Impact of Key Drivers on Energy Intensity and GHG Emissions in Manufacturing in the Baltic States

Abstract

:1. Introduction

- To provide an in-depth analysis of energy intensity trends in manufacturing in Estonia, Latvia, and Lithuania over the period 2010–2020.

- To examine the effects of EE and structural changes in activities underlying the decline in energy intensity in manufacturing in the Baltic countries.

- To examine the effects of changes in the number of employees, labour productivity, declining energy intensity, RES deployment, and the variation in emissions intensity that underlie the decline in GHG emissions in manufacturing in three Baltic countries.

- To compare the trends in the key drivers and their impact on the reduction in GHG emissions in three Baltic countries and in the EU−27 countries.

2. Literature Review

3. Methodology

3.1. Data and Their Preparation

3.2. Calculation of Final Energy Intensity in Manufacturing and Its Branches

3.3. Calculation of Energy Savings

3.4. Calculation of Changes in GHG Emissions

4. Results

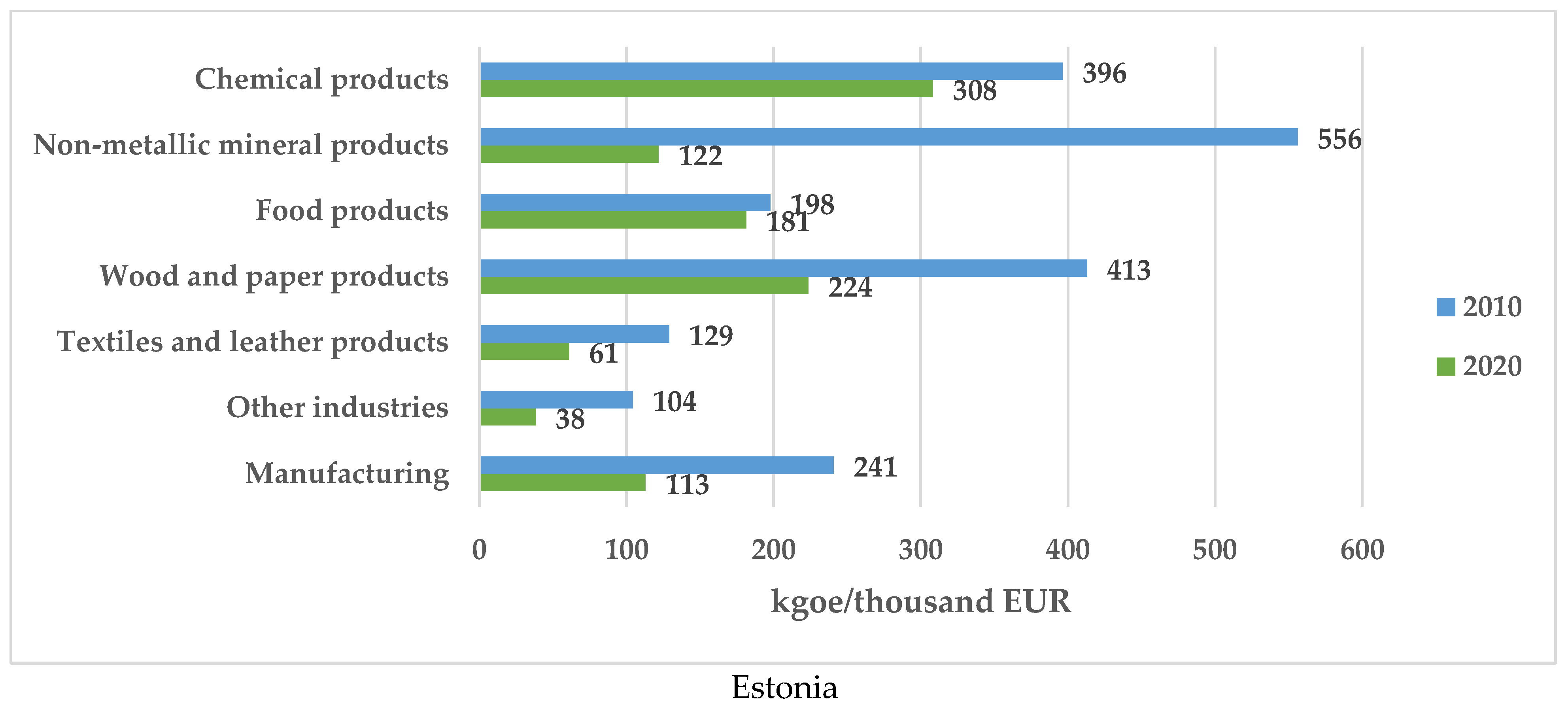

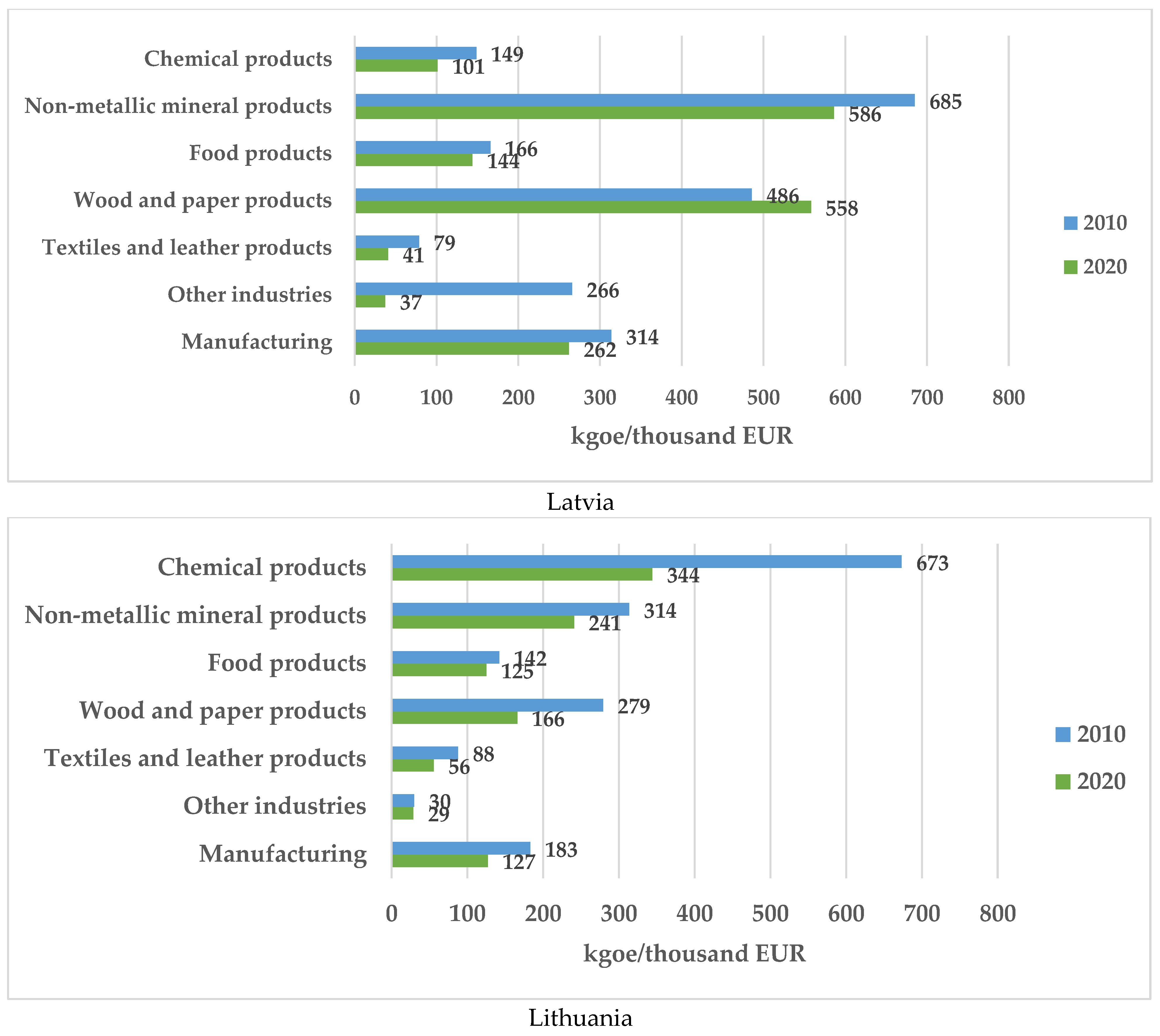

4.1. Developments in Energy Intensity

