Environmental Damage of Different Waste Treatment Scenarios by Considering Avoided Emissions Based on System Dynamics Modeling

Abstract

:1. Introduction

2. Materials and Methods

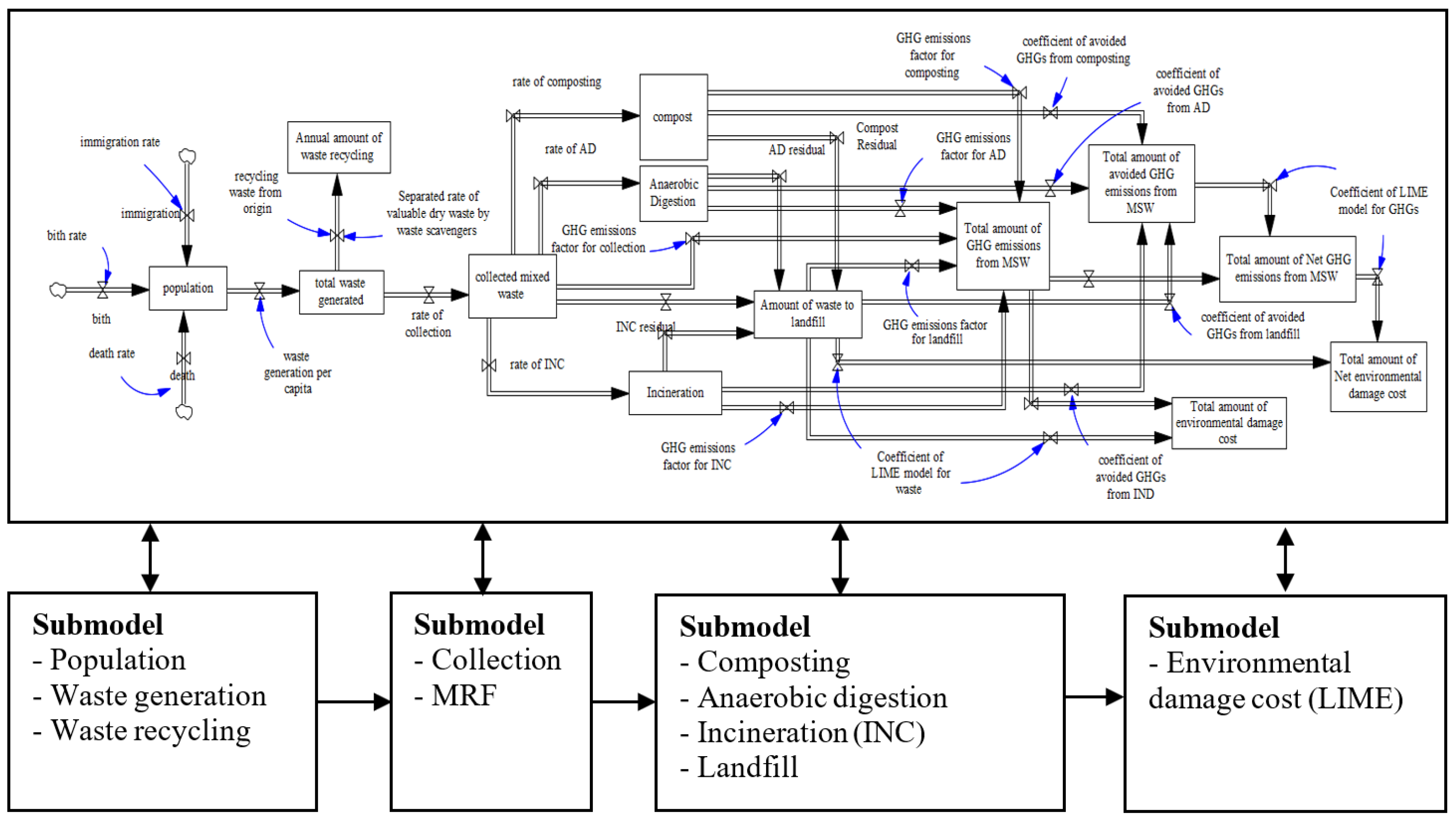

2.1. SD Model

2.2. Model Structure

2.3. GHGs in Waste Stream

2.4. LIME Model

2.5. Model Quantification, Implementation, and Scenario Settings

2.6. Model Validation Test

3. Results and Discussion

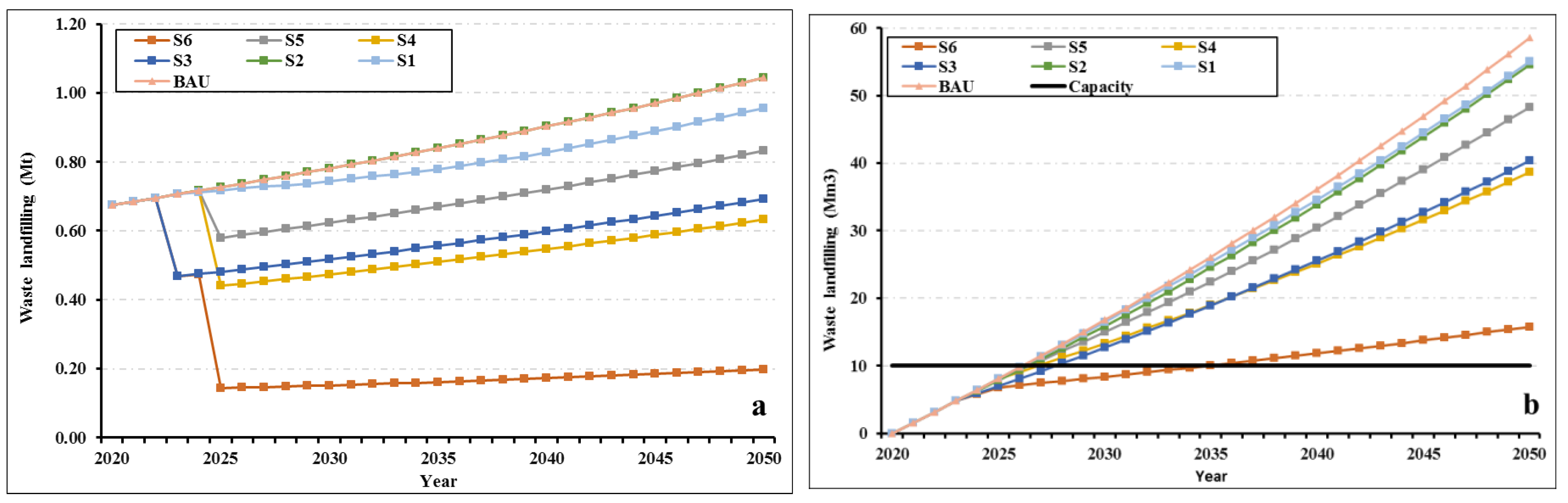

3.1. Amount of Waste Sent to Landfill

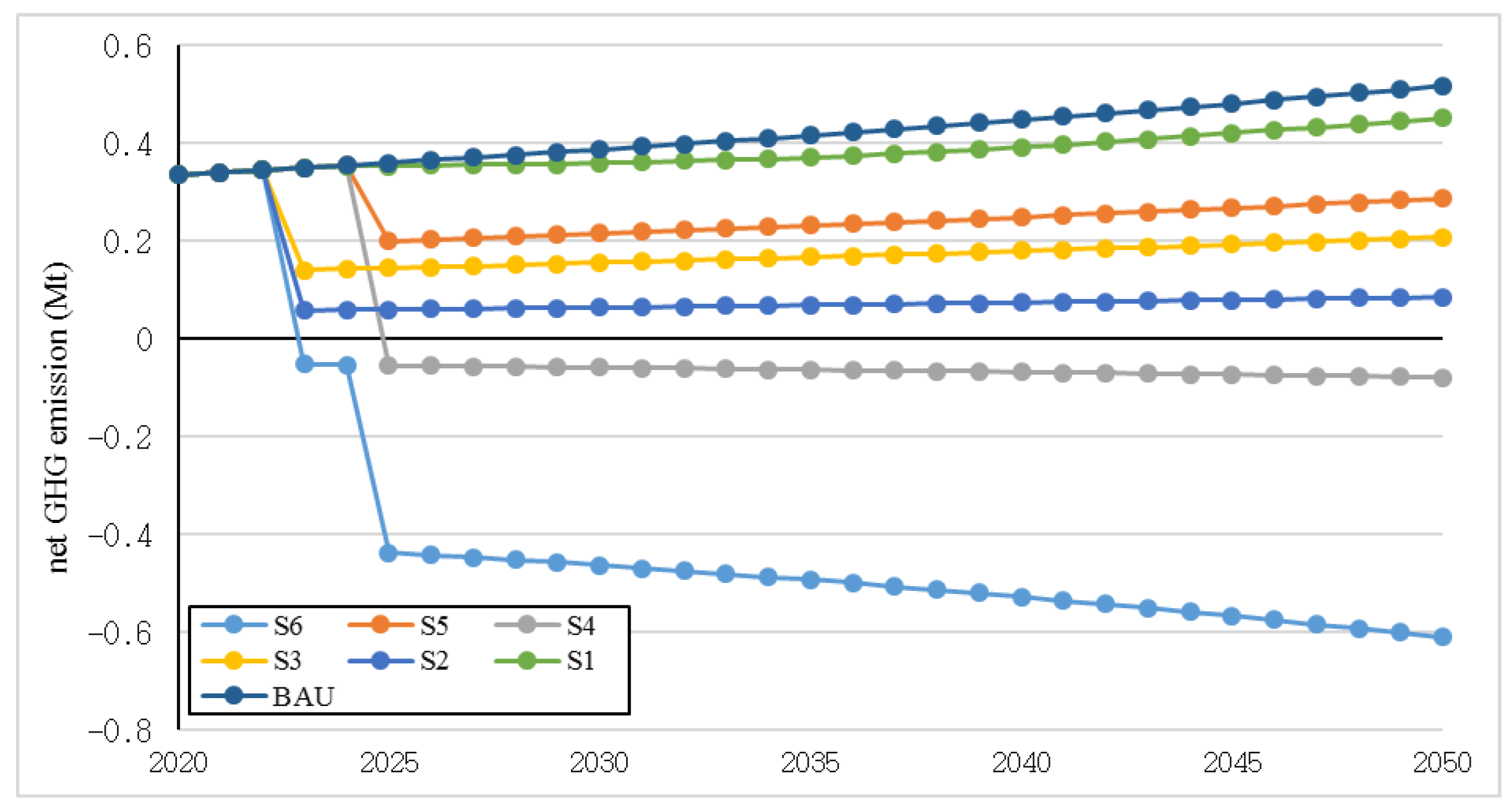

3.2. GHGs in Different Scenarios

3.3. Cumulative Amount of GHGs under Different Scenarios

3.4. Damage Assessment through the Endpoint Approach

3.5. Damage Cost Assessment through the Endpoint Approach

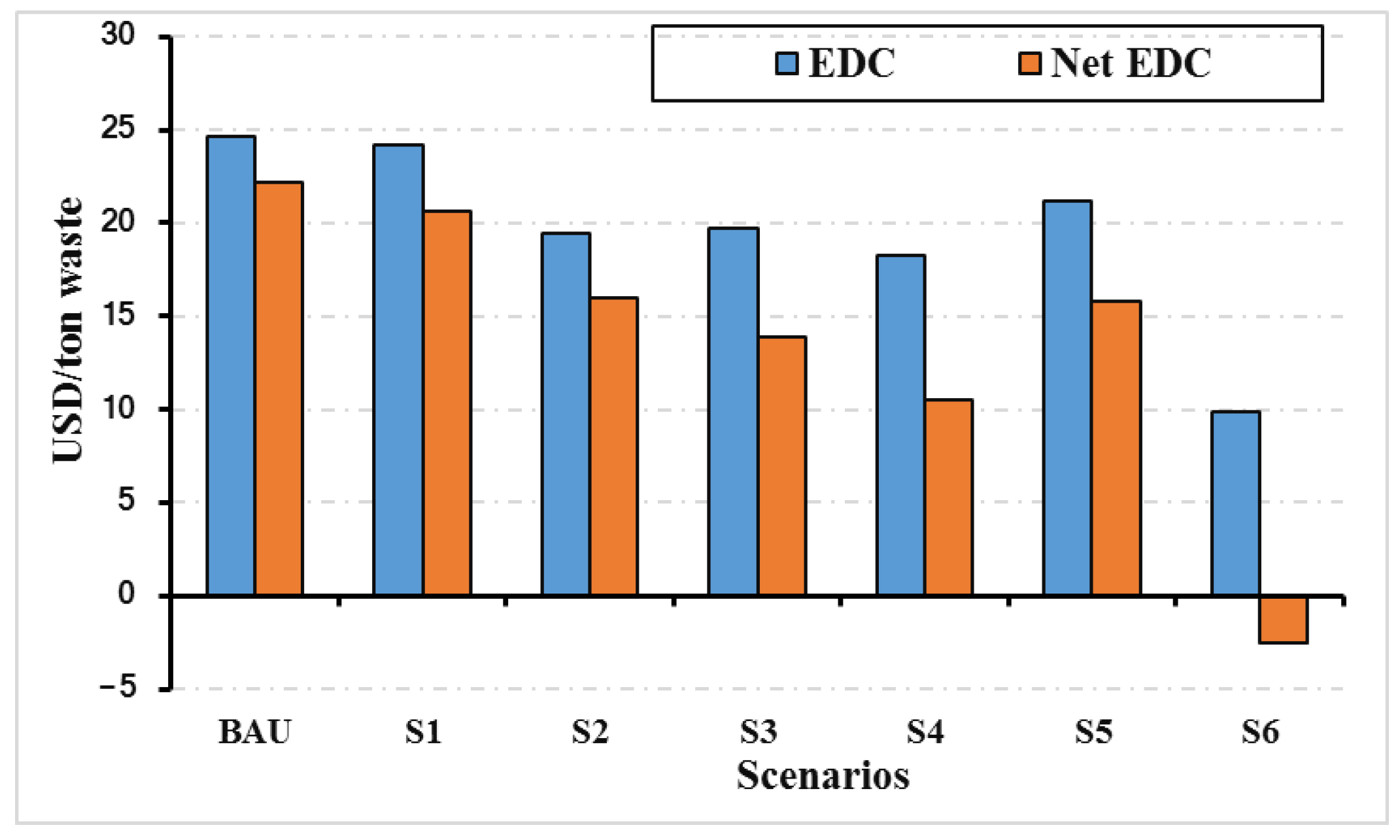

3.6. Environmental Damage Cost

3.7. Contribution of Safeguard Subjects to EDC

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| List of Abbreviations | ISWM | Integrated Solid Waste Management | |

| AD | Anaerobic Digestion | J | Types of Waste (OW, M, P, PL, D) |

| AV | Avoided GHGs from Using Tech | K | Potassium |

| BD | Biodiversity | LCIA | Life Cycle Impact Assessment |

| C | Carbon | LF | Conventional Landfill without Gas Recovery |

| CCW | The Ratio of Carbon in Household Waste | LFE | Landfill with Gas Recovery |

| CE | The Combustion Efficiency of the Waste Incinerator | M | Metal |

