; 15(20):15102. https://doi.org/10.3390/su152015102

Chicago/Turabian StyleDe La Cruz-Noriega, Magaly, Santiago M. Benites, Segundo Rojas-Flores, Claudio Quiñones-Cerna, Nicole Terrones Rodríguez, Heber Robles-Castillo, Johnny Huanes-Carranza, and Karol Mendoza-Villanueva. 2023. "Production of Bioferments from Artichoke and Asparagus Waste with High Unicellular Protein and Carotenoid Content Using R. mucilaginosa" Sustainability 15, no. 20: 15102. https://doi.org/10.3390/su152015102