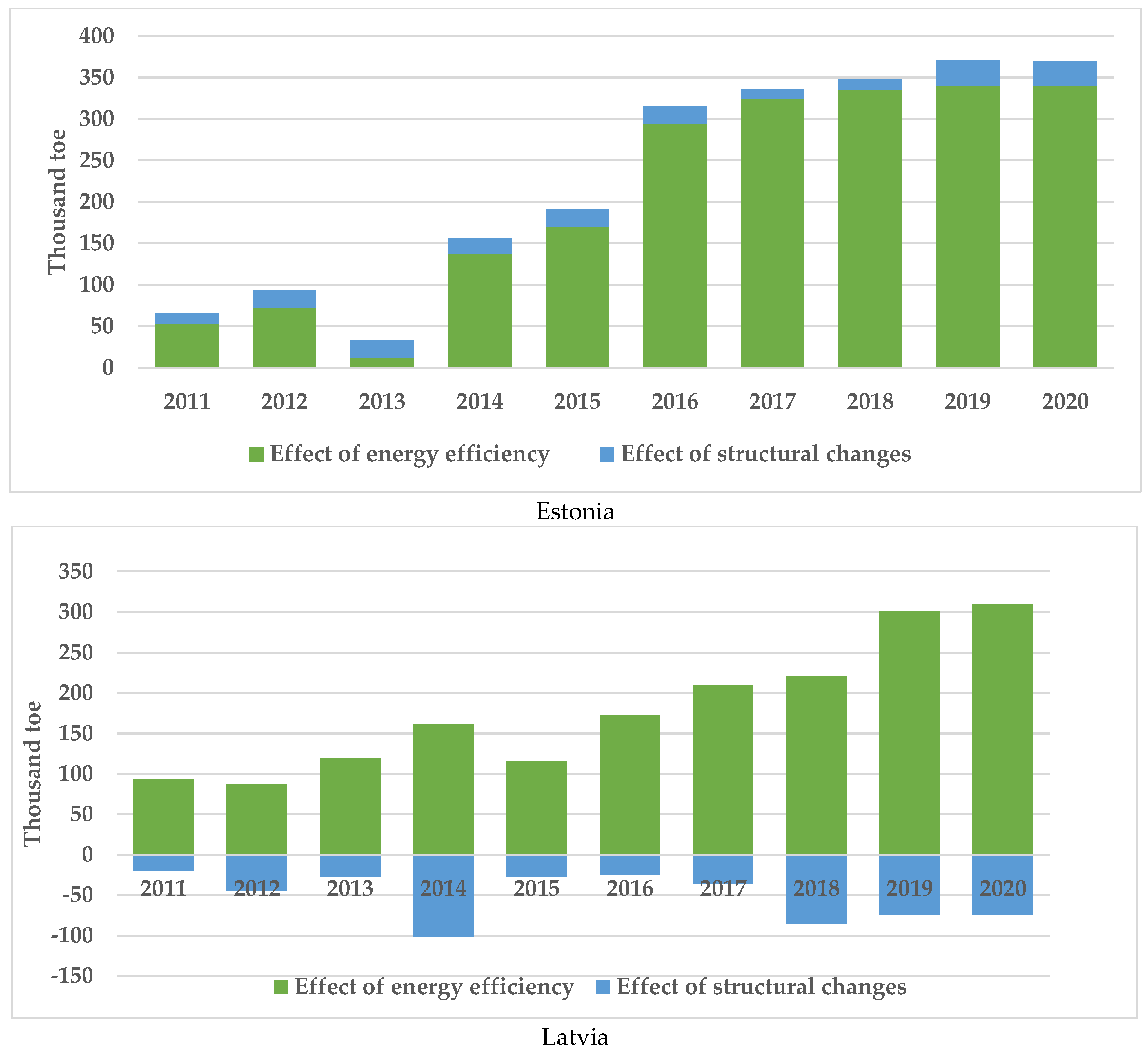

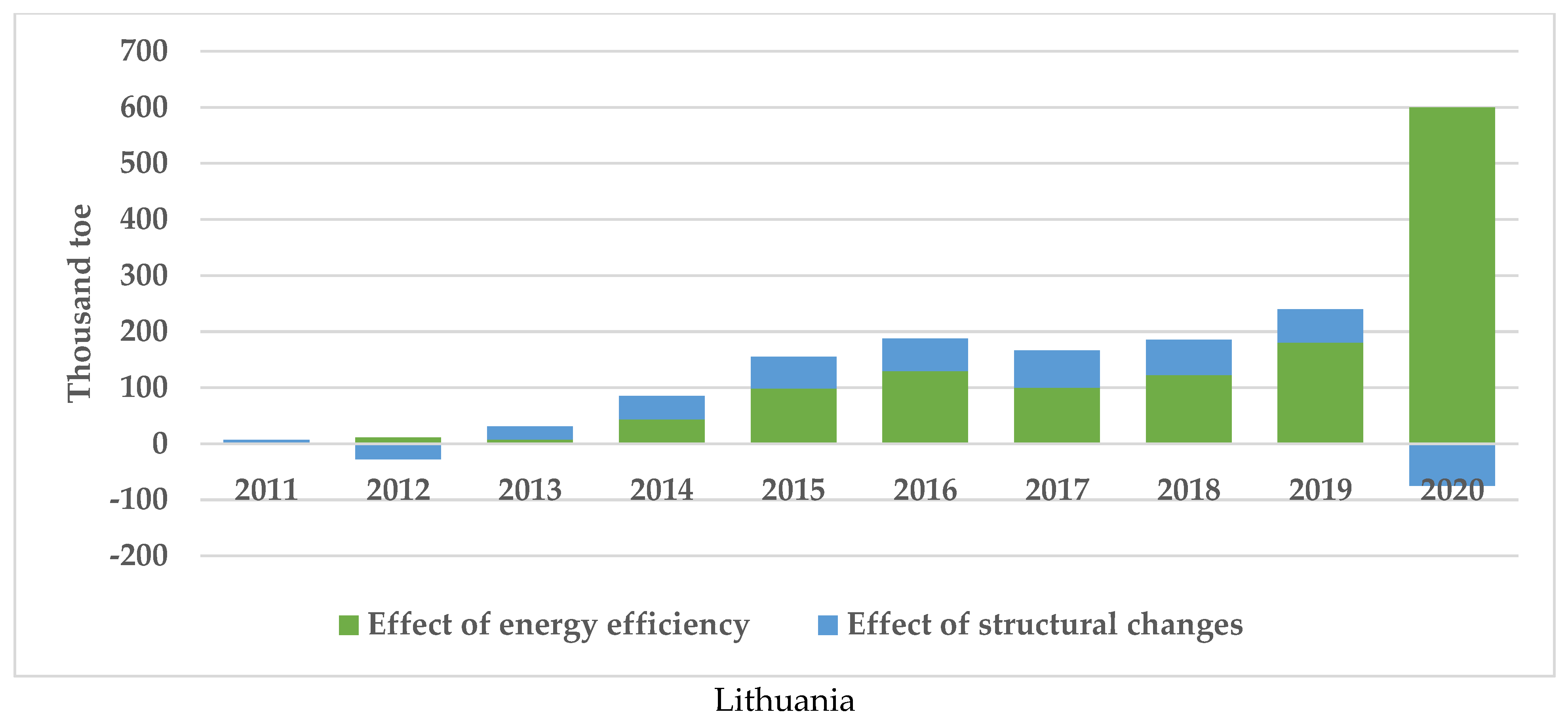

4.2. Impact of Developments in Energy Intensity and Its Key Drivers on Energy Savings

4.3. Impact on GHG Emissions

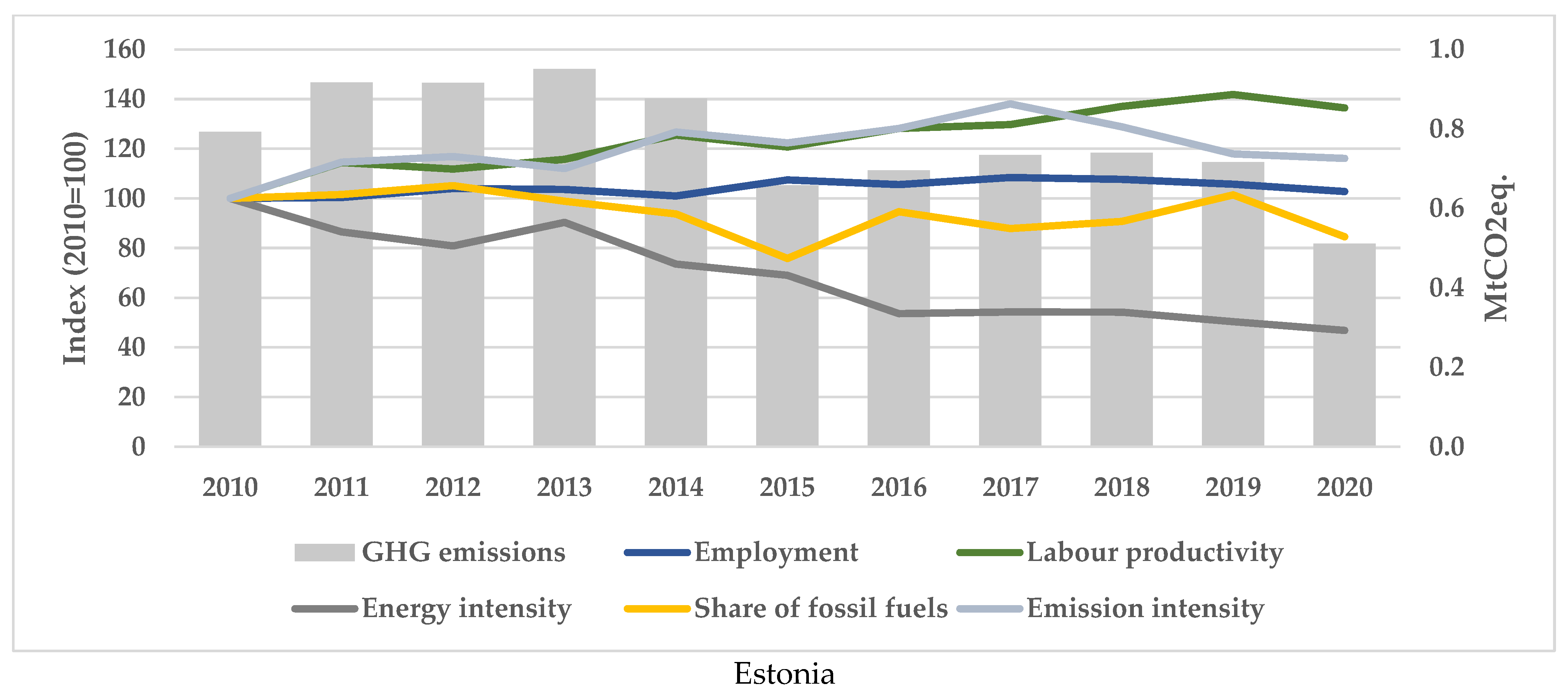

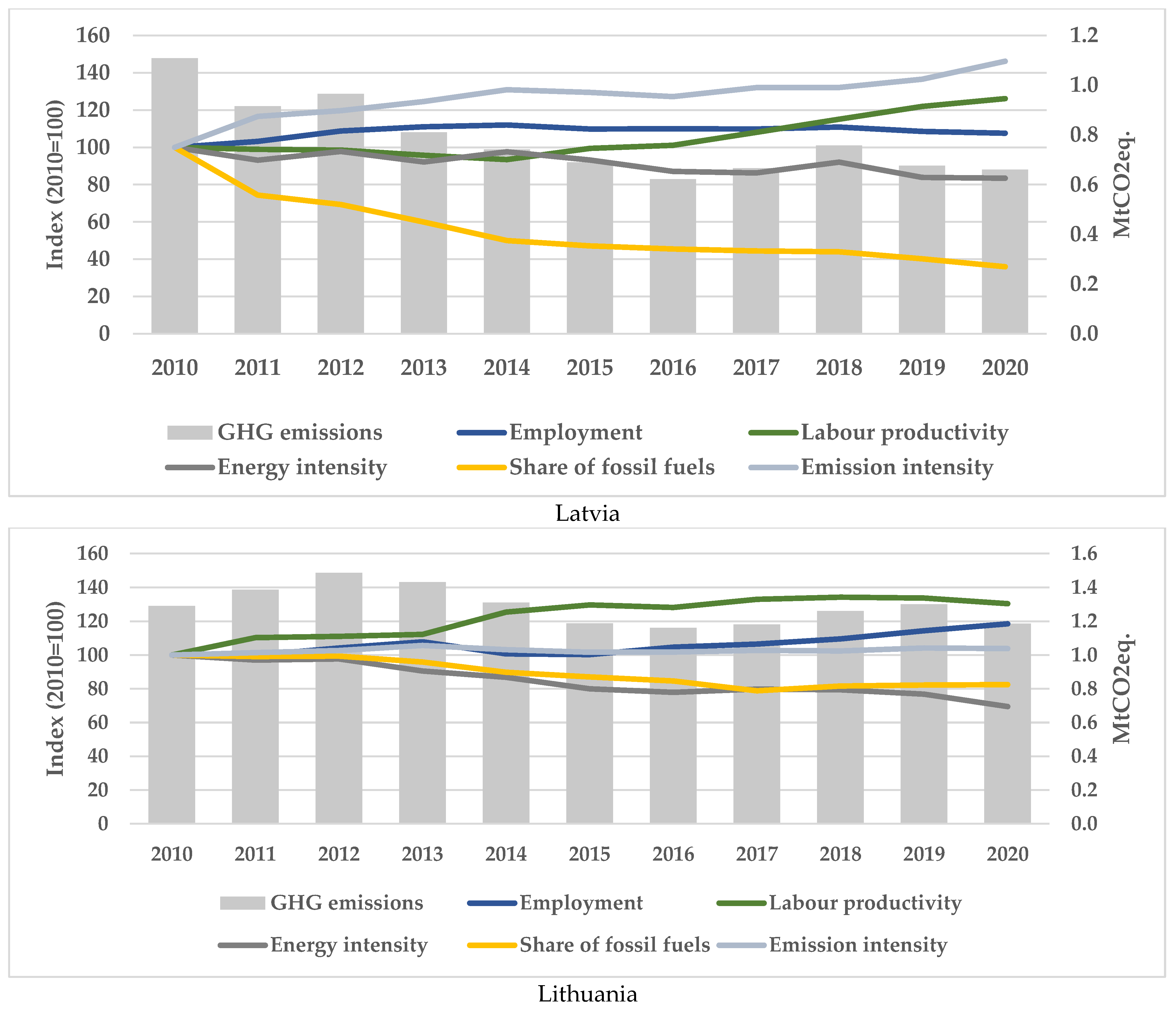

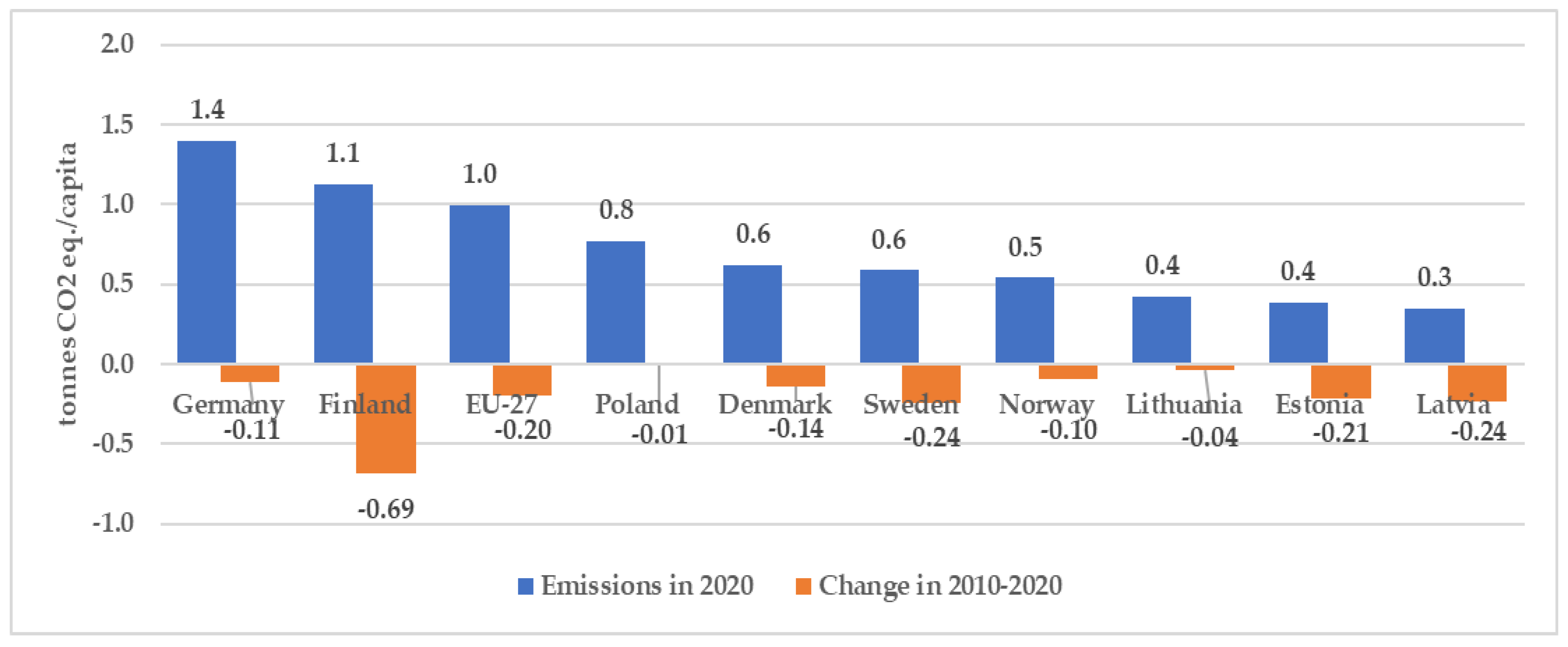

4.3.1. Trends in GHG Emissions and Their Key Drivers

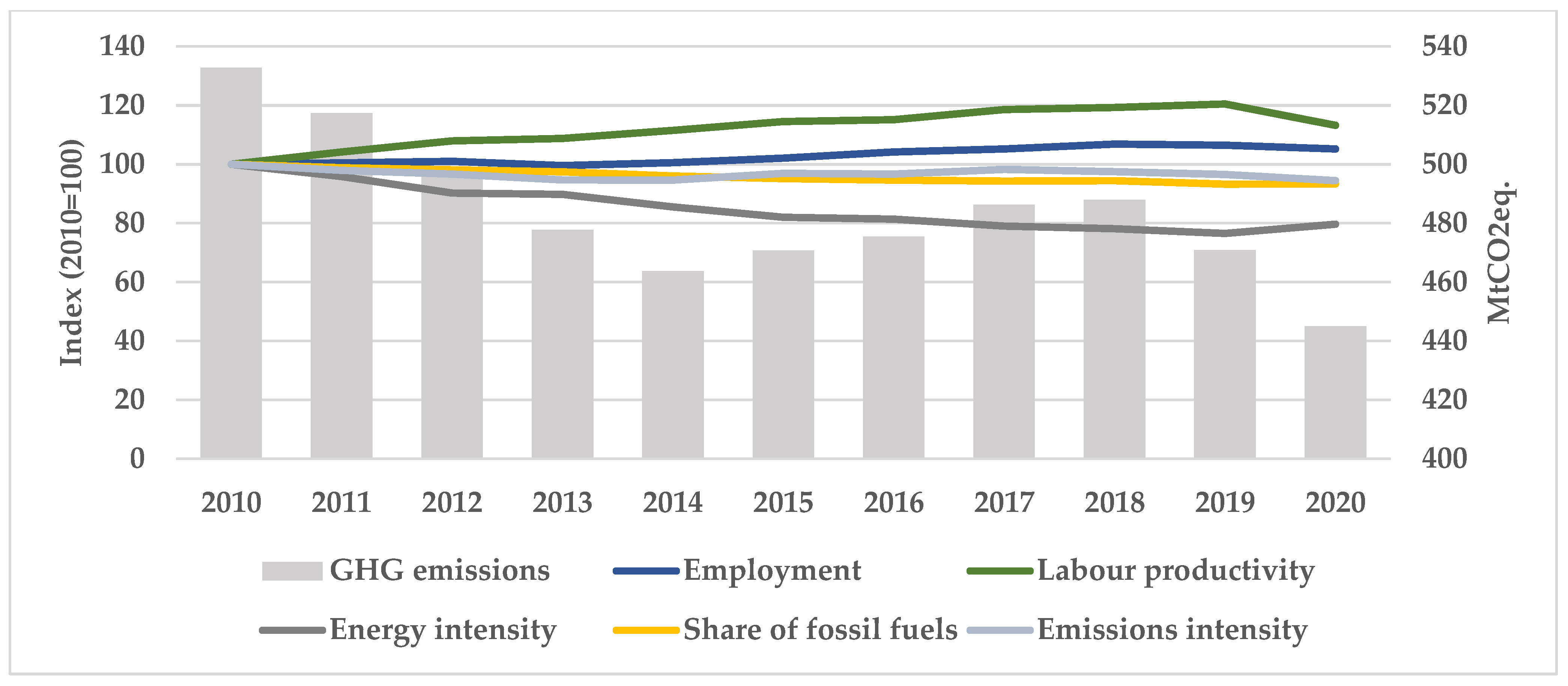

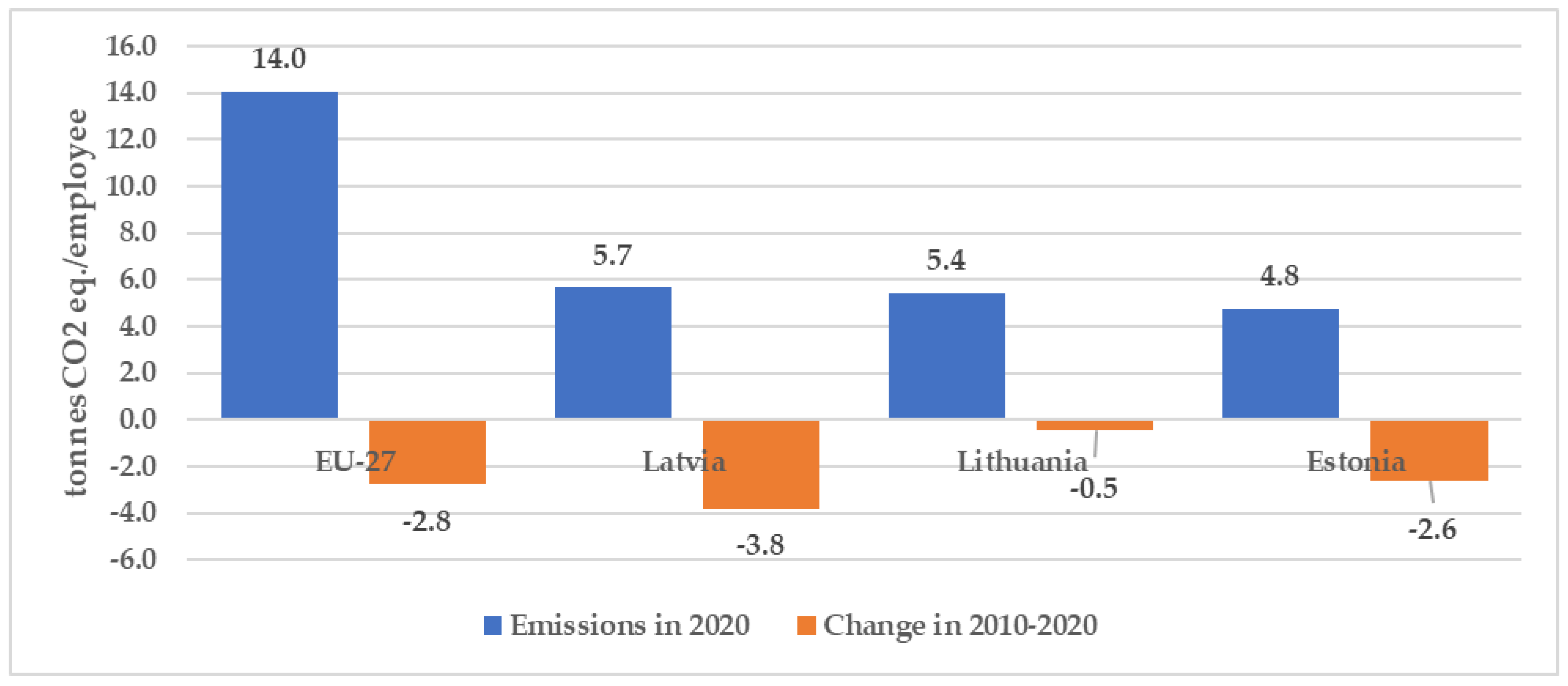

4.3.2. Absolute Changes in GHG Emissions by Effect of Key Drivers

5. Discussion

6. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EE | energy efficiency |

| ES | energy sufficiency |

| EU | European Union |

| EC | European Commission |

| Eurostat | statistical bureau of the European Union |

| GDP | gross domestic product |

| GHG | greenhouse gas |

| IEA | International Energy Agency |

| kgoe | kilogramme of oil equivalent |

| LEI | Lithuanian Energy Institute |

| LMDI | Logarithmic Mean Divisia Index |

| RES | renewable energy sources |

| toe | tonne of oil equivalent |

| VA | value added |

References

- A Clean Planet for All—A European Strategic Long-Term Vision for A Prosperous, Modern, Competitive and Climate Neutral Economy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52018DC0773 (accessed on 10 September 2022).

- Summary of Main Findings in Estonia. Available online: https://ec.europa.eu/clima/sites/lts/lts_ee_summary_en.pdf (accessed on 11 September 2022).

- Summary of Main Findings in Latvia. Available online: https://ec.europa.eu/clima/sites/lts/lts_lv_summary_en.pdf (accessed on 11 September 2022).

- Summary of Main Findings in Lithuania. Available online: https://ec.europa.eu/clima/sites/lts/lts_lt_summary_en.pdf (accessed on 10 September 2022).