| CFCO2Z | The Coefficient of CO2 Emission from Z | Mm3 | Million Cubic Meter |

| COM | Composting | MSW | Municipal Solid Waste |

| D | Dry Waste | Mt | Million Ton |

| DALY | Disability-Adjusted Life Years | MW | The Molecular Weight Proportion of CO2/C |

| DAP | Diammonium Phosphate | N | Nitrogen |

| DEM | Direct Emission of GHGs from Tech | Net GHGTech | The Net GHG Emissions Y in Tech |

| DF | Damage Factor | NVD | Nonvaluable Dry Waste |

| EDC | Environmental Damage Cost | OW | Organic Waste |

| EFXTech | The Estimated Factor of X Emission in Tech | P | Paper |

| EEFX,JTech | The Estimated X Emission Factor for K Types in Tech | Ph | Phosphor |

| EINES | Expected Increase in Number of Extinct Species | PL | Plastic and Rubber |

| EL | Electricity | PP | Primary Productivity |

| FCF | The Fraction of Fossil Carbon in Waste | PR | The Produced Energy Using Different Technologies |

| FU | Fuel | RC | Recycling |

| FURQTech | The Required Fuel by Different Tech | RG | The Required Energy by Different Technologies |

| FUSVTech | The Savings in Fuel from Using Different Tech | SA | Social Assets |

| GHG | Greenhouse Gas | SD | System Dynamics |

| GHGYTech | The GHG Emissions of Y in Tech | SOP | Potassium Sulfate |

| GWP | Global Warming Potential | SV | Saving |

| HH | Human Health | Tech | Different Technologies (LFE, LF, INC, RC, COM, AD) |

