Response Surface Methodology: The Improvement of Tropical Residual Soil Mechanical Properties Utilizing Calcined Seashell Powder and Treated Coir Fibre

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

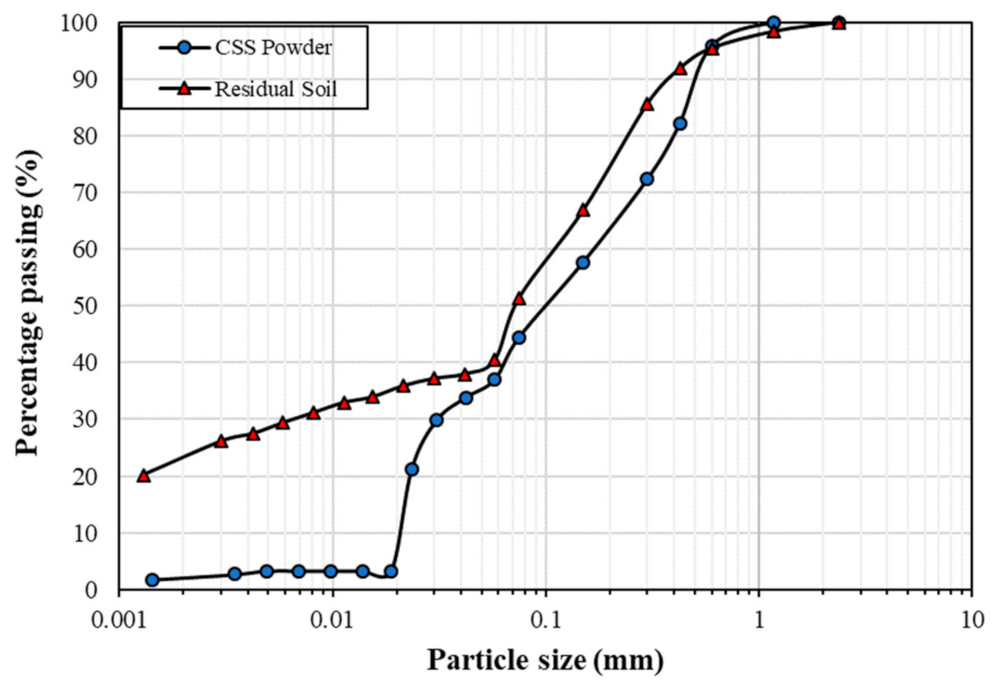

2.1.1. Tropical Residual Soil

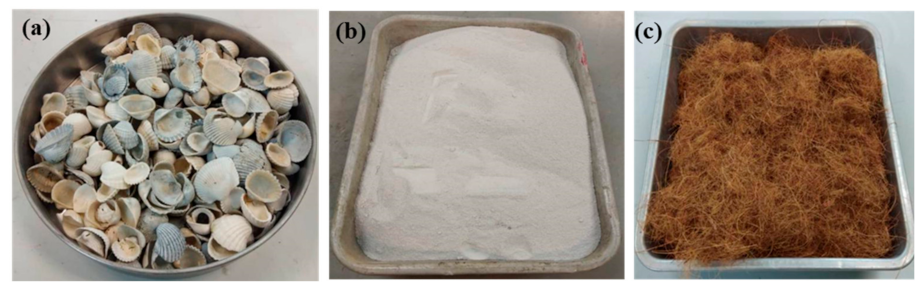

2.1.2. Seashells

2.1.3. Coir Fibre

2.2. Methods

2.2.1. Modification of Coir Fibre by Alkali Treatment

2.2.2. Soil Sample Preparation

2.2.3. Testing Methods: Geotechnical Tests

2.2.4. Testing Methods: Microstructural Tests

2.3. Response Surface Methodology (RSM)

2.3.1. Experimental Design

2.3.2. Model Development and Optimization

2.3.3. Statistical Analysis

3. Results and Discussion

3.1. Effect of CSS Powder and Treated CF on Geotechnical Properties

3.1.1. Atterberg Limits

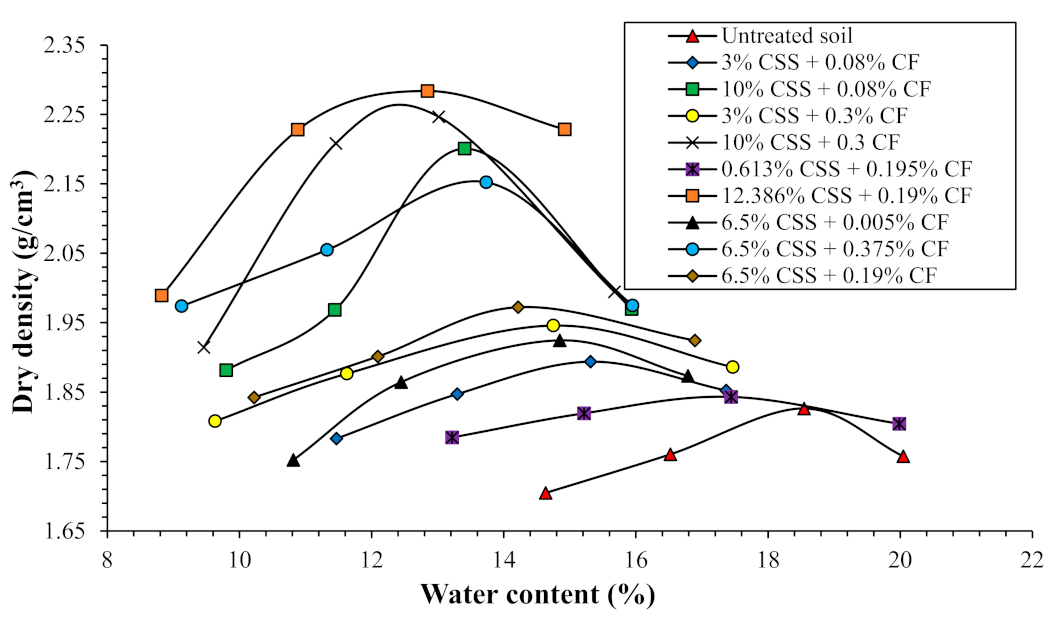

3.1.2. Compaction Characteristics

3.1.3. Unconfined Compressive Strength

3.1.4. Flexural Strength

3.1.5. Indirect Tensile Strength

3.2. Regression Model and Statistical Assessment

3.2.1. Regression Model Development

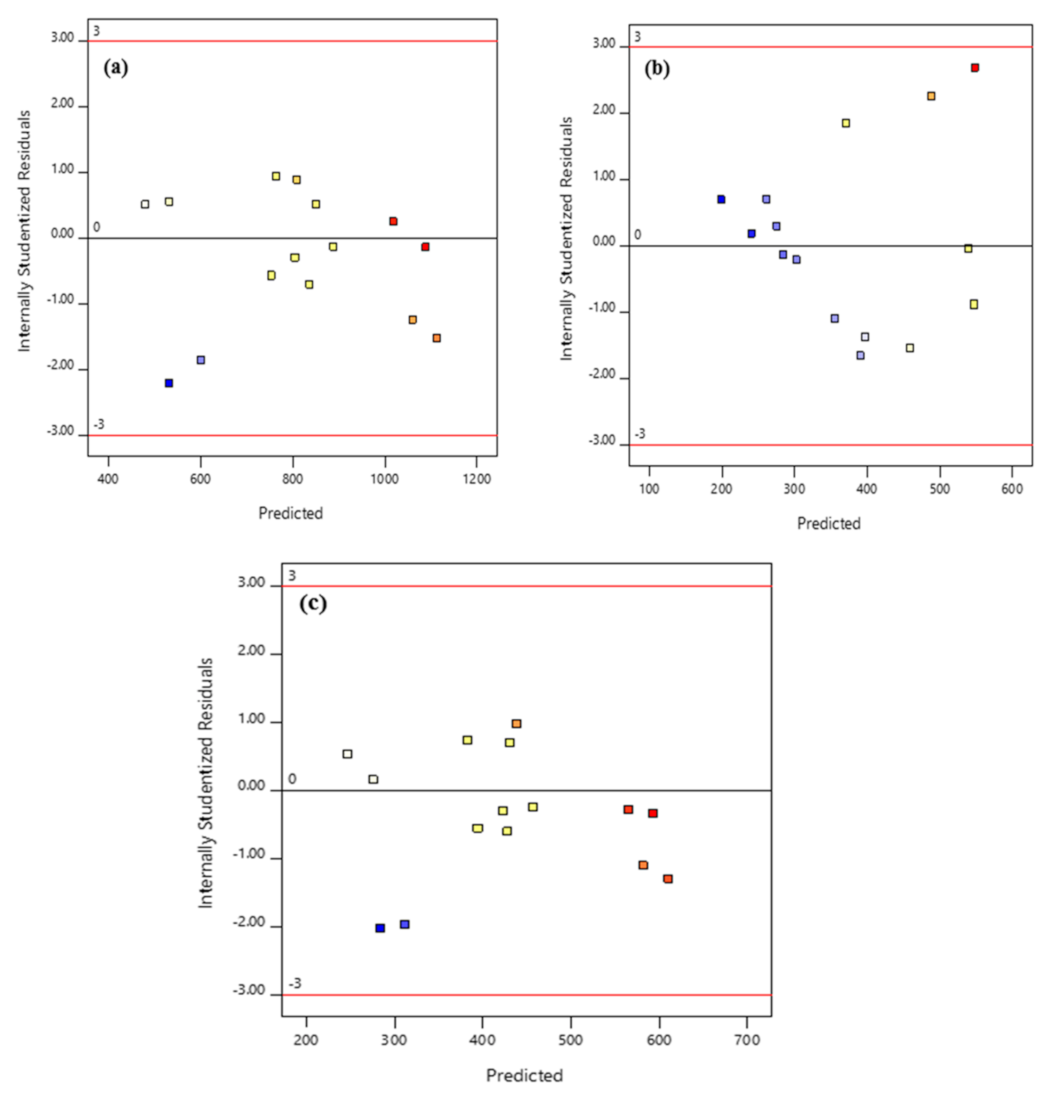

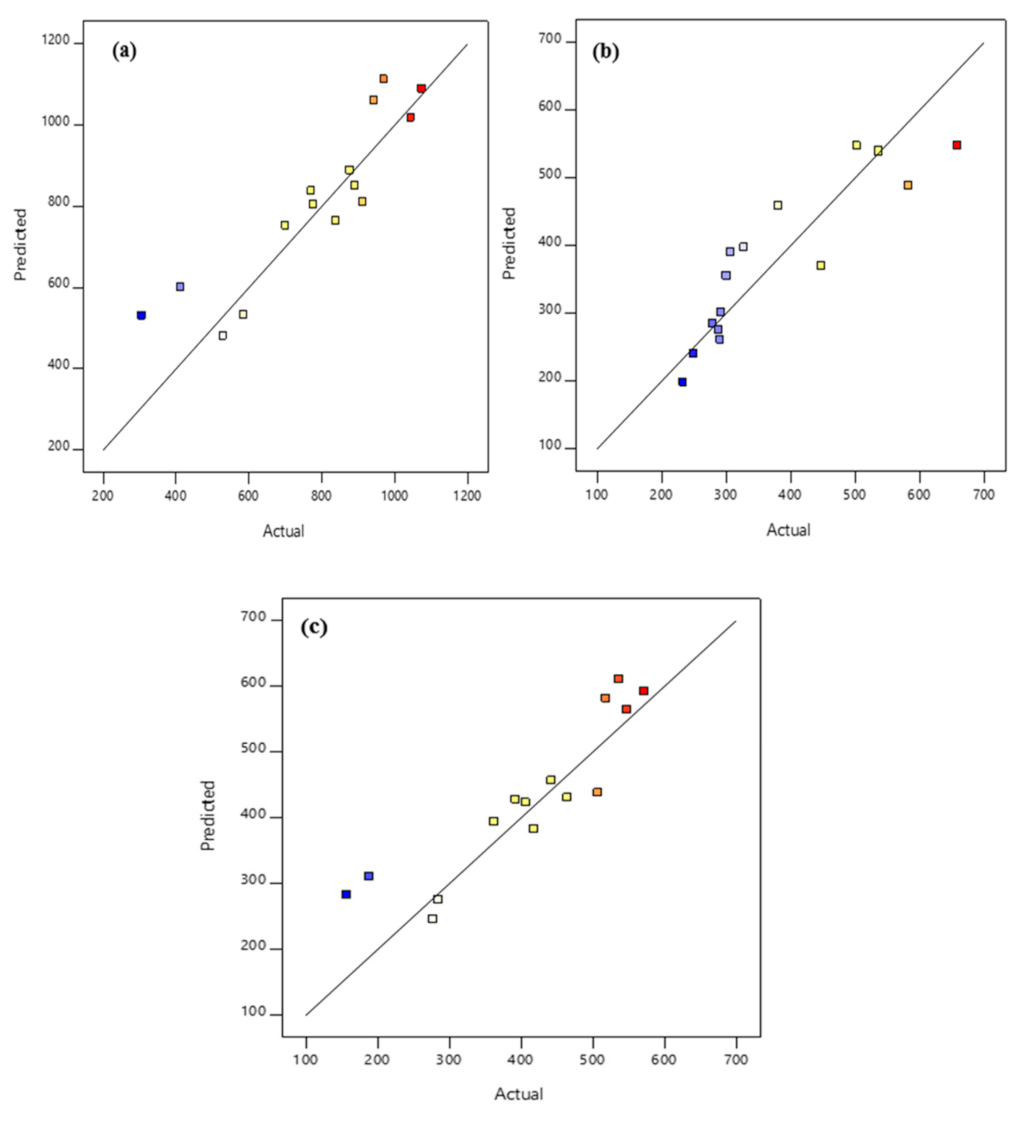

3.2.2. Statistical Assessment of Experimental Results

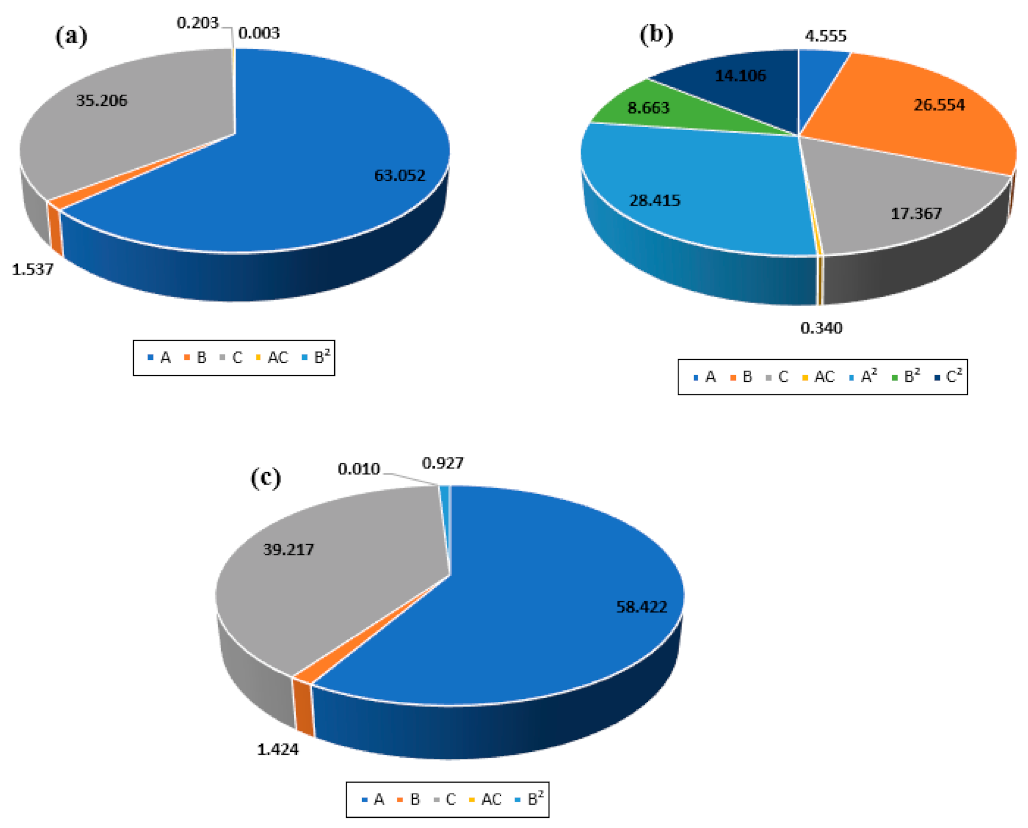

3.3. Effects of the Independent Variables on the UCS, FS, and ITS

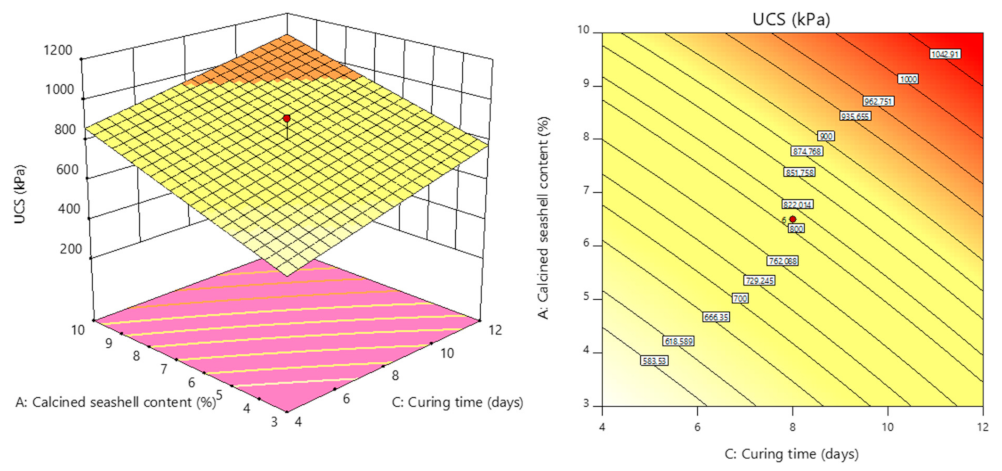

3.3.1. The Effect of Independent Variables on the UCS

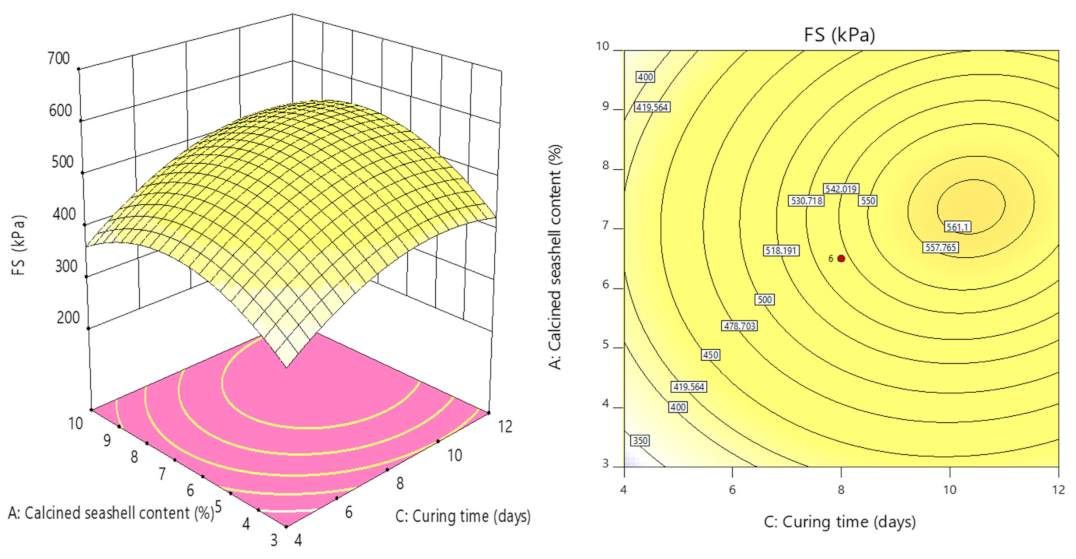