- Buchmann, M.; Kusznir, J.; Brunekreeft, G. Assessment of the drafted German integrated National Energy and Climate Plan. Econ. Policy Energy Environ. 2019, 85–96. [Google Scholar] [CrossRef]

- De Paoli, L. The Italian draft National Energy-Climate Plan. Econ. Policy Energy Environ. 2019, 97–118. [Google Scholar] [CrossRef]

- Pluta, M.; Suwała, W.; Wyrwa, A. Review of the Polish integrated National Energy and Climate draft Plan 2021–2030. Econ. Policy Energy Environ. 2019, 149–160. [Google Scholar] [CrossRef]

- Štreimikienė, D.; Kyriakopoulos, G.L.; Stankūnienė, G. Review of Energy and Climate Plans of Baltic States: The Contribution of Renewables for Energy Production in Households. Energies 2022, 15, 7728. [Google Scholar] [CrossRef]

- Fujimori, S.; Krey, V.; van Vuuren, D.; Oshiro, K.; Sugiyama, M.; Chunark, P.; Limmeechokchai, B.; Mittal, S.; Nishiura, O.; Park, C.; et al. A framework for national scenarios with varying emission reductions. Nat. Clim. Change 2021, 11, 472–480. [Google Scholar] [CrossRef]

- Lu, J.; Chen, H.; Cai, X. From global to national scenarios: Exploring carbon emissions to 2050. Energy Strategy Rev. 2022, 41, 100860. [Google Scholar] [CrossRef]

- Zheng, X.; Lu, Y.; Yuan, J.; Baninla, Y.; Zhang, S.; Stenseth, N.C.; Hessen, D.O.; Tian, H.; Obersteiner, M.; Chen, D. Drivers of change in China’s energy-related CO2 emissions. Proc. Natl. Acad. Sci. USA 2020, 117, 29–36. [Google Scholar] [CrossRef]

- Ouyang, X.; Lin, B. An analysis of the driving forces of energy-related carbon dioxide emissions in China’s industrial sector. Renew. Sustain. Energy Rev. 2015, 45, 838–849. [Google Scholar] [CrossRef]

- Lin, B.; Tan, R. Sustainable development of China’s energy intensive industries: From the aspect of carbon dioxide emissions reduction. Renew. Sustain. Energy Rev. 2017, 77, 386–394. [Google Scholar] [CrossRef]

- Wang, M.; Feng, C. Understanding China’s industrial CO2 emissions: A comprehensive position framework. J. Clean. Prod. 2017, 166, 1335–1346. [Google Scholar] [CrossRef]

- Yuan, J.; Xu, Y.; Hu, Z.; Zhao, C.; Xiong, M.; Guo, J. Peak energy consumption and CO2 emissions in China. Energy Policy 2014, 68, 508–523. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, Y.; Yuan, Z.; Ou, X. Peak energy consumption and CO2 emissions in China’s industrial sector. Energy Strategy Rev. 2018, 20, 113–123. [Google Scholar] [CrossRef]

- Eurostat Database. Energy Intensity of GDP in Chain Linked Volumes (2010). Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_ind_ei/default/table?lang=en (accessed on 6 November 2022).

- International Energy Agency. World Energy Balances; OECD/IAE: Paris, France, 2021. [Google Scholar]

- Lin, Y.; Ma, L.; Li, Z.; Ni, W. The carbon reduction potential by improving technical efficiency from energy sources to final services in China: An extended Kaya identity analysis. Energy 2023, 263, 125963. [Google Scholar] [CrossRef]

- Li, M.; Tao, W. Review of methodologies and polices for evaluation of energy efficiency in high energy-consuming industry. Appl. Energy 2017, 187, 203–215. [Google Scholar] [CrossRef]

- Miskinis, V.; Galinis, A.; Konstantinavičiute, I.; Lekavicius, V.; Neniskis, E. Comparative analysis of energy efficiency trends and driving factors in the Baltic States. Energy Strategy Rev. 2020, 30, 100514. [Google Scholar] [CrossRef]

- Cui, Q.; Kuang, H.; Wu, C.; Li, Y. The changing trend and influencing factors of energy efficiency: The case of nine countries. Energy 2014, 64, 1026–1034. [Google Scholar] [CrossRef]

- Song, F.; Zheng, X. What drives the change in China’s energy intensity: Combining decomposition analysis and econometric analysis at the provincial level. Energy Policy 2012, 51, 445–453. [Google Scholar] [CrossRef]

- Yang, M.; Patino-Echeverri, D.; Yang, F.; Williams, E. Industrial energy efficiency in China: Achievements, challenges and opportunities. Energy Strategy Rev. 2015, 6, 20–29. [Google Scholar] [CrossRef]

- Kermeli, K.; Graus, W.H.J.; Worrel, E. Energy efficiency improvement potentials and a low energy demand scenario for the global industrial sector. Energy Effic. 2014, 7, 987–1011. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Basilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Zhao, Y.; Ke, J.; Ni, C.C.; McNeil, M.; Khanna, N.Z.; Zhou, N.; Fridley, D.; Li, Q. A comparative study of energy consumption and efficiency of Japanese and Chinese manufacturing industry. Energy Policy 2014, 70, 45–56. [Google Scholar] [CrossRef]

- Dolge, K.; Azis, R.; Lund, P.D.; Blumberga, D. Importance of Energy Efficiency in Manufacturing Industries for Climate and Competitiveness. Environ. Clim. Technol. 2021, 25, 306–317. Available online: https://sciendo.com/article/10.2478/rtuect-2021-0022 (accessed on 10 September 2022). [CrossRef]

- Dzikuc, M.; Gorączkowska, J.; Piwowar, A.; Dzikuc, M.; Smolenski, R.; Kułyk, P. The analysis of the innovative potential of the energy sector and low-carbon development: A case study for Poland. Energy Strategy Rev. 2021, 38, 100769. [Google Scholar] [CrossRef]

- Korkmaz, P.; Schmid, D.; Fahl, U. Incorporating uncertainties towards a sustainable European energy system: A stochastic approach for decarbonization paths focusing on the transport sector. Energy Strategy Rev. 2021, 38, 100707. [Google Scholar] [CrossRef]

- Panoutsou, C.; Germer, S.; Karka, P.; Papadokostantakis, S.; Kroyan, Y.; Wojcieszyk, M.; Maniatis, K.; Marchand, P.; Landalv, I. Advanced biofuels to decarbonise European transport by 2030: Markets, challenges, and policies that impact their successful market uptake. Energy Strategy Rev. 2021, 34, 100633. [Google Scholar] [CrossRef]

- Moula, M.M.E.; Nyari, J.; Bartel, A. Public acceptance of biofuels in the transport sector in Finland. Int. J. Sustain. Built Environ. 2017, 6, 434–441. [Google Scholar] [CrossRef]

- Zhao, B. Why will dominant alternative transportation fuels be liquid fuels, not electricity or hydrogen? Energy Policy 2017, 108, 712–714. [Google Scholar] [CrossRef]

- Andrés, L.; Padilla, E. Driving factors of GHG emissions in the EU transport activity. Transp. Policy 2018, 61, 60–74. [Google Scholar] [CrossRef]

- Lipscy, P.Y.; Schipper, L. Energy efficiency in the Japanese transport sector. Energy Policy 2013, 56, 248–258. [Google Scholar] [CrossRef]

- Chung, W.; Zhou, G.; Yeung, I.M.H. A study of energy efficiency of transport sector in China from 2003 to 2009. Appl. Energy 2013, 112, 1066–1077. [Google Scholar] [CrossRef]