| HU | Humus | UR | Urea |

| IAV | Avoided GHGs from Input Material Savings | VJTech | The Volume of Waste Type K Used in Tech |

| IEM | GHG Emissions from Input Material | WF | Weighting Factor |

| IF | Integration Factor | X | Types of GHGs (CO2, CH4, N2O) |

| INC | Incineration | Y | Types of Emissions (DEM, IEM, AV, IAV) |

| IPCC | Intergovernmental Panel on Climate Change | Z | (FU, EL, UR, DAP, SOP, HU) |

References

- Rodić, L.; Wilson, D.C. Resolving Governance Issues to Achieve Priority Sustainable Development Goals Related to Solid Waste Management in Developing Countries. Sustainability 2017, 9, 404. [Google Scholar] [CrossRef]

- Sadeghi Ahangar, S.; Sadati, A.; Rabbani, M. Sustainable design of a municipal solid waste management system in an integrated closed-loop supply chain network using a fuzzy approach: A case study. J. Ind. Prod. Eng. 2021, 38, 323–340. [Google Scholar] [CrossRef]

- Browning, S.; Beymer-Farris, B.; Seay, J.R. Addressing the challenges associated with plastic waste disposal and management in developing countries. Curr. Opin. Chem. Eng. 2021, 32, 100682. [Google Scholar] [CrossRef]

- Patwa, N.; Sivarajah, U.; Seetharaman, A.; Sarkar, S.; Maiti, K.; Hingorani, K. Towards a circular economy: An emerging economies context. J. Bus. Res. 2021, 122, 725–735. [Google Scholar] [CrossRef]