3.3.2. The Effect of Independent Variables on the FS

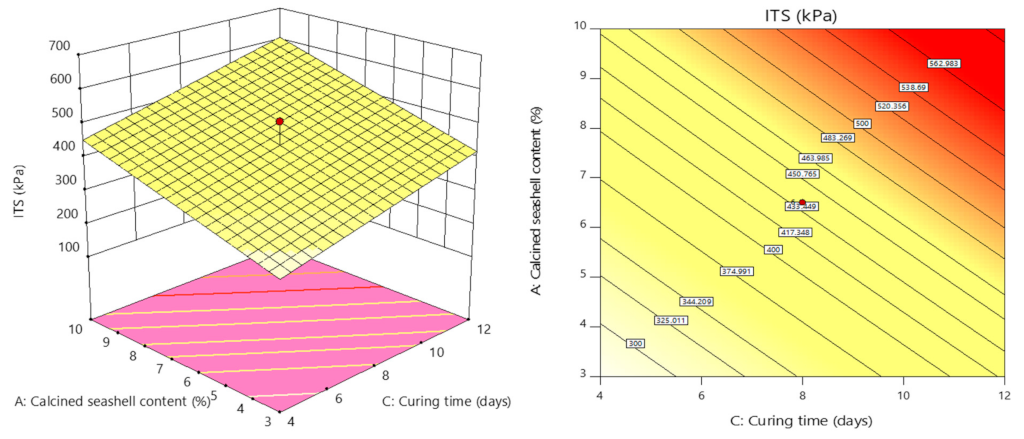

3.3.3. The Effect of Independent Variables on the ITS

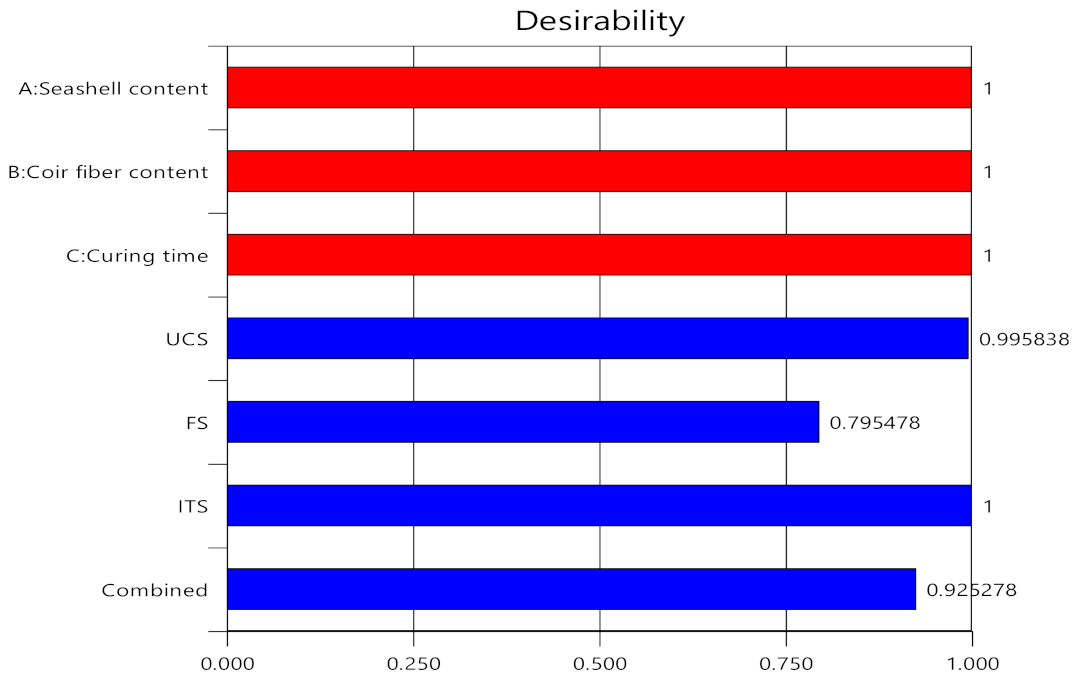

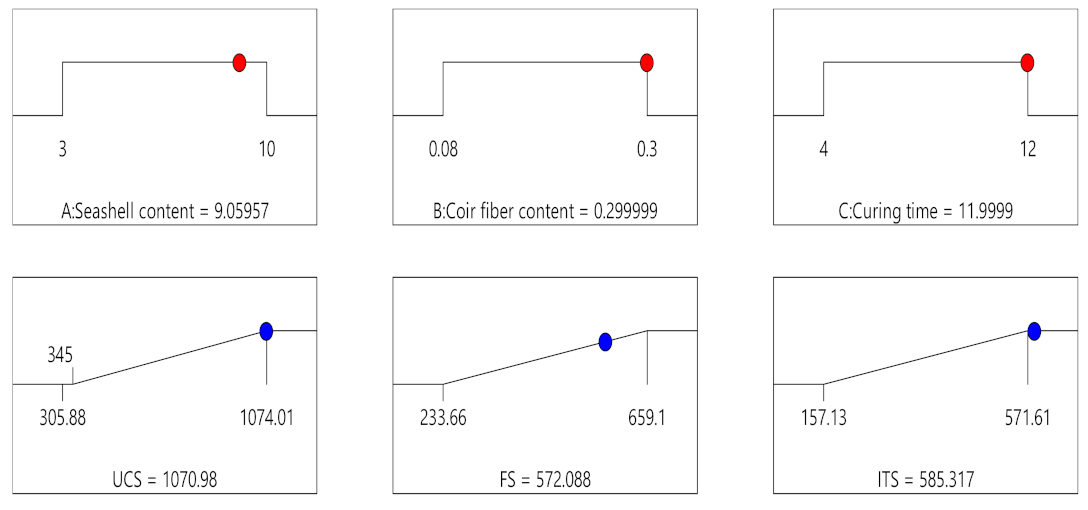

3.4. Optimization Analysis

3.5. Microstructural Properties

3.5.1. X-ray Diffraction

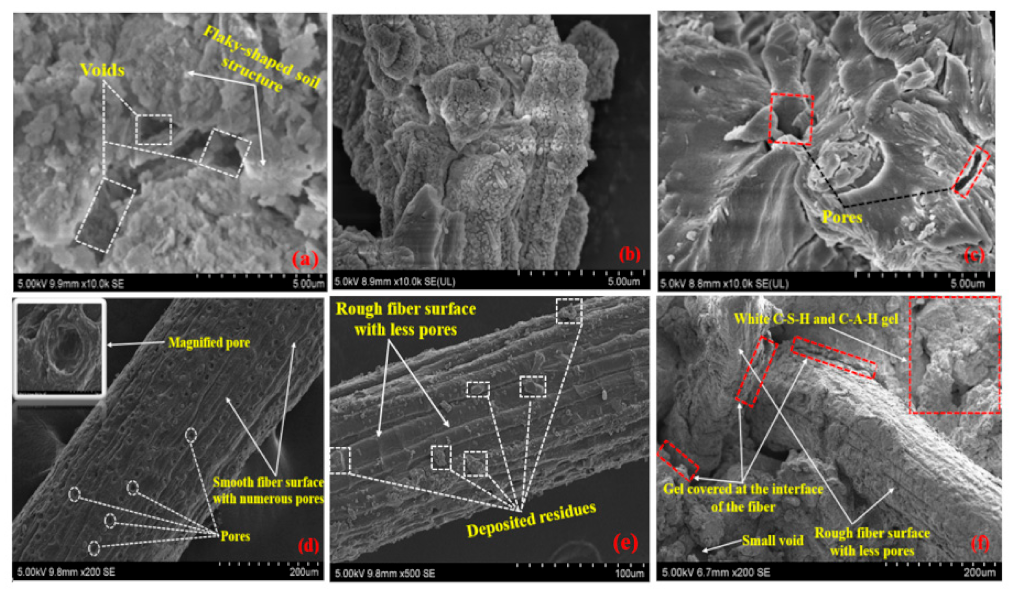

3.5.2. FESEM Analysis

4. Summary and Conclusions

5. Recommendation for Future Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, G.H.; Liu, S.Y.; Zheng, X. Influence of drying-wetting cycles on engineering properties of carbonated silt admixed with reactive MgO. Constr. Build. Mater. 2019, 204, 84–93. [Google Scholar] [CrossRef]

- Ghadir, P.; Ranjbar, N. Clayey soil stabilization using geopolymer and portland cement. Constr. Build. Mater. 2018, 188, 361–371. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Phetchuay, C.; Chinkulkijniwat, A.; Cholaphatsorn, A. Strength development in silty clay stabilized with calcium carbide residue and fly ash. Soils Found. 2013, 53, 477–486. [Google Scholar] [CrossRef] [Green Version]

- Tan, T.; Huat, B.B.K.; Anggraini, V.; Shukla, S.K.; Nahazanan, H. Strength behavior of fly ash-stabilized soil reinforced with coir fibers in alkaline environment. J. Nat. Fibers 2019, 18, 1556–1569. [Google Scholar] [CrossRef]