- Zell-Ziegler, C.; Thema, J.; Best, B.; Wiese, F.; Lage, J.; Schmidt, A.; Toulouse, E.; Stagl, S. Enough? The role of sufficiency in European energy and climate plans. Energy Policy 2021, 157, 112483. [Google Scholar] [CrossRef]

- Maduta, C.; Melica, G.; D’Agostino, D.; Bertoldi, P. Towards a decarbonised building stock by 2050: The meaning and the role of zero emission buildings (ZEBs) in Europe. Energy Strategy Rev. 2022, 44, 101009. [Google Scholar] [CrossRef]

- Ramos, A.; Gago, A.; Labandeira, X.; Linares, P. The role of information for energy efficiency in the residential sector. Energy Econ. 2015, 52, 517–529. [Google Scholar] [CrossRef]

- Banfi, S.; Farsi, M.; Filippini, M.; Jakob, M. Willingness to pay for energy-saving measures in residential buildings. Energy Econ. 2008, 30, 503–516. [Google Scholar] [CrossRef]

- Streimikiene, D.; Balezentis, T.; Alebaite, I. Climate change mitigation in households between market failures and psychological barriers. Energies 2020, 13, 2797. [Google Scholar] [CrossRef]

- Piekut, M. Patterns of energy consumption in Polish one-person households. Energies 2020, 13, 5699. [Google Scholar] [CrossRef]

- Bobinaite, V.; Konstantinaviciute, I.; Galinis, A.; Bartek-Lesi, M.; Rácz, V.; Dézsi, B. Energy Sufficiency in the Household Sector of Lithuania and Hungary: The Case of Heated Floor Area. Sustainability 2022, 14, 16162. [Google Scholar] [CrossRef]

- Best, B.; Thema, J.; Zell-Ziegler, C.; Wiese, F.; Barth, J.; Breidenbach, S.; Nascimento, L.; Wilke, H. Building a database for energy sufficiency policies [version 2; peer review: 2 approved]. F1000Research 2022, 11, 229. [Google Scholar] [CrossRef]

- Štreimikienė, D.; Baležentis, A.; Ališauskaitė-Šeškienė, I.; Stankūnienė, G.; Simanavičienė, Ž. A Review of Willingness to Pay Studies for Climate Change Mitigation in the Energy Sector. Energies 2019, 12, 1481. [Google Scholar] [CrossRef]

- Štreimikienė, D.; Kyriakopoulos, G.L.; Lekavičius, V.; Pažėraitė, A. How to support sustainable energy consumption in households? Acta Montan. Slovaca. 2022, 27, 479–490. [Google Scholar] [CrossRef]

- Luttenberger, L.R. The barriers to renewable energy use in Croatia. Renew. Sustain. Energy Rev. 2015, 49, 646–654. [Google Scholar] [CrossRef]

- Štreimikienė, D.; Lekavičius, V.; Stankūnienė, G.; Pažėraitė, A. Renewable Energy Acceptance by Households: Evidence from Lithuania. Sustainability 2022, 14, 8370. [Google Scholar] [CrossRef]

- Value Added (ESA 2010) by Year at Chain-Linked Volume in Estonia (Reference Year 2015). Available online: https://andmed.stat.ee/en/stat/majandus__rahvamajanduse-arvepidamine__sisemajanduse-koguprodukt-(skp)__sisemajanduse-koguprodukt-tootmise-meetodil/RAA0045/table/tableViewLayout2 (accessed on 17 October 2022).

- Energy Balance Sheet by Type of Fuel or Energy in Estonia. Annual Statistics 2022. Available online: https://andmed.stat.ee/en/stat/majandus__energeetika__energia-tarbimine-ja-tootmine__aastastatistika/KE0240/table/tableViewLayout2 (accessed on 4 October 2022).

- Total Gross Value Added at Chain-Linked Volume in Latvia (Reference Year 2015). Available online: https://data.stat.gov.lv/pxweb/en/OSP_PUB/START__VEK__IK__IKP/IKP060/table/tableViewLayout1/ (accessed on 30 September 2022).

- Energy Balance in Latvia 2008–2021. Available online: http://data.csb.gov.lv/pxweb/en/vide/vide__ikgad__energetika/?tablelist=true&rxid=a79839fe-11ba-4ecd-8cc3-4035692c5fc8 (accessed on 6 October 2022).

- Total Value Added in Lithuania at Chain-Linked Volume (Reference Year 2015). Available online: https://osp.stat.gov.lt/statistiniu-rodikliu-analize?indicator=S7R208#/ (accessed on 3 October 2022).

- Environment and Energy in Lithuania. Available online: http://osp-old.stat.gov.lt/web/guest/statistiniu-rodikliu-analize/ (accessed on 20 September 2022).

- National Inventory Submissions 2022. Available online: https://unfccc.int/ghg-inventories-annex-i-parties/2022 (accessed on 5 November 2022).

- Eurostat Database. Final Energy Consumption in Industry by Type of Fuel [TEN00129]. Available online: https://ec.europa.eu/eurostat/databrowser/view/ten00129/default/table?lang=en (accessed on 15 November 2022).

- Eurostat Database. Gross Value Added and Income by A*10 Industry Breakdowns [NAMA_10_A10__Custom_3859420]. Available online: https://ec.europa.eu/eurostat/databrowser/view/NAMA_10_A10__custom_3858659/default/table?lang=en (accessed on 15 November 2022).

- Eurostat Database. Employment by Sex, Age and Economic Activity (from 2008 Onwards, NACE Rev. 2)—1000 [lfsa_egan2]. Available online: https://eige.europa.eu/gender-statistics/dgs/indicator/ta_wrklab_lab_employ_inter_sector__lfsa_egan2/datatable (accessed on 8 November 2022).

- Eurostat Database. Population on 1 January by Age and Sex [Demo_Pjan]. Available online: https://ec.europa.eu/eurostat/databrowser/view/demo_pjan/default/table?lang=en (accessed on 17 November 2022).

- Office of Energy Efficiency & Renewable Energy. Energy Efficiency vs. Energy Intensity. Analysis. Available online: https://www.energy.gov/eere/analysis/energy-efficiency-vs-energy-intensity (accessed on 28 January 2023).

- Golušin, M.; Dodić, S.; Popov, S. Chapter 2—Energy and Sustainable Development. In Sustainable Energy Management; Academic Press: Cambridge, MA, USA, 2013; pp. 7–57. ISBN 9780124159785. [Google Scholar] [CrossRef]

- Martínez, D.M.; Ebenhack, B.W.; Wagner, T.P. Chapter 3—Primary energy trends. In Energy Efficiency; Elsevier Science: Amsterdam, The Netherlands, 2019; pp. 67–99. ISBN 9780128121115. [Google Scholar] [CrossRef]

- Ang, B.W.; Zhang, F.Q. A survey of index decomposition analysis in energy and environmental studies. Energy 2000, 25, 1149–1176. [Google Scholar] [CrossRef]

- Ang, B.W. Decomposition analysis for policy making in energy: Which is the preferred method? Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Boyd, G.A.; Roop, J.M. A Note on the Fisher Ideal Index Decomposition for Structural Change in Energy Intensity. Energy J. 2004, 25, 87–102. [Google Scholar] [CrossRef]

- De Boer, P.; Rodrigues, J.F.D. Decomposition Analysis: When to Use Which Method? Econ. Syst. Res. 2019, 32, 1–28. [Google Scholar] [CrossRef]

- Corporate Finance Institute. Fisher Price Index. 2022. Available online: https://corporatefinanceinstitute.com/resources/economics/fisher-price-index/ (accessed on 10 January 2023).