- Siddiqi, A.; Haraguchi, M.; Narayanamurti, V. Urban waste to energy recovery assessment simulations for developing countries. World Dev. 2020, 131, 104949. [Google Scholar] [CrossRef]

- Maiurova, A.; Kurniawan, T.A.; Kustikova, M.; Bykovskaia, E.; Othman, M.H.D.; Singh, D.; Goh, H.H. Promoting digital transformation in waste collection service and waste recycling in Moscow (Russia): Applying a circular economy paradigm to mitigate climate change impacts on the environment. J. Clean. Prod. 2022, 354, 131604. [Google Scholar] [CrossRef]

- Song, J.; Feng, R.; Yue, C.; Shao, Y.; Han, J.; Xing, J.; Yang, W. Reinforced urban waste management for resource, energy and environmental benefits: China’s regional potentials. Resour. Conserv. Recycl. 2022, 178, 106083. [Google Scholar] [CrossRef]

- Moeinaddini, M.; Khorasani, N.; Danehkar, A.; Darvishsefat, A.A.; Zienalyan, M. Siting MSW landfill using weighted linear combination and analytical hierarchy process (AHP) methodology in GIS environment (case study: Karaj). Waste Manag. 2010, 30, 912–920. [Google Scholar] [CrossRef]

- González Martínez, T.; Bräutigam, K.-R.; Seifert, H. The potential of a sustainable municipal waste management system for Santiago de Chile, including energy production from waste. Energy Sustain. Soc. 2012, 2, 24. [Google Scholar] [CrossRef]

- Tsai, F.M.; Bui, T.-D.; Tseng, M.-L.; Lim, M.K.; Hu, J. Municipal solid waste management in a circular economy: A data-driven bibliometric analysis. J. Clean. Prod. 2020, 275, 124132. [Google Scholar] [CrossRef]

- Liao, N.; Bolyard, S.C.; Lü, F.; Yang, N.; Zhang, H.; Shao, L.; He, P. Can waste management system be a Greenhouse Gas sink? Perspective from Shanghai, China. Resour. Conserv. Recycl. 2022, 180, 106170. [Google Scholar] [CrossRef]

- Zhang, C.; Dong, H.; Geng, Y.; Song, X.; Zhang, T.; Zhuang, M. Carbon neutrality prediction of municipal solid waste treatment sector under the shared socioeconomic pathways. Resour. Conserv. Recycl. 2022, 186, 106528. [Google Scholar] [CrossRef]

- Christensen, T.H.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.A.; Starostina, V.; Boldrin, A.; Astrup, T.F.; et al. Application of LCA modelling in integrated waste management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef] [PubMed]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of life cycle assessment in municipal solid waste management: A worldwide critical review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar] [CrossRef]

- Dijkgraaf, E.; Vollebergh, H.R.J. Burn or bury? A social cost comparison of final waste disposal methods. Ecol. Econ. 2004, 50, 233–247. [Google Scholar] [CrossRef]

- Yi, S.; Kurisu, K.H.; Hanaki, K. Life cycle impact assessment and interpretation of municipal solid waste management scenarios based on the midpoint and endpoint approaches. Int. J. Life Cycle Assess. 2011, 16, 652–668. [Google Scholar] [CrossRef]

- Liu, C.; Dong, H.; Cao, Y.; Geng, Y.; Li, H.; Zhang, C.; Xiao, S. Environmental damage cost assessment from municipal solid waste treatment based on LIME3 model. Waste Manag. 2021, 125, 249–256. [Google Scholar] [CrossRef]

- Ooi, J.K.; Woon, K.S.; Hashim, H. A multi-objective model to optimize country-scale municipal solid waste management with economic and environmental objectives: A case study in Malaysia. J. Clean. Prod. 2021, 316, 128366. [Google Scholar] [CrossRef]

- Amaral, R.E.C.; Brito, J.; Buckman, M.; Drake, E.; Ilatova, E.; Rice, P.; Sabbagh, C.; Voronkin, S.; Abraham, Y.S. Waste Management and Operational Energy for Sustainable Buildings: A Review. Sustainability 2020, 12, 5337. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Ghanavati, H.; Dashti, B.B.; Heijungs, R.; Aghbashlo, M.; Tabatabaei, M. Electricity generation and GHG emission reduction potentials through different municipal solid waste management technologies: A comparative review. Renew. Sustain. Energy Rev. 2017, 79, 414–439. [Google Scholar] [CrossRef]

- Sauve, G.; Van Acker, K. The environmental impacts of municipal solid waste landfills in Europe: A life cycle assessment of proper reference cases to support decision making. J. Environ. Manag. 2020, 261, 110216. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Guo, Z.; Liu, Y.; Li, J.; Feng, W.; Lei, H.; Gao, Y. Reduction potential of GHG emissions from municipal solid waste incineration for power generation in Beijing. J. Clean. Prod. 2019, 241, 118283. [Google Scholar] [CrossRef]

- Lu, H.R.; Qu, X.; El Hanandeh, A. Towards a better environment—The municipal organic waste management in Brisbane: Environmental life cycle and cost perspective. J. Clean. Prod. 2020, 258, 120756. [Google Scholar] [CrossRef]

- Nevrlý, V.; Šomplák, R.; Putna, O.; Pavlas, M. Location of mixed municipal waste treatment facilities: Cost of reducing greenhouse gas emissions. J. Clean. Prod. 2019, 239, 118003. [Google Scholar] [CrossRef]

- Salmeron, J.L.; Vidal, R.; Mena, A. Ranking fuzzy cognitive map based scenarios with TOPSIS. Expert Syst. Appl. 2012, 39, 2443–2450. [Google Scholar] [CrossRef]

- Kollikkathara, N.; Feng, H.; Yu, D. A system dynamic modeling approach for evaluating municipal solid waste generation, landfill capacity and related cost management issues. Waste Manag. 2010, 30, 2194–2203. [Google Scholar] [CrossRef]

- Babalola, M.A. A System Dynamics-Based Approach to Help Understand the Role of Food and Biodegradable Waste Management in Respect of Municipal Waste Management Systems. Sustainability 2019, 11, 3456. [Google Scholar] [CrossRef]

- Sukholthaman, P.; Sharp, A. A system dynamics model to evaluate effects of source separation of municipal solid waste management: A case of Bangkok, Thailand. Waste Manag. 2016, 52, 50–61. [Google Scholar] [CrossRef]