- Hendriks, C.A.; Worrell, E.; De Jager, D.; Blok, K.; Riemer, P. Emission reduction of greenhouse gases from the cement industry. In Proceedings of the Fourth International Conference on Green House Gas Control Technologies, Interlaken, Switzerland, 30 August–2 September 1998; pp. 939–944. [Google Scholar]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

- Gawu, S.K.Y.; Gidigasu, S.S.R. The effect of spent carbide on the geotechnical characteristics of two lateritic soils from the Kumasi area. Int. J. Eng. 2013, 6, 311–321. [Google Scholar]

- Hataf, N.; Ghadir, P.; Ranjbar, N. Investigation of soil stabilization using chitosan biopolymer. J. Clean. Prod. 2018, 170, 1493–1500. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, D. Behavior of cement-stabilized fiber-reinforced pond ash, rice husk ash–soil mixtures. Geotext. Geomembr. 2016, 44, 466–474. [Google Scholar] [CrossRef]

- Latifi, N.; Marto, A.; Eisazadeh, A. Physicochemical behavior of tropical laterite soil stabilized with non-traditional additive. Acta Geotech. 2015, 11, 433–443. [Google Scholar] [CrossRef]

- Mounika, K.; Narayana, B.S.; Manohar, D.; Vardhan, K.S.H. Influence of sea shells powder on black cotton soil during stabilization. Int. J. Adv. Eng. Technol. 2014, 7, 1476–1482. [Google Scholar]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Shahbazi, M.; Rowshanzamir, M.; Abtahi, S.M.; Hejazi, S.M. Optimization of carpet waste fibers and steel slag particles to reinforce expansive soil using response surface methodology. Appl. Clay Sci. 2017, 142, 185–192. [Google Scholar] [CrossRef]