- Kaya, Y. Impact of Carbon Dioxide Emission Control on Gnp Growth: Interpretation of Proposed Scenarios; IPCC Energy and Industry Subgroup, Response Strategies Working Group: Paris, France, 1990. [Google Scholar]

- Ang, B.W. The LMDI approach to decomposition analysis: A. practical guide. Energy Policy 2005, 33, 867–871. [Google Scholar] [CrossRef]

- Xiang, X.; Ma, X.; Ma, Z.; Ma, M.; Cai, W. Python-LMDI: A Tool for Index Decomposition Analysis of Building Carbon Emissions. Buildings 2022, 12, 83. [Google Scholar] [CrossRef]

- Daldoul, M.; Dakhlaoui, A. Using the LMDI Decomposition Approach to Analyze the Influencing Factors of Carbon Emissions in Tunisian Transportation Sector. Int. J. Energy Econ. Policy 2018, 8, 22–28. Available online: https://www.econjournals.com/index.php/ijeep/article/view/7016/3988 (accessed on 26 January 2023).

- Dai, Y.; Zhu, J.; Song, H. Using LMDI approach to analyze changes in carbon dioxide emissions of China’s logistics industry. J. Ind. Eng. Manag. (JIEM) 2015, 8, 840–860. [Google Scholar] [CrossRef] [Green Version]

| Estonia | Latvia | Lithuania | ||||

|---|---|---|---|---|---|---|

| Energy Use | Value Added | Energy Use | Value Added | Energy Use | Value Added | |

| Food products and beverages | 20.3 | 12.6 | 9.7 | 17.6 | 19.5 | 19.8 |

| Wood and paper products | 41.6 | 21.0 | 61.1 | 28.7 | 15.7 | 12.0 |

| Non-metallic mineral products | 9.6 | 8.9 | 21.3 | 9.5 | 18.7 | 9.9 |

| Chemical products | 9.2 | 3.4 | 2.6 | 6.8 | 34.6 | 12.8 |

| Textile and leather products | 2.5 | 4.6 | 0.6 | 3.8 | 2.7 | 6.3 |

| Other industries | 16.8 | 49.5 | 4.8 | 33.6 | 8.9 | 39.3 |

| Energy Intensity, kgoe/Thousand EUR | Intensity Index | Efficiency Index | Activity Index | ||

|---|---|---|---|---|---|

| 2010 | 2020 | 2020 | 2020 | 2020 | |

| Estonia | |||||

| Food products and beverages | 198 | 181 | 0.73 | 0.92 | 0.79 |

| Wood and paper products | 413 | 224 | 0.57 | 0.54 | 1.05 |

| Non-metallic mineral products | 556 | 122 | 0.13 | 0.22 | 0.59 |

| Chemical products | 396 | 308 | 0.46 | 0.78 | 0.59 |

| Textile and leather products | 129 | 61 | 0.31 | 0.47 | 0.66 |

| Other manufacturing | 104 | 38 | 0.43 | 0.37 | 1.17 |

| Total manufacturing | 241 | 113 | 0.47 | 0.50 | 0.94 |

| Latvia | |||||

| Food products and beverages | 166 | 144 | 0.65 | 0.87 | 0.75 |

| Wood and paper products | 486 | 558 | 1.26 | 1.15 | 1.10 |

| Non-metallic mineral products | 685 | 586 | 0.70 | 0.86 | 0.82 |

| Chemical products | 149 | 101 | 0.56 | 0.68 | 0.82 |

| Textile and leather products | 79 | 41 | 0.33 | 0.52 | 0.64 |

| Other manufacturing | 266 | 37 | 0.17 | 0.14 | 1.21 |

| Total manufacturing | 314 | 262 | 0.83 | 0.79 | 1.06 |

| Lithuania | |||||

| Food products and beverages | 142 | 125 | 0.71 | 0.88 | 0.81 |

| Wood and paper products | 279 | 166 | 0.67 | 0.59 | 1.13 |

| Non-metallic mineral products | 314 | 241 | 0.94 | 0.77 | 1.22 |

| Chemical products | 673 | 344 | 0.63 | 0.51 | 1.22 |

| Textile and leather products | 88 | 56 | 0.51 | 0.63 | 0.80 |

| Other manufacturing | 30 | 29 | 1.02 | 0.96 | 1.07 |

| Total manufacturing | 183 | 127 | 0.69 | 0.66 | 1.05 |

| GHG Emissions | Number of Employees | Labour Productivity | Energy Intensity | Share of Fossil Fuels | Emissions Intensity | |

|---|---|---|---|---|---|---|

| Estonia | −4.29 | 0.27 | 3.15 | −7.30 | −1.66 | 1.51 |

| Latvia | −5.05 | 0.73 | 2.35 | −1.79 | −9.72 | 3.87 |

| Lithuania | −0.84 | 1.71 | 2.69 | −3.58 | −1.91 | 0.38 |

| EU−27 | −1.78 | 0.51 | 1.25 | −2.25 | −0.69 | −0.57 |

| ΔC/Employee | Employee Effect | Labour Productivity | Energy Intensity | Effect of Fossil Fuels | Emission Intensity | |

|---|---|---|---|---|---|---|

| Estonia | −2.62 | 0.16 | 1.85 | −4.53 | −1.00 | 0.89 |

| Latvia | −3.83 | 0.54 | 1.72 | −1.34 | −7.57 | 2.81 |

| Lithuania | −0.48 | 0.96 | 1.51 | −2.07 | −1.10 | 0.21 |

| EU−27 | −2.77 | 0.78 | 1.91 | −3.51 | −1.06 | −0.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miskinis, V.; Galinis, A.; Bobinaite, V.; Konstantinaviciute, I.; Neniskis, E. Impact of Key Drivers on Energy Intensity and GHG Emissions in Manufacturing in the Baltic States. Sustainability 2023, 15, 3330. https://doi.org/10.3390/su15043330

Miskinis V, Galinis A, Bobinaite V, Konstantinaviciute I, Neniskis E. Impact of Key Drivers on Energy Intensity and GHG Emissions in Manufacturing in the Baltic States. Sustainability. 2023; 15(4):3330. https://doi.org/10.3390/su15043330

Chicago/Turabian StyleMiskinis, Vaclovas, Arvydas Galinis, Viktorija Bobinaite, Inga Konstantinaviciute, and Eimantas Neniskis. 2023. "Impact of Key Drivers on Energy Intensity and GHG Emissions in Manufacturing in the Baltic States" Sustainability 15, no. 4: 3330. https://doi.org/10.3390/su15043330