- Di Nola, M.F.; Escapa, M.; Ansah, J.P. Modelling solid waste management solutions: The case of Campania, Italy. Waste Manag. 2018, 78, 717–729. [Google Scholar] [CrossRef]

- Lee, C.K.M.; Ng, K.K.H.; Kwong, C.K.; Tay, S.T. A system dynamics model for evaluating food waste management in Hong Kong, China. J. Mater. Cycles Waste Manag. 2019, 21, 433–456. [Google Scholar] [CrossRef]

- Xiao, S.; Dong, H.; Geng, Y.; Tian, X.; Liu, C.; Li, H. Policy impacts on Municipal Solid Waste management in Shanghai: A system dynamics model analysis. J. Clean. Prod. 2020, 262, 121366. [Google Scholar] [CrossRef]

- Dyson, B.; Chang, N.-B. Forecasting municipal solid waste generation in a fast-growing urban region with system dynamics modeling. Waste Manag. 2005, 25, 669–679. [Google Scholar] [CrossRef] [PubMed]

- Estay-Ossandon, C.; Mena-Nieto, A. Modelling the driving forces of the municipal solid waste generation in touristic islands. A case study of the Balearic Islands (2000–2030). Waste Manag. 2018, 75, 70–81. [Google Scholar] [CrossRef] [PubMed]

- Dianati, K.; Schäfer, L.; Milner, J.; Gómez-Sanabria, A.; Gitau, H.; Hale, J.; Langmaack, H.; Kiesewetter, G.; Muindi, K.; Mberu, B.; et al. A system dynamics-based scenario analysis of residential solid waste management in Kisumu, Kenya. Sci. Total Environ. 2021, 777, 146200. [Google Scholar] [CrossRef]

- Wang, W.-J.; You, X.-Y. Benefits analysis of classification of municipal solid waste based on system dynamics. J. Clean. Prod. 2021, 279, 123686. [Google Scholar] [CrossRef]

- Xiao, S.; Dong, H.; Geng, Y.; Tian, X. Low carbon potential of urban symbiosis under different municipal solid waste sorting modes based on a system dynamic method. Resour. Conserv. Recycl. 2022, 179, 106108. [Google Scholar] [CrossRef]

- Hosseinalizadeh, R.; Shakouri, G.H.; Izadbakhsh, H. Planning for energy production from municipal solid waste: An optimal technology mix via a hybrid closed-loop system dynamics-optimization approach. Expert Syst. Appl. 2022, 199, 116929. [Google Scholar] [CrossRef]

- Sterman, J. System Dynamics: Systems Thinking and Modeling for a Complex World; MIT Sloan School of Management: Cambridge, MA, USA, 2002. [Google Scholar]

- Hu, W.; Camacho, E.F.; Xie, L. Feedforward and feedback control of dynamic systems. IFAC Proc. Vol. 2014, 47, 7741–7748. [Google Scholar] [CrossRef]

- Amjad, J. Effectiveness Assessment of Air Pollution Reduction Plans in Karaj Waste Collection System Based on Life Cycle Prespective. Master’s Thesis, Department of Environment, Faculty of Natural Resources, College of Agriculture and Natural Resources, University of Tehran, Tehran, Iran, 2021. [Google Scholar]

- Tsewng, C.-H.; Hsu, Y.-C.; Chen, Y.-C. System dynamics modeling of waste management, greenhouse gas emissions, and environmental costs from convenience stores. J. Clean. Prod. 2019, 239, 118006. [Google Scholar] [CrossRef]

- Yang, N.; Li, F.; Liu, Y.; Dai, T.; Wang, Q.; Zhang, J.; Dai, Z.; Yu, B. Environmental and Economic Life-Cycle Assessments of Household Food Waste Management Systems: A Comparative Review of Methodology and Research Progress. Sustainability 2022, 14, 7533. [Google Scholar] [CrossRef]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. (Eds.) IPCC Guidelines for National Greenhouse Gas Inventories; Prepared by the National Greenhouse Gas Inventories Programme; IGES: Hayama, Japan, 2006. [Google Scholar]

- Fertilizers Europe. Average Emissions Year 2014. Fertilizers Europe Environmental Report (Internal). Used for Updated Energy and GHG Emission in Carbon Footprint Calculator; Fertilizers Europe: Tehran, Iran, 2006. [Google Scholar]

- Rashid, M.I.; Shahzad, K. Food waste recycling for compost production and its economic and environmental assessment as circular economy indicators of solid waste management. J. Clean. Prod. 2021, 317, 128467. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Economic and environmental assessment of electricity generation using biogas from organic fraction of municipal solid waste for the city of Ibadan, Nigeria. J. Clean. Prod. 2018, 203, 718–735. [Google Scholar] [CrossRef]

- Hosseinalizadeh, R.; Izadbakhsh, H.; Shakouri, G.H. A planning model for using municipal solid waste management technologies- considering Energy, Economic, and Environmental Impacts in Tehran-Iran. Sustain. Cities Soc. 2021, 65, 102566. [Google Scholar] [CrossRef]

- Haupt, M.; Kagi, T.; Hellweg, S. Life cycle inventories of waste management processes. Data Brief 2018, 19, 1441–1457. [Google Scholar] [CrossRef]

- Cadena, E.; Colón, J.; Artola, A.; Sánchez, A.; Font, X. Environmental impact of two aerobic composting technologies using life cycle assessment. Int. J. Life Cycle Assess. 2009, 14, 401–410. [Google Scholar] [CrossRef]

- Opatokun, S.A.; Lopez-Sabiron, A.; Ferreira, G.; Strezov, V. Life Cycle Analysis of Energy Production from Food Waste through Anaerobic Digestion, Pyrolysis and Integrated Energy System. Sustainability 2017, 9, 1804. [Google Scholar] [CrossRef]

- Damgaard, A.; Riber, C.; Fruergaard, T.; Hulgaard, T.; Christensen, T.H. Life-cycle-assessment of the historical development of air pollution control and energy recovery in waste incineration. Waste Manag. 2010, 30, 1244–1250. [Google Scholar] [CrossRef]