- Jayaganesh, K.; Yuvaraj, S.; Yuvaraj, D.; Nithesh, C.; Karthik, G. Effect of bitumen emulsion and sea shell powder in the unconfined compressive strength of black cotton soil. Int. J. Eng. Res. Appl. 2012, 2, 242–245. [Google Scholar]

- Martínez-García, C.; González-Fonteboa, B.; Martínez-Abella, F.; Carro-López, D. Performance of mussel shell as aggregate in plain concrete. Constr. Build. Mater. 2017, 139, 570–583. [Google Scholar] [CrossRef]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Lee, S.C.; Goh, W.I.; Yuen, C.W. Recycling of seashell waste in concrete: A review. Constr. Build. Mater. 2018, 162, 751–764. [Google Scholar] [CrossRef]

- Othman, N.H.; Bakar, B.H.A.; Don, M.M.; Johari, M.A.M. Cockle shell ash replacement for cement and filler in concrete. Fundamental properties. Malays. J. Civ. Eng. 2013, 25, 200–211. [Google Scholar]

- Yang, E.I.; Yi, S.T.; Leem, Y.M. Effect of oyster shell substituted for fine aggregate on concrete characteristics: Part I. Fundamental properties. Cem. Concr. Res. 2005, 35, 2175–2182. [Google Scholar]

- Yoon, G.L.; Kim, B.T.; Kim, B.O.; Han, S.H. Chemical–mechanical characteristics of crushed oyster-shell. Waste Manag. 2003, 23, 825–834. [Google Scholar] [CrossRef] [PubMed]

- Dhakane, S.F.; Moulavi, M.H. Sea shell derived CaCO3 nanorods as calcium rich fertilizer in agriculture. Int. Res. J. Sci. Eng. 2017, A1, 189–191. [Google Scholar]