- Hong, J.; Li, X.; Zhaojie, C. Life cycle assessment of four municipal solid waste management scenarios in China. Waste Manag. 2010, 30, 2362–2369. [Google Scholar] [CrossRef]

- PRI. Compilation of Pollution Atlas of Power Plants in the Country; Power Research Institute: Tehran, Iran, 2008. (In Persion) [Google Scholar]

- McDougall, F.R.; White, P.R.; Franke, M.; Hindle, P. Integrated Solid Waste Management: A Life Cycle Inventory; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Haight, M. Integrated Solid Waste Management Model; Technical Report; University of Waterloo, School of Planning: Waterloo, ON, Canada, 2004. [Google Scholar]

- Itsubo, N.; Inaba, A. A new LCIA method: LIME has been completed. Int. J. Life Cycle Assess. 2003, 8, 305. [Google Scholar] [CrossRef]

- Itsubo, N.; Inaba, A. LIME2 Life-Cycle Impact Assessment Method Based on Endpoint Modeling; Life-Cycle Assessment Society of Japan: Tokyo, Japan, 2012. [Google Scholar]

- Itsubo, N.; Murakami, K.; Kuriyama, K.; Yoshida, K.; Tokimatsu, K.; Inaba, A. Development of weighting factors for G20 countries—Explore the difference in environmental awareness between developed and emerging countries. Int. J. Life Cycle Assess. 2018, 23, 2311–2326. [Google Scholar] [CrossRef]

- Matsuno, Y.; Itsubo, N.; Hondo, H.; Nakano, K. LCA in Japan in the twenty-first century. Int. J. Life Cycle Assess. 2013, 18, 278–284. [Google Scholar] [CrossRef]

- Mak, T.M.W.; Chen, P.-C.; Wang, L.; Tsang, D.C.W.; Hsu, S.C.; Poon, C.S. A system dynamics approach to determine construction waste disposal charge in Hong Kong. J. Clean. Prod. 2019, 241, 118309. [Google Scholar] [CrossRef]

- Sinha, R.; Laurenti, R.; Singh, J.; Malmström, M.E.; Frostell, B. Identifying ways of closing the metal flow loop in the global mobile phone product system: A system dynamics modeling approach. Resour. Conserv. Recycl. 2016, 113, 65–76. [Google Scholar] [CrossRef]

- Qudrat-Ullah, H.; Seong, B.S. How to do structural validity of a system dynamics type simulation model: The case of an energy policy model. Energy Policy 2010, 38, 2216–2224. [Google Scholar] [CrossRef]

- Robalino-López, A.; Mena-Nieto, Á.; García-Ramos, J.-E.; Golpe, A.A. Studying the relationship between economic growth, CO2 emissions, and the environmental Kuznets curve in Venezuela (1980–2025). Renew. Sustain. Energy Rev. 2015, 41, 602–614. [Google Scholar] [CrossRef]

- Lewis, C.D. Industrial and Business Forecasting Methods: A Practical Guide to Exponential Smoothing and Curve Fitting; Butterworth Scientific London: London, UK, 1982. [Google Scholar]

- Zuberi, M.J.S.; Ali, S.F. Greenhouse effect reduction by recovering energy from waste landfills in Pakistan. Renew. Sustain. Energy Rev. 2015, 44, 117–131. [Google Scholar] [CrossRef]

- Lino, F.A.M.; Ismail, K.A.R. Evaluation of the treatment of municipal solid waste as renewable energy resource in Campinas, Brazil. Sustain. Energy Technol. Assess. 2018, 29, 19–25. [Google Scholar] [CrossRef]

- Abdelaal, A.H.; McKay, G.; Mackey, H.R. Food waste from a university campus in the Middle East: Drivers, composition, and resource recovery potential. Waste Manag. 2019, 98, 14–20. [Google Scholar] [CrossRef]

- Rafiee, R. Conducting Studies and Presenting an Operational Plan for Standardization and Improvement of Waste Processing and Disposal Processes and Leachate Management in Halghedareh; Department of Environment, Faculty of Natural Resources, College of Agriculture and Natural Resources, University of Tehran: Tehran, Iran, 2020. [Google Scholar]

- Bogner, J.; Pipatti, R.; Hashimoto, S.; Diaz, C.; Mareckova, K.; Diaz, L.; Kjeldsen, P.; Monni, S.; Faaij, A.; Gao, Q.; et al. Mitigation of global greenhouse gas emissions from waste: Conclusions and strategies from the Intergovernmental Panel on Climate Change (IPCC) Fourth Assessment Report. Working Group III (Mitigation). Waste Manag. Res. 2008, 26, 11–32. [Google Scholar] [CrossRef]

- Di Trapani, D.; Di Bella, G.; Viviani, G. Uncontrolled methane emissions from a MSW landfill surface: Influence of landfill features and side slopes. Waste Manag. 2013, 33, 2108–2115. [Google Scholar] [CrossRef]

- Moghadam, M.A.; Feizi, R.; Panahi Fard, M.; Haghighi Fard, N.J.; Omidinasab, M.; Faraji, M.; Shenavar, B. Estimating greenhouse emissions from sanitary landfills using Land-GEM and IPCC model based on realistic scenarios of different urban areas: A case study of Iran. J. Environ. Health Sci. Eng. 2021, 19, 819–830. [Google Scholar] [CrossRef] [PubMed]

- Calabrò, P.S. Greenhouse gases emission from municipal waste management: The role of separate collection. Waste Manag. 2009, 29, 2178–2187. [Google Scholar] [CrossRef] [PubMed]

- Weitz, K.A.; Thorneloe, S.A.; Nishtala, S.R.; Yarkosky, S.; Zannes, M. The Impact of Municipal Solid Waste Management on Greenhouse Gas Emissions in the United States. J. Air Waste Manag. Assoc. 2002, 52, 1000–1011. [Google Scholar] [CrossRef] [PubMed]

- Rena; Arya, S.; Chavan, D.; Aiman, S.; Kumar, S. Reducing Greenhouse Gas Emission From Waste Landfill. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhury, I.A., Eds.; Elsevier: Oxford, UK, 2020; pp. 685–701. [Google Scholar] [CrossRef]

- Liu, Y.; Ni, Z.; Kong, X.; Liu, J. Greenhouse gas emissions from municipal solid waste with a high organic fraction under different management scenarios. J. Clean. Prod. 2017, 147, 451–457. [Google Scholar] [CrossRef]