- Seco-Reigosa, N.; Peña-Rodríguez, S.; Nóvoa-Muñoz, J.C.; Arias-Estévez, M.; Fernández-Sanjurjo, M.J.; Álvarez-Rodríguez, E.; Núñez-Delgado, A. Arsenic, chromium and mercury removal using mussel shell ash or a sludge/ashes waste mixture. Environ. Sci. Pollut. Res. 2013, 20, 2670–2678. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Nworgu, A.T.; Odetoyan, A.O.; Kareem, M.; Enabulele, D.O.; Bassey, D.E. Sustainable use of seashells as binder in concrete production: Prospect and challenges. J. Build. Eng. 2021, 34, 101864. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hasaniyah, M.W.; Zeyad, A.M.; Awad, M.M.; Alaskar, A.; Mohamed, A.M.; Alyousef, R. Durability and mechanical properties of seashell partially-replaced cement. J. Build. Eng. 2020, 31, 101328. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E.; Li, L. Characterization on the recycling of waste seashells with Portland cement towards sustainable cementitious materials. J. Clean. Prod. 2019, 220, 235–252. [Google Scholar] [CrossRef]

- Peow, W.C.; Ngian, S.P.; Tahir, M. Engineering properties of bio-inspired cement mortar containing seashell powder. In Proceedings of the National Seminar on Civil Engineering Research SEPKA, Skudai, Johor, 14–15 April 2014; pp. 1–14. [Google Scholar]

- Ong, B.P.; Kassim, U. Performance of concrete incorporating of clam shell as partially replacement of ordinary Portland cement (OPC). J. Adv. Res. Appl. Mech. 2020, 55, 12–21. [Google Scholar]

- Soltanzadeh, F.; Emam-Jomeh, M.; Edalat-Behbahani, A.; Soltan-Zadeh, Z. Development and characterization of blended cements containing seashell powder. Constr. Build. Mater. 2018, 161, 292–304. [Google Scholar] [CrossRef]

- Correia, A.A.; Oliveira, P.J.V.; Custódio, D.G. Effect of polypropylene fibres on the compressive and tensile strength of a soft soil, artificially stabilised with binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef] [Green Version]

- Sukontasukkul, P.; Jamsawang, P. Use of steel and polypropylene fibers to improve flexural performance of deep soil–cement column. Constr. Build. Mater. 2012, 29, 201–205. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Farzadnia, N.; Jahangirian, H.; Huat, B.B.K. Effects of coir fibres modified with Ca(OH)2 and Mg(OH)2 nanoparticles on mechanical properties of lime-treated marine clay. Geosynth. Int. 2016, 23, 206–218. [Google Scholar] [CrossRef]

- Jairaj, C.; Prathap, K.M.T.; Raghunandan, M.E. Compaction characteristics and strength of BC soil reinforced with untreated and treated coir fibers. Innov. Infrastruct. Solut. 2018, 3, 21. [Google Scholar] [CrossRef]

- Ahmad, F.; Bateni, F.; Azmi, M. Performance evaluation of silty sand reinforced with fibres. Geotext. Geomembr. 2010, 28, 93–99. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Mohamed, M.H.; Arulrajah, A.; Horpibulsuk, S.; Anggraini, V. Practical approach to predict the shear strength of fibre-reinforced clay. Geosynth. Int. 2018, 25, 50–66. [Google Scholar] [CrossRef]

- Onyejekwe, S.; Ghataora, G.S. Effect of fiber inclusions on flexural strength of soils treated with nontraditional additives. J. Mater. Civ. Eng. 2014, 26, 1–9. [Google Scholar] [CrossRef]

- Tan, T.; Huat, B.B.K.; Anggraini, V.; Shukla, S.K. Improving the engineering behaviour of residual soil with fly ash and treated natural fibres in alkaline condition. Int. J. Geotech. Eng. 2021, 15, 313–326. [Google Scholar] [CrossRef]

- Lucarelli, D.C.; Pitanga, H.N.; Marques, M.E.S.; Silva, T.O.; Ferraz, R.L.; Nunes, D.M. Study of the geotechnical behavior of soil-cement reinforced with plastic bottle fibers. Acta Sci. Technol. 2022, 44, 1–13. [Google Scholar] [CrossRef]

- Ng, Y.C.H.; Xiao, H.; Armediaz, Y.; Pan, Y.; Lee, F.H. Effect of short fibre reinforcement on the yielding behaviour of cement-admixed clay. Soils Found. 2020, 60, 439–453. [Google Scholar] [CrossRef]

- Tran, K.Q.; Satomi, T.; Takahashi, H. Improvement of mechanical behavior of cemented soil reinforced with waste cornsilk fibers. Constr. Build. Mater. 2018, 178, 204–210. [Google Scholar] [CrossRef]

- Nguyen, L.; Fatahi, B.; Khabbaz, H. Predicting the behaviour of fibre reinforced cement treated clay. Procedia Eng. 2016, 143, 153–160. [Google Scholar] [CrossRef]

- Raghavendra, T.; Rohini, B.; Divya, G.; Sharooq, S.A.; Kalyanbabu, B. Stabilization of black cotton soil using terrasil and zycobond. Int. J. Creat. Res. Thoughts 2018, 6, 300–303. [Google Scholar]

- Botero, E.; Ossa, A.; Sherwell, G.; Ovando-Shelley, E. Stress-strain behavior of a silty soil reinforced with polyethylene terephthalate (PET). Geotext. Geomembr. 2015, 43, 363–369. [Google Scholar] [CrossRef]

- Chen, M.; Shen, S.L.; Arulrajah, A.; Wu, H.N.; Hou, D.W.; Xu, Y.S. Laboratory evaluation on the effectiveness of polypropylene fibers on the strength of fiber-reinforced and cement-stabilized Shanghai soft clay. Geotext. Geomembr. 2015, 43, 515–523. [Google Scholar] [CrossRef]

- Ramesh, H.K.M.; Krishna, M. Performance of coated coir fibers on the compressive strength behavior of reinforced soil. Int. J. Earth Sci. Eng. 2011, 4, 26–29. [Google Scholar]

- Dassanayake, S.M.; Mousa, A.; Fowmes, G.J.; Susilawati, S.; Zamara, K. Forecasting the moisture dynamics of a landfill capping system comprising different geosynthetics: A NARX neural net-work approach. Geotext. Geomembr. 2023, 51, 282–292. [Google Scholar] [CrossRef]

- Dassanayake, S.M.; Mousa, A.; Sheng, L.J.; Chian, C.C. A statistical inference of hydraulic shear and clogging in internally unstable soils. Géotech. Lett. 2020, 10, 67–72. [Google Scholar] [CrossRef]

- Dassanayake, S.M.; Mousa, A. Flow dependent constriction-size distribution in gap-graded soils: A statistical inference. Géotech. Lett. 2022, 12, 46–54. [Google Scholar] [CrossRef]

- Dassanayake, S.M.; Mousa, A.A.; Ilankoon, S.; Fowmes, G.J. Internal instability in soils: A critical review of the fundamentals and ramifications. Transp. Res. Rec. 2022, 2676, 1–26. [Google Scholar] [CrossRef]

- Yi, S.; Su, Y.; Qi, B.; Su, Z.; Wan, Y. Application of response surface methodology and central composite rotatable design in optimizing the preparation conditions of vinyltriethoxysilane modified silicalite/polydimethylsiloxane hybrid pervaporation membranes. Sep. Purif. Technol. 2010, 71, 252–262. [Google Scholar] [CrossRef]

- Sahu, J.N.; Acharya, J.; Meikap, B.C. Response surface modeling and optimization of chromium (VI) removal from aqueous solution using Tamarind wood activated carbon in batch process. J. Hazard. Mater. 2009, 172, 818–825. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.Z.; Muyibi, S.A.; Toramae, J. Statistical optimization of adsorption processes for removal of 2, 4-dichlorophenol by activated carbon derived from oil palm empty fruit bunches. J. Environ. Sci. 2007, 19, 674–677. [Google Scholar] [CrossRef]

- Mahalik, K.; Sahu, J.N.; Patwardhan, A.V.; Meikap, B.C. Statistical modelling and optimization of hydrolysis of urea to generate ammonia for flue gas conditioning. J. Hazard. Mater. 2010, 182, 603–610. [Google Scholar] [CrossRef]

- Babu, G.; Srivastava, A. Response Surface Methodology (RSM) in the Reliability analysis of geotechnical systems. In Proceedings of the 12th International Association for Computer Methods and Advances in Geomechanics, Goa, India, 1–6 October 2008; pp. 4147–4165. [Google Scholar]