- Hansen, T.L.; Bhander, G.S.; Christensen, T.H.; Bruun, S.; Jensen, L.S. Life cycle modelling of environmental impacts of application of processed organic municipal solid waste on agricultural land (EASEWASTE). Waste Manag Res 2006, 24, 153–166. [Google Scholar] [CrossRef]

- Menikpura, S.N.M.; Sang-Arun, J.; Bengtsson, M. Integrated Solid Waste Management: An approach for enhancing climate co-benefits through resource recovery. J. Clean. Prod. 2013, 58, 34–42. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Gori, M.; Lubello, C. European trends in greenhouse gases emissions from integrated solid waste management. Environ. Technol. 2015, 36, 2125–2137. [Google Scholar] [CrossRef]

- Panepinto, D.; Genon, G. Carbon dioxide balance and cost analysis for different scenarios of solid waste management. WIT Trans. Ecol. Environ. 2011, 144, 445–456. [Google Scholar]

- Gentil, E.; Christensen, T.H.; Aoustin, E. Greenhouse gas accounting and waste management. Waste Manag. Res. 2009, 27, 696–706. [Google Scholar] [CrossRef]

- Tabata, T.; Hishinuma, T.; Ihara, T.; Genchi, Y. Life cycle assessment of integrated municipal solid waste management systems, taking account of climate change and landfill shortage trade-off problems. Waste Manag. Res 2011, 29, 423–432. [Google Scholar] [CrossRef]

- Wang, K.; Nakakubo, T. Comparative assessment of waste disposal systems and technologies with regard to greenhouse gas emissions: A case study of municipal solid waste treatment options in China. J. Clean. Prod. 2020, 260, 120827. [Google Scholar] [CrossRef]

- Koroneos, C.J.; Nanaki, E.A. Integrated solid waste management and energy production—A life cycle assessment approach: The case study of the city of Thessaloniki. J. Clean. Prod. 2012, 27, 141–150. [Google Scholar] [CrossRef]

- Menikpura, S.N.; Gheewala, S.H.; Bonnet, S. Framework for life cycle sustainability assessment of municipal solid waste management systems with an application to a case study in Thailand. Waste Manag. Res. 2012, 30, 708–719. [Google Scholar] [CrossRef]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2011. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2012. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2013. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2014. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2015. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2016. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2017. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2018. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2019. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2020. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2021. [Google Scholar]

- SYAP. Statistical Yearbook of Alborz Province, Program and Budget Organization; SYAP: Alborz, Iran, 2022. [Google Scholar]

- WNA. World Nuclear Association, Carbon Dioxide Emissions From Electricity. Available online: https://www.world-nuclear.org/information-library/energy-and-the-environment/carbon-dioxide-emissions-from-electricity.aspx (accessed on 1 January 2022).

- Fernández-González, J.M.; Grindlay, A.L.; Serrano-Bernardo, F.; Rodríguez-Rojas, M.I.; Zamorano, M. Economic and environmental review of Waste-to-Energy systems for municipal solid waste management in medium and small municipalities. Waste Manag. 2017, 67, 360–374. [Google Scholar] [CrossRef]

- IPCC. IPCC Fifth Assessment Report—Synthesis Report; IPCC: New York, NY, USA, 2014. [Google Scholar]

- TWMO. Waste Production in Tehran; Tehran Waste Management Organization: Tehran, Iran, 2019. [Google Scholar]

- Worrell, W.A.; Vesilind, P.A.J. Solid Waste Engineering; CL Engineering: Chonburi, Thailand, 2012. [Google Scholar]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Life cycle assessment of waste-to-energy (WtE) technologies for electricity generation using municipal solid waste in Nigeria. Appl. Energy 2017, 201, 200–218. [Google Scholar] [CrossRef]

- KWMO. Waste Production in Alborz; Karaj Waste Management Organization: Alborz, Iran, 2020. [Google Scholar]

- Kamarehie, B.; Jafari, A.; Ghaderpoori, M.; Azimi, F.; Faridan, M.; Sharafi, K.; Ahmadi, F.; Karami, M.A. Qualitative and quantitative analysis of municipal solid waste in Iran for implementation of best waste management practice: A systematic review and meta-analysis. Environ. Sci. Pollut. Res. 2020, 27, 37514–37526. [Google Scholar] [CrossRef]

- Rahmandad, H.; Sterman, J.D. Reporting guidelines for simulation-based research in social sciences. Syst. Dyn. Rev. 2012, 28, 396–411. [Google Scholar] [CrossRef]

| Scenario | Name | Purposes | Assumptions |

|---|---|---|---|

| BAU Scenario | Unmanaged landfilling | Investigating the environmental effects of continuing the current conditions | Continuation of the current situation, in which only 10% of the valuable dry waste is separated at the source and the rest is disposed of in an unmanaged landfill. |

| Scenario S1 | Recycling | Predicting the plan of municipalities regarding source separation to achieve sustainable development | Increase in the participation of citizens in valuable dry waste separation from 10% in the current situation to 70% starting in 2035. |

| Scenario S2 | Sanitary landfilling | Reducing GHG emissions, electricity production | Change from an unmanaged landfill in the BAU Scenario to a sanitary landfill for energy extraction. |

| Scenario S3 | Composting | Reducing the landfill, further exploitation of the landfill site | Application of the compost process to 50% of the organic waste in 2023 to modify the effect of the organic waste treatment’s structure and the optimization of the treatment’s structure. |

| Scenario S4 | Anaerobic digestion | Reducing the landfill, further exploitation of the landfill site | Application of the anaerobic digestion process to 50% of the organic waste in 2025 to modify the effect of the organic waste treatment’s structure and the optimization of the treatment’s structure. |

| Scenario S5 | Incineration | Management of residual dry waste and energy production | Application of incineration to residual dry waste in 2025. |

| Scenario S6 | ISWM | Taking advantage of all scenarios | Simultaneous implementation of the recycling, composting, anaerobic digestion, and incineration scenarios for the integrated management of all waste. |

| Year | Total Population (Ten Thousand Persons) | Total Waste Generated (Million Tons) | ||||