- Behera, S.K.; Meena, H.; Chakraborty, S.; Meikap, B.C. Application of response surface methodology (RSM) for optimization of leaching parameters for ash reduction from low-grade coal. Int. J. Min. Sci. Technol. 2018, 28, 621–629. [Google Scholar] [CrossRef]

- Güllü, H.; Fedakar, H.İ. Response surface methodology for optimization of stabilizer dosage rates of marginal sand stabilized with Sludge Ash and fiber based on UCS performances. KSCE J. Civ. Eng. 2017, 21, 1717–1727. [Google Scholar] [CrossRef]

- Hamrouni, A.; Dias, D.; Sbartai, B. Reliability analysis of shallow tunnels using the response surface methodology. Undergr. Space 2017, 2, 246–258. [Google Scholar] [CrossRef]

- Lakehal, R.; Djemili, L. Studying the effect of a variation in the main parameters on stability of homogeneous earth dams using design experiment. J. Water Land Dev. 2017, 34, 173–179. [Google Scholar] [CrossRef] [Green Version]

- Anggraini, V.; Asadi, A.; Syamsir, A.; Huat, B.B. Three point bending flexural strength of cement treated tropical marine soil reinforced by lime treated natural fiber. Measurement 2017, 111, 158–166. [Google Scholar]

- Dutta, R.; Khatri, V.N.; Venkataraman, G. Effect of addition of treated coir fibres on the compression behaviour of clay. Jordan J. Civ. Eng. 2012, 6, 476–488. [Google Scholar]

- Parida, C.; Dash, S.K.; Das, S.C. Effect of fiber treatment and fiber loading on mechanical properties of luffa-resorcinol composites. Indian J. Mater. Sci. 2015, 2015, 658064. [Google Scholar] [CrossRef] [Green Version]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. Behaviour of cement stabilized treated coir fibre-reinforced clay-pond ash mixtures. J. Build. Eng. 2016, 8, 131–140. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Huang, L.; Kasal, B. Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr. Build. Mater. 2016, 112, 168–182. [Google Scholar] [CrossRef]

- Lindon, J.C.; Tranter, G.E.; Koppenaal, D. Encyclopedia of Spectroscopy and Spectrometry, 3rd ed.; Academic Press: London, UK, 2017; Volume 1. [Google Scholar]

- BS 1377; Methods of Testing Soils for Civil Engineering Purposes, Methods of Testing Soils for Civil Engineering Purposes. British Standards Institution: London, UK, 1990.

- Consoli, N.C.; Lopes, L.S.; Prietto, P.D.M.; Festugato, L.; Cruz, R.C. Variables controlling stiffness and strength of lime-stabilized soils. J. Geotech. Geoenviron. Eng. 2011, 137, 628–632. [Google Scholar] [CrossRef]

- ASTM D1635/D1635M-12; Standard Test Method for Flexural Strength of Soil-Cement Using Simple Beam with Third-Point Loading. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D3967-16; Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- Dexter, A.R.; Kroesbergen, B. Methodology for determination of tensile strength of soil aggregates. J. Agric. Eng. Res. 1985, 31, 139–147. [Google Scholar] [CrossRef]

- Garg, U.K.; Kaur, M.P.; Garg, V.K.; Sud, D. Removal of nickel (II) from aqueous solution by adsorption on agricultural waste biomass using a response surface methodological approach. Bioresour. Technol. 2008, 99, 1325–1331. [Google Scholar] [CrossRef]

- Tan, I.A.W.; Ahmad, A.L.; Hameed, B.H. Optimization of preparation conditions for activated carbons from coconut husk using response surface methodology. Chem. Eng. J. 2008, 137, 462–470. [Google Scholar] [CrossRef]

- Can, M.Y.; Kaya, Y.; Algur, O.F. Response surface optimization of the removal of nickel from aqueous solution by cone biomass of Pinus sylvestris. Bioresour. Technol. 2006, 97, 1761–1765. [Google Scholar] [CrossRef]

- Islam, M.A.; Sakkas, V.; Albanis, T.A. Application of statistical design of experiment with desirability function for the removal of organophosphorus pesticide from aqueous solution by low-cost material. J. Hazard. Mater. 2009, 170, 230–238. [Google Scholar] [CrossRef]

- Consoli, N.C.; Lopes, L.L.; Heineck, K.H. Key parameters for the control of lime stabilized soils. J. Mater. Civ. Eng. 2009, 21, 210–216. [Google Scholar] [CrossRef]

- Harichane, K.; Ghrici, M.; Kenai, S. Effect of the combination of lime and natural pozzolana on the compaction and strength of soft clayey soils: A preliminary study. Environ. Earth Sci. 2012, 66, 2197–2205. [Google Scholar] [CrossRef]

- Saride, S.; Puppala, A.J.; Chikyala, S.R. Swell-shrink and strength behaviors of lime and cement stabilized expansive organic clays. Appl. Clay Sci. 2013, 85, 39–45. [Google Scholar] [CrossRef]

- Khatri, V.N.; Dutta, R.K.; Venkataraman, G.; Shrivastava, R. Shear strength behaviour of clay reinforced with treated coir fibres. Period. Polytech. Civ. Eng. 2016, 60, 135–143. [Google Scholar]

- Dutta, R.K.; Khatri, V.N.; Gayathri, V. Effect of treated coir fibres on the compaction and CBR behaviour of clay. Int. J. Geotech. Environ. 2013, 5, 19–33. [Google Scholar]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef] [Green Version]

- Al-Swaidani, A.; Hammound, I.; Meziab, A. Effect of adding natural pozzolana on geotechnical properties of lime-stabilized clayey soil. J. Rock Mech. Geotech. Eng. 2016, 8, 714–725. [Google Scholar] [CrossRef] [Green Version]

- Dang, L.C.; Fatahi, B.; Khabbaz, H. Behaviour of expansive soils stabilized with hydrated lime and bagasse fibres. Procedia Eng. 2016, 143, 658–665. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Tran, K.Q.; Satomi, T.; Takahashi, H. Effect of waste cornsilk fiber reinforcement on mechanical properties of soft soils. Transp. Geotech. 2018, 16, 76–84. [Google Scholar] [CrossRef]

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing compressive strength of soil using natural fibers. Constr. Build. Mater. 2015, 93, 943–949. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Namdar, P.; Javadi, A.A. Behavior of cement-stabilized clay reinforced with nylon fiber. Geosynth. Int. 2012, 19, 85–92. [Google Scholar] [CrossRef]

- Li, J.; Tang, C.; Wang, D.; Pei, X.; Shi, B. Effect of discrete fibre reinforcement on soil tensile strength. J. Rock Mech. Geotech. Eng. 2014, 6, 133–137. [Google Scholar] [CrossRef] [Green Version]

- Das, D.; Meikap, B.C. Optimization of process condition for the preparation of amine-impregnated activated carbon developed for CO2 capture and applied to methylene blue adsorption by response surface methodology. J. Environ. Sci. Health Part A 2017, 52, 1164–1172. [Google Scholar] [CrossRef]

- Yetilmezsoy, K.; Demirel, S.; Vanderbei, R.J. Response surface modeling of Pb (II) removal from aqueous solution by Pistacia vera L.: Box–Behnken experimental design. J. Hazard. Mater. 2009, 171, 551–562. [Google Scholar] [CrossRef]

- ASTM D4609; Standard Guide for Evaluating Effectiveness of Admixtures for Soil Stabilization. ASTM International: West Conshohocken, PA, USA, 2003.

- Bahmani, S.H.; Huat, B.B.; Asadi, A.; Farzadnia, N. Stabilization of residual soil using SiO2 nanoparticles and cement. Constr. Build. Mater. 2014, 64, 350–359. [Google Scholar] [CrossRef]

- Latifi, N.; Eisazadeh, A.; Marto, A.; Meehan, C.L. Tropical residual soil stabilization: A powder form material for increasing soil strength. Constr. Build. Mater. 2017, 147, 827–836. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Surface modifications of natural fibers and performance of the resulting biocomposites: An overview. Compos. Interfaces 2001, 8, 313–343. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Sand (%) | 48.56 |

| Clay (%) | 20.22 |

| Gravel (%) | - |

| Silt (%) | 31.22 |

| D50 (mm) | 0.07 |

| Plastic limit (%) | 21.80 |

| Liquid limit (%) | 50.10 |

| Plasticity index (%) | 28.30 |

| Fines content | 51.44 |

| Activity | 1.40 |

| Linear shrinkage (%) | 8.57 |

| MDD (g/cm3) 1 | 1.82 |

| OMC (%) 2 | 18.50 |

| UCS (kPa) 3 | 153.11 |

| FS (kPa) 4 | 125.15 |

| ITS (kPa) 5 | 137.98 |

| pH | 9.31 |

| Specific gravity | 2.62 |

| Significant Oxides | Concentration (wt.%) |

|---|---|

| SiO2 | 55.35 |

| Al2O3 | 28.68 |

| Fe2O3 | 5.93 |

| TiO2 | 1.10 |

| CaO | 0.01 |

| Na2O | 0.03 |

| K2O | 0.32 |

| MgO | 0.16 |

| P2O5 | 0.07 |

| SO3 | 0.15 |

| LOI | 8.20 |

| Significant Oxides | Concentration (wt.%) |

|---|---|

| CaO | 99.24 |

| Fe2O3 | 0.16 |

| SrO | 0.40 |

| Cr2O3 | 0.20 |

| D50 (mm) | 0.1 |

| CC | 0.25 |

| CU | 9.0 |

| Sand (%) | 55.52 |

| Silt (%) | 42.75 |

| Clay (%) | 1.73 |

| Specific gravity | 2.74 |

| Properties | Values |

|---|---|

| Chemical composition | |

| Ash (%) | 3 |

| Cellulose (%) | 41 |

| Lignin (%) | 46 |

| Water soluble (%) | 6 |

| Chemical composition | |

| Unit weight (g/cm3) | 1.35 |

| Breaking elongation (%) | 28 |

| Tensile strength (MPa) | 65–140 |

| Independent Variable | Symbol | Values | ||||

|---|---|---|---|---|---|---|

| Chemical composition | −α −1.682 | Low −1 | Medium −1 | High −1 | +α +1.682 | |

| Calcined seashell content (wt.%) | A | 0.61 | 3 | 6.5 | 10 | 12.39 |

| Coir fibre content (wt.%) | B | 0.005 | 0.08 | 0.19 | 0.3 | 0.38 |

| Curing duration (days) | C | 1 | 4 | 8 | 12 | 15 |

| Independent Variables in Coded Form | Independent Variables in Actual Form | Dependent Variables | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Standard Run No. | A | B | C | A (%) | B (%) | C (Days) | UCS kPa | FS kPa | ITS kPa |

| 1 | −1 | −1 | −1 | 3 | 0.08 | 4 | 528.11 | 233.66 | 277.49 |

| 2 | +1 | −1 | −1 | 10 | 0.08 | 4 | 771.19 | 249.78 | 392.88 |

| 3 | −1 | +1 | −1 | 3 | 0.3 | 4 | 584.41 | 300.50 | 284.30 |

| 4 | +1 | +1 | −1 | 10 | 0.3 | 4 | 876.37 | 327.83 | 442.45 |

| 5 | −1 | −1 | +1 | 3 | 0.08 | 12 | 699.64 | 291.53 | 362.60 |

| 6 | +1 | −1 | +1 | 10 | 0.08 | 12 | 944.03 | 306.76 | 518.57 |

| 7 | −1 | +1 | +1 | 3 | 0.3 | 12 | 777.01 | 381.46 | 406.15 |

| 8 | +1 | +1 | +1 | 10 | 0.3 | 12 | 969.42 | 502.40 | 536.26 |

| 9 | −α | 0 | 0 | 0.61 | 0.19 | 8 | 305.88 | 290.72 | 157.13 |

| 10 | +α | 0 | 0 | 12.39 | 0.19 | 8 | 1074.01 | 447.39 | 571.61 |

| 11 | 0 | −α | 0 | 6.5 | 0.005 | 8 | 837.46 | 278.88 | 418.06 |

| 12 | 0 | +α | 0 | 6.5 | 0.38 | 8 | 890.48 | 659.10 | 464.76 |

| 13 | 0 | 0 | −α | 6.5 | 0.19 | 1 | 411.92 | 287.85 | 188.80 |

| 14 | 0 | 0 | +α | 6.5 | 0.19 | 15 | 1043.11 | 582.10 | 547.34 |

| 15 | 0 | 0 | 0 | 6.5 | 0.19 | 8 | 912.29 | 536.50 | 507.52 |

| 16 | 0 | 0 | 0 | 6.5 | 0.19 | 8 | 912.37 | 536.62 | 507.63 |

| 17 | 0 | 0 | 0 | 6.5 | 0.19 | 8 | 912.25 | 536.45 | 507.47 |

| 18 | 0 | 0 | 0 | 6.5 | 0.19 | 8 | 912.32 | 536.55 | 507.56 |

| 19 | 0 | 0 | 0 | 6.5 | 0.19 | 8 | 912.30 | 536.53 | 507.60 |

| 20 | 0 | 0 | 0 | 6.5 | 0.19 | 8 | 912.20 | 536.40 | 507.43 |

| Soil Mixture | LL (%) | PL (%) | PI (%) | Soil Mixture | LL (%) | PL (%) |

|---|---|---|---|---|---|---|

| 0% CSS + 0% CF (control) | 50.10 | 21.80 | 28.30 | 0% CSS + 0% CF (control) | 50.10 | 21.80 |

| 3% CSS + 0.08% CF | 39.80 | 16.84 | 22.96 | 3% CSS + 0.08% CF | 39.80 | 16.84 |

| 10% CSS + 0.08% CF | 36.0 | 15.04 | 20.96 | 10% CSS + 0.08% CF | 36.0 | 15.04 |

| 3% CSS + 0.3% CF | 35.20 | 15.31 | 19.89 | 3% CSS + 0.3% CF | 35.20 | 15.31 |

| 10% CSS + 0.3% CF | 30.40 | 13.31 | 17.09 | 10% CSS + 0.3% CF | 30.40 | 13.31 |

| 0.61% CSS + 0.19% CF | 45.71 | 19.01 | 26.70 | 0.61% CSS + 0.19% CF | 45.71 | 19.01 |

| 12.39% CSS + 0.19% CF | 30.70 | 16.37 | 14.33 | 12.39% CSS + 0.19% CF | 30.70 | 16.37 |

| 6.5% CSS + 0.005% CF | 35.30 | 16.22 | 19.08 | 6.5% CSS + 0.005% CF | 35.30 | 16.22 |

| 6.5% CSS + 0.19% CF | 35.70 | 17.66 | 18.04 | 6.5% CSS + 0.19% CF | 35.70 | 17.66 |

| 6.5% CSS + 0.37% CF | 35.60 | 17.72 | 17.88 | 6.5% CSS + 0.37% CF | 35.60 | 17.72 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | Remarks |

|---|---|---|---|---|---|---|

| Model | 5.951 × 105 | 5 | 1.190 × 105 | 8.15 | 0.0009 | Significant |

| A—CSS content | 3.752 × 105 | 1 | 3.752 × 105 | 25.69 | 0.0002 | Significant |

| B—CF content | 9145.42 | 1 | 9145.42 | 0.6262 | 0.4419 | |

| C—Curing time | 2.095 × 105 | 1 | 2.095 × 105 | 14.35 | 0.0020 | Significant |

| AC | 1206.39 | 1 | 1206.39 | 0.0826 | 0.778 | |

| B2 | 16.36 | 1 | 16.36 | 0.0011 | 0.9738 | |

| Residual | 2.045 × 105 | 14 | 14,604.32 | |||

| Lack of fit | 2.045 × 105 | 9 | 22,717.82 | |||

| Pure error | 0.0000 | 5 | 0.0000 | |||

| Correlation total | 7.996 × 105 | 19 | R2 | 0.7443 | ||

| Mean | 809.34 | Adjusted R2 | 0.6530 | |||

| C.V. (%) | 14.93 | Predicted R2 | 0.4780 response surface reduced quadratic model | |||

| PRESS | 4.173 × 105 | Adequate precision | 9.5327 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | Remarks |