|---|---|---|---|---|---|---|

| Actual | Estimated | Error | Actual | Estimated | Error | |

| 2011 | 241.25 | 241.25 | 0.00 | 0.557 | 0.567 | −0.009 |

| 2012 | 245.70 | 246.56 | −0.86 | 0.602 | 0.592 | 0.010 |

| 2013 | 250.20 | 252.15 | −1.95 | 0.634 | 0.619 | 0.015 |

| 2014 | 254.80 | 257.91 | −3.11 | 0.667 | 0.647 | 0.020 |

| 2015 | 259.40 | 264.05 | −4.65 | 0.664 | 0.676 | −0.012 |

| 2016 | 271.24 | 270.39 | 0.85 | 0.606 | 0.706 | −0.100 |

| 2017 | 276.60 | 276.71 | −0.11 | 0.609 | 0.722 | −0.112 |

| 2018 | 281.60 | 282.97 | −1.36 | 0.619 | 0.730 | −0.111 |

| 2019 | 286.50 | 288.67 | −2.17 | 0.643 | 0.737 | −0.094 |

| 2020 | 291.30 | 293.80 | −2.50 | 0.697 | 0.742 | −0.045 |

| Variable | MAE | MSE | RMSE | MAPE (%) |

|---|---|---|---|---|

| Population | 1.76 | 4.94 | 2.22 | 0.66 |

| Total waste generated | 0.053 | 0.005 | 0.068 | 8.43 |

| Scenarios | Emission (Mt) | Avoided (Mt) | Accumulated Net GHGs 2020–2050 (Mt) | Accumulated Net GHGs Compared to BAU Scenario (Mt) | ||

|---|---|---|---|---|---|---|

| GHGs from Different Treatment | GHGs from Input Material | GHGs from Products | GHGs from Input Material Reduction | |||

| S6 | 9.67 | 1.716 | 23.19 | 0.046 | −11.86 | 24.3 (−195%) |

| S5 | 15.18 | 1.010 | 8.47 | 0.017 | 7.70 | 4.8 (−38.3) |

| S4 | 12.42 | 0.941 | 13.26 | 0.023 | 0.08 | 12.4 (−99.3%) |

| S3 | 14.13 | 1.514 | 10.01 | 0.023 | 5.62 | 6.9 (−55%) |

| S2 | 7.91 | 0.283 | 5.27 | 0.010 | 2.91 | 9.6 (−76.7) |

| S1 | 15.43 | 0.508 | 4.55 | 0.019 | 11.37 | 1.1 (−8.9) |

| BAU | 14.59 | 0.283 | 2.39 | 0.010 | 12.48 | 0 |

| Unit | BAU | S1 | S2 | S3 | S4 | S5 | S6 | |

|---|---|---|---|---|---|---|---|---|

| SA | USD | 1.7 × 108 | 1.5 × 108 | 1.5 × 108 | 1.1 × 108 | 1.5 × 108 | 1.3 × 108 | 4.3 × 107 |

| USD | 4.3 × 108 | 4.0 × 108 | 4.0 × 108 | 3.0 × 108 | 4.0 × 108 | 3.2 × 108 | 1.1 E× 108 | |

| PP | Kg | 2.3 × 108 | 2.1 × 108 | 2.1 × 108 | 1.6 × 108 | 2.1 × 108 | 1.7 × 108 | 5.8 × 107 |

| USD | 1.3 × 107 | 1.2 × 107 | 1.2 × 107 | 8.9 × 106 | 1.2 × 107 | 9.5 × 106 | 3.2 × 106 | |

| HH | DALY | 5.9 × 103 | 6.3 × 103 | 3.1 × 103 | 5.7 × 103 | 6.3 × 103 | 6.2 × 103 | 3.9 × 103 |

| USD | 1.4 × 108 | 1.5 × 108 | 7.5 × 107 | 1.4 × 108 | 1.5 × 108 | 1.5 × 108 | 9.2 × 107 | |

| Net HH | DALY | 8.2 × 10−3 | 7.4 × 10−3 | 1.7 × 10−3 | 3.5 × 10−3 | 7.6 × 10−3 | 4.9 × 10−3 | −8.3 × 10−3 |

| USD | 9.0 × 107 | 8.2 × 107 | 1.8 × 107 | 3.9 × 107 | 8.4 × 107 | 5.4 × 107 | −9.1 × 107 | |

| BD | EINES | 9.9 × 10−3 | 1.0 × 10−2 | 5.4 × 10−3 | 9.6 × 10−3 | 1.1 × 10−2 | 1.0 × 10−2 | 6.6 × 10−3 |

| USD | 1.1 × 108 | 1.2 × 108 | 5.9 × 107 | 1.1 × 108 | 1.2 × 108 | 1.1 × 108 | 7.2 × 107 | |

| Net BD | EINES | 8.2 × 10−3 | 7.4 × 10−3 | 1.7 × 10−3 | 3.5 × 10−3 | 7.6 × 10−3 | 4.9 × 10−3 | −8.3 × 10−3 |

| USD | 9.0 × 107 | 8.2 × 108 | 1.9 × 107 | 3.9 × 107 | 8.4 × 107 | 5.4 × 107 | −9.1 × 107 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahbazi, A.; Moeinaddini, M.; Abdoli, M.A.; Hosseinzadeh, M.; Jaafarzadeh, N.; Sinha, R. Environmental Damage of Different Waste Treatment Scenarios by Considering Avoided Emissions Based on System Dynamics Modeling. Sustainability 2023, 15, 16158. https://doi.org/10.3390/su152316158

Shahbazi A, Moeinaddini M, Abdoli MA, Hosseinzadeh M, Jaafarzadeh N, Sinha R. Environmental Damage of Different Waste Treatment Scenarios by Considering Avoided Emissions Based on System Dynamics Modeling. Sustainability. 2023; 15(23):16158. https://doi.org/10.3390/su152316158

Chicago/Turabian StyleShahbazi, Ali, Mazaher Moeinaddini, Mohammad Ali Abdoli, Mahnaz Hosseinzadeh, Neamatollah Jaafarzadeh, and Rajib Sinha. 2023. "Environmental Damage of Different Waste Treatment Scenarios by Considering Avoided Emissions Based on System Dynamics Modeling" Sustainability 15, no. 23: 16158. https://doi.org/10.3390/su152316158