|---|---|---|---|---|---|---|

| Model | 2.915 × 105 | 7 | 41,635.93 | 9.56 | 0.0004 | Significant |

| A—CSS content | 14,376.91 | 1 | 14,376.91 | 3.30 | 0.0943 | |

| B—CF content | 83,819.46 | 1 | 83,819.46 | 19.24 | 0.0009 | Significant |

| C—Curing time | 54,818.87 | 1 | 54,818.87 | 12.58 | 0.004 | Significant |

| AC | 1074.62 | 1 | 1074.62 | 0.2467 | 0.6284 | |

| A2 | 89,693.67 | 1 | 89,693.67 | 20.59 | 0.0007 | Significant |

| B2 | 27,343.79 | 1 | 27,343.79 | 6.28 | 0.0276 | Significant |

| C2 | 44,526.65 | 1 | 44,526.65 | 10.22 | 0.0077 | Significant |

| Residual | 52,272.80 | 12 | 4356.07 | |||

| Lack of fit | 52,272.77 | 7 | 7467.54 | 1.249 × 106 | <0.0001 | significant |

| Pure error | 0.0299 | 5 | 0.0060 | |||

| Correlation total | 3.437 × 105 | 19 | R2 | 0.8479 | ||

| Mean | 417.95 | Adjusted R2 | 0.7592 | |||

| C.V. (%) | 15.79 | Predicted R2 | 0.2635 | |||

| PRESS | 2.532 × 105 | Adequate precision | 8.3642 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | Remark |

|---|---|---|---|---|---|---|

| Model | 1.979 × 105 | 5 | 39,582.01 | 7.27 | 0.0015 | Significant |

| A—CSS content | 1.156 × 105 | 1 | 1.156 × 105 | 21.24 | 0.0004 | Significant |

| B—CF content | 2817.53 | 1 | 2817.53 | 0.5175 | 0.4838 | |

| C—Curing time | 77,599.66 | 1 | 77,599.66 | 14.25 | 0.002 | Significant |

| AC | 19.66 | 1 | 19.66 | 0.0036 | 0.9529 | |

| B2 | 1833.93 | 1 | 1833.93 | 0.3368 | 0.5709 | |

| Residual | 76,227.25 | 14 | 5444.80 | |||

| Lack of fit | 76,227.22 | 9 | 8469.69 | 1.443 × 105 | <0.0001 | Significant |

| Pure error | 0.0294 | 5 | 0.0059 | |||

| Correlation total | 2.741 × 105 | 19 | R2 | 0.7219 | ||

| Mean | 430.68 | Adjusted R2 | 0.6226 | |||

| C.V. (%) | 17.13 | Predicted R2 | 0.4634 | |||

| PRESS | 1.471 × 105 | Adequate precision | 8.9946 |

| Name | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight | Importance |

|---|---|---|---|---|---|---|

| A: Seashell content | Is in range | 3 | 10 | 1 | 1 | 3 |

| B: Coir fibre content | Is in range | 0.08 | 0.30 | 1 | 1 | 3 |

| C: Curing time | Is in range | 4 | 12 | 1 | 1 | 3 |

| UCS | Maximize | 345 | 1074.01 | 1 | 1 | 3 |

| FS | Maximize | 233.66 | 659.10 | 1 | 1 | 3 |

| ITS | Maximize | 157.13 | 571.61 | 1 | 1 | 3 |

| Solution Number | CSS Content | CF Content | Curing Time | UCS | FS | ITS | Desirability |

|---|---|---|---|---|---|---|---|

| 1 | 9.06 | 0.30 | 12 | 1070.99 | 572.09 | 585.32 | 0.925 |

| 2 | 9.09 | 0.30 | 12 | 1072.15 | 571.54 | 586.04 | 0.925 |

| 3 | 9.04 | 0.30 | 12 | 1069.93 | 572.57 | 584.68 | 0.925 |

| 4 | 9.12 | 0.30 | 12 | 1073.59 | 570.85 | 586.92 | 0.925 |

| 5 | 9.01 | 0.30 | 12 | 1068.63 | 573.16 | 583.90 | 0.925 |

| 6 | 8.97 | 0.30 | 12 | 1067.12 | 573.83 | 582.97 | 0.925 |

| 7 | 9.10 | 0.29 | 12 | 1072.38 | 571.35 | 586.69 | 0.925 |

| 8 | 8.98 | 0.29 | 12 | 1067.03 | 573.82 | 583.36 | 0.925 |

| 9 | 9.07 | 0.30 | 12 | 1069.10 | 572.68 | 584.05 | 0.925 |

| 10 | 8.87 | 0.29 | 12 | 1062.30 | 575.85 | 580.33 | 0.925 |

| 11 | 8.93 | 0.30 | 12 | 1062.79 | 575.46 | 580.20 | 0.925 |

| 12 | 9.01 | 0.30 | 12 | 1065.27 | 574.26 | 581.65 | 0.925 |

| 13 | 8.71 | 0.29 | 12 | 1054.84 | 578.66 | 576.32 | 0.924 |

| 14 | 9.28 | 0.30 | 12 | 1074.01 | 569.29 | 586.75 | 0.924 |

| 15 | 9.08 | 0.28 | 12 | 1067.58 | 571.96 | 586.82 | 0.924 |

| 16 | 8.86 | 0.30 | 11 | 1049.57 | 579.62 | 571.61 | 0.923 |

| 17 | 9.32 | 0.24 | 12 | 1068.93 | 557.61 | 593.33 | 0.911 |

| 18 | 9.40 | 0.20 | 12 | 1063.75 | 536.62 | 592.63 | 0.889 |

| 19 | 6.63 | 0.28 | 12 | 962.33 | 584.09 | 521.12 | 0.849 |

| Solution Number | Optimized Model Values | Experimental Run Values | Percentage Error | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UCS | FS | ITS | UCS | FS | ITS | UCS | ITS | FS | |

| kPa | kPa | kPa | kPa | kPa | kPa | (%) | (%) | (%) | |

| 1 | 1070.98 | 572.09 | 585.32 | 1054.21 | 564.05 | 573.96 | 1.59 | 1.43 | 2.44 |

| 2 | 1072.15 | 571.54 | 586.04 | 1058.41 | 560.22 | 572.06 | 1.30 | 2.02 | 2.44 |

| 3 | 1069.93 | 572.57 | 584.68 | 1048.32 | 565.38 | 569.77 | 2.06 | 1.27 | 2.62 |

| 4 | 1073.59 | 570.85 | 586.92 | 1055.09 | 558.79 | 571.05 | 1.75 | 2.16 | 2.78 |

| 5 | 1068.63 | 573.16 | 583.90 | 1050.02 | 564.98 | 570.43 | 1.77 | 1.45 | 2.36 |

| 6 | 1067.12 | 573.83 | 582.97 | 1043.56 | 562.11 | 567.32 | 2.26 | 2.09 | 2.76 |

| 7 | 1072.38 | 571.35 | 586.69 | 1058.02 | 559.32 | 573.85 | 1.36 | 2.15 | 2.24 |

| 8 | 1067.03 | 573.82 | 583.36 | 1041.78 | 562.78 | 568.64 | 2.42 | 1.96 | 2.59 |

| 9 | 1069.10 | 572.68 | 584.05 | 1044.21 | 560.34 | 570.77 | 2.38 | 2.20 | 2.33 |

| 10 | 1062.30 | 575.85 | 580.33 | 1040.98 | 566.21 | 563.99 | 2.05 | 1.70 | 2.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anggraini, V.; Dassanayake, S.; Emmanuel, E.; Yong, L.L.; Kamaruddin, F.A.; Syamsir, A. Response Surface Methodology: The Improvement of Tropical Residual Soil Mechanical Properties Utilizing Calcined Seashell Powder and Treated Coir Fibre. Sustainability 2023, 15, 3588. https://doi.org/10.3390/su15043588

Anggraini V, Dassanayake S, Emmanuel E, Yong LL, Kamaruddin FA, Syamsir A. Response Surface Methodology: The Improvement of Tropical Residual Soil Mechanical Properties Utilizing Calcined Seashell Powder and Treated Coir Fibre. Sustainability. 2023; 15(4):3588. https://doi.org/10.3390/su15043588

Chicago/Turabian StyleAnggraini, Vivi, Sandun Dassanayake, Endene Emmanuel, Lee Li Yong, Fatin Amirah Kamaruddin, and Agusril Syamsir. 2023. "Response Surface Methodology: The Improvement of Tropical Residual Soil Mechanical Properties Utilizing Calcined Seashell Powder and Treated Coir Fibre" Sustainability 15, no. 4: 3588. https://doi.org/10.3390/su15043588